Showing 72 items matching "cooling of engines"

-

Moorabbin Air Museum

Moorabbin Air MuseumBook - Aircraft engines

... Cooling of engines... Superchargers Cooling of engines Altitude effect on engine power Engine ...Overview of principles & results of research on internal combustion engines for aircraft engineers, circa 1941non-fictionOverview of principles & results of research on internal combustion engines for aircraft engineers, circa 1941petrol engine peformance, the combustion process, aircraft engine fuels, carburettors & fuel systems, superchargers, cooling of engines, altitude effect on engine power, engine temperatures, atmospheric pressures, radiators -

B-24 Liberator Memorial Restoration Australia Inc

B-24 Liberator Memorial Restoration Australia IncPratt & Whitney R 1830 Radial Engine (Informational Entry)

... cooled radial engine with a capacity of 1830 cubic inches (30... cylinder air cooled radial engine with a capacity of 1830 cubic ...Between Pratt & Whitney and numerous licensed companies, there were over 180,000 of these engines manufactured in a number of specifications. The B-24 Liberator would have been their major recipient but other famous aircraft using the same engine were the Consolidated Catalina flying boat and the Douglas DC3/C47/Dakota. Refer Wikipedia link for other aircraft that used this engine.As a result of the significant and ongoing usage of these engines in civil aircraft such as the Douglas DC3, they are by no means rare. Many parts can still be sourced new and there are several companies that have the capacity to rebuild these engines to an airworthy standard.The Pratt & Whitney R 1830 is a double row 14 cylinder air cooled radial engine with a capacity of 1830 cubic inches (30 litres), developing some 1200 horsepower at a maximum 2700 rpm.radial engine, twin wasp, r1830 -

B-24 Liberator Memorial Restoration Australia Inc

B-24 Liberator Memorial Restoration Australia IncPratt & Whitney R 1830 Radial Engine, TR 261

... cooled radial engine with a capacity of 1830 cubic inches, (30... is a double row 14 cylinder air cooled radial engine with a capacity ...This motor was assembled over a twelve-month period (c.2007) from various components the B-24 Liberator restoration group had stored. It was the first exercise to allow the group to understand the configuration of these motors as well as get experience in general methods of repair. This motor was nicknamed 'The Bitza', referring to how it came to be. While it may not be of a high standard, it is capable of being run on the test rig for visitors. The Pratt & Whitney R 1830 is a double row 14 cylinder air cooled radial engine with a capacity of 1830 cubic inches, (30 litres), developing some 1200 horsepower at a maximum 2700 rpm.Engine Number TR 261radial engine, pratt & whitney -

B-24 Liberator Memorial Restoration Australia Inc

B-24 Liberator Memorial Restoration Australia IncPratt & Whitney R 1830 Radial Engine, 490571

... cooled radial engine with a capacity of 1830 cubic inches, (30... is a double row 14 cylinder air cooled radial engine with a capacity ...This motor was purchased from New Zealand (2bx c2008). This motor came with a log book showing it had operated for a total of 1577 hours and was removed from service because it was approaching the deadline of 1600 hours which required it to be overhauled or replaced. No starter motor came with it, so the B-24 Liberator restoration group reconditioned one from stock, After a thorough health check, and basic adjustments, this engine was first run in May 2009 and has been cycled through regular engine run schedule ever since.The Pratt & Whitney R 1830 is a double row 14 cylinder air cooled radial engine with a capacity of 1830 cubic inches, (30 litres), developing some 1200 horsepower at a maximum 2700 rpm.Engine Number 490571 -

B-24 Liberator Memorial Restoration Australia Inc

B-24 Liberator Memorial Restoration Australia IncPratt & Whitney R 1830 Radial Engine, 722

... cooled radial engine with a capacity of 1830 cubic inches, (30... air cooled radial engine with a capacity of 1830 cubic inches ...This engine was used by RAAF 21 Squadron personnel to manufacture and fit up exhaust systems and had been left standing for a long time without any preservation treatment. Much effort was put in to free up the motor and after it had been made to turn, checks by borescope showed some fretting had occurred in the cylinder bores. This was deemed not serious enough to warrant a strip down. It did need repairs to the ignition looms and various other adjustments but first started on the 16 July 2009. Various fuel problems were evident and repairs have been done and it now runs very well. All parts used in getting this motor to run successfully came from the fund's own stock or parts included in other purchases. The Pratt & Whitney R 1830 is a double row 14 cylinder air cooled radial engine with a capacity of 1830 cubic inches, (30 litres), developing some 1200 horsepower at a maximum 2700 rpm.Engine Number 722 -

B-24 Liberator Memorial Restoration Australia Inc

B-24 Liberator Memorial Restoration Australia IncPratt & Whitney R 1830 Radial Engine, 54828 (CAC)

... cooled radial engine with a capacity of 1830 cubic inches, (30... is a double row 14 cylinder air cooled radial engine with a capacity ...This engine was a Commonwealth Aircraft Corporation (CAC) build, and had been upgraded to 92 specification at some time. This engine as acquired, was completely seized and great difficulty was encountered in dismantling it. The pistons in Nos 1, 13, 3, 2 and 5 had "grown" into the cylinder bores requiring some unorthodox methods to remove them. The cylinder barrels have been brought up to a reasonable standard, those beyond repair were replaced from stock. After getting various parts from the US, this engine was eventually brought up to running order.The Pratt & Whitney R 1830 is a double row 14 cylinder air cooled radial engine with a capacity of 1830 cubic inches, (30 litres), developing some 1200 horsepower at a maximum 2700 rpm.Engine Number 54828 -

B-24 Liberator Memorial Restoration Australia Inc

B-24 Liberator Memorial Restoration Australia IncPratt & Whitney R 1830 Radial Engine, 361184

... cooled radial engine with a capacity of 1830 cubic inches, (30... aspect of the 1830 engine. The engine was then re-assembled ...Early experience resulted in this motor being partially dismantled to investigate load knocking when turned over on the starter motor. Subsequently it was discovered that the "noise" was normal, a unique aspect of the 1830 engine. The engine was then re-assembled to an operational state using parts from stock.The Pratt & Whitney R 1830 is a double row 14 cylinder air cooled radial engine with a capacity of 1830 cubic inches, (30 litres), developing some 1200 horsepower at a maximum 2700 rpm.Engine Number 361184 -

B-24 Liberator Memorial Restoration Australia Inc

B-24 Liberator Memorial Restoration Australia IncArmstrong Siddeley Cheetah Engine

... Seven-cylinder air cooled radial engine produced... aircraft. radial engine A9600 8739D 790 S Seven-cylinder air cooled ...Some 37,200 of these engines were built, major application was in the Airspeed Oxford aircraft.Seven-cylinder air cooled radial engine produced by Armstrong Siddeley (UK). Widely used in Airspeed Oxford and Avro Anson aircraft of WWII era. This example is in running order after having been rebuilt by team members from a very neglected state.A9600 8739D 790 Sradial engine -

National Wool Museum

National Wool MuseumPhotograph, Cooper 2-stand semi-poratble sheating plant

... by pilot air cooled petrol engine circa 1949 Photography by Athol... cooled petrol engine circa 1949 Photography by Athol Shmith Pty ...Photograph of Coooper shearing plant.Photograph of Coooper shearing plant.Cooper 2-stand semi-poratble sheating plant powered by pilot air cooled petrol engine circa 1949 Photography by Athol Shmith Pty Ltd 125 Collins St. Melbourne No. ......shearing machinery, cooper engineering company pty ltd athol shmith pty ltd -

Moorabbin Air Museum

Moorabbin Air MuseumMachine - ADC Cirrus II 60Hp Air Cooled Inline 4 Cylinder

... an upright 4 cylinder air cooled inline engine. The engine powered... engine to produce an upright 4 cylinder air cooled inline engine ...Historical Details: . Description: The ADC Cirrus engine was developed in Britain for the de Havilland Moth aircraft and was produced by cutting in half an Airdisco V8 aero engine to produce an upright 4 cylinder air cooled inline engine. The engine powered many aircraft including the. Level of Importance: State -

Moorabbin Air Museum

Moorabbin Air MuseumMachine - Bristol Hercules 672 - 1700 HP Air Cooled Twin Row 18 Cyl

... cooled radial engine was one of the most powerful British aero... row air cooled radial engine was one of the most powerful ...Historical Details: . Description: Developed in Britain in 1938 the Bristol Hercules sleeve valve 18 cylinder twin row air cooled radial engine was one of the most powerful British aero engines of the day. It powered the Beaufighter and Bristol Freighter amongst other aircraft.. Level of Importance: s/n 167516 -

Moorabbin Air Museum

Moorabbin Air MuseumMachine - Bristol Hercules 734 - 1700 Hp Air Cooled Twin Row 18 Cylinder Radial

... cooled radial engine was one of the most powerful British aero... row air cooled radial engine was one of the most powerful ...Historical Details: . Description: Developed in Britain in 1938 the Bristol Hercules sleeve valve 18 cylinder twin row air cooled radial engine was one of the most powerful British aero engines of the day. It powered the Beaufighter and Bristol Freighter amongst other aircraft. Donated. Level of Importance: State -

Federation University Historical Collection

Federation University Historical CollectionBook, The Institution of Engineers, Australia Victoria Division Country Convention 1981, 1981

... of Producer gas in a 24kW Air-Cooled Diesel Engine (J. Stephenson... in a 24kW Air-Cooled Diesel Engine (J. Stephenson and R.R. Raine ...The conference was held at Ballarat.Yellow soft covered book of conference papers for the "New Generation Transport Fuels". Papers include * Vegetable Oils as Diesel Fuel (G. Stecher) * University of Melbourne's Hydrogen Fuelled Spark Ignition Engine (J. Edsell and E. Milkins) * Use of Producer gas in a 24kW Air-Cooled Diesel Engine (J. Stephenson and R.R. Raine) * Small Scale Liquid Fuel Production (G. Tippett, Horsham) * New Generation transport Fuels (L. Cubitt, Ballarat College of Advanced Education) * Hydrogen as Fuel for Motor Vehicles (Mercedes Benz Australia) Loose advertising material, letters and associated material is included.engineers, engineering, fuel, transport, institution of engineers, australia, e.j. barker, jack barker -

Moorabbin Air Museum

Moorabbin Air MuseumMachine - DeHaviland Gipsy Queen Mk 30 - 240Hp Air Cooled In Line 6 Cylinder

... , air cooled 6 cylinder engine. It powered many aircraft..., inverted, air cooled 6 cylinder engine. It powered many aircraft ...Historical Details: . Description: The de Havilland Gipsy Queen engine was developed in 1936 and is an inline, inverted, air cooled 6 cylinder engine. It powered many aircraft including the de Havilland Dove and the Percival Proctor.. Level of Importance: StateS/N DH 8.32 -

Dandenong/Cranbourne RSL Sub Branch

Dandenong/Cranbourne RSL Sub BranchPainting - Large wooden framed painting

... by a pair of Bristol Mercury V111 air cooled radial engines capable... by a pair of Bristol Mercury V111 air cooled radial engines capable ...Michael Turner born in 1934 is a British painter and illustrator specialising in motoring and aviation paintings. After leaving school he attended Art College followed by National Service with the Royal Electrical and Mechanical Engineers for 2 years. On leaving National Service he worked with a London advertising studio before turning freelance in1957. The Bristol Blenheim depicted in the painting was a British light bomber used extensively for 2 years of the Second World War. It was powered by a pair of Bristol Mercury V111 air cooled radial engines capable of developing 860 bhp. armament was a combination of Vickers, Browning and Lewis machine guns in .303 ( 7.7mm ). A 1000lb (450kg ) could be carried in the internal bomb bay in the centre section of the fuselage. The 114 Squadron was a Squadron of the British Royal Air Force formed in India during the First World War. The Squadron was disbanded in 1971.Large wooden framed painting of an RAF WW2 bomber in flight.Below the painting is the wording " A 114 Squadron Blenheim 1V on a low level bombing run over the power station at Knapsack Cologne, in August 1941 - donated by Laurie Pillar". -

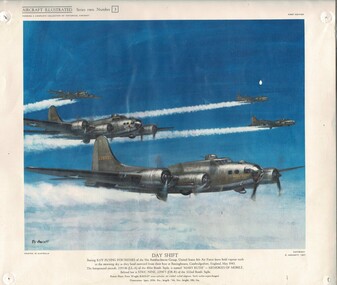

Lara RSL Sub Branch

Lara RSL Sub BranchColoured Print of Boeing B.17F Flying Fortress, Day Shift

... Plant: Four Wright R1820-97 nine cylinder air cooled radial...: Four Wright R1820-97 nine cylinder air cooled radial engines ...A rectangular Coloured Print of a group of Boeing B.17F's Boeing B.17F Flying Fortresses of the 91st Bombardment Group, United States 8th Air Force leave vapour trails in the morning sky as they head eastward from their base at Bassingbourn, Cambridgeshire, England, May 1943. The foreground aircraft, 229536 (LL-A) of the 401st Bomb SQN. is named "Mary Ruth"- Memories of mobile. Behind her is "Stric Nine, 229475 (OR-R) of the 322nd Bomb SQN. Power Plant: Four Wright R1820-97 nine cylinder air cooled radial engines. Each turbo-supercharged. Dimensions: Span 103ft 9in, Length: 74ft 9in, Height: 19ft 1in. -

National Wool Museum

National Wool MuseumMachine - Shearing Motor, Sunbeam, 1960-69

... -cooled engine from contaminants. At the front of the engine...-cooled engine from contaminants. At the front of the engine ...With more and more woolsheds being connected to power lines, the need for electric shearing gear markedly increased from the 1960s onwards. The greater economy made electric gear an attractive proposition to many graziers. Requiring only an electric shearing motor, for small and medium scale operations, electric shearing motors were a more economical way of shearing a wool clip. The other option for graziers was Overhead shearing gear, which also required an Engine to provide shared power to a row of shearing stations. Still working, this Sunbeam Electric Shearing Motor – Heavy Duty Model, features a slow speed motor totally enclosed for protection against dust and insects. The full bearing down tube is easily removed and stored to be out of the way when not in use (not pictured). Providing 0.5 hp, which is twice the power ever needed for shearing sheep, this buffer allows for fluctuations in voltages that can occur in rural districts. Inventor Frederick Wolseley made the world's first commercially successful power-shearing system in Australia in 1888. US company Cooper, which had been founded in 1843 as a maker of sheep dip, began selling Wolseley equipment in the USA in 1895. The Chicago Flexible Shaft Company successfully entered the power-shearing market a few years later and entered into a joint venture with Cooper. It set up a branch in Sydney and sold shearing sets, and engines to power them, into the Australian market. In 1921 the US parent company, realising it needed to make products whose sales were not as seasonal as those of shearing equipment, made its first household appliances and branded them Sunbeam. In 1933, changes in exchange rates and taxes led the company to manufacture engines and shearing equipment in Australia via subsidiary Cooper Engineering, which changed its name to Sunbeam in 1946. Although most Australians know of this company as a major manufacturer of household appliances, its rural division flourished and retained the Sunbeam name for shearing equipment even after it was taken over by New Zealand company Tru-Test in 2001. This 0.5 horsepower vertical brushed motor air-cooled engine was designed to drive a single shearing plant. From the central cylinder which features a yellow “Sunbeam” sticker, a grey 240v power lead can be found on the left-hand side. A blue capacitor is located next to this power lead. Below, two legs extend and meet to form a foot which is fastened to a wall. On the right-hand side of the engine, a specification plate is located on the central cylinder. A yellow directional arrow sticker is located on the rotating section of the engine below the specification plate (location for photography, this section is designed to rotate and hence this sticker is not fixed in this location). At the rear of the cylinder, a plastic cap with small air cut outs protects the air-cooled engine from contaminants. At the front of the engine, the location for securing the bearing down tube is located. On the right-hand side of the lock for the bearing down tube is the handle, to which a string is often attached for switching the motor on and off by a shearer bent at the waist (not pictured). Sticker. Gold writing. Front of shearing motor “Sunbeam” Plate. Inscribed. Side of shearing motor. “Sunbeam / SHEARING MOTOR / MADE IN AUSTRALIA / 0.5 H.P. / 220/240 V / 1 PHASE A.C. / 4.0 AMPS / 50 C/S. / CONT. RTG. / 1425 R.P.M. / CLASS A INSUL / NO. J244560 / TYPE: NSB5C2/49." sheep sheering, shearing equipment, sunbeam, electric shearing motor -

Maldon Vintage Machinery Museum Inc

Maldon Vintage Machinery Museum IncVertical Petrol Engine

... Water cooled vertical cylinder stationary petrol engine... in front of the engine. Galvanised iron cooling water tank mounted ...Water cooled vertical cylinder stationary petrol engine with magneto ignition. Painted green and black. Two flywheels. Cylindrical fuel tank mounted in front of the engine. Galvanised iron cooling water tank mounted on a stand behind the engine. All mounted on a steel frame with casters. On a cast crank-case cover :- "Manufactured by / R. A. Lister / & Co. Ltd. / 2 1/2 HP No. 2727 / Dursley England"machinery ... engine ... petrol ... metalwork -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Document - BILL ASHMAN COLLECTION: CORRESPONDENCE

... in the water they used for cooling their natural gas engines. Since... and they are contemplating installing in the water they used for cooling ...Seven copies of a letter from W. W. Eden, Mgr., F. W. Woolworth Co., dated November 12,1937 to Paul A. Douden & Co. He mentions that since installing the Scalebuoys over two years ago they have had no trouble with scale in the water systems where the Scale buoys were installed and they are contemplating installing in the water they used for cooling their natural gas engines. Since installing the scalebuoys there has been considerable savings on soap powders.sciences, instruments - general, scalebuoy, bill ashman collection - correspondence, f w woolworth co, paul a douden & co, w w eden -

Maldon Vintage Machinery Museum Inc

Maldon Vintage Machinery Museum IncOil Engine

... Bartram type AK, 5 HP horizontal cylinder water cooled... horizontal cylinder water cooled magneto ignition oil Engine mounted ...Bartram type AK, 5 HP horizontal cylinder water cooled magneto ignition oil Engine mounted on a metal and timber chassis with 4 wheels. It has its own cam driven water pump which pumps cooling water over metal gauze for evaporative cooling. Painted green. It has two flywheels, one at each end of the crankshaft, with a flat belt pulley attached to one flywheel. Cooling tank of galvanised steel with Bartram stencilled on one side. In working order.Cast nameplate on front of crankcase with a Bartram logo cast on also "Bertram / Type / AK" -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Document - BILL ASHMAN COLLECTION: F. W. WOOLWORTH CO

... for the water used for cooling the natural gas engines. This water... for cooling the natural gas engines. This water didn't come in contact ...Letter dated November 12, 1937 to Paul A. Douden & Co. from W. W. Eden, Mgr. F. W. Woolworth Co. W. W. Eden mentions that since installing Scale Buoys over two years age we have had no trouble from scale or lime deposits at all in our system, except for the water used for cooling the natural gas engines. This water didn't come in contact with the Scale Buoys and they contemplated additional units to treat it. They also had no scale in the coffee makers and dish washers.sciences, instruments - general, scalebuoy, bill ashman collection, f w woolworth co, paul a douden & co, scale buoys, w w eden -

Australian Gliding Museum

Australian Gliding MuseumMachine - Auto-Tug Engine, 1983 or prior

... – sailplane Piper Pawnee PA-25-150 tug with a water-cooled engine... – sailplane Piper Pawnee PA-25-150 tug with a water-cooled engine ...The 1982 Ford V6 engine, built at the Ford Essex Engine Plant at Windsor in Ontario Canada, was released by Ford for installation in a number of car and light truck models manufactured in Canada, United States, Mexico and Venezula. Production probably exceeded 7 million items. The Australian Gliding Museum’s exhibit was an engine converted for aircraft use that was bought for the Gliding Federation of Australia “Auto-Tug” program from Javelin Aircraft Company in Wichita in USA. “Auto-Tug” was an experimental program sponsored by the Gliding Federation of Australia to equip a glider – sailplane Piper Pawnee PA-25-150 tug with a water-cooled engine to alleviate the costs of running and maintaining the Lycoming engines fitted to Pawnee tugs in Australia. The program began in 1988 and was aimed at obtaining limited certification for converting dedicated glider – sailplane tow planes. The engine equipped with modified intake manifolds produced 198 hp for flight with the same propeller RPM for take-off as the original Lycoming 0-540 engine. However, fuel consumption was halved as the water cooling of the Ford engine enabled quicker descents with throttle closed following the release of the sailplane. Based on the results of GFA’s program, CASA concluded that engine was quite suitable for an aircraft installation and rated it more reliable than the equivalent Lycoming and Continental aircraft engine. The use of the 1982 Ford V6 engine type for Pawnee tug conversions was discontinued when the General Motors LS1 5.7 litre V8 became available. It is understood that a small number of conversions have been done using the LS1 engine. This brief history is based on information obtained from Mike Burns and David Sharples who were involved in the Auto-Tug program from 1988 to 1992. Technical information relating to the 1982 Ford V6 automotive engine is contained in a paper by D.L. Armstrong and G.F. Stirrat of the Engine Engineering Office at Ford. Indicative of technological experimentation in the sport of glidingFord auto engine mounted on mobile standaustralian gliding, glider, sailplane, auto-tug, pawnee, tug, auto, engine, motor, ford, gliding federation of australia, burns, sharples. -

Department of Energy, Environment and Climate Action

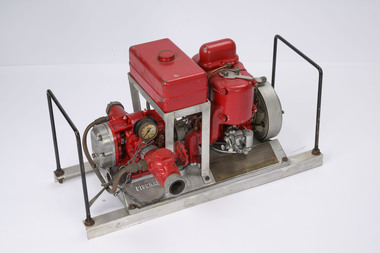

Department of Energy, Environment and Climate ActionPacific Marine pump Type Y

... unique design was the water-cooled engine and muffler... unique design was the water-cooled engine and muffler ...The Pacific Marine company was based in Seattle on the west coast of America and manufactured its first satisfactory portable fire pump 1925. These early Type N pumps were replaced in 1933 by the more familiar Type Y pumps. The updated pumps proved popular with the US Forest Service, and a large number were purchased by the Forests Commission as part of the equipment upgrade program in the wake of the 1939 bushfires. The Pacific Marine had a 9.8 Hp, two-cylinder, two-stroke petrol motor running with a high oil mix ratio of 16:1, so it blew vast clouds of blue smoke as the motor screamed at 4500 rpm. Part of its unique design was the water-cooled engine and muffler. But if the flow of water was interrupted the engine would quickly overheat and seize, so it needed constant monitoring and attention. Water was driven through a pair of bronze impeller gears which also needed a constant flow of water otherwise they would also self-destruct. When running properly, a Pacific Marine could pump 63 US gallons per minute, or about enough to fill a 200-litre drum. But its main feature was its high pressure of up to 225 psi. Pacific Marine pumps were often mounted on top of departmental fire tankers and used to spray water into the tops of burning trees. Compared to other pumps of the era it was light weight at only 70 pounds and was often mounted on a wooden stretcher frame. But they were cantankerous things to start with the rope pull and many exasperated novices came away with skinned knuckles. Modern Honda motors, which were more reliable and smoother running, replaced the Pacific Marines as the pump of choice for forest firefighters in the 1980s.High pressure Pacific marine Pumpforests commission victoria (fcv), bushfire, fire pump -

Department of Energy, Environment and Climate Action

Department of Energy, Environment and Climate ActionPacific Marine pump Type Y with wooden carry frame

... unique design was the water-cooled engine and muffler... unique design was the water-cooled engine and muffler ...The Pacific Marine company was based in Seattle on the west coast of America and manufactured its first satisfactory portable fire pump 1925. These early Type N pumps were replaced in 1933 by the more familiar Type Y pumps. The updated pumps proved popular with the US Forest Service, and a large number were purchased by the Forests Commission as part of the equipment upgrade program in the wake of the 1939 bushfires. The Pacific Marine had a 9.8 Hp, two-cylinder, two-stroke petrol motor running with a high oil mix ratio of 16:1, so it blew vast clouds of blue smoke as the motor screamed at 4500 rpm. Part of its unique design was the water-cooled engine and muffler. But if the flow of water was interrupted the engine would quickly overheat and seize, so it needed constant monitoring and attention. Water was driven through a pair of bronze impeller gears which also needed a constant flow of water otherwise they would also self-destruct. When running properly, a Pacific Marine could pump 63 US gallons per minute, or about enough to fill a 200-litre drum. But its main feature was its high pressure of up to 225 psi. Pacific Marine pumps were often mounted on top of departmental fire tankers and used to spray water into the tops of burning trees. Compared to other pumps of the era it was light weight at only 70 pounds and was often mounted on a wooden stretcher frame. But they were cantankerous things to start with the rope pull and many exasperated novices came away with skinned knuckles. Modern Honda motors, which were more reliable and smoother running, replaced the Pacific Marines as the pump of choice for forest firefighters in the 1980s.High pressure Pacific marine Pumpforests commission victoria (fcv), bushfire, fire pump -

Melton City Libraries

Melton City LibrariesPhotograph, The Cairn- Jimmy Melrose's plane crash site, 1988

... inverted in-line air-cooled engine. Six Phoenix were built; five... inverted in-line air-cooled engine. Six Phoenix were built; five ...Edna Barrie at the cairn, photo received from Graeme Minns in 1988. The cairn marks the site of Jimmy Melrose's plane crash in Melton South. The accident which happened on July 5th 1936. In 1934 Melrose made headlines with a series of spectacular flights. In July of that year, he set around Australia record and in that year established a new solo Australia England record when he flew to England to compete in the MacRoberston race with a De Havilland Puss Moth VH- YQO. The only Australian and the only solo pilot to complete the course within the time limit. He was seventh in finishing order and third in the handicap section making news again during the race with a dramatic landing in Darwin with empty fuel tanks. Late in 1935 Melrose imported the Phoenix for his “Adelaide to Anywhere” Charter Service. The previous year the Heston Aircraft Company had taken over the interests of the well known Comper Aircraft Company, and the first production of the new firm was the Phoenix, a single-engined all wooden five seater machine of sesquiplane configuration. The forward half of the fuselage was a streamlined rectangular section and the rear portion was a monocogue shell; the whole was of plywood fabric covered. The wing was built up of spruce box spars and lattice ribs, ply covered from the leading edge to the front spar and the fabric covered over the remainder. The tail surfaces were of similar construction. The most notable feature of the design was the lower stub wing which ran right across the fuselage embodying two box spars, plywood covered it housed the main undercarriage wheels when retracted and provided a substantial anchorage for the Nu form wing struts. The Dowty undercarriage retracted inwards, operated manually by hydraulic packs, Dual control fitted, with side by side seating for the pilots and three passenger seats behind. Power was a 200 h.p. De Havilland Gipsy VI 6 cylinder inverted in-line air-cooled engine. Six Phoenix were built; five of them registered in Great Britain and one of those was later sold abroad the remaining four were impressed into the R.A.F. in 1940. Specifications were: 40 feet 4 inches length 30 ft 2 ins height, 9ft 7ins, wing area 270 sq ft, Tare weight 2,600lbs loaded weight 3,300lbs; cruising speed 360 m.p.h. landing 50mph ceiling 14,000 ft range 700 miles. Melrose’s machine the first production aircraft was built early in 1936 and test flown of the 24th March. Painted green it carries the words “South Australian Centenary 1936” in silver of the fuselage and the name “Billing on the engine cowling in honor of Melrose’s uncle Noel Pemberton Billing, pioneer designer and founder of the Supermarine Aviation Company. The delivery flight was planned as a goodwill mission to publicise the forthcoming South Australian Centenary celebrations. Melrose left Dympne on the 9th April 1936, and flying via Marseilles, Naples, Athens, Baghdad, Basra, Karachi, Jodphur, Calcutta, Akyab, Penang, Singapore, Lombok, Darwin, Newcastle Waters and Alice Springs reached Adelaide on the 25th of April. Continuing the goodwill flight to other States, he visited Melbourne, Sydney, Newcastle, Grafton, Brisbane, Coff’s Harbour, Sydney again, Launceston, Hobart and Mount Gambier before returning to Adelaide on the 13th May. During June Jimmy made some charter flights and early in July was engaged by Mr. A.J. Campbell a director of several mining companies from Melbourne to Darwin to commence at Essendon on the4th July. However on that day low cloud and steady rain caused the postponement. There was little improvement and Melrose was advised to delay the departure again. However he wished to reach Oodnadatta that night, and when he observed the break in the clouds decided to leave. He planned to climb above the cloud and fly to Adelaide at 3,000 feet. The aircraft was airborne about 8.10 a.m. and was last seen from Essendon climbing above the clouds. At 8.45 people at Melton (30 miles West of Melbourne) heard an approaching aircraft. The engine noise increased abnormally and eye witnesses saw the machine fall out of control from the cloud base about 800 feet and then disintegrate, fragments were scattered for 1½ miles and both occupants were killed. Hand written carbon copy by Edna Barrie.Typed by Wendy Barrie March 2014 Last Flight of Jimmy Melrose by John Burke Parade Magazine July 1972 Page 2 –4 This article gives the take off time of 7.50 am from Essendon Airport Eyewitness account at the time Maisie Arthur’s description. Newspaper article. Edna Barrie at the site of the 'Cairn'local identities, local significant events -

Puffing Billy Railway

Puffing Billy RailwayLister Auto Truck

... . The engines were single-cylinder and air-cooled. Ignition.... The engines were single-cylinder and air-cooled. Ignition ...The Lister Auto-Truck was a small monowheel tractor built for moving light loads around factories, railway yards and similar sites. They were built by R A Lister and Company of Dursley, Gloucestershire, well known for their range of small stationary engines The Auto-Truck was one of several monowheel tractors to appear in the 1920s and '30s, with the availability of small, reliable petrol engines, as developed for motorcycles and the stationary engines for which Lister were already known. These were tricycle vehicles, with the single leading wheel used for both drive and steering. Their simple construction carried most of the mechanism on this wheel as a single unit, the chassis with the trailing wheels being little more than a trailer for balance. Simplicity was a key feature. The engines were single-cylinder and air-cooled. Ignition was by magneto, rather than requiring a battery and electrical system. One of these designs was produced in the 1920s by George Grist of the Auto Mower Co., Norton St Philip, Somerset. The engine was a JAP 600 cc four-stroke air-cooled sidevalve, a typical small engine of the time. The Auto Mower Co. were Lister agents and when Lister heard of this 'Auto-Truck' they bought one for use in their own factory. It was used to carry heavy engine castings from the foundry to the machine shop. Lister customers saw them and there was such interest in wanting to buy them that Lister negotiated with Auto Mower to build them under licence. Although Lister were already well known for their small petrol stationary engines, these were heavy cast-iron engines with water hopper cooling and unsuitable for vehicle use. Lister remained with the JAP engine for the Auto-Truck. The Auto-Truck was designed for use in factories or other places with smooth surfaces of concrete or tarmac. This allowed the use of small solid-tyred wheels with only simple suspension, making the vehicle simple, cheap and lightweight. They had little ability on soft surfaces though and could even topple over if driven carelessly across slopes. Their design was a compromise between the top-heavy nature of the tall engine grouping above its wheel and a well thought-out chassis for stability. The bearing between them was a large diameter ring roller bearing, mounted at the lowest part of the chassis. This gave rigidity and stability, even after long wear. A ring of rolled channel girder was attached to the engine group and rollers on the chassis carried the load upon this. On early Auto-Trucks this bearing is set very low, in line with the chassis members, and is covered by thin steel plates. The front panel of the engine cover is distinctive with large ventilation holes and a Lister signature cut through it. Strangely this panel is made of thick cast iron, providing substantial weight high on the engine and only adding to its top heaviness. To improve visibility of moving vehicles in noisy factories, this panel was often painted white, the rest of the vehicle being Lister's usual brunswick green. The driver was seated on a Brooks bicycle saddle, which in recognition of the lack of vehicle suspension, was carried on the end of a cantilevered bar that acted as a leaf spring. A wide handlebar on the engine group was used for steering. A squeeze bar the width of this handlebar engaged the clutch. Controls included a hand throttle, a gear lever with two forward and one reverse gears, and a large handbrake lever. The engine unit rotated freely for a full 360° rotation. When used in reverse, the Auto-Truck could either be driven from the saddle, looking backwards over the driver's shoulder; or they could dismount, swivel the engine unit around and control it as a pedestrian-controlled truck from behind. Under the engine cover were two equal diameter tanks, a fuel tank for petrol and a shorter oil tank. Engine and chain-drive lubrication used a total-loss oil system, controlled by a small pump and needle valve. Info Ref: Lister Auto-Truck - Wikipedia https://en.wikipedia.org/wiki/Lister_Auto-TruckHistoric - Industrial monowheel tractor for moving light loads around factories, railway yards and similar sites.The Lister Auto-Truck - small monowheel tractor Made of steel with three wheels. Powered by a J.A.P single cylinder petrol motor which is Hand Cranked to start.Lister puffing billy, lister, lister auto truck, monowheel tractor -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Chest of Drawers, British Imperial Oil Company Ltd, 1905-1927

This early 20th-century chest of drawers is unique. It was made from recycled timber kerosene boxes and metal tins. The case was made in South Australia between 1905 and 1927 by the British Imperial Oil Company Ltd, which was the first business to import bulk petroleum products into Australia. Before this, ships carried crates of kerosene as cargo. Items salvaged from the 1880 wreck of the vessel Eric the Red included kerosene boxes. Kerosene replaced plant and animal-based fuel, such as whale oil, for lighting in homes and for the lamps in lighthouses and on marine vessels. It was also used for cooking and heating and as engine fuel. The last kerosene-fueled lighthouse lamp was transferred to solar power in 1985. The chest of drawers is one-of-a-kind. The original uses for the components of the chest of drawers, the wooden box and metal tins were for containing and transporting kerosene. Kerosene was used from the late 19th century for fuel in lamps, heating, and cooling. Previously whale oil was used for the lamps in lighthouses. The company providing the kerosene was the first to import it into Australia in bulk quantities. The set of drawers is one of the many ways that inventive Australians were able to repurpose materials.Chest of drawers; wooden frame and rails, metal drawers with vertical metal handles. The frame has been constructed from the wooden panels of a vintage oil and kerosene box. The three drawers have been created from empty kerosene cans that were cut in half from top to bottom, some with the round opening closed over. Inscriptions from the original box and cams are stencilled on the top and base of the frame and impressed or painted on the metal cans. The frame has provision for a further drawer. The wooden case and metal tins were made in Australia.Top and base of frame; "THE BRITISH IMPERIAL OIL CO. LTD." "OIL ENGINE KEROSENE" "CASE ANDTINS AUSTRALIAN MADE" On tin; "POWIRIN" "BIOCO LTD" Logo [cross} with inscription on horizontal bar "CROSS" Impressed in timber drawer dividers (indecipherable text) Side of drawer, painted in orange on black; "TY -, REG U S - TIDE - "flagstaff hill, warrnambool, maritime village, maritime museum, shipwreck coast, great ocean road, antique, domestic equipment, chest of drawers, tool box, furniture, storage, recycled tin, recycled box, kerosene, fossil fuel, lighthouse lamp fuel, british imperial oil company ltd. -

Gippsland Vehicle Collection

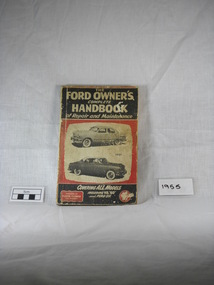

Gippsland Vehicle CollectionBook, FLOYD CLYMER, The FORD OWNER'S complete HANDBOOK of Repair and Maintenance, 1949 (exact)

... and maintenance ford engine clutch body chassis shockers cooling system ...This Ford Handbook is in good condition. This book covers at least 97% of the instructions necessary for servicing the 1950 and 1951 models.Repair and Maintenance book covering all models of ford including V8, "60" and FORD SIXOn page 106 of the handbook there is, in handwriting, CABLE OPERATED BRAKES, Spring, Colour & Position Guide. Hand drawn picture with details marking the layout and details of the spring, colour & position.electrical, steering, ford, engine, transmission, accessory, ford owners, car repair, v8, 60, ford six, repair and maintenance, ford engine, clutch, body, chassis, shockers, cooling system, fuel system, suspension, rear, axle, brakes, shock absorbers, rear axle -

Federation University Historical Collection

Federation University Historical CollectionBook - Report, Former Ballarat Brewery Conservation Analysis, 1994, 1994

... boiler and engine room cooling tower 124 page report copied onto ...The former Ballarat Brewery site was purchased by the Ballarat School of Mines in 1993 who commissioned the conservation management plan. It has closed as a brewery in 1989 and the plant and fittings auctioned. The buildings were demolished and a new educational facility known as the brewery Complex was built, using some elements of the former brewery in its design. 124 page report copied onto A4 white paper, with additional appendices and definitions. Contents include brewing in Australia, site history, Tulloch & McLaren Royal Standarg Brewery, Henry Caselli, Ballarat Brewing Company, Physical Survey and comparitive analysis.ballarat school of mines, henry richards caselli, henry caselli, chimney, ballarat brewery, carlton and united breweries, tulloch and mclaren, henry r caselli, ballarat brewing company, cub, brewing tower, brew tower, boiler and engine room, cooling tower -

Moorabbin Air Museum

Moorabbin Air MuseumBooklet (item) - A Cooling Calibration Of An R2800-31 Wasp Engine In Ventura Aircraft A59-4 -0 Report E.39