Showing 108 items matching " smart moves"

-

Musculoskeletal Health Australia (now held by the Glen Eira Historical Society)

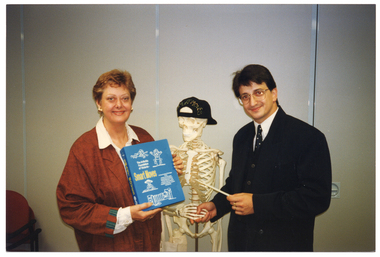

Musculoskeletal Health Australia (now held by the Glen Eira Historical Society)Photograph - Group photo, 1997

... smart moves... with the Arthritis Foundation of Victoria (AFV) as a sponsor of the Smart... of Victoria (AFV) as a sponsor of the Smart Moves school curriculum ...In 1997, Priceline Pharmacy became involved with the Arthritis Foundation of Victoria (AFV) as a sponsor of the Smart Moves school curriculum program. In this photo, AFV CEO, Shirley Caulfield, poses for a photo with Stan Kakkasis, Priceline's National Advertising Manager. A similar photo depicting Stan Kakkasis with Meredith Ericson, AFV's Manager for Community Information, appears on page 6 of the Vol 10 Issue 2, Winter 1997 edition of the Arthritis Foundation of Victoria's quarterly magazine, Arthritis Update.Colour photo of a woman and a man with a plastic skeleton on a stand between them. The woman is holding a large blue folder. The man is pointing to the folder with a short plastic pointing stick, and shaking the skeleton's hand. The skeleton is wearing a black cap, back to front.arthritis foundation of victoria, afv, osteoporosis victoria, ov, smart moves, school curriculum program, shirley caulfield, ceo, stan kakkasis, priceline pharmacy, national advertising manager, corporate sponsor, skeleton, bridget bones, 1997 -

Bendigo Military Museum

Bendigo Military MuseumAdministrative record - MEMBERSHIP RECORDS, BENDIGO RSL, C. 1960's onwards

.1) These membership records date from 1961/62 through to 2001/2. .2) These memberships records date from 1961/2 through to 2011. These records were originally in a large black heavy folder. When the Bendigo RSL Office moved from Pall Mall (SMI) in 2007 to the Bendigo District RSL in Havilah Road the records were then digitized and put in these box trays.. The card shown in the photos is William James Norman Smart Life Member of the Bendigo RSL He was Treasurer for 13 years. He on his own raised $250,000 for the RSL Appeals..1) Membership card index, paper, alphabetical order with dividers in a wood tray, rectangular shape, all hand written in blue/red pen. .2) Membership card index, paper, alphabetical order with dividers in wood tray rectangular shape, cards all written in blue/red pen. There is a detached section from the alphabetical listing and unused forms..1) On side of tray, " Old inactive members". .2) On side of tray, "Current members.brsl, smirsl, memberships -

Eltham District Historical Society Inc

Eltham District Historical Society IncPhotograph, 3rd and 4th Class, Eltham State School No. 209, c.1886

Bottom seated row, right side end, Alex and Alfred (Tommy) Smart. Donated by May Smart, (c/o Pine Tree Village, 330 Springfield Road), student at Eltham State School 1915-1923, daughter of Alex Smart Alexander Wilson Smart, father of Edward Alexander and Alfred Francis abandoned his family and moved to Perth in Western Australia where he was convicted of bigamy and murder and sentenced to death by hanging. Photo used on the cover of "We did open a school in Little Eltham", Eltham Primary School (2006) David Clark Head Teacher 1855-1888 and Assistant, Catherine Clark, his sister. Note: Photo is a Class not Grade (examination level). Photo taken c. 1886. Edward Alexander Smart was May Smart's father and Alfred Francis Smart her Uncle - Tommy the MilkmanSepia photographic print mounted on card Details on reverse re donor and Smart children identifiedeltham, state school no. 209, dalton street, alex smart, alfred (tommy) smart, alfred francis (tommmy) smart, david clark, edward alexander (alex) smart, eltham primary school, may smart, victoria may kamm (nee smart), alfred francis (tommy) smart, catherine clark, david george clark, eltham state school, eltham state school no. 209 -

Kew Historical Society Inc

Kew Historical Society IncArchive (Sub-series) - Subject File, Barnard Grove (Kew), 1985

Dorothy Benyei & Rosemary SmartReference, Research, InformationKHS OrderSubject file containing responses to a survey of residents of Barnard Grove, Kew (Vic), issued in 1985. The questionnaire requested information about when the respondee/s moved into the street, whether alterations had been made to their house, the reason why they moved to Barnard Grove, its good points and its limitations, and further comments. Rosemary Smart and Dorothy Benyei conducted the survey on behalf of the Society. The file contains many interesting responses from those who returned the surveys.barnard grove - kew east (vic.)barnard grove - kew east (vic.) -

Kew Historical Society Inc

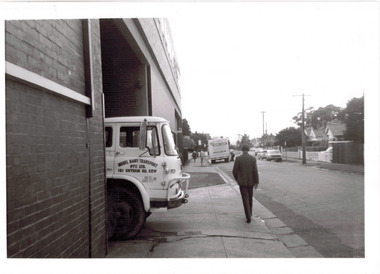

Kew Historical Society IncPhotograph - The Model Dairy Pty Ltd, 1968

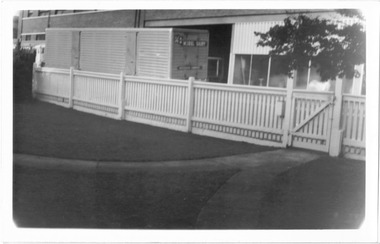

This well-known Kew business, which would become known as The Model Dairy, was founded in 1863 by James Venn Morgan. Morgan sold the company in the 1890s to John Simonton who renamed the business The Model Dairy Co. Simonton had experience in the local dairying industry having previously leased the Willsmere Park Dairy. He moved the business to Belmont Avenue in c.1899. In 1924, following his retirement, the company expanded to become The Model Dairy Pty Ltd with Arnold Thompson Simonton and John Tanner as its owner/directors. With new techniques and processes such a pasteurisation, the Belmont Avenue site no longer met required standards for processing and bottling, so its operations moved to 191 Cotham Road. The company celebrated its centenary in 1963. A new factory, built in 1959 to a design by Bates, Smart & McCutcheon, was purchased by Bib Stillwell Motors after the dairy closed. The entire site has since been redeveloped.Original black and white photographic positive of a Model Dairy Truck emerging onto Kent Street, Kew.the model dairy pty ltd, the model dairy co, john simonton, james venn morgan, john tanner, cotham road, kent street, ridgeway avenue, bates smart & mccutcheon, dairies -- kew (vic.) -

Kew Historical Society Inc

Kew Historical Society IncPhotograph - The Model Dairy Pty Ltd, 1968

This well-known Kew business, which would become known as The Model Dairy, was founded in 1863 by James Venn Morgan. Morgan sold the company in the 1890s to John Simonton who renamed the business The Model Dairy Co. Simonton had experience in the local dairying industry having previously leased the Willsmere Park Dairy. He moved the business to Belmont Avenue in c.1899. In 1924, following his retirement, the company expanded to become The Model Dairy Pty Ltd with Arnold Thompson Simonton and John Tanner as its owner/directors. With new techniques and processes such a pasteurisation, the Belmont Avenue site no longer met required standards for processing and bottling, so its operations moved to 191 Cotham Road. The company celebrated its centenary in 1963. A new factory, built in 1959 to a design by Bates, Smart & McCutcheon, was purchased by Bib Stillwell Motors after the dairy closed. The entire site has since been redeveloped.Original black and white photographic positive of a Model Dairy Truck emerging onto Kent Street, Kew.the model dairy pty ltd, the model dairy co, john simonton, james venn morgan, john tanner, cotham road, kent street, ridgeway avenue, bates smart & mccutcheon, dairies -- kew (vic.) -

Kew Historical Society Inc

Kew Historical Society IncPhotograph - The Model Dairy Pty Ltd, 1968

This well-known Kew business, which would become known as The Model Dairy, was founded in 1863 by James Venn Morgan. Morgan sold the company in the 1890s to John Simonton who renamed the business The Model Dairy Co. Simonton had experience in the local dairying industry having previously leased the Willsmere Park Dairy. He moved the business to Belmont Avenue in c.1899. In 1924, following his retirement, the company expanded to become The Model Dairy Pty Ltd with Arnold Thompson Simonton and John Tanner as its owner/directors. With new techniques and processes such a pasteurisation, the Belmont Avenue site no longer met required standards for processing and bottling, so its operations moved to 191 Cotham Road. The company celebrated its centenary in 1963. A new factory, built in 1959 to a design by Bates, Smart & McCutcheon, was purchased by Bib Stillwell Motors after the dairy closed. The entire site has since been redeveloped.Original black and white photographic positive of a Model Dairy Truck emerging onto Kent Street, Kew.the model dairy pty ltd, the model dairy co, john simonton, james venn morgan, john tanner, cotham road, kent street, ridgeway avenue, bates smart & mccutcheon, dairies -- kew (vic.) -

Kew Historical Society Inc

Kew Historical Society IncPhotograph - The Model Dairy Pty Ltd, 1968

This well-known Kew business, which would become known as The Model Dairy, was founded in 1863 by James Venn Morgan. Morgan sold the company in the 1890s to John Simonton who renamed the business The Model Dairy Co. Simonton had experience in the local dairying industry having previously leased the Willsmere Park Dairy. He moved the business to Belmont Avenue in c.1899. In 1924, following his retirement, the company expanded to become The Model Dairy Pty Ltd with Arnold Thompson Simonton and John Tanner as its owner/directors. With new techniques and processes such a pasteurisation, the Belmont Avenue site no longer met required standards for processing and bottling, so its operations moved to 191 Cotham Road. The company celebrated its centenary in 1963. A new factory, built in 1959 to a design by Bates, Smart & McCutcheon, was purchased by Bib Stillwell Motors after the dairy closed. The entire site has since been redeveloped.Original black and white photographic positive of a Model Dairy Truck emerging onto Kent Street, Kew.the model dairy pty ltd, the model dairy co, john simonton, james venn morgan, john tanner, cotham road, kent street, ridgeway avenue, bates smart & mccutcheon, dairies -- kew (vic.) -

Kew Historical Society Inc

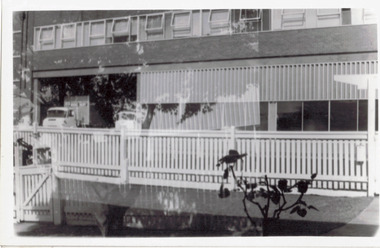

Kew Historical Society IncPhotograph - The Model Dairy Pty Ltd, 1968

This well-known Kew business, which would become known as The Model Dairy, was founded in 1863 by James Venn Morgan. Morgan sold the company in the 1890s to John Simonton who renamed the business The Model Dairy Co. Simonton had experience in the local dairying industry having previously leased the Willsmere Park Dairy. He moved the business to Belmont Avenue in c.1899. In 1924, following his retirement, the company expanded to become The Model Dairy Pty Ltd with Arnold Thompson Simonton and John Tanner as its owner/directors. With new techniques and processes such a pasteurisation, the Belmont Avenue site no longer met required standards for processing and bottling, so its operations moved to 191 Cotham Road. The company celebrated its centenary in 1963. A new factory, built in 1959 to a design by Bates, Smart & McCutcheon, was purchased by Bib Stillwell Motors after the dairy closed. The entire site has since been redeveloped.Original black and white photographic positive of a Model Dairy Truck parked in Kent Street, Kew.the model dairy pty ltd, the model dairy co, john simonton, james venn morgan, john tanner, cotham road, kent street, ridgeway avenue, bates smart & mccutcheon, dairies -- kew (vic.) -

Kew Historical Society Inc

Kew Historical Society IncPhotograph - The Model Dairy Pty Ltd, 1968

This well-known Kew business, which would become known as The Model Dairy, was founded in 1863 by James Venn Morgan. Morgan sold the company in the 1890s to John Simonton who renamed the business The Model Dairy Co. Simonton had experience in the local dairying industry having previously leased the Willsmere Park Dairy. He moved the business to Belmont Avenue in c.1899. In 1924, following his retirement, the company expanded to become The Model Dairy Pty Ltd with Arnold Thompson Simonton and John Tanner as its owner/directors. With new techniques and processes such a pasteurisation, the Belmont Avenue site no longer met required standards for processing and bottling, so its operations moved to 191 Cotham Road. The company celebrated its centenary in 1963. A new factory, built in 1959 to a design by Bates, Smart & McCutcheon, was purchased by Bib Stillwell Motors after the dairy closed. The entire site has since been redeveloped.Original black and white photographic positive of a Model Dairy Truck parked in Kent Street, Kew.the model dairy pty ltd, the model dairy co, john simonton, james venn morgan, john tanner, cotham road, kent street, ridgeway avenue, bates smart & mccutcheon, dairies -- kew (vic.) -

Kew Historical Society Inc

Kew Historical Society IncPhotograph - The Model Dairy Pty Ltd, 1968

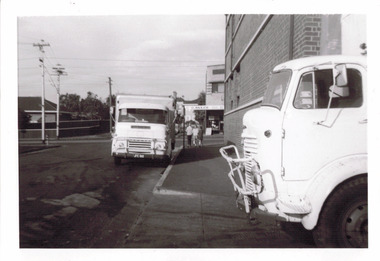

This well-known Kew business, which would become known as The Model Dairy, was founded in 1863 by James Venn Morgan. Morgan sold the company in the 1890s to John Simonton who renamed the business The Model Dairy Co. Simonton had experience in the local dairying industry having previously leased the Willsmere Park Dairy. He moved the business to Belmont Avenue in c.1899. In 1924, following his retirement, the company expanded to become The Model Dairy Pty Ltd with Arnold Thompson Simonton and John Tanner as its owner/directors. With new techniques and processes such a pasteurisation, the Belmont Avenue site no longer met required standards for processing and bottling, so its operations moved to 191 Cotham Road. The company celebrated its centenary in 1963. A new factory, built in 1959 to a design by Bates, Smart & McCutcheon, was purchased by Bib Stillwell Motors after the dairy closed. The entire site has since been redeveloped.Original black and white photographic positive of two Model Dairy Trucks in Kent Street, Kew. Barenya Court and Cotham Shopping Centre in distancethe model dairy pty ltd, the model dairy co, john simonton, james venn morgan, john tanner, cotham road, kent street, ridgeway avenue, bates smart & mccutcheon, dairies -- kew (vic.) -

Kew Historical Society Inc

Kew Historical Society IncPhotograph - The Model Dairy Pty Ltd, 1968

This well-known Kew business, which would become known as The Model Dairy, was founded in 1863 by James Venn Morgan. Morgan sold the company in the 1890s to John Simonton who renamed the business The Model Dairy Co. Simonton had experience in the local dairying industry having previously leased the Willsmere Park Dairy. He moved the business to Belmont Avenue in c.1899. In 1924, following his retirement, the company expanded to become The Model Dairy Pty Ltd with Arnold Thompson Simonton and John Tanner as its owner/directors. With new techniques and processes such a pasteurisation, the Belmont Avenue site no longer met required standards for processing and bottling, so its operations moved to 191 Cotham Road. The company celebrated its centenary in 1963. A new factory, built in 1959 to a design by Bates, Smart & McCutcheon, was purchased by Bib Stillwell Motors after the dairy closed. The entire site has since been redeveloped.Original black and white photographic positive of Model Dairy Trucks in Kent Street, Kew. Barenya Court and Cotham Shopping Centre in distancethe model dairy pty ltd, the model dairy co, john simonton, james venn morgan, john tanner, cotham road, kent street, ridgeway avenue, bates smart & mccutcheon, dairies -- kew (vic.) -

Kew Historical Society Inc

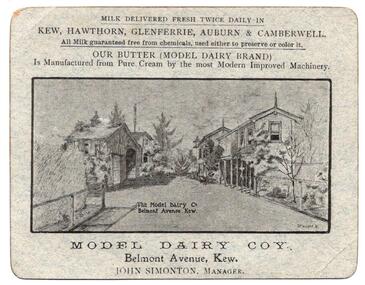

Kew Historical Society IncCard - Model Dairy Coy: Belmont Avenue, Kew, c.1907

This well-known Kew business, which would become known as The Model Dairy, was founded in 1863 by James Venn Morgan. Morgan sold the company in the 1890s to John Simonton who renamed the business The Model Dairy Co. Simonton had experience in the local dairying industry having previously leased the Willsmere Park Dairy. He moved the business to Belmont Avenue in c.1899. In 1924, following his retirement, the company expanded to become The Model Dairy Pty Ltd with Arnold Thompson Simonton and John Tanner as its owner/directors. With new techniques and processes such a pasteurisation, the Belmont Avenue site no longer met required standards for processing and bottling, so its operations moved to 191 Cotham Road. The company celebrated its centenary in 1963. A new factory, built in 1959 to a design by Bates, Smart & McCutcheon, was purchased by Bib Stillwell Motors after the dairy closed. The entire site has since been redeveloped.Digital copy of a business card advertising the Model Dairy in Belmont Avenue, Kew, managed by John Simonton. (The card was donated by John Harvey Simonton in 2021,)"Milk delivered fresh twice daily in / Kew, Hawthorn & Camberwell / All Milk guaranteed free from chemicals, used either to preserve or colour it / Our butter (Model Dairy Brand) / I Manufactured from Pure Cream by the most improved Machinery / [DRAWING] The Model Dairy Co Belmont Avenue Kew / Model Dairy Co / Belmont Avenue, Kew / John Simonton, Manager"model dairy -- kew (vic.), john simonton, belmont avenue -- kew (vic.), dairies -- kew (vic.) -

Kew Historical Society Inc

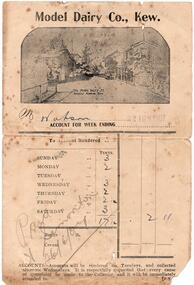

Kew Historical Society IncDocument - Account for Week ending 22 June 1907

This well-known Kew business, which would become known as The Model Dairy, was founded in 1863 by James Venn Morgan. Morgan sold the company in the 1890s to John Simonton who renamed the business The Model Dairy Co. Simonton had experience in the local dairying industry having previously leased the Willsmere Park Dairy. He moved the business to Belmont Avenue in c.1899. In 1924, following his retirement, the company expanded to become The Model Dairy Pty Ltd with Arnold Thompson Simonton and John Tanner as its owner/directors. With new techniques and processes such a pasteurisation, the Belmont Avenue site no longer met required standards for processing and bottling, so its operations moved to 191 Cotham Road. The company celebrated its centenary in 1963. A new factory, built in 1959 to a design by Bates, Smart & McCutcheon, was purchased by Bib Stillwell Motors after the dairy closed. The entire site has since been redeveloped.Digital copy of the front side of an invoice, for week ending 22 June 1907 by John Simonton of the Model Dairy in Belmont Avenue to Watson for delivery of 17 bottles of milk on six occasions during the week . A drawing of the Model Dairy is printed at the top of the invoice. (The card was donated by John Harvey Simonton in 2021,)"[To M] Watson" / "Paid A Simonton 26/6.07"model dairy -- kew (vic.), john simonton, belmont avenue -- kew (vic.), dairies -- kew (vic.), invoices -

Kew Historical Society Inc

Kew Historical Society IncFunctional object - Model Dairy Commemorative Salver 1863-1963

This well-known Kew business, which would become known as The Model Dairy, was founded in 1863 by James Venn Morgan. Morgan sold the company in the 1890s to John Simonton who renamed the business The Model Dairy Co. Simonton had experience in the local dairying industry having previously leased the Willsmere Park Dairy. He moved the business to Belmont Avenue in c.1899. In 1924, following his retirement, the company expanded to become The Model Dairy Pty Ltd with Arnold Thompson Simonton and John Tanner as its owner/directors. With new techniques and processes such a pasteurisation, the Belmont Avenue site no longer met required standards for processing and bottling, so its operations moved to 191 Cotham Road. The company celebrated its centenary in 1963. A new factory, built in 1959 to a design by Bates, Smart & McCutcheon, was purchased by Bib Stillwell Motors after the dairy closed. The entire site has since been redeveloped.Rare silver plate salver commemorating one of Kew's most famous businesses. The salver is one of a pair, identically engraved with Model Dairy 1963-1963.Hecworth reproduction old sheffield plate salver with foliate edge on three feet, with impressed maker mark on reverse rim and engraved with the words 'Model Dairy 1963-1963' in the centre of the reverse. "Heckworth Plate was made by Platers Pty Ltd at 39 Greeves St, St Kilda, Melbourne, Victoria. Platers introduced 'Hecworth' Sheffield Reproduction Silverware in 1940 and in 1946 'Hecworth' was acquired by Rodd Pty Ltd." (MAAS)MODEL DAIRY 1863 - 1963model dairy -- kew (vic.), commemorative silver, john tanner, tanner family -

Kew Historical Society Inc

Kew Historical Society IncFunctional object - Model Dairy Commemorative Salver 1863-1963

This well-known Kew business, which would become known as The Model Dairy, was founded in 1863 by James Venn Morgan. Morgan sold the company in the 1890s to John Simonton who renamed the business The Model Dairy Co. Simonton had experience in the local dairying industry having previously leased the Willsmere Park Dairy. He moved the business to Belmont Avenue in c.1899. In 1924, following his retirement, the company expanded to become The Model Dairy Pty Ltd with Arnold Thompson Simonton and John Tanner as its owner/directors. With new techniques and processes such a pasteurisation, the Belmont Avenue site no longer met required standards for processing and bottling, so its operations moved to 191 Cotham Road. The company celebrated its centenary in 1963. A new factory, built in 1959 to a design by Bates, Smart & McCutcheon, was purchased by Bib Stillwell Motors after the dairy closed. The entire site has since been redeveloped.Rare silver plate salver commemorating one of Kew's most famous businesses. The salver is one of a pair, identically engraved with Model Dairy 1963-1963.Hecworth reproduction old sheffield plate salver with foliate edge on three feet, with impressed maker mark on reverse rim and engraved with the words 'Model Dairy 1963-1963' in the centre of the reverse. "Heckworth Plate was made by Platers Pty Ltd at 39 Greeves St, St Kilda, Melbourne, Victoria. Platers introduced 'Hecworth' Sheffield Reproduction Silverware in 1940 and in 1946 'Hecworth' was acquired by Rodd Pty Ltd." (MAAS)MODEL DAIRY 1863 - 1963model dairy -- kew (vic.), commemorative silver, john tanner, tanner family -

Bendigo Military Museum

Bendigo Military MuseumPhotograph - APPEALS BRSL, Post 2005

This photograph was taken on the Portico of the Soldiers Memeorial Institute Pall Mall Bendigo. The man in the photo is "William James Norman Smart" known by all as Norm. He was a legend in Bendigo RSL Appeals having raised near $250,000.00 over the years. His selling spot was Coles Central where he sat for up to a fortnight each Appeal, ANZAC and Poppy. He had a loyal clientele who only bought their tokens from Norm. On ANZAC day especially he would come into the kitchen at the Soldiers Memorial about 5.00am and sort his tray out while others there were making the Rum and Coffee. He would then go out and walk among the people before the Dawn Service selling tokens. Norm was still selling tokens after he turned 90 years. he retired from all Volunteer work in the Bendigo RSL in August 2015. Refer Cat No 8131.2P for Norms RSL history. Norm enlisted in the CMF on 5.11.1941 No V245294 in the 38th Battalion, the unit later moved to WA by train 30.3.1942, he transferred to the AIF No VX88596 on 31.7.1942, they entrained back to Vic on 19.1.1943, then entrained again to the NT 0n 18.6.1943, transfer to the AIF No VX88596 on 8.8.1944 in the 11th Aust Infantry Battalion, embark for New Britain 25.11.1944, embark from Rabaul for Aust on 8.1.1946, discharged from the AIF on 5.2.1946..1) Photograph, gold timber frame with photo in a black inset showing a man in a hat with a Tray of poppies for sale, he is wearing a name tag and a red poppy. .2) Funeral card of "W.J.N. Smart", double sided with a portrait one side and wedding photo the other.On the name tag, "RSL Welfare Appeals - RSL unpaid collector", name hand written, "Norm Smart"brsl, smirsl, photograph, appeals, norm -

Kew Historical Society Inc

Kew Historical Society IncBiographical information, Ronald Horace Setford (1915–1988)

Ronald Horace Setford was born in April 1915 at 18 Church Street, Hawthorn, at his family’s home above their decorator shop. He was the second of three sons born to Horace Turner Setford (1880-1944) and Mabel Crofts (1887-1943). He attended Hawthorn West Primary School and then Swinburne before beginning work in his family’s business ‘Setford and Son’ in October 1930. This was formalised in April 1931 when he became a carpentry and joinery apprentice. In 1934 he graduated as a grade four carpenter. Ron worked in the family business until 1964 and then worked at J S Kidd and Co Pty Ltd as a storeman until his retirement in December 1973. Ron married Grace Muriel Agnes Perrey (1915-2001) in 1936 and they first lived in Kew around 1940, at 38 Marshall Avenue. Ron served in the Citizen Military Forces as a sapper with the 9 Australian Army Transport Company, Royal Australian Engineers, signing up a week after Darwin had been bombed. He spent time in Darwin, Wayville (South Australia), Herberton and Grovely (Queensland). Afterwards he refused to eat rice, never spoke of the war, nor took part in any ANZAC day proceedings. In 1941, Ron and Grace bought their block of land at 9 Tanner Avenue, East Kew, part of the Old Golf Links Estate, for £225. It was not until December 1945 that Ron started building their home and they moved in during May 1947. Ron and Grace remained there for thirty-seven years until the house was sold to their nephew in 1984. It has since been demolished. Ron’s great passion was photography and in the early 1960s he purchased his Minolta camera. Slide evenings at Tanner Avenue were a regular occurrence. Ron made his own title slides, interval slides and end slides. As well as many holiday photos (around Australia and their world trip in 1966), he enjoyed photographing local landmarks, flowers, insects and family. One of Ron’s photography projects was to record the progress of the building of the Eastern Freeway. This was near their home, and he’d walk down to the works on a regular basis, dressed smartly, with his camera in hand. The workers thought he was an official photographer, and he was allowed on site to take his photos. In 1984, Ron and Grace downsized and moved to Bayswater. Ron passed away on 31 October 1988 at the Maroondah Hospital in Ringwood East, at age 73. His ashes were spread on his beloved rose bushes at Tanner Avenue. Lauren Thomson, 2025ron setford, 9 tanner avenue -- kew east (vic, setford and son -- 18 church st (hawthorn), grace muriel agnes perrey, 9 australian army transport company, j s kidd and co pty ltd, eastern freeway, f19 freeway -

Ithacan Historical Society

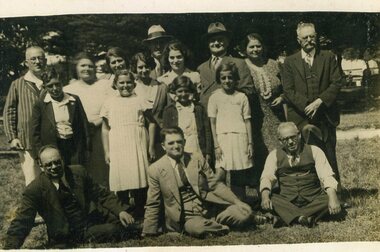

Ithacan Historical SocietyPhotograph, Picnic group, c late1930s

The group gathered for the photograph were enjoying themselves at an annual Ithacan Picnic during the 1930s. The picnic was most likely held at Maddingley Park, Bacchus Marsh as it was the regular site for the picnic up until 1980 following which a move was made to the Ferny Creek Reserve, now the regular venue. Notable from early picnic photos is the effort that was made to dress for the picnic; men in suits and women in smart outfits.A black and white photograph of people standing in an sports ground. There are seven men and five ladies as well as three young girls and a boy. Three of the men are sitting in front of the group on the ground. -

National Wool Museum

National Wool MuseumTextile - Children's Jumper, Kathryn Knitwear, c.1953-1965

Kathryn Knitwear, founded by Robert Blake, manufactured high quality children’s knitwear in Melbourne from the 1940s – 1980s. Robert Blake began manufacturing children’s knitwear in his bedroom in Strathmore using a hand powered machine in the late 1940s. The operation moved to Ascot Vale and Essendon, before eventually establishing a factory in Moonee Ponds in the early 1950s. The business continued to expand, necessitating a move to a new factory in Broadmeadows. By 1962, the Broadmeadows factory was producing an average of 20,000 garments per month, which increased to 24,000 by 1964. Robert Blake’s Son, Brendan recalls that “The Kathryn brand was famous around Australia, anywhere children needed to keep warm and dress smartly. It also won a number of wool fashion awards”, including the 1969 Wool Awards, which was held by the Australian Wool Bureau and published in Women’s Weekly. The Kathryn range was designed for durability, comfort and care, without sacrificing style. They used patterning techniques that increase stretchiness, comfort and fit, as well as integrating decorative elements into the fabric to prevent them from being bulky, uncomfortable or tight. Making longevity of style a priority, Brendan Blake remembers that “there was one particular garment that was in the range for at least thirty years”. He also recalls “In the past, when women have found out that I was associated with Kathryn Knitwear, they would often relate to me the story of a garment they had purchased or received as a gift and, when their child had grown out of it, they would hand it on to another child. Several ladies have told me of purchasing garments for their daughters’ glory box, or saving a particular garment after their daughter had grown out of it. Brendan Blake: “At the peak of their operation they employed approximately two hundred people, mainly women and girls. A family would often seek to send their daughter to work in this company because they knew they would be looked after and safe. One lady wrote to me telling me that working at the Moonee Ponds Factory prior to getting married was the happiest time of her life.” In 1963, workers at the Kathryn factory earned £13 per week, which was 8 shillings and 8 pence higher than the minimum weekly wage for female workers in the textile manufacturing industry (£12 11s 4d). By 1970, the Kathryn Knitwear brand expanded from children’s knitwear into womenswear under the brand name ‘Lady Kathryn’, and for boys and men under ‘Robert Blake’. Continuing to diversify their distribution, they also began exporting ‘Kathryn’ garments to New Zealand, the Pacific Islands, and Japan. ‘Kathryn Knitwear’ was well-known for their early adoption of modern materials and techniques that had broad appeal to their customer base. This is shown in their early use of the acrylic fibre ‘Orlon’ in the 50s and 60s and ‘Superwash’ wool in the 1970s. Many of Kathryn Knitwear’s styles, particularly those that were long running staples of the brand, were available in both wool and Orlon to suit the consumer’s preference. Wool has been renowned for its excellent properties for thousands of years, by people from all over the world. Not only good for thick winter woollens, it can help keep you cool in summer, as well as being durable and resistant to water, fire, ultraviolet light, stains and odour. Far from the humble origins of one man in his bedroom with a hand-cranked machine; at its closure in 1980, the Broadmeadows factory of ‘Kathryn’ housed more than 100 machines, including 53 sewing machines and 45 knitting machines. Robert Blake was “a passionate advocate for wool and Australian Made” throughout his whole life. A strong thread that ties through the lifespan of Robert Blake and Kathryn Knitwear is a balance between adopting new innovations without sacrificing the core values of durability, comfort, care and style that had made the brand so well known. Their legacy forms an integral part of both Australian social and manufacturing history.Red children's wool jumper with green and white geometric tartan/plaid pattern on front. Has long sleeves with ribbed cuffs and ribbed crew neck and closes with four red plastic buttons at back neck. Coloured pattern is worked in lines on top of finished fabric in surface crochet in pattern of green, white, green[white label at back neck with blue stitching] ALL WOOLknitwear, clothing, children's clothing, jumper, manufacturing, fashion textile production, machine knitting -

National Wool Museum

National Wool MuseumTextile - Children's Jumper, Kathryn Knitwear, c.1970

Kathryn Knitwear, founded by Robert Blake, manufactured high quality children’s knitwear in Melbourne from the 1940s – 1980s. Robert Blake began manufacturing children’s knitwear in his bedroom in Strathmore using a hand powered machine in the late 1940s. The operation moved to Ascot Vale and Essendon, before eventually establishing a factory in Moonee Ponds in the early 1950s. The business continued to expand, necessitating a move to a new factory in Broadmeadows. By 1962, the Broadmeadows factory was producing an average of 20,000 garments per month, which increased to 24,000 by 1964. Robert Blake’s Son, Brendan recalls that “The Kathryn brand was famous around Australia, anywhere children needed to keep warm and dress smartly. It also won a number of wool fashion awards”, including the 1969 Wool Awards, which was held by the Australian Wool Bureau and published in Women’s Weekly. The Kathryn range was designed for durability, comfort and care, without sacrificing style. They used patterning techniques that increase stretchiness, comfort and fit, as well as integrating decorative elements into the fabric to prevent them from being bulky, uncomfortable or tight. Making longevity of style a priority, Brendan Blake remembers that “there was one particular garment that was in the range for at least thirty years”. He also recalls “In the past, when women have found out that I was associated with Kathryn Knitwear, they would often relate to me the story of a garment they had purchased or received as a gift and, when their child had grown out of it, they would hand it on to another child. Several ladies have told me of purchasing garments for their daughters’ glory box, or saving a particular garment after their daughter had grown out of it. Brendan Blake: “At the peak of their operation they employed approximately two hundred people, mainly women and girls. A family would often seek to send their daughter to work in this company because they knew they would be looked after and safe. One lady wrote to me telling me that working at the Moonee Ponds Factory prior to getting married was the happiest time of her life.” In 1963, workers at the Kathryn factory earned £13 per week, which was 8 shillings and 8 pence higher than the minimum weekly wage for female workers in the textile manufacturing industry (£12 11s 4d). By 1970, the Kathryn Knitwear brand expanded from children’s knitwear into womenswear under the brand name ‘Lady Kathryn’, and for boys and men under ‘Robert Blake’. Continuing to diversify their distribution, they also began exporting ‘Kathryn’ garments to New Zealand, the Pacific Islands, and Japan. ‘Kathryn Knitwear’ was well-known for their early adoption of modern materials and techniques that had broad appeal to their customer base. This is shown in their early use of the acrylic fibre ‘Orlon’ in the 50s and 60s and ‘Superwash’ wool in the 1970s. Many of Kathryn Knitwear’s styles, particularly those that were long running staples of the brand, were available in both wool and Orlon to suit the consumer’s preference. Wool has been renowned for its excellent properties for thousands of years, by people from all over the world. Not only good for thick winter woollens, it can help keep you cool in summer, as well as being durable and resistant to water, fire, ultraviolet light, stains and odour. Far from the humble origins of one man in his bedroom with a hand-cranked machine; at its closure in 1980, the Broadmeadows factory of ‘Kathryn’ housed more than 100 machines, including 53 sewing machines and 45 knitting machines. Robert Blake was “a passionate advocate for wool and Australian Made” throughout his whole life. A strong thread that ties through the lifespan of Robert Blake and Kathryn Knitwear is a balance between adopting new innovations without sacrificing the core values of durability, comfort, care and style that had made the brand so well known. Their legacy forms an integral part of both Australian social and manufacturing history.Grey wool Jumper with Blue and grey cable design on front. Vertical cable pattern is two sets of intertwining grey blue cable pairs on a purl stitch background in alternating rows of blue and grey. Front panel of jumper has five cable panels separated by smooth stocking stitch panels. Jumper has long sleeves and crew neck with thick ribbed collar and cuffs. Style B/110, Colourway Silver/Denim, Size 8 .2) 2 Sample tags stapled together with manufacturing information, including sizes and colours available, as well as knit swatch samples for colourways Brown/Woodgrain, Denim/Blue Shadow and Pebble/Oyster.1) [white label at back neck with green and black printed writing] ROBERT BLAKE Size 8 / knitwear HEIGHT 130cm MADE IN AUSTRALIA .2) [blue sample label] STYLE B/110 Crew Neck Wool Pullover SIZES: 2 4 6 8 10 PRICE: $10 [amended to $11 in blue pen] $[written over in blue pen so as to be illegible] [handwritten in blue pen] $12.55 SIZES: 12 14 PRICE: [printed] $12.30 [handwritten over top in blue pen] $13.15 COLORS: Silver/Denim, Brown/Woodgrain, Denim/Blue Shadow, Pebble/Oyster. Dec on Del. [cream brand label] [OBVERSE] ROBERT BLAKE [REVERSE] ROBERT BLAKE KNITWEAR MELBOURNE, AUSTRALIAknitwear, clothing, children's clothing, jumper, manufacturing, fashion textile production, machine knitting -

National Wool Museum

National Wool MuseumTextile - Children's Jumper, Kathryn Knitwear, c.1970

Kathryn Knitwear, founded by Robert Blake, manufactured high quality children’s knitwear in Melbourne from the 1940s – 1980s. Robert Blake began manufacturing children’s knitwear in his bedroom in Strathmore using a hand powered machine in the late 1940s. The operation moved to Ascot Vale and Essendon, before eventually establishing a factory in Moonee Ponds in the early 1950s. The business continued to expand, necessitating a move to a new factory in Broadmeadows. By 1962, the Broadmeadows factory was producing an average of 20,000 garments per month, which increased to 24,000 by 1964. Robert Blake’s Son, Brendan recalls that “The Kathryn brand was famous around Australia, anywhere children needed to keep warm and dress smartly. It also won a number of wool fashion awards”, including the 1969 Wool Awards, which was held by the Australian Wool Bureau and published in Women’s Weekly. The Kathryn range was designed for durability, comfort and care, without sacrificing style. They used patterning techniques that increase stretchiness, comfort and fit, as well as integrating decorative elements into the fabric to prevent them from being bulky, uncomfortable or tight. Making longevity of style a priority, Brendan Blake remembers that “there was one particular garment that was in the range for at least thirty years”. He also recalls “In the past, when women have found out that I was associated with Kathryn Knitwear, they would often relate to me the story of a garment they had purchased or received as a gift and, when their child had grown out of it, they would hand it on to another child. Several ladies have told me of purchasing garments for their daughters’ glory box, or saving a particular garment after their daughter had grown out of it. Brendan Blake: “At the peak of their operation they employed approximately two hundred people, mainly women and girls. A family would often seek to send their daughter to work in this company because they knew they would be looked after and safe. One lady wrote to me telling me that working at the Moonee Ponds Factory prior to getting married was the happiest time of her life.” In 1963, workers at the Kathryn factory earned £13 per week, which was 8 shillings and 8 pence higher than the minimum weekly wage for female workers in the textile manufacturing industry (£12 11s 4d). By 1970, the Kathryn Knitwear brand expanded from children’s knitwear into womenswear under the brand name ‘Lady Kathryn’, and for boys and men under ‘Robert Blake’. Continuing to diversify their distribution, they also began exporting ‘Kathryn’ garments to New Zealand, the Pacific Islands, and Japan. ‘Kathryn Knitwear’ was well-known for their early adoption of modern materials and techniques that had broad appeal to their customer base. This is shown in their early use of the acrylic fibre ‘Orlon’ in the 50s and 60s and ‘Superwash’ wool in the 1970s. Many of Kathryn Knitwear’s styles, particularly those that were long running staples of the brand, were available in both wool and Orlon to suit the consumer’s preference. Wool has been renowned for its excellent properties for thousands of years, by people from all over the world. Not only good for thick winter woollens, it can help keep you cool in summer, as well as being durable and resistant to water, fire, ultraviolet light, stains and odour. Far from the humble origins of one man in his bedroom with a hand-cranked machine; at its closure in 1980, the Broadmeadows factory of ‘Kathryn’ housed more than 100 machines, including 53 sewing machines and 45 knitting machines. Robert Blake was “a passionate advocate for wool and Australian Made” throughout his whole life. A strong thread that ties through the lifespan of Robert Blake and Kathryn Knitwear is a balance between adopting new innovations without sacrificing the core values of durability, comfort, care and style that had made the brand so well known. Their legacy forms an integral part of both Australian social and manufacturing history.Brown and Grey children’s jacket with brown accents at pockets and shoulder, centre front zip, curved pocket detail.Style B/117, Colourway Woodgrain/Pebble, Size 8 .2) Sample tags stapled together with manufacturing information, including sizes and colours available, as well as knit swatch samples for colourways Green/Silver, Burgundy/Denim, Navy/Denim, and Rust/Pebble.1) [white label at back neck with green and black printed writing] ROBERT BLAKE Size 8 / knitwear HEIGHT 130cm MADE IN AUSTRALIA .2 [blue sample label] STYLE B/117 Jacket. Zip. Birdseye. Wool. SIZES: 2 4 6 8 10 PRICE: $11.75 [amended to $12.80 in blue pen] $13.85 [amended to $15.05 in blue pen] SIZES: 12 14 PRICE: [printed] $14.95 [amended to $16.15 in blue pen] COLORS: Woodgrain/Pebble Green/Silver [drawn through in black pen] Burgundy/Denim, Navy/Denim, Rust/Pebble Dec on Del. [cream brand label] [OBVERSE] ROBERT BLAKE [REVERSE] ROBERT BLAKE KNITWEAR MELBOURNE, AUSTRALIAknitwear, clothing, children's clothing, jumper, manufacturing, fashion textile production, machine knitting, children's knitwear -

National Wool Museum

National Wool MuseumTextile - Children's Jumper, Kathryn Knitwear, c.1975

Kathryn Knitwear, founded by Robert Blake, manufactured high quality children’s knitwear in Melbourne from the 1940s – 1980s. Robert Blake began manufacturing children’s knitwear in his bedroom in Strathmore using a hand powered machine in the late 1940s. The operation moved to Ascot Vale and Essendon, before eventually establishing a factory in Moonee Ponds in the early 1950s. The business continued to expand, necessitating a move to a new factory in Broadmeadows. By 1962, the Broadmeadows factory was producing an average of 20,000 garments per month, which increased to 24,000 by 1964. Robert Blake’s Son, Brendan recalls that “The Kathryn brand was famous around Australia, anywhere children needed to keep warm and dress smartly. It also won a number of wool fashion awards”, including the 1969 Wool Awards, which was held by the Australian Wool Bureau and published in Women’s Weekly. The Kathryn range was designed for durability, comfort and care, without sacrificing style. They used patterning techniques that increase stretchiness, comfort and fit, as well as integrating decorative elements into the fabric to prevent them from being bulky, uncomfortable or tight. Making longevity of style a priority, Brendan Blake remembers that “there was one particular garment that was in the range for at least thirty years”. He also recalls “In the past, when women have found out that I was associated with Kathryn Knitwear, they would often relate to me the story of a garment they had purchased or received as a gift and, when their child had grown out of it, they would hand it on to another child. Several ladies have told me of purchasing garments for their daughters’ glory box, or saving a particular garment after their daughter had grown out of it. Brendan Blake: “At the peak of their operation they employed approximately two hundred people, mainly women and girls. A family would often seek to send their daughter to work in this company because they knew they would be looked after and safe. One lady wrote to me telling me that working at the Moonee Ponds Factory prior to getting married was the happiest time of her life.” In 1963, workers at the Kathryn factory earned £13 per week, which was 8 shillings and 8 pence higher than the minimum weekly wage for female workers in the textile manufacturing industry (£12 11s 4d). By 1970, the Kathryn Knitwear brand expanded from children’s knitwear into womenswear under the brand name ‘Lady Kathryn’, and for boys and men under ‘Robert Blake’. Continuing to diversify their distribution, they also began exporting ‘Kathryn’ garments to New Zealand, the Pacific Islands, and Japan. ‘Kathryn Knitwear’ was well-known for their early adoption of modern materials and techniques that had broad appeal to their customer base. This is shown in their early use of the acrylic fibre ‘Orlon’ in the 50s and 60s and ‘Superwash’ wool in the 1970s. Many of Kathryn Knitwear’s styles, particularly those that were long running staples of the brand, were available in both wool and Orlon to suit the consumer’s preference. Wool has been renowned for its excellent properties for thousands of years, by people from all over the world. Not only good for thick winter woollens, it can help keep you cool in summer, as well as being durable and resistant to water, fire, ultraviolet light, stains and odour. In a world where wool garments all had to be washed by hand, the invention of machine-washable acrylic fibres and widespread adoption of washing machines in ordinary Australian homes in the 1950s and 60s posed a major risk to the wool industry, and by extension the entire Australian economy. With the price of wool falling, the CSIRO and the Australian Wool Board worked together from the 1950s on a number of developments to keep Australian wool competitive and desirable to the public, many of which came out of the Geelong research labs. While progress had been made in the preceding decades, 1970 saw a major breakthrough; the invention of a new method of making wool washable and shrink-proof, most commonly known as ‘Superwash’. It is a technology that is still highly used to this day, and is very recognisable to those who use commercial wool yarn to knit or crochet. Far from the humble origins of one man in his bedroom with a hand-cranked machine; at its closure in 1980, the Broadmeadows factory of ‘Kathryn’ housed more than 100 machines, including 53 sewing machines and 45 knitting machines. Robert Blake was “a passionate advocate for wool and Australian Made” throughout his whole life. A strong thread that ties through the lifespan of Robert Blake and Kathryn Knitwear is a balance between adopting new innovations without sacrificing the core values of durability, comfort, care and style that had made the brand so well known. Their legacy forms an integral part of both Australian social and manufacturing history.Blue wool turtleneck ‘skivvy’ jumper in all over rib pattern with long sleeves. .2) swing tag with woolmark logo for ‘Superwash Wool’1.)[white label at back neck with blue writing] KATHRYN REGD. (Woolmark Logo) PURE NEW WOOL Superwash SIZE 2 HGT. 92cm MADE IN AUSTRALIA 2.)[retail swing tag for ‘Superwash Wool’] [OBVERSE] [woolmark logo] [handwritten in blue pen] 314 [printed] PURE NEW WOOL [handwritten] 2 Superwash Wool Machine Washable [INTERNAL] [woolmark logo] PURE NEW WOOL YOU ARE NOW THE OWNER OF A SUPERWASH WOOL GARMENT That has been specially treated to withstand a lifetime of machine washing. SUPERWASH WOOL has all the desirable qualities of wool – soft handle, comfort, warmth and style. Not all wool knitwear has the SUPERWASH treatment so remember always to look for the special “SUPERWASH” label and swing ticket. To was SUPERWASH WOOL just follow the instructions of the garment label. [woolmark logo] PURE NEW WOOL SUPERWASH WOOL THE WOOL YOU WASH IN THE MACHINE.knitwear, children's knitwear, clothing, children's clothing, jumper, manufacturing, fashion textile production, machine knitting, csiro, national wool board, superwash, australian wool innovation -

National Wool Museum

National Wool MuseumTextile - Children's Cardigan, Kathryn Knitwear, c.1965

Kathryn Knitwear, founded by Robert Blake, manufactured high quality children’s knitwear in Melbourne from the 1940s – 1980s. Robert Blake began manufacturing children’s knitwear in his bedroom in Strathmore using a hand powered machine in the late 1940s. The operation moved to Ascot Vale and Essendon, before eventually establishing a factory in Moonee Ponds in the early 1950s. The business continued to expand, necessitating a move to a new factory in Broadmeadows. By 1962, the Broadmeadows factory was producing an average of 20,000 garments per month, which increased to 24,000 by 1964. Robert Blake’s Son, Brendan recalls that “The Kathryn brand was famous around Australia, anywhere children needed to keep warm and dress smartly. It also won a number of wool fashion awards”, including the 1969 Wool Awards, which was held by the Australian Wool Bureau and published in Women’s Weekly. The Kathryn range was designed for durability, comfort and care, without sacrificing style. They used patterning techniques that increase stretchiness, comfort and fit, as well as integrating decorative elements into the fabric to prevent them from being bulky, uncomfortable or tight. Making longevity of style a priority, Brendan Blake remembers that “there was one particular garment that was in the range for at least thirty years”. He also recalls “In the past, when women have found out that I was associated with Kathryn Knitwear, they would often relate to me the story of a garment they had purchased or received as a gift and, when their child had grown out of it, they would hand it on to another child. Several ladies have told me of purchasing garments for their daughters’ glory box, or saving a particular garment after their daughter had grown out of it. Brendan Blake: “At the peak of their operation they employed approximately two hundred people, mainly women and girls. A family would often seek to send their daughter to work in this company because they knew they would be looked after and safe. One lady wrote to me telling me that working at the Moonee Ponds Factory prior to getting married was the happiest time of her life.” In 1963, workers at the Kathryn factory earned £13 per week, which was 8 shillings and 8 pence higher than the minimum weekly wage for female workers in the textile manufacturing industry (£12 11s 4d). By 1970, the Kathryn Knitwear brand expanded from children’s knitwear into womenswear under the brand name ‘Lady Kathryn’, and for boys and men under ‘Robert Blake’. Continuing to diversify their distribution, they also began exporting ‘Kathryn’ garments to New Zealand, the Pacific Islands, and Japan. The decoration on this garment was embroidered by hand by a skilled worker at the Kathryn Knitwear factory. ‘Kathryn Knitwear’ was well-known for their early adoption of modern materials and techniques that had broad appeal to their customer base. This is shown in their early use of the acrylic fibre ‘Orlon’ in the 50s and 60s and ‘Superwash’ wool in the 1970s. Many of Kathryn Knitwear’s styles, particularly those that were long running staples of the brand, were available in both wool and Orlon to suit the consumer’s preference. Wool has been renowned for its excellent properties for thousands of years, by people from all over the world. Not only good for thick winter woollens, it can help keep you cool in summer, as well as being durable and resistant to water, fire, ultraviolet light, stains and odour. Far from the humble origins of one man in his bedroom with a hand-cranked machine; at its closure in 1980, the Broadmeadows factory of ‘Kathryn’ housed more than 100 machines, including 53 sewing machines and 45 knitting machines. Robert Blake was “a passionate advocate for wool and Australian Made” throughout his whole life. A strong thread that ties through the lifespan of Robert Blake and Kathryn Knitwear is a balance between adopting new innovations without sacrificing the core values of durability, comfort, care and style that had made the brand so well known. Their legacy forms an integral part of both Australian social and manufacturing history.Grey children’s cardigan with embroidered flowers and human figures in folk costume, and crocheted design around neck in green, yellow and red. Left panel has embroidered figure of man with blue lederhosen and yellow shirt, black shoes and hat, hat has red accent. Right front panel depicts woman wearing red skirt with white stripe, white shirt, and green headscarf with black stockings and shoes. Flowers are embroidered in pink, white and blue with green and yellow accents for stems and flower centres. Cardigan closes in front with five marbled grey plastic buttons[Label at back neck with blue lettering woven into label] KATHRYN REGD / 22 ALL WOOL CREATED BY ROBERT BLAKEchildren's knitwear, knitwear, clothing, children's clothing, cardigan, manufacturing, fashion textile production, machine knitting, embroidery, embroiderer, folk art, folk embroidery -

National Wool Museum

National Wool MuseumTextile - Children's Cardigan, Kathryn Knitwear, c.1960

Kathryn Knitwear, founded by Robert Blake, manufactured high quality children’s knitwear in Melbourne from the 1940s – 1980s. Robert Blake began manufacturing children’s knitwear in his bedroom in Strathmore using a hand powered machine in the late 1940s. The operation moved to Ascot Vale and Essendon, before eventually establishing a factory in Moonee Ponds in the early 1950s. The business continued to expand, necessitating a move to a new factory in Broadmeadows. By 1962, the Broadmeadows factory was producing an average of 20,000 garments per month, which increased to 24,000 by 1964. Robert Blake’s Son, Brendan recalls that “The Kathryn brand was famous around Australia, anywhere children needed to keep warm and dress smartly. It also won a number of wool fashion awards”, including the 1969 Wool Awards, which was held by the Australian Wool Bureau and published in Women’s Weekly. The Kathryn range was designed for durability, comfort and care, without sacrificing style. They used patterning techniques that increase stretchiness, comfort and fit, as well as integrating decorative elements into the fabric to prevent them from being bulky, uncomfortable or tight. Making longevity of style a priority, Brendan Blake remembers that “there was one particular garment that was in the range for at least thirty years”. He also recalls “In the past, when women have found out that I was associated with Kathryn Knitwear, they would often relate to me the story of a garment they had purchased or received as a gift and, when their child had grown out of it, they would hand it on to another child. Several ladies have told me of purchasing garments for their daughters’ glory box, or saving a particular garment after their daughter had grown out of it. Brendan Blake: “At the peak of their operation they employed approximately two hundred people, mainly women and girls. A family would often seek to send their daughter to work in this company because they knew they would be looked after and safe. One lady wrote to me telling me that working at the Moonee Ponds Factory prior to getting married was the happiest time of her life.” In 1963, workers at the Kathryn factory earned £13 per week, which was 8 shillings and 8 pence higher than the minimum weekly wage for female workers in the textile manufacturing industry (£12 11s 4d). By 1970, the Kathryn Knitwear brand expanded from children’s knitwear into womenswear under the brand name ‘Lady Kathryn’, and for boys and men under ‘Robert Blake’. Continuing to diversify their distribution, they also began exporting ‘Kathryn’ garments to New Zealand, the Pacific Islands, and Japan. ‘Kathryn Knitwear’ was well-known for their early adoption of modern materials and techniques that had broad appeal to their customer base. This is shown in their early use of the acrylic fibre ‘Orlon’ in the 50s and 60s and ‘Superwash’ wool in the 1970s. Many of Kathryn Knitwear’s styles, particularly those that were long running staples of the brand, were available in both wool and Orlon to suit the consumer’s preference. Cotton is a common material for knitwear worn in the warmer months, as it is very breathable and absorbs moisture easily. While we mostly associate knitwear with keeping us warm in the cold, the market for Australian knitwear would be very limited without options to wear all year round. Far from the humble origins of one man in his bedroom with a hand-cranked machine; at its closure in 1980, the Broadmeadows factory of ‘Kathryn’ housed more than 100 machines, including 53 sewing machines and 45 knitting machines. Robert Blake was “a passionate advocate for wool and Australian Made” throughout his whole life. A strong thread that ties through the lifespan of Robert Blake and Kathryn Knitwear is a balance between adopting new innovations without sacrificing the core values of durability, comfort, care and style that had made the brand so well known. Their legacy forms an integral part of both Australian social and manufacturing history.Royal blue double breasted cardigan 'Reefer Jacket' with short sleeves in a textured rib stitch with six chrome metal buttons in two rows down centre front. Style 319/J .2 is sample tag with manufacturing information, including sizes and colours available.1) [white label at back neck with blue stitching] KATHRYN REGD. CREATED BY ALL COTTON / 24 / ROBERT BLAKE .2) [sample label] [OBVERSE] STYLE: 319/J – Reefer Jacket – Combed Cot. SIZE: 22” 24” 26” 28” 30” 32” PRICE: 20/- 21/- 22/6 24/- 26/- 27/6 COLOR: NAVY ONLY. [REVERSE] KATHRYN Garments are • PRE-SHRUNK • STANDARD MEASUREMENTS • FIT EXACTLY • LAUNDER PERFECTLY Designed and Manufactured by ROBERT BLAKE, MELBOURNEknitwear, children's knitwear, clothing, children's clothing, cardigan, manufacturing, fashion textile production, machine knitting, fashion cotton -

National Wool Museum

National Wool MuseumTextile - Children's Jumper, Kathryn Knitwear, c.1970

Kathryn Knitwear, founded by Robert Blake, manufactured high quality children’s knitwear in Melbourne from the 1940s – 1980s. Robert Blake began manufacturing children’s knitwear in his bedroom in Strathmore using a hand powered machine in the late 1940s. The operation moved to Ascot Vale and Essendon, before eventually establishing a factory in Moonee Ponds in the early 1950s. The business continued to expand, necessitating a move to a new factory in Broadmeadows. By 1962, the Broadmeadows factory was producing an average of 20,000 garments per month, which increased to 24,000 by 1964. Robert Blake’s Son, Brendan recalls that “The Kathryn brand was famous around Australia, anywhere children needed to keep warm and dress smartly. It also won a number of wool fashion awards”, including the 1969 Wool Awards, which was held by the Australian Wool Bureau and published in Women’s Weekly. The Kathryn range was designed for durability, comfort and care, without sacrificing style. They used patterning techniques that increase stretchiness, comfort and fit, as well as integrating decorative elements into the fabric to prevent them from being bulky, uncomfortable or tight. Making longevity of style a priority, Brendan Blake remembers that “there was one particular garment that was in the range for at least thirty years”. He also recalls “In the past, when women have found out that I was associated with Kathryn Knitwear, they would often relate to me the story of a garment they had purchased or received as a gift and, when their child had grown out of it, they would hand it on to another child. Several ladies have told me of purchasing garments for their daughters’ glory box, or saving a particular garment after their daughter had grown out of it. Brendan Blake: “At the peak of their operation they employed approximately two hundred people, mainly women and girls. A family would often seek to send their daughter to work in this company because they knew they would be looked after and safe. One lady wrote to me telling me that working at the Moonee Ponds Factory prior to getting married was the happiest time of her life.” In 1963, workers at the Kathryn factory earned £13 per week, which was 8 shillings and 8 pence higher than the minimum weekly wage for female workers in the textile manufacturing industry (£12 11s 4d). By 1970, the Kathryn Knitwear brand expanded from children’s knitwear into womenswear under the brand name ‘Lady Kathryn’, and for boys and men under ‘Robert Blake’. Continuing to diversify their distribution, they also began exporting ‘Kathryn’ garments to New Zealand, the Pacific Islands, and Japan. ‘Kathryn Knitwear’ was well-known for their early adoption of modern materials and techniques that had broad appeal to their customer base. This is shown in their early use of the acrylic fibre ‘Orlon’ in the 50s and 60s and ‘Superwash’ wool in the 1970s. Many of Kathryn Knitwear’s styles, particularly those that were long running staples of the brand, were available in both wool and Orlon to suit the consumer’s preference. Orlon was developed by DuPont in the 1940s and became the first commercially successful acrylic fibre in the 1950s and 1960s. The development of Orlon coincided with an increase in availability of washing machines in everyday Australian homes. The great appeal of Orlon was that while wool garments still had to be hand-washed, Orlon’s shrink-resistant nature made it machine washable and dryable. This was a very appealing prospect, especially for the seemingly unending task of cleaning active children’s clothing. Machine washable wool would not be available until the development of the ‘Superwash’ treatment by the Australian Wool Board and CSIRO in 1970. Far from the humble origins of one man in his bedroom with a hand-cranked machine; at its closure in 1980, the Broadmeadows factory of ‘Kathryn’ housed more than 100 machines, including 53 sewing machines and 45 knitting machines. Robert Blake was “a passionate advocate for wool and Australian Made” throughout his whole life. A strong thread that ties through the lifespan of Robert Blake and Kathryn Knitwear is a balance between adopting new innovations without sacrificing the core values of durability, comfort, care and style that had made the brand so well known. Their legacy forms an integral part of both Australian social and manufacturing history.Forest Green Childrens jumper with geometric ‘alpine’ pattern with long sleeves and ribbed cuffs and round neck collar. Textured geometric pattern is created with purl stitches and extends both on the front and back of the jumper, as well as down the sleeves.[white label at back neck printed with blue ink] KATHRYN REGD SIZE 1 / LENGTH 84cm / WEIGHT 12kg / Made in Australia ACRYLIC/WOOLchildren's knitwear, knitwear, clothing, children's clothing, jumper, manufacturing, fashion textile production, machine knitting -

National Wool Museum

National Wool MuseumTextile - Children's Jumper, Kathryn Knitwear, c.1964-1970

Kathryn Knitwear, founded by Robert Blake, manufactured high quality children’s knitwear in Melbourne from the 1940s – 1980s. Robert Blake began manufacturing children’s knitwear in his bedroom in Strathmore using a hand powered machine in the late 1940s. The operation moved to Ascot Vale and Essendon, before eventually establishing a factory in Moonee Ponds in the early 1950s. The business continued to expand, necessitating a move to a new factory in Broadmeadows. By 1962, the Broadmeadows factory was producing an average of 20,000 garments per month, which increased to 24,000 by 1964. Robert Blake’s Son, Brendan recalls that “The Kathryn brand was famous around Australia, anywhere children needed to keep warm and dress smartly. It also won a number of wool fashion awards”, including the 1969 Wool Awards, which was held by the Australian Wool Bureau and published in Women’s Weekly. The Kathryn range was designed for durability, comfort and care, without sacrificing style. They used patterning techniques that increase stretchiness, comfort and fit, as well as integrating decorative elements into the fabric to prevent them from being bulky, uncomfortable or tight. Making longevity of style a priority, Brendan Blake remembers that “there was one particular garment that was in the range for at least thirty years”. He also recalls “In the past, when women have found out that I was associated with Kathryn Knitwear, they would often relate to me the story of a garment they had purchased or received as a gift and, when their child had grown out of it, they would hand it on to another child. Several ladies have told me of purchasing garments for their daughters’ glory box, or saving a particular garment after their daughter had grown out of it. Brendan Blake: “At the peak of their operation they employed approximately two hundred people, mainly women and girls. A family would often seek to send their daughter to work in this company because they knew they would be looked after and safe. One lady wrote to me telling me that working at the Moonee Ponds Factory prior to getting married was the happiest time of her life.” In 1963, workers at the Kathryn factory earned £13 per week, which was 8 shillings and 8 pence higher than the minimum weekly wage for female workers in the textile manufacturing industry (£12 11s 4d). By 1970, the Kathryn Knitwear brand expanded from children’s knitwear into womenswear under the brand name ‘Lady Kathryn’, and for boys and men under ‘Robert Blake’. Continuing to diversify their distribution, they also began exporting ‘Kathryn’ garments to New Zealand, the Pacific Islands, and Japan. ‘Kathryn Knitwear’ was well-known for their early adoption of modern materials and techniques that had broad appeal to their customer base. This is shown in their early use of the acrylic fibre ‘Orlon’ in the 50s and 60s and ‘Superwash’ wool in the 1970s. Many of Kathryn Knitwear’s styles, particularly those that were long running staples of the brand, were available in both wool and Orlon to suit the consumer’s preference. Far from the humble origins of one man in his bedroom with a hand-cranked machine; at its closure in 1980, the Broadmeadows factory of ‘Kathryn’ housed more than 100 machines, including 53 sewing machines and 45 knitting machines. Robert Blake was “a passionate advocate for wool and Australian Made” throughout his whole life. A strong thread that ties through the lifespan of Robert Blake and Kathryn Knitwear is a balance between adopting new innovations without sacrificing the core values of durability, comfort, care and style that had made the brand so well known. Their legacy forms an integral part of both Australian social and manufacturing history.White short-sleeved jumper with all-over pattern of aqua blue diamonds. Blue floated threads slightly show through white on main body, leading to an overall pale blue effect on body, with white collar and cuffs. Closes with three pearlescent plastic buttons at back neck. .2 is a retail tag marked with the style code, and includes generic information on care for garments of different material composition..1) [label stitched into back neck of garment] KATHRYN REGD CREATED BY ROBERT BLAKE .2) [retail tag, intended to be folded in three, printed on both sides] [OBVERSE] KATHRYN Children’s Knitwear STYLE: [blue pen] S/35B SIZE: PRICE: / KATHRYN Garments are… • PRE-SHRUNK • STANDARD MEASUREMENTS • FIT EXACTLY • LAUNDER PERFECTLY / NOW .. KATHRYN GOES TO . . SCHOOL Ask your retailer for SCHOOL PULLOVERS by KATHRYN [REVERSE] WASHING INSTRUCTIONS WOOL Wash frequently to AVOID HEAVY SOILING Wash garment BY HAND, in lukewarm Velvet Soap suds. ON NO ACCOUNT RUB SOAP ON GARMENT. Squeeze suds gently through garment but DO NOT RUB. Rubbing will cause garment to thicken. RINSE AT LEAST TWICE IN CLEAN WATER TO REMOVE ALL SOAP. TO dry, roll garment in a towel to remove excess moisture, turn garment inside out and pull it lengthwise, DRY IN SHADE… AVOID SUNLIGHT. When dry, place brown paper or pressing cloth over garment and press with iron at correct heat. ORLON Wash as wool Lay flat to dry but DO NOT IRON. To keep brushed suits like new, brush frequently with nylon brush supplied. COTTON Wash by hand for preference in Velvet Soap suds. Rinse thoroughly in cold water and remove all excess water before drying on line. Please do not use any harsh detergent or bleach. Designed and manufactured by ROBERT BLAKE Pty. Ltd., MELB. (handwritten in pencil) S35 (untintelligible)/5 / NOW KATHRYN GOES TO SCHOOL Ask your retailer for SCHOOL PULLOVERS by KATHRYNknitwear, children's knitwear, clothing, children's clothing, jumper, manufacturing, fashion textile production, machine knitting, colourwork -

National Wool Museum

National Wool MuseumTextile - Children's Jumper, Kathryn Knitwear, c.1975

Kathryn Knitwear, founded by Robert Blake, manufactured high quality children’s knitwear in Melbourne from the 1940s – 1980s. Robert Blake began manufacturing children’s knitwear in his bedroom in Strathmore using a hand powered machine in the late 1940s. The operation moved to Ascot Vale and Essendon, before eventually establishing a factory in Moonee Ponds in the early 1950s. The business continued to expand, necessitating a move to a new factory in Broadmeadows. By 1962, the Broadmeadows factory was producing an average of 20,000 garments per month, which increased to 24,000 by 1964. Robert Blake’s Son, Brendan recalls that “The Kathryn brand was famous around Australia, anywhere children needed to keep warm and dress smartly. It also won a number of wool fashion awards”, including the 1969 Wool Awards, which was held by the Australian Wool Bureau and published in Women’s Weekly. The Kathryn range was designed for durability, comfort and care, without sacrificing style. They used patterning techniques that increase stretchiness, comfort and fit, as well as integrating decorative elements into the fabric to prevent them from being bulky, uncomfortable or tight. Making longevity of style a priority, Brendan Blake remembers that “there was one particular garment that was in the range for at least thirty years”. He also recalls “In the past, when women have found out that I was associated with Kathryn Knitwear, they would often relate to me the story of a garment they had purchased or received as a gift and, when their child had grown out of it, they would hand it on to another child. Several ladies have told me of purchasing garments for their daughters’ glory box, or saving a particular garment after their daughter had grown out of it. Brendan Blake: “At the peak of their operation they employed approximately two hundred people, mainly women and girls. A family would often seek to send their daughter to work in this company because they knew they would be looked after and safe. One lady wrote to me telling me that working at the Moonee Ponds Factory prior to getting married was the happiest time of her life.” In 1963, workers at the Kathryn factory earned £13 per week, which was 8 shillings and 8 pence higher than the minimum weekly wage for female workers in the textile manufacturing industry (£12 11s 4d). By 1970, the Kathryn Knitwear brand expanded from children’s knitwear into womenswear under the brand name ‘Lady Kathryn’, and for boys and men under ‘Robert Blake’. Continuing to diversify their distribution, they also began exporting ‘Kathryn’ garments to New Zealand, the Pacific Islands, and Japan. ‘Kathryn Knitwear’ was well-known for their early adoption of modern materials and techniques that had broad appeal to their customer base. This is shown in their early use of the acrylic fibre ‘Orlon’ in the 50s and 60s and ‘Superwash’ wool in the 1970s. Many of Kathryn Knitwear’s styles, particularly those that were long running staples of the brand, were available in both wool and Orlon to suit the consumer’s preference. Wool has been renowned for its excellent properties for thousands of years, by people from all over the world. Not only good for thick winter woollens, it can help keep you cool in summer, as well as being durable and resistant to water, fire, ultraviolet light, stains and odour. Far from the humble origins of one man in his bedroom with a hand-cranked machine; at its closure in 1980, the Broadmeadows factory of ‘Kathryn’ housed more than 100 machines, including 53 sewing machines and 45 knitting machines. Robert Blake was “a passionate advocate for wool and Australian Made” throughout his whole life. A strong thread that ties through the lifespan of Robert Blake and Kathryn Knitwear is a balance between adopting new innovations without sacrificing the core values of durability, comfort, care and style that had made the brand so well known. Their legacy forms an integral part of both Australian social and manufacturing history.Orange jumper with multicoloured heathered tweed effect, white stripe accent on neck, upper arm and sleeve cuffs, two patch pockets mounted on diagonal outlined in thread matching accent colour .2 Sample tags with manufacturing information, including sizes and colours available, as well as knit swatch samples in colourways Blue Tweed/Sky/Magnolia and Cream Tweed/Magnolia/Pine.1) [tag stitched into back neck] KATHRYN REGD PURE NEW WOOL/ SIZE 6 HEIGHT 120cm MADE IN AUSTRALIA .2) [blue sample label] STYLE 589/Pullover S.47. Wool Tweed. SIZES: 2 4 6 8 PRICE: $9.80 [amended to $10.75 in blue pen] $0.35 [handwritten in blue pen] $11.40 COLORS: Pink Tw/Ochre/Mag, Blue Tweed/Sky/Magnolia Cream Tweed/Mag/Pine. [Crossed out in black ink] March on Del.children's knitwear, children's clothing, clothing, knitwear, jumper, manufacturing, fashion textile production, machine knitting, heathered yarn, tweed yarn, flecked yarn, colourwork -

National Wool Museum

National Wool MuseumTextile - Children's Lace Jumper, Kathryn Knitwear, c.1970