Showing 119 items matching " lathe"

-

Tatura Irrigation & Wartime Camps Museum

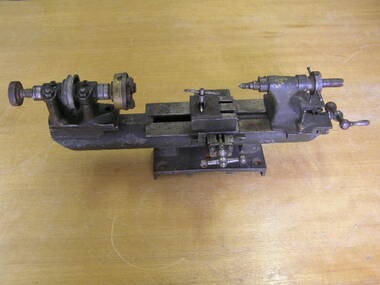

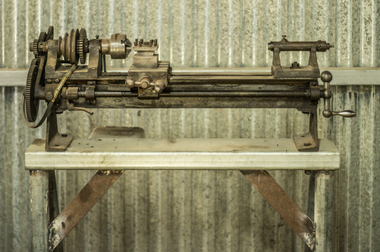

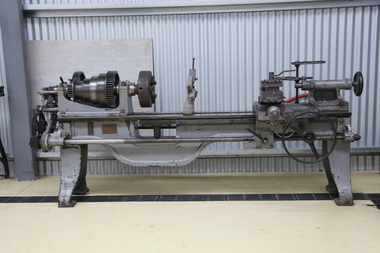

Tatura Irrigation & Wartime Camps MuseumTool - Lathe, Metal Lathe

Made at a forge outside the camp 3 perimeter by Gotthilf Kaltenbach & Manuel Kaltenbach. It is made from British Army scrap metal. Used for fine metal turning. The Witworth gauges were not used in Central Europe after 1918. The motor that was on it was a small electric sewing machine motor which was discarded about ten years ago in Germany. Sent from Germany by Elfriede & Paul Faig.Handmade metal turning lathe, 600mls long and weighing 16 kg. Made at a forge site outside the camp perimeter. All dimensions are in imperial inches, all threads are Witworth gauges. Painted in British Army colours.tatura, camp 3, lathe, metalworking, paul faig, gotthilf kaltenbach, manuel kaltenbach -

Stawell Historical Society Inc

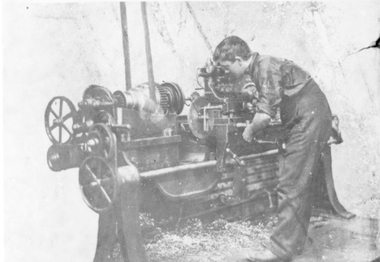

Stawell Historical Society IncPhotograph, Workman using belt driven Lathe at the Wimmera Motor Works

Workman using belt driven Lathe. Part of a set of photos of Wimmera Motor Works.Black and white photograph of a male working on a lathe. stawell industry -

Tatura Irrigation & Wartime Camps Museum

Tatura Irrigation & Wartime Camps MuseumPlan - Diagram/Plan, Lathe

Plan of a wood turning lathe made by internee at camp 3. diagram and description of each piece in the plan to make a wood turning lathe. Has been laminated.lathe plans, lathe diagram, rudy hoefer, woodworking equipment -

NMIT (Northern Melbourne Institute of TAFE)

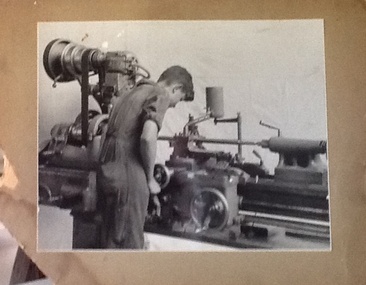

NMIT (Northern Melbourne Institute of TAFE)Photograph - Collingwood Technical School, Collingwood Technical School. Unemployed youth training scheme 1938-1940. Trainee engaged in cutting the screw thread on saddle traversing screw of 5 inch centre lathe

Collingwood Technical School trained apprentices in many trades. This photograph depicts a trainee engaged in cutting the screw thread on saddle traversing screw of 5 inch centre lathe.This is a high quality professional photograph taken circa 1940. In 1938-1940, CTS was part of the Unemployed Youth Training scheme. This photograph is a visual record of this scheme.Black and white photograph mounted on brown card. Caption pasted on back of photograph.Caption: Collingwood Technical School. / Unemployed Youth Training Scheme 1938-1940. / Trainee engaged in cutting the screw thread / on saddle traversing screw of 5 inch centre lathe. collingwood technical school, cts, unemplyed youth training scheme, apprentices, students, lathes, nmit, -

Ballarat Tramway Museum

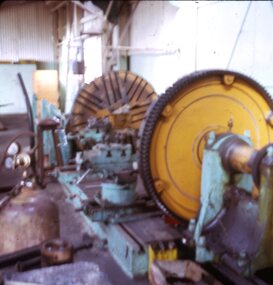

Ballarat Tramway MuseumSlide - 27 mm sq slide/s, Lilian Butler, wheel lathe at the depot, Sep. 1971

Yields information about the appearance of the wheel lathe at the SEC Ballarat depot.Colour 27 x 27 mm slide in Kodachrome white cardboard mount showing the wheel lathe at the depot - out of focus. Photo from the collection of Lilian Butler. Slide mount dated September 1971.ballarat, tramways, trams, depot, sec depot, lathe, equipment, workshops -

Stawell Historical Society Inc

Stawell Historical Society IncPhotograph, Young and Ledgars Engineering Works with a workman using Belt Driven Lathe

Man Using Belt Driven Lathe at Young and Ledgars Engineering Worksstawell industry -

Stawell Historical Society Inc

Stawell Historical Society IncPhotograph, Stawell Technical School Workshops with a student at work with a treadle lathe 1923-1924

Stawell Technical School Workshops 1923-1924. Student at work with a treadle lathe.stawell education -

Stawell Historical Society Inc

Stawell Historical Society IncPhotograph, Stawell Technical School Workshops with a student at work with foot operated potters lathe 1923-1924

Stawell Technical School Workshops 1923-1924. Student at work with foot operated potters lathe.stawell education -

Hand Tool Preservation Association of Australia Inc

Hand Tool Preservation Association of Australia IncLathe

This item is part of the Thomas Caine Tool Collection, owned by The National Trust of Australia (Victoria) and curated by the Hand Tools Preservation Association of Australia.lathe, f/o -

Hand Tool Preservation Association of Australia Inc

Hand Tool Preservation Association of Australia IncLathe

This item is part of the Thomas Caine Tool Collection, owned by The National Trust of Australia (Victoria) and curated by the Hand Tools Preservation Association of Australia.lathe, britannia, screw cutting f/o -

Warrnambool and District Historical Society Inc.

Warrnambool and District Historical Society Inc.Tools, George Panton & Sons, Jeweller Lathe, Early 20th century

This jewellery lathe (minus its rubber belt) came from the Warrnambool jewellery store of Michael Salamy and his son, Edward. The business was in two locations - in Timor Street, opposite the old Post Office, and at 179 Liebig Street. Michael Salamy erected two new buildings at 179 and 181 Liebig Street and the Salamy business was then headed by the son, Edward who was born in 1903 and died in 1977. The jewellery store was closed when Edward retired and Clancey Brothers men's store took over the building at 179 Liebig Street in 1966. Bill Clancey found the jewellery lathe in this building and donated it to the Historical Society. This lathe is of considerable interest as it comes from the prominent 20th century Warrnambool jewellery business of M.Salamy and Son. It is also an interesting memento of a 20th century industrial tool. This is a metal tool with several wheels connected with wing nuts. The large wheel has a wooden handle. A rubber belt connecting two of the wheels is missing. '0865 Panton Maker Glasgow'michael salamy and son, jewelers, warrnambool -

NMIT (Northern Melbourne Institute of TAFE)

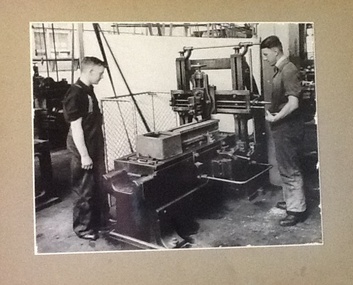

NMIT (Northern Melbourne Institute of TAFE)Photograph - CTS 1938-1940 student, Collingwood Technical School. Unemployed Adults Training Scheme, 1938-1940

Collingwood Technical School trained apprentices in many trades. In the late 1930s, CTS was involved in ttraining schemes for youth and adults.This photograph depicts two men learning to operate a lathe. This is a high quality professional photograph taken circa 1940. In 1938-1940, CTS was part of the Unemployed Adult Training scheme. This photograph is a visual record of this scheme.1 black and white photograph mounted on brown card. Photograph depicts trainees working with a 5" centre lathe.Photograph has a hand written caption on the back: 'Collingwood Technical School./ Unemployed Adults Training Scheme, 1938-1940./ Trainees planing the cast iron bed of a/ 5" centre lathe. 'collingwood technical school, cts, apprentices, students, unemplyed adult training scheme, lathes, machinery, machine parts, nmit -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageMachine - Lathe

Lathe large free standing machine with turning mechanics at centre incorporating wooden turning handle at end. Is attached to pulley and operated by steam engine. flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Maldon Vintage Machinery Museum Inc

Maldon Vintage Machinery Museum IncLathe

Small metal lathe mounted on a metal stand. Driven by a 1/4 HP 1425 RPM electric motor. Comes with a box of assorted chucks and fittings.Nonetrades, metal working -

Puffing Billy Railway

Puffing Billy RailwayTreadle Lathe

Industrial Treadle Lathe Possibly a Star Treadle LatheHistorical - Industrial Treadle Lathe Treadle Lathe made of Steel and wrought irontreadle lathe, puffing billy -

Dandenong & District Historical Society

Dandenong & District Historical SocietyBooklet, Gisholt Machine Co, Machine Tools - "3L High Production Turret lATHE", 1939/1941

Spare Parts for Turret Lathe Serial No 3303 x 32Well worn & used 1939-1941non-fictionSpare Parts for Turret Lathe Serial No 3303 x 32turret lathe 3l -

Flagstaff Hill Maritime Museum and Village

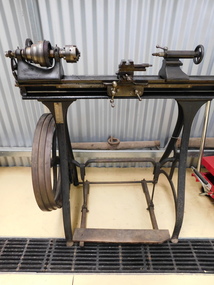

Flagstaff Hill Maritime Museum and VillageMachine - Treadle Lathe, 1920-1923

The lathe-making business incorporated in 1902 as Drummond Bros Ltd originated in the fertile mind of Mr Arthur Drummond, said to have been living at that time at Pinks Hill, on the southern edge of Broad Street Common, west of Guildford. Mr Drummond, whose accomplishments included several pictures hung in the Royal Academy, was unable to find a lathe suitable for use in model engineering. In 1896 he designed for himself a ‘small centre lathe … which had a compound slide rest with feed-screws and adjustable slides’. He also designed and built ‘lathes of 4.5 inch and 5 inch centre height, which had beds of a special form whereby the use of a gap piece was eliminated but the advantages of a gap-bed lathe were retained’. Assisted by his brother, Mr Frank Drummond, who had served an apprenticeship to an engineering firm at Tunbridge Wells, the first lathes were made in a workshop adjoining Arthur Drummond’s house. The demand that speedily built up led to the decision to form a company and manufacture the lathes for sale commercially. Land was acquired nearby, at Rydes Hill, and the first factory built. The enterprise was a success, and the company quickly established ‘a high reputation in this country and abroad for multi-tool and copying lathes, and gear-cutting machines’. Other lathes were added to the range, including the first of the ’round bed’ machines for which the firm became widely known. A Drummond 3.5 inch lathe was among the equipment of Captain Scott’s 1912 expedition to the South Pole, and large numbers of 3.5 inch and 4 inch designs were exported to Australia, Canada and India. By the outbreak of war in 1914, 5 inch, 6 inch and 7 inch screw cutting lathes, arranged for power drive, were on sale. Large orders were received from the government for 3.5 inch lathes, for use in destroyers and submarines, and 5 inch lathes for the mechanised section of the Army Service Corps. The latter were used in mobile workshops. The factory worked night and day to supply the forces’ needs, until production was disrupted by a fire which destroyed a large part of the works in May 1915. As soon as rebuilding was complete work restarted. At the end of the war the entire production was being taken by the Government departments, a special feature being a precision screw lathe, bought by the Ministry of Munitions in 1918. Between the wars Drummond Bros Ltd introduced new machines for the motor vehicle, and later the aircraft industry, and the works were extended on many occasions to fulfill the increasing orders. The Maxicut multi-tool lathe (1925), designed for high-production turning operations, was one of the first machines of this type to be built in England. It was followed (1928) by an hydraulic version for turning gear blanks, and similar work. Further developments provided machines which, during the Second World War, turned all the crankshafts and propeller shafts for Bristol engines. Others, ordered by the Ministry of Supply were employed in turning shells, and many other specific needs of vehicle and aircraft manufacture were catered for by new types of Drummond lathes. Production of the small centre lathes ceased during the war when the company needed to concentrate on building multi-tool lathes and gear shapers. After the war a completely new Maxicut range was introduced, replacing the older versions, and fully automatic. The types were continually developed, and new versions manufactured until the end of the company’s life in 1980. The disappearance from the scene of Mr Arthur Drummond in 1946, and the end of the company’s autonomous existence in 1953 when the company was acquired by William Asquith Ltd, which was in turn bought by Staveley in 1966, meant that the factory at Rydes Hill became one – albeit very effective – part of a large national engineering company. Achievements at the Guildford works during its last years included the development of automated Maxicut gear-shapers in what was ‘probably the most fully automated gear shop in the country’, while a machine from Guildford was sent to the Osaka Fair in 1962. In 1963 an agreement was signed with Hindustan Machine Tools for the manufacture of Maxicut gear-shapers in state owned factories in Bangalore and Chandigarh. During 1963 the two largest multi-tool lathes ever made in the UK were installed in Ambrose Shardlow’s works in Sheffield for handling cranks up to 14 foot long. In 1976 Drummond lathes were included in Staveley’s £14,000,000 installation in Moscow of an automated production line for Zil motor cars. Up to the end invention continued at Guildford: a new Drummond Multi-turn memory-controlled machine was shown at the International Machine Tool Exhibition in 1977. This could not save the works from the pressures of the late 1970s, and Staveley Industries closed its Guildford site in 1980.An early example of a lathe that was designed primarily for the hobbyist model maker. It is in good condition and sought today by collectors as many of it's attributes were innovative at the time and lead to further development and incorporation of some of its features into more industrial models of production machinery. Lathe, round bed, treadle powered lathe, Drummond Type A, Serial number and maker's inscription. 1920-1923, Made by Drummond Brothers in Guildford, Surrey, England. Lathe is complete with Chuck, Tool post and Tail Stock in situ (30 extra parts)"MADE BY DRUMMOND BROTHERS LIMITED - PATENT TEES - RYDE'S HILL n GUILDFORD SURREY", "Serial Number 01470," "L44" or "L45 " flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, lathe 1920-1923, round bed lathe, treadle lathe, drummond type a, guildford surrey, drummond brothers guildford surrey england, tread'e -

NMIT (Northern Melbourne Institute of TAFE)

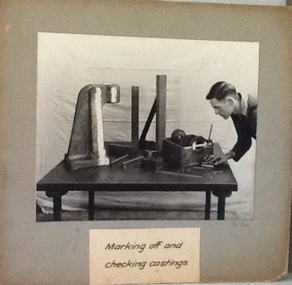

NMIT (Northern Melbourne Institute of TAFE)Photographs - Collingwood Technical School, Allan Studios, Mounted photographs of Trade School CTS, circa 1940, Early 1940s

Collingwood Technical School trained apprentices in many trades. These photographs depict some of the machines and machine parts built in class. Captions : 1. Marking off and checking castings 2. Examples of other machine parts, etc., being made in Youth Employment classes in engineering machine shop. 3. Cutting the traversing screw for a 5 ¼ inch lathe. 4. Grinding lathe spindle. 5. Cutting helical flutes in a shell end mill. 6. Arbor Press. Another valuable machine produced by Youth Employment and senior technical evening students. 7. Milling angular slides of lathe saddle. 8. 5 ¼ inch lathe product of Collingwood Technical School. These are high quality professional photographs taken circa 1940. 8 black and white photographs mounted on brown card. Photographs depict various aspects of lathe work.Each photograph has a hand written caption on the front. Also handwritten in black pen "Allan Studios".collingwood technical school, cts, apprentices, students, lathes, machinery, machine parts, nmit, -

Tatura Irrigation & Wartime Camps Museum

Tatura Irrigation & Wartime Camps MuseumLathe (Model)

"This is a rough model of the woodturning lathe Kurt Beilharz built from scrap as a 17 year old in Camp 3, Tatura. The drive wheel was a hollow redgum block from the firewood supply. The shaft was a 1/2" water pipe, the bearings of the spindle were 3/4" water pipe with tooth paste tubes melted into and honed out for the spindle. They had holes for oiling. The drive belt came from my Mother's sewing machine. I used screws in the model, but in reality bolts were used, which were bought as well as the framing timber"Wooden model of a lathe made and used at Camp 3. Triangular upright frame with a hollow drive wheel, driven by a piece of wire with a handle on one end. Drive belt is a piece of fine cord.lathe, model, beilharz, k, camp 3, tatura, ww2 camp 3, handcrafts, models -

Puffing Billy Railway

Puffing Billy RailwayLathe - Gap Bed, early 1900s

Possibly ex Victorian Railways Newport workshops Supplied by Bevan & Edwards Machinery Merchants, Melbourne Sebastian Lathes Described by its makers as the Utility School, Garage and Repair-shop Lathe, the machine immediately below, a Sebastian 15" (circa 1910 - 1926) was the Company's cheapest offering and, in its basic form, lacked a compound slide rest, the tailstock did not set over for taper turning and the bed lacked a gap. However, a friction-type countershaft unit was included in the price as well as a tool post, faceplate, drive plate, changewheels for screwcutting and a small tool kit. As with modern cars (especially BMW) everything worthwhile was on the options' list and by spending more it was possible to specify all those small but important extras. Although in its lowest-cost form this model was reduced to the fundamentals required for a useable, screwcutting centre (engine) lathe it was still reasonably specified and would certainly have fulfilled many requirements when installed in a school or training workshop. The true swing was 15.25", it was properly backgeared and screwcutting was through a conventional tumble-reverse mechanism that allowed both left and right-hand powered movement to the carriage by altering the position of just one lever. As standard it accepted 40" between centres, but any capacity could be ordered, in foot intervals, up to a maximum of 88" - when it is hoped that a central bed support might have been included …… The spindle, which ran in white-metal bearings, had a useful 15/8" hole and a No. 3 Morse taper centre. Some models appear to have had the leadscrew clasp-nut lever on the right-hand side of the apron, while on others it was positioned to the left.. Early Sebastian 13-inch lathe Typical of the Centre or "Engine" lathe made by many manufacturers from the late 1800s until the late 1930s, the basic flat-belt drive Sebastian, with separate countershaft, was eventually relegated to the economy end of the Company's range by the introduction of geared headstocks and self-contained motor-drive systems.Historic - Industrial Machinery - Gap Bed Lathe - Possibly ex Victorian Railways Newport workshops - Purchased and supplied from Bevan & Edwards Gap Bed Lathe - Grey with raw steel parts and a timber cupboard with gears and tools. Bevan & Edwards PTY,LTD Machinery Merchants Melbourne (possible government tag) 365bevan & edwards pty,ltd machinery merchants melbourne, puffing billy -

Tatura Irrigation & Wartime Camps Museum

Tatura Irrigation & Wartime Camps MuseumRings - Wooden, 1940's

Sent from Germany by Elfriede & Paul Faig.2 light coloured wooden rings made on small lathe (no. 2955) or wood turning bench.tatura, camp 3, lathe, faig, p, kaltenbach, handcrafts, woodwork -

Tatura Irrigation & Wartime Camps Museum

Tatura Irrigation & Wartime Camps MuseumCups - Wooden, 1940's

Sent from Germany by Elfriede & Paul Faig.2 solid dark wood cups made on the small lathe (no. 2955) or wood turning bench.tatura, camp 3, lathe, faig, p, kaltenbach, g, hermann, w, handcrafts, woodwork -

NMIT (Northern Melbourne Institute of TAFE)

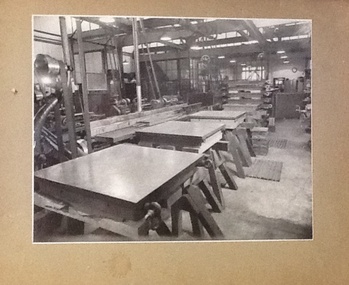

NMIT (Northern Melbourne Institute of TAFE)Photographs - CTS 1940-1943, Collingwood Technical School. Defence Training Scheme, 1940-1943

Collingwood Technical School trained apprentices in many trades. CTS was also invlved in Training Schemes during the late 1930s and during World War II. These photographs depict some of the machines and machine parts built in class. These are high quality professional photographs taken circa 1940-1943. At this time , CTS was part of the Defence Training scheme. These photographs are a visual record of this scheme.6 black and white photographs mounted on brown card. Photographs depict various aspects of lathe work undertaken during the Defence Training Scheme, 1940-43. Also a smaller photograph of a Moultar Thread Milling Machine 1941.Each photograph has a hand written caption on the back. Captions: 1. Finished surface plates for R.A.A.F. / standing on trestle after scraping. Stack of / others in background waiting for scraping. 2. Lathe bodies in foreground, with machined / parts of lathes in middle distance, and milling / cutters, gauges and bearings in background. 3. Frames of glass splitting machines, thread / rectifying machines, and two types of milling / machine vises made in technical schools. 4.View of engineering machine shop. Carbon dioxide / freezing box in foreground, and stack of / surface plates for RAAF in middle / distance. 5.Fan geared lathes, 6 inch centres, with / self-contained motor drives, made for / cartridge factory. To be used for making / this 6.Freezing of cast iron surface plates / in layers of solid carbon dioxide / blocks. Smaller photograph has a handwritten note on the reverse: 'this photograph shows how, with the aid of a 3ft. extension mounted in front of the tool box, on which Mr. Grubb sen. is seated, these large milling machine bases ... machinists at Collingwood Technical School. A Strang, Principal 21.4.1941'. collingwood technical school, cts, apprentices, students, defence training scheme, lathes, machinery, machine parts, nmit, -

Hand Tool Preservation Association of Australia Inc

Hand Tool Preservation Association of Australia IncWatchmakers bow

This item is part of the Thomas Caine Tool Collection, owned by The National Trust of Australia (Victoria) and curated by the Hand Tools Preservation Association of Australia.watchmakers bow lathe steel -

Hand Tool Preservation Association of Australia Inc

Hand Tool Preservation Association of Australia IncWooden suitcase

This item is part of the Thomas Caine Tool Collection, owned by The National Trust of Australia (Victoria) and curated by the Hand Tools Preservation Association of Australia.wooden suitcase containing lathe tooling -

Hand Tool Preservation Association of Australia Inc

Hand Tool Preservation Association of Australia IncWood turning

This item is part of the Thomas Caine Tool Collection, owned by The National Trust of Australia (Victoria) and curated by the Hand Tools Preservation Association of Australia.wood turning lathe f/o -

Federation University Art Collection

Federation University Art CollectionArtwork, other - Timber, Vic Wood, 'Compassionate' by Vic Wood, 1977

Vic WOOD (1939 - 02 October 2020) Born Melbourne, Victoria Vic Wood was an internationally renowned artist, craftsman and teacher from the 1970s. He studied gold and silversmithing, woodturning and cabinet making at Melbourne Teachers' College and Royal Melbourne Institute of Technology. He was a skilled woodturner who, as a lecturer at Melbourne College of Advanced Education, taught a generation of woodworkers. Best known as a master wood-turner, Vic Wood retired from lecturing in 1983 to become a full-time woodturner. He was a sought after demonstrator and presenter for all kinds of local and international events. His teaching philosophy was simple: ‘share everything, have nothing to hide, and have no secrets; for ultimately it is in giving that you receive’. Vic Wood was a foundation member and inaugural president of the Victorian Woodworkers Association (VWA). In 1923 the Victorian Woodworkers Association announced the establishment of an annual Vic Wood Scholarship. he intent of the award is to promote excellence in woodwork and to engender inclusive and supportive woodworking networks. This item is part of the Federation University Art Collection. The Art Collection features over 2000 works and was listed as a 'Ballarat Treasure' in 2007.Large lathe-turned sculptural relief. art, artwork, vic wood, wood, woodwork, sculptural relief -

Bendigo Historical Society Inc.

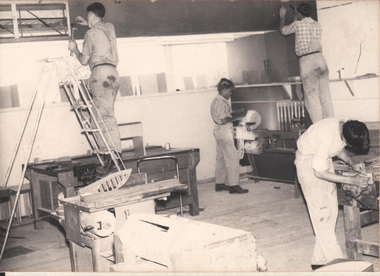

Bendigo Historical Society Inc.Photograph - SANDHURST BOYS CENTRE COLLECTION : WORKSHOP ACTIVITY

Residents working at various tasks, including lathe operation, using a vice, hammering. Machinery includes a lathe, saw bench with circular saw. -

Hand Tool Preservation Association of Australia Inc

Hand Tool Preservation Association of Australia IncChart

This item is part of the Thomas Caine Tool Collection, owned by The National Trust of Australia (Victoria) and curated by the Hand Tools Preservation Association of Australia.Chart, lathe drive & driven wheel ratios -

Tatura Irrigation & Wartime Camps Museum

Tatura Irrigation & Wartime Camps MuseumSpinning top, 1940's

Made by internee at Camp 3Wooden spinning top with groves for cord. Made on a lathetop - spinning, wood, beck h, camp 3, tatura, ww2 camp 3, tops, general