Showing 23 items matching "electric motor control"

-

Federation University Historical Collection

Federation University Historical CollectionBook, Ballarat School of Mines Proposed New Programs for 1979, 1979

... electric motor control... University Australia. ballarat school of mines courses electric motor ...Ballarat School of Mines is a predecessor institution of Federation University Australia. Yellow soft covered report with proposed new programs for 1979 at the Ballarat School of Mines. ballarat school of mines, courses, electric motor control, electrical drafting, camping and caravan park managers course, child care, record keeping for small businesses, introduction to sheetmetal, return to study -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyBook - S.E.C.V, Nilsen Switch Gear and Motor Control Equipment, 1963

Electrical workers working on the Kiewa Hydro Electric Scheme used equipment advertised in this book.The Kiewa Hydro Electric Scheme was built from the late 1940s by the State Electricity Commission of VictoriaSmall red, aqua and white cardboard covered book held together by 2 staples with 112 pages. It includes black and white photos of equipment.Trade Price List / Effective 1st May, 1963kiewa hydro electric scheme. secv. nilsen. switchboard.electricity. -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyFan - S.E.C.V

Electric fans were used for cooling rooms prior to air conditioning.This fan was used by S.E.C.V. office workers working on the Kiewa Hydro Electric Scheme. Small electric swivel fan. This heavy black metal fan has 4 curved 'wings' covered by protecting wire consisting of 2 wire rings joined by 6 curved pieces of wire covering the sides and front. Attached to the motor that can swivel and to the base is a black rubber covered electric cord. The base forms a stand with a control knob for speed and swivel options. On a plaque: Menominee / Fan Motor / 55182591 Serial No. 200 volts / ACC current 6 cycles / Menominee Electric Mfg. Co. / Menominee ..? Control knob: 0,1,2,3 along slotelectric fan; state electricity commission of victoria; kiewa hydro electric scheme; office furniture -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageInstrument - Balance Scale, Henry Crane (Crane Foundry), 1870-1900

The Crane foundry opened some time before 1827 and was known as Atherton’s Foundry, run by James Atherton and Henry Crane. Initially it was a brass foundry, but by 1827 iron castings were also produced on the site. The main products were castings for the building industry, ironmongery and brassware. In the 1830s castings for the hand tool and lock industries were added to the product range and by 1836 Henry Crane had taken control of the business. The company became known as the Crane Foundry in 1847 with its own registered trademark. By the 1850s iron weights were produced, and a design was registered in 1872 with roundels decorating the edge. Brass weights were also produced, mainly after the regulation of 1890 that required weights of 2oz. or less to be made of brass. In the early 1900s the foundry began to produce castings for electric motors and continued to do so throughout its life. The Crane family continued to control the company until 1917 when William Cyril Parkes of lock makers Josiah Parkes & Sons Limited, Willenhall became a majority shareholder. Things were going well until the company’s liabilities spiraled out of control with the rise in electricity and gas prices along with the loss of two of the company’s largest customers. The factory went into liquidation and then closed in 2006 an end to one of Wolverhampton’s oldest companies.An item made by one of England's foundry’s based in Wolverhampton that exported items all over the world for many years. The scale gives a snapshot into the commercial life not only of England by Australian colonial life before Federation.Beam scale with three weights (4lb, 2lb, 1lb), metal tray, corrodedMarked on 2lb weight "Wolverhampton Crane Foundry" flagstaff hill, warrnambool, flagstaff hill maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, scale, beam scale, pounds and ounces, imperial weight, grocers scale, domestic scale, henry crane, crane foundry -

Federation University Historical Collection

Federation University Historical CollectionObject, Synchronome Co. Ltd, Synchronome Frequency Checking Master Clock No. 2191, c1930

Information from Norman F. Dalton: Ballarat had a reticulated DC supply in the early part of last century and in 1905 had sufficient generating capacity to enable the trams to be changed from horse drawn to DC electricity. The use of electricity increased with the main power station located on Wendouree Parade, near Webster Street, under the ownership of The Electric Supply Company of Victoria. AC generating plant was installed in 1925 and conversion to AC proceeded. In 1934 the company was taken over by the State Electricity Commission Victoria (SECV) and more AC generation was installed and the changeover of customers was accelerated. This is around the time that the Synchronome Frequency Checking Mast Clock was installed at the Wendouree Parade Power Station. The SECV Annual Report of 1921 states: ::Section 11 of the act directed the COmmission to enquire into the question of securing the adoption of such standards of plant and equipment of a system, frequency and pressure for the generation and distribution of electricity as will admit of the efficient interconnection of undertakings throughout the State. In 1934 when the SECV took over the Ballarat operations the question of linking with the State grid had been a planned operation for some years but due to financial considerations had hindered it and in fact would continue to do so for a further 10 years. So while the need for close frequency control for interconnection was hardly an issue, the need to keep electric clocks correct was important, particularly as this item was a frequent sales point to cover the inconvenience and sometimes expense of converting from DC to AC. The clock is a very accurate pendulum clock with provision for varying effective length during operation for precise time regulation. There are two normal time dials and one is controlled by the pendulum and the other is operated by the system frequency. When the clock was in use it was installed by the MEter and Tests Laboratory and the time was checked daily by radio time signals. The two dials were repeated in the operators control panel in the Power Station. A maximum deviation between the two dials was set in the operating instructions (eg 5 seconds) and the operator would correct this when necessary by remote manual alteration of the turbine governor set point. The clock was used to drive and regulate a system of "slave" clocks which were used to display the time in various locations around the power station. A slave clock is a simple clock which is driven by a small electric motor, its accuracy is regulated by the master clock every 30 seconds to ensure that it and all the other slave clocks in the station are on exactly the right time; slave clocks were placed in various locations, from common rooms to workshops. A master clock could potentially run thousands of slave clocks at one plant. The clock also contains a rectifier. A rectifier is a device that is used to convert AC power to more stable DC current.Two clocks in a timber case. Both are electric, one is powered by the main pendulum mechanism, the other is a self contained electric clock. The main mechanism is of the gravity arm and roller type, which sends an impulse to the slave clocks every 30 seconds. The This Synchronome Frequency Checking Master Clock was used at the Ballarat Power Station. Below the main section of the case is a smaller cabinet containing a rectifier to provide consistent DC power for the clock. The rectifier was made by the Victorian company Hilco, which was located in Burwood. There is a high chance this is not the original rectifier from this clock as there appears to be brackets to hold a larger device in the space the rectifier occupies.Front below main clock face on front of case: "Patented Sychronome Brisbane" Lower left-hand clock face: "Frequency time" Lower right-hand clock face: "Standard Seconds" Synchronous electric clock mechanism on door (Frequency time clock): >200/250 V. 50~ >"Synchronomains" Made in England >Direction indicator for clock starting switch >"To start move lever in direction of arrow and release" >"Patent applied for" Mechanism for "standard seconds" clock: >"English Made" >"Patented" >Serial number "321" >0 above right-hand pillar on front-plate Mechanism for "standard seconds" clock: >"English Made" >"Patented" >Serial number "321" >0 above right-hand pillar on front-plate Mechanism for main clock face: >"English Made" >"Patented" >Serial number "8751" >0 above right-hand pillar on front-plate Inside case, back panel, top enamel plate: >Seconds Battery + Pos. > Battery Common or - Neg. >1/2 min dials Inside case, back panel, bottom enamel plate: external seconds dial Inside case, right hand side, electrical knobs: two switches, both "A.C. mains" Pendulum rod, below suspension spring: Serial number (?) 0000005 Rectifier in bottom cabinet: >"Hilco Rectifier" >"A.C. Volts 230/240" >"Model 1060/S" >"A.C. Amperes" >"Serial No. 1060/S >"Phases 1" >"D.C. Volts 6" >"C.P.S. 50" >"D.C. Amperes 1" >"Made in Australia by Hilco Transformers McIntyre St., Burwood, Victoria." Bakelite electrical plug: makers mark Lower cabinet, RH side panel, pressed tin plate: "AC" (upside down) Brass speed adjustment, outer right RH side: "S" and "F" Ivory and wood pendulum beat ruler: >Ruler, with 0 in centre and numbers 1-5 in ascending order from centre on left and right. > "Synchronome Patent." Steel plate, back panel, inside case, right hand side: >N R A" (descending) >"2191" serial number/part number Face of main clock: "Synchronome Electric" synchronome frequency checking master clock, electricity, state electricity commission, wendouree parade power station, secv, clock, time, pendulum, electric supply company of victoria, norman f. dalton, ballarat power station, rectifier, slave clock -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Tilting Saw Bench, W F & John Barnes, 1874 to 1880

he subject item is a pedal-powered rip saw with a tilting table made in the USA by W.F. & John Barnes Co. of Rockford, Illinois, between 1874 and 1890. The saw's blade moves rapidly in a circular motion and is driven by a pedal that spins a heavy flywheel with a leather belt attached to a gear drive that in turn drives the circular saw blade. The operator holds a wood workpiece on the table and moves it forward so the blade cuts it to the desired width and length. Company History: WF & John Barnes Co. was established in 1869, by making a formal partnership between William F. Barnes and John Barnes in 1872, and then incorporating in 1884. This company was an early manufacturer of pedal-powered equipment. By 1881 they were also making powered machinery such as lathes and pedestal drills. Many companies were making lightweight foot-powered equipment, but Barnes and the Seneca Falls Co. were the only ones to also make professional-grade workshop machines. From the beginning of their existence, they focused on pedal-powered machinery and specialised in making scroll saws. By 1937 the company focus had completely shifted to automotive assembly machinery, and custom-built machinery, machine tools, electrical, hydraulic, and mechanical controls and systems, including nuclear hardware. their production of foot-powered machinery had ceased. In the intervening years, they have got out of manufacturing completely. After a series of ownership changes, their equipment parts and stock were purchased in 1998 by LeBlond Ltd. of Amelia, Ohio. An item that although incomplete gives a snapshot into the manufacture and use of early woodworking machinery before the introduction of electricity or electric motors to power machines.A Treadle powered tilting table saw benchWF & J Barnes, Rockford Ill USA flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

The Ed Muirhead Physics Museum

The Ed Muirhead Physics MuseumMicrotome/W... (H.A. Waters)

Microtome for cutting resin embedded tissues for electron microscopy. In 1957 a modified hodge microtome redesigned and built by H.A. Waters of the Melbourne University Department of Physics was acquired. The Waters microtome is of thermal expansion type - the rod “A” is heated and by expansion pushes the resin block forward by a fraction. It is mounted on a long cast iron base. The movement of the block is eccentric drawing the specimen away from the knife after cutting, The glass knife ‘B’ is adjustable by means of a modified microscope column screws ‘C’. The microtrome is driven by a continuous action electric motor mounted on the common base. Hand cutting can also be done. The cutting was controlled by viewing through a Leitz Binocular microscope mounted on the same base. The original microscope was subjected to nine modifications by Dr S Weiner from whose PhD Thesis (1962) ‘Electron Microscopical Studies of the Liver’ this information was obtained. (text provided by Professor H Attwood) Microtome made of metal and enamelled in light blue. Components are identified by the use of stick on labels. The microtome is mounted on a long cast iron rectangular base and has an electrical cord for connection to a power point.Plaque on back: “Pathology Department, University of Melbourne Serial No. 0091. Date: 7/7/1968” -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Machine - Sewing Machine, 1941-42

Used by donor in family home.Portable electric singer sewing machine, rotating shuttle. There is a separate knee action control lever. Serial no. EG588844 .Black base with gold decoration. The wooden case top has 'Singer' on front. Motor K605945Singerdomestic items, sewing, textile machinery -

Ballarat Tramway Museum

Ballarat Tramway MuseumManual, Doug Prosser, "General Electric Data for Car Equipment Maintenance", 1998

A black plastic folder containing a set of 38 General Electric Data Sheets for MMTB and tramway trust equipment, dated July 8 1924. Contained in folder with flexible clips. Pages have been punched with four holes. Copy of document made for BTM Feb 1998 by Doug Prosser. For scan of list - see btm780sheet.pdf General Electric Data for Car Equipment Maintenance Contents For scan see btm780d1 (5 pages) Title sheet Data contents summary sheet showing manual prepared for Melbourne & Metropolitan Tramways Board Including Footscray Tramway Trust Hawthorne Tramways Trust Melbourne, Brunswick and Coburg Tramway Trust Prahran and Malvern Tramways Trust. 2 sheets dated July 8, 1924 giving equipment schedules for the various operators, and diagrams. - hard to read the background sheet information. Does not reference the tramcars. For scan see btm780d2 (54 sheets - items 1 to 27) 1. Methods of Removing the Armature from Box Frame Railway Motors Dated 9/1924, 7 pages 2. Instructions for order Magnet Frames for Railways and Mine Haulage Motors 2 pages, not dated 3 Winter Covers for Ventilated Railway Motors - 2 pages 4 Better Commutation for Railway Motors - 1 page 5 Commutator Grooving Machines - 1 page 6 Railway Motor Armature Coils - 2 pages 7 Carbon Brushes for Railway motors - including brush pressure adjustment - 2 pages 8 Renewable Carbon-Way Brush holders for Railway Motors - 2 pages 9 Commutator Grooving Machines (2nd version) - 2 pages 10 The Repair of Railway Motor Commutators - 3 pages 11 Dimensions of Electrical Apparatus used with 600-volv Type PC railway control equipment, (Sheet 15380, dated 2/1/1924) - 1 sheet including · US-13-E Trolley Base, · MS-118-A main switch, · MA-13-F Fuse Box, · MD3 - lightning Arrester, · BJ-386-B Distributing Box, · Type BG Railway Resistors. 12 Connections of Type KM-63-BR Railway Controllers and Equipment - Drawing 15257, 1 page, dated 1/3/1921 with dimension details on rear of type K-63-BR railway controller equipment including: · SG Resister, · BK-13-A Insulator, · MR11 - Circuit breaker, · MD3 - Lightning Arrester box, · K63-BR Controller, · US15C Trolley Base. 13 Method of Supporting Railway Resistors using Porcelain Bolt insulators for 600 and 1500 Volt Work. Drawing dated 1/11/1923, No. 15249B - 1 page 14 Dimensions of Electrical Apparatus used with 600-volv Type M railway control equipment, (Sheet 15381, dated 2/1/1924) - 1 sheet including · US-13-E Trolley Base, · MS-118-A main switch, · MA-13-F Fuse Box, · MD3 - lightning Arrester, · BJ-386-B Distributing Box, · Type BG Railway Resistors. 15 Dimensions of Electrical Apparatus used with 600Volt, Type PC Railway Control Equipment. Drawing No. 15382, dated 2/1/1924. Includes: · C129-A Master Controller, · DA82C Coupler sockets, · MS-14-G switch, · MS-46-H switch. 16 Dimensions of Electrical Apparatus used with 600-volv Type M railway control equipment, (Sheet 15383, dated 2/1/1924) - 1 sheet including · C-169-A Controller · DA-69-B Coupler Socket and DC-66-C Coupler Plug · MS-14-G Switch · MS-46-H-Switch 17 Method of Making Tap Connections for Car Cables -= SD 15468, 1/11/1924, 1 page 18 The Repair of 600 Volt Railway Motor Armatures, 64408, 9/2/1924, 4 pages 19 Proper Method of Mounting and Dismounting Railway Motor Pinions. - 2 pages 20 Pinion Pullers for Railway Motors - 2 pages, dated 8/1/1924. 21 The Care of Railway Motor Bearings - 4 pages 22 Oil Scraper Rings for Air Compressors - 64590 - May 1924 - 1 page 23 Finger Bases for type K 63 controller 1 page 24 Adjustment of Drum Controller fingers - 29/1/1924, 64600A - 1 page 25 Star Wheels for Type K Controllers - 64603 - 1 page 26 Soldering Aluminium Controller Cylinder Castings - 2 pages 27 Porcelain Bolt Insulators for Railway Service - and drawing on rear showing mounting arrangement of resistor Grids - 2 pages. For scan see btm780d3 (13 pages) 28 Connections of Armature and Field Winding for GE-201-F and GE 263A railway motors. DS37869 29 Connections of Armature and Field Winding for GE-201-I railway motors. K1629303 30 Connections of Armature and Field Winding for GE-202 motor, DS 10472 31 Connections of Armature and Field Winding for GE-203 A and GE 226 railway motors. DS23869. 32 Connections of Armature and Field Winding for GE-241 motors - K1629077 33 Connections of Armature and Field Winding for CP25A Air compressor 34 Connections of Armature and Field Winding for CP27A Air compressor 35 Connections of Armature and Field Winding for GE-258 and GE 264 railway motors. K1629343. 36A- Dimensions of Type K-63-BR Railway Controller Equipment 36 US-13-E Trolley Base for Railway Service - 3/1/1923, 64823 - 2 pages 37 Copy of M&MTB (Eastern System) Certificate of Competency as Motorman. 38 Photocopies of a series of four photos of 22E trucks under an SEC tramcar. For scan see btm780d4 (40 pages) 39 Sprague G-E Multiple Unit Control, Type PC, Instruction Book 84772 - Oct. 1922 - 40 Pages. Images of sheets added 2-11-15 trams, tramways, general electric, motors, controllers, trolley pole bases -

Ballarat Tramway Museum

Ballarat Tramway MuseumDocument - Instruction Book, Westinghouse Brake Company of Australasia Limited and The Westinghouse Brake & Saxby Signal Co. Ltd. of 82 York Road and Kings Cross London, "Westinghouse Railway Operating Data", 2000

Photocopy of 54 data sheets published by Westinghouse Electric & Manufacturing Company of East Pittsburgh Pa, USA c1920. Consists of plastic cover, header page with Westinghouse logo, contents sheets (2 pages), forward, 67 pages (single side photocopy) and heavy rear card cover bound with a green comb binder. Original material lent by Craig Tooke of the Melbourne Tramcar Preservation Association at Haddon. Photocopied by Warren Doubleday March 2000. List of contents produced 30/6/2000 and then bound. Contains data sheets regarding motors, commutators, brushes, armatures, bearings, field coils, pinions, lubrication, air piping, axle collars, resistance grids, gear cases and other technical information. Westinghouse Railway Operating Data 30/6/2000 List of Contents Page No. Care and repair of commutators 1 Undercutting commutators 2 Railway Motor carbon brushes 3 Brush holders 4 Flashing of railway motors 5 Soldering railway armatures 6 Armature Winding 7 Banding armatures 8 Railway Motor Bearings 9 Lubrication of railway motor bearings 10 How to babbitt motor bearings 11 Oil, grease and waster for motors and gears 12 Saturation of motor bearing waste 13 Testing Polarity of Field Coils 14 Charging of storage batteries on Interurban & street rail cars 15 Precautions to be taken with blower installations on motor cars 16 Putting on Railway Motor Pinions 17 How to take armatures out of box frame motors 18 Dipping and Baking of Railway Motors 19 War time dipping and baking outfits 20 Dipping and baking railway motors will decrease troubles 21 Protection of Motor Bearings from Dust 25 Winter Operation of Railway Motor equipments 26 Installation of Air piping to prevent freezing 27 Maintenance of Traction Brake Equipment 28 Maintenance of controller fingers and contacts 29 Hand operated circuit breakers 30 Railway Motor Testing I 31 Railway Motor Testing II 33 Railway Motor Testing III 35 Railway Motor Testing IV 36 Railway Motor Testing V 37 Removing and replacing railway motor armature shaft 39 Mounting and Maintenance of car resistors 40 Lubrication of control apparatus 41 Maintenance of fuse boxes for railway service 42 Does it pay to dip and bake armatures 43 Dipping and Baking as a financial asset 44 Shop Organisation 45 Tinning Malleable Iron Bearing shells 46 Life of armature bearings or railway motors 47 The assembly of complete sets of commutator segments 48 Electric welding as a factor in reclamation 50 Metal to Metal press, shrink and clamping fit allowances 52 Life of railway motor carbon brushes 54 General information of grid resistance design for the operating man 56 Stopping a car by braking with the motors 57 Railway Motor shafts and their maintenance 58 Axle collars 59 Gear cases 60 Ventilated railway motors 62 Revamping Loose armature bearings 64 Life of axle bearings of railway motors 65 Heat-treated bolts for railway service 66 Document imaged over 7 parts 7-9-2016 - see hi res files. trams, tramways, westinghouse, motors, data sheets, technical information -

Ballarat Tramway Museum

Ballarat Tramway MuseumSlide - 35mm slide/s, Travis Jeffrey, c1962

Agfa plastic mount (blue base, white cover) of a photograph of No. 36? Lydiard St Nth, before Provincial Hotel. Photo taken c1962. Has S.F. Motors (Mercedes Benz) dealership, the front verandah of the Provincial Hotel, ?? Commercial college and the Union Fidelity Trustees building in the background. Tram has a roof advertisement for the SEC "Everything's under control in my all electric kitchen". Slide rescanned at 3200 dpi 25-10-2020, jpg replaced, tiff file retained. This file was scanned in 2003 and may show colour changes."BAS 37" in penciltramways, trams, lydiard st north, sf motors, tram 36? -

Ballarat Tramway Museum

Ballarat Tramway MuseumSlide - 35mm slide/s, Travis Jeffrey, late 1960's

Agfa plastic mount (blue base, white cover) of a photograph of No. 33 southbound in Lydiard St Nth crossing Mair St. Photo taken late 1960's. Has Howard Smith building in the background and other buildings on the east side of Lydiard St. North and the rail level crossing gates. Photo taken from a motor car, just after sunset. Tramcar has Eureka Roofing tiles and Everything's under control in my all electric kitchen roof advertisement. Slide rescanned at 3200 dpi 25-10-2020, jpg replaced, tiff file retained. This file was scanned in 2003 and may show colour changes."BAS 47" in penciltramways, trams, mair st, lydiard st nth, tram 33 -

Wodonga & District Historical Society Inc

Wodonga & District Historical Society IncFunctional object - Singer Electric Sewing Machine, The Singer Manufacturing Company, 1950

Singer was first established as I. M. Singer & Co. in 1851 by Isaac Merritt Singer with New York lawyer Edward C. Clark. Best known for its sewing machines, it was renamed Singer Manufacturing Company in 1865, then the Singer Company in 1963. The Singer company began to market its machines internationally in 1855 and won first prize at the Paris world's fair that year. They had offices established in both Sydney and Melbourne by the mid-1960s. The company demonstrated the first workable electric sewing machine in 1910. Singer was also a marketing innovator and a pioneer in promoting the use of instalment payment plans, making their machines more affordable for many people. According to its serial number, this machine was manufactured in 1950 and was one of the new models designed to be more portable as it only weighed about 10 KG.This sewing machine is of local, national and international significance as it represents developments in technology and the impact this had upon the work of women.The Singer 99 was a sturdy and reliable machine that was easy to use. Lighter than other machines of its time, this machine weighed only 10 Kgs. It is mounted on a wooden base with a small compartment under the balance wheel to store accessories and bobbins. It has a 'Bentwood' (polished plywood) cover which also provided some room for storage. The machine is driven by a small electric motor and a light to illuminate the work area. It is decorated with gold decals and a filigree pattern. It includes a knee control which is inserted in a hole at the front of the machine. The serial number EG045782 indicates it was manufactured in 1950.Across the top in gold script: "The Singer Manufacturing Co. / Made in Great Britain" On light cover: "SINGER" Plate with specifications also attached. On front of machine in oval badge: A CENTURY OF SEWING SERVICE/ THE SINGER MANFG. CO. 1851 - 1951singer sewing macnine, domestic appliances, women's work, technology -

Melbourne Tram Museum

Melbourne Tram MuseumDocument - Personal Papers, John Prideaux, "Details of the Comeng Trams", 1975

Handwritten draft on ruled Foolscap folio sheet, folded in half and written on three of the four sides, titled "Details of the Comeng Trams". Could have been written by John Prideaux for the AETA Electric Traction. Gives details of the tram, designer, seating, doors, ASEA Equipment, motors, control equipment, braking, resilient wheels, testing. The final page is about the history of the East Preston and East Brunswick Routes.trams, tramways, z class, new trams, w7 class, 1041, prototype tramcar, bogies, trucks, asea, brakes, comeng, electric traction, aeta -

Melbourne Tram Museum

Melbourne Tram MuseumNewspaper, The News Adelaide, "Ways of Transport - City Tramways Indispensable - Favours Not Sought", 15/11/1926 12:00:00 AM

Newspaper clipping - from The News Adelaide, 15 Nov. 1926 (checked by searching Trove), titled "Ways of Transport - City Tramways Indispensable - Favours Not Sought". Notes the remarks made by Mr. W Riddell, Chairman of the MMBW who said electric tramways were obsolete. Quotes response by Mr. W Goodman who gives information on London congestion, journals issues with buses and motor vehicles. Item was pinned to Reg Item 3876.Has ink on top "The News"trams, tramways, tramways, electric traction, adelaide, mmbw, traffic control, london -

Melbourne Tram Museum

Melbourne Tram MuseumDocument - Radio Transcript, Melbourne & Metropolitan Tramways Board (MMTB), "Draft Wireless Report 28th May 1926", May. 1926

Radio transcript - 11 foolscap sheets, typed, titled "Draft Wireless Report 28th May 1926" of a talk possibly by the Manager Mr. Murdoch as it mentions the Assistant Manager Mr. Young. Document is a draft with pencil alterations and figures or numbers outstanding, some have been written in. Provides notes on running control, tickets, employment, training of both cable and electric drivers, driver training, Hawthorn school, braking, conversion from cable to electric driving, conductor training, monitoring of the services, rosters preparation, fare collection, speed of services, tram stops, passenger behaviour, issues with motor vehicles, collisions, accidents, safety and costs of extensions.In blue pencil in top right hand corner appears to be "Assist Mgr"trams, tramways, traffic staff, operations, training, radio stations, drivers, conductors, rosters, tickets, behaviour, accidents, safety -

Melbourne Tram Museum

Melbourne Tram MuseumDocument - Report, F R Thompson", "PCC - by F R Thompson", early 1960's

Report - four pages - stapled in top left hand corner, titled "PCC - by F R Thompson", describing the control systems in a PCC tramcar, eg No. 980. Refers to drawings that are not included. Describes the control circuits, car drive, equipment, electric brakes, emergency dynamic braking, and service braking.trams, tramways, tramcars, controllers, electrical engineering, electrical equipment, motors, electric traction, pcc -

Melbourne Tram Museum

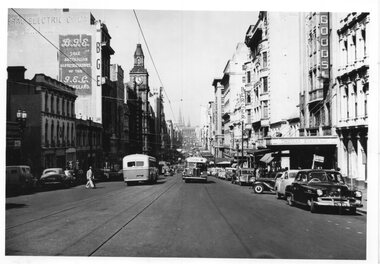

Melbourne Tram MuseumPhotograph - Set of 3 Black & White Photograph/s, Public Transport Corporation (PTC), early 1950's

Set of three black and white prints of Bourke St, early 1950's with extensive traffic photographed in the afternoon. Photos have the cable tram track, GEC Australia (General Electric), BGE, Coles and Garrard, Myer, Post Office, Berger Paint, London Stores, Foys .1 - Looking east from about Queen St at 4pm, with two Mk 3 buses. - PTC H188 .2 - ditto with a double deck bus east bound at 215pm, PTC H189 .3 - ditto at 3pm, nearer to Elizabeth St with multiple double deck buses in the block between Elizabeth and Swanston St and extensive motor vehicle traffic. This print has been photographed from an image - has a screen. Photos maybe MMTB origin to show traffic levels in the streets. Photographed prior to the removal of double deck buses in Bourke St by January 1954. All have PTC Copyright Stamp on rear.trams, tramways, bourke st, elizabeth st, buses, double deck buses, post office, traffic control -

Melbourne Tram Museum

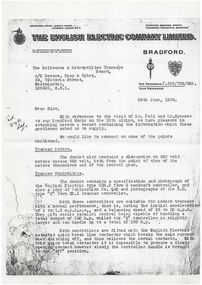

Melbourne Tram MuseumLetter, English Electric Co Ltd, English Electric Co Ltd of Bradford, Jun. 1938

Photocopy of a letter (four A4 pages of an unknown number of pages), from the English Electric Co Ltd of Bradford dated 29/6/1938, addressed to the MMTB via Heap and Ryley London. Follows the visit of Mr Bell and Mr Spencer to the Bradford works. Has notes on Tramway Motors, controllers, notch regulators, multi-notch remote control, trolley slider heads and Bow collectors. Refers to enclosures but not found with the document.trams, tramways, english electric, motors, controllers, trolley poles, bow pantograph -

Melbourne Tram Museum

Melbourne Tram Museumdrawing - Folder with papers, Melbourne & Metropolitan Tramways Board (MMTB), "PCM Tram Equipment", 1970's?

Foolscap Manila Folder titled "PCM Tram Equipment" with the following papers secured with an Arnos binder. Many of the documents seem to have been copied onto heat sensitive paper. Have tissue paper separating them. 1. Wiring Diagram - GE PCM Control Equipment - R4284B. 2. Westinghouse - Load test on Repair Railway Motors 3. Letter to Chief Engineer MMTB from Australian General Electric - 23/7/1935 - re delivery of 15 cases of PCM Equipment by ship and attaching drawings. 4. Drawings and maintenance notes for above - includes field shunts, magnet valves, cases, 5. GE Specification Ry-5313 - General Electric PCM Control for 4-40HP 600Volt Motors with Shunted FieldsOn rear cover in ink "To Norm Cross"trams, tramways, electro pneumatic, pcm, controllers, general electric, mmtb, tramcars -

Melbourne Tram Museum

Melbourne Tram MuseumFunctional object - Tramcar component, C. Brose Wuppertal Germany, Set of destination indicator equipment that was fitted to Z3 and A class trams, c1985

Set of destination indicator equipment that was fitted to Z3 and A class trams. Each item consists of various electronic parts contained within a metal case that could have been cabled together. Equipment manufactured by (Carl) C. Brose of Wuppertal Germany and maintained by Font Electronics of Melbourne - some items have the manufacturers details on them along with the details of the maintenance company and serial numbers etc. Photo .1 - shows the set of equipment as placed on display in the training room. .1 - set of two route number boxes, three individual controlled blinds, driven by a motor and control gear. Has a Fluro light fitted internally. See images .2 to .5 .2 - Small side destination indicator, with driven blind, electronic equipment with motor on the underside of the box - for use in Z class trams - see images .6 to .9 .3 - as for .2, but with motor mounted right side, used in A class trams, see images .10 to .12 .4 - set of two control panels with selection equipment for selecting the destination (by number) and route number with indicators and start button - see image .13 to 14 .5 - set of two long main rolls indicators, with control gear and Fluro light internally, driven by an internal electric motor - see images 17 and 18 .6 - set of two linking mechanism for the various boxes with large cables cut off for each of the four tram boxes. Would have been control panel item .4 - see image 15 and 16. See e-mail from Simon dated 17/11/2014. See reg Item 4617 for a small side destination roll.trams, tramways, destination indicators, a class, z3 class, transport equipment -

Ballarat Tramway Museum

Ballarat Tramway MuseumDocument - Ballarat Tramways - Training notes - Preliminary Draft, State Electricity Commission of Victoria (SECV), Sept. 1947

Set of draft notes or points for the training of motormen. Covers tramcar electrical equipment, defects, cutting out motors, tramcar braking, failure of brakes, emergency braking, automatic braking (dead man controls), electric signals, general instructions running in trams, tram stops, preparing trams, derailments and track cleaner tram. Dated 29/9/1947, has initials "AVM:VM"Yields information and demonstrates a set of draft training notes for tram motormen in Ballarat.Twenty foolscap typed sheets and one handwritten quarto sheet.secv, ballarat, trams, tramways, sec, tramcar equipment, motors, employees, training, motormen -

Melbourne Tram Museum

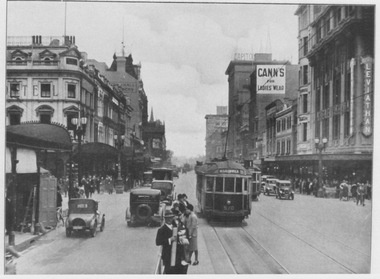

Melbourne Tram MuseumPhotograph - W2 tram 570 in Swanston St, 1930-31

Photograph looks southward along Swanston St as intending passengers stand on the safety zone at Bourke St. W2 570 with destination "Elsternwick, route 1" has just departed the safety zone and obscures another W2 travelling in the opposite direction. The street is busy with pedestrians and motor cars and new traffic lights (1928-29) control the intersection. The Leviathan Department Store can be seen to the right and workmen's ladders and equipment can bee seen far left. W2 570 was built in 1929 and fitted with newly adopted route number boxes. The W2 it is passing does not appear to have route number boxes fitted yet, which dates the photo to c1930-31.Yields information about early electric trams along Swanston St Black and white print with no note.swanston st, w2 class, 570, route number boxes, bourke st, safety zone, leviathan, elsternwick, route 1