Showing 37 items matching "dairy machine"

-

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Butter Churn, Malleys Ltd, 1930-1950

... dairy machine... dairy machine Malleys is written in raised letters on the base ...This is a steel, bench-mounted, hand-operated (60 rpm) butter churn for making small amounts of butter from cream in the home. It was made by the Sydney firm of Malleys Ltd from the 1930s until the 1950s and came in 3 and 5 quart sizes. Malleys Ltd was established in about 1890 by Francis Malley (1863-1932). This firm was located in the Sydney suburb of Alexandria, in McEvoy Street. They manufactured items for use in the dairy industry, as well as for hardware related to building and plumbing. Many of the Malley dairy products were sold under the "Sunrise" name. Malley retired in 1912. In 1931 there were branches at Parramatta, Hurstville & North Sydney. Butter churns were machines used to produce butter by the violent agitation of separated cream. Depending on the design of the churn, the agitation would be variously achieved by a repetitive thrashing, centrifugal motion or internal paddles. Churns were typically constructed from wood, glass and cast-iron; with tin or steel commonly used for some fixtures. The subject item gives an insight into domestic life where butter was made in the home.Heavy red cast iron base, with a long handle, wooden grip, connected to a shaft along the base, thence, to a cog wheel, and gear, to a second shaft and paddle in a metal basin. Basin has lid, and hole in base with a screw cap to allow the draining of the butter milk. Designed to be placed on a bench, with the handle over the edge. Malleys is written in raised letters on the base, and on the handle, '60 rev. pr. min.'warrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, malleys, butter churn, domestic object, dairy machine -

Numurkah & District Historical Society

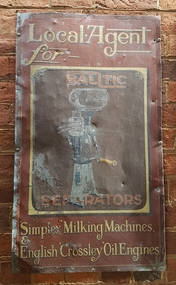

Numurkah & District Historical SocietySign - "Baltic Separators" sign

... high-country dairy milking separator machine farming ...Rectangular tin sign advertising Baltic Separators. Has yellow and brown print on brown backgroundsee photodairy, milking, separator, machine, farming, agriculture, sign -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyBottle Milk, early 1900's

... to late 1900's (1834 Victorian dairy industry was founded) up... milking machines in the late 1930's. The great increases in dairy ...This glass milk bottle was manufactured and used mid to late 1900's (1834 Victorian dairy industry was founded) up to the time that a cheaper container was invented(plastic bottles and polyethylene plastic lined cardboard cartons) and produced. In 1909 the supply of pure bottled milk was required for babies to overcome infant mortality due to unhygienic milk sources (unclean containers and unpasteurized milk). Due to the volume of milk being processed and hand milking could not keep up with demand, dairy farms introduced milking machines in the late 1930's. The great increases in dairy herds from the average of 18 cows per heard in 1950's to 142 cows per herd in 1996 required milk tankers to pick up the regions milk supply. This bottle was so constructed to be easily moved within the milk processing plants from the delivery vats/holding tanks to the final corking/sealing of the bottles for eventual distribution. From 1958 the milk bottle slowly became phased out of production. At this point in time Melbourne was drawing 160,000 bottles per week from the two major glass bottle works companies, e.g. Melbourne Glass Bottle Works Co. Victoria was the major state supplier of cows milk in the history of Australian milk production from the early 1800's. The Kiewa Valley and its region was a major contributor to meet that demand. Each bottle was "branded" during manufacturing to show the contents (pasteurized milk) and where it originated from (region and supplier). This method of recycling the bottles back to specific dairy farms was a good control method but an uneconomical "on cost" which was replaced by the "throw away" less costly plastic and cardboard containers. Kiewa Valley dairy herds had marked bottles bearing "90/9", "6/18", "6/33", "6/35" and "6/36" This heavy gauged glass milk bottle has a rim and a distinctive head at the top. This head has been manufactured to facilitate the movement of the bottled along the milk production line. The method of pouring milk into the bottle has been part of the "production line". This bottle has a one pint capacity and is made from "clear" glass. There are other milk bottles that have a "green" tint in them.Around the bottom side of the bottle and blown into the glass "ONE PINT" and on the opposite side "MILK". Below these markings is "This BOTTLE BELONGS TO MILK BOTTLES RECOVERY LTD" below this "AND CANNOT BE USED WITHOUT WRITTEN PERMISSION. On the base of the bottle is molded a big "M". An identification mark of "90" over "9" is beneath the "M". glass bottles, commercial milk containers, domestic milk bottles, pasteurized milk bottles, milk, dairy, farms, kiewa valley -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyBottle Milk, mid to late 1900's

... (1834 Victorian dairy industry was founded) to the time... milking machines in the late 1930's. The great increases in dairy ...This glass milk bottle was manufactured and used mid 1800's (1834 Victorian dairy industry was founded) to the time that a cheaper container was invented(plastic bottles and polyethylene plastic lined cardboard cartons). In 1909 the supply of pure bottled milk was required for babies to overcome infant mortality due to unhygienic milk sources (unclean containers and unpasteurized milk). Due to the large volume of milk being processed and hand milking could not keep up with demand, dairy farms introduced milking machines in the late 1930's. The great increases in dairy herds from the average of 18 cows per heard in 1950's to 142 cows per herd in 1996 required milk tankers to pick up the regions milk supply. This bottle was so constructed to be easily moved within the milk processing plants from the delivery vats/holding tanks to the final corking/sealing of the bottles for eventual distribution. From 1958 the milk bottle slowly became phased out of production. At this point in time Melbourne was drawing 160,000 bottles per week from the two major glass bottle works companies, e.g. Melbourne Glass Bottle Works Co.Victoria was the major state supplier of cows milk in the history of Australian milk production from the early 1800's. The Kiewa Valley and its region was a major contributor to meet that demand. Each bottle was "branded" during manufacturing to show the contents (pasteurized milk) and where it originated from (region and supplier). This method of recycling the bottles back to specific dairy farms was a good control method but an uneconomical "on cost" which was replaced by the "throw away" less costly plastic and cardboard containers. Kiewa Valley dairy herds had marked bottles bearing "90/9", "6/18", "6/33", "6/35" and "6/36"This heavy gauged glass milk bottle has a rim and a distinctive head at the top. This head has been manufactured to facilitate the movement of the bottled along the milk production line. The method of pouring milk into the bottle has been part of the "production line". This bottle has a one pint capacity and is made from "light green" coloured glass(a protection against sunlight penetration). There are other milk bottles that do not have a "green" tint in them. This thick glass bottle to contain milk required its thickness because of the extensive handling before final consumption. Milk was delivered by the "milk man" direct to the homes of consumers. During this period delivery to homes in cities and towns was made initially by horse and cart and later by truck.On the bottom end of this bottle a circle within it 6/33 and next to this "ONE PINT" and under this "THIS BOTTLE BELONGS TO MILK BOTTLE RECOVERY LTD" and below this "AND CANNOT BE USED WITHOUT WRITTEN PERMISSION" on the base "M" underneath this "4"glass bottles, commercial milk containers, domestic milk bottles, pasteurized milk bottles -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyBottle Milk, circa mid to late 1900's

... milking machines in the late 1930's. The great increases in dairy... machines in the late 1930's. The great increases in dairy herds ...This glass milk bottle was manufactured and used mid to late 1900's (1834 Victorian dairy industry was founded) up to the time that a cheaper container was invented(plastic bottles and polyethylene plastic lined cardboard cartons). In 1909 the supply of pure bottled milk was required for babies to overcome infant mortality due to unhygienic milk sources (unclean containers and unpasteurized milk). Due to the volume of milk being processed and hand milking could not keep up with demand, dairy farms introduced milking machines in the late 1930's. The great increases in dairy herds from the average of 18 cows per heard in 1950's to 142 cows per herd in 1996 required milk tankers to pick up the regions milk supply. This bottle was so constructed to be easily moved within the milk processing plants from the delivery vats/holding tanks to the final corking/sealing of the bottles for eventual distribution. From 1958 the milk bottle slowly became phased out of production. At this point in time Melbourne was drawing 160,000 bottles per week from the two major glass bottle works companies, e.g. Melbourne Glass Bottle Works Co.Victoria was the major state supplier of cows milk in the history of Australian milk production from the early 1800's. The Kiewa Valley and its region was a major contributor to meet that demand. Each bottle was "branded" during manufacturing to show the contents (pasteurized milk) and where it originated from (region and supplier). This method of recycling the bottles back to specific dairy farms was a good control method but an uneconomical "on cost" which was replaced by the "throw away" less costly plastic and cardboard containers. Kiewa Valley dairy herds had marked bottles bearing "90/9", "6/18", "6/33", "6/35" and "6/36" Found under house at 1 Beauty Ave., Mt Beauty.This heavy gauged glass milk bottle has a rim and a distinctive head at the top. This head was manufactured to facilitate the movement of the bottled along the milk production line. The method of pouring milk into the bottle has been part of the "production line". This bottle has a one pint capacity and is made from "light green" coloured glass(a protection against light penetration). There are other milk bottles that do not have a "green" tint in them. This thick glass bottle which contained milk required its thickness because of the extensive handling before final consumption. Milk was delivered by the "milk man" direct to the homes of consumers. During this period delivery to homes in cities and towns was made initially by horse and cart and later by truck.On the bottom end of this bottle a circle within it "6/18" and next to this "MILK" and opposite "ONE PINT". Below this "THIS BOTTLE BELONGS TO MILK BOTTLE RECOVERY LTD" and below this "AND CANNOT BE USED WITHOUT WRITTEN PERMISSION" on the base "M" underneath this "3"glass bottles, commercial milk containers, domestic milk bottles, pasteurized milk bottles -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyBottle Milk, mid to late 1900's

... milking machines in the late 1930's. The great increases in dairy... machines in the late 1930's. The great increases in dairy herds ...This glass milk bottle was manufactured and used mid to late 1900's (1834 Victorian dairy industry was founded) until the time that a cheaper container was invented(plastic bottles and polyethylene plastic lined cardboard cartons). In 1909 the supply of pure bottled milk was required for babies to overcome infant mortality due to unhygienic milk sources (unclean containers and unpasteurized milk). Due to the volume of milk being processed and hand milking could not keep up with demand, dairy farms introduced milking machines in the late 1930's. The great increases in dairy herds from the average of 18 cows per heard in 1950's to 142 cows per herd in 1996 required milk tankers to pick up the regions milk supply. This bottle was so constructed to be easily moved within the milk processing plants from the delivery vats/holding tanks to the final corking/sealing of the bottles for eventual distribution. From 1958 the milk bottle slowly became phased out of production. At this point in time Melbourne was drawing 160,000 bottles per week from the two major glass bottle works companies, e.g. Melbourne Glass Bottle Works Co.Victoria was the major state supplier of cows milk in the history of Australian milk production from the early 1800's. The Kiewa Valley and its region was a major contributor to meet that demand. Each bottle was "branded" during manufacturing to show the contents (pasteurized milk) and where it originated from (region and supplier). This method of recycling the bottles back to specific dairy farms was a good control method but an uneconomical "on cost" which was replaced by the "throw away" less costly plastic and cardboard containers. Kiewa Valley dairy herds had marked bottles bearing "90/9", "6/18", "6/33", "6/35" and "6/36" Found under house at 1 Beauty Ave., Mt Beauty.This heavy gauged glass milk bottle has a rim and a distinctive head at the top. This head has been manufactured to facilitate the movement of the bottle along the milk production line. The method of pouring milk into the bottle has been part of the "production line". This bottle has a one pint capacity and is made from "light green" coloured glass(a protection against light penetration). There are other milk bottles that do not have a "green" tint in them. This thick glass bottle to contain milk required its thickness because of the extensive handling before final consumption. Milk was delivered by the "milk man" direct to the homes of consumers. During this period delivery to homes in cities and towns was made initially by horse and cart and later by truck.On the bottom end of this bottle a circle within it "6/36" and next to this "MILK" and opposite "ONE PINT". Below this "THIS BOTTLE BELONGS TO MILK BOTTLE RECOVERY LTD" and below this "AND CANNOT BE USED WITHOUT WRITTEN PERMISSION" on the base "M" underneath this "15" glass bottles, commercial milk containers, domestic milk bottles, pasteurized milk bottles -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyBottle Milk, mid to late 1900's

... milking machines in the late 1930's. The great increases in dairy... milking machines in the late 1930's. The great increases in dairy ...This glass milk bottle was manufactured and used mid to late1900's (1834 Victorian dairy industry was founded) up until the time that a cheaper container was invented(plastic bottles and polyethylene plastic lined cardboard cartons). In 1909 the supply of pure bottled milk was required for babies to overcome infant mortality due to unhygienic milk sources (unclean containers and unpasteurized milk). Due to the volume of milk being processed and hand milking could not keep up with demand, dairy farms introduced milking machines in the late 1930's. The great increases in dairy herds from the average of 18 cows per heard in 1950's to 142 cows per herd in 1996 required milk tankers to pick up the regions milk supply. This bottle was so constructed to be easily moved within the milk processing plants from the delivery vats/holding tanks to the final corking/sealing of the bottles for eventual distribution. From 1958 the milk bottle slowly became phased out of production. At this point in time Melbourne was drawing 160,000 bottles per week from the two major glass bottle works companies, e.g. Melbourne Glass Bottle Works Co.Victoria was the major state supplier of cows milk in the history of Australian milk production from the early 1800's. The Kiewa Valley and its region was a major contributor to meet that demand. Each bottle was "branded" during manufacturing to show the contents (pasteurized milk) and where it originated from (region and supplier). This method of recycling the bottles back to specific dairy farms was a good control method but an uneconomical "on cost" which was replaced by the "throw away" less costly plastic and cardboard containers. Kiewa Valley dairy herds had marked bottles bearing "90/9", "6/18", "6/33", "6/35" and "6/36" Found under the house at 1 Beauty Ave., Mt BeautyThis heavy gauged glass milk bottle has a rim and a distinctive head at the top. This head has been manufactured to facilitate the movement of the bottled along the milk production line. The method of pouring milk into the bottle has been part of the "production line". This bottle has a one pint capacity and is made from "light green" coloured glass(a protection against light penetration). There are other milk bottles that do not have a "green" tint in them. This thick glass bottle to contain milk required its thickness because of the extensive handling before final consumption. Milk was delivered by the "milk man" direct to the homes of consumers. During this period delivery to homes in cities and towns was made initially by horse and cart and later by truck.On the bottom end of this bottle a circle within it "6/18" and next to this "MILK" and opposite "ONE PINT". Below this "THIS BOTTLE BELONGS TO MILK BOTTLE RECOVERY LTD" and below this "AND CANNOT BE USED WITHOUT WRITTEN PERMISSION" on the base "M" underneath this "4"glass bottles, commercial milk containers, domestic milk bottles, pasteurized milk bottles -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyBottle Milk, mid to late 1900's

... milking machines in the late 1930's. The great increases in dairy... machines in the late 1930's. The great increases in dairy herds ...This glass milk bottle was manufactured and used mid to late 1900's (1834 Victorian dairy industry was founded), until the time that cheaper containers were invented(plastic bottles and polyethylene plastic lined cardboard cartons). In 1909 the supply of pure bottled milk was required for babies to overcome infant mortality due to unhygienic milk sources (unclean containers and unpasteurized milk). Due to the volume of milk being processed and hand milking could not keep up with demand, dairy farms introduced milking machines in the late 1930's. The great increases in dairy herds from the average of 18 cows per heard in 1950's to 142 cows per herd in 1996 required milk tankers to pick up the regions milk supply. This bottle was so constructed to be easily moved within the milk processing plants from the delivery vats/holding tanks to the final corking/sealing of the bottles for eventual distribution. From 1958 the milk bottle slowly became phased out of production. At this point in time Melbourne was drawing 160,000 bottles per week from the two major glass bottle works companies, e.g. Melbourne Glass Bottle Works Co.Victoria was the major state supplier of cows milk in the history of Australian milk production from the early 1800's. The Kiewa Valley and its region was a major contributor to meet that demand. Each bottle was "branded" during manufacturing to show the contents (pasteurized milk) and where it originated from (region and supplier). This method of recycling the bottles back to specific dairy farms was a good control method but an uneconomical "on cost" which was replaced by the "throw away" less costly plastic and cardboard containers. Kiewa Valley dairy herds had marked bottles bearing "90/9", "6/18", "6/33", "6/35" and "6/36" Found under the house at 1 Beauty Ave., Mt BeautyThis heavy gauged glass milk bottle has a rim and a distinctive head at the top. This head has been manufactured to facilitate the movement of the bottled along the milk production line. The method of pouring milk into the bottle has been part of the "production line". This bottle has a one pint capacity and is made from "light green" coloured glass(a protection against light penetration). There are other milk bottles that do not have a "green" tint in them. This thick glass bottle, to contain milk, required its thickness because of the extensive handling (man and machine) before final consumption. Milk was delivered by the "milk man" direct to the homes of consumers. During this period delivery to homes in cities and towns was made initially by horse and cart and later by truck.On the bottom end of this bottle is a circle within it "6/35" and next to this "MILK" and opposite "ONE PINT". Below this "THIS BOTTLE BELONGS TO MILK BOTTLE RECOVERY LTD" and below this "AND CANNOT BE USED WITHOUT WRITTEN PERMISSION" on the base "M" underneath this "20"milk, dairy, glass bottle -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyBottle Milk, mid to late 1900's

... to late 1900's (1834 Victorian dairy industry was founded) up... milking machines in the late 1930's. The great increases in dairy ...This glass milk bottle was manufactured and used mid to late 1900's (1834 Victorian dairy industry was founded) up until the time that a cheaper container was invented(plastic bottles and polyethylene plastic lined cardboard cartons). In 1909 the supply of pure bottled milk was required for babies to overcome infant mortality due to unhygienic milk sources (unclean containers and unpasteurized milk). Due to the volume of milk being processed and hand milking could not keep up with demand, dairy farms introduced milking machines in the late 1930's. The great increases in dairy herds from the average of 18 cows per heard in 1950's to 142 cows per herd in 1996 required milk tankers to pick up the regions milk supply. This bottle was so constructed to be easily moved within the milk processing plants from the delivery vats/holding tanks to the final corking/sealing of the bottles for eventual distribution. From 1958 the milk bottle slowly became phased out of production. At this point in time Melbourne was drawing 160,000 bottles per week from the two major glass bottle works companies, e.g. Melbourne Glass Bottle Works Co.Victoria was the major state supplier of cows milk in the history of Australian milk production from the early 1800's. The Kiewa Valley and its region was a major contributor to meet that demand. Each bottle was "branded" during manufacturing to show the contents (pasteurized milk) and where it originated from (region and supplier). This method of recycling the bottles back to specific dairy farms was a good control method but an uneconomical "on cost" which was replaced by the "throw away" less costly plastic and cardboard containers. Kiewa Valley dairy herds had marked bottles bearing "90/9", "6/18", "6/33", "6/35" and "6/36" Found under the house at 1 Beauty Ave., Mt BeautyThis heavy gauged glass milk bottle has a rim and a distinctive head at the top. This head has been manufactured to facilitate the movement of the bottle along the milk production line. The method of pouring milk into the bottle has been part of the "production line". This bottle has a half pint capacity and is made from "clear" glass. There are other milk bottles that have a "green" tint in them and this tint was to protect the contents from sun damage. This thick glass bottle to contain milk required its thickness because of the extensive handling before final consumption. Milk was delivered by the "milk man" direct to the homes of consumers. During this period delivery to homes in cities and towns was made initially by horse and cart and later by truck.On the top half of this bottle is "MILK" and opposite "HALF PINT". Below this "THIS BOTTLE BELONGS TO MILK BOTTLE RECOVERY LTD" and below this "AND CANNOT BE USED WITHOUT WRITTEN PERMISSION" on the base is "2 M" underneath this "8/11" and underneath is "ISM -169"glass bottles, commercial milk containers, domestic milk bottles, pasteurized milk bottles -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyBottle Milk, Circa mid to late 1900's

... to late 1900's (1834 Victorian dairy industry was founded) up... milking machines in the late 1930's. The great increases in dairy ...This glass milk bottle was manufactured and used mid to late 1900's (1834 Victorian dairy industry was founded) up to the time that a cheaper container was invented(plastic bottles and polyethylene plastic lined cardboard cartons) and produced. In 1909 the supply of pure bottled milk was required for babies to overcome infant mortality due to unhygienic milk sources (unclean containers and unpasteurized milk). Due to the volume of milk being processed and hand milking could not keep up with demand, dairy farms introduced milking machines in the late 1930's. The great increases in dairy herds from the average of 18 cows per heard in 1950's to 142 cows per herd in 1996 required milk tankers to pick up the regions milk supply. This bottle was so constructed to be easily moved within the milk processing plants from the delivery vats/holding tanks to the final corking/sealing of the bottles for eventual distribution. From 1958 the milk bottle slowly became phased out of production. At this point in time Melbourne was drawing 160,000 bottles per week from the two major glass bottle works companies, e.g. Melbourne Glass Bottle Works Co. Victoria was the major state supplier of cows milk in the history of Australian milk production from the early 1800's. The Kiewa Valley and its region was a major contributor to meet that demand. Each bottle was "branded" during manufacturing to show the contents (pasteurized milk) and where it originated from (region and supplier). This method of recycling the bottles back to specific dairy farms was a good control method but an uneconomical "on cost" which was replaced by the "throw away" less costly plastic and cardboard containers. Kiewa Valley dairy herds had marked bottles bearing "90/9", "6/18", "6/33", "6/35" and "6/36" This particular one has "7/14".This heavy gauged glass milk bottle has a rim and a distinctive head at the top. This head has been manufactured to facilitate the movement of the bottled along the milk production line. The method of pouring milk into the bottle has been part of the "production line". This bottle has a one Imperial pint capacity and is made from "clear" glass. There are other milk bottles that have a "green" tint in them. Around the bottom side of the bottle and blown into the glass "ONE IMPERIAL PINT". Below these markings and stenciled is "KIEWA" (in freehand style and underlined) underneath is "PASTEURISED FULL CREAM MILK" underneath this ,in freehand stiyle is "USE" next to this in block style "KIEWA BUTTER, CREAM, AND ICE CREAM MIX" to the left of this ,and barely readable is stenciled "THIS BOTTLE ALWAYS REMAINS/ THE PROPERTY OF/ NORTH EASTERN DAIRY Co. Ltd". On the base of the bottle is molded a big "2". with a smaller "m". An identification mark of "7" over "14" is within a circled boundary. Below this is moulded "RM - 15". glass bottles, commercial milk containers, domestic milk bottles, pasteurized milk bottles -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageSeparator

Separator machine. Hand-crank operated milk separator, Crown Separator Co Pty Ltd. Multi-part separator stand with bowls (2) and attachments including a spanner small cone shaped objects on homemade stand. ."42D022" stamped on 2x separator chutes.Manufacture's plate "MADE IN SWEDEN" , "CROWN SEPARATOR / HEAD OFFICE 547 FLINDERS ST MELBOURNE". ."42D022" stamped on 2x separator chutes. flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, milk separator, farm machinery, dairy machinery, dairy industry, crown spearator co, cream -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageSeparator

Hand-cranked separating maching, made in Sweden for Melbourne Crown Separator Co. Pty Ltd. Machine is used for separating cream from milk, with the machine speed being 70 revs per minute.Separator machine. Hand-crank operated milk separator, small, painted red, Crown Separator Co Pty Ltd. Base and spinning mechanism only (mechanism spins very rettly). Stamped on handle "70 per minute", Stamped on body "S7071", Manufacturer plate "SYLVIA NO. 19/ MADE IN SWEDEN / CROWN SEPARATOR CO PTY LTD / 547 FLINDERS ST, MELBOURNE" Stamped on handle "70 per minute", Stamped on body "S7071", Manufacturer plate "SYLVIA NO. 19/ MADE IN SWEDEN / CROWN SEPARATOR CO PTY LTD / 547 FLINDERS ST, MELBOURNE" flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, milk separator, cream separator, dairy machinery, farming machinery, crown separator co pty ltd -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyCream Separator

Dairy farms used cream separators to separate the milk and the cream before using it themselves or selling it to the dairy companies, shops or directly to the public.This cream separator was used by P & R Creamer on their dairy farm in the Kiewa Valley.3 parts - top brass lid with hollow cylinder enclosed across its top and extending beyond its circumference. 2. Stainless Steel hollow cylinders that fit the base and the lid but has 2 long curved spouts extending out - one for the milk and one for the cream to come out 3. Black cast iron stand that houses the gear mechanisms that drive the separator cones. The gear speed reduction wheel is on one side. "Alfa-Laval MOB / 80 Gall Capacity per hr / 48 Rev of Crank per Minute / Alfa-Laval Separator / Co. Ltd / 299 Sussex St. / Sydney" - on bottom side of the machinedairy; cream separator; kiewa valley; creamer family -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyMilking Cups - Dairy

... machines. The dairy industry is and has been one of the major ...This milking equipment was used in the early days of milking using machines. The dairy industry is and has been one of the major industries of the Kiewa Valley. This equipment was used on local farmers, P & R. Creamer's dairy farm.Set of early mechanical milking cups. 4 cups - 2 each side of 2 hollow metal (steel) rods which are attached to hollow rubber tubes that lead towards the main milking machine. The metal cups have black ends at the opening where they are attached to the cow. The outlet from the cups is via 2 metal tubes that lead into the rods that in turn lead to the tubes.At opening at end of cups: "Utility" possibly more but too difficult to read. milking machinery; dairy; kiewa valley; creamer family; -

Bendigo Military Museum

Bendigo Military Museumphotograph - Fortuna - 1st Year of Army Occupation in Bendigo, 1942

This is a set of 17 photographs taken during the first year of Army occupation at Fortuna, Bendigo in 1942. The photos provide an insight into the preparatory work performed on the Fortuna Villa and surrounding buildings, by the Working Party 5th Army Troop and Ordnance Training Depot, before its occupation by personnel from LHQ Cartographic Company, Royal Australian Survey Corps. The annotation on the back of Photos .9P and .10P is misspelt. The correct spelling is ‘Nell Gwynne’. The poppet head of the Central Nell Gwynne mine is still an iconic landmark in Bendigo, lying just down the road from the poppet head lookout at Victoria Hill. The Central Nell Gwynne was the premier mine of Bendigo's 1930s mining revival and is of high historical value, due to the extensive and relatively intact features which remain at the site. The annotation on the back of Photo .17P is incorrect. The location of HQ 5th Army Troop was ‘Reynard St, Coburg.’ By late 1941 as Japan extended its control throughout Indo-China, resolving the accommodation problem of AHQ Cartographic Company located in Melbourne became more urgent. The steady Japanese advance made the bombing of Melbourne no longer a remote possibility, and in accordance with a general policy of dispersion, the Deputy Chief of the General Staff, Major General Sidney Rowell instructed Major William Sarll, in the interests of security of plant and to provide against possible damage of air attack, to investigate suitable safer inland accommodation for AHQ Cartographic Company. Major Sarll inspected many properties before finding one that would meet the requirements of the Cartographic Company. In late 1941, he came to inspect Fortuna, a rambling old mansion with about fifteen acres of ground in central Bendigo. Initially there was no intention to occupy the site beyond the end of the war, although Major Sarll's report to the Director of Survey noted many advantages in moving the Company to Bendigo. Major General Rowell quickly approved the selection of Fortuna before other authorities, which were investigating the evacuation of school children, could get in ahead of the Cartographic Company. On 23 March 1942, the Commonwealth of Australia, under the provisions of the National Security Act of 1939, took possession of the house, the old battery buildings and the fifteen acres of grounds. Under Warrant Officer J. Trist’s direction, over fifty Parks and Works tradesmen completed building works necessary to accommodate the Survey Corps’ military, map making and printing requirements. The building program was still under way when the first officer, Lieutenant Ralph Westgarth, arrived in May 1942 with the advance party which received and positioned all equipment as it came up from Melbourne in semi-trailers. Once the equipment was installed the rest of the Cartographic Company completed its shift to Bendigo by 11th June 1942. The first year of the Survey Corps’ occupation of Fortuna is covered in more detail with additional historic photographs, in pages 17-22 of Valerie Lovejoy’s book 'Mapmakers of Fortuna – A history of the Army Survey Regiment’ ISBN: 0-646-42120-4.This is a set of 17 photographs taken during the first year of Army Occupation at Fortuna, Bendigo in 1942. The black and white photographs were printed on photographic paper and are part of the Army Survey Regiment’s Collection. The photographs were scanned at 300 dpi. .1) - Photo, black & white, 1942. Bendigo Parks and Works tradesmen at Fortuna. L to R: Cliff Day, Ernie Arnold, Norm? .2) - Photo, black & white, 1942. “Don” - possibly SGT Don Sutcliffe. Fortuna, Bendigo. .3) - Photo, black & white, 1942. Parks and Works tradesmen in garden at Fortuna, Bendigo. L to R: Fred & Ernie. .4) - Photo, black & white, 1942. Benny Jack Williams at Fortuna, Bendigo. Accommodation tents were erected above the lake, which later became the parade ground. .5) - Photo, black & white, 1942. Working dress - Giggle suits. Parks and Works tradesmen at Fortuna, Bendigo. L to R: Cliff and Harry on big roof. .6) - Photo, black & white, 1942. Parks and Works tradesmen at Fortuna, Bendigo. Ted on big roof. .7) - Photo, black & white, 1942. Gold crusher battery just behind Fortuna. .8) - Photo, black & white, 1942. Scene of Bendigo from Fortuna. .9) - Photo, black & white, 1942. Nell Gwynne Mine from mullock heap at Victoria Hill near Fortuna, Bendigo. .10) - Photo, black & white, 1942. Nell Gwynne Mine and crusher near Fortuna, Bendigo. .11) - Photo, black & white, 1942. Sluicing for gold at Eaglehawk. .12) - Photo, black & white, 1942. Fortuna, Bendigo taken from the far side of tennis courts. .13) - Photo, black & white, 1942. Fortuna, Bendigo & its reflection from across the lake. .14) - Photo, black & white, 1942. Fortuna, Bendigo from the fishpond. .15) - Photo, black & white, 1942. Fortuna, Bendigo. .16) - Photo, black & white, 1942. First Fortuna Football Team at unknown location. L to R: 5th Bob Wright, 11th SGT Don Sutcliffe. .17) - Photo, black & white, 1942. Working Party from 5th Army Troop and Ordnance Training Depot at Fortuna, Bendigo.Some personnel are identified. Annotated with date within photos. .1) – Annotated on back ‘Cliff, Ernie, Norm, Dec ‘42. Cliff Day - dairy farmer, plasterers’ labourer. Ernie Arnold – hard plasterer. Norm? - QM Store for tools etc. QM Store was the Stables.’ .2) - Annotated on back ‘Don. Fortuna 1942’ .3) - Annotated on back ‘Fred & Ernie. Dec 1942. Carpenters. Note the state of the gardens.’ .4) - Annotated on back ‘Benny Jack Williams Fortuna Bendigo. Tents were erected where present day parade ground is above the lake.’ .5) - Annotated on back ‘Working dress - Giggle suits. June 42. Cliff and Harry on big roof. This photo was taken as the ventilating ridge was being installed on the building housing the printing machines. The machines were installed later by civilian labour when building was complete.’ .6) - Annotated on back ‘Ted on big roof Fortuna Bendigo.’ .7) - Annotated on back ‘Gold crusher battery – Bendigo for slay heap – 1942. 12 stamp battery. Just behind Fortuna. Was working at night when the “Army” came to Bendigo. Later removed to “Coolgardie - WA. Present site of Southern Cross TV.’ .8) - Annotated on back ‘Scene of Bendigo from Fortuna. June 1942.’ .9) - Annotated on back ‘Nell Gwyne Mine from mullock heap (Victoria Hill) Sept 1942.’ .10) - Annotated on back ‘Nell Gwyne Mine and crusher September 1942.’ .11) - Annotated on back ‘Sluicing for gold at Eaglehawk. August 1942.’ .12) - Annotated on back ‘Fortuna Bendigo 1942. Taken from far side of tennis courts.’ .13) - Annotated on back ‘ “Fortuna” across the lake & reflection.’ .14) - Annotated on back ‘Fortuna from fishpond June 1942.’ .15) - Annotated on back ‘Fortuna Dec 1942.’ .16) - Annotated on front ‘X’ x2. Annotated on back First Fortuna Football Team 1942‘Bob Wright’, ‘SGT Don Sutcliffe’. .17) - Annotated ‘Working Party at Fortuna before one of the drafts’, Working Party 5th Army Troop and Ordnance Training Depot Showgrounds, now the Sportsground Bendigo’, ‘HQ of 5th Army Troop was Reynards Rd, Coburg.’royal australian survey corps, rasvy, army survey regiment, army svy regt, fortuna, asr -

Marysville & District Historical Society

Marysville & District Historical SocietyPhotograph (Item) - Colour photograph, Unknown

... machine in the Marysville Dairy in Victoria.... machine in the Marysville Dairy in Victoria.... with a milk bottle machine in the Marysville Dairy in Victoria ...A colour photograph of Tino Gianforte with a milk bottle machine in the Marysville Dairy in Victoria.A colour photograph of Tino Gianforte with a milk bottle machine in the Marysville Dairy in Victoria. The Marysville Dairy was owned and operated by a local man, Tino Gianforte and was located on Falls Road in Marysville.MARYSVILLE DAIRY/ TINO GIANFORTE/ MILK/ BOTTLE MACHINE/ 1958-1960/ 600 BOTTLES PER/ DAYmarysville, victoria, tino gianforte, northern milk transport, marysville dairy -

Kiewa Valley Historical Society

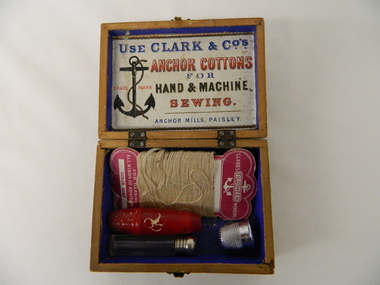

Kiewa Valley Historical SocietyBox Sewing Kit, pre 1952

This "sewing and darning" box was purchased before 1952 (the date that the Clark Brothers merged with J&P Coats). It was in an era where the production and alteration/modification to any household or personal clothing was carried out by a family member/s. This was at the period where self sufficiency in rural and especially remote areas was a requirement and not just a hobby. Clothing modifications and "hand me downs" was a way of life. The long and tiresome journey from home to millinery shops was a great force to ensure that home sewing was carried out in the majority of residential and farm areas.This sewing box was donated by a pioneer family in the Kiewa Valley. Its significance points to an era before the establishment of the Kiewa Hydro Electricity Scheme and the establishment of the Mount Beauty Township. It was a time when the rural industries of the Kiewa Valley was rich in production of beef, dairy products, tobacco leaf and before the mass of alpine adventurers that tourism sparked. It was a time rural enterprises out shone tourism.This wooden sewing box is covered with decorative paper. The lid is fastened to the bottom section with two small hinges each having four screws. Each side is fixed to the other by a mortise groove. At the front of the box is a small clasp for complete closure. The box contains needles, darrning thread, thimble, a glass vial with metal screwtop and a red plastic cylindrical container with a thimble screw on top(contains a small reel with three different cotton thread compartments).On outside lid "FROM A FRIEND. I DO NOT WISH THEE GRANDEUR, NOR YET A STORE OF WEALTH, I WISH THEE RICHER TREASURE, CONTENTMENT, PEACE & HEALTH", On inside lid "USE CLARK & CO ANCHOR COTTONS FOR HAND & MACHINE SEWING ANCHOR MILLS, PAISLEY" Each of the different sewing boxes from the Clark Bros. has a label with different "friend" passages.sewing box, hand stitching, domestic clothes alterations, haberdashery -

Cheese World Museum

Cheese World MuseumPhotograph, Unknown photographer, The first mechanical milking machine public demonstration in Allansford district, 1905

The Percy Uebergang family lived at Tooram Park, Allansford from 1912 until 1992. Percy and Myrtle Uebergang's children were twins, Ray and Joyce born in 1926 who lived at Tooram Park until their deaths, Ray in 1986 and Joyce in 1992. Neither Ray nor Joyce married and following the death of her brother Joyce set up the Ray and Joyce Uebergang Foundation which supports the local community. This photograph is part of the collection of items given into the care of the Cheese World Museum. Uebergang catalogue No. Photograph tells the story of a special celebration marking the occssion of the demonstration of the first mechanical milking machine on the Ernst Uebergang property Briarwood at Cudgee Victoria. Ernst Uebergang is inside the shed. Reported in Warrnambool Standard 5 June 1905.Photo on badly damaged brown mount board. Image depicts LKG milking machine demonstration. Dignitories, farmers and children present. Two men are inside the shed with two cows. Written on back of photo 'LKG Milking Machine Lawrence Kennedy 1902/ Mr Ernst Uebergang inside shed.'uebergang, dairy industry, rural industry, food manufacture, machinery, lkg, cudgee, briarwood, milking machine, children, cows, dignitories, farmers, bucket -

Cheese World Museum

Cheese World MuseumButter Churn, Taco butter churn, 1880 (estimated)

These glass churns came in several different sizes. A 3 and 1/2 pint vessel could churn 2 pints of cream into butter. A similar glass churn is advertised in the mail order catalogue for D & W Chandler Ltd, Melbourne. Issue No.49, page 168. Listed as 'Butter machines (Glass) Makes butter equal to the best wooden churn, and quicker. Prices-2 qts, 9/6; 3 quts, 13/3; 4 qts, 14/6 each.'Taco butter churn with square clear glass jar with round mouth and round green painted metal lid with a small wedge of airholes. The lid has a round turning mechanism with attached wooden handle. A shaft with a metal paddle goes down into the jar to beat the cream. A paper label is attached to the bottom.'Taco Burnley England' on turning mechanism on lid, 'British Foreign Pats Pending' on reverse. 'Made in England' imprinted on base. Paper label attached to base 'Kraft Foods Ltd' 'M.G.'butter, allansford, dairy industry, dairy utensils, butter churns, kraft foods ltd, taco -

Cheese World Museum

Cheese World MuseumMilking Machine, Bartram & Son, LKG Steam Operated Machine, 1906 (estimated)

... -ocean-road This machine was the first double action (suction ...This machine was the first double action (suction and pulsator) milking machine. This method is still in use today. Invented by Alexander Gillies,of Terang. The LKG milking machine is of State significance because it represents a high degree of technical achievement. It demonstrates the innovation developed by a Western District farmer, Alexander Gillies, that enabled dairy farms throughout Victoria to move successfully from hand milking to machine milking, thus contributing to the mechanisation of one of Victoria's major rural industries. Source: Cheese World Museum Significance Assessment, Lesley Alves, December 2009Cone shaped metal pail with a carry handle attached near the top and a tipping handle near the base. Removable top has pulsator mechanism which sealed the pail. Brass cover plateBrass cover plate inscribed Trade Mark LKG. Metal disc inscribed K136.dairy industry, machinery, milking machines, alexander gillies, terang -

Cheese World Museum

Cheese World MuseumMachine, rope maker, Continental Trading Corp Ltd, 1911

... 1900s. Cudgee dairy industry rope machines New Era Rope Machine ...Used on the Hunt property at Cudgee from the early 1900s.Rope making machine consisting of a circular metal disk with four rotating hooks; cogs which turn the machine are visible on the inner side; and a curved metal handle with a wooden grip on the reverse side.Continental Trading Corp Ltd, Chicago, USA. Patented July 1911. The New Era Rope Machine. Keep oiled.cudgee, dairy industry, rope machines, new era rope machine, continental trading corp ltd, ropes, machinery -

Cheese World Museum

Cheese World MuseumPump, dairy vacuum

From the dairy farm of Leon Miller, Swans Lane, AllansfordMilking machine chain driven vacuum pump made of cast iron, marked on the circular cylinder cap with an identification number.209allansford, machinery, dairy machinery, dairying, pumps, milking machines, leon miller -

Cheese World Museum

Cheese World MuseumButter printer, J Bartram & Son, c1900

The Percy Uebergang family lived at Tooram Park, Allansford from 1912 until 1992. Percy and Myrtle Uebergang's children were twins, Ray and Joyce born in 1926 who lived at Tooram Park until their deaths, Ray in 1986 and Joyce in 1992. Neither Ray nor Joyce married and following the death of her brother Joyce set up the Ray and Joyce Uebergang Foundation which supports the local community. This butter cutter is part of the collection of items given into the care of the Cheese World Museum. It was in the early 1900s for hand-use in home dairies or small factories. An example of an early butter packaging machine.Wooden Eureka brand butter printer and weigher with dovetailed corners on the bulk butter box, wooden rollers for moving butter along once cut and wire cutter.Eureka/J Bartram & Son/sole makers Uebergang No. U027butter cutters, uebergang, allansford, dairy manufacture -

Cheese World Museum

Cheese World MuseumCentrifuge, electric

This Babcock tester was used in the laboratory at the Kraft cheese factory, Allansford. When it was superseded it was passed to one of the users of the machine, Les O'Callaghan, president of the Warrnambool & District Historical Society who placed it in the historical society collection. In 2009 when the historical society premises were upgraded there was insufficient room to store the tester so it was donated to Cheese World Museum. The machine was used to test the butterfat content of milk. Prior to dairy factories coming into existence farmers made butter individually on farms. There was no need for milk testing until farmers supplied factories for payment. Payment was based on a gallon of milk weighing 10lbs (pounds) and this led to richer milk, containing a high degree of butterfat for use in buttermaking, being paid at the same rate as lesser quality milk. In 1890 Stephen Moulton Babcock, an American professor at the University of Wisconsin-Madison, developed a method of determining the amount of butterfat in milk, thus providing a standardised and fairer system for payment. Babcock Test Process 1. 18 grams of milk (17.6ml) was put into a test tube 2. The same amount of sulphuric acid was added 3. A centrifuge at 50ºC was rotated at more than 900 revs per minute 4. The fat floating on top of the liquid in the test tube was measured The Babcock Test provided fairer compensation to farmers and also helped produce a consistent product for consumers. It also allowed for selective breeding when dairy herd testing evolved. ‘The Babcock Test is so simple that it can be used by any careful person, and it is inexpensive to operate. From the very beginning it was so complete in every detail that no change has had to be made in it.’ (Babcock Test http://www.en.wikipedia.org/wki/Babcock_test 31 March 2009) Round green metal container with opening lid. Inside houses a spinning rotor with 20 test tube holders around the outside in two circular rows.7173 BABCOCKTESTER 190allansford, dairy manufacturing, milk testing, babcock test, babcock, stephen moulton, butter, warrnambool cheese and butter factory company -

Cheese World Museum

Cheese World MuseumCheese press, Perfect Cheese company

Perfect Cheese Company was founded in 1930 by newly-arrived Italian migrant Natale Paquale Italiano. The company specialised in traditional Italian-style cheese but also produced Greek, Cypriot and Maltese origin cheeses. The cheeses were sold in Australia and Italy with all products being matured and non-processed. The company remained in operation until the early 2000s.This cheese press is significant as it represents the machinery used by an early cheese production company.Stainless cheese press machine with three steel supports and two threaded rods will spring tension wheels to screw down to pressurise the hoops containing cheese.J & T YOUNG AYR UKallansford, perfect cheese company, avery, cheese manufacturing, dairy industry -

Cheese World Museum

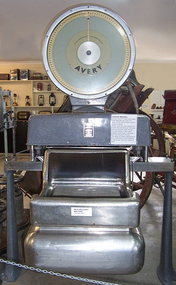

Cheese World MuseumMilk weighing machine, Perfect Cheese company weighing machine

Perfect Cheese Company was founded in 1930 by newly-arrived Italian migrant Natale Paquale Italiano. The company specialised in traditional Italian-style cheese but also produced Greek, Cypriot and Maltese origin cheeses. The cheeses were sold in Australia and Italy with all products being matured and non-processed. The company remained in operation until the early 2000s.This weighing machine is significant as it represents the machinery used by an early cheese production company.Large metal machine with cast iron with a cast iron frame and a stainless steel rectangular bowl in a cradle. The round weighing scale at the top shows a weight scale up to 1100 pounds. A mesh stainless steel baffle strains the milk.Made in England Birmingham - AVERY SOLE AGENTSallansford, perfect cheese company, avery, cheese manufacturing, dairy industry -

Cheese World Museum

Cheese World MuseumMachine - Separator, dairy, Lister CR70

... Lister CR70 Machine Separator, dairy ...dairy farming, r.a. lister and co. ltd, cream, separator -

Cheese World Museum

Cheese World MuseumExercise Book, A Carroll Exercise Book

This exercise book was donated by Donna Daly, who found it among her parents belongings. Her parents were Josie and Tich Kelly and she was unsure of the connection with A Carroll.This document is significant as it indicates records kept on-farm by some farmers. It records prices received for milk, calves, pigs and the amount of the government subsidy during this period which covers the time of World War II. It provides an interesting comparison with the Taylor milk passbook from 1895 and associated milk slips which are also held by Warrnambool Cheese & Butter Factory.Fawn coloured exercise book with pictures of old sewing machines on the front cover and Arithmetic tables on the back in blue printing. The contents include farm records from 1935 to 1945 documenting income from dairy, calves and pigs.A Carroll (front cover) A Carroll, Mepunga West (back cover) -

Cheese World Museum

Cheese World MuseumCatalogue, To Dairymen & Agriculturalists: Milk Cream and Butter

This catalogue belonged to Alderdice Brass Foundry in Warrnambool. It was donated to the museum by John Downing from the foundry. The catalogue is for the firm of J Bartram & Son who were suppliers of dairy equipment. They were one of the earliest suppliers of mechanical milking machines in Victoria.The catalogue is significant as it is from an early dairy supplier and shows early dairy equipment. The Alderdice Brass Foundry has been in operation since the 19th century.Blue covered catalogue booklet with white text and illustrations of a cow, separator, butter maker and butter slicer machines.To Dairymen &/Agriculturalists/Milk/Cream/and/Butter J.BARTRAM & SON. PTY. LTD./586-588 BOURKE ST./MELBOURNEcatalogues, dairy industry, j bartram & son pty ltd, dairy machinery, milk, cream, butter -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Clothing - Clothing, lady's silk nightgown c1930, c1930

After surviving the Depression Years many market gardeners changed to poultry farming and egg supply to build a multi million dollar industry . Women were able to follow the fashion trends even if they still made the clothes themselves. The City of Moorabbin was declared in 1934. A lady's beige silk nightgown with a lace bodice and long waist ties c1930. Bias cutsilk, machine lace, lingerie, clothing, moorabbin, cheltenham, bentleigh, early settlers, market gardeners, blackburn nance, city of moorabbin, poultry farmers, dairy farmers,