Showing 397 items matching "hand power"

-

Darebin Art Collection

Darebin Art CollectionPhotograph, Gerhard Hillmann, Hand-Y-Cap (the Power of Fragility), 2002

... Hand-Y-Cap (the Power of Fragility)...Hand-Y-Cap (the Power of Fragility) Photograph Gerhard ...My interpretation of the organic world is embedded deep within each artwork I create. Because I believe we are all part of the landscape & not separate, many of my images explore this human nature connection. I feel compelled to respond to the environment in a creative way & aim to promote a deeper appreciation and understanding of nature. Beyond linguistics, an image has the ability to transcend language barriers and travel the world -

Puffing Billy Railway

Puffing Billy RailwayC2N Type Trolly - Former Victorian Railways Gauge 2'6", circa 1910

... hand power... victorian railways hand power narrow gauge puffing billy trolly C2N ...This type of trolly is known to date from prior to 1910 and were in use before petrol engines were used to transport workmen along the railway lines. The exhibit was located at Colac in 1961, after being used on the Colac to Beech Forest and Crowes narrow gauge railway. This type of trolly was built in two versions; one for the Victorian Railways broad gauge lines, and one for the narrow gauge lines.Historic - Victorian Railways narrow gauge - track work vehicle. This vehicle was used in the days before petrol engines were used to drive vehicles transporting workmen along the railway line.C2N Type Trolly - Victorian Railways Gauge 2'6" Trolly Has a flat piece of wood that you would stand on with four metal wheels, one under each corner.c2n, trolley, victorian railways, hand power, narrow gauge, puffing billy, trolly -

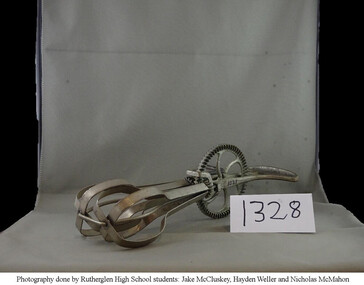

Rutherglen Historical Society

Rutherglen Historical SocietyEgg beater

... Hand powered egg beater made of a silver coloured metal...-country Hand powered egg beater made of a silver coloured metal ...Hand powered egg beater made of a silver coloured metal -

Mont De Lancey

Mont De LanceyEgg beater

... Hand powered egg beater made of a silver coloured metal...-and-dandenong-ranges egg-beaters kitchenware Hand powered egg beater ...Hand powered egg beater made of a silver coloured metal with wooden handle.egg-beaters, kitchenware -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyBuck Saw

... A bucksaw is a hand powered frame saw similar to bow saw... is a hand powered frame saw similar to bow saw and generally used ...A bucksaw is a hand powered frame saw similar to bow saw and generally used with a sawbuck to cut logs or firewood to length (bucking).Used by residents of the Kiewa Valley for clearing land, chopping firewood, cutting lumber. Also used while camping because it is portableFormerly UKV 239. Buck Saw with Lightning Tooth Blade. Operated by two men.Ref. Page 10 Tools for all Trade Catalogue. It consists of 3 horizontal bars, the top one being twisted wire and the bottom one being the metal blade with a wood bar in between. They are attached at each end to curved wooden bars. tool for wood, saw, buck saw -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Marking Gauge

... This marking gauge has a round head. It is a hand-powered.... It is a hand-powered tool and is used to measure and mark a scribed ...This marking gauge has a round head. It is a hand-powered tool and is used to measure and mark a scribed line onto the surface of the wood for the purpose of cutting or aligning. It would have been used by a tradesperson such as a cabinet maker, wood worker or carpenter. The hand tool shows signs of much use. It appears to be appreciated as a tool due to the initials carved into the side of the block. The marking gauge is an example of a hand powered woodworking tool used over the past few centuriesMarking gauge: wooden staff with half-round block secured by a wedge. there is a metal marker on one end. Inscription "WS" crudely engraved in end of block.Carved "W.S."flagstaff hill, warrnambool, maritime museum, maritime village, shipwreck coast, hand tool, woodwork, marking gauge, w.s., measuring tool -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietySewing Machine - Singer

... belt powered, hand powered and eventually electric powered... belt powered, hand powered and eventually electric powered ...Singer began to market its machines internationally in 1855. They began mass-producing domestic electric machines in 1910. Treadle machines were powered mechanically by a foot pedal that is pushed back and forth by the operator's foot. There were also machines belt powered, hand powered and eventually electric powered. Treadle machines were made into the 1950s but they were most common during the late Victorian years (up to 1901). This machine is c1894.This machine was owned and used by a resident of the Kiewa Valley. It was used for domestic sewing such as for making clothes for the family, making toys for eg. a fete and making useful items eg. a bag for school readersSinger Fiddle Base treadle sewing machine with decoration of flowers. Straight stitch. No stand. A little rusty.Top: 'the Singer Manufacturing'. Front: 'Singer' and the Metal Plaque 'The Singer MFC Cony'singer manufacturing co., clothes, sewing, domestic -

Orbost & District Historical Society

Orbost & District Historical Societyscythe blade, late 19th - early 20th century

... with a crank handle on one side. This was hand powered and used... with a crank handle on one side. This was hand powered and used ...Scythes were used to manually mow wheat or grass. Scythes were used with a long sweeping movement which made them much less tiring for labourers to use than reaping hooks or sickles though they still involved great physical labour and considerable skill to perfect. Both hands were in use and the operator did not have to bend his back to reach down to the crop. On farms scythes were sharpened on a sandstone wheel mounted on an axle with a crank handle on one side. This was hand powered and used with water. Scythes were not used as often on farms after the mechanisation of harvesting. They were still used for cutting awkward shaped small plots and for opening a path for the tractors. This item is an example of a tool used by the early settlers of the Orbost district. An iron scythe blade, curved and tapered. There is no handle and the blade is rusted and pitted."ROSE"scythe tool agriculture rural -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Wood Mitre & Trimmer Guillotine, Early 20th century

... The mitre trimmer is a classic hand-powered tool... Warrnambool great-ocean-road The mitre trimmer is a classic hand ...The mitre trimmer is a classic hand-powered tool for picture framers and trim carpenters that has remained relatively unchanged for decades. It is heavy, simple, and sturdily built of cast iron with tempered steel guillotine blades. It is used for taking super accurate, paper-thin slices off the ends of mitres and butt joints, and leaving behind a glassy-smooth surface. Also used in picture frame making or cabinet woodworking, by placing a piece of timber in one side after setting the desired angle and pulling a handle that operates a guillotine blade thereby cutting the timber or decorative trim to the required angle.A significant tool still in use today in many cabinet makers workshops. The subject tool gives insight into how this type of tool development, design and use has not progressed since it’s original invention. It is still for sale from many tool manufacturing companies and use in small craftsmen boutique workshops today as it was many decades ago.Cast Iron wood Trimmer bench like construction on raised feet with 2 adjustable gates. Noneflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, cabinet makers tools, picture framing, mitre cutting, wood trimming -

Orbost & District Historical Society

Orbost & District Historical Societyhand drill

... of Stuttgart, Germany. Hand-powered devices have been used... of Stuttgart, Germany. Hand-powered devices have been used ...The invention of a hand drill is credited to Arthur James Arnot and William Blanch Brain of Melbourne, Australia who patented the electric drill in 1889. In 1895, the first portable handheld drill was created by brothers Wilhem & Carl Fein of Stuttgart, Germany. Hand-powered devices have been used for millennia. However, during the last quarter of the 19th century a radically improved generation of tools appeared. These tools took advantage of modern mass production machinery and processes (like interchangeable parts) and an increased availability in superior material (metal instead of wood). One of the outcomes included an array of new drilling machines. These human-powered tools were a vast improvement over earlier tools.This item is an example of a commonly used domestic tool - pre power tools.A Stanley hand drill with two wooden handles. The red wheel is painted metal. On red wheel - STANLEY ENGLANDwoodwork tool hand-drill -

The Ed Muirhead Physics Museum

The Ed Muirhead Physics MuseumPhotograph, Cyclotron accelerator

... CANS”, “FINAL AMPLIFIER” Handwritten in bottom right hand...: “SHIELDING CANS”, “FINAL AMPLIFIER” Handwritten in bottom right hand ...Builit in 1950s and used till the mid 1970s within the Physics Department used in Melbourne. John Rouse and David Caro was involved in the construction.Black and white photo of cyclotron (nuclear physics accelerator): Shielding cans and final amplifier. Sticky typed labels on back from left to right: “SHIELDING CANS”, “FINAL AMPLIFIER” Handwritten in bottom right hand croner: “RF Power Amplifier” -

Blacksmith's Cottage and Forge

Blacksmith's Cottage and ForgeLamp, 1900 (estimated)

... Painted black metal(tin) candle power, hand held or placed... bicycle lamp blackout Painted black metal(tin) candle power, hand ...This item type was used during the First World War throughout Europe. This item is an artillery siege lamp. It was used by artillery units. The lamps were powered by a single candle, the light being magnified by a lens. A shutter closes over the lens to give an illuminated vertical line. They were used originally in fortified siege artillery posititions as a general purpose lamp. They were also used as aiming lamps when they were placed in front of artillery posititions and used as a guide in aiming at night. Further research has suggested that this item may have been attached to bicycles for illuminating the way in the blackout.This item is considered rare and important. It is historically and technically siginficant at a national level. Painted black metal(tin) candle power, hand held or placed on flat area, open base so candle can be inserted and 'screwed' in, side door for lighting, fron magnifying glass, metal lens cover with vertical slit. There is considerable damage to the black paint in the external regions of the lamp.world war one, military, candle, artillery, europe, lamp, black, artillery siege lamp, artillery units, candle power, aiming lamp, wwi, 1900, australian war memorial, bike light, bike, bicycle, bicycle lamp, blackout -

The Ed Muirhead Physics Museum

The Ed Muirhead Physics MuseumPhotograph, Cyclotron accelerator

... CAPACITORS” Handwritten in pen in bottom right hand corner: “RF Power... CAPACITORS” Handwritten in pen in bottom right hand corner: “RF Power ...Builit in 1950s and used till the mid 1970s within the Physics Department used in Melbourne. John Rouse and David Caro was involved in the construction.Black and white photo of cyclotron (nuclear physics accelerator): R.F. power amplifier - tank coil & tuning capacitors. Duplicate of 190. Sticky typed labels on back from top and left to right: “VIEW INSIDE FINAL AMPLIFIER SHOWING TANK COIL & TUNING CAPACITORS” Handwritten in pen in bottom right hand corner: “RF Power Amplifier” -

The Ed Muirhead Physics Museum

The Ed Muirhead Physics MuseumPhotograph, Cyclotron accelerator

... STABILIZER” Handwritten in pen on bottom right hand corner: “RF Power... STABILIZER” Handwritten in pen on bottom right hand corner: “RF Power ...Builit in 1950s and used till the mid 1970s within the Physics Department used in Melbourne. John Rouse and David Caro was involved in the construction.Black and white photo of cyclotron (nuclear physics accelerator): 14kV stabiliser & RF power amplifier. Duplicate of 216Sticky typed labels on back from top to bottom: “14KV STABILIZER” Handwritten in pen on bottom right hand corner: “RF Power Amplifier DC Stabilizer” Handwritten in pencil on top left hand corner: “2” -

The Ed Muirhead Physics Museum

The Ed Muirhead Physics MuseumPhotograph, Cyclotron accelerator

... : “MAIN SWITCHBOARD” Handwritten in pencil on upper left hand...: “MAIN SWITCHBOARD” Handwritten in pencil on upper left hand ...Builit in 1950s and used till the mid 1970s within the Physics Department used in Melbourne. John Rouse and David Caro was involved in the construction.Black and white photo of cyclotron (nuclear physics accelerator): Main switchboard. Sticky typed labels on back from top and left to right: “MAIN SWITCHBOARD” Handwritten in pencil on upper left hand corner: “9” Handwritten in pen on bottom right hand corner: “AC power in from substation” -

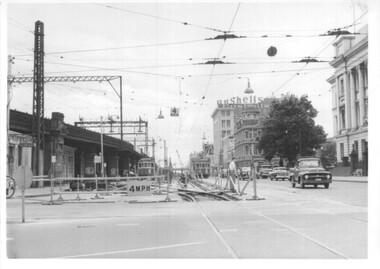

Melbourne Tram Museum

Melbourne Tram MuseumPhotograph - Set of 12 - construction of King St overpass in Flinders St, 1959

... - Tram lines diverted onto the new overpass. Note the hand... - Tram lines diverted onto the new overpass. Note the hand ...Photos show the construction of King St overpass in Flinders St which was part of the project to construct a bridge over the Yarra River and provide a new southern outlet road between the city and eventually St Kilda Junction. The overpass construction was commenced in 1959 with tramway works first commencing. It was demolished in 2005. 1 - looking west at Market St. 2 - looking east from Spencer and Flinders St with the railway viaduct behind. 3 - Tram lines diverted onto the new overpass. Note the hand-powered overhead tower on the left behind the compressor. 4 - Tracks partially diverted. 5 - Looking east at Spencer and Flinders St with a Dunlop tyre truck in the view. 6 - prior to the diversion onto the new bridge. 7 - Looking east near William St. with W2 451 (Route 48, North Balwyn) in the view. 8 - Bridge works near King St. Original tracks still in use. 9 - Looking east prior to the introduction of the temporary tracks on the south side of the new overpass. 10 - SW6 852 and a W2 on new overpass trackwork - old trackwork being demolished. 11 - Cross over at Spencer St in Flinders St, prior to change over. 12 - Looking west at Flinders and Spencer St with SW6 853 turning into Spencer St.Yields information about the construction of the King St overpass in Flinders St during 1959.Set of 12 black and white prints of the construction of the King St overpass in Flinders St.trams, tramways, flinders st, king st overpass, construction, bridges, w2 class, sw6 class, tram 451, tram 853, tram 852 -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Marking Gauge

... such as timber for measuring and cutting. It is a hand-powered tool.... It is a hand-powered tool that would have been used by a tradesperson ...This mortice marking gauge has an adjustable sliding arm. The gauge is used for scribing two lines on a flat surface such as timber for measuring and cutting. It is a hand-powered tool that would have been used by a tradesperson such as a cabinet maker, woodworker or carpenter. The hand tool shows signs of much use. The ‘W. Maples & Sons, Hibernia’s catalogue of 1867 had a very similar tool, called a Mortice Gauge, column 2, page 15. W. MARPLES & SONS- William Marples Snr. had a business on the Sheffield Moor in 1773/74. In 1821 his son William Jnr. At 12 years old began in his father’s joinery business. 1833 the firm was known as a tool manufacturer. In 1838 Marples called his business Hibernian Works and moved to 67-69 Spring Lane, Sheffield. When he moved to Westfield Terrace in 1856, he called his business Hibernia Works (no ‘n’ on the end). The business remained at this address for 116 years. In about 1859 the firm began using the Lyre (Irish harp) mark. In 1860 or so the two brothers, Edwin and William Marples, became partners and the firm became William Marples and Sons. The firm introduced the single shamrock symbol in 1860-61. The boys’ brother Albert joins the firm in 1863. In 1875 the company registered both the name ‘Hibernia’ and the trade mark symbol of a Triple Shamrock and the use of these trademarks continued for many decades, into the 1940 and the firm, with many changes, was still in business in the early 21st century. About Shamrock and Hibernia, both are related to Ireland and W. Marples named his products the Shamrock brand.The marking gauge is an example of a hand powered woodworking tool used over the past few centuries. Its maker was well known for his good quality tools and his business grew because of his reputation.Mortice marking gauge: wooden staff with block and green, adjustable sliding arm within the staff. The end of the staff has a facility for holding the scribe marker. The block has a hole into which a peg or wedge would be inserted to hold the sliding arm in place. Inscription with maker's name and almost indecipherable mark is stamped onto one side of the block. Made by W Marples & Sons, Sheffield.Stamped into block “W. MARPLES & SONS / HIBERNIA WORKS” above Logo of ‘Trefoil’ image [three, three-leafed clovers on the same stem]flagstaff hill, warrnambool, maritime museum, maritime village, shipwreck coast, hand tool, woodwork, marking gauge, measuring tool, mortice gauge, mortice marking gauge, william marples, w marples & sons, hibernia, shamrock, trifoil, tripple shamrock, carpenter's tool, cabinet maker, woodworking tool, drawing, planning, tool, wooden scribe, vintage, carpenter, marking tool, antique, marking out, joiner -

Glenelg Shire Council Cultural Collection

Glenelg Shire Council Cultural CollectionEquipment - Equipment - Diving amplifier, n.d

... , fittings for power supply on right hand end, control panel at front... for power supply on right hand end, control panel at front of case ...Port of Portland CollectionFront: Diving amplifier equipment/TYPE 957 SERIAL No 260/ Navy Department Bureau of Ships/ date 11-4-43/ GUIDED RADIO CORPORATION NEW YORK N.Y.port of portland archives -

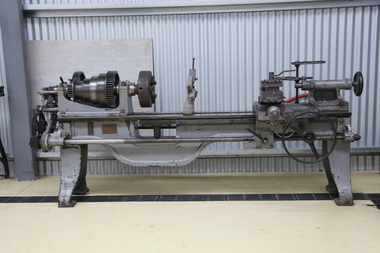

Puffing Billy Railway

Puffing Billy RailwayLathe - Gap Bed, early 1900s

... tumble-reverse mechanism that allowed both left and right-hand... left and right-hand powered movement to the carriage ...Possibly ex Victorian Railways Newport workshops Supplied by Bevan & Edwards Machinery Merchants, Melbourne Sebastian Lathes Described by its makers as the Utility School, Garage and Repair-shop Lathe, the machine immediately below, a Sebastian 15" (circa 1910 - 1926) was the Company's cheapest offering and, in its basic form, lacked a compound slide rest, the tailstock did not set over for taper turning and the bed lacked a gap. However, a friction-type countershaft unit was included in the price as well as a tool post, faceplate, drive plate, changewheels for screwcutting and a small tool kit. As with modern cars (especially BMW) everything worthwhile was on the options' list and by spending more it was possible to specify all those small but important extras. Although in its lowest-cost form this model was reduced to the fundamentals required for a useable, screwcutting centre (engine) lathe it was still reasonably specified and would certainly have fulfilled many requirements when installed in a school or training workshop. The true swing was 15.25", it was properly backgeared and screwcutting was through a conventional tumble-reverse mechanism that allowed both left and right-hand powered movement to the carriage by altering the position of just one lever. As standard it accepted 40" between centres, but any capacity could be ordered, in foot intervals, up to a maximum of 88" - when it is hoped that a central bed support might have been included …… The spindle, which ran in white-metal bearings, had a useful 15/8" hole and a No. 3 Morse taper centre. Some models appear to have had the leadscrew clasp-nut lever on the right-hand side of the apron, while on others it was positioned to the left.. Early Sebastian 13-inch lathe Typical of the Centre or "Engine" lathe made by many manufacturers from the late 1800s until the late 1930s, the basic flat-belt drive Sebastian, with separate countershaft, was eventually relegated to the economy end of the Company's range by the introduction of geared headstocks and self-contained motor-drive systems.Historic - Industrial Machinery - Gap Bed Lathe - Possibly ex Victorian Railways Newport workshops - Purchased and supplied from Bevan & Edwards Gap Bed Lathe - Grey with raw steel parts and a timber cupboard with gears and tools. Bevan & Edwards PTY,LTD Machinery Merchants Melbourne (possible government tag) 365bevan & edwards pty,ltd machinery merchants melbourne, puffing billy -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Compass Saw, Mid to late 20th Century

... . This force may be applied by hand, or powered by steam, water... or continuously forward. This force may be applied by hand, or powered ...A saw is a tool consisting of a tough blade, wire, or chain with a hard-toothed edge. It is used to cut through material, very often wood, though sometimes metal or stone. The cut is made by placing the toothed edge against the material and moving it forcefully forth and less vigorously back or continuously forward. This force may be applied by hand, or powered by steam, water, electricity or other power sources. An abrasive saw has a powered circular blade designed to cut through metal or ceramic. In ancient Egypt, open (unframed) saws made of copper are documented as early as the Early Dynastic Period, circa 3,100–2,686 BC. Many copper saws were found in tombs dating to the 31st century BC. Models of saws have been found in many contexts throughout Egyptian history. As the saw developed, teeth were raked to cut only on the pull stroke and set with the teeth projecting only on one side, rather than in the modern fashion with an alternating set. Saws were also made of bronze and later iron. In the Iron Age, frame saws were developed holding the thin blades in tension. The earliest known sawmill is the Roman Hierapolis sawmill from the third century AD used for cutting stone.The subject item is believed to date from around the mid to late 20th century and is regarded as a modern item. The maker is unknown but the pattern or design and type of wood used indicate it is a tool of modern manufacture. Compass saw blade with wooden handle attached with wingnut.Noneflagstaff hill, warrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, wood cutting, wood saw, cross cut saw, cabinet makers tools, wood working tools, tool -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Compass Saw, Mid to late 20th Century

... . This force may be applied by hand, or powered by steam, water... or continuously forward. This force may be applied by hand, or powered ...A saw is a tool consisting of a tough blade, wire, or chain with a hard-toothed edge. It is used to cut through material, very often wood, though sometimes metal or stone. The cut is made by placing the toothed edge against the material and moving it forcefully forth and less vigorously back or continuously forward. This force may be applied by hand, or powered by steam, water, electricity or other power sources. An abrasive saw has a powered circular blade designed to cut through metal or ceramic. In ancient Egypt, open (unframed) saws made of copper are documented as early as the Early Dynastic Period, circa 3,100–2,686 BC. Many copper saws were found in tombs dating to the 31st century BC. Models of saws have been found in many contexts throughout Egyptian history. As the saw developed, teeth were raked to cut only on the pull stroke and set with the teeth projecting only on one side, rather than in the modern fashion with an alternating set. Saws were also made of bronze and later iron. In the Iron Age, frame saws were developed holding the thin blades in tension. The earliest known sawmill is the Roman Hierapolis sawmill from the third century AD used for cutting stone.The subject item is believed to date from around the mid to late 20th century and is regarded as a modern item. The maker is unknown but the pattern or design and type of wood used indicate it is a tool of modern manufacture.Compass saw with wooden handle and metal blade. Small teeth. flagstaff hill, warrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, wood cutting, wood saw, cross cut saw, cabinet makers tools, wood working tools, tool, compass saw -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Compass Saw, Mid to late 20th Century

... . This force may be applied by hand, or powered by steam, water... or continuously forward. This force may be applied by hand, or powered ...A saw is a tool consisting of a tough blade, wire, or chain with a hard-toothed edge. It is used to cut through material, very often wood, though sometimes metal or stone. The cut is made by placing the toothed edge against the material and moving it forcefully forth and less vigorously back or continuously forward. This force may be applied by hand, or powered by steam, water, electricity or other power sources. An abrasive saw has a powered circular blade designed to cut through metal or ceramic. In ancient Egypt, open (unframed) saws made of copper are documented as early as the Early Dynastic Period, circa 3,100–2,686 BC. Many copper saws were found in tombs dating to the 31st century BC. Models of saws have been found in many contexts throughout Egyptian history. As the saw developed, teeth were raked to cut only on the pull stroke and set with the teeth projecting only on one side, rather than in the modern fashion with an alternating set. Saws were also made of bronze and later iron. In the Iron Age, frame saws were developed holding the thin blades in tension. The earliest known sawmill is the Roman Hierapolis sawmill from the third century AD used for cutting stone.The subject item is believed to date from around the mid to late 20th century and is regarded as a modern item. The maker is unknown but the pattern or design and type of wood used indicate it is a tool of modern manufacture. Compass saw with wooden handle broken and metal blade. Small teeth.Noneflagstaff hill, warrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, wood cutting, wood saw, cross cut saw, cabinet makers tools, wood working tools, tool, compass saw -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Wood Saw, Mid to late 20th century

... . This force may be applied by hand, or powered by steam, water... or continuously forward. This force may be applied by hand, or powered ...A saw is a tool consisting of a tough blade, wire, or chain with a hard-toothed edge. It is used to cut through material, very often wood, though sometimes metal or stone. The cut is made by placing the toothed edge against the material and moving it forcefully forth and less vigorously back or continuously forward. This force may be applied by hand, or powered by steam, water, electricity or other power sources. An abrasive saw has a powered circular blade designed to cut through metal or ceramic. In ancient Egypt, open (unframed) saws made of copper are documented as early as the Early Dynastic Period, circa 3,100–2,686 BC. Many copper saws were found in tombs dating to the 31st century BC. Models of saws have been found in many contexts throughout Egyptian history. As the saw developed, teeth were raked to cut only on the pull stroke and set with the teeth projecting only on one side, rather than in the modern fashion with an alternating set. Saws were also made of bronze and later iron. In the Iron Age, frame saws were developed holding the thin blades in tension. The earliest known sawmill is the Roman Hierapolis sawmill from the third century AD used for cutting stone. The subject item at this time cannot be associated with an historical event, person or place, provenance is unknown, as the maker is unknown but the pattern or design and type of wood used indicate it is a tool of modern manufacture around the mid to late 20th century.Wood hand saw with wooden handle attached to saw by 4 rivets. No blade markings Noneflagstaff hill, warrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, handsaw, wood saw, carpenders tools, cabinet makers tools, wood cutting -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Saw, Mid 20th Century

... . This force may be applied by hand, or powered by steam, water... or continuously forward. This force may be applied by hand, or powered ...A saw is a tool consisting of a tough blade, wire, or chain with a hard-toothed edge. It is used to cut through material, very often wood, though sometimes metal or stone. The cut is made by placing the toothed edge against the material and moving it forcefully forth and less vigorously back or continuously forward. This force may be applied by hand, or powered by steam, water, electricity or other power sources. An abrasive saw has a powered circular blade designed to cut through metal or ceramic. In ancient Egypt, open (unframed) saws made of copper are documented as early as the Early Dynastic Period, circa 3,100–2,686 BC. Many copper saws were found in tombs dating to the 31st century BC. Models of saws have been found in many contexts throughout Egyptian history. As the saw developed, teeth were raked to cut only on the pull stroke and set with the teeth projecting only on one side, rather than in the modern fashion with an alternating set. Saws were also made of bronze and later iron. In the Iron Age, frame saws were developed holding the thin blades in tension. The earliest known sawmill is the Roman Hierapolis sawmill from the third century AD used for cutting stone.The subject item is believed to date from around the mid to late 20th century and is regarded as a modern item. The maker is unknown but the pattern or design and type of wood used indicate it is a tool of modern manufacture. Compass saw blade with wooden with open handle blade attached with wingnut lever at side to adjust long narrow blade Noneflagstaff hill, warrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, wood cutting, wood saw, cross cut saw, cabinet makers tools, wood working tools, tool -

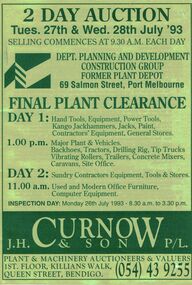

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Document - IAN DYETT COLLECTION: AUCTION CATALOGUE - DEPT PLANNING AND DEVELOPMENT CONSTRUCTION

... . For sale on day 1 were hand tools, equipment, power tools... former Plant Depot, Port Melbourne. For sale on day 1 were hand ...Pale green auction catalogue with dark green printing for a sale held on the 27th and 28th July '93 for Dept. Planning and Development Construction Group former Plant Depot, Port Melbourne. For sale on day 1 were hand tools, equipment, power tools, jackhammers, jacks, paint, contractors' equipment, general stores, major plant & vehicles, backhoes, tractors, drilling rig, tip trucks, vibrating rollers, trailers, concrete mixers, caravans and site office. On Day 2 were sundry contractors equipment, tools & stores, used and modern office furniture and computer equipment. J. H. Curnow & Son P/L were the auctioneers.business, auctioneers, j h curnow & son pty ltd, ian dyett collection - auction catalogue - dept. planning and development construction group former plant depot, j h curnow & son p/l, noel dyett, fred dyett, ian dyett, bolton bros p/l -

Federation University Historical Collection

Federation University Historical CollectionEquipment - Casette Tape Recorder, Sanyo, Sanyo Casette Tape Recorder

... , and were typically hand-held battery-powered devices with built... typically hand-held battery-powered devices with built ...Early recorders were intended for dictation and journalists, and were typically hand-held battery-powered devices with built-in microphones and automatic gain control on recording. Tape recorder audio-quality had improved by the mid-1970s, and a cassette deck with manual level controls and VU meters became a standard component of home high-fidelity systems.[1] Eventually the reel-to-reel recorder was completely displaced, in part because of the usage constraints presented by their large size, expense, and the inconvenience of threading and rewinding the tape reels - cassettes are more portable and can be stopped and immediately removed in the middle of playback without rewinding. Cassettes became extremely popular for automotive and other portable music applications. Although pre-recorded cassettes were widely available, many users would combine (dub) songs from their vinyl records or cassettes to make a new custom mixtape cassette. (http://en.wikipedia.org/wiki/Cassette_deck) Black and silver electric or battery powered plastic tape recorder wit 5 black and 1 red push button to operate and record on the equipment. The recorder also has a counter and a rec.batter light. electronics, cassetter recorder, recording, tape recorder -

Melbourne Tram Museum

Melbourne Tram MuseumPhotograph - Black and White photograph/s - mounted, Darge Photos, early to mid 1920's?

... Power House operated by The North Melbourne and Electric... Trams tramways Power Station Personnel Equipment Essendon NMETL ...Black and White photograph, mounted onto grey impressed and lined card of 8 men in a doorway a the Essendon or Ascot Vale Power House operated by The North Melbourne and Electric Tramways and Lighting Company. NMETL Has the power station equipment in the background. Photo by "Darge" Photos, 175 Collins St Melbourne, printed on the bottom right hand corner. Mr Murdoch the manager, most likely in the right hand of the top row. Others unknown. May have been taken a the time of the hand over of Essendon Power Station to the SEC / MMTBOne person has been arrowed the expression "ME" written onto the photograph.trams, tramways, power station, personnel, equipment, essendon, nmetl, substation -

National Wool Museum

National Wool MuseumTextile - Children's Jumper, Kathryn Knitwear, c.1964-1970

... in his bedroom in Strathmore using a hand powered machine... in his bedroom in Strathmore using a hand powered machine ...Kathryn Knitwear, founded by Robert Blake, manufactured high quality children’s knitwear in Melbourne from the 1940s – 1980s. Robert Blake began manufacturing children’s knitwear in his bedroom in Strathmore using a hand powered machine in the late 1940s. The operation moved to Ascot Vale and Essendon, before eventually establishing a factory in Moonee Ponds in the early 1950s. The business continued to expand, necessitating a move to a new factory in Broadmeadows. By 1962, the Broadmeadows factory was producing an average of 20,000 garments per month, which increased to 24,000 by 1964. Robert Blake’s Son, Brendan recalls that “The Kathryn brand was famous around Australia, anywhere children needed to keep warm and dress smartly. It also won a number of wool fashion awards”, including the 1969 Wool Awards, which was held by the Australian Wool Bureau and published in Women’s Weekly. The Kathryn range was designed for durability, comfort and care, without sacrificing style. They used patterning techniques that increase stretchiness, comfort and fit, as well as integrating decorative elements into the fabric to prevent them from being bulky, uncomfortable or tight. Making longevity of style a priority, Brendan Blake remembers that “there was one particular garment that was in the range for at least thirty years”. He also recalls “In the past, when women have found out that I was associated with Kathryn Knitwear, they would often relate to me the story of a garment they had purchased or received as a gift and, when their child had grown out of it, they would hand it on to another child. Several ladies have told me of purchasing garments for their daughters’ glory box, or saving a particular garment after their daughter had grown out of it. Brendan Blake: “At the peak of their operation they employed approximately two hundred people, mainly women and girls. A family would often seek to send their daughter to work in this company because they knew they would be looked after and safe. One lady wrote to me telling me that working at the Moonee Ponds Factory prior to getting married was the happiest time of her life.” In 1963, workers at the Kathryn factory earned £13 per week, which was 8 shillings and 8 pence higher than the minimum weekly wage for female workers in the textile manufacturing industry (£12 11s 4d). By 1970, the Kathryn Knitwear brand expanded from children’s knitwear into womenswear under the brand name ‘Lady Kathryn’, and for boys and men under ‘Robert Blake’. Continuing to diversify their distribution, they also began exporting ‘Kathryn’ garments to New Zealand, the Pacific Islands, and Japan. ‘Kathryn Knitwear’ was well-known for their early adoption of modern materials and techniques that had broad appeal to their customer base. This is shown in their early use of the acrylic fibre ‘Orlon’ in the 50s and 60s and ‘Superwash’ wool in the 1970s. Many of Kathryn Knitwear’s styles, particularly those that were long running staples of the brand, were available in both wool and Orlon to suit the consumer’s preference. Far from the humble origins of one man in his bedroom with a hand-cranked machine; at its closure in 1980, the Broadmeadows factory of ‘Kathryn’ housed more than 100 machines, including 53 sewing machines and 45 knitting machines. Robert Blake was “a passionate advocate for wool and Australian Made” throughout his whole life. A strong thread that ties through the lifespan of Robert Blake and Kathryn Knitwear is a balance between adopting new innovations without sacrificing the core values of durability, comfort, care and style that had made the brand so well known. Their legacy forms an integral part of both Australian social and manufacturing history.White short-sleeved jumper with all-over pattern of aqua blue diamonds. Blue floated threads slightly show through white on main body, leading to an overall pale blue effect on body, with white collar and cuffs. Closes with three pearlescent plastic buttons at back neck. .2 is a retail tag marked with the style code, and includes generic information on care for garments of different material composition..1) [label stitched into back neck of garment] KATHRYN REGD CREATED BY ROBERT BLAKE .2) [retail tag, intended to be folded in three, printed on both sides] [OBVERSE] KATHRYN Children’s Knitwear STYLE: [blue pen] S/35B SIZE: PRICE: / KATHRYN Garments are… • PRE-SHRUNK • STANDARD MEASUREMENTS • FIT EXACTLY • LAUNDER PERFECTLY / NOW .. KATHRYN GOES TO . . SCHOOL Ask your retailer for SCHOOL PULLOVERS by KATHRYN [REVERSE] WASHING INSTRUCTIONS WOOL Wash frequently to AVOID HEAVY SOILING Wash garment BY HAND, in lukewarm Velvet Soap suds. ON NO ACCOUNT RUB SOAP ON GARMENT. Squeeze suds gently through garment but DO NOT RUB. Rubbing will cause garment to thicken. RINSE AT LEAST TWICE IN CLEAN WATER TO REMOVE ALL SOAP. TO dry, roll garment in a towel to remove excess moisture, turn garment inside out and pull it lengthwise, DRY IN SHADE… AVOID SUNLIGHT. When dry, place brown paper or pressing cloth over garment and press with iron at correct heat. ORLON Wash as wool Lay flat to dry but DO NOT IRON. To keep brushed suits like new, brush frequently with nylon brush supplied. COTTON Wash by hand for preference in Velvet Soap suds. Rinse thoroughly in cold water and remove all excess water before drying on line. Please do not use any harsh detergent or bleach. Designed and manufactured by ROBERT BLAKE Pty. Ltd., MELB. (handwritten in pencil) S35 (untintelligible)/5 / NOW KATHRYN GOES TO SCHOOL Ask your retailer for SCHOOL PULLOVERS by KATHRYNknitwear, children's knitwear, clothing, children's clothing, jumper, manufacturing, fashion textile production, machine knitting, colourwork -

National Wool Museum

National Wool MuseumTool - The Austral Unit Calculator, Industrial Consultants, c.1960

... in his bedroom in Strathmore using a hand powered machine... in his bedroom in Strathmore using a hand powered machine ...Kathryn Knitwear, founded by Robert Blake, manufactured high quality children’s knitwear in Melbourne from the 1940s – 1980s. Robert Blake began manufacturing children’s knitwear in his bedroom in Strathmore using a hand powered machine in the late 1940s. The operation moved to Ascot Vale and Essendon, before eventually establishing a factory in Moonee Ponds in the early 1950s. The business continued to expand, necessitating a move to a new factory in Broadmeadows. By 1962, the Broadmeadows factory was producing an average of 20,000 garments per month, which increased to 24,000 by 1964. Robert Blake’s Son, Brendan recalls that “The Kathryn brand was famous around Australia, anywhere children needed to keep warm and dress smartly. It also won a number of wool fashion awards”, including the 1969 Wool Awards, which was held by the Australian Wool Bureau and published in Women’s Weekly. The Kathryn range was designed for durability, comfort and care, without sacrificing style. They used patterning techniques that increase stretchiness, comfort and fit, as well as integrating decorative elements into the fabric to prevent them from being bulky, uncomfortable or tight. Making longevity of style a priority, Brendan Blake remembers that “there was one particular garment that was in the range for at least thirty years”. He also recalls “In the past, when women have found out that I was associated with Kathryn Knitwear, they would often relate to me the story of a garment they had purchased or received as a gift and, when their child had grown out of it, they would hand it on to another child. Several ladies have told me of purchasing garments for their daughters’ glory box, or saving a particular garment after their daughter had grown out of it. Brendan Blake: “At the peak of their operation they employed approximately two hundred people, mainly women and girls. A family would often seek to send their daughter to work in this company because they knew they would be looked after and safe. One lady wrote to me telling me that working at the Moonee Ponds Factory prior to getting married was the happiest time of her life.” In 1963, workers at the Kathryn factory earned £13 per week, which was 8 shillings and 8 pence higher than the minimum weekly wage for female workers in the textile manufacturing industry (£12 11s 4d). By 1970, the Kathryn Knitwear brand expanded from children’s knitwear into womenswear under the brand name ‘Lady Kathryn’, and for boys and men under ‘Robert Blake’. Continuing to diversify their distribution, they also began exporting ‘Kathryn’ garments to New Zealand, the Pacific Islands, and Japan. ‘Kathryn Knitwear’ was well-known for their early adoption of modern materials and techniques that had broad appeal to their customer base. This is shown in their early use of the acrylic fibre ‘Orlon’ in the 50s and 60s and ‘Superwash’ wool in the 1970s. Many of Kathryn Knitwear’s styles, particularly those that were long running staples of the brand, were available in both wool and Orlon to suit the consumer’s preference. Far from the humble origins of one man in his bedroom with a hand-cranked machine; at its closure in 1980, the Broadmeadows factory of ‘Kathryn’ housed more than 100 machines, including 53 sewing machines and 45 knitting machines. Robert Blake was “a passionate advocate for wool and Australian Made” throughout his whole life. A strong thread that ties through the lifespan of Robert Blake and Kathryn Knitwear is a balance between adopting new innovations without sacrificing the core values of durability, comfort, care and style that had made the brand so well known. Their legacy forms an integral part of both Australian social and manufacturing history.Measuring instrument with five circular white layers and one long transparent plastic ruler on top. Transparent layer is now yellowed, was likely originally clear. All of the layers connected with a metal rivet at the centre, allowing the discs and line indicator to move in relation to each other. Discs are labelled (inside – outside) Cost per Thousand Overall Unit Hour U/S [units] produced in 1000s No. of persons Bonus Percentage 9017.2 Black leather case with white block letter printing [9017.3 - 9017.5] Inside case are three notes (one printed, two handwritten) that provide instructions for using the calculator[label on obverse of case] THE AUSTRAL UNIT CALCULATOR ISSUED BY INDUSTRIAL CONSULTANTS, MELB MADE BY MELB >W&G< AUST.business, business history, manufacturing history, calculator, textile fibres textile history -

National Wool Museum

National Wool MuseumTextile - Fabric Sample, Kathryn Knitwear, 1980

... in his bedroom in Strathmore using a hand powered machine... in his bedroom in Strathmore using a hand powered machine ...Kathryn Knitwear, founded by Robert Blake, manufactured high quality children’s knitwear in Melbourne from the 1940s – 1980s. Robert Blake began manufacturing children’s knitwear in his bedroom in Strathmore using a hand powered machine in the late 1940s. The operation moved to Ascot Vale and Essendon, before eventually establishing a factory in Moonee Ponds in the early 1950s. The business continued to expand, necessitating a move to a new factory in Broadmeadows. By 1962, the Broadmeadows factory was producing an average of 20,000 garments per month, which increased to 24,000 by 1964. Robert Blake’s Son, Brendan recalls that “The Kathryn brand was famous around Australia, anywhere children needed to keep warm and dress smartly. It also won a number of wool fashion awards”, including the 1969 Wool Awards, which was held by the Australian Wool Bureau and published in Women’s Weekly. The Kathryn range was designed for durability, comfort and care, without sacrificing style. They used patterning techniques that increase stretchiness, comfort and fit, as well as integrating decorative elements into the fabric to prevent them from being bulky, uncomfortable or tight. Making longevity of style a priority, Brendan Blake remembers that “there was one particular garment that was in the range for at least thirty years”. He also recalls “In the past, when women have found out that I was associated with Kathryn Knitwear, they would often relate to me the story of a garment they had purchased or received as a gift and, when their child had grown out of it, they would hand it on to another child. Several ladies have told me of purchasing garments for their daughters’ glory box, or saving a particular garment after their daughter had grown out of it. Brendan Blake: “At the peak of their operation they employed approximately two hundred people, mainly women and girls. A family would often seek to send their daughter to work in this company because they knew they would be looked after and safe. One lady wrote to me telling me that working at the Moonee Ponds Factory prior to getting married was the happiest time of her life.” In 1963, workers at the Kathryn factory earned £13 per week, which was 8 shillings and 8 pence higher than the minimum weekly wage for female workers in the textile manufacturing industry (£12 11s 4d). By 1970, the Kathryn Knitwear brand expanded from children’s knitwear into womenswear under the brand name ‘Lady Kathryn’, and for boys and men under ‘Robert Blake’. Continuing to diversify their distribution, they also began exporting ‘Kathryn’ garments to New Zealand, the Pacific Islands, and Japan. ‘Kathryn Knitwear’ was well-known for their early adoption of modern materials and techniques that had broad appeal to their customer base. This is shown in their early use of the acrylic fibre ‘Orlon’ in the 50s and 60s and ‘Superwash’ wool in the 1970s. Many of Kathryn Knitwear’s styles, particularly those that were long running staples of the brand, were available in both wool and Orlon to suit the consumer’s preference. Far from the humble origins of one man in his bedroom with a hand-cranked machine; at its closure in 1980, the Broadmeadows factory of ‘Kathryn’ housed more than 100 machines, including 53 sewing machines and 45 knitting machines. Robert Blake was “a passionate advocate for wool and Australian Made” throughout his whole life. A strong thread that ties through the lifespan of Robert Blake and Kathryn Knitwear is a balance between adopting new innovations without sacrificing the core values of durability, comfort, care and style that had made the brand so well known. Their legacy forms an integral part of both Australian social and manufacturing history.Strip of knitted fabric samples showing the nine wool colour options for the boys line of Robert Blake/Kathryn knitwear in the winter season of 1980. Label printed in pale blue paper lists season and colour names and is attached to sample strip with two metal staplesBOYS WOOL WINTER 1980 COLOR SWATCH RED BURGUNDY BROWN RYE PEBBLE OYSTER NAVY BLUE SHADOW DENIM GRANITE GREYfabric sample, textile sample, fabric swatch, textile swatch, fashion textile production, textile manufacturing