Showing 49 items matching "high heat"

-

The Beechworth Burke Museum

The Beechworth Burke MuseumGeological specimen - Greenstone / Gabbro, Unknown

... high heat... condition under the effect of high heat, high pressure or hot... condition under the effect of high heat, high pressure or hot ...This specimen was recovered from Ceres West of Geelong, Victoria. Greenstone is the name for any metamorphosed basic igneous rock (in the case of this specimen, Gabbro) that gains its greenish colour to the presence of the minerals chlorite, actinolite, or epidote, hence the term 'green' and 'stone'. Greenstone is often formed through metamorphsis along a convergent plate boundary. In the rock cycle (the series of processes that creates the various types of rocks) there are identified three different types of rocks, which are the sedimentary, the igneous and the metamorphic. Metamorphic rocks started out as sedimentary, igneous or earlier metamorphic rocks but changed from their original condition under the effect of high heat, high pressure or hot, mineral-rich fluid. However, if pressure or heat is too high, then the rock will melt, resulting in the formation of an igneous rock. The name used to describe these types of rocks reflects this specific inherent trait of change, since the word “metamorphic” derives from the Greek word “metamorphosis”, meaning “change of form or structure”. Metamorphic rocks form in the Earth`s crust but can be also found on the surface, due to elevation of the Earth`s surface. They are divided into two categories: the foliated metamorphic and the non-foliated metamorphic rocks. Gabbro is a highly useful mineral that is often polished to create cemetery markers and kitchen benches. It is notable for its qualities of durability, being able to withstand extreme elements and wear. Whilst not rare, Gabbro is of great utility and has been highly desirable for its qualities. This specimen is part of a larger collection of geological and mineral specimens collected from around Australia (and some parts of the world) and donated to the Burke Museum between 1868-1880. A large percentage of these specimens were collected in Victoria as part of the Geological Survey of Victoria that begun in 1852 (in response to the Gold Rush) to study and map the geology of Victoria. Collecting geological specimens was an important part of mapping and understanding the scientific makeup of the earth. Many of these specimens were sent to research and collecting organisations across Australia, including the Burke Museum, to educate and encourage further study.Greenstone is a solid hand-sized metamorphic mineral of a green colour. Greenstone is the name for any metamorphosed basic igneous rock (in the case of this specimen, Gabbro) that gains its greenish colour to the presence of the minerals chlorite, actinolite, or epidote, hence the term 'green' and 'stone'. Gabbro is a medium to coarse grained rocks that consist primarily of plagioclase feldspar and pyroxene. Greenstone is often formed through metamorphsis along a convergent plate boundary. Gabbro forms due to cooling and crystallization of magma underneath Earth's surface. Greenstone/Gabbro/from Ceres west/of Geelong. Has old Geological Survey label/and probably collected by/Richard Daintree in 1861/C.Willam 15/4/21/ Other label: 62 /greenstone, metamorphosed, igneous rock, gabbro, chlorite, actinolite, epidote, metamorphsis, rock cycle, various types of rocks, sedimentary, high heat, high pressure, mineral-rich fluid, metamorphosis, foliated metamorphic, non-foliated metamorphic, convergent plate boundary, greenish colour, minerals -

The Beechworth Burke Museum

The Beechworth Burke MuseumGeological specimen - Laterite

... a process that is called laterization, where high heat and seasonal... during a process that is called laterization, where high heat ...Laterite refers to both a rock and a soil type that is rich in clay, as well as Iron and Aluminium. It is created during a process that is called laterization, where high heat and seasonal heavy rainfall cause there to be wet and dry periods, which over time hardens the soil into rock. Because of this, most laterite is formed between tropics of Cancer and Capricorn. The iron oxide in laterite is what gives it it’s orange-red colouring. The largest religious complex in the world, Angkor Wat in Cambodia, is partially constructed of laterite, particularly its foundations, as laterite is porous and allows rainwater to drain. This specimen of laterite was collected from the Democratic Republic of Congo while it was colonised by Belgium in the 19th century. Laterite forms in many parts of the world, particularly between the tropics. It is used both for ore and as a building material, and comparing specimens from different parts of the world allows us to document the different compositions that this mineral can have when formed at different locations. This specimen is part of a larger collection of geological and mineral specimens collected from around Australia (and some parts of the world) and donated to the Burke Museum between 1868-1880. A large percentage of these specimens were collected in Victoria as part of the Geological Survey of Victoria that begun in 1852 (in response to the Gold Rush) to study and map the geology of Victoria. Collecting geological specimens was an important part of mapping and understanding the scientific makeup of the earth. Many of these specimens were sent to research and collecting organisations across Australia, including the Burke Museum, to educate and encourage further study.a palm-sized solid iron-aluminium oxide mineral specimen in shades of brown, orange and greyburke museum, beechworth, geological, geological specimen, laterite, laterite specimen, geology -

Bendigo Historical Society Inc.

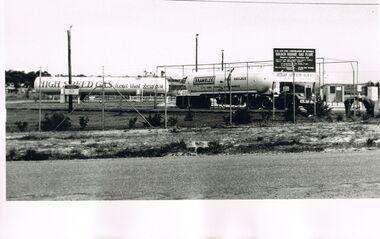

Bendigo Historical Society Inc.Photograph - CASTLEMAINE GAS COMPANY COLLECTION: PHOTO GOLDEN SQUARE DEPOT

... Square Gas Plant'' Tank of ''High Speed Gas heat that obeys you... of Victoria '' Golden Square Gas Plant'' Tank of ''High Speed Gas heat ...L.P.G. Plan Gas and fuel Corporation of Victoria '' Golden Square Gas Plant'' Tank of ''High Speed Gas heat that obeys you '' at centre left side and a brambles baulk haulage truck at centre right.. Date Unknownorganisation, industry, gas and fuel -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Tools, Blowtorch 'Sievert', 20thC

... where a diffuse high temperature naked flame heat is required.... The blowtorch is commonly used where a diffuse high temperature naked ...A blowtorch or blowlamp is a fuel-burning tool used for applying flame and heat to various applications, usually metalworking. Early blowlamps used liquid fuel, carried in a refillable reservoir attached to the lamp. Modern blowtorches are mostly gas-fuelled. The blowlamp is of ancient origin and was used as a tool by gold and silversmiths. They began literally as a "blown lamp", a wick oil lamp with a mouth-blown tube alongside the flame. This type of lamp, with spirit fuel, continued to be in use for such small tasks into the late 20th century. In 1882, a new vaporizing technique was developed by Carl Richard Nyberg in Sweden, and the year after, the production of the Nyberg blow lamp started. It was quickly copied or licensed by many other manufacturers. Carl Richard Nyberg (May 28, 1858, – 1939) was the founder of Max Sievert’s Lödlampfabrik, then one of the largest industries in Sundbyberg, Sweden. After school he started working for a jeweller and later he moved to Stockholm and worked with various metalworks. 1882 and set up a workshop at Luntmakargatan in Stockholm making blowtorches. However the business didn't work well because it took too long to both manufacture and sell them. In 1886 he met Max Sievert (1849 - 1913) at a country fair and Sievert became interested in Nyberg's blowtorch and started selling it. In 1922 the company was sold to Max Sievert who continued to own it until 1964 when it was bought by Esso. The blowtorch is commonly used where a diffuse high temperature naked flame heat is required but not so hot as to cause combustion or welding: soldering, brazing, softening paint for removal, melting roof tar, or pre-heating large castings before welding such as for repairing. It is also common for use in weed control by controlled burn methods, melting snow and ice from pavements and driveways in cold climate areas, road repair crews may use a blowtorch to heat asphalt or bitumen for repairing cracks in preventive maintenance. It is also used in cooking; one common use is for the creation of the layer of hard caramelised sugar in a crème brûlée. A brass blowtorch, 'Sievert' with a wooden handleSIEVERTtools, blow torches, blow lamps, welding, brazing, jewellery, cookery, soldering, nyberg carl, sievert max, stockholm, sweden, spirit fuel, kerosene, gas fuel, moorabbin, bentleigh, cheltenham, market gardeners, pioneers, early settlers, plumbing, carpenters, -

The Beechworth Burke Museum

The Beechworth Burke MuseumGeological specimen - Loellingite in Rhodonite

Rhodonite is a reddish-pink manganese silicate material and often contains iron, magnesium and calcium. It is usually found in metamorphic rocks (rocks which have been altered by heat, pressure or chemical process). It can range in size from tiny to massive. Because of their composition they are not suitable for use in jewellery because they are hard enough. It is quite rare to find, though has been found in Australia, North America, South America and Europe.This specimen is part of a larger collection of geological and mineral specimens collected from around Australia (and some parts of the world) and donated to the Burke Museum between 1868-1880. A large percentage of these specimens were collected in Victoria as part of the Geological Survey of Victoria that begun in 1852 (in response to the Gold Rush) to study and map the geology of Victoria. Collecting geological specimens was an important part of mapping and understanding the scientific makeup of the earth. Many of these specimens were sent to research and collecting organisations across Australia, including the Burke Museum, to educate and encourage further study. This specimen is a palm shaped piece of loellingite within rhodonite. It is mostly reddish-pink coloured, with flecks of light and dark grey. Loellingite is a grey iron arsenide which often forms into crystal shapes. It is mostly found in mesothermal veins (caused by immense heat) with sulfides or in limestone. It is toxic when heated or struck. rhodonite, loellingite, burke museum, beechworth, geological survey of victoria -

The Beechworth Burke Museum

The Beechworth Burke MuseumGeological specimen - Brown coal

This particular specimen was recovered from the Lal Lal Coal and Iron Mine in Victoria, 19km from Ballarat. Brown Coal was discovered here in 1857, just alongside the Geelong to Ballarat Railway line. This discovery of lignite (brown coal) was the first in Victoria, which would bring important benefits to the region and state, both of which had previously been reliant on coal imports. In the 1860s, iron ore was found just 5km from Lal Lal, and the area was converted into an Iron Ore Mine. The Lal Lal Iron Mining Company took over operations in 1874, who then peaked iron production in 1884. This mine continued operations until June 1884, when the blast furnace was extinguished and never recommenced. The blast furnace at Lal Lal is considered one of the most important and highly significant sites ion early industrial history in Australia, as it is the only remaining best furnace from the nineteenth century in the Southern Hemisphere. The furnace ruins are 17 metres high, and are clearly visible today on Iron Mine Road, Lal Lal, near the Bungal Dam. This specimen of Lignite (brown coal) is significant, as it was mined from the area where brown coal was first discovered in Victoria, leading to an important and controversial future of the mining and use of brown coal in this State. The Victorian Heritage Database has listed the Lal Lal Coal Mine with local significance, with their Statement of Significance stating: "The Lal Lal coal mine is historically significant as the site of the first discovery of lignite (brown coal) in Victoria, and one that promised important benefits to regional and state industries that were reliant on coal imports at the time. The significance of the stie is reduced by the poor state of preservation of the coal mining and processing fabric". This specimen is part of a larger collection of geological and mineral specimens collected from around Australia (and some parts of the world) and donated to the Burke Museum between 1868-1880. A large percentage of these specimens were collected in Victoria as part of the Geological Survey of Victoria that begun in 1852 (in response to the Gold Rush) to study and map the geology of Victoria. Collecting geological specimens was an important part of mapping and understanding the scientific makeup of the earth. Many of these specimens were sent to research and collecting organisations across Australia, including the Burke Museum, to educate and encourage further study.A hand-sized light-weight, soft and combustable sedimentary rock specimen, that is dark brown in colour. The specimen has jagged edges, as though parts of the rock have crumbled away. Brown coal, or Lignite, is formed naturally from compressed peat, and is typically found in natural basins. The stages to the formation of coal ('coalification') begin with plant material and wood, which will decay if it is not subjected to deep burial or heating, and turn into Peat. Peat, when sufficiently compressed naturally, will turn into Brown Coal (Lignite), and finally into Black Coal (sub-bituminous, bituminous and anthracite). Each successive stage has a higher energy content and lower water content. It is brownish-black in colour. Brown Coal has a high moisture content, between 50 and 75 percent, and a low carbon content. Some Brown Coals may be stratified, with layers of plant matter, which means little coalification has occurred beyond the peat natural processing stage. When Brown Coal is submerged in dilute nitric acid or boiling potassium hydroxide solution, it reacts to produce a reddish solution, of which higher-ranked coals do not. When brown coal is pulverised and burned in boilers, the steam is used to drive turbines, which generates electricity. It is the lowest rank of coal, as when burned, it creates a relatively low heat content, which in turn does not create a great output of steam. burke museum, beechworth, indigo shire, beechworth museum, geological, geological specimen, mineralogy, brown coal, brown coal specimen, lignite, lal lal, lal lal coal mine, lal lal iron mine, ballarat, blast furnace -

The Beechworth Burke Museum

The Beechworth Burke MuseumGeological specimen - Brown Coal

Brown Coal is typically found as rocks. During formation the Brown Coal starts as peats, which is an acidic brown deposit resembling soil, and over time when subjected to pressure and heat these peats form the Coal. Brown Coal is the lowest rank of coal as it has a low carbon (energy) content, and a high moisture content. This high moisture content makes Brown Coal unsuitable for overseas exports. This particular specimen was recovered from the Yallourn Mine in Latrobe Valley, Victoria as part of the geological survey of Victoria being carried out by Alfred Selwyn. Otherwise known as the 'Yallourn Power Station', the Yallourn Mine is Australia's second largest mine. Yallourn Mine was first built in 1920, and since then it has been providing over 1 billion tonnes of Brown Coal to Australia every year. The Yallourn Mine is responsible for 22% of Victoria's electricity and 8% of Australia's electricity. As of 2021 the mine employs around 500 people. Due to ongoing maintenance issues and Australia's move to cleaner energy, the Yallourn Mine intends to shut down permanently as of 2028. Soon after gold was discovered in 1851, Victoria’s Governor La Trobe wrote to the Colonial Office in London, urging ‘the propriety of selecting and appointing as Mineral Surveyor for this Colony a gentleman possessed of the requisite qualifications and acquaintance with geological science and phenomena’. Alfred Selwyn was appointed geological surveyor in Australia in 1852 which began the Geological Survey of Victoria. In 1853-69 the Geological Survey issued under Selwyn's direction sixty-one geological maps and numerous reports; they were of such high standard that a writer in the Quarterly Journal of the Geological Society of London bracketed the survey with that of the United States of America as the best in the world. During his years spent in Australia, Selwyn collected numerous significant geological specimens, examples of which are held in collections such as the Burke Museum.Brown coal is considered to be an essential rock to Australia's energy consumption. Although plentiful in sources, Brown Coal is not able to be exported overseas due to its high moisture content. As Australia moves towards cleaner energy, Brown Coal is going become less used. This specimen is part of a larger collection of geological and mineral specimens collected from around Australia (and some parts of the world) and donated to the Burke Museum between 1868-1880. A large percentage of these specimens were collected in Victoria as part of the Geological Survey of Victoria that begun in 1852 (in response to the Gold Rush) to study and map the geology of Victoria. Collecting geological specimens was an important part of mapping and understanding the scientific makeup of the earth. Many of these specimens were sent to research and collecting organisations across Australia, including the Burke Museum, to educate and encourage further study.A solid hand-sized sedimentary rock that is a dark shade of brown.13 / BROWN COAL / Showing Woody structure / Locality: Yallourn, Vic. | Label probably / correct but / can't find reference / no. 13 to match in / registers. / C Willman / 15/4/21burke museum, beechworth, indigo shire, beechworth museum, geological, geological specimen, mineralogy, yallourn, yallourn mine, victoria, coal, brown coal, brown coal specimen, alfred selwyn, geological survey of victoria, geological survey, yallourn power station -

The Beechworth Burke Museum

The Beechworth Burke MuseumGeological specimen - Marble, Unknown

A granular metamorphic rock, marble is derived from limestone or dolomite and composed of calcite or dolomite interlocking grains. Heat and pressure from overlying sediments form it from limestone buried deep in Earth's crust. Graphite, pyrite, quartz, mica, and iron oxides can affect rock texture and colour. This specimen was found in Carrara, Italy. Carrara marble is the most common marble found in Italy, and it gets its name from the region where it is located. The marble was also called Luna marble and was used as a decorative element in buildings and sculptures. It has been quarried since Roman times in the Lunigiana, the northernmost tip of Tuscany, just outside the city of Carrara in the province of Massa and Carrara.Marble is one of the most popular and expensive rocks used in sculpture, architecture, interior decorations, statues, table tops, and novelties. It is available in various colors and textures depending on the chemical composition. The strength of the rock and its ability to hold finer details have made it a favorite among designers. This specimen is part of a larger collection of geological and mineral specimens collected from around Australia (and some parts of the world) and donated to the Burke Museum between 1868-1880. A large percentage of these specimens were collected in Victoria as part of the Geological Survey of Victoria that begun in 1852 (in response to the Gold Rush) to study and map the geology of Victoria. Collecting geological specimens was an important part of mapping and understanding the scientific makeup of the earth. Many of these specimens were sent to research and collecting organisations across Australia, including the Burke Museum, to educate and encourage further study.A solid hand sized Marble (metamorphic rock) predominantly white with specks light grey and ochre geological specimen, geology, geology collection, burke museum, beechworth, marble, carrara marble, italian marble, marble specimen, tuscany -

The Beechworth Burke Museum

The Beechworth Burke MuseumGeological specimen - Chiastolite

It is made up of andalusite. Andalusite is a rock-forming mineral, sometimes found in granite or schist. It is often used to make glass, ceramic products, chemicals, and heat-resistant bricks as it can withstand high temperatures without changing. The chiastolite contains particles of graphite, which arranges in geometric patterns. When crystal growth occurs in the rock, the granite particles concentrate at crystal interfaces and can result in cross shapes. These ‘cross stones’ have been valued and used for their spiritual or religious meaning and used as charms, gems, or amulets. Chiastolite was first discovered in 1754, seen in a description in a published book by a palaeontologist, Franciscan priest, and Spanish author, Jose Torrubia. Deposits have been found in Australia, France, the USA, Chile, Canada, Spain, Brazil, Sri Lanka, and Russia. Deposits have been found in Western Australia and South Australia. This particular specimen was found in Bimbowrie, South Australia. Other chiastolite specimens have been found in Bimbowrie, along with jasper, quartz, and aventurine in the form of rolled pebbles or schist. This chiastolite specimen is socially and historically significant. It is a very rare sort of andalusite mineral. It is from one of only two locations where it is regularly found in Australia. The carbon cross has made it an important religious symbol in the past. Its ability to withstand high temperatures has made it a common ingredient in heat-resistant bricks and ceramics today. This specimen is part of a larger collection of geological and mineral specimens collected from around Australia (and some parts of the world) and donated to the Burke Museum between 1868-1880. A large percentage of these specimens were collected in Victoria as part of the Geological Survey of Victoria that begun in 1852 (in response to the Gold Rush) to study and map the geology of Victoria. Collecting geological specimens was an important part of mapping and understanding the scientific makeup of the earth. Many of these specimens were sent to research and collecting organisations across Australia, including the Burke Museum, to educate and encourage further study.A metamorphic mineral consisting of andalusite, with a cross shaped graphite pattern in colours of grey, brown and yellowburke museum, beechworth, geological, geological specimen, andalusite, chiastolite, geometric, cross stone, spiritual, religious, australia, south australia, bimbowrie, quartz, jasper, aventurine, schist -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietySafe Coolgardie, circa early 1900s

The harsh summer temperatures and the isolated rural environment(of the 1890's) provided the inventor of the "Coolgardie safe" (Arthur Patrick McCormick) with an idea to cool perishable foods by using water soaked "hessian" cloth to provide the "coolant" for the evaporation process to cool the inside temperature of the "safe". Items such as meat,cream/milk/butter and cool "drinks" are a few perishables that need cool environments , especially in isolated "ice free" locations. Cities during this time period had large "ice works" which delivered block ice to all areas that required a form of refrigeration. These ice blocks where held in early refrigerators to keep perishables cool to cold. This "Coolardie" safe was the next best thing for isolated rural households and travellers/campers/stockmen to provide a cooler environment for foodstuff affected by heat. Ice filled "esky" coolers and ice boxes are a modern day off shoot to the original Coogardie safe however they still rely on ice or frozen coolant bricks for cooling.This "Coogardie" safe is very significant to the Kiewa Valley and the Bogong High Plains because it represents not only the initiative thinking of the early settlers and communities but also the "primitive" solution to an everyday (1800s to 1930s) problem (before gas and electric run refrigerators) of keeping "perishables" at a low temperature and thereby prolonging their "shelf" life. This was before electricity and gas was available to the inhabitants of the Kiewa Valley and Bogong High Plains. Another cooling method for food was to have "water tight" containers dipped into the very cold streams running from the "cooler" alpine mountains and the Bogong High Plains. This however could not be carried out in all situations eg. fast flowing currents and locations away from streams. This "Coolgardie safe" is made from a medium grade steel enclosure and its appearance is of a perforated box with a wire handle and one side (long side) being a hinged "door" with a clasp securing "lock". There are air holes grouped into a small "boxed" pattern. Each "box" is divided by a crossed pattern, dividing the "holed" sections(4) into a diamond configuration of 49 small holes each. There are four sides (long) which have the perforations except for the base which does not. The base has an indentation with a loose "catch" tray to catch water spills. When in use the "box" is covered with a water "soaked" cloth. The wet cloth is used as "coolant" ie. fibers in the cloth hold the water droplets seep out evaporating the area and thereby (in mass) cooling the air inside the container.domestic refrigeration cabinets, coolgardie "safe", insect and vermin proof food containers, electric and gas free cold storage containers -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyIron - Kerosene

Kerosene irons were used c1930 - 1950 especially where electricity wasn't available. Shelite was another fuel that could be used instead of kerosene. The advantage of the kerosene iron was that it didn't require a stove to be lit (especially in summer) to heat the iron and it didn't require electricity.Residents in the Kiewa Valley used kerosene irons.This black iron is made of cast iron with a steel base and a black wooden handle. This Comfort iron has a ball shaped container with a screw-on lid to hold the fuel (kerosene or Shelite). At the bottom of this ball is a pipe going down then meeting another pipe at right angles to it leading into the iron. At the pipe junction there is a handle on a screw to limit the amount of fuel. The Kerosene would flow through this pipe. There is a filler plug air stem on top. This is a self-heating iron.Comfort iron / Self Heating Comfort Iron MFD by / National Stamping and Electric Works / made in U.S.A. Chicago iron, domestic, laundry, pressing clothes, household, kerosene, shelite -

Ballarat Clarendon College

Ballarat Clarendon CollegeTrophy

From 1884 College Cups were donated by the Old Collegians Association for the outstanding athlete amongst ‘present boys’ and ‘past boys’. It is obvious from written records and the inscriptions on the cups themselves that two cups were awarded to students – a Junior Cup and a Senior Cup.The Old Collegians Cup was a prestigious award presented in the early days of Ballarat College for private retention. At the Annual Sports Day almost the entire athletics program was devoted to the heats associated with the awarding of the College Cup (Senior) and the Old Collegians Cup. Competitors had to run in three handicapped races over 120, 250 and 440 yards respectively. So high was the regard for the winner of the Senior Cup that Old Collegians would refer to past events as happening 'in the year X won the College Cup'. The Ballarat Old Collegians Association notes in The Minervan 1913 that "each year the Association presents to the College Sports committee the College Cups (Senior and Junior), the Old Collegians Cup and the Veterans Plate. Raymond Dawson Vaughan attended Ballarat College under Principal Major John Garbutt until 1909. He was one of the first students to enrol in the new Agricultural Science Course at Ballarat High School in 1910. he completed this course with credits and high honours. After leaving school he was involved in agricultural and pastoral pursuits at Lorcan in the West Wimmera. Ray served in WW1 and was killed in action, aged 25, on 9 June 1917 at Messines. His plaque in No 2041 in the Ballarat Avenue of Honour. Medium, ornate, double-handled cup on silver standInscribed on face of cup: Old Collegians Cup / 1911 / R D VAUGHAN Inscribed on rear of cup: Ballarat College crestold-collegians-cup, ray-d-vaughan, athletics, sports day -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageContainer - Try pot, c.20th century

This try-pot is one of a set of three. Whalers used large iron pots, called try-pots to liquefy large chunks of whale blubber down into oil. Early on in the history of whaling, small whaling boats had no means to process blubber at sea and had to bring it into whaling stations for processing at shore-based try-works. Later, when bay whaling evolved and large scale vessel were utilised for hunting whales, try pots were mounted onto the top deck. This advance had its benefits as the processing facilities were mobile, whalers could move operations to follow whales and discover new whaling grounds. The deceased whale would be tied up alongside the ship, the crewmen cut away the blubber, or outer fat layer, in long strips. They hauled the strips aboard, cut them into smaller pieces, and tossed them into boiling cauldrons on deck to render the fat into oil. The whale oil was stored in barrels in the cargo hold, and brought to put for sale. The oil was much sought after as a good quality fuel tor heating, light and lubrication. Try pots were used in the whaling industry, one of the very early industries in Colonial Australia, including here on the southwest coast of Victoria. The high grade oil was a much sought after product and used for essential services such as fuelling the lights of the lighthouses. Commercial whaling ceased in Australia in 1979.Try pot, one of a set of three. A large cast-iron cauldron of about 200 gallons in capacity. Round metal container with rounded base and flat extended lip. It was used to heat whale blubber to remove the oil.flagstaff hill, warrnambool, maritime museum, shipwreck coast, try pot, trypot, cauldron, whale oil, whaling, fuel -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageContainer - Try pot, c. 20th century

This try-pot is one of a set of three. Whalers used large iron pots, called try-pots to liquefy large chunks of whale blubber down into oil. Early on in the history of whaling, small whaling boats had no means to process blubber at sea and had to bring it into whaling stations for processing at shore-based try-works. Later, when bay whaling evolved and large scale vessel were utilised for hunting whales, try pots were mounted onto the top deck. This advance had its benefits as the processing facilities were mobile, whalers could move operations to follow whales and discover new whaling grounds. The deceased whale would be tied up alongside the ship, the crewmen cut away the blubber, or outer fat layer, in long strips. They hauled the strips aboard, cut them into smaller pieces, and tossed them into boiling cauldrons on deck to render the fat into oil. The whale oil was stored in barrels in the cargo hold, and brought to put for sale. The oil was much sought after as a good quality fuel tor heating, light and lubrication. Try pots were used in the whaling industry, one of the very early industries in Colonial Australia, including here on the southwest coast of Victoria. The high grade oil was a much sought after product and used for essential services such as fuelling the lights of the lighthouses. Commercial whaling ceased in Australia in 1979.Try pot, one of a set of three. A large cast-iron cauldron of about 180 gallons in capacity. Round metal container with rounded base and flat extended lip. It was used to heat whale blubber to remove the oil.flagstaff hill, warrnambool, maritime museum, shipwreck coast, try pot, trypot, cauldron, whale oil, whaling, fuel -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Household Equipment, Earthenware hot water bottle 'Hoffmann', c1900

Large stoneware hot water bottle also called a foot warmer. The stoneware hot water bottle has a rubber cap, often the original stone cap would be replaced with a cork alternative to seal the hot water. Because they were mass produced and very robust many survived so the antique value is not great. Many stoneware hot water bottles are still in use today and will be for years to come. Stoneware is a certain clay fired at a particularly high temperature and glazed so that it resembles polished stone.The bottle was filled with hot water, close the stopper securely and stand them in a bed, upright, on their small flat ends so that the sheets and blankets formed a tent-like structure over them. The peak of the 'tent' was the special feature of the rounded knob opposite the flat end, which also served as a carrying handle. Used this way, the hot water bottle was supposed to heat more of the bed Josef Hoffmann (1870–1956) attended the Academy of Fine Arts in Vienna and studied architecture under Otto Wagner. As a designer, Hoffmann was creative and prolific. His design portfolio encompassed commissions for buildings and interiors but extended to things as diverse as textiles, umbrella knobs, walking stick handles, tea pots, caskets and book covers as well as glass and ceramics.In 1903, with Koloman Moser and financier Fritz Waerndorfer, Hoffmann founded the Wiener Werkstätte. The collaboration of artists, designer architects and artisans enabled the realisation of the ‘total artwork’. Hoffmann’s designs were based on simple and clear proportions and employed rich, high-quality materials. Everyday objects were conceived as part of a whole living environment and were considered works of art. A large earthenware hot water bottle.HOFFMANNearly settlers, moorabbin mckinnon, ormond, bentleigh, pottery, craftwork, earthenware, pioneers, hoffmann josef, waerndorfer fritz, moser kololan, weiner werkstatte, vienna, austria, brumpton frances -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietySaucepan, circa mid to late 1900's

This large deep pan (with a long handle) was used by pioneer families, mainly rural folk, that needed a pan which could cope with an open fire heat source, in or mainly outside the homestead. This pan was used in the early to late 1900's for the "stews" and other meals required by hard working stock men and farmers that had irregular "lunch and dinner" breaks under sometimes hard and gruelling conditions. Hot plates were normally not in use.This "open fire" saucepan belonged, and was used by a Kiewa Valley, pioneer family, the Roper Family. This saucepan was moved from their Kiewa Valley property to their hut built on the Bogong High Plains. This saucepan was one of an array of "open fire" cooking utensils used in the "camp draft" grazing in the Bogong High Plains and this could take up to six weeks. This kettle belonged and was used by a Kiewa Valley, pioneer family, the Roper Family. This kettle was moved from their Kiewa Valley property to their hut built on the Bogong High Plains. A scientific study started in 1947 to study the impact of grazing cattle on the natural Alpine and sub Alpine vegetation found grazing cattle had an adverse affect on the natural Alpine and sub alpine vegetation, and grazing on the plains was stopped by the Victorian Government in 2005.This large (black, soot infused) cast iron saucepan has a "ten pint" holding capacity and was used on the "open fire", possible on the fire direct. It has a long all metal handle coming from the top half of the pot and angled at approximately sixty degrees upwards. This angle insures that both distance from flame intensity and least bending of knees when lifting is at a minimum.On bottom of pan (underside) "N0. 8 JSJ SIDDONS" on the other side "WEST BROMWICH 5 QUARTS"camp fire cooking utensils, hot plate, cast iron cooking appliance, drovers kitchen -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyVacuum Flask

Ron White (1920-2019) worked for the SECV and was superintendent engineer of the Kiewa Hydro Electric Scheme after its completion. He used this 'thermos'. See KVHS 1282Ron White lived in Mt Beauty and worked for the SECV until he retired in 1985. See KVHS 1282Original box Gold Coin Brand / Vacuum Flask / Superior in Styling / Endurably Heat Preserving. / Trade Mark is Chinese & written in Chinese. Bright red steel cylinder with most of the gold label missing. Cork in top. Plastic lid is not the original.Base: 'Freezinhot Bottle Made in Hong Kong' is embossed around the perimeter.vacuum flask, gold coin brand, thermos, ron white -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietySoldering Irons x3

A soldering iron is a hand tool used in soldering. It supplies heat to melt solder so that it can flow into the joint between two workpieces. The iron was heated over a fire or in a charcoal brazier. Soldering irons were primarily used by tinsmiths and coppersmiths to work with thin sheet metal. These hand soldering irons have been replaced by electric ones.Used by coppersmiths and tinsmiths and workers in the Kiewa Valley.The soldering irons have a wooden handle, an iron rod and are made of copper at the pointy end (the bit).shaped like a pyramid.soldering iron, hand tool, coppersmith, tinsmith -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyBottle - Kruschen Salts

Sole manufacturer ef. "Kruschen": Evan Griffiths Hughes, chemists of County of Lancashire, England. Keuschen Salts was an electrolyte replenisher to prevent heat cramps caused by too much sweating.Used by a resident of te Kiewa Valley.Amber coloured glass bottle with metal screwtop lid, remnants of a label.Lid: "Kruschen" stamped inside a circle on the tin. Base also has 'Kruschen' in raised lettering.kruschen salts, electrolyte, medicinal -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyIron Hand Kerosene, mid to late 1900s

The 1950's saw a revolution in small appliances for use in the average household. This hand held self heating(kerosene) iron was introduced as a time saving and more convenient iron for pressing clothes and other cloth fabrics. It replaced irons needing a separate fire source to heat the ironing plate. These irons continued to be in service, even when electricity was available in cities and larger rural towns (domestic electric steam irons were invented in 1938). This item was used before and during the electricity supplies available from the Kiewa Hydro Electricity Scheme. These irons remained in use within regional rural areas that had limited or unreliable electrical reticulation.In the 1950s and later the Kiewa Valley was still a relatively isolated region which was home to rural properties and small settlements. The availability of electricity and or the financial means to afford new types of electric hand irons ensured that older and sometimes less efficient ironing remained for an extended period covering the 1960s to 1970s. Kerosene products, such as this kerosene iron was a cheaper method for farm based domestic and other rural activities requiring a heat source. The use of kerosene as a heat/light source was able to be supplied in bulk and able to be used when floods severed vital roads into this region. The supply of electricity was in summer time subject to interruption from bush fire damaged wooden poles carrying the electrical cables. Self sufficiency by rural populations was the backbone of survival and the ability to store energy sources "on the farm" was a prerequisite of isolated regions, such as the Kiewa Valley, circa 1950s.This Coleman kerosene iron has a solid steel chrome plated(press) base with a painted (blue) wooden handle. The handle is stud fastened onto an oblong shaped rolled steel handle frame and screwed (two screws) onto the base plate. Both the heating plate and the top securing plate are shaped similar to a river boat. The main housing enclosing the heating element is enamel coated(blue in colour) steel and has a half hole for lighting the kerosene at the rear end. Behind the handle and protruding upwards is a stainless steel fully enclosed container (bowl shaped) for the main supply of kerosene to the burner or generator(enclosed within the main body of the iron. The bowl has an air valve and inlet for pressurised air intake (hand pump) On the bottom rear of the fuel bowl there is a screw regulated fuel pump. The fuel heated base plate provides the heat for this advertised "self heating iron(instant lighting). See KVHS 0347B- Instruction sheet; KVHS 0347C- Wrench; and KVHS 0347D Fuel can.Stamped on the base plate of the handle, front region "COLEMAN LAMP & STOVE CO." below this "WICHITA KAN" below this"TORONTO CAN". In the middle of the handle base and in larger print "COLEMAN Instant-Lite" At the rear location in large print "MODEL 4" in smaller print below "MADE IN U.S.A." below this "PAT#1718473"household appliances, alternative non electrical ironing appliances, domestic appliances, kerosene appliances -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyCan Fuel Measuring, circa 1950

The 1950's saw a revolution in small appliances for use in the average household. The hand held self heating(kerosene) iron for which this filling can was provided ,was introduced as a time saving and more convenient iron for pressing clothes and other cloth fabrics. It replaced irons needing an external fire source to heat the ironing plate. These irons continued to be in service, even when electricity was available in cities and larger rural towns. This item was used before and during the electricity supplies available from the Kiewa Hydro Electricity Scheme. These irons remained in use within regional rural areas that had limited or unreliable electrical reticulation and the ability to service them from this filling can was an essential part.n the 1950s and later the Kiewa Valley was still a relatively isolated region which was home to rural properties and small settlements. The availability of electricity and or the financial means to afford new types of electric hand irons ensured that older and sometimes less efficient ironing appliances remained for an extended period covering the 1960s to 1970s. Kerosene products, such as the kerosene self heating (KVHS 0347A) iron and this kerosene filling item, was a cheaper method for farm based domestic and other rural activities requiring a heat source. The use of kerosene as a heat/light source was able to be supplied in bulk and able to be used when floods severed vital roads into this region. The supply of electricity was in summer time subject to interruption from bush fire damaged wooden poles carrying the electrical cables. Self sufficiency by rural populations was the backbone of survival and the ability to store energy sources "on the farm" was a prerequisite of isolated regions, such as the Kiewa Valley, circa 1950s.This specially spout fitted can was provided with the Coleman self heating kerosene iron (see KVHS 0347A). On one side of the half enclosed top of the can there is a small spout(for poring the appropriate liquid into the egg shaped fount container) at the rear end of the hand iron. The can is made from tin. See KVHS 0347B- Instruction sheet; KVHS 0347C- Wrench.On one side of the can in black print on yellow background is "FUEL MEASURING CAN" underneath is "For Coleman Instant-Lite Iron" underneath are four numbered paragraphs detailing the use of this can. Below this is the name and places of manufacture. On the other side of the can is printed "BE SURE" with filling and maintenance instructionskerosene can, ironing, domestic appliances, household appliances -

Federation University Historical Collection

Federation University Historical CollectionCeramic Crucible, Morgan Fluxing Pot

A crucible is a vessel made of a refractory substance such as graphite or porcelain, used for melting and calcining materials at high temperatures. (http://www.thefreedictionary.com/crucible) Morgan Crucible was established in 1856. See http://ubshwiki.ballarat.edu.au/index.php/Morgan_Crucible_Co. A crucible is used to hold small amounts of chemicals during heating at high temperatures. The lid covers the bowl so nothing escapes, or to keep oxygen out of the reaction. (http://wiki.answers.com/Q/What_is_a_crucible_and_how_is_it_used_in_a_laboratory)Two used narrow high shape crucibles with small spouts made by Morgan of England. They are heat-resistant containers used to melt ores, metals, and other materials. One has green (copper origin?) glaze like material on the base and sidecrucible, assaying, morgan -

Federation University Historical Collection

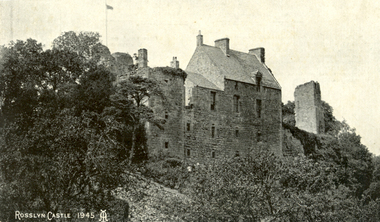

Federation University Historical CollectionPostcard, Roslin, c1945

Roslin Castle, the seat of the St Clair Family, was founded in 1304. It is partly in ruins. According to legend some millions of pounds worth of treasure being hidden in the vaults. it is said to be under the charge of a lady of the ancient St Clair family. She is to wake from her slumber and point out the spot where the treasure lies. It is located near the village of Roslin in Midlothian, Scotland. It is located around 9 miles south of Edinburgh, on the north bank of the North Esk, only a few hundred metres from the famous Rosslyn Chapel. (See http://en.wikipedia.org/wiki/Roslin_Castle)Three postcards showing different views of Roslin Castle. .1) A stone building on a hill side, with flying flag, .2) The Courtyard, Roslin Castle .3) The Bakehouse, Roslin Castle.1) This a fine view taken from the Glen. Formerly the castle was eight storeys high, five above and three underground. .2) While at Edinburgh I went out to Roslin saw there the Castle and Church. They are both very old dating back 500 hundred years. .3) The hole in the wall is the oven, is an immense thing. A fire was lit in the oven then pulled out and the heat in the stone did the baking.roslin, rosslyn, roslin castle, st clair, spirit, ghost, baking, oven, bread -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageAnimal specimen - Whale bone, Undetermined

Prior to carrying out a detailed condition report of the cetacean skeletons, it is useful to have an understanding of the materials we are likely to encounter, in terms of structure and chemistry. This entry invites you to join in learning about the composition of whale bone and oil. Whale bone (Cetacean) bone is comprised of a composite structure of both an inorganic matrix of mainly hydroxylapatite (a calcium phosphate mineral), providing strength and rigidity, as well as an organic protein ‘scaffolding’ of mainly collagen, facilitating growth and repair (O’Connor 2008, CCI 2010). Collagen is also the structural protein component in cartilage between the whale vertebrae and attached to the fins of both the Killer Whale and the Dolphin. Relative proportions in the bone composition (affecting density), are linked with the feeding habits and mechanical stresses typically endured by bones of particular whale types. A Sperm Whale (Physeter macrocephalus Linnaeus, 1758) skeleton (toothed) thus has a higher mineral value (~67%) than a Fin Whale (Balaenoptera physalus Linnaeus, 1758) (baleen) (~60%) (Turner Walker 2012). The internal structure of bone can be divided into compact and cancellous bone. In whales, load-bearing structures such as mandibles and upper limb bones (e.g. humerus, sternum) are largely composed of compact bone (Turner Walker 2012). This consists of lamella concentrically deposited around the longitudinal axis and is permeated by fluid carrying channels (O’Connor 2008). Cancellous (spongy) bone, with a highly porous angular network of trabeculae, is less stiff and thus found in whale ribs and vertebrae (Turner Walker 2012). Whale oil Whales not only carry a thick layer of fat (blubber) in the soft tissue of their body for heat insulation and as a food store while they are alive, but also hold large oil (lipid) reserves in their porous bones. Following maceration of the whale skeleton after death to remove the soft tissue, the bones retain a high lipid content (Higgs et. al 2010). Particularly bones with a spongy (porous) structure have a high capacity to hold oil-rich marrow. Comparative data of various whale species suggests the skull, particularly the cranium and mandible bones are particularly oil rich. Along the vertebral column, the lipid content is reduced, particularly in the thoracic vertebrae (~10-25%), yet greatly increases from the lumbar to the caudal vertebrae (~40-55%). The chest area (scapula, sternum and ribs) show a mid-range lipid content (~15-30%), with vertically orientated ribs being more heavily soaked lower down (Turner Walker 2012, Higgs et. al 2010). Whale oil is largely composed of triglycerides (molecules of fatty acids attached to a glycerol molecule). In Arctic whales a higher proportion of unsaturated, versus saturated fatty acids make up the lipid. Unsaturated fatty acids (with double or triple carbon bonds causing chain kinks, preventing close packing (solidifying) of molecules), are more likely to be liquid (oil), versus solid (fat) at room temperature (Smith and March 2007). Objects Made From the Whaling Industry We all know that men set forth in sailing ships and risked their lives to harpoon whales on the open seas throughout the 1800s. And while Moby Dick and other tales have made whaling stories immortal, people today generally don't appreciate that the whalers were part of a well-organized industry. The ships that set out from ports in New England roamed as far as the Pacific in hunt of specific species of whales. Adventure may have been the draw for some whalers, but for the captains who owned whaling ships, and the investors which financed voyages, there was a considerable monetary payoff. The gigantic carcasses of whales were chopped and boiled down and turned into products such as the fine oil needed to lubricate increasing advanced machine tools. And beyond the oil derived from whales, even their bones, in an era before the invention of plastic, was used to make a wide variety of consumer goods. In short, whales were a valuable natural resource the same as wood, minerals, or petroleum we now pump from the ground. Oil From Whale’s Blubber Oil was the main product sought from whales, and it was used to lubricate machinery and to provide illumination by burning it in lamps. When a whale was killed, it was towed to the ship and its blubber, the thick insulating fat under its skin, would be peeled and cut from its carcass in a process known as “flensing.” The blubber was minced into chunks and boiled in large vats on board the whaling ship, producing oil. The oil taken from whale blubber was packaged in casks and transported back to the whaling ship’s home port (such as New Bedford, Massachusetts, the busiest American whaling port in the mid-1800s). From the ports it would be sold and transported across the country and would find its way into a huge variety of products. Whale oil, in addition to be used for lubrication and illumination, was also used to manufacture soaps, paint, and varnish. Whale oil was also utilized in some processes used to manufacture textiles and rope. Spermaceti, a Highly Regarded Oil A peculiar oil found in the head of the sperm whale, spermaceti, was highly prized. The oil was waxy, and was commonly used in making candles. In fact, candles made of spermaceti were considered the best in the world, producing a bright clear flame without an excess of smoke. Spermaceti was also used, distilled in liquid form, as an oil to fuel lamps. The main American whaling port, New Bedford, Massachusetts, was thus known as "The City That Lit the World." When John Adams was the ambassador to Great Britain before serving as president he recorded in his diary a conversation about spermaceti he had with the British Prime Minister William Pitt. Adams, keen to promote the New England whaling industry, was trying to convince the British to import spermaceti sold by American whalers, which the British could use to fuel street lamps. The British were not interested. In his diary, Adams wrote that he told Pitt, “the fat of the spermaceti whale gives the clearest and most beautiful flame of any substance that is known in nature, and we are surprised you prefer darkness, and consequent robberies, burglaries, and murders in your streets to receiving as a remittance our spermaceti oil.” Despite the failed sales pitch John Adams made in the late 1700s, the American whaling industry boomed in the early to mid-1800s. And spermaceti was a major component of that success. Spermaceti could be refined into a lubricant that was ideal for precision machinery. The machine tools that made the growth of industry possible in the United States were lubricated, and essentially made possible, by oil derived from spermaceti. Baleen, or "Whalebone" The bones and teeth of various species of whales were used in a number of products, many of them common implements in a 19th century household. Whales are said to have produced “the plastic of the 1800s.” The "bone" of the whale which was most commonly used wasn’t technically a bone, it was baleen, a hard material arrayed in large plates, like gigantic combs, in the mouths of some species of whales. The purpose of the baleen is to act as a sieve, catching tiny organisms in sea water, which the whale consumes as food. As baleen was tough yet flexible, it could be used in a number of practical applications. And it became commonly known as "whalebone." Perhaps the most common use of whalebone was in the manufacture of corsets, which fashionable ladies in the 1800s wore to compress their waistlines. One typical corset advertisement from the 1800s proudly proclaims, “Real Whalebone Only Used.” Whalebone was also used for collar stays, buggy whips, and toys. Its remarkable flexibility even caused it to be used as the springs in early typewriters. The comparison to plastic is apt. Think of common items which today might be made of plastic, and it's likely that similar items in the 1800s would have been made of whalebone. Baleen whales do not have teeth. But the teeth of other whales, such as the sperm whale, would be used as ivory in such products as chess pieces, piano keys, or the handles of walking sticks. Pieces of scrimshaw, or carved whale's teeth, would probably be the best remembered use of whale's teeth. However, the carved teeth were created to pass the time on whaling voyages and were never a mass production item. Their relative rarity, of course, is why genuine pieces of 19th century scrimshaw are considered to be valuable collectibles today. Reference: McNamara, Robert. "Objects Made From the Whaling Industry." ThoughtCo, Jul. 31, 2021, thoughtco.com/products-produced-from-whales-1774070.Whale bone was an important commodity, used in corsets, collar stays, buggy whips, and toys.Whale bone in two pieces. Advanced stage of calcification as indicated by deep pitting. Off white to grey.None.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, whale bones, whale skeleton, whales, whale bone, corsets, toys, whips -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageAnimal specimen - Whale bone, Undetermined

Prior to carrying out a detailed condition report of the cetacean skeletons, it is useful to have an understanding of the materials we are likely to encounter, in terms of structure and chemistry. This entry invites you to join in learning about the composition of whale bone and oil. Whale bone (Cetacean) bone is comprised of a composite structure of both an inorganic matrix of mainly hydroxylapatite (a calcium phosphate mineral), providing strength and rigidity, as well as an organic protein ‘scaffolding’ of mainly collagen, facilitating growth and repair (O’Connor 2008, CCI 2010). Collagen is also the structural protein component in cartilage between the whale vertebrae and attached to the fins of both the Killer Whale and the Dolphin. Relative proportions in the bone composition (affecting density), are linked with the feeding habits and mechanical stresses typically endured by bones of particular whale types. A Sperm Whale (Physeter macrocephalus Linnaeus, 1758) skeleton (toothed) thus has a higher mineral value (~67%) than a Fin Whale (Balaenoptera physalus Linnaeus, 1758) (baleen) (~60%) (Turner Walker 2012). The internal structure of bone can be divided into compact and cancellous bone. In whales, load-bearing structures such as mandibles and upper limb bones (e.g. humerus, sternum) are largely composed of compact bone (Turner Walker 2012). This consists of lamella concentrically deposited around the longitudinal axis and is permeated by fluid carrying channels (O’Connor 2008). Cancellous (spongy) bone, with a highly porous angular network of trabeculae, is less stiff and thus found in whale ribs and vertebrae (Turner Walker 2012). Whale oil Whales not only carry a thick layer of fat (blubber) in the soft tissue of their body for heat insulation and as a food store while they are alive, but also hold large oil (lipid) reserves in their porous bones. Following maceration of the whale skeleton after death to remove the soft tissue, the bones retain a high lipid content (Higgs et. al 2010). Particularly bones with a spongy (porous) structure have a high capacity to hold oil-rich marrow. Comparative data of various whale species suggests the skull, particularly the cranium and mandible bones are particularly oil rich. Along the vertebral column, the lipid content is reduced, particularly in the thoracic vertebrae (~10-25%), yet greatly increases from the lumbar to the caudal vertebrae (~40-55%). The chest area (scapula, sternum and ribs) show a mid-range lipid content (~15-30%), with vertically orientated ribs being more heavily soaked lower down (Turner Walker 2012, Higgs et. al 2010). Whale oil is largely composed of triglycerides (molecules of fatty acids attached to a glycerol molecule). In Arctic whales a higher proportion of unsaturated, versus saturated fatty acids make up the lipid. Unsaturated fatty acids (with double or triple carbon bonds causing chain kinks, preventing close packing (solidifying) of molecules), are more likely to be liquid (oil), versus solid (fat) at room temperature (Smith and March 2007). Objects Made From the Whaling Industry We all know that men set forth in sailing ships and risked their lives to harpoon whales on the open seas throughout the 1800s. And while Moby Dick and other tales have made whaling stories immortal, people today generally don't appreciate that the whalers were part of a well-organized industry. The ships that set out from ports in New England roamed as far as the Pacific in hunt of specific species of whales. Adventure may have been the draw for some whalers, but for the captains who owned whaling ships, and the investors which financed voyages, there was a considerable monetary payoff. The gigantic carcasses of whales were chopped and boiled down and turned into products such as the fine oil needed to lubricate increasing advanced machine tools. And beyond the oil derived from whales, even their bones, in an era before the invention of plastic, was used to make a wide variety of consumer goods. In short, whales were a valuable natural resource the same as wood, minerals, or petroleum we now pump from the ground. Oil From Whale’s Blubber Oil was the main product sought from whales, and it was used to lubricate machinery and to provide illumination by burning it in lamps. When a whale was killed, it was towed to the ship and its blubber, the thick insulating fat under its skin, would be peeled and cut from its carcass in a process known as “flensing.” The blubber was minced into chunks and boiled in large vats on board the whaling ship, producing oil. The oil taken from whale blubber was packaged in casks and transported back to the whaling ship’s home port (such as New Bedford, Massachusetts, the busiest American whaling port in the mid-1800s). From the ports it would be sold and transported across the country and would find its way into a huge variety of products. Whale oil, in addition to be used for lubrication and illumination, was also used to manufacture soaps, paint, and varnish. Whale oil was also utilized in some processes used to manufacture textiles and rope. Spermaceti, a Highly Regarded Oil A peculiar oil found in the head of the sperm whale, spermaceti, was highly prized. The oil was waxy, and was commonly used in making candles. In fact, candles made of spermaceti were considered the best in the world, producing a bright clear flame without an excess of smoke. Spermaceti was also used, distilled in liquid form, as an oil to fuel lamps. The main American whaling port, New Bedford, Massachusetts, was thus known as "The City That Lit the World." When John Adams was the ambassador to Great Britain before serving as president he recorded in his diary a conversation about spermaceti he had with the British Prime Minister William Pitt. Adams, keen to promote the New England whaling industry, was trying to convince the British to import spermaceti sold by American whalers, which the British could use to fuel street lamps. The British were not interested. In his diary, Adams wrote that he told Pitt, “the fat of the spermaceti whale gives the clearest and most beautiful flame of any substance that is known in nature, and we are surprised you prefer darkness, and consequent robberies, burglaries, and murders in your streets to receiving as a remittance our spermaceti oil.” Despite the failed sales pitch John Adams made in the late 1700s, the American whaling industry boomed in the early to mid-1800s. And spermaceti was a major component of that success. Spermaceti could be refined into a lubricant that was ideal for precision machinery. The machine tools that made the growth of industry possible in the United States were lubricated, and essentially made possible, by oil derived from spermaceti. Baleen, or "Whalebone" The bones and teeth of various species of whales were used in a number of products, many of them common implements in a 19th century household. Whales are said to have produced “the plastic of the 1800s.” The "bone" of the whale which was most commonly used wasn’t technically a bone, it was baleen, a hard material arrayed in large plates, like gigantic combs, in the mouths of some species of whales. The purpose of the baleen is to act as a sieve, catching tiny organisms in sea water, which the whale consumes as food. As baleen was tough yet flexible, it could be used in a number of practical applications. And it became commonly known as "whalebone." Perhaps the most common use of whalebone was in the manufacture of corsets, which fashionable ladies in the 1800s wore to compress their waistlines. One typical corset advertisement from the 1800s proudly proclaims, “Real Whalebone Only Used.” Whalebone was also used for collar stays, buggy whips, and toys. Its remarkable flexibility even caused it to be used as the springs in early typewriters. The comparison to plastic is apt. Think of common items which today might be made of plastic, and it's likely that similar items in the 1800s would have been made of whalebone. Baleen whales do not have teeth. But the teeth of other whales, such as the sperm whale, would be used as ivory in such products as chess pieces, piano keys, or the handles of walking sticks. Pieces of scrimshaw, or carved whale's teeth, would probably be the best remembered use of whale's teeth. However, the carved teeth were created to pass the time on whaling voyages and were never a mass production item. Their relative rarity, of course, is why genuine pieces of 19th century scrimshaw are considered to be valuable collectibles today. Reference: McNamara, Robert. "Objects Made From the Whaling Industry." ThoughtCo, Jul. 31, 2021, thoughtco.com/products-produced-from-whales-1774070.Whale bone was an important commodity, used in corsets, collar stays, buggy whips, and toys.Whale bone piece. Advanced stage of calcification as indicated by deep pitting. Off white to grey.None.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, whales, whale bone, corsets, toys, whips -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageAnimal specimen - Whale bone, Undetermined

Prior to carrying out a detailed condition report of the cetacean skeletons, it is useful to have an understanding of the materials we are likely to encounter, in terms of structure and chemistry. This entry invites you to join in learning about the composition of whale bone and oil. Whale bone (Cetacean) bone is comprised of a composite structure of both an inorganic matrix of mainly hydroxylapatite (a calcium phosphate mineral), providing strength and rigidity, as well as an organic protein ‘scaffolding’ of mainly collagen, facilitating growth and repair (O’Connor 2008, CCI 2010). Collagen is also the structural protein component in cartilage between the whale vertebrae and attached to the fins of both the Killer Whale and the Dolphin. Relative proportions in the bone composition (affecting density), are linked with the feeding habits and mechanical stresses typically endured by bones of particular whale types. A Sperm Whale (Physeter macrocephalus Linnaeus, 1758) skeleton (toothed) thus has a higher mineral value (~67%) than a Fin Whale (Balaenoptera physalus Linnaeus, 1758) (baleen) (~60%) (Turner Walker 2012). The internal structure of bone can be divided into compact and cancellous bone. In whales, load-bearing structures such as mandibles and upper limb bones (e.g. humerus, sternum) are largely composed of compact bone (Turner Walker 2012). This consists of lamella concentrically deposited around the longitudinal axis and is permeated by fluid carrying channels (O’Connor 2008). Cancellous (spongy) bone, with a highly porous angular network of trabeculae, is less stiff and thus found in whale ribs and vertebrae (Turner Walker 2012). Whale oil Whales not only carry a thick layer of fat (blubber) in the soft tissue of their body for heat insulation and as a food store while they are alive, but also hold large oil (lipid) reserves in their porous bones. Following maceration of the whale skeleton after death to remove the soft tissue, the bones retain a high lipid content (Higgs et. al 2010). Particularly bones with a spongy (porous) structure have a high capacity to hold oil-rich marrow. Comparative data of various whale species suggests the skull, particularly the cranium and mandible bones are particularly oil rich. Along the vertebral column, the lipid content is reduced, particularly in the thoracic vertebrae (~10-25%), yet greatly increases from the lumbar to the caudal vertebrae (~40-55%). The chest area (scapula, sternum and ribs) show a mid-range lipid content (~15-30%), with vertically orientated ribs being more heavily soaked lower down (Turner Walker 2012, Higgs et. al 2010). Whale oil is largely composed of triglycerides (molecules of fatty acids attached to a glycerol molecule). In Arctic whales a higher proportion of unsaturated, versus saturated fatty acids make up the lipid. Unsaturated fatty acids (with double or triple carbon bonds causing chain kinks, preventing close packing (solidifying) of molecules), are more likely to be liquid (oil), versus solid (fat) at room temperature (Smith and March 2007). Objects Made From the Whaling Industry We all know that men set forth in sailing ships and risked their lives to harpoon whales on the open seas throughout the 1800s. And while Moby Dick and other tales have made whaling stories immortal, people today generally don't appreciate that the whalers were part of a well-organized industry. The ships that set out from ports in New England roamed as far as the Pacific in hunt of specific species of whales. Adventure may have been the draw for some whalers, but for the captains who owned whaling ships, and the investors which financed voyages, there was a considerable monetary payoff. The gigantic carcasses of whales were chopped and boiled down and turned into products such as the fine oil needed to lubricate increasing advanced machine tools. And beyond the oil derived from whales, even their bones, in an era before the invention of plastic, was used to make a wide variety of consumer goods. In short, whales were a valuable natural resource the same as wood, minerals, or petroleum we now pump from the ground. Oil From Whale’s Blubber Oil was the main product sought from whales, and it was used to lubricate machinery and to provide illumination by burning it in lamps. When a whale was killed, it was towed to the ship and its blubber, the thick insulating fat under its skin, would be peeled and cut from its carcass in a process known as “flensing.” The blubber was minced into chunks and boiled in large vats on board the whaling ship, producing oil. The oil taken from whale blubber was packaged in casks and transported back to the whaling ship’s home port (such as New Bedford, Massachusetts, the busiest American whaling port in the mid-1800s). From the ports it would be sold and transported across the country and would find its way into a huge variety of products. Whale oil, in addition to be used for lubrication and illumination, was also used to manufacture soaps, paint, and varnish. Whale oil was also utilized in some processes used to manufacture textiles and rope. Spermaceti, a Highly Regarded Oil A peculiar oil found in the head of the sperm whale, spermaceti, was highly prized. The oil was waxy, and was commonly used in making candles. In fact, candles made of spermaceti were considered the best in the world, producing a bright clear flame without an excess of smoke. Spermaceti was also used, distilled in liquid form, as an oil to fuel lamps. The main American whaling port, New Bedford, Massachusetts, was thus known as "The City That Lit the World." When John Adams was the ambassador to Great Britain before serving as president he recorded in his diary a conversation about spermaceti he had with the British Prime Minister William Pitt. Adams, keen to promote the New England whaling industry, was trying to convince the British to import spermaceti sold by American whalers, which the British could use to fuel street lamps. The British were not interested. In his diary, Adams wrote that he told Pitt, “the fat of the spermaceti whale gives the clearest and most beautiful flame of any substance that is known in nature, and we are surprised you prefer darkness, and consequent robberies, burglaries, and murders in your streets to receiving as a remittance our spermaceti oil.” Despite the failed sales pitch John Adams made in the late 1700s, the American whaling industry boomed in the early to mid-1800s. And spermaceti was a major component of that success. Spermaceti could be refined into a lubricant that was ideal for precision machinery. The machine tools that made the growth of industry possible in the United States were lubricated, and essentially made possible, by oil derived from spermaceti. Baleen, or "Whalebone" The bones and teeth of various species of whales were used in a number of products, many of them common implements in a 19th century household. Whales are said to have produced “the plastic of the 1800s.” The "bone" of the whale which was most commonly used wasn’t technically a bone, it was baleen, a hard material arrayed in large plates, like gigantic combs, in the mouths of some species of whales. The purpose of the baleen is to act as a sieve, catching tiny organisms in sea water, which the whale consumes as food. As baleen was tough yet flexible, it could be used in a number of practical applications. And it became commonly known as "whalebone." Perhaps the most common use of whalebone was in the manufacture of corsets, which fashionable ladies in the 1800s wore to compress their waistlines. One typical corset advertisement from the 1800s proudly proclaims, “Real Whalebone Only Used.” Whalebone was also used for collar stays, buggy whips, and toys. Its remarkable flexibility even caused it to be used as the springs in early typewriters. The comparison to plastic is apt. Think of common items which today might be made of plastic, and it's likely that similar items in the 1800s would have been made of whalebone. Baleen whales do not have teeth. But the teeth of other whales, such as the sperm whale, would be used as ivory in such products as chess pieces, piano keys, or the handles of walking sticks. Pieces of scrimshaw, or carved whale's teeth, would probably be the best remembered use of whale's teeth. However, the carved teeth were created to pass the time on whaling voyages and were never a mass production item. Their relative rarity, of course, is why genuine pieces of 19th century scrimshaw are considered to be valuable collectibles today. Reference: McNamara, Robert. "Objects Made From the Whaling Industry." ThoughtCo, Jul. 31, 2021, thoughtco.com/products-produced-from-whales-1774070. Whale bone was an important commodity, used in corsets, collar stays, buggy whips, and toys.Whale bone vertebrae. Advanced stage of calcification as indicated by deep pitting. Off white to grey.None.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, whales, whale bone, corsets, toys, whips -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageCeramic - Stoneware Bottle, Henry Kennedy Pottery, Late 1800s to early 1900s

This bottle was made in Scotland and recovered decades later from a shipwreck along the coast of Victoria. It may have been amongst the ship's cargo, its provisions or amongst a passenger's personal luggage. It is now part of the John Chance collection. Stoneware bottles similar to this one were in common use during the mid-to-late 19th century. They were used to store and transport. The bottles were handmade using either a potter's wheel or in moulds such as a plaster mould, which gave the bottles uniformity in size and shape. The bottle would then be fired and glazed in a hot kiln. Makers often identified their bottles with the impression of a small symbol or adding a colour to the mouth. The manufacturer usually stamped their bottles with their name and logo, and sometimes a message that the bottle remained their property and should be returned to them. The bottles could then be cleaned and refilled. The Barrowfield pottery was founded in 1866 by Henry Kennedy, an Irish native, in the Camlachie district east of Glasgow, close to the Campbellfield and Mount Blue potteries. It is believed that Kennedy started with just one kiln but by 1871 was employing forty men and six boys and such was the success of the enterprise that by 1880, no less than eight kilns were in operation and a year later one hundred and the pottery was employing eighteen people. Stoneware bottle production was a mainstay of the pottery and over “1500 dozen” were being turned out daily along with other wares, including 30-gallon ironstone containers. With so many kilns in operation, six hundred saggars were required every week but, unlike some potteries, these were made on the premises from Garnkirk and Glenboig fire clays. Pottery production reaches a high scale which presented a high risk of fire and Barrowfield was no exception. In April 1884 heat from a kiln set fire to the roof resulting in significant structural damage, the loss of unfinished wares alone amounting to £10,000 a very substantial sum in 1884. The pottery recovered from this reverse but then Henry Kennedy died in July 1890. The terms of his will indicated that he and his sons John and Joseph were partners and this was reflected in a change of title in the 1891-92 Post Office Directory to Henry Kennedy & Sons. Despite the growth of the business there was still space enough, however, to allow china, earthenware and glass retailers Daniel and John McDougall to commence production of their Nautilus wares there in 1894, the success of which allowed them to soon move to permanent quarters at the empty Saracen Pottery, Possil. In around 1900 John Kennedy left to resurrect the liquidated Cleland Pottery and although Barrowfield remained listed as Henry Kennedy & Sons, brother Joseph was in control. In 1911 Henry Kennedy & Sons Ltd was formed, with two of the four directors being the Kennedy brothers. The pottery’s growth to this point was reflected in the eighteen kilns the largest pottery kilns then recorded in Scotland. However, the disruption of the First World War and the combined effects of subsequent economic depression, US prohibition, hygiene regulations and competition from alternative materials posed severe challenges for stoneware potteries in the post-war years as they competed with each other for diminishing markets. Competitors such as Eagle and Caledonian Potteries fell by the wayside and finally, Barrowfield closed in 1929. This stoneware bottle is historically significant for its manufacture and use in the late 19th to the early 20th century. The bottle is also significant as it was recovered by John Chance, a diver, from a wreck on the coast of Victoria in the 1960s-70s. Items that come from several wrecks along Victoria's coast have since been donated to the Flagstaff Hill Maritime Village’s museum collection by his family, illustrating this item’s level of historical value. Stoneware was produced at Barrowfield pottery for the domestic and export markets, with South America being a large market. Barrowfield stoneware can be found throughout the world. Its longevity and abundant production makes the subject item a significant addition to the Flagstaff Hill Maritime Museum collection.Bottle, salt glazed stoneware, beige, some discolouration above base. Chip on base and on neck. Inscriptions stamped near base.Makers lozenge stamped, H Kennedy Barrowfield Pottery GLASGOW at base.flagstaff hill, warrnambool, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, john chance, h kennedy pottery, stoneware, ironstone, pottery, barrowfield glasgow -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageAnimal specimen - Whale bone, Undetermined