Showing 21 items matching " manufacture of munitions"

-

Ballarat Tramway Museum

Ballarat Tramway MuseumDocument - Rule Book, Commonwealth Government, "Ballarat Gun Cotton Factory Rules", 1940's

... Manufacture of Munitions... Parade Ballarat Ballarat goldfields Trams tramways Manufacture ...A commonwealth of Australia Rule Book - For use at the Gun Cotton Factory at Ballarat- WWII. 17 numbered pages- printed one side only. Cover sheet- addendum with hand stamp p6. Images of cover and inside page added 5/9/13.Opposite page 6 - addendum date 21/7/1943.trams, tramways, manufacture of munitions, factory rules, gun cotton, ordnance -

Dandenong/Cranbourne RSL Sub Branch

Dandenong/Cranbourne RSL Sub BranchMemorabilia, 30mm Gun Cartridges

... manufactured by the Munitions Factory in Footscray Vic. in June 1971... on these cartridges, they were manufactured by the Munitions Factory ...Two alloy ammunition cartridges from a 30mm DEFA (Direction des Études et Fabrications d'Armement) revolving gun used in aircraft. According to the markings on these cartridges, they were manufactured by the Munitions Factory in Footscray Vic. in June 1971. They were most likely used in the guns of the Mirage aircraft of the RAAF. 30-550-DEFA, 6MF71, FR on base. 30-550-DEFA AP 5401MEM and some illegible marks on the side. -

Bendigo Military Museum

Bendigo Military MuseumBadge - MUNITION WORKERS BADGE, Post 1915

... workers who went to the United Kingdom to work in Munitions... Manufacture. numismatics-badges-civilian metalcraft-pewter Munitions ...Instituted in August 1916. Issued to successful skilled workers who went to the United Kingdom to work in Munitions Manufacture.Pewter badge, Australian coat of arms with scroll and word "Australia" curved underneath.On scroll: "Munitions Worker" On back: "357 Dept of Defence"numismatics-badges-civilian, metalcraft-pewter, munitions worker -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFreezer, circa 1930's

... manufactured munitions and mines for the war. At the time of Alfred's.... In the late 1880's A Simpson and Son manufactured munitions and mines ...This ice cream freezer, manufactured in South Australia in the 1930's, was advertised to "keep the contents of the cream compartment frozen for many hours". It was promoted for use at picnics to keep salads cool. Its design is very similar to other freezers of The Frigid name which were made in 1939; those freezers were all one colour whereas this one is blue around the top and bottom of the barrel and cream in the centre with blue/green lettering. The process of making ice cream was to pack the outer chamber full with a combination of 3 parts ice cubes of about 1 inch (2.cm) to one part coarse salt, then pour into the chamber about 1 cup of cold water. After this, the ingredients for ice cream or sorbet were poured into the inner chamber, then attach the lid and turn The Frigid freezer upside down for about 40 minutes or until the right consistency is reached. Advice as given to open the freezer every 20 minutes and stir around the contents that were frozen against the sides of the inner chamber. The ingredients for the ice cream could include cream, sugar, vanilla and eggs. The label on the box of The Frigid shows the address of A Simpson and Son to be at Pirie Street, Adelaide. This address was used as early as 1876 and later catalogues, 1931 - 1960 still show this address. Alfred Simpson and his family emigrated from England, arriving in South Australia in 1849. He had already completed his apprenticeship as a tinplate worker but he tried various other occupations, including trying out the gold mines in Victoria, before he established himself as a tinsmith in 1853. His products included many agricultural items. His son, Alfred Muller Simpson, joined the business when he turned 21. In the 1860 Simpson's products included 'explosion proof' safes. In the late 1880's A Simpson and Son manufactured munitions and mines for the war. At the time of Alfred's death in 1891, A Simpson and Son had the largest metal manufacturing plant in Australia. From 1898 the company's reputation grew from the process of enamel plating with porcelain. During the First World War, Simpsons returned to the manufacture of munitions. Alfred M. Simpson's sons (Alfred Allen, known as Allen, and Fredrick Neighbour) joined the company when they finished their schooling. Allen was also associated with the Royal Geological Society over many years and when the CT Madigan surveyed Central Australia in 1929, the Simpson Desert was named in his honour. Cape Simpson in Antarctica is also named after him due to his assistance to Douglas Mawson. A new factory was opened at Dudley Park in the 1940s and the company began the manufacture of whitegoods. In 1963 A. Simpson and Son merged with Pope Industries to form Simpson Pope Holdings. Alfred Simpson became chairman of the board of Simpson Pope Holdings. The Simpson brand, now owned by Electrolux, continues to produce a variety of household appliances. (Reference: State Library of South Australia) A Simpson and Son was an early colonial business that has lasted well into the 20th century and the name Simpson is still associated with whitegoods. Freezer, 2 quart (1.8 litre) capacity, made by A Simpson and Son Ltd, marked "The Frigid". Cylinder shaped, constructed from enamelled sheet metal, has two catches one on the base and one on top. Inner cylinder for holding contents for freezing. Slightly rusted. Freezer is inside original cardboard box with yellow label showing manufacturer details. Circa 1930'sOutside of freezer is printed in blue"The Frigid". Box includes "THE "FRIGID" FREEZER" and branded "S & S" inside a circle.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, a. simpson & son limited, manufacturer, foundry, freezer, 2 quart freezer, portable freezer, kitchen appliance, the frigid, ice cream freezer, ice cream maker 1930's -

Wodonga & District Historical Society Inc

Wodonga & District Historical Society IncEquipment - Knapsack spray unit for agriculture and firefighting, A. Simpson & Son, c1939

... World War I the company also manufactured munitions as well... the company also manufactured munitions as well as ordnance ...This model of knapsack sprayer was used for both agricultural and firefighting purposes throughout Australia. The manufacturer, A. Simpson & Son who had a long history as a prominent metals manufacturer in Adelaide, South Australia. Alfred Simpson arrived in South Australia in 1849 and by the mid 1950s had established himself as a tinsmith. His son, also Alfred, joined the business in 1864. By the time of Alfred senior's death in 1891, A. Simpson and Son had the largest metal manufacturing plant in Australia. The business was incorporated in 1910, with Alfred as chairman, and his sons Allen and Frederick as directors. During World War I the company also manufactured munitions as well as ordnance. In the 1920s the company expanded into the production of tools for use in agriculture and in the 1940s they began the manufacture of whitegoods. In 1963 A. Simpson and Son merged with Pope Industries to form Simpson Pope Holdings.This item is representative of agricultural equipment used throughout Australia by a major Australian manufacturer. They were used extensively in the Wodonga district. A Backpack Sprayer unit made from galvanised iron used for agricultural and fire-fighting purposes. It has a nozzle spray attachment and originally had leather straps.On side: SIMPSON PAT. 11?472 23/7/39fire equipment, a. simpson & son, agricultural tools -

Orbost & District Historical Society

Orbost & District Historical Societysprockets and ring gear, 1941

... munitions and defence equipment were manufactured by state ...Ron Peck machined the driving sprockets for Bren Gun Carriers which were sent to North Africa. The Rats of Tobruk, the Egypt and Rommell campaign used these munitions. He boarded at Orbost House while doing 12 hour day shifts.During WW11 munitions and defence equipment were manufactured by state government and private engineering firms, co-ordinated by the Commonwealth government. They worked together to meet Australia’s defence needs and create ‘mass production, on a nation-wide scale, of materials and articles of a higher degree of complexity and accuracy than had before been attempted in Australia. These sprockets were manufactured locally.Two metal sprockets for a Bren Gun carrier. One metal ring gear.munitions sprockets bren-gun-carrier peck-james-ronald orbost-motor-works -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDrill Press, early to mid-20th century

This post drill press has been made by Melbourne business, Dawn Manufacturing Company. It can be operated manually or by a pulley driven flywheel, with the aid of an engine connected to a power supply. In the late 1800s early 1900s a drill press like this would have been driven by steam from a boiler, the main power source for manufacturer’s power at that time. Dawn’s Golden Anniversary 1917-1967 Catalogue describes this model 611 drill as … “Ruggedly constructed with accurately reamed bearings. The coupling between the main spindle and feed screw engages the full circumference of the spindle, and embraces a ball-bearing thrust race. The pillar, as in all “Dawn Drilling Machines” is a solid bright steel bar, in place of the usual light tubing. Adjustable automatic feed.” And “F. & l. Pulleys extra, if required”. DAWN MANUFACTURING CO. The Dawn Manufacturing Co. was founded in Coburg, Melbourne, in 1917 by the four Blake brothers, who were all engineers. After World War I Dawn was supplying drills Australia wide and the company was growing at a healthy rate. During the depression they remained busy, with employees working 60-80 hour weeks. Dawn was contracted to supply vices and clamps to the Australian Defence Department and munitions factory during the World War II. - 1959 the company was taken over by G.N. Raymond Group. - 1967 the Dawn Manufacturing Co. had distributors in Australia and overseas, including USA, Canada, New Zealand, Asia and the Middle East. - 1973 the Siddons Ramset Limited acquired Dawn. - December 1991, Dawn became a unit of the United States owned Stanley Works Pty. Ltd. - November 1998 Dawn became 100 per cent Australian owned. The drill is a typical tool of a blacksmith, cart wright, wheelwright and garage business. It is an example of the tools of the blacksmiths’ trade in Victoria in the early to mid-20th century.Post type drill press machine with gear driven flywheel. Drill press is attached to a post and is fitted with a pulley belt and will run at a speed of maxim 200 r.p.m. The machine can also be manually operated. It has an aperture in the centre, a chuck, for the drill bit and has two metal handles at the centre, on the right hand side. Gear ratio 2:1 main drive, 6" diam, 3:1 reduction gear. Made by Dawn of Melbourne, Australia. Model No. 611, Code No. 9157"DAWN MFG COY”, “MELB. AUSTRALIA", " 611"flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, blacksmiths, blacksmith’s drill, blacksmith tools, dawn drill model no. 611, dawn drill code no. 9157, dawn manufacturing coy melbourne, dawn manufacturing coy coburg, dawn post drill, drilling machine, drill with gear driven flywheel, forging tool, metal working tool, post drill, steam powered drill, trade tool, warrnambool district 1900s -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDrill Press, 1920s-1950s

This drill once belonged to Goodall and Sons, who were blacksmiths in Terang. The smith was called upon to do a variety of work. In the early 1900s he was often the nearest person to be able to perform an engineer’s services for many miles around. The Dawn Ball-bearing Post Drill no. 611 is described in McPherson’s Catalogue as a “drilling machine with adjustable automatic feed, with improved Dawn coupler and ball-bearing thrust’. The heavy design of the flywheel enables it to maintain momentum” and is “fitted with pulleys for belt drive if desired” The hand crank drives an automatic feed to work off a cam-follow system opposite a large wheel. Made by Dawn Manufacturing Co. Australia 1920-1950. DAWN MANUFACTURING CO. Dawn Manufacturing Co. was founded in Coburg, Melbourne, in 1917 by the four Blake brothers, who were all engineers. After World War I Dawn was supplying drills Australia wide and the company was growing at a healthy rate. During the depression they remained busy, with employees working 60-80 hour weeks. Dawn was contracted to supply vices and clamps to the Australian Defence Department and munitions factory during the World War II. In 1959 the company was taken over by G.N. Raymond Group, then in 1973 the Siddons Ramset Limited acquired Dawn. In December 1991, Dawn became a unit of the United States owned Stanley Works Pty. Ltd. In November 1998 Dawn became 100 per cent Australian owned. HENRY GOODALL & SONS Henry Goodall (1870-1936) was proprietor of garages as H. Goodall & Sons Pty. Ltd., at both Terang (McKinnon and High Streets) and Mortlake (Dunlop Street). His business was in operation in at least in 1916 and perhaps well before, considering the date of the tyre bender and its use for wagons with wooden wheels. It was still in operation in 1953, chasing up debtors in Mount Gambier Court. Amongst the employees of H. Goodall & Sons Pty. Ltd. was Ernie Entwistle, a blacksmith (a soldier who died in 1916 ) and Alfred Hodgetts, radio expert (killed in a fatal accident in 1943, when he was in his early 30s ). Henry Goodall was involved in the community as a Justice of Peace, a deputy coroner, President of the Mortlake Hospital, trustee of the Soldiers’ Memorial Hall, and as a prominent Freemason. He and his wife had two sons (Charles and John) and one daughter (Mrs. Chas. Newton, of Skipton). The drill is locally significant as it was used by a local company in Terang and Mortlake in their blacksmith, wheelwright and garage business. It is an example of the tools of the blacksmiths’ trade in Victoria in the 1920s-1950s.Dawn Ball-bearing Post Drill no. 611, made by Dawn of Melbourne, model no 611. Hand operated drill press. Self-feeding blacksmiths’ drill-press. This drill once belonged to Harry Goodall & Sons, blacksmiths of Terang. Dated 1920s-1950s. Gear ratio 2:1 main drive, 6" diam, 3:1 reduction gear. "Dawn", "Melbourne"flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, h. goodall & sons of terang, terang blacksmith, h. goodall & sons pty ltd, mortlake, ernie entwistle blacksmith, alfred hodgetts radio expert, charles goodall, john goodall, mrs. chas. newton nee goodall, terang 1900s, warrnambool district 1900s, post drill, blacksmith’s drill, dawn post drill, dawn ball-bearing post drill no. 611, blacksmiths, dawn of melbourne -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDrill Press, 1930s

Dawn commenced operations in the Melbourne suburb of Coburg, Victoria in 1917 under the name of Dawn Manufacturing Co. It was founded by four brothers named Blake, who were all engineers. The first products manufactured were vices. After the first world war, Dawn grew considerably and was selling its products all over Australia. They were very busy during the depression with each employee working 60-80 hours a week. During the second world war, Dawn was supplying vices and clamps to the Australian Defence Department along with munitions. In 1959, the company was taken over by the G.N. Raymond Group. The Dawn catalogue was expanded to now included a wide range of engineer's vices, woodworker's vices, plumber's vices & equipment, G-clamps, quick-action clamps and toggle clamps. In 1973, Dawn was acquired by Siddons Ramset Limited. In December 1991, Dawn became a unit of the United States owned Stanley Works Pty. Ltd. In November 1998, Dawn regained its 100% Australian ownership and now as a separate strategic business unit, began to improve and expand its manufacturing and marketing operations in Australia and overseas. Drill Press, Self-feeding, belt-driven. Embossed within the casting "Dawn Melb Australia Mfg".flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, machinery, dawn drill press, drill press -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageInstrument - Clock, 1900's

In August 1884, Alfred Hirst who had started his trade as a watch repairer and was described as a watchmaker extraordinaire established Hirst Brothers and Company, on Union Street in Oldham Manchester. He took his two stepbrothers into the business and the company was set up to produce timepieces and jewellery as well as importing “Limit company” Swiss watches and precision machine tools for the watch and clock trade. By 1902 Hirst Brothers. had become a limited company and was still growing, adding other businesses in Manchester in 1904 and at Birmingham in 1907. The quality of the clocks and watches was such that Alfred Hirst realised his greatest ambition in 1912 with a range of watches which carried the "Limit" trademark. These watch movements had originally been made in Switzerland and shipped to Hirst Bros. to be put into British made “Dennison” cases. This trade brought even more growth with additional sales offices opening in London and Glasgow. At the outbreak of the First World War in 1914 found them manufacturing aircraft parts including revolution counters and optical instruments. The firm had been tasked by the Ministry of Munitions to solve the problem of pilots dropping bombs by hand and as a result, they effectively created the first bomb rack. After the war, the company once again began to prosper and with the demand for their products increasing they looked to build a new purpose-built factory to manufacture their products. In 1917 they purchased a seven-acre field site at Tame Side Dobcross, the designing of the new factory was passed onto local architect AJ Howcroft. His brief for the design of the clockworks would have been prompted by Alfred Hirst who having visited modern factories in the United States was inspired by the latest factory designs providing as much daylight as possible during working hours. The factory was eventually completed in 1920, by the mid-1920s there were cheap clock imports from Germany and production turned to radio sets and other components as well as counter and gas meters for the "Parkinson and Cowan" company who was later to take over the business. In 1926 came the cotton crash and the District Bank who had loans with the company foreclosed on the Hirst loan. The company did survive and throughout the second World, War II were involved in munitions work at the factory as well as making instruments for various aircraft. In the 1950’s they were producing meters and high grade measuring equipment but by the 1970's the business had closed and the factory was demolished in the mid-1980 "s The item is a good example of the later use of an early mechanism “Fusee” that was originally invented around 1525 in Prague. This type of clock mechanism was replaced as watchmakers looked for mechanisms that could reduce the size of clocks and watches, it appears England was the only country to continue making clocks with a Fusee device until around 1900,s of which our clock is an example. The use of a Fusee movement eventually became obsolete in 1970,s. The item is significant for the collection as it is a clock with a movement that has long since been made obsolete. Fusee type gallery wall clock made by Tame Side with an 8-day mechanical fusee movement. The white enamel dial is a little crazed and some of the Roman Numeral numbers are fading due to over-cleaning. The movement has a hexagonal iron pendulum bob hooking onto a pendulum rod with a spring-wound anchor escapement.Only mark is stamped on the movement believed to be a production number "13490" and made in Tame Side. (If the clock had been made after 1912 it would have had a trade mark "Limit")flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, clock, wall clock, fusee, gallery clock, alfred hirst, tame side -

4th/19th Prince of Wales's Light Horse Regiment Unit History Room

4th/19th Prince of Wales's Light Horse Regiment Unit History RoomPrincess Mary Gift Tin, 1914

In November 1914, an advertisement was placed in the national press inviting monetary contributions to a 'Sailors & Soldiers Christmas Fund' which had been created by Princess Mary, the seventeen year old daughter of King George V and Queen Mary. The purpose was to provide everyone wearing the King's uniform and serving overseas on Christmas Day 1914 with a 'gift from the nation'. The response was truly overwhelming, and it was decided to spend the money on an embossed brass box, based on a design by Messrs Adshead and Ramsey. The contents varied considerably; officers and men on active service afloat or at the front received a box containing a combination of pipe, lighter, 1 oz of tobacco and twenty cigarettes in distinctive yellow monogrammed wrappers. Non-smokers and boys received a bullet pencil and a packet of sweets instead. Indian troops often got sweets and spices, and nurses were treated to chocolate. Many of these items were despatched separately from the tins themselves, as once the standard issue of tobacco and cigarettes was placed in the tin there was little room for much else apart from the greeting card All boxes, irrespective of recipient, contained a Christmas card and a picture of the Princess. Those which were not distributed until after Christmas were sent out with a card wishing the recipient a 'victorious new year'. The wounded on leave or in hospital, nurses, and the widows or parents of those killed were also entitled to the gift. Prisoners of war at the time had theirs reserved until they were repatriated. Great efforts were made to distribute the gifts in time for Christmas, and huge demands were made on an already stretched postal service. More than 355,000 were successfully delivered by the deadline. As time pressed on, a shortage of brass meant that many entitled personnel did not receive their gift until as late as the summer of 1916, and in January 1919 it was reported that 'considerable' numbers had still not been distributed. Orders for brass strip were placed with the USA, who were not yet involved in the war, and a large consignment was lost with the ship 'Lusitania'. As so much brass was being consumed in the production of weapons and munitions, the quality of the boxes which were manufactured late on was poor, being of a plated inferior alloy, when compared with the earlier pure brass examples. When the fund finally closed in 1920, almost £200,000 had been donated for the provision of more than two and a half million boxes with contents. The 'tin' is approximately 5" long by 3¼" wide by 1¼" deep with a double-skinned, hinged, lid. The surface of the lid depicts the head of Princess Mary in the centre, surrounded by a laurel wreath and flanked on either side by the 'M' monogram. At the top, a decorative cartouche contains the words 'Imperium Britannicum' with a sword and scabbard either side. On the lower edge, another cartouche contains the words 'Christmas 1914', which is flanked by the bows of battleships forging through a heavy sea. In the corners, small roundels house the names of the Allies: Belgium, Japan, Montenegro and Servia; France and Russia are at the edges, each superimposed on three furled flags or standards. -

Puffing Billy Railway

Puffing Billy RailwaySteam Driven Weir Pump, 1900s

G. and J. Weir of Holm Foundry, Cathcart, Glasgow and now known as the Weir Group. The company was established in 1871 as an engineering firm by two brothers, George and James Weir, founding G. & J. Weir Ltd. The Weir brothers produced numerous groundbreaking inventions in pumping equipment, primarily for the Clyde shipyards and the steam ships built there. These pumps became extremely well known for their use as boiler feedwater pumps, and for ship's auxiliary equipment such as evaporators. Under W D Weir, the company turned to producing munitions and war material in the First World War. As well as shells, they manufactured aircraft including the Royal Aircraft Factory F.E.2 fighter and bomber. James George Weir (aviator, son of James Galloway Weir) a director of the company formed the Cierva Autogiro Company. G & J Weir would be a financial supporter of the company during its existence. In 1943, they provided the finances for the construction of the W.9, an experimental helicopter, to Air Ministry requirements. It was first listed on the London Stock Exchange in 1946. Double-acting Weir steam pumps were virtually standard fitment on British-built steamships, being used for pumping water, fuel, air and much else well into the 1950s, as well as being used on other ships worldwide. Historic - Double-acting Weir steam pumpSteam Driven Pump made of iron & steel puffing billy, weir pump, weir, steam driven pump -

Puffing Billy Railway

Puffing Billy RailwayGreenbat Battery Loco, Greenwood & Batley ltd

Greenbat Battery Loco Built by Greenwood & Batley Ltd Builders No. 420363/2 This Greenbat Battery Loco has been loaned to the Museum by the Walhalla Goldfields Railway, who had acquired it in 2013 along with a large quantity of narrow gauge trollies and light rail from Orica’s now closed munitions factory in Melbourne’s western suburbs. The trolley on display was one of two in use from the 1970s. Orica - Deer Park Munitions factory Orica Deer Park in Melbourne’s west has been used since circa 1875 for various forms of manufacturing and storage of chemicals. Although the site is bounded by Ballarat Road, Station Street, Tilburn Road and the Western Ring Road, the current entry point for industrial operations is situated at Gate 6 off Tilburn Road. Operations include: • a specialty chemicals facility producing products for mining services operations • quarry services • other chemical manufacture activities. The Deer Park factory complex is of historical significance as the location of the first plant for the manufacture of high explosives in Australia and has been, for its entire history, the most important, if not only, commercial manufacturer of high explosives in Australia. It commenced operation under the importer Jones Scott and Co, and then the Australian Lithofracteur Company (Krebs Patent), a rival to Nobel's dynamite patent. The factory was producing nitro-glycerine based explosives in Australia only a couple of years after Nobel's Ardeer factory began operating in Scotland. The explosives factories complex is of historical significance for the association with the Australian Lithofracteur Company, Australian Explosives and Chemicals, the Nobel company and later ICIANZ, which grew to become one of the largest explosives, chemical and plastics manufacturers in Australia. It was the pioneer of the industry and retained its dominance through monopolistic practices, taking over most of its competitors in the Australasian region. Substantial parts of the pre-Second World War layout of the site remain which, with a number of significant buildings dating back to the 1920s and '30s, indicate past and present processes of manufacturing, the necessary safety measures required and the integrated nature of the explosives and chemical industry. The narrow gauge tramway, which ran through the explosives section, was a rare survivor of nineteenth century materials-handling methods into the 21st Century. Greenwood & Batley were a large engineering manufacturer with a wide range of products, including armaments, electrical engineering, and printing and milling machinery. They also produced a range of battery-electric railway locomotives under the brand name Greenbat. The works was in Armley, Leeds, UK. Greenbat was the trade name for the railway locomotives built by Greenwood & Batley. The company specialised in electric locomotives, particularly battery-powered types for use in mines and other hazardous environments. Historic - Industrial Narrow Gauge Railway - Battery Locomotive - Orica - Deer Park Munitions factory - Deep park, Victoria, Australia Battery Locomotive - made of iron puffing billy, greenbat battery loco, battery locomotive, industrial narrow gauge railway, orica - deer park munitions factory -

Puffing Billy Railway

Puffing Billy RailwayExplosives Wagon, unkown

This 2 foot 6 inch (762mm) gauge wagon was used for carrying explosives and was used with the Greenbat Battery loco. It was donated to the Walhalla Goldfields Railway on long term loan in 2013 along with a large quantity of narrow gauge trollies and light rail from Orica’s now closed munitions factory in Melbourne’s western suburbs. Orica - Deer Park Munitions factory Orica Deer Park in Melbourne’s west has been used since circa 1875 for various forms of manufacturing and storage of chemicals. Although the site is bounded by Ballarat Road, Station Street, Tilburn Road and the Western Ring Road, the current entry point for industrial operations is situated at Gate 6 of Tilburn Road. Operations include: • a specialty chemicals facility producing products for mining services operations • quarry services • other chemical manufacture activities. The Deer Park factory complex The factory complex is of historical significance for the major role it played in Australia's manufacturing and mining industries through the development of progressively more efficient and safer explosives. It also contributed to wartime production in ammunition, initiators and the development of synthetic ammonia production and construction of the Defence Explosives Annexe No 5 (later the Albion Explosives Factory) during World War Two. The factory complex is also of technical significance for the unusual and specialised design of many of the buildings and structures, both in the layout of the works and the individual design of buildings. Blast protection and safety measures such as mounds around the buildings, 'cleanways' and buffer zones between production areas were employed extensively. A characteristic of many production buildings was the elimination of cavities where explosive compounds could lodge. The combination of concrete barriers and light-weight construction was designed to direct explosion debris away from operators or other buildings. The narrow gauge tramway, which ran through the explosives section, is a rare survivor of nineteenth century materials-handling methods. Historic - Industrial Narrow Gauge Railway - Wagon for carrying Explosives at the Orica - Deer Park Munitions factory, Deer park, Victoria, Australia Wagon for carrying explosives made from Timber and steelwagon for carrying explosives, puffing billy, industrial narrow gauge railway, orica - deer park munitions factory, explosives wagon -

Dandenong/Cranbourne RSL Sub Branch

Dandenong/Cranbourne RSL Sub BranchWeapon - Shell Fuse Cap, Galt Manufacturing Company

Galt Mfg Co in Canada produced shell percussion caps for allied munitions during WWI. This cap would have been attached to the end of a shell and provided the ignition to cause the shell to explode. It has a small arrow in a circle on the base which indicates use in the Australian Military.This object can tell the story of allied war production, showing that it was produced in Canada and used in Australian munitions. Brass shell fuse, rounded pyramid in shape.m Has multiple sections and a ring of measurements around the circumference. Lighter coloured cap on the top. Has a number of holes on the surface.Underneath: Galt Around the cirumference: DC, and measurements 1-22 cmgalt, shell, percusssion, cap, munition, brass, manufacturing, war, wwi -

Beechworth RSL Sub-Branch

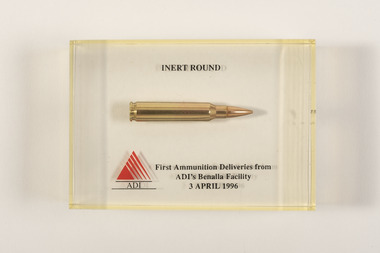

Beechworth RSL Sub-BranchSouvenir - Cartridge, Memorial, 3 April 1996

Australian munitions is the largest supplier of explosive munitions to the Australian Defence Force. Australian Munitions can trace its ammunition heritage back to the late 19th century, through the establishment of the Colonial Ammunition Company in Victoria. Manufacturing is based at two main regional sites – Benalla in Victoria and Mulwala in New South Wales. The Benalla site produces ammunition, explosive ordnance and other munitions.This cartridge represents the first ammunition delivery from the site upon its opening in 1996.Single 5.56mm cartridge, encased in resin. Text and images on resin."INERT ROUND" "First Ammunition Deliveries from" "ADI'S Benalla Facility" "3 April 1996"cartridge, ammunition, round, adi, australian munitions, bullet -

Bendigo Historical Society Inc.

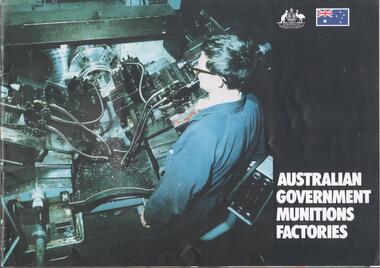

Bendigo Historical Society Inc.Booklet - Australian Defence Industries (ADI) - 38 assorted brochures covering Defence Technology

Australian Defence Industries (ADI) - Thirty-eight assorted coloured brochures covering Defence Technology, Australian Government Munitions Factories and promotional material for manufactured items.adi history -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageWeapon - Shell Case, Australian Army, 1940 -1941

These shell cases were donated along with other items from the St Nicholas' Mission to Seamen's Church at 139 Nelson Place, Williamstown, Victoria. The Church was operated by the Mission to Seamen organisation. The symbol of the broad arrow on the base of the shell case signifies that it was owned by the Australian Army. The dates of the shell cases - 1940 and 1941 - link the shell cases with World War II. Both cases' headstamps have "N", which could indicate that they were made for use by the Navy. Shell Case 1298.01: The headstamp code on the label "MEC" means that it was made by the Explosives Factory Maribyrnong - Cordite Annexe, Maribyrnong, Melbourne, which made cordite propellant for cartridges and shells. Shell Case 1298.02: The headstamp "MF" indicates it was made by the Small Arms Manufacturing Factory in Footscray, Melbourne, and the stamped year was 1941. THE MISSIONS TO SEAMEN (Brief History): - The Missions to Seamen was an Anglican charity that has served seafarers of the world since 1856 in Great Britain. Its symbol is a Flying Angel, inspired by a Bible verse. Today, there are centres in over 200 ports worldwide where seamen of all backgrounds are offered a warm welcome and provided with a wide range of facilities. In Victoria, the organisation began in Williamstown in 1857 as a Sailors’ Church, also known as ‘Bethel’ or the ‘Floating Church’ in an old hulk floating in Hobson’s Bay, Port of Melbourne. It soon became part of the Missions to Seamen, Victoria. In the year 2000, the organisation, now named Mission to Seafarers, still operated locally in Melbourne, Portland, Geelong and Hastings. The Ladies’ Harbour Lights Guild was formed in 1906 to support the Missions to Seamen in Melbourne and other centres, such as Williamstown. Two of the most significant ladies of the Guild were founder Ethel Augusta Godfrey and foundation member Alice Sibthorpe Tracy (who established a branch of the Guild in Warrnambool in 1920). The Guild continued its work until the 1960s. In 1943, a former Williamstown bank was purchased for the Missions to Seaman Club. The chapel was named St Nicholas’ Seamen’s Church and was supported by the Ladies’ Harbour Lights Guild, the Williamstown Lightkeepers’ Auxiliary and the League of Soldiers’ and Sailors’ Friends. It ceased operation in 1966. A Missions to Seamen Chapel and Recreation Room was a significant feature of ports during the late 1800s and into the 1900s. It seemed appropriate for Flagstaff Hill to include such a representation within the new Maritime Village, so the Melbourne Board of Management of Missions to Seamen Victoria gave its permission on 21st May 1979 for the entire furnishings of the Williamstown chapel to be transferred to Flagstaff Hill. The St Nicholas Seamen’s Church was officially opened on October 11, 1981, and closely resembles the Williamstown chapel. These shell cases are significant for their relationship with the Australian Army in general and in particular with the defence of Australia during World War II. The may have also been made for the Navy. Their significance is increased by their association with the Williamstown Missions To Seamen, which donated them to Flagstaff Hill in 1979, an organisation that has supported seafarers for many years.Shell case: two brass 4" rimmed shell cases with headstamps (inscriptions) on the base plate around the firing pin three holes evenly spaced around the centre of the base. A label is attached to one shell. The shell cases are part of the St. Nicholas Seamen's Church Collection. Shell Case 1298.01 - Printed stamp “P.2BT” “M.E.C.111” “I.E. 10/43”. Stamped into base “N”, “1940” “W [within lozenge]”, “S” symbol [Australian Government Arrow] “360“ . Around firing pin “MF I 422” “ME” “II” “4 I N” “5-“ ”MF [within rectangle]” “f” “B – [within circle]”, Shell Case 1298.02 - headstamp “N 1941 MF / F symbol [square box] LOT 679”, [in oval] 101 / 4 / S /U2) M GUNS 7 “, symbol [Australian Government Arrow], Stencil [in red circle] “B J”, symbol [Diamond with line top to bottom] Stamped in red ink “R5G 11 1 2B7”flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, munitions, shell case, ammunition 1940, ammunition 1941, firearms, cannon, australian government, borad arrow, australian army, wwii, world war 2, australian defence, australian ordinance, small arms manufacturing factory, explosives factory maribyrnong, cordite, world war ii, ww2, 1940, 1941, defence, n headstamp, footscray -

Ringwood RSL Sub-Branch

Ringwood RSL Sub-BranchEquipment - Equipment, Ammunition Box, munitions box, 19-5-66

Case believed to have been manufactured to hold ammunition for the Vietnam conflict.Brown metal box with yellow and white writing665 cart 9mm ball mk2z ctn mf 19-5-66 Australian government explosive Safety class 6 -

City of Melbourne Libraries

City of Melbourne LibrariesPhotograph, Spectators at Australian Women's Golf Championship

Description: Crowd of spectators gathered around a green at Royal Melbourne Golf Course, Cheltenham for the Australian Women’s Golf Championship in 1935. The winner was Irish player Pat Walker. Runner-up was Australian Susie Morpeth. Research by project volunteer, Fiona Collyer: 18 year-old Miss Pamela Barton of England is teeing off at the ninth hole, watched by her competitor Miss Janet Gardiner of Queensland and a gallery of intensely focussed spectators. Both women went on to have diverse, non-sporting careers. During the Blitz and the Battle of Britain, Pam Barton (1917-1943) drove ambulances before joining the WAAF as a radio operator. Later she gained a commission as a Flight Officer in command of a staff of 600. In 1943, Pam was killed instantly when the RAF plane piloted by her unofficial fiancée crashed in heavy weather. The Pam Barton Memorial Salver is awarded to the winner of the British Ladies Amateur Golf Championship. The inscription reads “In Affectionate Memory of Pam Barton”. During WWII, Janet Gardiner (Mrs Jobson-Scott, 1907-1987) began manufacturing liquid hosiery at the Red Cross Link rooms as a fundraiser. Donated oyster bottles were used and they charged 2/6 for four ounces. However, in April 1942, in a broadcast to the women of Australia, the Minister for War Organisation of Industry, Mr Dedman, announced that leg make-up preparations were now a prohibited item. They contained titanium oxide, an essential ingredient in the manufacture of paints used for camouflaging military equipment. Other items of a woman’s “battle array” such as nail lacquer, some creams and suntan lotions were also banned as they contained ingredients used in munitions and medical supplies. Glass slide Photographer notations on slide: "Vic Women's Ch'ship 1935 B98"golf, royal melbourne golf club, women golfers -

City of Melbourne Libraries

City of Melbourne LibrariesPhotograph, Spectators at Australian Women's Championship 1935

The women watch on… 18 year-old Miss Pamela Barton of England is teeing off at the ninth hole, watched by her competitor Miss Janet Gardiner of Queensland and a gallery of intensely focussed spectators. Both women went on to have diverse, non-sporting careers. During the Blitz and the Battle of Britain, Pam Barton (1917-1943) drove ambulances before joining the WAAF as a radio operator. Later she gained a commission as a Flight Officer in command of a staff of 600. In 1943, Pam was killed instantly when the RAF plane piloted by her unofficial fiancée crashed in heavy weather. The Pam Barton Memorial Salver is awarded to the winner of the British Ladies Amateur Golf Championship. The inscription reads “In Affectionate Memory of Pam Barton”. During WWII, Janet Gardiner (Mrs Jobson-Scott, 1907-1987) began manufacturing liquid hosiery at the Red Cross Link rooms as a fundraiser. Donated oyster bottles were used and they charged 2/6 for four ounces. However, in April 1942, in a broadcast to the women of Australia, the Minister for War Organisation of Industry, Mr Dedman, announced that leg make-up preparations were now a prohibited item. They contained titanium oxide, an essential ingredient in the manufacture of paints used for camouflaging military equipment. Other items of a woman’s “battle array” such as nail lacquer, some creams and suntan lotions were also banned as they contained ingredients used in munitions and medical supplies. MCK136 Published: The Age 30 August 1935 Photographer notations on slide: "Vic Women's Ch'ship 1935 B98" Published: The Age 30 August 1935 p. 9 Published title: CHAMPIONSHIP GOLF. WOMEN'S TITLE. Second Qualifying Round. BRITISH WOMEN IN FIRST FOUR PLACES. Published caption: Miss PAM BARTON who established a new course record at Royal Melbourne in the second qualifying round of the Australian women's championship. Trove article identifier: http://nla.gov.au/nla.news-article203989644 Research by project volunteer, Fiona Collyer: MISS PAMELA BARTON Miss Pamela Espeut Barton (1917–1943) was an English golf champion. Her tournament wins included the 1934 French International Ladies Golf Championship, the 1936 British Ladies Amateur and U S Women’s Amateur and the 1939 British Ladies Amateur. Pam was part of the British Women’s Golf Team that travelled to Australia in 1935 to compete in the Australian Woman’s Golf Championship at Royal Melbourne Golf Course. At 18 years of age, she was the youngest British golfer in the visiting team. She was eliminated in the second round by Miss Betty Nankivell of Melbourne. The press described Pam, “the baby of the team”, as a "natural" at golf and a good sport who never wore a hat and "hit like a man"! During the Blitz and The Battle of Britain, Pam drove ambulances for the London Ambulance Service, before joining the WAAF as a radio operator. Later she gained a commission as a Flight Officer in command of a staff of 600. Pam was stationed at RAF Manston, Kent where she met Flight Lieutenant Angus Ruffhead and they became romantically involved and reportedly “unofficially” engaged. On Saturday 12 November 1943, Pam and Angus attended a dinner dance at RAF Detling, however as Pam was on duty at RAF Manston the next morning, Angus arranged to fly her. There had been heavy rain during the day, however by the end of the dance conditions had improved and the couple set off in the de Havilland Tiger Moth. Soon after the plane left the ground, it struck an aviation fuel tank and was engulfed in flames. Pam was killed instantly and Angus was injured. Pam was buried at St John’s Margate church cemetery, her grave marked by a white military headstone. On January 6 1944, Angus led a mission of four planes over Le Touquet where they met intense fire. He took a direct hit and was pronounced Killed in Action. Angus is buried at Boulogne Eastern Cemetery, France. The “Pam Barton Memorial Salver” is awarded to the winner of the British Ladies Amateur Golf Championship. The inscription reads – “In Affectionate Memory of Pam Barton”. An 18-hole golf course has been named after her at Royal Mid-Surrey Golf Club, Richmond, London. MISS JANET GARDINER In 1935, Janet Margaret Grenville Gardiner (Mrs Janet Jobson-Scott, 1907-1987) competed in the Australian Women’s Golf Championship at Royal Melbourne Golf Course against the five visiting British women golfers. She was eliminated by Englishwoman Mrs Greenlees. During WWII, Janet was involved in fundraising for the Red Cross and the Australian Comforts Fund. Nylon stockings were becoming increasingly difficult to acquire as nylon was needed for manufacturing parachutes, ropes and nets. She began to manufacture liquid hosiery (leg make up) at the Red Cross Line, Brisbane. They used donated oyster bottles and it was available in two shades “Rose Beige” and “Suntan”, costing 2/6 shillings for four ounces. In 1941, a fashion parade was held at Brisbane’s Lennon’s Hotel in aid of Air Force House and Janet’s job was to apply liquid hosiery to the 12 mannequins. The parade featured beach fashion through the ages. In April 1942, in a broadcast to the women of Australia, the Minister for War Organisation of Industry, Mr John Dedman, announced that leg makeup preparations were now a prohibited item. It contained titanium oxide, an essential ingredient in the manufacture of paints used for camouflaging army trucks and tanks. Other items which formed part of a woman’s “battle array” such as nail lacquer, and some creams and suntan lotions were also banned as they contained important ingredients used in munitions and medical supplies. In 1942 Janet married “Tobruk Rat” Lieutenant David Collins Jobson-Scott of the AIF. After the war they lived at their property “Ballancar” in Inglewood Queensland. Janet died in 1987.Photographer notations on slide: "Vic Women's Ch'ship 1935 B98"golf, women golfers, royal melbourne golf club