Showing 40 items matching " core sample"

-

Ringwood and District Historical Society

Ringwood and District Historical SocietyGeological specimen - Core sample, Section of core sample taken from Eastland Stage 5 - November 2014, Nov-14

... Core sample...Section of core sample taken from Eastland Stage 5...Section of core sample taken from Eastland Stage 5 Nov 2014...Section of core sample taken from Eastland Stage 5 November... Road Ringwood North melbourne Section of core sample taken from ...Section of core sample taken from Eastland Stage 5 Nov 2014 - Donated by Terry Ahern, obtained through Probuild building contractorsSection of core sample taken from Eastland Stage 5 November 2014 +Additional Keywords: Eastland / Ahern, Terry / Probuild -

Glenelg Shire Council Cultural Collection

Glenelg Shire Council Cultural CollectionGeological specimen - Geological Specimen - Core Sample from site of silos, n.d

... Geological Specimen - Core Sample from site of silos... Core Sample...Core sample from site of silos..... Port of Portland Port of Portland Archives Core Sample Silos ...Display in History House. Port of Portlandport of portland archives, core sample, silos site -

Coal Creek Community Park & Museum

Coal Creek Community Park & MuseumDrill core sample

... Drill core sample...8390.1 - Drill core sample.... Korumburra gippsland 8390.1 - Drill core sample. Drill core sample ...8390.1 - Drill core sample. -

Coal Creek Community Park & Museum

Coal Creek Community Park & MuseumDrill core sample

... Drill core sample...8391.1 - Drill core sample.... Korumburra gippsland 8391.1 - Drill core sample. Drill core sample ...8391.1 - Drill core sample. -

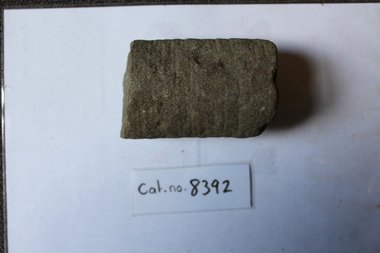

Coal Creek Community Park & Museum

Coal Creek Community Park & MuseumDrill core sample

... Drill core sample...8392.1 - Drill core sample... Korumburra gippsland 8392.1 - Drill core sample Drill core sample ...8392.1 - Drill core sample -

Coal Creek Community Park & Museum

Coal Creek Community Park & MuseumDrill core sample

... Drill core sample...8393.1 - Drill core sample.... Korumburra gippsland 8393.1 - Drill core sample. Drill core sample ...8393.1 - Drill core sample. -

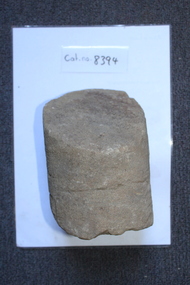

Coal Creek Community Park & Museum

Coal Creek Community Park & MuseumDrill core sample

... Drill core sample...8394.1 - Drill core sample... Korumburra gippsland 8394.1 - Drill core sample Drill core sample ...8394.1 - Drill core sample -

Coal Creek Community Park & Museum

Coal Creek Community Park & MuseumDrill core sample

... Drill core sample...8395.1 - Drill core sample... Korumburra gippsland 8395.1 - Drill core sample Drill core sample ...8395.1 - Drill core sample -

Coal Creek Community Park & Museum

Coal Creek Community Park & MuseumDrill core sample

... Drill core sample...8389.1 - Drill core sample, seems to be weathered.... Korumburra gippsland 8389.1 - Drill core sample, seems ...8389.1 - Drill core sample, seems to be weathered. -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Photograph - Kangaroo Flat Gold Mine Collection: core samples

... Core samples are cylindrical sections of a naturally... of core samples. Core samples are placed side by side...Core samples are cylindrical sections of a naturally ...Core samples are cylindrical sections of a naturally-occurring substance, such as sediment or rock, that are obtained by drilling with a special drill and brought to the surface for examination. Core samples are used in underground or undersea exploration and prospecting. . The hole made for the core sample is called the "core hole"1. Colour photocopy of original photo. Four separate images of core samples. Core samples are placed side by side, lengthwise. western mining corporation, goldmining, kangaroo flat gold mine, rock samples, core samples, exploration -

University of Melbourne, School of Chemistry

University of Melbourne, School of ChemistryCore Sample

... Core Sample... (for oil, or water?) Core Sample ...Core from an early drilling (for oil, or water?) -

Glenelg Shire Council Cultural Collection

Glenelg Shire Council Cultural CollectionPhotograph - Bromide Photograph- Image of core samples from concrete, n.d

... Image of core samples from concrete... Authority Archives Port of Portland Archives Image of core samples ...Port of Portland Authority Archivesport of portland archives -

Coal Creek Community Park & Museum

Coal Creek Community Park & Museumdrill core samples

... 7 different pieces of drill core samples of varying lengths... pieces of drill core samples of varying lengths and diameters ...purpose: unknown location: local7 different pieces of drill core samples of varying lengths and diameters -

Stawell Historical Society Inc

Stawell Historical Society IncGeological specimen - Mining, Broken Dimond Drill Pieces

... 2X Cylindrical Broken used Dimond Drill - Core Samples... a Power Pole 2X Cylindrical Broken used Dimond Drill - Core ...Used to drill through the red Iron stone - reefs end of Stawell. Found along Darlington Road after drilling to erect a Power Pole 2X Cylindrical Broken used Dimond Drill - Core Samples, Basalt - granite -

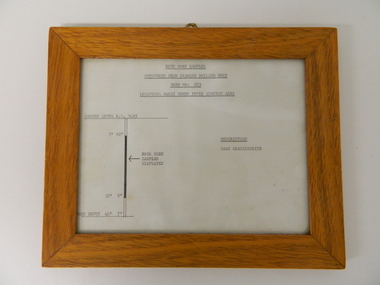

Kiewa Valley Historical Society

Kiewa Valley Historical SocietySketch Rock Core Display, circa mid to late 1900's

... engineers from the core samples would be used also...The sign heading "ROCK CORE SAMPLES RECOVERED FROM DIAMOND... This framed sketch details, in graphic form, where the core samples ...This framed sketch details, in graphic form, where the core samples in the display cabinet were removed. The drilling was a precursor to the decision where to locate, in this case, the McKay Creek Power Station. The information gained by structural engineers from the core samples would be used also for the placements of underground tunnels entry and exit points and the overall effective size of the plant. This would have included drill and blast techniques(rock characteristics play an import part of explosion control), requirements for support structures and reinforcing cement/steel forms. The use and replenishment of diamond drill bits(the strongest available, see KVHS 0280) was dependent on the "type" of rock found. Support beams for reinforced ceilings and floors was also a necessity.The visual derails of where the rock core samples were removed is very significant in the formulation and placement of the underground Power Stations and their maze of tunnels(in and out) for a successful implementation of the Hydro Scheme. The amount of pre-planning and scientific studies required for such a large scheme must be undertaken to ensure that a "white elephant" was not the result.This framed and glass front rock core display sketch has type written information of the rock samples displayed in KVHS 0279 (A). It has a softwood stained and glossed frame with a fixed(nailed) back board and a brass fixture for mounting onto a wall.The paper and type are slighted faded (sunlight affected). The sign heading "ROCK CORE SAMPLES RECOVERED FROM DIAMOND DRILLED BORE" underneath this "BORE NO: 883" and below this "LOCATION: McKAY CREEK POWER STATION AREA" to the left a sketch incorporating the ground level point "GROUND LEVEL R.L.3493", and the core depth point "CORE DEPTH 40' 7". In between and representing( in visual form) the core location areain question.alternate energy supplies, alpine feasibility studies temperature, rainfall, sec, kiewa hydro scheme, electricity -

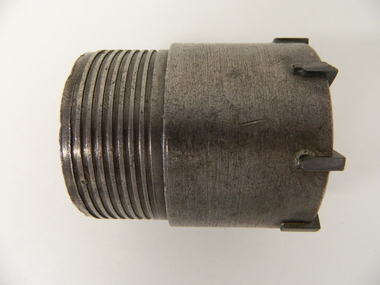

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyDrill Bit Diamond, circa mid to late 1900's

... This hollow core bit has hard cutting inserts for drilling... material to obtain 50mm core samples.. Three quarters down... in a "coring" of rock. The use of "coring" to obtained samples ...This hollow core bit has hard cutting inserts for drilling into rock. It was used to drill and recover 50mm diameter (most common size) rock cores. The rock cores were assessed by geologists and engineers to provide information for design of structures such as tunnels, dams and underground power stations (eg. McKay Creek Power Station, West Kiewa Power Station). This type of bit was also used where damage to the surrounding rock had to be minimised. The Diamond Drill Bit,used in the early 1900's, when it was primarily used as a method of sampling rock for ore deposits and oil exploration resulting in a "coring" of rock. The use of "coring" to obtained samples for the SEC Kiewa Hydro Electricity Scheme(1920's onward) was to analyse the core to obtain temperature and rainfall patterns shown by the levels of layered solidified soil(rock). This diamond drill would have been used in the early 1900's to provide a sub strata map of temperature and water patterns (over an long period of time). This was a pre requisite to any decisions about the viability of the region to provide the water needed for a successful hydro electricity scheme.This diamond drill for core sampling was at the forefront of the analysis whether to construct a hydro electrical facility in the Kiewa Valley and the adjoining alpine region. The rock core samples produced were assessed by geologists and structural engineers. It was only after extensive core drilling covering the region that solid scientific evidence could be provided to start the "SEC Vic Hydro Electricity Scheme" within its current boundaries.This "diamond" drill bit has eight "teeth" at its cutting edge. The drill creates an 55mm hole in extremely hard rock material to obtain 50mm core samples.. Three quarters down the shank it has thread screw channels to attach the bit to the drill pipe. The coring pipe attaches via screwing it onto this bit. Core samples are the main objective of this tool.alternate energy supplies, alpine feasibility studies temperature, rainfall, sec, kiewa hydro electric scheme, electricity -

Department of Energy, Environment and Climate Action

Department of Energy, Environment and Climate ActionIncrement borer

... (the core extractor) that fits inside the auger bit. The core sample... to extract a core sample of wood tissue from a living tree. The tool ...An increment borer is a specialised tool to extract a core sample of wood tissue from a living tree. The tool consists of a handle, an auger bit and a small, half circular metal tray (the core extractor) that fits inside the auger bit. The core sample can be used to count the rings, to reveal the age of the tree and its growth rate.Increment borer. The central core is stuck. AGN Mattison - Sweden #4333forest measurement, forests commission victoria (fcv) -

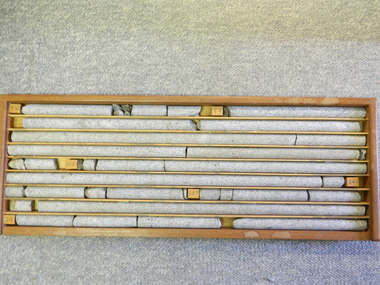

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyCore Rock Samples

... The core samples in the display cabinet were obtained from... the core samples would be used also for the placements ...The core samples in the display cabinet were obtained from the various sites at which drilling into the rock surface was carried out (under the control of design and structural engineers of the SEC Kiewa Hydro Scheme - late 1940's). This function was a precursor to the decision where to locate, in this case, the McKay Creek Power Station. The information gained by structural engineers from the core samples would be used also for the placements of underground tunnels entry and exit points and the overall effective size of the generator plant. This would have included drill and blast techniques (rock characteristics play an import part of explosion control), requirements for support structures and reinforcing cement/steel forms. The use and replenishment of diamond drill bits(the strongest available, see KVHS 0280) was dependent on the "type" of rock found (harder rock required greater numbers of drill bits). Support beams for reinforced ceilings and floors was also a necessity.These rock core samples are very significant in the formulation and placement of the underground Power Stations and their maze of tunnels (in and out) for a successful implementation of the Hydro Scheme. The amount of pre-planning and engineering studies required for such a large scheme must be undertaken to ensure that a "white elephant" was not the result.There are nine columns of rock cores, each 30mm in diameter, set in a wooden display rack. A clear plastic (slide out) protective panel is installed to the front section. Within each column are block details of the depth from which that section was brought from. See KVHS for the appropriate sketch details.Depth levels (retrieved from) are shown for each section on wooden Blocks: 1st Block: "7'10" (seven feet, ten inches), 2nd Block:"9'4" (nine feet, four inches), 3rd Block: "19'3" (nineteen feet, three inches), 4th Block: "24'2" (twenty four feet, two inches), 5th Block: "25'7"( twenty five feet, seven inches) and last block: "30' (thirty feet)"alternate energy supplies, alpine feasibility studies temperature, rainfall, sec, kiewa hydro scheme, electricity -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyS.E.C.V. Transmission Cables Board, c1940's

Differing gauges of transmission line was/is used in the Kiewa Hydro Electric Scheme. Some carried 330KV, 220KV, 66KV (Mount Beauty to Bright) and (Clover to Mount Beauty) and 22KV. All the cables have a core of steel for strength and an aluminium outer layer for transmission. Examples include 66KV copper cable, copper earth wire from the towers, copper cable found along the aqueducts for telemetering and copper earth wire. The 24 Volt Communication cables were/are used for linking different sites on remote SEC equipment.The State Electricity Commission of Victoria constructed the Kiewa Hydro Electric Scheme during the late 1930's to 1960's. A wooden board with samples of differing gauges of transmission cables used for the transmission of power and 24 volt communication cables used for communication linking different sites on remote S.E.C. equipment. The cables No.s 1 to 9 have a core of steel for strength and an aluminium outer layer for transmission. The copper cables No.s 10 - 14 are used for earthing and are in the ground as copper doesn't rust or corrode (steel does). Copper is three times heavier (dense) than aluminium. Each of the outside aluminium wires are wound in the opposite direction so that when the cable is stretched under load, they tighten.state electricity commission of victoria. kiewa hydro electric scheme. cable. communication. transmission. telemetering. power. electricity. -

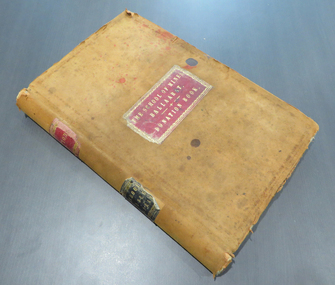

Federation University Historical Collection

Federation University Historical CollectionBook - Book - Ledger, Ballarat School of Mines Donation Book, 1978-1896, 01/01/1878 - 01/08/1896

Leather bound ledger with hand written details on donations to the Ballarat School of Mines Museum or the Ballarat School of Mines Library. The Ledger was made by J. McHutchison, Bookbinder, paper ruler and Account Book Manufacturer. 267. 07 July 1880 - John Lynch Junior - Smythesdale - Cast of "Golden Age" nugget found at Browns by Co-operative Party - 12 men. Weight 75 oz 12 dwts 12 grs 294. 24 June 1880 - W.H. Shaw - Ballarat - 94 numbers of 'The Engineer'. 295. 28 June 1880 - Rivett Henry Bland - Clunes - Specimen of water pipe from the Port Phillip Consols Mine encrusted with Carbonates of lime and magnesia and sulphate of lime with earthy matter. 418. 17 June 1881 - F. Ratte - Sydney - Catalogue of Rocks, minerals, etc of New Caledonia. 462. 28 September 1881 - Dr Bunce - Ballarat - Concretionary Basalt with Car. Lime and Magnesia. 465. 06 September 1881 - J.J. Sleep (Chairman of the Board) per favor of E.W. Spain, Esq, Manr - Ballarat - Diamond drill core from "Carisbrook Freehold Estate" - cut at a depth of 150 feet. Dedrites from Munster Gully ... 517. 20 January 1882 - William Lester - Ballarat - The Agricultural Teacher 549. 24 March 1882 - C.E. Grainger Manager Ballarat Woollen Mills - Ballarat - Samples of dyed and raw wool and dye material. 600. 04 July 1882 - Henry Sutton - Ballarat - 13th Annual Report of the Aeronautical Society of Great Britain. 1222. 31 October 1884 - Trooper Dowling - Miner's Rest - Owl 1223. 04 November 1884 - W. McKeenan - 3, Adair St, Ballarat - Flying Squirrel. 1259. 16 January 1885 - A.A. Buley - Ballarat - Prospective of Grenville College 1885 1428. 06 October 1885 - Ballarat - Collection of mineral specimens from Silverton (Collected by Mr James Murray). 1442. 20 October 1885 - Ballarat - Specimen of fossil fruits collected by Haddon by Charles Brown. 1682. 28 February 1887 - James Lamb - Ballarat - Copy of the Ballarat Times Newspaper of 3rd December 1854, framed and protected on both sides with glass. 1730. 23 May 1887 - Bella Guerin - Ballarat - Copy of the Victorian Review No 74 December 1885 4786. 27 March 1894 - James Oddie - Ballarat - 3 mineral specimens 4835. 01 August 1896 - P.V> Barnard - Ballarat - {ortion of Mining truck wheel altered to oxide of iron found in the old workings of the Golden Gate Mine at a depth of 200 feet. (4235 is last entry)ballarat school of mines, ballarat school of mines museum, donations, henry sutton, bella guerin -

Ballarat Tramway Museum

Ballarat Tramway MuseumFunctional Object - Tramcar - materials

1330.1 - Approx 110m long section of a compressor armature end binding from the compressor of tram No. 40. The binding section consists of string which has been impregnated with insulating varnish. Located between the end of the armature and the commutator and retains the mica core. Small pieces of mica on the inside. Has a circular shape inherent from its use. - Not numbered. 1330.2 - approx. 25mm long section strip of red silicone tape with glass fibre reinforcement - 25mm wide with a plastic separation strip. Supplied by XLNT Enterprises - see fax on W.A.Doubleday files dated 5/1/2000. 1330.3 - as above, but two sections of this tape joined together as a sample. 1330.2 used to wrap the armature - two layers applied cut to be about 22mm wide instead of 25mm - repair done on 3/3/2000. See W.A. Doubleday personal btm files for period and car record book.armatures, repairs, materials, insulation -

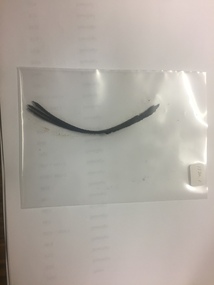

Melbourne Tram Museum

Melbourne Tram MuseumMemorabilia - Sample of worn cable tram rope

... fibre core. Memorabilia Sample of worn cable tram rope ...Section of worn cable tram wire rope. One of the two ferrules has been engraved with "243 Weeks 341591 Miles" and the other "ANTD 12 Weeks" - "ANTD" is thought to be an abbreviation for anticipated. On this basis, the cable rope lasted 20 times its expected life! Demonstrates a worn cable tram wire rope that has been sampled and its use recorded.Section of worn Melbourne cable tram wire rope with engraved retaining brass ferrules on each end consisting of seven wound (12 wires) around a central fibre core.See contexttramways, cable trams, cable ropes, cables, mmtb -

National Wool Museum

National Wool MuseumTextile - Children's Jumper, Kathryn Knitwear, c.1970

Kathryn Knitwear, founded by Robert Blake, manufactured high quality children’s knitwear in Melbourne from the 1940s – 1980s. Robert Blake began manufacturing children’s knitwear in his bedroom in Strathmore using a hand powered machine in the late 1940s. The operation moved to Ascot Vale and Essendon, before eventually establishing a factory in Moonee Ponds in the early 1950s. The business continued to expand, necessitating a move to a new factory in Broadmeadows. By 1962, the Broadmeadows factory was producing an average of 20,000 garments per month, which increased to 24,000 by 1964. Robert Blake’s Son, Brendan recalls that “The Kathryn brand was famous around Australia, anywhere children needed to keep warm and dress smartly. It also won a number of wool fashion awards”, including the 1969 Wool Awards, which was held by the Australian Wool Bureau and published in Women’s Weekly. The Kathryn range was designed for durability, comfort and care, without sacrificing style. They used patterning techniques that increase stretchiness, comfort and fit, as well as integrating decorative elements into the fabric to prevent them from being bulky, uncomfortable or tight. Making longevity of style a priority, Brendan Blake remembers that “there was one particular garment that was in the range for at least thirty years”. He also recalls “In the past, when women have found out that I was associated with Kathryn Knitwear, they would often relate to me the story of a garment they had purchased or received as a gift and, when their child had grown out of it, they would hand it on to another child. Several ladies have told me of purchasing garments for their daughters’ glory box, or saving a particular garment after their daughter had grown out of it. Brendan Blake: “At the peak of their operation they employed approximately two hundred people, mainly women and girls. A family would often seek to send their daughter to work in this company because they knew they would be looked after and safe. One lady wrote to me telling me that working at the Moonee Ponds Factory prior to getting married was the happiest time of her life.” In 1963, workers at the Kathryn factory earned £13 per week, which was 8 shillings and 8 pence higher than the minimum weekly wage for female workers in the textile manufacturing industry (£12 11s 4d). By 1970, the Kathryn Knitwear brand expanded from children’s knitwear into womenswear under the brand name ‘Lady Kathryn’, and for boys and men under ‘Robert Blake’. Continuing to diversify their distribution, they also began exporting ‘Kathryn’ garments to New Zealand, the Pacific Islands, and Japan. ‘Kathryn Knitwear’ was well-known for their early adoption of modern materials and techniques that had broad appeal to their customer base. This is shown in their early use of the acrylic fibre ‘Orlon’ in the 50s and 60s and ‘Superwash’ wool in the 1970s. Many of Kathryn Knitwear’s styles, particularly those that were long running staples of the brand, were available in both wool and Orlon to suit the consumer’s preference. Wool has been renowned for its excellent properties for thousands of years, by people from all over the world. Not only good for thick winter woollens, it can help keep you cool in summer, as well as being durable and resistant to water, fire, ultraviolet light, stains and odour. Far from the humble origins of one man in his bedroom with a hand-cranked machine; at its closure in 1980, the Broadmeadows factory of ‘Kathryn’ housed more than 100 machines, including 53 sewing machines and 45 knitting machines. Robert Blake was “a passionate advocate for wool and Australian Made” throughout his whole life. A strong thread that ties through the lifespan of Robert Blake and Kathryn Knitwear is a balance between adopting new innovations without sacrificing the core values of durability, comfort, care and style that had made the brand so well known. Their legacy forms an integral part of both Australian social and manufacturing history.Grey wool Jumper with Blue and grey cable design on front. Vertical cable pattern is two sets of intertwining grey blue cable pairs on a purl stitch background in alternating rows of blue and grey. Front panel of jumper has five cable panels separated by smooth stocking stitch panels. Jumper has long sleeves and crew neck with thick ribbed collar and cuffs. Style B/110, Colourway Silver/Denim, Size 8 .2) 2 Sample tags stapled together with manufacturing information, including sizes and colours available, as well as knit swatch samples for colourways Brown/Woodgrain, Denim/Blue Shadow and Pebble/Oyster.1) [white label at back neck with green and black printed writing] ROBERT BLAKE Size 8 / knitwear HEIGHT 130cm MADE IN AUSTRALIA .2) [blue sample label] STYLE B/110 Crew Neck Wool Pullover SIZES: 2 4 6 8 10 PRICE: $10 [amended to $11 in blue pen] $[written over in blue pen so as to be illegible] [handwritten in blue pen] $12.55 SIZES: 12 14 PRICE: [printed] $12.30 [handwritten over top in blue pen] $13.15 COLORS: Silver/Denim, Brown/Woodgrain, Denim/Blue Shadow, Pebble/Oyster. Dec on Del. [cream brand label] [OBVERSE] ROBERT BLAKE [REVERSE] ROBERT BLAKE KNITWEAR MELBOURNE, AUSTRALIAknitwear, clothing, children's clothing, jumper, manufacturing, fashion textile production, machine knitting -

National Wool Museum

National Wool MuseumTextile - Children's Jumper, Kathryn Knitwear, c.1970

Kathryn Knitwear, founded by Robert Blake, manufactured high quality children’s knitwear in Melbourne from the 1940s – 1980s. Robert Blake began manufacturing children’s knitwear in his bedroom in Strathmore using a hand powered machine in the late 1940s. The operation moved to Ascot Vale and Essendon, before eventually establishing a factory in Moonee Ponds in the early 1950s. The business continued to expand, necessitating a move to a new factory in Broadmeadows. By 1962, the Broadmeadows factory was producing an average of 20,000 garments per month, which increased to 24,000 by 1964. Robert Blake’s Son, Brendan recalls that “The Kathryn brand was famous around Australia, anywhere children needed to keep warm and dress smartly. It also won a number of wool fashion awards”, including the 1969 Wool Awards, which was held by the Australian Wool Bureau and published in Women’s Weekly. The Kathryn range was designed for durability, comfort and care, without sacrificing style. They used patterning techniques that increase stretchiness, comfort and fit, as well as integrating decorative elements into the fabric to prevent them from being bulky, uncomfortable or tight. Making longevity of style a priority, Brendan Blake remembers that “there was one particular garment that was in the range for at least thirty years”. He also recalls “In the past, when women have found out that I was associated with Kathryn Knitwear, they would often relate to me the story of a garment they had purchased or received as a gift and, when their child had grown out of it, they would hand it on to another child. Several ladies have told me of purchasing garments for their daughters’ glory box, or saving a particular garment after their daughter had grown out of it. Brendan Blake: “At the peak of their operation they employed approximately two hundred people, mainly women and girls. A family would often seek to send their daughter to work in this company because they knew they would be looked after and safe. One lady wrote to me telling me that working at the Moonee Ponds Factory prior to getting married was the happiest time of her life.” In 1963, workers at the Kathryn factory earned £13 per week, which was 8 shillings and 8 pence higher than the minimum weekly wage for female workers in the textile manufacturing industry (£12 11s 4d). By 1970, the Kathryn Knitwear brand expanded from children’s knitwear into womenswear under the brand name ‘Lady Kathryn’, and for boys and men under ‘Robert Blake’. Continuing to diversify their distribution, they also began exporting ‘Kathryn’ garments to New Zealand, the Pacific Islands, and Japan. ‘Kathryn Knitwear’ was well-known for their early adoption of modern materials and techniques that had broad appeal to their customer base. This is shown in their early use of the acrylic fibre ‘Orlon’ in the 50s and 60s and ‘Superwash’ wool in the 1970s. Many of Kathryn Knitwear’s styles, particularly those that were long running staples of the brand, were available in both wool and Orlon to suit the consumer’s preference. Wool has been renowned for its excellent properties for thousands of years, by people from all over the world. Not only good for thick winter woollens, it can help keep you cool in summer, as well as being durable and resistant to water, fire, ultraviolet light, stains and odour. Far from the humble origins of one man in his bedroom with a hand-cranked machine; at its closure in 1980, the Broadmeadows factory of ‘Kathryn’ housed more than 100 machines, including 53 sewing machines and 45 knitting machines. Robert Blake was “a passionate advocate for wool and Australian Made” throughout his whole life. A strong thread that ties through the lifespan of Robert Blake and Kathryn Knitwear is a balance between adopting new innovations without sacrificing the core values of durability, comfort, care and style that had made the brand so well known. Their legacy forms an integral part of both Australian social and manufacturing history.Brown and Grey children’s jacket with brown accents at pockets and shoulder, centre front zip, curved pocket detail.Style B/117, Colourway Woodgrain/Pebble, Size 8 .2) Sample tags stapled together with manufacturing information, including sizes and colours available, as well as knit swatch samples for colourways Green/Silver, Burgundy/Denim, Navy/Denim, and Rust/Pebble.1) [white label at back neck with green and black printed writing] ROBERT BLAKE Size 8 / knitwear HEIGHT 130cm MADE IN AUSTRALIA .2 [blue sample label] STYLE B/117 Jacket. Zip. Birdseye. Wool. SIZES: 2 4 6 8 10 PRICE: $11.75 [amended to $12.80 in blue pen] $13.85 [amended to $15.05 in blue pen] SIZES: 12 14 PRICE: [printed] $14.95 [amended to $16.15 in blue pen] COLORS: Woodgrain/Pebble Green/Silver [drawn through in black pen] Burgundy/Denim, Navy/Denim, Rust/Pebble Dec on Del. [cream brand label] [OBVERSE] ROBERT BLAKE [REVERSE] ROBERT BLAKE KNITWEAR MELBOURNE, AUSTRALIAknitwear, clothing, children's clothing, jumper, manufacturing, fashion textile production, machine knitting, children's knitwear -

National Wool Museum

National Wool MuseumTextile - Children's Cardigan, Kathryn Knitwear, c.1960

Kathryn Knitwear, founded by Robert Blake, manufactured high quality children’s knitwear in Melbourne from the 1940s – 1980s. Robert Blake began manufacturing children’s knitwear in his bedroom in Strathmore using a hand powered machine in the late 1940s. The operation moved to Ascot Vale and Essendon, before eventually establishing a factory in Moonee Ponds in the early 1950s. The business continued to expand, necessitating a move to a new factory in Broadmeadows. By 1962, the Broadmeadows factory was producing an average of 20,000 garments per month, which increased to 24,000 by 1964. Robert Blake’s Son, Brendan recalls that “The Kathryn brand was famous around Australia, anywhere children needed to keep warm and dress smartly. It also won a number of wool fashion awards”, including the 1969 Wool Awards, which was held by the Australian Wool Bureau and published in Women’s Weekly. The Kathryn range was designed for durability, comfort and care, without sacrificing style. They used patterning techniques that increase stretchiness, comfort and fit, as well as integrating decorative elements into the fabric to prevent them from being bulky, uncomfortable or tight. Making longevity of style a priority, Brendan Blake remembers that “there was one particular garment that was in the range for at least thirty years”. He also recalls “In the past, when women have found out that I was associated with Kathryn Knitwear, they would often relate to me the story of a garment they had purchased or received as a gift and, when their child had grown out of it, they would hand it on to another child. Several ladies have told me of purchasing garments for their daughters’ glory box, or saving a particular garment after their daughter had grown out of it. Brendan Blake: “At the peak of their operation they employed approximately two hundred people, mainly women and girls. A family would often seek to send their daughter to work in this company because they knew they would be looked after and safe. One lady wrote to me telling me that working at the Moonee Ponds Factory prior to getting married was the happiest time of her life.” In 1963, workers at the Kathryn factory earned £13 per week, which was 8 shillings and 8 pence higher than the minimum weekly wage for female workers in the textile manufacturing industry (£12 11s 4d). By 1970, the Kathryn Knitwear brand expanded from children’s knitwear into womenswear under the brand name ‘Lady Kathryn’, and for boys and men under ‘Robert Blake’. Continuing to diversify their distribution, they also began exporting ‘Kathryn’ garments to New Zealand, the Pacific Islands, and Japan. ‘Kathryn Knitwear’ was well-known for their early adoption of modern materials and techniques that had broad appeal to their customer base. This is shown in their early use of the acrylic fibre ‘Orlon’ in the 50s and 60s and ‘Superwash’ wool in the 1970s. Many of Kathryn Knitwear’s styles, particularly those that were long running staples of the brand, were available in both wool and Orlon to suit the consumer’s preference. Cotton is a common material for knitwear worn in the warmer months, as it is very breathable and absorbs moisture easily. While we mostly associate knitwear with keeping us warm in the cold, the market for Australian knitwear would be very limited without options to wear all year round. Far from the humble origins of one man in his bedroom with a hand-cranked machine; at its closure in 1980, the Broadmeadows factory of ‘Kathryn’ housed more than 100 machines, including 53 sewing machines and 45 knitting machines. Robert Blake was “a passionate advocate for wool and Australian Made” throughout his whole life. A strong thread that ties through the lifespan of Robert Blake and Kathryn Knitwear is a balance between adopting new innovations without sacrificing the core values of durability, comfort, care and style that had made the brand so well known. Their legacy forms an integral part of both Australian social and manufacturing history.Royal blue double breasted cardigan 'Reefer Jacket' with short sleeves in a textured rib stitch with six chrome metal buttons in two rows down centre front. Style 319/J .2 is sample tag with manufacturing information, including sizes and colours available.1) [white label at back neck with blue stitching] KATHRYN REGD. CREATED BY ALL COTTON / 24 / ROBERT BLAKE .2) [sample label] [OBVERSE] STYLE: 319/J – Reefer Jacket – Combed Cot. SIZE: 22” 24” 26” 28” 30” 32” PRICE: 20/- 21/- 22/6 24/- 26/- 27/6 COLOR: NAVY ONLY. [REVERSE] KATHRYN Garments are • PRE-SHRUNK • STANDARD MEASUREMENTS • FIT EXACTLY • LAUNDER PERFECTLY Designed and Manufactured by ROBERT BLAKE, MELBOURNEknitwear, children's knitwear, clothing, children's clothing, cardigan, manufacturing, fashion textile production, machine knitting, fashion cotton -

National Wool Museum

National Wool MuseumTextile - Children's Jumper, Kathryn Knitwear, c.1975

Kathryn Knitwear, founded by Robert Blake, manufactured high quality children’s knitwear in Melbourne from the 1940s – 1980s. Robert Blake began manufacturing children’s knitwear in his bedroom in Strathmore using a hand powered machine in the late 1940s. The operation moved to Ascot Vale and Essendon, before eventually establishing a factory in Moonee Ponds in the early 1950s. The business continued to expand, necessitating a move to a new factory in Broadmeadows. By 1962, the Broadmeadows factory was producing an average of 20,000 garments per month, which increased to 24,000 by 1964. Robert Blake’s Son, Brendan recalls that “The Kathryn brand was famous around Australia, anywhere children needed to keep warm and dress smartly. It also won a number of wool fashion awards”, including the 1969 Wool Awards, which was held by the Australian Wool Bureau and published in Women’s Weekly. The Kathryn range was designed for durability, comfort and care, without sacrificing style. They used patterning techniques that increase stretchiness, comfort and fit, as well as integrating decorative elements into the fabric to prevent them from being bulky, uncomfortable or tight. Making longevity of style a priority, Brendan Blake remembers that “there was one particular garment that was in the range for at least thirty years”. He also recalls “In the past, when women have found out that I was associated with Kathryn Knitwear, they would often relate to me the story of a garment they had purchased or received as a gift and, when their child had grown out of it, they would hand it on to another child. Several ladies have told me of purchasing garments for their daughters’ glory box, or saving a particular garment after their daughter had grown out of it. Brendan Blake: “At the peak of their operation they employed approximately two hundred people, mainly women and girls. A family would often seek to send their daughter to work in this company because they knew they would be looked after and safe. One lady wrote to me telling me that working at the Moonee Ponds Factory prior to getting married was the happiest time of her life.” In 1963, workers at the Kathryn factory earned £13 per week, which was 8 shillings and 8 pence higher than the minimum weekly wage for female workers in the textile manufacturing industry (£12 11s 4d). By 1970, the Kathryn Knitwear brand expanded from children’s knitwear into womenswear under the brand name ‘Lady Kathryn’, and for boys and men under ‘Robert Blake’. Continuing to diversify their distribution, they also began exporting ‘Kathryn’ garments to New Zealand, the Pacific Islands, and Japan. ‘Kathryn Knitwear’ was well-known for their early adoption of modern materials and techniques that had broad appeal to their customer base. This is shown in their early use of the acrylic fibre ‘Orlon’ in the 50s and 60s and ‘Superwash’ wool in the 1970s. Many of Kathryn Knitwear’s styles, particularly those that were long running staples of the brand, were available in both wool and Orlon to suit the consumer’s preference. Wool has been renowned for its excellent properties for thousands of years, by people from all over the world. Not only good for thick winter woollens, it can help keep you cool in summer, as well as being durable and resistant to water, fire, ultraviolet light, stains and odour. Far from the humble origins of one man in his bedroom with a hand-cranked machine; at its closure in 1980, the Broadmeadows factory of ‘Kathryn’ housed more than 100 machines, including 53 sewing machines and 45 knitting machines. Robert Blake was “a passionate advocate for wool and Australian Made” throughout his whole life. A strong thread that ties through the lifespan of Robert Blake and Kathryn Knitwear is a balance between adopting new innovations without sacrificing the core values of durability, comfort, care and style that had made the brand so well known. Their legacy forms an integral part of both Australian social and manufacturing history.Orange jumper with multicoloured heathered tweed effect, white stripe accent on neck, upper arm and sleeve cuffs, two patch pockets mounted on diagonal outlined in thread matching accent colour .2 Sample tags with manufacturing information, including sizes and colours available, as well as knit swatch samples in colourways Blue Tweed/Sky/Magnolia and Cream Tweed/Magnolia/Pine.1) [tag stitched into back neck] KATHRYN REGD PURE NEW WOOL/ SIZE 6 HEIGHT 120cm MADE IN AUSTRALIA .2) [blue sample label] STYLE 589/Pullover S.47. Wool Tweed. SIZES: 2 4 6 8 PRICE: $9.80 [amended to $10.75 in blue pen] $0.35 [handwritten in blue pen] $11.40 COLORS: Pink Tw/Ochre/Mag, Blue Tweed/Sky/Magnolia Cream Tweed/Mag/Pine. [Crossed out in black ink] March on Del.children's knitwear, children's clothing, clothing, knitwear, jumper, manufacturing, fashion textile production, machine knitting, heathered yarn, tweed yarn, flecked yarn, colourwork -

National Wool Museum

National Wool MuseumTextile - Diaper Set, Kathryn Knitwear, c.1960

Kathryn Knitwear, founded by Robert Blake, manufactured high quality children’s knitwear in Melbourne from the 1940s – 1980s. Robert Blake began manufacturing children’s knitwear in his bedroom in Strathmore using a hand powered machine in the late 1940s. The operation moved to Ascot Vale and Essendon, before eventually establishing a factory in Moonee Ponds in the early 1950s. The business continued to expand, necessitating a move to a new factory in Broadmeadows. By 1962, the Broadmeadows factory was producing an average of 20,000 garments per month, which increased to 24,000 by 1964. Robert Blake’s Son, Brendan recalls that “The Kathryn brand was famous around Australia, anywhere children needed to keep warm and dress smartly. It also won a number of wool fashion awards”, including the 1969 Wool Awards, which was held by the Australian Wool Bureau and published in Women’s Weekly. The Kathryn range was designed for durability, comfort and care, without sacrificing style. They used patterning techniques that increase stretchiness, comfort and fit, as well as integrating decorative elements into the fabric to prevent them from being bulky, uncomfortable or tight. Making longevity of style a priority, Brendan Blake remembers that “there was one particular garment that was in the range for at least thirty years”. He also recalls “In the past, when women have found out that I was associated with Kathryn Knitwear, they would often relate to me the story of a garment they had purchased or received as a gift and, when their child had grown out of it, they would hand it on to another child. Several ladies have told me of purchasing garments for their daughters’ glory box, or saving a particular garment after their daughter had grown out of it. Brendan Blake: “At the peak of their operation they employed approximately two hundred people, mainly women and girls. A family would often seek to send their daughter to work in this company because they knew they would be looked after and safe. One lady wrote to me telling me that working at the Moonee Ponds Factory prior to getting married was the happiest time of her life.” In 1963, workers at the Kathryn factory earned £13 per week, which was 8 shillings and 8 pence higher than the minimum weekly wage for female workers in the textile manufacturing industry (£12 11s 4d). By 1970, the Kathryn Knitwear brand expanded from children’s knitwear into womenswear under the brand name ‘Lady Kathryn’, and for boys and men under ‘Robert Blake’. Continuing to diversify their distribution, they also began exporting ‘Kathryn’ garments to New Zealand, the Pacific Islands, and Japan. ‘Kathryn Knitwear’ was well-known for their early adoption of modern materials and techniques that had broad appeal to their customer base. This is shown in their early use of the acrylic fibre ‘Orlon’ in the 50s and 60s and ‘Superwash’ wool in the 1970s. Many of Kathryn Knitwear’s styles, particularly those that were long running staples of the brand, were available in both wool and Orlon to suit the consumer’s preference. Cotton is a common material for knitwear worn in the warmer months, as it is very breathable and absorbs moisture easily. While we mostly associate knitwear with keeping us warm in the cold, the market for Australian knitwear would be very limited without options to wear all year round. The decoration on this garment was embroidered by hand by a skilled worker at the Kathryn Knitwear factory. Far from the humble origins of one man in his bedroom with a hand-cranked machine; at its closure in 1980, the Broadmeadows factory of ‘Kathryn’ housed more than 100 machines, including 53 sewing machines and 45 knitting machines. Robert Blake was “a passionate advocate for wool and Australian Made” throughout his whole life. A strong thread that ties through the lifespan of Robert Blake and Kathryn Knitwear is a balance between adopting new innovations without sacrificing the core values of durability, comfort, care and style that had made the brand so well known. Their legacy forms an integral part of both Australian social and manufacturing history.White diaper set. Short sleeved white top with two inverted box pleats along whole length, stitched at shoulder and mid chest. Embroidered in half cross stitch with two blue dogs on front. Closes in centre back with three plastic pearlescent buttons. White baby diaper shorts with ribbing at waist and leg holes .3 is a sample tag with manufacturing information, including price, size and colours available .4 is a swing tag with manufacturer care instructions.1 [label at back neck of top] Kathryn Reg’d / All Cotton / 18 .3 [sample label] [Obverse] STYLE: 314. Diaper Sat [sic] – Emb top. Combed Cotton. SIZE: 18” PRICE: 26/- COLOR: BLUE. LEMON. WHITE. [reverse] KATHRYN Garments are •PRE-SHRUNK •STANDARD MEASUREMENTS •FIT EXACTLY •LAUNDER PERFECTLY Designed and Manufactured by ROBERT BLAKE, MELBOURNE .4 [retail label] [obverse] Kathryn PRE-SHRUNK KNITWEAR Style: 314 [handwritten] DESIGNED & MANUFACTURED BY Robert Blake MELBOURNE [reverse] IMPORTANT. Special care should be taken with white and pastel shades. Rinse thoroughly. Do NOT dry in sunlight. WASHING INSTRUCTIONS 1.Wash frequently to AVOID HEAVY SOILING 2.Wash garment BY HAND, in lukewarm Velvet Soap suds. ON NO ACCOUNT RUB SOAP ON GARMENT. 3.Squeeze suds gently through garment but DO NOT RUB. Rubbing will cause garment to thicken. 4.RINSE AT LEAST TWICE IN CLEAN WATER TO REMOVE ALL SOAP. 5.To dry, roll garment in a towel to remove excess moisture, turn garment inside out and pull it lengthwise, then safety-pin to line through shoulder tape. 6.To keep Brushed Wool garments like new brush frequently with nylon brush.children's knitwear, children's clothing, knitwear, clothing, manufacturing, fashion textile production, embroidery, embroiderer, hand embroidery, dog embroidery, animal embroidery, animal motif, dog motif, dog, animal, baby clothes, baby knitwear, baby clothing -

National Wool Museum

National Wool MuseumTextile - Children's Dress, Kathryn Knitwear, c.1960

Kathryn Knitwear, founded by Robert Blake, manufactured high quality children’s knitwear in Melbourne from the 1940s – 1980s. Robert Blake began manufacturing children’s knitwear in his bedroom in Strathmore using a hand powered machine in the late 1940s. The operation moved to Ascot Vale and Essendon, before eventually establishing a factory in Moonee Ponds in the early 1950s. The business continued to expand, necessitating a move to a new factory in Broadmeadows. By 1962, the Broadmeadows factory was producing an average of 20,000 garments per month, which increased to 24,000 by 1964. Robert Blake’s Son, Brendan recalls that “The Kathryn brand was famous around Australia, anywhere children needed to keep warm and dress smartly. It also won a number of wool fashion awards”, including the 1969 Wool Awards, which was held by the Australian Wool Bureau and published in Women’s Weekly. The Kathryn range was designed for durability, comfort and care, without sacrificing style. They used patterning techniques that increase stretchiness, comfort and fit, as well as integrating decorative elements into the fabric to prevent them from being bulky, uncomfortable or tight. Making longevity of style a priority, Brendan Blake remembers that “there was one particular garment that was in the range for at least thirty years”. He also recalls “In the past, when women have found out that I was associated with Kathryn Knitwear, they would often relate to me the story of a garment they had purchased or received as a gift and, when their child had grown out of it, they would hand it on to another child. Several ladies have told me of purchasing garments for their daughters’ glory box, or saving a particular garment after their daughter had grown out of it. Brendan Blake: “At the peak of their operation they employed approximately two hundred people, mainly women and girls. A family would often seek to send their daughter to work in this company because they knew they would be looked after and safe. One lady wrote to me telling me that working at the Moonee Ponds Factory prior to getting married was the happiest time of her life.” In 1963, workers at the Kathryn factory earned £13 per week, which was 8 shillings and 8 pence higher than the minimum weekly wage for female workers in the textile manufacturing industry (£12 11s 4d). By 1970, the Kathryn Knitwear brand expanded from children’s knitwear into womenswear under the brand name ‘Lady Kathryn’, and for boys and men under ‘Robert Blake’. Continuing to diversify their distribution, they also began exporting ‘Kathryn’ garments to New Zealand, the Pacific Islands, and Japan. ‘Kathryn Knitwear’ was well-known for their early adoption of modern materials and techniques that had broad appeal to their customer base. This is shown in their early use of the acrylic fibre ‘Orlon’ in the 50s and 60s and ‘Superwash’ wool in the 1970s. Many of Kathryn Knitwear’s styles, particularly those that were long running staples of the brand, were available in both wool and Orlon to suit the consumer’s preference. Orlon was developed by DuPont in the 1940s and became the first commercially successful acrylic fibre in the 1950s and 1960s. The development of Orlon coincided with an increase in availability of washing machines in everyday Australian homes. The great appeal of Orlon was that while wool garments still had to be hand-washed, Orlon’s shrink-resistant nature made it machine washable and dryable. This was a very appealing prospect, especially for the seemingly unending task of cleaning active children’s clothing. Machine washable wool would not be available until the development of the ‘Superwash’ treatment by the Australian Wool Board and CSIRO in 1970. Far from the humble origins of one man in his bedroom with a hand-cranked machine; at its closure in 1980, the Broadmeadows factory of ‘Kathryn’ housed more than 100 machines, including 53 sewing machines and 45 knitting machines. Robert Blake was “a passionate advocate for wool and Australian Made” throughout his whole life. A strong thread that ties through the lifespan of Robert Blake and Kathryn Knitwear is a balance between adopting new innovations without sacrificing the core values of durability, comfort, care and style that had made the brand so well known. Their legacy forms an integral part of both Australian social and manufacturing history.Cream baby dress with long sleeves, blue stripe and cream faux cable textured details at yoke and hem. Body is gathered and attaches at yoke. Dress has a drawstring tie at neck accented with cream pompoms and closes at centre back with three pearlescent plastic buttons. Back opening is reinforced with grosgrain ribbon. .2 is a sample tag with manufacturing information, including sizes and colours available .3 is a retail tag with style, care instructions and brand marketing[label stitched into back neck] KATHRYN 100% Orlon .2 [sample label] [Obverse] 802/F – BABIES ORLON FROCK. 16” – LENGTH 24/6 BLUE/WHT LEMON/WHT PINK/WHT WHT/BLUE WHT/LEMON WHT/PINK .3 [Obverse] KATHRYN Children’s Knitwear STYLE [handwritten] 802/F SIZE PRICE [reverse] KATHRYN Garments are •PRE-SHRUNK •STANDARD MEASUREMENTS •FIT EXACTLY •LAUNDER PERFECTLYclothing, children's clothing, knitwear, children's knitwear, manufacturing, fashion textile production, colourwork, pom-pom, pom poms -

National Wool Museum

National Wool MuseumTextile - Children's Clothing Set, Kathryn Knitwear, c.1970

Kathryn Knitwear, founded by Robert Blake, manufactured high quality children’s knitwear in Melbourne from the 1940s – 1980s. Robert Blake began manufacturing children’s knitwear in his bedroom in Strathmore using a hand powered machine in the late 1940s. The operation moved to Ascot Vale and Essendon, before eventually establishing a factory in Moonee Ponds in the early 1950s. The business continued to expand, necessitating a move to a new factory in Broadmeadows. By 1962, the Broadmeadows factory was producing an average of 20,000 garments per month, which increased to 24,000 by 1964. Robert Blake’s Son, Brendan recalls that “The Kathryn brand was famous around Australia, anywhere children needed to keep warm and dress smartly. It also won a number of wool fashion awards”, including the 1969 Wool Awards, which was held by the Australian Wool Bureau and published in Women’s Weekly. The Kathryn range was designed for durability, comfort and care, without sacrificing style. They used patterning techniques that increase stretchiness, comfort and fit, as well as integrating decorative elements into the fabric to prevent them from being bulky, uncomfortable or tight. Making longevity of style a priority, Brendan Blake remembers that “there was one particular garment that was in the range for at least thirty years”. He also recalls “In the past, when women have found out that I was associated with Kathryn Knitwear, they would often relate to me the story of a garment they had purchased or received as a gift and, when their child had grown out of it, they would hand it on to another child. Several ladies have told me of purchasing garments for their daughters’ glory box, or saving a particular garment after their daughter had grown out of it. Brendan Blake: “At the peak of their operation they employed approximately two hundred people, mainly women and girls. A family would often seek to send their daughter to work in this company because they knew they would be looked after and safe. One lady wrote to me telling me that working at the Moonee Ponds Factory prior to getting married was the happiest time of her life.” In 1963, workers at the Kathryn factory earned £13 per week, which was 8 shillings and 8 pence higher than the minimum weekly wage for female workers in the textile manufacturing industry (£12 11s 4d). By 1970, the Kathryn Knitwear brand expanded from children’s knitwear into womenswear under the brand name ‘Lady Kathryn’, and for boys and men under ‘Robert Blake’. Continuing to diversify their distribution, they also began exporting ‘Kathryn’ garments to New Zealand, the Pacific Islands, and Japan. ‘Kathryn Knitwear’ was well-known for their early adoption of modern materials and techniques that had broad appeal to their customer base. This is shown in their early use of the acrylic fibre ‘Orlon’ in the 50s and 60s and ‘Superwash’ wool in the 1970s. Many of Kathryn Knitwear’s styles, particularly those that were long running staples of the brand, were available in both wool and Orlon to suit the consumer’s preference. Orlon was developed by DuPont in the 1940s and became the first commercially successful acrylic fibre in the 1950s and 1960s. The development of Orlon coincided with an increase in availability of washing machines in everyday Australian homes. The great appeal of Orlon was that while wool garments still had to be hand-washed, Orlon’s shrink-resistant nature made it machine washable and dryable. This was a very appealing prospect, especially for the seemingly unending task of cleaning active children’s clothing. Machine washable wool would not be available until the development of the ‘Superwash’ treatment by the Australian Wool Board and CSIRO in 1970. Far from the humble origins of one man in his bedroom with a hand-cranked machine; at its closure in 1980, the Broadmeadows factory of ‘Kathryn’ housed more than 100 machines, including 53 sewing machines and 45 knitting machines. Robert Blake was “a passionate advocate for wool and Australian Made” throughout his whole life. A strong thread that ties through the lifespan of Robert Blake and Kathryn Knitwear is a balance between adopting new innovations without sacrificing the core values of durability, comfort, care and style that had made the brand so well known. Their legacy forms an integral part of both Australian social and manufacturing history.Children’s two-piece outfit set, consisting of a top and leggings. Knitted in colour blocks of navy, red and white. Top has ribbed navy bodice section with white stripe separating red skirt and closes at back neck with two navy plastic buttons. Leggings are primarily red, with a white stripe at the ankle and navy-blue feet. Leggings are constructed primarily as one piece and seamed up at centre back and inseam, with additional gusset piece..1) [tag stitched into back neck of top] KATHRYN REGD 100% ACRYLIC FIBRE SIZE 0 WEIGHT 10 LENGTH 76 MADE IN AUSTRALIA .3) [blue sample label] STYLE 574/ Pop Top and B’tts S.26. Acrylic. SIZES: 00 0 PRICE: $8.95 COLORS: Navy/Wht/Red Red/Wht/Navy P.Blue/Wht/Navy Dec on Del.knitwear, clothing, children's knitwear, children's clothing, manufacturing, fashion textile production, machine knitting, clothing set -

National Wool Museum

National Wool MuseumTextile - Fabric Sample, Kathryn Knitwear, 1980

Kathryn Knitwear, founded by Robert Blake, manufactured high quality children’s knitwear in Melbourne from the 1940s – 1980s. Robert Blake began manufacturing children’s knitwear in his bedroom in Strathmore using a hand powered machine in the late 1940s. The operation moved to Ascot Vale and Essendon, before eventually establishing a factory in Moonee Ponds in the early 1950s. The business continued to expand, necessitating a move to a new factory in Broadmeadows. By 1962, the Broadmeadows factory was producing an average of 20,000 garments per month, which increased to 24,000 by 1964. Robert Blake’s Son, Brendan recalls that “The Kathryn brand was famous around Australia, anywhere children needed to keep warm and dress smartly. It also won a number of wool fashion awards”, including the 1969 Wool Awards, which was held by the Australian Wool Bureau and published in Women’s Weekly. The Kathryn range was designed for durability, comfort and care, without sacrificing style. They used patterning techniques that increase stretchiness, comfort and fit, as well as integrating decorative elements into the fabric to prevent them from being bulky, uncomfortable or tight. Making longevity of style a priority, Brendan Blake remembers that “there was one particular garment that was in the range for at least thirty years”. He also recalls “In the past, when women have found out that I was associated with Kathryn Knitwear, they would often relate to me the story of a garment they had purchased or received as a gift and, when their child had grown out of it, they would hand it on to another child. Several ladies have told me of purchasing garments for their daughters’ glory box, or saving a particular garment after their daughter had grown out of it. Brendan Blake: “At the peak of their operation they employed approximately two hundred people, mainly women and girls. A family would often seek to send their daughter to work in this company because they knew they would be looked after and safe. One lady wrote to me telling me that working at the Moonee Ponds Factory prior to getting married was the happiest time of her life.” In 1963, workers at the Kathryn factory earned £13 per week, which was 8 shillings and 8 pence higher than the minimum weekly wage for female workers in the textile manufacturing industry (£12 11s 4d). By 1970, the Kathryn Knitwear brand expanded from children’s knitwear into womenswear under the brand name ‘Lady Kathryn’, and for boys and men under ‘Robert Blake’. Continuing to diversify their distribution, they also began exporting ‘Kathryn’ garments to New Zealand, the Pacific Islands, and Japan. ‘Kathryn Knitwear’ was well-known for their early adoption of modern materials and techniques that had broad appeal to their customer base. This is shown in their early use of the acrylic fibre ‘Orlon’ in the 50s and 60s and ‘Superwash’ wool in the 1970s. Many of Kathryn Knitwear’s styles, particularly those that were long running staples of the brand, were available in both wool and Orlon to suit the consumer’s preference. Far from the humble origins of one man in his bedroom with a hand-cranked machine; at its closure in 1980, the Broadmeadows factory of ‘Kathryn’ housed more than 100 machines, including 53 sewing machines and 45 knitting machines. Robert Blake was “a passionate advocate for wool and Australian Made” throughout his whole life. A strong thread that ties through the lifespan of Robert Blake and Kathryn Knitwear is a balance between adopting new innovations without sacrificing the core values of durability, comfort, care and style that had made the brand so well known. Their legacy forms an integral part of both Australian social and manufacturing history.Strip of knitted fabric samples showing the nine wool colour options for the boys line of Robert Blake/Kathryn knitwear in the winter season of 1980. Label printed in pale blue paper lists season and colour names and is attached to sample strip with two metal staplesBOYS WOOL WINTER 1980 COLOR SWATCH RED BURGUNDY BROWN RYE PEBBLE OYSTER NAVY BLUE SHADOW DENIM GRANITE GREYfabric sample, textile sample, fabric swatch, textile swatch, fashion textile production, textile manufacturing