Showing 174 items matching "furnaces"

-

Federation University Historical Collection

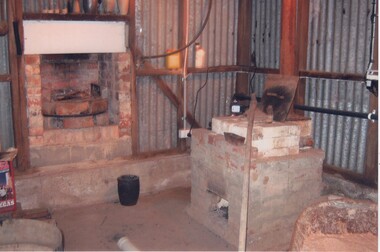

Federation University Historical CollectionPhotograph, Clare Gervasoni, Clunes School of Mines furnaces, 2003

... Clunes School of Mines furnaces...furnaces ...The Clunes School of Mines was a division of the Ballarat School of Mines. Interior views of the furnaces inside the former Clunes School of Mnesclunes school of mines, furnaces, metallurgy -

Federation University Historical Collection

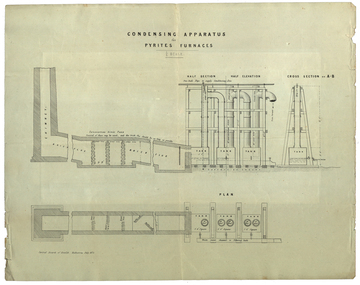

Federation University Historical CollectionPlan, Central Board of Health, Condensing Apparatus for Pyrites Furnaces, 07/1873

... Condensing Apparatus for Pyrites Furnaces ...Possibly linked in some way to Patent for the Ballarat School of Mines self-acting Pyrites Furnace.Printed plan for a condensing Apparatus for Pyrites Furnacespyrites, pyrities, pyrites furnace, condensing apparatus -

Buninyong & District Historical Society

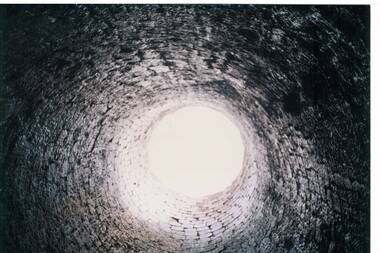

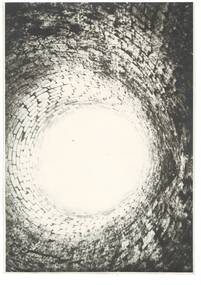

Buninyong & District Historical SocietyPhotograph - Colour photograph of interior of Lal Lal Blast Furnace, Interior of Lal Lal Blast Furnace

The Lal Lal Blast Furnace ruins is the only one from the nineteenth century remaining in Australia and represents the only attempt to smelt iron ore in VictoriaThe Lal Lal Iron Mining Company was formed in 1874 and reached its peak in 1884 when 160 men were employed View of interior of Lal Lal Blast FurnaceInside the Lal Lal Blast Furnace 1991lal lal, blast furnace, iron ore smelting, industrial history, mining -

Federation University Historical Collection

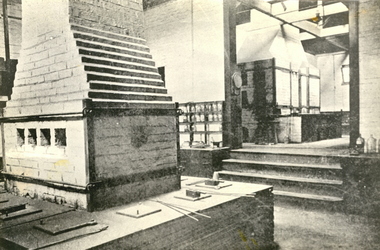

Federation University Historical CollectionPhotograph - Photograph - Black and White, Ballarat School of Mines Assay Room, c1900, c1901

The depicted Ballarat School of Mines Assaying Furnace probably dates back to the mid 1890s. The photo first appears in the Ballarat School of Mines Calendar for 1900, but references to these facilities were mentioned in 1887. These facilities were updated and expanded on several occasions. Black and white photograph of the assay furnaces at the Ballarat School of Mines. The Assay-room contained 16 smelting furnaces, 16 muffle furnaces fro coke, charcoal, bituminous coal and gas, and featured all the usual tools and appliances. There was an adjoining weighing room.ballarat school of mines, scientific equipment, assaying, laboratory, mining -

Federation University Historical Collection

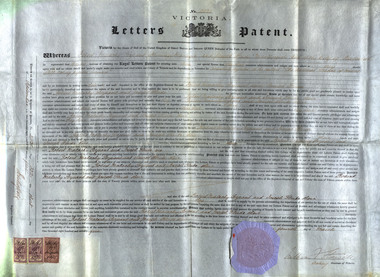

Federation University Historical CollectionDocument, Letters Patent for an Invention for Roasting Pyrites, 1875, 1875

R.M. Serjeant was listed as a mining manager and Joseph Flude as a metallurgist. In 1875 they were both living in Ballarat. The patent number is A.D.1875, 4th March. No 2031. According to the patent the hearth of the furnace is in the form of a cone revolving horizontally. The feed is supplied to the apex of the cone by an archimedian screw. The crown of the furnace comprises a double covering or roof with an intermediate chamber for receiving heated air. The inner covering is pierced to admit of the heated air being brought into contact with the pyrites on the face of the revolving hearth. The discharge of the roasted substance is affected by means of a scraper at the base of the cone. It was claimed that this was a new mode of introducing heated air, and the exclusion of flame during the operation of roasting pyrites. The self-acting charge and discharge of the furnace and the peculiar construction of the hot air chambers, and the use of perforated bricks through which the supply of air is affected were also new. (http://patentsvictoria.net/002031.html) From the Goulburn Herald, 14 September 1878 "A feature connected with the school of mines is the yet unfinished pyrites works. The extraction of the gold from pyrites and the utilization for commercial purposes of other substances connected with pyrites are peculiarly important to Ballarat, because were a simple and inexpensive method devised there are millions and millions of tons of quartz that would then be made remunerative. With this thought in their minds two scientific gentlemen invented the school of mines self-acting rotatory furnace. This, for lack of funds, has not been completed as yet, but the amount in hand for the purpose is daily increasing, and it will eventually be an accomplished fact. It is in contemplation also to erect machinery shops in connection with the school, and it is purposed to con struct a steam-engine to do at once the work of the pyrites treatment and the ma chine room. A model shaft and mine too are being prepared for on the reserve, so that practical mining of the most thorough character may be taught on the ground.'Letters Patent for an Invention for Roasting Pyrites to be called 'the Ballarat School of Mines Self-Acting Pyrites Furnace' to Robert Malachy Serjeant and Joseph Flude. The large document is on a vellum type paper complete with stamps and seal. The document is signed by Acting-Governor William Stawell.Written on verso: "Date of Patent 4th March 1875 No 2031 Letters Patent for An invention for roasting pyrities to be called "The Ballarat School of Mines Self-acting Pyrities Furnace" to Robert Malachy Serjeant and Joseph Flude Melbourne, Victoriaballarat school of mines, serjeant, r.m. serjeant, robert m. serjeant, flude, joseph flude, richard gibbs, stawell, william stawell, pyrities furnace, philately, statute stamp, seal (victoria), ballarat school of mines self-acting pyrities furnace, ballarat school of mines self-acting pyrites furnace -

Rutherglen Historical Society

Rutherglen Historical SocietyImage, c1990

This photograph shows the pre-heater on the left and the furnace on the right. After clean up of stamper table, amalgam is placed in a retort, then placed in the furnace where mercury is condensed and runs down the small pipe into an enamel bucket and can be reused. This is one of a series of photographs of the Rutherglen Gold Battery. The battery's purpose was to crush quartz from nearby quartz reefs and extract gold from within. The battery was erected in 1908 and consists of a five-head battery, Wilfrey table, Bergin pan, portable steam engine and shed. The battery was restored in 2011/12 and can be viewed daily between 9.00am and 5.00pm. See website for details.Colour photograph of the interior of a room with corrugated iron walls, with a fireplace on the left and a furnace on the right.gold battery, gold processing -

Federation University Historical Collection

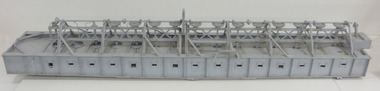

Federation University Historical CollectionUnknown - Model, Edwards' Ore Reduction Furnace Model, pre 1924

This model of a mechanical ore roasting and chloridising furnace was invented and patented by Thomas Edwards of the Edwards Pyrites Smelting and Ore Reduction Company. This new type of furnace produced a high standard of sulphur free ore known as ‘sweet roasted’. Edwards used this model for demonstrations in the USA. Of note is the central large vertical cogwheel (externally driven) which drives small vertical cogwheels via angled cogging drives. These in turn drive a horizontal wheel. Each side of the vertical wheel is set on an opposite side to the horizontal wheel of its neighbours, resulting in opposite direction rotation of neighbouring horizontal wheels. Each horizontal wheel turns a rabble (set of vertical iron paddles) within the furnace. These rabbles, each turning in opposite direction to its neighbours, move the roasting ore in a zig-zag path through the furnace. The elongated furnace with its line of rabbles produced a much ‘sweeter’ roasted ore than could be obtained from a typical tank-shaped furnace. In 1924, when the model was donated to the Ballarat School of Mines, Ballarat’s Courier newspaper reported, ‘Apart from its historical and education value, the gift should serve to stimulate the inventive faculties of the students who have to win fame for the school and for themselves in the metallurgical world.’ The furnace model was donated to Ballarat School of Mines and used as an educational prop from 1924. The model relates to the mining industry which is a significant part of Ballarat's history and heritage. Ballarat School of Mines is the oldest Technical School in Australia and is celebrating 150 years in 2020.Metal model of Edwards' Ore Reduction Furnace. The model includes cogwheels, rabbles and other details. Scale is thought to be around 1:20M259ballarat school of mines, edwards, pyrites, ore reducation, edward retallack, mining, model -

University of Melbourne, School of Chemistry

University of Melbourne, School of ChemistryMetal Burner Tube

Metal Burner Tube, for Furnace. -

University of Melbourne, School of Chemistry

University of Melbourne, School of ChemistryFletcher Burner

Number of parts: 0.5. Fletcher Burner, for furnace -

University of Melbourne, School of Chemistry

University of Melbourne, School of ChemistryLaggings

Number of parts: 18. Fireclay Furnace Laggings -

Federation University Historical Collection

Federation University Historical CollectionDocument, Indenture Between Robert M. Serjeant, Joseph Flude and the Trustees of the Ballarat School of Mines regarding Letters of Patents for the Benefit of the Ballarat School of Mines, 1877, 04/03/1875

R.M. Serjeant was listed as a mining manager and Joseph Flude as a metallurgist. In 1875 they were both living in Ballarat. The patent number is A.D.1875, 4th March. No 2031. According to the patent the hearth of the furnace is in the form of a cone revolving horizontally. The feed is supplied to the apex of the cone by an archimedian screw. The crown of the furnace comprises a double covering or roof with an intermediate chamber for receiving heated air. The inner covering is pierced to admit of the heated air being brought into contact with the pyrites on the face of the revolving hearth. The discharge of the roasted substance is affected by means of a scraper at the base of the cone. It was claimed that this was a new mode of introducing heated air, and the exclusion of flame during the operation of roasting pyrites. The self-acting charge and discharge of the furnace and the peculiar construction of the hot air chambers, and the use of perforated bricks through which the supply of air is affected were also new. (http://patentsvictoria.net/002031.html) From the Goulburn Herald, 14 September 1878 "A feature connected with the school of mines is the yet unfinished pyrites works. The extraction of the gold from pyrites and the utilization for commercial purposes of other substances connected with pyrites are peculiarly important to Ballarat, because were a simple and inexpensive method devised there are millions and millions of tons of quartz that would then be made remunerative. With this thought in their minds two scientific gentlemen invented the school of mines self-acting rotatory furnace. This, for lack of funds, has not been completed as yet, but the amount in hand for the purpose is daily increasing, and it will eventually be an accomplished fact. It is in contemplation also to erect machinery shops in connection with the school, and it is purposed to con struct a steam-engine to do at once the work of the pyrites treatment and the ma chine room. A model shaft and mine too are being prepared for on the reserve, so that practical mining of the most thorough character may be taught on the ground.'Large indenture on red bordered vellum. The indenture was regarding a patent for the benefit of the Ballarat School of Mines. Letters Patent for an Invention for Roasting Pyrites to be called 'the Ballarat School of Mines self-Acting Pyrites Furnace" to Robery Malachy Serjeant and Joseph Flude. The large document is on a vellum type paper complete with stamps and seal. The document is signed by Acting-Governor William Stawell. Inscriptions and Markings Written on verso: "Date of Patent 4th March 1875 No 2031 Letters Patent for An invention for roasting pyrities to be called "The Ballarat School of Mines Self-acting Pyrities Furnace" to Robert Malachy Serjeant and Joseph Flude Melbourne, Victoriaballarat school of mines, serjeant, r.m. serjeant, robert m. serjeant, flude, joseph flude, patent, barry, redmond barry, rogers, judge rogers, bland, rivett henry bland, john airy, warrington rogers, establishment, indenture, legal, cuthbert, ballarat school of mines trustees, william stawell, john warrington rogers -

Federation University Historical Collection

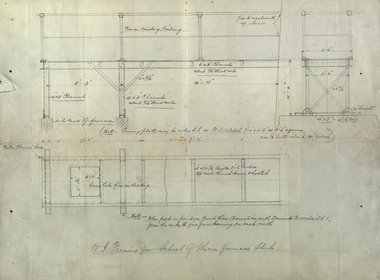

Federation University Historical CollectionPlan, W. I. Framing for School of Mines Furnace Sheds, 1908, 1908

Pencil drawings of plans for the Ballarat School of Mines Furnace Sheds.ballarat school of mines, assaying, w.i. framing -

Victorian Interpretive Projects Inc.

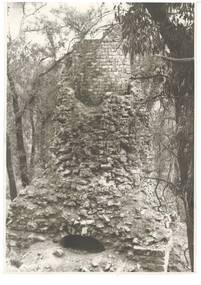

Victorian Interpretive Projects Inc.Photograph - Colour, Clare Gervasoni, Lal Lal Blast Furnace, 2014, 09/2014

Colour photographs of the Lal Lal Blast Furnace near Ballarat.lal lal blast furnace, lal lal -

Buninyong & District Historical Society

Buninyong & District Historical SocietyPhotograph - Original Photograph, BCAE Metallurgy Staff, Lal Lal Blast Furnace, 1977

detail of historic buildingB/W Photograph, Lal Lal Blast Furnace, exterior in 1977buninyong, lal lal, blast furnace -

Buninyong & District Historical Society

Buninyong & District Historical SocietyPhotograph - Original Photograph, BCAE Metallurgy Staff, Lal Lal Blast Furnace, interior, 1977

detail of historic buildingB/W Photograph, Lal Lal Blast Furnace, interior, in 1977buninyong, lal lal, blast furnace -

Federation University Historical Collection

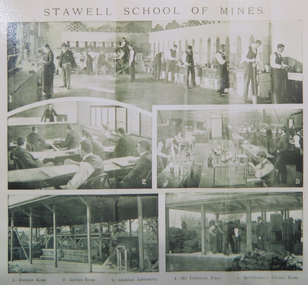

Federation University Historical CollectionPhotograph, Stawell School of Mines, c1904, c1904

The Stawell School of Mines was established in 1890.Photograph of the Stawell School of Mines as depicted in the 1904-5 Stawell School of Mines Prostectus. The image includes the Furnace Room, Lecture Room, Chemical Laboratory, Re Treatment Plant and the Revernertory Furnace Room.stawell school of mines, stawell, schools of mines -

Federation University Historical Collection

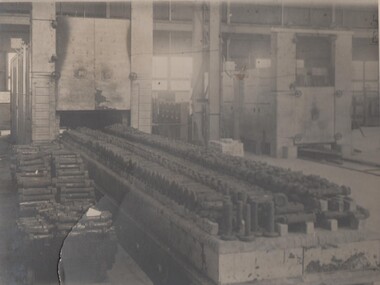

Federation University Historical CollectionPhotograph - Black and White Photograph, The Maddern Roasting Furnace in the Ballarat School of Mines Mining Laboratory, 1904

Interior view of the Maddern Roasting Furnace in the Ballarat School of Mines Model Minemaddern roasting furnace, ballarat school of mines model mine, ballarat school of mines battery -

Phillip Island and District Historical Society Inc.

Phillip Island and District Historical Society Inc.Photograph

This photograph was taken by the Herald & Weekly Times and donated to Audrey McFee. Chicory was first grown on Phillip Island in 1870. It was used in coffee essence and for medicinal purposes.Wood being loaded on to the trolley before being taken to the furnace. Jimmy McFee on the job.local history, photography, photographs, slides, film, chicory industry, black & white photograph, audrey mcfee, chicory, phillip island -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyTuyere Pipe, circa mid to late 1900's

This tuyere (word from French origin) was used by professional blacksmiths and or cattlemen before and during the Kiewa Hydro Electricity Scheme was being constructed. The need to use a furnace or forge in the shaping of metal rods, horse shoes and pipes is both a rural necessity and a construction, on site requirement. The "inventiveness" of cattlemen and construction workers to produce metal objects not available "off the shelf" is one of the inherent traits not only of rural self sufficiency but in the "pioneer" days of rural isolation one of survival.This tuyere is of great significance to the Kiewa Valley and its regions because it highlights one of the greatest strengths of the rural (especially isolated) life and its folk living there, and that is the great human factor of adaptability and survival techniques in sometimes harsh and demanding environmental circumstances. The inventiveness and the attitude, "she'll be right mate", demonstrates life on the land where specialised blacksmith activities can be found in non "professionals" because of the fact that "someone" has to do the job. This is one of the differences between country "rural" life and that found in cities and larger towns.This iron cone shaped tuyere has a small hole (diamenter 25mm) starting within an ever enlarging cone (amplification of the air pressure going through) delivering varying hot or extremely hot air into a furnace or hearth which intensifies the heat to allow the "shaping" of metal objects. The larger "flared" cone extension allows for the directed air to be spread and not concentrated.blacksmith tool, tue, bellows, fashioning metal, forge manufacturing process -

Phillip Island and District Historical Society Inc.

Phillip Island and District Historical Society Inc.Photograph

This photograph was taken by the Herald & Weekly Times and donated to Audrey McFee. Chicory was first grown on Phillip Island in 1870. It was used in coffee essence and for medicinal purposes.The fire in the furnace below the chicory floor. It is built up to raise a floor temperature of 300 degrees F.local history, photography, photographs, slides, film, chicory industry, black & white photograph, audrey mcfee, chicory, phillip island -

Federation University Historical Collection

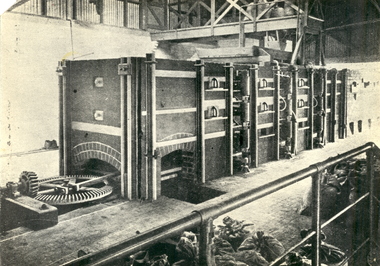

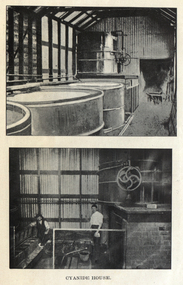

Federation University Historical CollectionPhotograph, Cyanide House and Maddern Roasting Furnace, 1908

The Ballarat School of Mines had a functioning model mine.Two photographic images of the Ballarat School of Mines Cyanide House and the Maddern Roasting Furnace from the 1908 SMB Calendar.ballarat school of mines, maddern furnace, cyanide house, model mine -

Port Melbourne Historical & Preservation Society

Port Melbourne Historical & Preservation SocietyPhotograph - Peter Griffin supervising, Grimwade Castings, Port Melbourne, 1950s

B&W photo of Peter Griffin supervising the molten metal being taken from the furnace at Grimwade Castings, 1950sindustry - manufacturing - foundries, peter griffin, grimwade castings pty ltd -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Photograph - BENDIGO ORDINANCE FACTORY COLLECTION: UPSET FORGINGS ON ELECTRIC BOGIE HEARTH FURNACE FOR NORMALIZING

Photo titled 'Upset Forgings on Electric Bogie Hearth Furnace for Normalizing' Undated B&W print mounted on stiff cardboard -

Federation University Historical Collection

Federation University Historical CollectionObject, Slag from the Ballarat School of Mines Assay Furnace, c2008, c2008

A number of pieces of slag that was found n close proximity to the original Ballarat School of Mines Assay Furnace, when it was at Mt Helen Campus c2008ballarat school of mines, assay furnace, slag -

Federation University Historical Collection

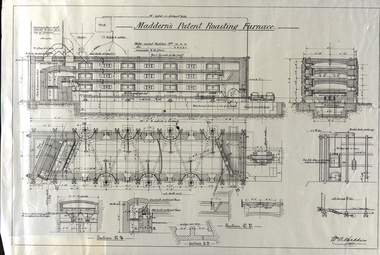

Federation University Historical CollectionEngineering drawings, Maddern's Patent Roasting Furnace, 1902

Printed technical drawings of 'Maddern's Patent Roasting Furnace' .1) Assembly drawings with dimensions (4 copies) .2) Details for Maddern's roaster (3 copies)w. maddern, roasting furnace, assaying, engineering drawings, w.a. maddern, maddern's roasting furnace -

Melbourne Tram Museum

Melbourne Tram MuseumMagazine, Victorian Railways (VR), "Railwaymen as Tramwaymen", June 1930

Page 9 to 10 has an article titled "Railwaymen as Tramwaymen", written by S. C. Weetman, looking at the St Kilda Brighton Electric Railway, notes Elwood Depot, Tramway Inspector, James Griffiths, number of trams, operations, drivers and conductors, maintenance, safeworking. Has a short section on the Sandringham Black Rock tramway. Photos - three photos looking out the front of the tram with the driver's arm on the controller and one of a maintenance man checking the underside of a tramcar. - See Reg Items 6414 and 6416 for prints of the original photos.Yields information about the VR St Kilda Brighton tramway system from a Railway perspective.Victorian Railways Magazine, June 1930, (52 pages, centre stapled), with a single colour cover of tradesmen at Newport Workshop feeding a round billet into a furnace.trams, tramways, vr trams, victorian railways, st kilda brighton electric tramway, sandringham, elwood depot -

Federation University Historical Collection

Federation University Historical CollectionBooklet, Arthur Raistrick, Books relating to ironworks, 1975

.1) David and Sampson: A pair of blast furnace blowing engines, Ironbridge Gorge Museum Trust Seven page booklet on a pair of blast furnace blowing engines which stand at the entrance to Blists Hill Open Air Museum. .2) The Coalbrookdale Ironworks, Ironbridge Gorge Museum Trust Twenty page book on the Coalbrookdale Ironworks including a synopsis of some important events in the history of the company.blast furnace, blowing engines, ironbridge gorge museum trust, industrial heritage -

Federation University Historical Collection

Federation University Historical CollectionMagazine, Ballarat School of Mines Students' Magazine, Vol. 12, No. 4., Fourth Term, 1909, 1909

Tan soft covered magazine on 17 pages. Contents include: Ambulance class, Meteorites, Werribee gorge, Ovens Valley dredging, Electrical Furnace in Iron Metallurgy ballarat school of mines, ballarat school of mines students' magazine, ambulance class, gold treatment, e.c. hurdsfield, jack adam, w.e. burbridge, d.w. bonar, j. booth, r.e. cowles, r. clinton, t.e. copeland, g. evans, w.e. figgis, a.a. gibson, j. gryles, hubert f. hall, e. heighway, o.e. jager, w. kingston, h.r. koefoed, w.j. lamb, v. leggo, c. lund, w.s. macartney, r. ingram-moore, v.a. nico, h.b. owen, p.a. pratt, e.h. prendergast, j.a. reid, w.t. sayer, . stuckey, albert e. tandy, r. vale, j. wallace, s. white, r. williamson, account keeping, meteorites, werribee gorge, ovens valley dredging, electrcution, e. scholes, george baillie, a.d. gilchrist, v. tucker, electric furnace, c. corrie, william baragwanath, a.c. hesselmann -

Stawell Historical Society Inc

Stawell Historical Society IncMemorabilia - Realia, Stawell

Arch Key Brick "Stawell Pressed Brick Co" from George Kay and Co Foundry furnace. Corner of Sloane and Wimmera Streets. Iron and Brass foundry.stawell, manufacturing, industry -

Maldon Vintage Machinery Museum Inc

Maldon Vintage Machinery Museum IncLINO TYPE MACHINE, prior to 1998

This item was used at "The Tarrengower Times" Maldon, Vic by Ron ADAMSLino-type casting machine with furnace for casting lead plates. Makes type used in printing. Motor made by Crompton Patison. Keyboard to select letters to be cast.MODEL 78 No 17175trades; printing; machinery; casting ; tarrengower times