Showing 31 items matching "household appliances"

-

Federation University Historical Collection

Federation University Historical CollectionCorrespondence, Correspondence from General Motors - Holden's Limited to the Principal, The School of Mines and Industries, regarding the loan of a household refrigerator, 30/05/1949

... . McCullagh, Frigidaire and Household Appliances.... A. A. McCullagh, manager of Frigidaire and Household Appliances stated.... A. A. McCullagh, manager of Frigidaire and Household Appliances stated ...Letter to the Principal of The School of Mines and Industries Ballarat from General Motors - Holden's Limited, stating the Principals' previous letter to Mr W. W. Watson had not been received. A. A. McCullagh, manager of Frigidaire and Household Appliances stated the matter for the loan of a domestic refrigerator will be looked in to. Quarto paper colour letterhead the school of mines and industries ballarat, general motors - holden's limited, principal, mr w. w. watson, a. a. mccullagh, frigidaire and household appliances -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyIron Hand Kerosene, mid to late 1900s

... household appliances... saw a revolution in small appliances for use in the average ...The 1950's saw a revolution in small appliances for use in the average household. This hand held self heating(kerosene) iron was introduced as a time saving and more convenient iron for pressing clothes and other cloth fabrics. It replaced irons needing a separate fire source to heat the ironing plate. These irons continued to be in service, even when electricity was available in cities and larger rural towns (domestic electric steam irons were invented in 1938). This item was used before and during the electricity supplies available from the Kiewa Hydro Electricity Scheme. These irons remained in use within regional rural areas that had limited or unreliable electrical reticulation.In the 1950s and later the Kiewa Valley was still a relatively isolated region which was home to rural properties and small settlements. The availability of electricity and or the financial means to afford new types of electric hand irons ensured that older and sometimes less efficient ironing remained for an extended period covering the 1960s to 1970s. Kerosene products, such as this kerosene iron was a cheaper method for farm based domestic and other rural activities requiring a heat source. The use of kerosene as a heat/light source was able to be supplied in bulk and able to be used when floods severed vital roads into this region. The supply of electricity was in summer time subject to interruption from bush fire damaged wooden poles carrying the electrical cables. Self sufficiency by rural populations was the backbone of survival and the ability to store energy sources "on the farm" was a prerequisite of isolated regions, such as the Kiewa Valley, circa 1950s.This Coleman kerosene iron has a solid steel chrome plated(press) base with a painted (blue) wooden handle. The handle is stud fastened onto an oblong shaped rolled steel handle frame and screwed (two screws) onto the base plate. Both the heating plate and the top securing plate are shaped similar to a river boat. The main housing enclosing the heating element is enamel coated(blue in colour) steel and has a half hole for lighting the kerosene at the rear end. Behind the handle and protruding upwards is a stainless steel fully enclosed container (bowl shaped) for the main supply of kerosene to the burner or generator(enclosed within the main body of the iron. The bowl has an air valve and inlet for pressurised air intake (hand pump) On the bottom rear of the fuel bowl there is a screw regulated fuel pump. The fuel heated base plate provides the heat for this advertised "self heating iron(instant lighting). See KVHS 0347B- Instruction sheet; KVHS 0347C- Wrench; and KVHS 0347D Fuel can.Stamped on the base plate of the handle, front region "COLEMAN LAMP & STOVE CO." below this "WICHITA KAN" below this"TORONTO CAN". In the middle of the handle base and in larger print "COLEMAN Instant-Lite" At the rear location in large print "MODEL 4" in smaller print below "MADE IN U.S.A." below this "PAT#1718473"household appliances, alternative non electrical ironing appliances, domestic appliances, kerosene appliances -

Kiewa Valley Historical Society

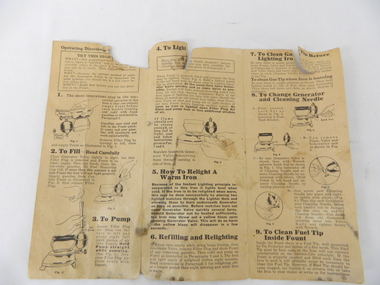

Kiewa Valley Historical SocietyDocument Instruction and Parts Sheet, Instructions for Operating the Coleman Self Heating Iron Model No. 4 Instant Lighting, circa 1950

... household appliances... household appliances ironing domestic ironing Printed in U.S.A ...This operating and parts information sheet was supplied to consumers to help users of this kerosene iron, not only understand the operation of this self lighting iron, but also to be able to order any replacement parts that may be required for this high level usage appliance. At this period in time(1950's), this item was at the leading edge of ironing technology. During the earlier 1900's and before "the throw away" culture evolved(circa 1950's), reliability and long term application of domestic appliances was a necessity above all costs, especially in isolated rural areas. The construction of these appliances was geared to a longer service life and not to a cheaper two to three year life warranty. With levels of world wide technology at an ever increasing pace, long term reliability of any appliance was no longer sought after. Appliance upgrades and new improved model accessibility especially in rural areas has changed rural consumer's buying patterns. Although the concept of instructional and parts/warranty information booklets has not become obsolete, the ability to access information via electronic means has vastly improved the ability to obtain qualified technical help through local avenues. This access was not available in the time period(circa 1950), when the appliance covered by this document was issued. The rate of development within the home appliance field has mushroomed during the time period post 1950. The costs and the increased levels of product choices and consumer awareness has provided rural areas (once isolated e.g. Kiewa Valley) with a greater ability to satisfy their needs because of a greater diverse range of domestic appliances offered.This discoloured, sepia paper has black print and is folded into three equal pages. The information contained covers operational and part numbers for the kerosene fired hand held iron. there are kerosene stains on the last page and these have soaked through onto the second page. The form no.-3-3C- McACO.-4363Printed in U.S.A.instructions, household appliances, ironing, domestic ironing -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyCan Fuel Measuring, circa 1950

... household appliances... ironing domestic appliances household appliances On one side ...The 1950's saw a revolution in small appliances for use in the average household. The hand held self heating(kerosene) iron for which this filling can was provided ,was introduced as a time saving and more convenient iron for pressing clothes and other cloth fabrics. It replaced irons needing an external fire source to heat the ironing plate. These irons continued to be in service, even when electricity was available in cities and larger rural towns. This item was used before and during the electricity supplies available from the Kiewa Hydro Electricity Scheme. These irons remained in use within regional rural areas that had limited or unreliable electrical reticulation and the ability to service them from this filling can was an essential part.n the 1950s and later the Kiewa Valley was still a relatively isolated region which was home to rural properties and small settlements. The availability of electricity and or the financial means to afford new types of electric hand irons ensured that older and sometimes less efficient ironing appliances remained for an extended period covering the 1960s to 1970s. Kerosene products, such as the kerosene self heating (KVHS 0347A) iron and this kerosene filling item, was a cheaper method for farm based domestic and other rural activities requiring a heat source. The use of kerosene as a heat/light source was able to be supplied in bulk and able to be used when floods severed vital roads into this region. The supply of electricity was in summer time subject to interruption from bush fire damaged wooden poles carrying the electrical cables. Self sufficiency by rural populations was the backbone of survival and the ability to store energy sources "on the farm" was a prerequisite of isolated regions, such as the Kiewa Valley, circa 1950s.This specially spout fitted can was provided with the Coleman self heating kerosene iron (see KVHS 0347A). On one side of the half enclosed top of the can there is a small spout(for poring the appropriate liquid into the egg shaped fount container) at the rear end of the hand iron. The can is made from tin. See KVHS 0347B- Instruction sheet; KVHS 0347C- Wrench.On one side of the can in black print on yellow background is "FUEL MEASURING CAN" underneath is "For Coleman Instant-Lite Iron" underneath are four numbered paragraphs detailing the use of this can. Below this is the name and places of manufacture. On the other side of the can is printed "BE SURE" with filling and maintenance instructionskerosene can, ironing, domestic appliances, household appliances -

RMIT Design Archives

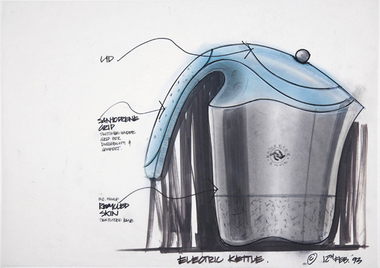

RMIT Design ArchivesDesign drawings, Paul Taylor for Form Australia, Kambrook Axis Kettle concept rendering

... household appliances... is historically significant as an early eco-design project. household ...The Axis Kettle was developed through the EcoRedesign project funded by the Federal Government and based at RMIT in the 1980s and 1990s. The project involved the expertise of significant Victorian designers such as Paul Taylor, Gerry Mussett, Liam Fennessy and Michael Grima, as well as prominent sustainability experts such as academics John Gertsakis, Chris Ryan and Alan Pears. Axis changed the way kettles were used, guiding users to save resources through their behaviour. It is regarded globally by academics from prominent design institutions such as Loughborough and Delft as one of the first successful eco-design projects. The drawing is part of the Centre for Design collection, RMIT University. Simon Lockrey, 2017 The drawing is historically significant as an early eco-design project. Design drawing of KambrookKettle by Paul Taylor for Form Australia as part of the Centre for Design at RMIT University, featuring electric kettle drawn in black pen + ink with blue ink where kettle lid is. Written design descriptions appear along side the image and title below.LID / SANHOPRENE / GRIP / RECYCLED SKIN / ELECTRIC KETTLE. c 12TH FEB. '93household appliances, industrial design, sustainability, rmit university -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyStove - electric

... . It was a manufacturer of household appliances based in Adelaide, Australia... of household appliances based in Adelaide, Australia. This stove has ...Simpson was founded in 1853 by Alfred M. Simpson. It was a manufacturer of household appliances based in Adelaide, Australia. This stove has only 3 hotplates (not the usual 4) and may have been used in the 1950s.Used by a resident of the Kiewa Valley.Green ceramic stove with 3 hot plates - 2 solid (one small and one large) at the back and one at the front with coils (large). 5 black knobs - 2 for the oven and 3 for the hotplates. The oven has a tray and adjustable shelving. At the bottom there is a warming drawer. The stove is electric and has a warming drawer at the bottom. The handles are black."Simpson" on the front on the vertical panel and also on the control panel.ceramic stove, simpson stove -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyMincer Meat, early to mid 1900's

... household cast iron appliances... most appliances (be they household) where manufactured... Commonwealth". It was a period when most appliances (be they household ...This cast iron kitchen appliance was made in England in the early 1900's and shipped to the "colony" Australia. This was before World War II and the "growing up" of a colony to an independent member of "the British Commonwealth". It was a period when most appliances (be they household) where manufactured in England and shipped to Australian ports. It was not until the late 1960's that the Asian manufacturing giant woke up and started to dominate the market palce.This domestic kitchen appliance is very significant to the Kiewa Valley because it highlights the "made at home" period when food processing was made "in house" due to inability to source food from specialised shops e.g. the butcher or slaughter houses. It was a period before mass food processing factories were established and roads constructed up to the standard for distribution to semi remote regions such as Kiewa Valley was in the beginning of the 1900's.This cast iron (malleable iron) mincer for meat products has a large "funnel" to direct "chunks" of meat to the grinding "wheels". These "star" shaped wheels with "teeth" of three different cutting surfaces (fine, medium and coarse) provide for texture types of the final meat product. The meat is placed into the "loading" funnel and push downwards(gravity feed) through the mincing chamber and out through the front side. There is a long "screw worm" which is rotated by turning the handle. The appliance is table mounted by a vice "G" screw on clamp (hand operated). "BEATRICE No. 3" and "MADE IN ENGLAND", "P 3181"household cast iron appliances, food processors -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyWrench Coleman, circa 1950

... iron maintenance tool domestic appliances household This item ...The 1950's saw a revolution in small appliances for use in the average household. This hand held wrench was provided exclusively for the Coleman self heating kerosene (KVHS 0347A) iron and used for the regular changing the kerosene used in it. The iron was used before and during the electricity supplies available from the Kiewa Hydro Electricity Scheme. These irons remained in use within regional rural areas that had limited or unreliable electrical reticulation. Kerosene supplies were cheaper than electricity but also more inconvenient than electric. Electrical appliances become cheaper to buy and maintain in the later part of the 1900's and the now older kerosene iron was faded out.This wrench was required to open the fuel container which stored kerosene in the Coleman hand iron(see KVHS 0347A). This item was part of the maintenance requirement of this particular hand iron. In the 1950s and later the Kiewa Valley was still a relatively isolated region which was home to rural properties and small settlements. The availability of electricity and or the financial means to afford new types of electric hand irons ensured that older and sometimes less efficient ironing remained for an extended period covering the 1960s to 1970s. Kerosene products, such as this kerosene iron was a cheaper method for farm based domestic and other rural activities requiring a heat source. The use of kerosene as a heat/light source was able to be supplied in bulk and able to be used when floods severed vital roads into this region. The supply of electricity was in summer time subject to interruption from bush fire damaged wooden poles carrying the electrical cables. Self sufficiency by rural populations was the backbone of survival(use of this wrench was a part of rural life). The ability to store energy sources "on the farm" was a prerequisite of isolated regions, such as the Kiewa Valley, circa 1950s.This item is a flat cast iron wrench, which has been specifically made for KVHS 0347A (kerosene iron). The wrench has four specific forms cut into the steel which fit firmly around their targeted nut and other fixtures. Also see See KVHS 0347B- Instruction sheet; and KVHS 0347D Fuel can.ironing, iron maintenance tool, domestic appliances, household -

Wodonga & District Historical Society Inc

Wodonga & District Historical Society IncDomestic object - Charcoal Iron, c1850 - 1930s

... of electricity. Domestic appliances Household items Women's work "S ...This iron was used by women to press the clothes from the mid 19th century. Coal embers were put inside, heating the base of the iron. Small bellows could be used to fire up the embers in order to keep the iron hot. This item is significant as it represents the appliances used by women from the mid 19th century until the advent of electricity.This charcoal iron is made of cast iron. It has a hinged lid so that embers can be put inside as the source of heat. The lid has a curved funnel and a wooden handle. The funnel kept the smoke away from the clothing. Bellows would be used to blow air into the iron and keep the coals burning. It has a wooden handle and the lever used to open the lid is also made from wood. There is a hole with a swivel cover at the back of the iron to check the coals. "S" on the swivel cover.domestic appliances, household items, women's work -

Surrey Hills Historical Society Collection

Surrey Hills Historical Society CollectionWork on paper - Vertical file, Armitstead family

... in the days before refrigerators were a usual household appliance... in the days before refrigerators were a usual household appliance ...The Armitstead family's first woodyard in Surrey Hills was located in Croydon Road but later they moved to 153-157 Union Road, Surrey Hills. The business delivered timber and briquettes for heating to homes in the local area but also blocks of ice in the days before refrigerators were a usual household appliance. The timber was unloaded from railway trucks at a siding at Surrey Hills station; some came from the Armitstead's property of 130 acres of timbered land near Killara. They also sold mallee roots and briquettes.A vertical file containing the following documents: 1. Land Victoria map of Surrey Hills including Union Road from Bedford Street to Montrose Street, showing location of woodyard (undated) (1 A3 page). 2. Possibly ‘Sun’ article ‘When Surrey Hills ran short of wood’, Michael Sefton (undated) (1 page). 3. Plaque for the red mechanism of the weighbridge at Centre, by convenor, Surrey Hills Heritage Group, 12.11.2002 (1 page). 4. Pooley and Sons weighbridge, notes by Dennis Armstrong, in email to Sue Barnett, 4.4.2013 (2 pages). 5. Laminated diagram and notes by Ken Hall re weighbridge from Armitstead’s woodyard, and photocopy, undated (3 pages). 6. ‘Armitstead’s woodyard’ 153-7 Union Road (now Neighbourhood Centre), typed Progress Leader article, 13.1.1982 (2 pages). pooley and sons weighbridge, armitstead family, woodyard, armitstead's woodyard, union road -

National Wool Museum

National Wool MuseumTool - Grinder, 1960-69

... of shearing equipment, made its first household appliances and branded... not as seasonal as those of shearing equipment, made its first household ...Cooper S.E. Ball Bearing Grinder made and guaranteed by Sunbeam Corporation Limited. Grinders like this example have been made the same since the early 1900s, with this grinder thought to have been produced in the 1960s. It is belt driven, with the other end of the belt being attached to an engine; the same engine that would have powered the overhead shearing equipment in shearing sheds. It was common for shearing teams to bring their own equipment, especially pre-1960 as most shearing sheds were not connected to power, and shearers preferred to work with their own equipment. The engines that powered the shears and grinder were typically fuelled with kerosene or petrol. The large circular disks are attached to the bolt that protrudes from the grinder and fastened tightly with a nut. An example of seeing a similar grinder in action can be found on the following link - https://www.youtube.com/watch?v=O7eimI_Gm9o. Inventor Frederick Wolseley made the world's first commercially successful power-shearing system in Australia in 1888. US company Cooper, which had been founded in 1843 as a maker of sheep dip, began selling Wolseley equipment in the USA in 1895. The Chicago Flexible Shaft Company successfully entered the power-shearing market a few years later and entered a joint venture with Cooper. It set up a branch in Sydney and sold shearing sets, and engines to power them, into the Australian market. In 1921 the US parent company, realising it needed to make products whose sales were not as seasonal as those of shearing equipment, made its first household appliances and branded them Sunbeam. In 1933, changes in exchange rates and taxes led the company to manufacture engines and shearing equipment in Australia via subsidiary Cooper Engineering, which changed its name to Sunbeam in 1946. Although most Australians know of this company as a major manufacturer of household appliances, its rural division flourished and retained the Sunbeam name for shearing equipment even after it was taken over by New Zealand company Tru-Test in 2001. The grinder is formed from a central arch shaped block of green painted metal. Much of this paint has been lost to age, leaving the grinder in a ‘farm used’ condition with much surface oxidation present. On the front of the arch is a specification plate, reading “Cooper S.E. ball bearing grinder. Made and guaranteed by Sunbeam”. At the foot of the arch, three bolt holes are found for securing the grinder to the base of a solid wooden surface. Two of the bolt holes are found on the front of the grinder, with another found on the rear. From the central arch, a bolt protrudes to the right of the grinder. This large bolt is for securing a grinding plate to the grinder. Above the central arch is a pendulum which holds the comb / cutter that is being sharpened. From the pendulum, a large arm extends down (not pictured) to meet and strike the plate spinning at a rapid speed. On the left-hand side of the central arch of the grinder, a wheel is found which a belt is attached to for power. This belt is then attached to a separate engine, spinning the wheel and hence powering the grinder. The wheel is partially covered with a section of protective bent tube, designed to provide protection from the rapidly spinning wheel. Below this wheel is the belt shifter. It is designed to move the protective bent tube from one side of the grinder to the other, to accommodate the grinder in the setup of different shearing sheds. The two separate grinding plates are identical. They have a slight slope for sharpening the comb and cutters in the correct method, with a slight bias towards the base, or “tooth”, of the equipment. The disks have a large central bolt for attaching to the grinder. They have tags on the horizontal axis of the grinding plates, for securing the plates in transportation, and to help with initial alignment when setting up the grinder. The reverse of these grinding plates has the same green painted metal finish found on the grinder. This paint is also in a ‘farm used’ condition, with surface oxidation present. The grinder would be provided from the factory with a comb holder, shifter for securing the grinding plates, emery cloth and emery glue. The emery cloth is what does the actual grinding and is applied to the grinding disks, replacing once well worn. These items can be seen in the final images in the multimedia section, showcasing advertising for this grinder. Plate. Inscribed. “Cooper / S.E. BALL BEARING GRINDER / MADE AND GUARANTEED BY / Sunbeam / CORPORATION LIMITED / SYDNEY MELBOURNE / ADELAIDE BRISBANE ”sheep shearing, shearing equipment, sunbeam, grinder -

National Wool Museum

National Wool MuseumMachine - Shearing Motor, Sunbeam, 1960-69

... of shearing equipment, made its first household appliances and branded... first household appliances and branded them Sunbeam. In 1933 ...With more and more woolsheds being connected to power lines, the need for electric shearing gear markedly increased from the 1960s onwards. The greater economy made electric gear an attractive proposition to many graziers. Requiring only an electric shearing motor, for small and medium scale operations, electric shearing motors were a more economical way of shearing a wool clip. The other option for graziers was Overhead shearing gear, which also required an Engine to provide shared power to a row of shearing stations. Still working, this Sunbeam Electric Shearing Motor – Heavy Duty Model, features a slow speed motor totally enclosed for protection against dust and insects. The full bearing down tube is easily removed and stored to be out of the way when not in use (not pictured). Providing 0.5 hp, which is twice the power ever needed for shearing sheep, this buffer allows for fluctuations in voltages that can occur in rural districts. Inventor Frederick Wolseley made the world's first commercially successful power-shearing system in Australia in 1888. US company Cooper, which had been founded in 1843 as a maker of sheep dip, began selling Wolseley equipment in the USA in 1895. The Chicago Flexible Shaft Company successfully entered the power-shearing market a few years later and entered into a joint venture with Cooper. It set up a branch in Sydney and sold shearing sets, and engines to power them, into the Australian market. In 1921 the US parent company, realising it needed to make products whose sales were not as seasonal as those of shearing equipment, made its first household appliances and branded them Sunbeam. In 1933, changes in exchange rates and taxes led the company to manufacture engines and shearing equipment in Australia via subsidiary Cooper Engineering, which changed its name to Sunbeam in 1946. Although most Australians know of this company as a major manufacturer of household appliances, its rural division flourished and retained the Sunbeam name for shearing equipment even after it was taken over by New Zealand company Tru-Test in 2001. This 0.5 horsepower vertical brushed motor air-cooled engine was designed to drive a single shearing plant. From the central cylinder which features a yellow “Sunbeam” sticker, a grey 240v power lead can be found on the left-hand side. A blue capacitor is located next to this power lead. Below, two legs extend and meet to form a foot which is fastened to a wall. On the right-hand side of the engine, a specification plate is located on the central cylinder. A yellow directional arrow sticker is located on the rotating section of the engine below the specification plate (location for photography, this section is designed to rotate and hence this sticker is not fixed in this location). At the rear of the cylinder, a plastic cap with small air cut outs protects the air-cooled engine from contaminants. At the front of the engine, the location for securing the bearing down tube is located. On the right-hand side of the lock for the bearing down tube is the handle, to which a string is often attached for switching the motor on and off by a shearer bent at the waist (not pictured). Sticker. Gold writing. Front of shearing motor “Sunbeam” Plate. Inscribed. Side of shearing motor. “Sunbeam / SHEARING MOTOR / MADE IN AUSTRALIA / 0.5 H.P. / 220/240 V / 1 PHASE A.C. / 4.0 AMPS / 50 C/S. / CONT. RTG. / 1425 R.P.M. / CLASS A INSUL / NO. J244560 / TYPE: NSB5C2/49." sheep sheering, shearing equipment, sunbeam, electric shearing motor -

Wodonga & District Historical Society Inc

Wodonga & District Historical Society IncDomestic object - Universal Cake Mixer, Landers, Frary & Clark, c1905

... in 1862. The firm produced a variety of household products... in 1862. The firm produced a variety of household products ...Landers, Frary & Clark was a housewares company based in New Britain, Connecticut. The firm traced its origins to 1842, when George M. Landers and Josiah Dewey entered into a partnership named Dewey and Landers, which manufactured various metal products. The company was reorganized as Landers, Frary & Clark in 1862. The firm produced a variety of household products and appliances, including many electric appliances. Some of Landers, Frary & Clark's most successful products included the Universal Bread Maker, the Universal Food Chopper, and the Coffee Percolator. In 1965, the majority of the Landers, Frary & Clark was taken over by the J.B. Williams Company of New York, the food chopper division was acquired by the Union Manufacturing Company, and the electrical appliance operations was purchased by General Electric. The mixer consists of a bowl made of tinned iron with accessories including wire twin beaters, a dough hook, a table /bench clamp, and a handle with a wooden hand grip. An arched cross bar attached to the top of the pan with wing nuts holds the handle and beaters or hook in place when in use. Manufacturer and patent information is inscribed on the cross bar.On the cross piece: UNIVERSAL/CAKEMAKER/PATENTED/JAN.14,96.APRIL18,05./JULY.18,05.NOV.7,05 LANDERS,FRARY/CLARK/NEW BRITAIN/CONN/USAdomestic appliances, cooking utensils -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFreezer, circa 1930's

... by Electrolux, continues to produce a variety of household appliances... to produce a variety of household appliances. (Reference: State ...This ice cream freezer, manufactured in South Australia in the 1930's, was advertised to "keep the contents of the cream compartment frozen for many hours". It was promoted for use at picnics to keep salads cool. Its design is very similar to other freezers of The Frigid name which were made in 1939; those freezers were all one colour whereas this one is blue around the top and bottom of the barrel and cream in the centre with blue/green lettering. The process of making ice cream was to pack the outer chamber full with a combination of 3 parts ice cubes of about 1 inch (2.cm) to one part coarse salt, then pour into the chamber about 1 cup of cold water. After this, the ingredients for ice cream or sorbet were poured into the inner chamber, then attach the lid and turn The Frigid freezer upside down for about 40 minutes or until the right consistency is reached. Advice as given to open the freezer every 20 minutes and stir around the contents that were frozen against the sides of the inner chamber. The ingredients for the ice cream could include cream, sugar, vanilla and eggs. The label on the box of The Frigid shows the address of A Simpson and Son to be at Pirie Street, Adelaide. This address was used as early as 1876 and later catalogues, 1931 - 1960 still show this address. Alfred Simpson and his family emigrated from England, arriving in South Australia in 1849. He had already completed his apprenticeship as a tinplate worker but he tried various other occupations, including trying out the gold mines in Victoria, before he established himself as a tinsmith in 1853. His products included many agricultural items. His son, Alfred Muller Simpson, joined the business when he turned 21. In the 1860 Simpson's products included 'explosion proof' safes. In the late 1880's A Simpson and Son manufactured munitions and mines for the war. At the time of Alfred's death in 1891, A Simpson and Son had the largest metal manufacturing plant in Australia. From 1898 the company's reputation grew from the process of enamel plating with porcelain. During the First World War, Simpsons returned to the manufacture of munitions. Alfred M. Simpson's sons (Alfred Allen, known as Allen, and Fredrick Neighbour) joined the company when they finished their schooling. Allen was also associated with the Royal Geological Society over many years and when the CT Madigan surveyed Central Australia in 1929, the Simpson Desert was named in his honour. Cape Simpson in Antarctica is also named after him due to his assistance to Douglas Mawson. A new factory was opened at Dudley Park in the 1940s and the company began the manufacture of whitegoods. In 1963 A. Simpson and Son merged with Pope Industries to form Simpson Pope Holdings. Alfred Simpson became chairman of the board of Simpson Pope Holdings. The Simpson brand, now owned by Electrolux, continues to produce a variety of household appliances. (Reference: State Library of South Australia) A Simpson and Son was an early colonial business that has lasted well into the 20th century and the name Simpson is still associated with whitegoods. Freezer, 2 quart (1.8 litre) capacity, made by A Simpson and Son Ltd, marked "The Frigid". Cylinder shaped, constructed from enamelled sheet metal, has two catches one on the base and one on top. Inner cylinder for holding contents for freezing. Slightly rusted. Freezer is inside original cardboard box with yellow label showing manufacturer details. Circa 1930'sOutside of freezer is printed in blue"The Frigid". Box includes "THE "FRIGID" FREEZER" and branded "S & S" inside a circle.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, a. simpson & son limited, manufacturer, foundry, freezer, 2 quart freezer, portable freezer, kitchen appliance, the frigid, ice cream freezer, ice cream maker 1930's -

Orbost & District Historical Society

Orbost & District Historical Societyiron, 19th Century

Used in the Orbost district prior to electicity being connected. Was heated on the top of a wood-fired stove. This is an example of a common domestic appliance used before electricity was widely connected to households.A small triangular shaped cast iron clothes iron on a metal stand. The stand has small legs and holes in its base. The iron has a Salter brand.A symbol on the top of the iron in the shape of a bow.iron clothes-iron household-item -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyTicket Theatre, Circa 1950

... household entertainment appliance. The Kiewa valley was for a very ...This ticket was used in the 1950's to gain entry into the Mount Beauty Cinema, located in the community Hall. This ticket was donated by the person who attended one film shown in this theatre. This was in an era where before the start of screening, the "British" anthem was played and all patrons were required to be up-stand. Sometimes if somebody was not standing the usher would advise the patron of their patriotic duties to the "Queen" required them to stand unless they were physically incapacitated. This act demonstrated the strong bond to "mother England". From the late 1960's onward this strong show of loyalty "faded away" into history.This theatre ticket is very significant to Mount Beauty because it was the access by the Kiewa Valley residents to "big city" movies. This was in a time frame when television was just beginning to be a popular household entertainment appliance. The Kiewa valley was for a very long time "out of range" for television reception and the only form of screen images were attending the Mount beauty Theatre (just like the big cities but on a more intimate level). Just like the city movie Theatres, the Mount Beauty Theatre, was the centre of the "after five o'clock" entertainment hub. This was a time when going to the theatre was a big event and townsfolk "got dressed up" for this special occasion.It was the gathering place for young and old.This thick cardboard Cinema ticket to the Mount Beauty Theatre (cinema) has two distinctive sections separated by a single perforation. One section for the doorkeeper and one section to "kindly retain". The colour is light green with black print. The ticket was printed by RENWICK PRIDE.On each side of the perforation is printed, "Mt. BEAUTY" underneath in smaller print "THEATRE" underneath a dividing line "RES. SEAT" and stamped underneath "F" "13". Below these on the left side "DOORKEEPER" and on the right side "KINDLY KEEP"ticket, small theatre, local entertainment, public movie theatre, mount beauty cinema -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyMixmaster and attachments

Household item used in the kitchen for mixing food. It belonged to Ron White.Ron White (1920 - 2019) worked for the SECV and was superintendent engineer of the Kiewa Hydro Electric Scheme after its completion. He lived in Mt Beauty and worked until he retired in 1985. See KVHS 1282 Mixmaster blender box made by Sunbeam, Australia Cat. No. AMB-O. It includes a rectangular glass container with a black bakelite lid. It fits onto a steel attachment and is held by 4 black bakelite stands. Second box consists of - Sunbeam / Meat Grinder / and / Food Chopper / Attachment / with Power Transfer Unit / for Sunbeam Mixmaster / Cat No. FC 6 / Made in Australia Attachments are boxed inside.kitchen appliance, blender, vitamiser, mixmaster sunbeam, ron white, meat grinder, food chopper -

Learmonth and District Historical Society Inc.

Learmonth and District Historical Society Inc.Washing Machine, Circa 1876

... washing machine 1876.household appliance.... washing machine 1876.household appliance F.WOLTER & ECHBERG"S ...This is an early example of a mechanical device for the washing of clothes.It worked on a rocking motion making the chore of washday easier for the housewife.This is an early example of a mechanical device for washing of clothes.This Washing Machine is made of wood and the main barrel part is a rectangular shaped box with slopping sides.On the top is the lid and a handle.It is set on a stand which allowes it to be used with a rocking motion.F.WOLTER & ECHBERG"S PATENT WASHING MACHINE .NO 2955. 6 RUSSELL STREET MELBOURNE.ROYAL LETTERS PATENT GRANTED 1876.washing machine 1876.household appliance -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Can Opener, Bottle Opener & Corkscrew

It took 15 years to invent the can. It took 100 more to invent a standard way to open it. In the 19th century, decades after the invention of canning, there were virtually no can openers. Canned food, such as sardines, came with its own "key" to peel back the tin lid. Birth of the can One of the oddest things about the can opener is that the can predates it by almost 150 years. Though common today, cans were once military-grade technology. In 1795, Napoleon, to whom the phrase "an army marches on its stomach" is attributed, offered 12,000 francs to anyone who could find a way to preserve food. Without any knowledge of bacteria or their role in food spoilage, scientists didn't even know where to begin. It took 15 years before a chef named Nicholas Appert claimed the prize after successfully jarring food. Soon after that, his countryman Philippe de Girard came up with a variant on Appert's method—metal tins—and sold the idea to the British. Spoiled food, and the sickness it caused, was a widespread problem. The public would have benefited from canned food, but for decades cans were almost exclusively for the army and the navy. The canning process, with its hours of boiling and steaming, its scrupulous cleanliness, its heated metal, and its need for a great deal of disposable material, made canned food far too expensive for anyone but the military. No can openers were needed or even possible. The metal of early cans was too thick to make openers practical. Soldiers and sailors had plenty of sharp objects on hand and made ample use of them when they wanted to eat. During the 19th century, the process of canning was refined and mechanised, and the metal wall of the average can slimmed down enough that a civilian could get it open—if that civilian had the right tool. No one had that tool yet, so early cans had to open themselves. In other words, they came with built-in openers. The result was a confusing but pleasing free-for-all, in terms of product engineering. Each type of food came with its own kind of can, and each kind of can came with its own kind of opener. Tinned fish and meat were often sold in rectangular cans. These cans were fitted with a "key" that would roll down the top of the can. Coffee, beans, and other types of meat were packaged in cylinders with metal strips that could be peeled back with their own kinds of built-in keys. Cans of milk, which didn't need to be completely opened, came with puncture devices. As tinned food became more common, its containers became more regular. A nice cylindrical can became the norm, and, as these cans filled kitchens, more engineers put their minds to finding a convenient way to open all of them. The first standalone can opener worked on a simple principle: point, stab, and pull. From the mid-19th century to the end of World War I, the typical can opener looked roughly like a wrench, if the lower 'jaw' of the wrench were replaced with a blade. People used the blade to puncture the top of the can near its edge, push the upper jaw against the side of the can, and drag the blade through the metal along the rim. Because meat was the first and most popular canned substance, these can openers were often shaped to look like cows and given the nickname 'bully beef can openers'. The bully beef can opener, popular in the mid-19th century, resulted in many lost fingers. Later, a corkscrew was added that was seated in the handle, and could be pulled out for use. Bully beef can openers were so common, effective, and sturdy that they are still frequently available on collectors' sites. Some are advertised as “still working,” and every last one of them is, without a doubt, soaked in the blood of our ancestors. Dragging a sharp blade along the edge of a can is certain to cause injury sooner or later. So once people got a reliable can shape and a reliable way to get the can open, the search was on for a reliable way to get a can open without the possibility of losing a finger. The answer came in 1925, from the Star Can Opener Company of San Francisco. This is probably the first can opener that resembles the one people have in their kitchens today. Instead of using a blade to pry open a metal can, buyers could clamp the edge of the can between two wheels and twist the handle of one of the wheels to move the blade around the lip. The Star can openers weren't perfect. Compared to the bully beef model, they were flimsy and breakable, but they probably prevented a few injuries. Six short years after the Star model came to market, the first electric can opener was invented. It was patented in 1931 by the Bunker Clancey Company of Kansas City, who had already been sued by the Star Can Opener Company for trying sell a double-wheeled can opener like the Star model (the case was dismissed). The electric can opener must have seemed like the wave of the future and a sure-fire seller, but it proved to be too far ahead of its time. In 1931 not that many households had electricity, and those that did weren't interested in buying can openers. The Bunker Clancey Company was subsequently bought by the Rival Company, which still makes small appliances like can openers today. It took another 25 years for electrically powered can openers to become practical. In the 1950s, Walter Hess Bodle and his daughter, Elizabeth Bodle, developed an electric can opener in the family garage. Walter came up with the opener's blades and motor, and Elizabeth sculpted the outside. Their can opener was a free-standing unit that could sit on the kitchen counter. The Udico brand of the Union Die Casting Company put it on the market in time for Christmas in 1956 and had great success with it. Over the next few years it came out in different styles and colours, and, like the bully beef can opener, has become a collector's item. Also like the bully beef model, Udico can openers often still work. They don't make 'em like they used to. Although there have been some design changes and refinements over the last sixty years, there have yet to be any more leaps forward in can opener technology. If you're resentfully opening a can, you are almost certainly doing it using the Star design, manually forcing the can between two wheels, or the Bodle design, clamping the can into a free-standing electrical opener. Whether or not you enjoy your holiday meals, at least you can be happy that you are not getting poisoned by your own food or cutting open your hand with the blade you use to get at it. That's something, right?The can opener, Bottle opener and the corkscrew are still very important and essential items in most kitchens.Metal can opener, chromed, with bottle opener, and a corkscrew seated in the handle.None.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, canning, can opener, corkscrew, bottle opener, kitchen equipment -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Can Opener

It took 15 years to invent the can. It took 100 more to invent a standard way to open it. In the 19th century, decades after the invention of canning, there were virtually no can openers. Canned food, such as sardines, came with its own "key" to peel back the tin lid. Birth of the can One of the oddest things about the can opener is that the can predates it by almost 150 years. Though common today, cans were once military-grade technology. In 1795, Napoleon, to whom the phrase "an army marches on its stomach" is attributed, offered 12,000 francs to anyone who could find a way to preserve food. Without any knowledge of bacteria or their role in food spoilage, scientists didn't even know where to begin. It took 15 years before a chef named Nicholas Appert claimed the prize after successfully jarring food. Soon after that, his countryman Philippe de Girard came up with a variant on Appert's method—metal tins—and sold the idea to the British. Spoiled food, and the sickness it caused, was a widespread problem. The public would have benefited from canned food, but for decades cans were almost exclusively for the army and the navy. The canning process, with its hours of boiling and steaming, its scrupulous cleanliness, its heated metal, and its need for a great deal of disposable material, made canned food far too expensive for anyone but the military. No can openers were needed or even possible. The metal of early cans was too thick to make openers practical. Soldiers and sailors had plenty of sharp objects on hand and made ample use of them when they wanted to eat. During the 19th century, the process of canning was refined and mechanised, and the metal wall of the average can slimmed down enough that a civilian could get it open—if that civilian had the right tool. No one had that tool yet, so early cans had to open themselves. In other words, they came with built-in openers. The result was a confusing but pleasing free-for-all, in terms of product engineering. Each type of food came with its own kind of can, and each kind of can came with its own kind of opener. Tinned fish and meat were often sold in rectangular cans. These cans were fitted with a "key" that would roll down the top of the can. Coffee, beans, and other types of meat were packaged in cylinders with metal strips that could be peeled back with their own kinds of built-in keys. Cans of milk, which didn't need to be completely opened, came with puncture devices. As tinned food became more common, its containers became more regular. A nice cylindrical can became the norm, and, as these cans filled kitchens, more engineers put their minds to finding a convenient way to open all of them. The first standalone can opener worked on a simple principle: point, stab, and pull. From the mid-19th century to the end of World War I, the typical can opener looked roughly like a wrench, if the lower 'jaw' of the wrench were replaced with a blade. People used the blade to puncture the top of the can near its edge, push the upper jaw against the side of the can, and drag the blade through the metal along the rim. Because meat was the first and most popular canned substance, these can openers were often shaped to look like cows and given the nickname 'bully beef can openers'. The bully beef can opener, popular in the mid-19th century, resulted in many lost fingers. Bully beef can openers were so common, effective, and sturdy that they are still frequently available on collectors' sites. Some are advertised as “still working,” and every last one of them is, without a doubt, soaked in the blood of our ancestors. Dragging a sharp blade along the edge of a can is certain to cause injury sooner or later. So once people got a reliable can shape and a reliable way to get the can open, the search was on for a reliable way to get a can open without the possibility of losing a finger. The answer came in 1925, from the Star Can Opener Company of San Francisco. This is probably the first can opener that resembles the one people have in their kitchens today. Instead of using a blade to pry open a metal can, buyers could clamp the edge of the can between two wheels and twist the handle of one of the wheels to move the blade around the lip. The Star can openers weren't perfect. Compared to the bully beef model, they were flimsy and breakable, but they probably prevented a few injuries. Six short years after the Star model came to market, the first electric can opener was invented. It was patented in 1931 by the Bunker Clancey Company of Kansas City, who had already been sued by the Star Can Opener Company for trying sell a double-wheeled can opener like the Star model (the case was dismissed). The electric can opener must have seemed like the wave of the future and a sure-fire seller, but it proved to be too far ahead of its time. In 1931 not that many households had electricity, and those that did weren't interested in buying can openers. The Bunker Clancey Company was subsequently bought by the Rival Company, which still makes small appliances like can openers today. It took another 25 years for electrically powered can openers to become practical. In the 1950s, Walter Hess Bodle and his daughter, Elizabeth Bodle, developed an electric can opener in the family garage. Walter came up with the opener's blades and motor, and Elizabeth sculpted the outside. Their can opener was a free-standing unit that could sit on the kitchen counter. The Udico brand of the Union Die Casting Company put it on the market in time for Christmas in 1956 and had great success with it. Over the next few years it came out in different styles and colours, and, like the bully beef can opener, has become a collector's item. Also like the bully beef model, Udico can openers often still work. They don't make 'em like they used to. Although there have been some design changes and refinements over the last sixty years, there have yet to be any more leaps forward in can opener technology. If you're resentfully opening a can, you are almost certainly doing it using the Star design, manually forcing the can between two wheels, or the Bodle design, clamping the can into a free-standing electrical opener. Whether or not you enjoy your holiday meals, at least you can be happy that you are not getting poisoned by your own food or cutting open your hand with the blade you use to get at it. That's something, right?The can opener is still a very important and essential item in most kitchens.Can opener, right handed, metal, upper blade section serrated, inscription 'Peerless Pat.Feb 11-90'.Peerless Pat.Feb 11-90flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, cannning, can opener, kitchen equipment -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Domestic object - Kitchen equipment, gas-fuelled flat iron, c1900 - 30

Sad-irons or "solid" irons were made by blacksmiths and used to smooth out material by pressing the hot iron over it. A piece of sheet -iron was placed over the kitchen fire and the irons placed on it could be heated whilst remaining clean of ash.. The women used 2 irons - one heating while the other was used. Thick cloth or gloves protected their hands from the hot irons. The handle was removed from the cool iron and re- attached to remove the hot iron from the fire. The cool iron was replaced on the fire or stove to heat again. These irons were cleaned with steel wool to prevent them marking the material. If the iron was too hot the material would scorch. Most homes set aside one day for ironing and some large households had an ironing room with a special stove designed to heat irons. However, most women had to work with a heavy, hot iron close to the fireplace even in summer. Thomas Fletcher (1840-1903). By 1880s he had a gas appliance manufactory in Thynne Street, Warrington. By 1895 the company had become Fletcher Russell and Co Gas Engineers, his firm having merged with Alexander and William Russell of Pendleton Iron Works. Circa 1950, the firm merged into Radiation Ltd which was later acquired by 'TI New World'; 1902: Fletcher, Russell & Co. Ltd., Palatine Works, Warrington In 1880 gas -fuelled irons were connected by rubber tubing to the gas light-fittings of the house or to gas canisters. However , not many houses had access to a gas supply until much later and this iron was popular in 1920’sThese sad irons remind us of the difficult circumstances experienced in their daily routines by the pioneers and early settlers of Moorabbin Shire The family of Miss M Curtis were early settlers in Moorabbin Shire.A gas-fuelled flat iron, made in USA , It would have been attached to a gas hose fitting that was also used at night for light in the house. There is a small chimney to allow for air and to try to control the amount of heat in the iron. A 'shield' is under the leather covered handle to protect the user's hand from the heat, however it is made of copper metal - a heat conductor.FLETCHER RUSSELL CO. / LIM/ PATENT/ WARRINGTON on right side of handle 'Registered' on left side of handle ' Fletcher Russell Co L / Warrington, Manchester / & London.sad iron, kitchen equipment, fletcher russell co. ltd., england, warrington, manchester, pioneers, early settlers, market gardeners, sewing, craftwork, clothing, moorabbin, brighton, bentleigh, fireplaces, stoves, domestic gas supply, gas-light, gas cannisters -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Ice Chest, 1927

This particular small ice chest was once part of the domestic furniture of Dr W.R. Angus and his young family in 1927 when they lived in the Nhill and Ballarat districts. The family relocated to Warrnambool in 1939 and brought the ice chest with them. An ice chest, also called an icebox or refrigerator, was invented by Thomas Moore in 1802 and had become a common home appliance from the mid-1800s until around the 1930s, when electric refrigerators became affordable and safe. The non-mechanical ice chest allowed perishable food to be kept fresh for longer than the food-safe or ‘Coolgardie’ used in colonial days in Australia. It required the use of ice blocks, which were delivered to households by the ‘iceman' and his horse and cart. The ice man would use an ice pick to cut the blocks into the right size for the buyer’s ice chest. The ice came from an ‘ice house’, a factory where the ice was made. The ice chest required a block of ice to be placed into the insulated top section on top of the corrugated iron stand. The ice would cool the air and the cool air would flow downwards through the oval hole under the stand and into the refrigerator compartment below. The water from the melted ice would drain from the sloping floor of the top compartment and into the hooded pipe. The pipe went through the refrigerator and ended below its floor, where the drained water would be collected in the metal bowl placed there for that purpose. The lip on the bowl allowed it to be easily removed and emptied at regular intervals before it overflowed. W.R. Angus Collection- The W R Angus Collection spans from 1885 to the mid-1900s and includes historical medical and surgical equipment and instruments from the doctors Edward and Thomas Ryan of Nhill, Victoria. Dr Angus married Gladys in 1927 at Ballarat, the nearest big city to Nhill where he began as a Medical Assistant. He was also Acting House surgeon at the Nhill hospital where their two daughters were born. He and his family moved to Warrnambool in 1939, where Dr Angus operated his own medical practice. He later added the part-time Port Medical Officer responsibility and was the last person appointed to that position. Dr Angus and his wife were very involved in the local community, including the early planning stages of the new Flagstaff Hill, where they contributed to the layout of the gardens. Dr Angus passed away in March 1970.This ice chest is significant for representing a method of refrigeration and food preservation used in the 19th to mid-20th centuries when people were beginning to afford powered domestic refrigerators. After the second world war, most households replaced their food storage cupboards and ice chests with refrigerator appliances. The ice chest is also significant for its connection with the domestic furniture of Dr W.R. Angus and his family, and its inclusion in the W.R. Angus Collection.Ice chest; single front wooden cabinet with two doors and a flap, and three accessories. The top door is a lid with a metal handle at the front and two metal hinges along the back. The front door has two metal hinges on the right-hand side and has a metal lever catch. A hinged flap fits between the front legs at bottom of the ice chest and swings upwards. The front legs have wheels. The insulated top compartment has a metal lining and its floor slopes towards the centre of the back wall. In the floor are a formed oval air-flow hole and the open end of a pipe that has a hood partly covering it. The front compartment is an insulated metal-lined cupboard with a vertical pipe down the centre of the back wall and horizontal rails in the centre of each side wall. The accessories are a rectangular corrugated iron stand, a rectangular wire grid shelf and a round aluminium bowl with a lip and two sides pushed in. The ice chest was made circa 1927 and is part of the W.R. Angus Collection.flagstaff hill, warrnambool, maritime village, maritime museum, shipwreck coast, great ocean road, dr w r angus, dr roy angus, dr ryan, doctor angus, dr angus, ice chest, ice box, antique, food preservation, refrigeration, domestic equipment, kitchen appliance, refrigerator, non-electric refrigerator, non-mechanical refrigerator, w.r. angus collection -

Hume City Civic Collection

Hume City Civic CollectionDomestic object - Self-Generating Gas Iron, The "STAR" Self-Generating Gas Iron

... of the household. social history Domestic appliance Irons George Evans ...This iron was given to Isobel and Stan Campbell by another woman in Boort Victoria pre 1999 as per the letter attached with the Donation form. These irons were manufactured in Australia as per the printing on the cardboard box and instruction sheet. These self-generating gas irons used methylated spirits in the small tank at the back of the iron. The irons would have been used prior to electricity being available to be connected to a house and used for ironing clothes and other woven material items used by the members of the household.Brown cardboard box with separate lid with black printing on the front and back of box and lid. A heavy silver iron with 13 holes along each side there is a black handle screwed to top of iron and a small round container attached to the back. An instruction sheet. Box front and back - The "STAR"/Self-Generating Gas iron/(Registered)/Is Made In Australia!/By Australian Workers!/From Australian Material!/ Instruction sheet - MADE IN AUSTRALIA/.../The "STAR' is the most economical Iron ever put on the Market , and/being manufactured of the best materials only, will last a life-time./...social history, domestic appliance, irons, george evans collection, isobel campbell, 1990s -

Wodonga & District Historical Society Inc

Wodonga & District Historical Society IncFunctional object - Dazey Churn, 1922

In the early 1900's, E.B. Jones developed a small glass churn for home use. Nathan Dazey purchased Jones' business and relocated it to St. Louis, Missouri as the Dazey Churn and Manufacturing Co. Dazey churns were manufactured up until 1945. Although best known for its butter churns, the company also made can openers, knife sharpeners and other kitchen products. Thes churns were widely used throughout households in rural Australia during the first half of the 20th century.This item was typical of kitchenware used widely in the early twentieth century when households produced more basic food items. A round glass churn with metal lid and mechanism. The handle was turned to rotate the paddle at the base of the mechanism in the jar. The jar holds 2 quarts of milk.The embossed Jar lettering is as follows: DAZEY CHURN No. 20 Patented February 12,1922 DAZEY CHURN & MFG. CO. ST. LOUIS, MO. MADE IN U.S.A.domestic appliances, kitchen appliances -

Wodonga & District Historical Society Inc

Wodonga & District Historical Society IncDomestic object - Kerosene Lantern

During the Victorian goldrushes of the 1850s thousands of Chinese migrants arrived to seek their fortunes. At that time many came to the lucrative gold fields of Northeast Victoria. After the Gold rush, many Chinese migrants returned home. However, a number settled in the area as merchants, hawkers and market gardeners in surrounding towns including Wodonga, the Ovens, King, Buffalo River and Kiewa Valleys. They also rented lands and established themselves in the hops and tobacco farming industries. Items of Chinese origin made their way into many households. Importation of Chinese mass produced items such as this lantern continued well into the 20th century and were common domestic items across Australia before households were connected to electricity.This item is representation of kerosene / paraffin lamps used throughout Australia to provide lighting inside and outdoors prior to the widespread availability of electricity.A small hurricane lamp with a rounded tank and small carry handle attached to the top. A larger handle is also attached at the top of the frame. It has a lever to open the glass tank. It has a metal base which is filled with kerosene. It has a screw knob to open the kerosene receptacle. The metal hood also has vents. The Chinese characters around the base translate to "Shanghai Guanghuaheng".Around base : Chinese characters. On top : "Made in China KWANG HWA"kerosene lamp, domestic appliances, chinese artefacts -

Wodonga & District Historical Society Inc

Wodonga & District Historical Society IncDomestic object - Lady Sunbeam Home Hair Dryer, Sunbeam Corporation Australia, c1960

Sunbeam produced a wide range of hair dryers in a variety of sizes and shapes throughout the 1960s. Lady Sunbeam was promoted as providing unequalled efficiency as well as extra convenience and comfort. Whilst you dried your hair, you were able to sit and relax, read a book, write letters, knit or apply your nail enamel. The added convenient shoulder strap enabled you to complete other small household chores such as ironing - as long as they could be carried out within the distance of the power cord. Sunbeam History The Sunbeam Corporation began in Australia in 1902 as a small branch of the American group, Chicago Flexible Shaft Company.In 1946, this company changed its name to Sunbeam Corporation and developed the slogan "Best Electric Appliances Made". The company became publicly traded in 1952 and came into Australian ownership in 1987. In 1948 the company launched the Sunbeam Mixmaster®, the first small electrical appliance to be manufactured in Australia. In 2020, the company changed its name to Newell Australia.This item is representative of a range of domestic appliances used across Australia in the 1960s to make home life simpler and more convenient.Hair dryer in portable round plastic hinged case with motor fitted within the base. Plastic wire coiled hose is attached to the motor. A plastic hood edged with elastic and lace adjustment is fitted to the end of the hose. The hood has a pattern of gold embossed flowers. The motor has settings off, cool, warm, med, hot. An electric cord and plug are attached to the motor. The lid closes with a sprung knob and has a plastic carry handle. The "Lady Sunbeam" Logo is embossed on the lid.On lid: Lady Sunbeam / HAIR DRYER Underneath unit: MODEL AHD-7 220-250V 50CYC 300W.AC. ONLY/ PATENT PENDING RD.NO.42.338 MADE IN AUSTRALIA / Sunbeam CORPORATION LIMITEDsunbeam australia, domestic appliances, hair dryers -

Wodonga & District Historical Society Inc

Wodonga & District Historical Society IncFunctional object - Cast iron tin opener

... in relatively good condition. Household items Cast iron appliances can ...Commercial tin openers first appeared in the mid 19th century and this model dates from the early 20th century. An improved version when a second serrated wheel was added came into operation about the mid 1920s. Tins (now cans) of food with sealed tops became popular in the 20th century and all households needed a tin opener. Today the can opener is still used but increasingly the can lids have an inbuilt clip that is pulled out to open the can.This tin opener has been retained as an early model of a tin opener from the past. It was used locally in Wodonga and donated by a Wodonga resident. It is also in relatively good condition.This is a cast iron tin opener with a cutting blade attached to a piece of metal with a screw. The metal handle curves out from the metal piece holding the blade. The opener is a little rusty in parts. The name ‘Guard ’ is on both sides of the handle in raised metal letters. "GUARD" in raised letters on both sides of the handle.household items, cast iron appliances, can openers -

Wodonga & District Historical Society Inc

Wodonga & District Historical Society IncFunctional object - Metal table balance scales, Pre 1970s

Sets of scales similar to these were very common in households throughout Australia. Between 1960 and 1988 Australia gradually adopted the SI units (Standard International) or metric units. In 1970 the Australian parliament passed the metric conversion act, and the Australian building trades made it the standard in 1974. This information helps to date the set of weights to before the1970s.Domestic scales such as these were common throughout Australian homes. They are now primarily superceded by plastic items, often electronic.Metal table scales with 6 weights graduated in sizes including 1 oz., 2 oz, 4oz, 8oz, 1lb and 2 lbs. Each weight marked "MACK/ MADE IN AUSTRALIA"domestic appliances, weights and measures australia -

Wodonga & District Historical Society Inc

Wodonga & District Historical Society IncFunctional object - Metal balance scales with weights, C. 1900

Sets of scales similar to these were very common in households throughout Australia. Between 1960 and 1988 Australia gradually adopted the SI units (Standard International) or metric units. In 1970 the Australian parliament passed the metric conversion act, and the Australian building trades made it the standard in 1974. This information helps to date the set of weights to before the1970s.Domestic scales such as these were common throughout Australian homes. They are now primarily superceded by plastic items, often electronic. Metal table scales with imperial weights weights and measures australia, table scales, domestic appliances -

Glenelg Shire Council Cultural Collection

Glenelg Shire Council Cultural CollectionFunctional object - Foot Warmer, Hecla Electrics Pty Ltd, c. 1920

From Museum Victoria: Made in about 1927 by Hecla Electrics Pty Ltd and sold under the model name 'Foot Warma'. The foot warmer was made from the late 1920s until the 1950s and did not change substantially in design during this time. The Hecla brand name and logo was registered in 1918 by Clarence Marriott. It was inspired by the recent eruption of Iceland's volcano Mt Heckla. Clarence and his father James were metal workers who had made Australia's first carbon filament electric radiators in 1899, and also built an early steam car. As electricity use exploded in the 1920s and 1930s, 'Hecla' became a household name in Melbourne. They made a wide range of appliances for the home, and supplied commercial appliances to cafés, hospitals and offices. In 1927, the company shifted from small premises in the city to a bigger, electric-powered factory in South Yarra. Hecla had no retail stores of its own - instead it sold products through wholesalers and retailers, including the State Electricity Commission (SEC). The company promoted its goods through advertisements in home magazines and displays in shop windows, home shows and the 1935 All-Electricity Exhibition. A popular advertising slogan in the 1930s was 'Hecla household helps make happy healthy housewives!'. Hecla ceased manufacturing in Melbourne in the 1980s.Documentation of how people lived and is an example of early domestic electrical appliances. From Museum Victoria: Hecla Electrics Pty Ltd were a significant Melbourne manufacturing company, who became a household name in the 1920s making small electric appliances such as heaters and kettles. They also made a variety of other electrical appliances for domestic, commercial and military use. The company manufactured electric appliances in Melbourne from about 1922 until the 1980s, although Clarence Marriott, who formed the company, had begun making radiators with his father James in 1899. The company had a reputation for quality products. The company also played an important role within the Australian domestic and commercial appliance industry, both as a leading innovator and through its role in training skilled staff, many of whom went on to work for competitors such as Kambrook, Electrolux and Sunbeam. This electric coffee percolator represents the typical small domestic appliance that the Hecla company was famous for. Along with other items in the Hecla Collection, it highlights the diversity of electric appliances that the company made. This object also highlights the legacy of high quality design and metal construction work that Clarence and James established for the company, stemming from their early work as talented art metal workers. It also represents the first major period of the take-up of electricity use in the home. This take-up began in the 1920s and 1930s with the use of small appliances, and by the 1950s electricity had become commonplace in the home, and large appliances such as refrigerators and stoves became standard.Square metal object. The top surface is heavy cast iron and patterned with floral motifs. In the centre is a circle with the words ' Hecla Foot Warma' inside. Under the top is a black metal base with two feet at either end which extend the length of the base. The back foot is higher than the front foot. There is a circular disk from which extends the electrical cord. The cord is brown and white checks. At the end of the cord is a plug on which is printed 250V AMP S.2 EARTH 5. The plug is brown and made from Bakelite. On the base is a rectangular label which has words printed - HECLA Australia.Top: HECLA/-FOOT-/WARMA Base: Volts / 230/250 / WATTS / 80 / HECLA / Australia / CAT. NO. F26domestic, city of portland, glenelg shire council, electrical, foot warmer, heating, hecla, manufacture