Showing 10 items matching " the department of munitions"

-

Bendigo Historical Society Inc.

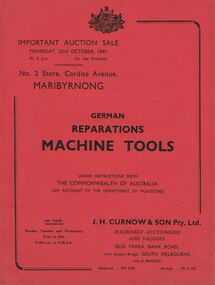

Bendigo Historical Society Inc.Document - IAN DYETT COLLECTION: AUCTION CATALOGUE - GERMAN REPARATIONS MACHINE TOOLS

... the Department of Munitions... (on account of the Department of Munitions) at No. 2 Store... The Commonwealth of Australia the Department of Munitions J H Curnow & Son ...Red cover, catalogue for a sale of German Reparations Machine Tools under instruction from The Commonwealth of Australia (on account of the Department of Munitions) at No. 2 Store, Maribyrnong on 23/10/1947. Special Notice and Conditions of Sale printed in catalogue. J. H. Curnow & Son Pty. Ltd. were the auctioneers.business, auctioneers, j h curnow & son pty ltd, ian dyett collection - auction catalogue - german reparations machine tools, the commonwealth of australia, the department of munitions, j h curnow & son pty ltd, the prahran telegraph printing co -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDrill Press, early to mid-20th century

... to the Australian Defence Department and munitions factory during the World... vices and clamps to the Australian Defence Department ...This post drill press has been made by Melbourne business, Dawn Manufacturing Company. It can be operated manually or by a pulley driven flywheel, with the aid of an engine connected to a power supply. In the late 1800s early 1900s a drill press like this would have been driven by steam from a boiler, the main power source for manufacturer’s power at that time. Dawn’s Golden Anniversary 1917-1967 Catalogue describes this model 611 drill as … “Ruggedly constructed with accurately reamed bearings. The coupling between the main spindle and feed screw engages the full circumference of the spindle, and embraces a ball-bearing thrust race. The pillar, as in all “Dawn Drilling Machines” is a solid bright steel bar, in place of the usual light tubing. Adjustable automatic feed.” And “F. & l. Pulleys extra, if required”. DAWN MANUFACTURING CO. The Dawn Manufacturing Co. was founded in Coburg, Melbourne, in 1917 by the four Blake brothers, who were all engineers. After World War I Dawn was supplying drills Australia wide and the company was growing at a healthy rate. During the depression they remained busy, with employees working 60-80 hour weeks. Dawn was contracted to supply vices and clamps to the Australian Defence Department and munitions factory during the World War II. - 1959 the company was taken over by G.N. Raymond Group. - 1967 the Dawn Manufacturing Co. had distributors in Australia and overseas, including USA, Canada, New Zealand, Asia and the Middle East. - 1973 the Siddons Ramset Limited acquired Dawn. - December 1991, Dawn became a unit of the United States owned Stanley Works Pty. Ltd. - November 1998 Dawn became 100 per cent Australian owned. The drill is a typical tool of a blacksmith, cart wright, wheelwright and garage business. It is an example of the tools of the blacksmiths’ trade in Victoria in the early to mid-20th century.Post type drill press machine with gear driven flywheel. Drill press is attached to a post and is fitted with a pulley belt and will run at a speed of maxim 200 r.p.m. The machine can also be manually operated. It has an aperture in the centre, a chuck, for the drill bit and has two metal handles at the centre, on the right hand side. Gear ratio 2:1 main drive, 6" diam, 3:1 reduction gear. Made by Dawn of Melbourne, Australia. Model No. 611, Code No. 9157"DAWN MFG COY”, “MELB. AUSTRALIA", " 611"flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, blacksmiths, blacksmith’s drill, blacksmith tools, dawn drill model no. 611, dawn drill code no. 9157, dawn manufacturing coy melbourne, dawn manufacturing coy coburg, dawn post drill, drilling machine, drill with gear driven flywheel, forging tool, metal working tool, post drill, steam powered drill, trade tool, warrnambool district 1900s -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDrill Press, 1920s-1950s

... to the Australian Defence Department and munitions factory during the World... vices and clamps to the Australian Defence Department ...This drill once belonged to Goodall and Sons, who were blacksmiths in Terang. The smith was called upon to do a variety of work. In the early 1900s he was often the nearest person to be able to perform an engineer’s services for many miles around. The Dawn Ball-bearing Post Drill no. 611 is described in McPherson’s Catalogue as a “drilling machine with adjustable automatic feed, with improved Dawn coupler and ball-bearing thrust’. The heavy design of the flywheel enables it to maintain momentum” and is “fitted with pulleys for belt drive if desired” The hand crank drives an automatic feed to work off a cam-follow system opposite a large wheel. Made by Dawn Manufacturing Co. Australia 1920-1950. DAWN MANUFACTURING CO. Dawn Manufacturing Co. was founded in Coburg, Melbourne, in 1917 by the four Blake brothers, who were all engineers. After World War I Dawn was supplying drills Australia wide and the company was growing at a healthy rate. During the depression they remained busy, with employees working 60-80 hour weeks. Dawn was contracted to supply vices and clamps to the Australian Defence Department and munitions factory during the World War II. In 1959 the company was taken over by G.N. Raymond Group, then in 1973 the Siddons Ramset Limited acquired Dawn. In December 1991, Dawn became a unit of the United States owned Stanley Works Pty. Ltd. In November 1998 Dawn became 100 per cent Australian owned. HENRY GOODALL & SONS Henry Goodall (1870-1936) was proprietor of garages as H. Goodall & Sons Pty. Ltd., at both Terang (McKinnon and High Streets) and Mortlake (Dunlop Street). His business was in operation in at least in 1916 and perhaps well before, considering the date of the tyre bender and its use for wagons with wooden wheels. It was still in operation in 1953, chasing up debtors in Mount Gambier Court. Amongst the employees of H. Goodall & Sons Pty. Ltd. was Ernie Entwistle, a blacksmith (a soldier who died in 1916 ) and Alfred Hodgetts, radio expert (killed in a fatal accident in 1943, when he was in his early 30s ). Henry Goodall was involved in the community as a Justice of Peace, a deputy coroner, President of the Mortlake Hospital, trustee of the Soldiers’ Memorial Hall, and as a prominent Freemason. He and his wife had two sons (Charles and John) and one daughter (Mrs. Chas. Newton, of Skipton). The drill is locally significant as it was used by a local company in Terang and Mortlake in their blacksmith, wheelwright and garage business. It is an example of the tools of the blacksmiths’ trade in Victoria in the 1920s-1950s.Dawn Ball-bearing Post Drill no. 611, made by Dawn of Melbourne, model no 611. Hand operated drill press. Self-feeding blacksmiths’ drill-press. This drill once belonged to Harry Goodall & Sons, blacksmiths of Terang. Dated 1920s-1950s. Gear ratio 2:1 main drive, 6" diam, 3:1 reduction gear. "Dawn", "Melbourne"flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, h. goodall & sons of terang, terang blacksmith, h. goodall & sons pty ltd, mortlake, ernie entwistle blacksmith, alfred hodgetts radio expert, charles goodall, john goodall, mrs. chas. newton nee goodall, terang 1900s, warrnambool district 1900s, post drill, blacksmith’s drill, dawn post drill, dawn ball-bearing post drill no. 611, blacksmiths, dawn of melbourne -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDrill Press, 1930s

... Defence Department along with munitions. In 1959, the company... and clamps to the Australian Defence Department along with munitions ...Dawn commenced operations in the Melbourne suburb of Coburg, Victoria in 1917 under the name of Dawn Manufacturing Co. It was founded by four brothers named Blake, who were all engineers. The first products manufactured were vices. After the first world war, Dawn grew considerably and was selling its products all over Australia. They were very busy during the depression with each employee working 60-80 hours a week. During the second world war, Dawn was supplying vices and clamps to the Australian Defence Department along with munitions. In 1959, the company was taken over by the G.N. Raymond Group. The Dawn catalogue was expanded to now included a wide range of engineer's vices, woodworker's vices, plumber's vices & equipment, G-clamps, quick-action clamps and toggle clamps. In 1973, Dawn was acquired by Siddons Ramset Limited. In December 1991, Dawn became a unit of the United States owned Stanley Works Pty. Ltd. In November 1998, Dawn regained its 100% Australian ownership and now as a separate strategic business unit, began to improve and expand its manufacturing and marketing operations in Australia and overseas. Drill Press, Self-feeding, belt-driven. Embossed within the casting "Dawn Melb Australia Mfg".flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, machinery, dawn drill press, drill press -

Melbourne Tram Museum

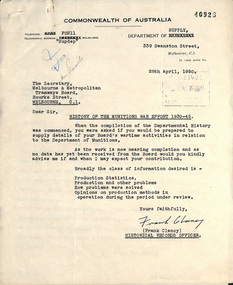

Melbourne Tram MuseumDocument - Report, Commonwealth of Australia, Melbourne and Metropolitan Tramways Board, "History of the Munitions War Effort 1939-45", 1950

... of the Commonwealth of Australia, Department of Supply (with Munitions over... of Australia, Department of Supply (with Munitions over typed ...Letter, response and report on quarto paper - 10 sheets .1 - Letter from Frank Clancy, Historical Records Officer of the Commonwealth of Australia, Department of Supply (with Munitions over typed), to the MMTB dated 28/4/1950 asking for a summary of the Board's wartime activities. Letter response by Lewis Russell, MMTB Publicity Officer. Response dated 4/5/1950 saying the original letter had not been received, attaching further information. .2 - A second document (7 sheets) that was with the first, a response dated 3/8/48, primarily concerned with the provision of bus services to Munitions and aircraft factories, purchase of chassis, for buses, issues with supply, bus and tram numbers, services, Fisherman's Bend, patronage, tramcar construction and a table giving passenger numbers over the war period.In pencil and ink on top of the first sheet of 3843.2 - "Supplied to Official Historian Canberra 3/8/48" and a note "Affixed? by Foreman? 2/8/48"trams, tramways, world war 2, buses, munitions factory, fisherman's bend, workshops, commonwealth government -

Frankston RSL Sub Branch

Frankston RSL Sub BranchBadge, Sokes and Sons

... Australian coat of arms, munitions worker, Australia... of arms, munitions worker, Australia, issued by Department ...badgeAustralian coat of arms, munitions worker, Australia, issued by Department of Defence (reverse),Stokes and Sons Melbourne (reverse), 357munitions worker badge, metal -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageMachine - Treadle Lathe, 1920-1923

The lathe-making business incorporated in 1902 as Drummond Bros Ltd originated in the fertile mind of Mr Arthur Drummond, said to have been living at that time at Pinks Hill, on the southern edge of Broad Street Common, west of Guildford. Mr Drummond, whose accomplishments included several pictures hung in the Royal Academy, was unable to find a lathe suitable for use in model engineering. In 1896 he designed for himself a ‘small centre lathe … which had a compound slide rest with feed-screws and adjustable slides’. He also designed and built ‘lathes of 4.5 inch and 5 inch centre height, which had beds of a special form whereby the use of a gap piece was eliminated but the advantages of a gap-bed lathe were retained’. Assisted by his brother, Mr Frank Drummond, who had served an apprenticeship to an engineering firm at Tunbridge Wells, the first lathes were made in a workshop adjoining Arthur Drummond’s house. The demand that speedily built up led to the decision to form a company and manufacture the lathes for sale commercially. Land was acquired nearby, at Rydes Hill, and the first factory built. The enterprise was a success, and the company quickly established ‘a high reputation in this country and abroad for multi-tool and copying lathes, and gear-cutting machines’. Other lathes were added to the range, including the first of the ’round bed’ machines for which the firm became widely known. A Drummond 3.5 inch lathe was among the equipment of Captain Scott’s 1912 expedition to the South Pole, and large numbers of 3.5 inch and 4 inch designs were exported to Australia, Canada and India. By the outbreak of war in 1914, 5 inch, 6 inch and 7 inch screw cutting lathes, arranged for power drive, were on sale. Large orders were received from the government for 3.5 inch lathes, for use in destroyers and submarines, and 5 inch lathes for the mechanised section of the Army Service Corps. The latter were used in mobile workshops. The factory worked night and day to supply the forces’ needs, until production was disrupted by a fire which destroyed a large part of the works in May 1915. As soon as rebuilding was complete work restarted. At the end of the war the entire production was being taken by the Government departments, a special feature being a precision screw lathe, bought by the Ministry of Munitions in 1918. Between the wars Drummond Bros Ltd introduced new machines for the motor vehicle, and later the aircraft industry, and the works were extended on many occasions to fulfill the increasing orders. The Maxicut multi-tool lathe (1925), designed for high-production turning operations, was one of the first machines of this type to be built in England. It was followed (1928) by an hydraulic version for turning gear blanks, and similar work. Further developments provided machines which, during the Second World War, turned all the crankshafts and propeller shafts for Bristol engines. Others, ordered by the Ministry of Supply were employed in turning shells, and many other specific needs of vehicle and aircraft manufacture were catered for by new types of Drummond lathes. Production of the small centre lathes ceased during the war when the company needed to concentrate on building multi-tool lathes and gear shapers. After the war a completely new Maxicut range was introduced, replacing the older versions, and fully automatic. The types were continually developed, and new versions manufactured until the end of the company’s life in 1980. The disappearance from the scene of Mr Arthur Drummond in 1946, and the end of the company’s autonomous existence in 1953 when the company was acquired by William Asquith Ltd, which was in turn bought by Staveley in 1966, meant that the factory at Rydes Hill became one – albeit very effective – part of a large national engineering company. Achievements at the Guildford works during its last years included the development of automated Maxicut gear-shapers in what was ‘probably the most fully automated gear shop in the country’, while a machine from Guildford was sent to the Osaka Fair in 1962. In 1963 an agreement was signed with Hindustan Machine Tools for the manufacture of Maxicut gear-shapers in state owned factories in Bangalore and Chandigarh. During 1963 the two largest multi-tool lathes ever made in the UK were installed in Ambrose Shardlow’s works in Sheffield for handling cranks up to 14 foot long. In 1976 Drummond lathes were included in Staveley’s £14,000,000 installation in Moscow of an automated production line for Zil motor cars. Up to the end invention continued at Guildford: a new Drummond Multi-turn memory-controlled machine was shown at the International Machine Tool Exhibition in 1977. This could not save the works from the pressures of the late 1970s, and Staveley Industries closed its Guildford site in 1980.An early example of a lathe that was designed primarily for the hobbyist model maker. It is in good condition and sought today by collectors as many of it's attributes were innovative at the time and lead to further development and incorporation of some of its features into more industrial models of production machinery. Lathe, round bed, treadle powered lathe, Drummond Type A, Serial number and maker's inscription. 1920-1923, Made by Drummond Brothers in Guildford, Surrey, England. Lathe is complete with Chuck, Tool post and Tail Stock in situ (30 extra parts)"MADE BY DRUMMOND BROTHERS LIMITED - PATENT TEES - RYDE'S HILL n GUILDFORD SURREY", "Serial Number 01470," "L44" or "L45 " flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, lathe 1920-1923, round bed lathe, treadle lathe, drummond type a, guildford surrey, drummond brothers guildford surrey england, tread'e -

Creswick Campus Historical Collection - University of Melbourne

Creswick Campus Historical Collection - University of MelbourneMixed media - Moisture control samples board, Kiln Seasoning & Reconditioning: specimens illustrating process control and finished product

... Munitions Supply Laboratories. Munitions Supply Board.... Munitions Supply Board. Department of Defence Timber demonstration ...Specimens illlustrating process control & finished product.Timber demonstration wall panelMunitions Supply Laboratories. Munitions Supply Board. Department of Defence -

Melbourne Legacy

Melbourne LegacyPoster, Join the AIF now!, 1941

A framed Australian Commonwealth Military Forces Second World War recruitment poster by Richard Haughton James (source AWM). The poster is an offset lithograph on paper framed by a blue border, mounted in a black frame. It is an early example of the work of the Commonwealth Advertising Division, set up in 1941 within the Department of Information, primarily to advertise recruitment drives for men's and women's services, munitions work, war loans and national savings campaigns.A record that Legacy holds some war memorabilia as Legatees were once solely returned servicemen.Black and white sketch of a wartime lady holding a soldier's hat used as a recruiting poster in a black frame.Test of the poster "Mister, here's your hat! JOIN THE AIF NOW!"world war two, recruitment, aif -

Moorabbin Air Museum

Moorabbin Air MuseumBook - Aircraft construction early 1920s, Reports on Materials of Construction Used In Aircraft and Aircraft Engines

... Report by aircraft department of Ministry of Munitions ...Report by aircraft department of Ministry of Munitions on aircraft /aircraft engine construction materials, circa 1920Report by aircraft department of Ministry of Munitions on aircraft /aircraft engine construction materials, circa 1920aircraft construction materials