Showing 66 items matching "barrel making"

-

Stawell Historical Society Inc

Stawell Historical Society IncPhotograph, Stawell Brewery in Stawell West showing Cooper Barrel Making c1900

... Stawell Brewery in Stawell West showing Cooper Barrel...Stawell Brewery Stawell West a Cooper Barrel Making at Work... grampians Stawell Brewery Stawell West a Cooper Barrel Making ...Stawell Brewery Stawell West a Cooper Barrel Making at Work. C1900.stawell -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Broad Axe, Prior to 1950

... Barrel Making... dressing of staves and heading pieces used in the making of barrels... in the making of barrels and other associated items made from wood ...A cooper's broad axe (or Cooper's side axe) is a short one-handed axe that has a long cutting edge intended for initial dressing of staves and heading pieces used in the making of barrels and other associated items made from wood.A tool of the cooper and other woodworking tradesmen that has been in use since the making of barrels and wooden buckets for hundreds of years without much change to the design or how the tool is used.Broad head axe with wooden handle with handle on an angle to allow use. Nonewarrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, maritime village, coopers tools, broad axe, barrel making, cutting staves -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Bick Iron, Prior to 1950

... barrel making... tools barrel making barrels None Bick Iron or Coopers Anvil ...A Bick or coopers anvil is a tool used to fabricate the iron hoops that a cooper would produce to hold a barrel together. The hoops are first cut to the required length and then beaten into shape and riveted on the Bick or Tee anvil. They are then driven into place on the barrel with a hammer and iron tipped, wedged shaped driver.The subject Item is used as a tool to produce steel hoops for wooden barrels but at this time cannot be associated with an historical event, person or place, provenance is therefore unknown, item assessed as a collection asset as it is believed to have been produced and used before 1950.Bick Iron or Coopers Anvil, attaches to a removeable wooden base, Metal anvil with pointed end & flat shaped topNoneflagstaff hill, warrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, brick iron, anvil, coopers tools, barrel making, barrels -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Spokeshave, Prior to 1950

... barrel making... that has been in use since the making of barrels and wooden buckets ...A spokeshave was made with a wooden body and metal cutting blade. With industrialization metal bodies displaced wood in mass-produced tools. Spokeshaves can be made from flat-bottom, concave, or convex soles, depending on the type of job to be performed. They can include one or more sharpened notches along which the wooden shaft is pulled in order to shave it down to the proper diameter. Historically, spokeshave blades were made of metal, and the body and handles were wood. Unlike a drawknife, but like a plane, spokeshaves typically have a sole plate that fixes the angle of the blade relative to the surface being worked. By the twentieth-century metal handles and detachable blades had become the most common. A convex, wooden, variant of the spokeshave is called a travisher; at one time mostly used in chairmaking.A tool of the cooper and other woodworking tradesmen that has been in use since the making of barrels and wooden buckets for hundreds of years without much change to the design or how the tool is used.Spokeshave, with two wooden handles on either side. Noneflagstaff hill, warrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, coopers tools, spokeshave, barrel making, wood plane -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Hand Adze, A Mathieson and Son, First quarter of the 20th Century

... barrel making... woodworking barrel making working timber joiners tools carpenters ...An adze is an ancient and versatile cutting tool similar to an axe but with the cutting edge perpendicular to the handle rather than parallel. Adzes are used for smoothing or carving wood in hand woodworking, and as a hoe for agriculture and horticulture. Two basic forms of an adze are the hand adze (short hoe) a short handled tool swung with one hand and the foot adze (hoe) a long handled tool capable of powerful swings using both hands, the cutting edge usually striking at foot or shin level. Mathieson & Sons Maker: In 1792 John Manners had set up a workshop making woodworking planes at 14 Saracens Lane Glasgow. He also had employed an apprentice Alexander Mathieson (1773-1851). But in the following year at Saracen's Lane, the 1841 census describes Alexander Mathieson as a master plane-maker now at 38 Saracen Lane with his son Thomas Adam working with him as a journeyman plane-maker. Presumably, Alexander must have taken over the premises and business of John Manners. Now that the business had Thomas Adam Mathieson working with his father it gradually grew and became more diversified, and it is recorded at the time by the Post-Office Glasgow Annual Directory that by 1847-1848 Alexander Mathieson was a “plane, brace, bit, auger & edge tool maker” In 1849 the firm of James & William Stewart at 65 Nicolson Street, Edinburgh was taken over and Thomas was put in charge of the business, trading under the name Thomas A. Mathieson & Co. as plane and edge-tool makers. Thomas's company went on to acquire the Edinburgh edge-tool makers “Charles & Hugh McPherson” and took over their premises in Gilmore Street. In the Edinburgh directory of 1856/7, the business is recorded as being Alexander Mathieson & Son, plane and edge-tool makers at 48 Nicolson Street and Paul's Work, Gilmore Street Edinburgh. The 1851 census Alexander is recorded as working as a tool and plane-maker employing eight men. Later that year Alexander died and his son Thomas took over the business. Under the heading of an edge-tool maker in the 1852/3 Post-Office Glasgow Annual Directory the firm is now listed as Alexander Mathieson & Son, with further entries as "turning-lathe and vice manufacturers". By the early 1850s, the business had moved to 24 Saracen Lane. The directory for 1857/8 records that the firm had moved again only a few years later to East Campbell Street, off the Gallowgate area, and that through further diversification was also manufacturing coopers' and tinmen's tools. The ten-yearly censuses report the firm's growth in 1861 stating that Thomas was a tool manufacturer employing 95 men and 30 boys; in 1871 he had 200 men working for him and in 1881 300 men. By 1899 the firm had been incorporated as Alexander Mathieson & Sons Ltd, even though only Alexander's son Thomas appears ever to have joined the firm so the company was still in his fathers' name. In September 1868 Thomas Mathieson put a notice in the newspapers of the Sheffield & Rotherham Independent and the Sheffield Daily Telegraph stating that his firm had used the trade-mark of a crescent and star "for some time" and that "using or imitating the Mark would be proceeded against for infringement". The firm had acquired its interest in the crescent-and-star mark from the heirs of Charles Pickslay, the Sheffield cutler who had registered it with the Cutlers' Company in 1833 and had died in 1852. The year 1868 seems also to be the one in which the name Saracen Tool Works was first adopted; not only does it figure at the foot of the notice in the Sheffield press, it also makes its first appearance in the firm's entry in the Post-Office Glasgow Annual Directory in the 1868/9 edition. As Thomas Mathieson's business grew, so too did his involvement in local public life and philanthropy. One of the representatives of the third ward on the town council of Glasgow, he became a river bailie in 1868, a magistrate in 1870 and a preceptor of Hutcheson's Hospital in 1878. He had a passion for books and was an "ardent Ruskinian". He served on the committee handling the bequest for the setting up of the Mitchell Library in Glasgow. When he died at Coulter Maynes near Biggar in 1899, he left an estate worth £142,764. The firm of Alexander Mathieson & Sons was one of the leading makers of hand tools in Scotland. Its success went hand in hand with the growth of the shipbuilding industries on the Firth of Clyde in the nineteenth century and the emergence of Glasgow as the "second city of the Empire". It also reflected the firm's skill in responding to an unprecedented demand for quality tools by shipyards, cooperages and other industries, both locally and far and wide.Hand Adze or Cooper's adze No 4 A Mathieson & Sons Glasgowflagstaff hill, warrnambool, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, adze mathieson & sons, cooperage tools, woodworking, barrel making, working timber, joiners tools, carpenters tools -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Coopers Downright/Pluckers Plane, Prior to 1950

... Barrel Making... in the production of making wooden barrels a design that has not changed ...The downright shave is a tool used by coopers in the preliminary stages of smoothing the outside of a cask, before it is finished with a buzz shave. The shave is pushed downwards, hence its name, away from the operator to take away the wood shavings. A significant tool used by a cooper in the production of making wooden barrels a design that has not changed much in many hundreds of years of barrel making.Coopers Downright/Pluckers PlaneNoneflagstaff hill, warrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, coopers tools, coopers plane, barrel making, carpenters tools, smoothing plane -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Coopers Flagging Iron, Prior to 1950

... Barrel Making... in the making and repairing of wooden barrels and an essential tool ...A cooper would use a flagging iron to insert reeds around the head of a barrel to tighten the head and stop any leaks. First the cooper removes the full and quarter metal hoops around the barrel, this loosens the staves and insert reeds around the head, prying the stave apart from the head with a flagging iron. Then he replaces the hoops to tighten the staves against the head and the inserted reeds to form a leakproof seal.An age old tool used for many hundreds of years in the making and repairing of wooden barrels and an essential tool in a coopers tool kit.Flagging iron metal painted black Nonewarrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, flagging iron, coopers tools, barrel making, repairing barrel leaks, barrel head tightening -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Coopers Croze, Prior to 1950

... Barrel Making... the making of barrels and wooden buckets for hundreds of years ...A Croze is a tool used by a cooper for cutting a groove of a barrel, cask, etc., into which the edge of both the heads of a barrel fits. The cooper uses a Croze to cut a groove into either end of the inside of the staves of the bucket or barrel so the lid or bottom would fit securely against the wood. The cooper had to make sure the pieces of wood fit tightly together so none of the contents, such as beer, milk or grain, would seep out.A tool of the cooper that is specific to his trade, this wood grooving plane has been in use since the making of barrels and wooden buckets for hundreds of years without much change to the design or how the tool is used.Croze, has 2 Lance teeth and 1 Hawk tooth.Noneflagstaff hill, warrnambool, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, croze, coopers tools, barrel making -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Barrel bung hole reamer, 1851 - 1872

... Barrel Making... Hole Reamer Barrels Barrel Making A Timmins & Sons stamped ...R Timmins & Sons were makers of heavy steel 'toys' - toy in this context means any small metal object, including hand tools. The company was founded in 1790 by Richard Timmins and was situated in Hurst St, and later in Pershore Street, Birmingham. In 1850 Richard Timmins died aged 60 and the company continued with his wife Ann and their son Henry who were the executors of his will. In 1889 they were taken over by another Birmingham maker, W & C Wynn of Suffolk Street also edge tool makers and the business moved to Commercial Street Birmingham in 1872. For a few years, both companies continued to operate under their original names. In 1892 they were incorporated as Wynn, Timmins & Co, and in 1897 the premises in Commercial St were renamed Century Works. The company survived until 1969 when they were taken over by Balfour Dawins Ltd of Sheffield, and the works in Birmingham then closed.A significant item given its age having the probability of having been made after Richard Timmins had died and before the take over in 1872 during the time the company was being run by his wife Ann and son Henry. Given the inscription on the item is "A Timmins & Sons". The items significance is social given it was used to clean bungholes in barrels and was possibly used in the early cooperage industries of the early Australian colony. Bung reamer metal with wooden handle. A Timmins & Sons stamped on blade.warrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, coopers tools, bung hole reamer, barrels, barrel making -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Socket driver, Prior to 1950

... barrel making... that was made as a tool to enable a cooper to position hoops on a barrel ...Scotch Driver is a tool that is used to knock the iron hoops on a barrel into position they are grooved to prevent them from slipping off the hoop as they are struck with a hammer to drive the hoop over the staves.A coopers driver that was made as a tool to enable a cooper to position hoops on a barrel that has not changed for hundreds of years. Item at this time cannot be associated with an historical event, person or place, provenance is unknown, item assessed as a collection asset as it is believed to have been produced before 1950..Socket driver Scotch pattern wood and metalNoneflagstaff hill, warrnambool, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, scotch driver, barrel making, coopers tools -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Spokeshave, Prior to 1950

... barrel making... that has been in use since the making of barrels and wooden buckets ...A spokeshave was made with a wooden body and metal cutting blade. With industrialization metal bodies displaced wood in mass-produced tools. Spokeshaves can be made from flat-bottom, concave, or convex soles, depending on the type of job to be performed. They can include one or more sharpened notches along which the wooden shaft is pulled in order to shave it down to the proper diameter. Historically, spokeshave blades were made of metal, and the body and handles were wood. Unlike a drawknife, but like a plane, spokeshaves typically have a sole plate that fixes the angle of the blade relative to the surface being worked. By the twentieth-century metal handles and detachable blades had become the most common. A convex, wooden, variant of the spokeshave is called a travisher; at one time mostly used in chairmaking.A tool of the cooper and other woodworking tradesmen that has been in use since the making of barrels and wooden buckets for hundreds of years without much change to the design or how the tool is used.Spokeshave, with two wooden handles on either side. Noneflagstaff hill, warrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, coopers tools, spokeshave, barrel making, wood plane, wagon making, joiners tools, carpenter tools -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Coopers Flagging Iron, Prior to 1950

... barrel making... in the making and repairing of wooden barrels and an essential tool ...A cooper would use a flagging iron to insert reeds around the head of a barrel to tighten the head and stop any leaks. First the cooper removes the full and quarter metal hoops around the barrel, this loosens the staves and insert reeds around the head, prying the stave apart from the head with a flagging iron. Then he replaces the hoops to tighten the staves against the head and the inserted reeds to form a leakproof seal.An age old tool used for many hundreds of years in the making and repairing of wooden barrels and an essential tool in a coopers tool kit.Coopers small Flagging iron metal painted black Nonewarrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, flagging iron, coopers tools, barrel making, repairing barrel leaks, barrel head tightening -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Coopers Croze, Prior to 1950

... barrel making... the making of barrels and wooden buckets for hundreds of years ...A Croze is a tool used by a cooper for cutting a groove of a barrel, cask, etc., into which the edge of both the heads of a barrel fits. The cooper uses a Croze to cut a groove into either end of the inside of the staves of the bucket or barrel so the lid or bottom would fit securely against the wood. The cooper had to make sure the pieces of wood fit tightly together so none of the contents, such as beer, milk or grain, would not seep out.A tool of the cooper that is specific to his trade, this wood grooving plane has been in use since the making of barrels and wooden buckets for hundreds of years without much change to the design or how the tool is used.Coopers adjustable Croze, Noneflagstaff hill, warrnambool, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, croze, coopers tools, barrel making -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Croze, Prior to 1950

... barrel making... the making of barrels and wooden buckets. Item at this time cannot ...A Croze is a tool used by a cooper for cutting a groove of a barrel, cask, etc., into which the edge of the head or bottom fits. The cooper uses a Croze to cut a groove into either end of the inside of the staves of the bucket or barrel so the lid or bottom would fit securely against the wood. The cooper had to make sure the pieces of wood fit tightly together so none of the contents, such as beer, milk or grain, would seep out.A tool of the cooper that has been in use since the making of barrels and wooden buckets. Item at this time cannot be associated with an historical event, person or place, provenance is unknown, item assessed as a collection asset as it is believed to have been produced before 1950.Coopers Croze wood with metal bladeNoneflagstaff hill, warrnambool, flagstaff-hill-maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, croze, cooper, barrel making, tool -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Socket driver, Prior to 1950

... barrel making... that was made as a tool to enable a cooper to position hoops on a barrel ...Scotch Driver is a tool that is used to knock the iron hoops on a barrel into position they are grooved to prevent them from slipping off the hoop as they are struck with a hammer to drive the hoop over the staves.A coopers driver that was made as a tool to enable a cooper to position hoops on a barrel that has not changed for hundreds of years. Item at this time cannot be associated with an historical event, person or place, provenance is unknown, item assessed as a collection asset as it is believed to have been produced before 1950.Coopers Socket driver Scotch pattern wood and metalNoneflagstaff hill, warrnambool, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, scotch driver, barrel making, coopers tools, socket driver -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Socket driver, Prior to 1950

... barrel making... that was made as a tool to enable a cooper to position hoops on a barrel ...Scotch Driver is a tool that is used to knock the iron hoops on a barrel into position they are grooved to prevent them from slipping off the hoop as they are struck with a hammer to drive the hoop over the staves.A coopers driver that was made as a tool to enable a cooper to position hoops on a barrel that has not changed for hundreds of years. Item at this time cannot be associated with an historical event, person or place, provenance is unknown, item assessed as a collection asset as it is believed to have been produced before 1950.Coopers Socket driver Scotch pattern wood and metalNoneflagstaff hill, warrnambool, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, scotch driver, barrel making, coopers tools, socket driver -

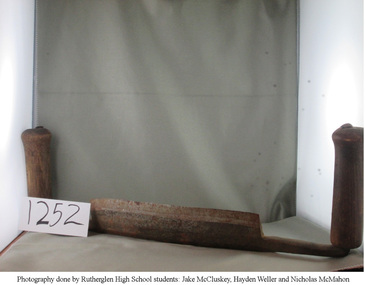

Rutherglen Historical Society

Rutherglen Historical SocietyTool - Swift Plane, Alan, !900s to1920s (Approximate)

... Coopers tool for making wine barrels...-country Coopers tool for making wine barrels Alan Patent Cast ...Coopers tool for making wine barrelsWooden handled bow shaped planeAlan Patent Cast Steel -

Rutherglen Historical Society

Rutherglen Historical SocietyHollow Knife, 1900s (Approximate)

... Coopers tool for making wine barrels...-country Coopers tool for making wine barrels Wooden handles ...Coopers tool for making wine barrelsWooden handles at both ends with a metal shaving tool attached -

Rutherglen Historical Society

Rutherglen Historical SocietyHeading Knife, Gepins, 1900s (Approximate)

... Coopers tool for making wine barrels...-country Coopers tool for making wine barrels Made in England ...Coopers tool for making wine barrelsWooden handles at both ends with a metal shaving tool attachedMade in England Gilpins X -

Rutherglen Historical Society

Rutherglen Historical SocietyHollow Knife, 1900s (Approximate)

... Coopers tool for making wine barrels...-country Coopers tool for making wine barrels Wooden handles ...Coopers tool for making wine barrelsWooden handles at both ends with a metal shaving tool attached -

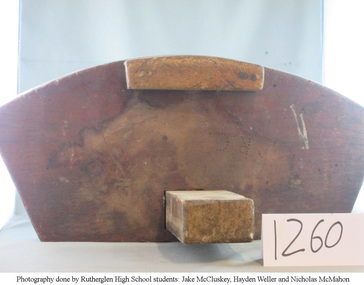

Rutherglen Historical Society

Rutherglen Historical SocietyCowes, 1900s (Approximate)

... Coopers tool for making wine barrels...-country Coopers tool for making wine barrels Solid timber arch ...Coopers tool for making wine barrelsSolid timber arch with a piece of timber slotted through with a metal attachment Wooden handle form which a metal cutting tool extends from -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Coopered Bucket, 1960 to 1980

... made by coopers, who had expertise in making wooden barrels... such as this were made by coopers, who had expertise in making wooden ...This bucket was made from vertical planks of wood with bands of metal around it for strength. Buckets such as this were made by coopers, who had expertise in making wooden barrels. Wood or animal skin was used to make buckets in colonial times when other materials were unavailable. Buckets had many uses in domestic and agricultural life including carrying, measuring and storing. Cooper tradesmen used carpentry and blacksmithing skills to make a wide range of wooden containers and other objects. They sometimes used water or steam to bend and mould the timber.The bucket is an example of a product made from wood and iron by an experienced Cooper. In early colonial timeswhen ready-made products were scarce so the trades of coopers, blacksmiths, metal smiths, carpenters, builders and others were necessary for domestic, commercial and industrial establishment.Wooden coopered bucket; three metal bands around vertical wooden planks that form the body of the bucket. Two lugs extend higher than the planks and have a rope joined between them.warrnambool, shipwreck coast, flagstaff hill, flagstaff hill maritime museum, flagstaff hill maritime village, bucket, wooden bucket, container, domestic bucket, cooper, cooper trade, coopered bucket -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Circle/Convex Faced Plane, Prior to 1950

... Before setting the barrel head, the cooper smooths... or steel hoops. Making the barrel has taken a number of planes ...Before setting the barrel head, the cooper smooths the inside surface of some barrels with a stoup, compass or circle plane and an inside shave (or in shave plane). A stoup or compass plane has a convex sole in both directions to work within the doubly curved staves of a barrel. The cooper smooths the outside of the barrel with a downright, another large-handled shave, and a similar scraping tool to finish off called a buzz. The final step is to fit the head and drive on wooden or steel hoops. Making the barrel has taken a number of planes similar but different from those of other trades, each perfectly adapted to a cooper’s work shaping curved surfaces. And if he has done his work well, the barrel will hold the exact amount of liquid and not leak.A tool unique to the cooper used to smooth out the inside of a barrel that has been in use since the making of wooden barrels and buckets for hundreds of years without much change to the design or how the tool is used.Compass or Circle face PlaneNoneflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Circle/Convex Faced Plane, Prior to 1950

... Before setting the barrel head, the cooper smooths... or steel hoops. Making the barrel has taken a number of planes ...Before setting the barrel head, the cooper smooths the inside surface of some barrels with a stoup, compass or circle plane and an inside shave (or in shave plane). A stoup or compass plane has a convex sole in both directions to work within the doubly curved staves of a barrel. The cooper smooths the outside of the barrel with a downright, another large-handled shave, and a similar scraping tool to finish off called a buzz. The final step is to fit the head and drive on wooden or steel hoops. Making the barrel has taken a number of planes similar but different from those of other trades, each perfectly adapted to a cooper’s work shaping curved surfaces. And if he has done his work well, the barrel will hold the exact amount of liquid and not leak.A tool unique to the cooper used to smooth out the inside of a barrel that has been in use since the making of wooden barrels and buckets for hundreds of years without much change to the design or how the tool is used.Compass or Circle face PlaneNonewarrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, coopers tools, joiners plane, coopers plane, woodworking tools, circle plane, convex plane, carpenters wood planes -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Jointing Plane, Prior to 1950

... by craftsmen in the making of wooden barrels for the storage of wines ...A long coopers joiner plane is used to to shape the staves that form casks and kegs, with these types of plane reaching up to 180 cm in length. Unlike other planes these are used when lying stationary with the sole uppermost (base). The cooper would push the stave along the upturned sole with the sole towards the cutter. Because of the long length, Cooper’s jointer's were often mounted on legs at the rear and angled at about 60 degrees, with the toe resting on the ground or rabbeted to fit into a floor cleat or bench.A specialised tool used in the making of barrels, this type of tool has been used for many hundreds of years by coopers all around the world. It is a tool that has not changed in design during this time and is still used today by craftsmen in the making of wooden barrels for the storage of wines etc. The subject item at this time cannot be associated with an historical event, person or place, provenance is unknown, item assessed as a collection asset as it is believed to have been produced before 1950.Coopers long Jointer Plane with wooden "A" frame stand, also called "Coopers' Long plane".Noneflagstaff hill, warrnambool, flagstaff-hill-maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, plane, coopers tools, coopers long plane, barrels -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Draw Knife, Prior to 1950

... such as in making staves for barrels.... such as in making staves for barrels. A specialised tool used in many ...A draw knife or drawing knife, draw shave, shaving knife is a traditional woodworking hand tool used to shape wood by removing shavings. It consists of a blade with a handle at each end. The blade is much longer along the cutting edge than it is deep (from cutting edge to back edge). It is pulled or "drawn" toward the user. A draw knife is commonly used to remove large slices of wood for flat faceted work, to debark trees, or to create roughly rounded or cylindrical billets for further work on a lathe, or it can shave like a spokeshave plane, where finer finishing is less of concern than a rapid result. The thin blade lends itself to create complex concave or convex curves such as in making staves for barrels.A specialised tool used in many different types of wood working and in the making of barrels, this type of tool has been used for many hundreds of years by coopers and other woodworking craftsmen all around the world. It is a tool that has not changed in design during this time and is still used today by craftsmen in the making of wooden barrels for the storage of wines etc. However this item at this time cannot be associated with an historical event, person or place, provenance is unknown, item assessed as a collection asset as it is believed to have been produced before 1950.Draw knife with metal blade and two wooden handlesNoneflagstaff hill, warrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, draw knife, coopers tools, woodworking tools, knife, cooperage -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Howel Plane, Prior to 1950

... in use since the making of barrels and wooden buckets ...The Howel plane is really no different from a compass or circle plane, it is attached to a large curved fence that rides along the top of the staves. The Howel cuts a smooth shallow hollow, to give a level place to cut into with the next tool the Croze which cuts a narrow groove for the barrel head. The Croze has a similar wide fence that rides on the ends of the staves, but with either a saw-tooth type cutter or two nickers and a single tooth like a router plane. The head of the barrel fits into this groove and is made up of two or three boards doweled together and smoothed with a large shave called a swift. The cooper cuts the edges to a fine bevel of the head to fit snugly into the groove cut by the Croze. A tool specific to the cooper that has been in use since the making of barrels and wooden buckets for hundreds of years without much change to the design or how the tool is used. Howel Coopers Plane Noneflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Bow Saw, Prior to 1950

... of a Coopers tool kit and used in the production of making barrels ...A coopers turning or bow saw is a woodworking tool used for straight or curved cuts. A bow saw is a type of frame saw with a thin toothed blade that is held in tension by a frame with two long narrow handles called "cheeks" that are supported and separated by a thin stretcher in the center of the handles, making a wide H shape (the cheeks form the uprights of the H, the stretcher the crossbar of the H). The blade is kept in tension with a turnbuckle that runs parallel to the blade between the two cheeks but on the opposite side of the stretcher.An age old tool used for cutting timber for hundreds of years before the modern cross cut saws were invented. This design of saw was part of a Coopers tool kit and used in the production of making barrels. However this item at this time cannot be associated with an historical event, person or place, provenance is unknown, item assessed as a collection asset as it is believed to have been produced before 1950.Bow saw wooden handle with metal blade missingNonewarrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, bow saw, turning saw, coopers tools, cutting wood, sawing timber, coopering -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Churn, small domestic butter, c1880

A butter churn is a device used to convert cream into butter. This is done through a mechanical process, via a crank used to manually turn a rotating device inside the barrel shaped churn. The agitation of the cream, caused by the mechanical motion of the device, disrupts the milk fat. The membranes that surround the fats are broken down, subsequently forming clumps known as butter grains. These butter grains, during the process of churning, fuse with each other and form larger fat globules. Air bubbles are introduced into these fat globules via the continued mechanical action of the churn. The butter grains become more dense as fat globules attach to them while the air is forced out of the mixture. This process creates a liquid known as buttermilk. With constant churning, the fat globules eventually form solid butter and separate from the buttermilk. The buttermilk is then drained off and the butter is squeezed to eliminate excess liquid and to form it into a solid mass. Then rinsing could be done simply by washing in water, followed by draining, salting and working or "kneading" the butter with a pair of wooden butter pats, or with bare hands. This is a paddle churn, a barrel that contains a paddle, which is operated by a handle. The paddle churned the butter inside the container when the handle was turned. Early settlers had to be self sufficient, growing their own vegetables, making tools and clothing and usually had a house cow to produce their milk supplyThis domestic butter churn is an example of the skill of the pioneer craftsman, carpenters and tool makers c1900. As pioneers and early settlers had to be self sufficient they usually kept a dairy cow or 'house cow' to provide milk for drinking and for butter and cheese to made by the family.A small wooden, domestic butter churn with a lid and a crank that manually rotated the paddle inside. E. CHERRY / MAKER / GISBORNE / VICTORIA / Apioneers, early settlers, market gardeners, moorabbin, brighton, cheltenham, dairy products. dairy farmers, milk, butter, dairies -

Learmonth and District Historical Society Inc.

Learmonth and District Historical Society Inc.Washing Machine, Circa 1876

This is an early example of a mechanical device for the washing of clothes.It worked on a rocking motion making the chore of washday easier for the housewife.This is an early example of a mechanical device for washing of clothes.This Washing Machine is made of wood and the main barrel part is a rectangular shaped box with slopping sides.On the top is the lid and a handle.It is set on a stand which allowes it to be used with a rocking motion.F.WOLTER & ECHBERG"S PATENT WASHING MACHINE .NO 2955. 6 RUSSELL STREET MELBOURNE.ROYAL LETTERS PATENT GRANTED 1876.washing machine 1876.household appliance