Showing 24 items matching "meat processing"

-

The Beechworth Burke Museum

The Beechworth Burke MuseumAudio - Oral History, Jennifer Williams, Mr Alfred Spencer, 17th February 2000

... meat processing... black springs butchers meat processing butcher road road network ...Alfred 'Alf' Spencer grew up on a dairy farm run by his mother, west south west of Beechworth 'down Robertson Road', and was very well connected to the wider Beechworth area. In this oral history, he recalls his time driving the milk cart around Beechworth as well as the time he spent buying lollies and seeing the pictures. He talks extensively about working as a butcher at his brother's store, including how the butchers interacted with the rest of the town and the staff, as well as his time constructing roads and the pipe network of Beechworth. He discusses the dynamics of other workplaces around Beechworth, describing issues with how the local tannery treated its workers as well as how post-war migrants integrated across the town. He briefly discusses racial tensions between Chinese migrants and other miners on the goldfields. He also discusses the experience of health care in a rural area during his childhood. This oral history recording was part of a project conducted by Jennifer Williams in the year 2000 to capture the everyday life and struggles in Beechworth during the twentieth century. This project involved recording seventy oral histories on cassette tapes of local Beechworth residents which were then published in a book titled: Listen to what they say: voices of twentieth century Beechworth. These cassette tapes were digitised in July 2021 with funds made available by the Friends of the Burke.Alfred Spencer's oral history of his life around Beechworth during the 20th century is historically and socially significant to the cultural history of the region and Victoria. There is a lot of detail about workplaces, their staff, and how the resources of the town interacted. He explores themes that are important to Victorian history, such as migration. This oral history account is socially and historically significant as it is a part of a broader collection of interviews conducted by Jennifer Williams which were published in the book 'Listen to what they say: voices of twentieth-century Beechworth.' While the township of Beechworth is known for its history as a gold rush town, these accounts provide a unique insight into the day-to-day life of the town's residents during the 20th century, many of which will have now been lost if they had not been preserved.This is a digital copy of a recording that was originally captured on a cassette tape. The cassette tape is black with a horizontal white strip and is currently stored in a clear flat plastic rectangular container. It holds up to 40 minutes of recordings on each side.Mr Alfred Spencer /listen to what they say, beechworth, oral history, burke museum, spencer, alfred spencer, migration, post-war migration, goldfields, health care, farm, farming, dairy farm, black springs, butchers, meat processing, butcher, road, road network, labour relations -

Federation University Historical Collection

Federation University Historical CollectionDocument - Document - News sheet, VIOSH: University of Ballarat; "VIOSH Australia News", 1996 to 2000, 1996-2000

... Meat processing... Meat processing Jenni Marsh Andrews Stevens herbert werner ...Victorian Institute of Occupational Safety and Health (VIOSH) Australia is the Asia-Pacific centre for teaching and research in occupational health and safety (OHS) and is known as one of Australia's leaders on the field. VIOSH has a global reputation for its innovative approach within the field of OHS management. VIOSH had its first intake of students in 1979. At that time the Institution was known as the Ballarat College of Advanced Education. In 1990 it became known as Ballarat University College, then in 1994 as University of Ballarat. It was 2014 that it became Federation University. VIOSH Australia students are safety managers, senior advisors and experienced OHS professionals. They come from all over Australia and industry. Students are taught active research and enquiry; rather than textbook learning and a one-size fits all approach. VIOSH accepts people into the Graduate Diploma of Occupational Hazard Management who have no undergraduate degree - on the basis of extensive work experience and knowledge. VIOSH Australia News provided information on aspects of the course at Ballarat. They were printed twice a year - Autumn and Spring.Nine newsletters, A3 size folded. Printed on 4 sides. Photographs includedVIOSH emblem. Dates of publication.viosh, victorian institute of occupational safety and health, ballarat, viosh news, 1996 - 2000, eric wigglesworth, shearing, worksafe, dennis else, occupational health and safety, oliver shoes, anne tayler, robin hood, dulcie brooke, fiji, kim whytcross, john culvenor, geoff dell, thomas mitchell, tony thatcher, trevor bailey, david borys, shelley kirkham, phil royce, noise, jane lean, shearing ergonomics, meat processing, jenni marsh, andrews stevens, herbert werner frederick de nully, maria bachelor, joanne dyer, peter tight, safety, jim kent, michael lawrence -

Glenelg Shire Council Cultural Collection

Glenelg Shire Council Cultural CollectionMixed media - Oral History Interview - Borthwicks, Clarrie Tonkin Interview - Borthwicks, c. 2014

... meat processing... was run by Thomas Borthwick & Sons. Borthwicks meat processing ...Borthwick's Meat works was run by Thomas Borthwick & Sons.DVD unedited. Interview with Clarrie Tonkinborthwicks, meat processing, industry, portland -

Warrnambool and District Historical Society Inc.

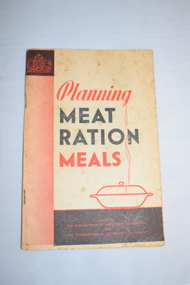

Warrnambool and District Historical Society Inc.Booklet, Planning Meat Rations, 1940s

... because much of the meat processed in Australia was sent overseas... much of the meat processed in Australia was sent overseas ...This booklet was issued to householders in Australia giving information on meat rationing during World War Two. Meat was rationed because much of the meat processed in Australia was sent overseas to Britain and to soldiers in war areas. The booklet includes hints on how to make the most of the meat ration. Meat and other key foods such as tea, sugar and butter were rationed during World War Two. Each person in Australia was allowed two meat coupons a week and, depending on the type of meat, this equated to one pound to two pounds of meat per coupon. Products such as sausages, brains, tripe, poultry, rabbits, bacon and ham were not rationed (but few people could afford poultry). This booklet is of interest because it is a memento of the times in World War Two when several food items were rationedThis is a small booklet of 10 pages. The front cover has a beige background with an orange border, red and black printing, a Commonwealth Government crest and a sketch of a casserole dish. The back cover has red and black printing on a beige background. The cover is slightly faded. The pages have red and black sketches and black print. The contents include recipes, meal plans and hints for cooking and storing meat. The booklet has been bound with metal staples. world war two, food rationing in world war two, history of warrnambool -

City of Greater Bendigo - Civic Collection

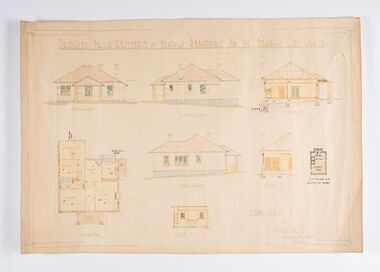

City of Greater Bendigo - Civic CollectionWork on paper - Architectural Drawing, City of Bendigo, Proposed Brick Residence at Bendigo Abbatoirs (sic) for the Bendigo City Council, Not dated

... and in particular meat processing buildings, designing major freezing works... and in particular meat processing buildings, designing major freezing works ...Situated at 47 Lansell Street, Bendigo, the original 1911-12 Charles D'Ebro designed brick Bendigo Municipal Abattoir, comprising twin slaughter and hanging rooms for cattle, sheep and pigs, and two smaller ancillary brick buildings. After the buildings were acquired by the Country Roads Board in 1945, a substantial but sympathetic addition was made to the south-eastern end of the old cattle abattoir. The abattoir is significant for historic, architectural and technical reasons at a state level. as a rare surviving municipal abattoir, and represents the development of hygienic slaughtering through municipal regulations, thus improving standards of public health in Victoria. It is historically significant to the City of Greater Bendigo as a key to the primary production industry that centred on this precinct from the 1860s to the mid 1990s; they are an important surviving component of one of the largest regional livestock markets in Victoria. D'Ebro was critically influential in the development of industrial and in particular meat processing buildings, designing major freezing works and abattoirs throughout Victoria and Australia.(Source, National Trust Database). The Bendigo facility finally closed in 1945, when all slaughtering for local consumption passed to a joint export and local slaughtering facility at the Bendigo Inland Meat Authority. Ink, pen, pencil and watercolour architectural drawing for the proposed brick residence at Bendigo abattoirs. Proposed Brick Residence at Bendigo Abbatoirs (sic) For The Bendigo City Council. / Front Elevation / Easter Elevation / Section A. D. / Ground Plan / Wester Elevation / Section C.D. / Section I. P. ? Existing Building to be / Converted into Laundry ? Scale 1/8" to 1 FT / Geo. Austen Architect / Commonwealth Bank Chambers / Bendigocity of greater bendigo commerce, charles d'ebro -

Wodonga & District Historical Society Inc

Wodonga & District Historical Society IncDomestic object - Meat mincer / Food chopper

... as a device that not only ground meat, but also processed vegetables... that not only ground meat, but also processed vegetables. The number 2 ...The Universal Food Chopper was a common domestic item internationally and throughout Australia. It was manufactured by the Landers, Frary & Clark company ( L.F. &C.). It was first sold in 1897, and proved to be so popular that the company still featured it in their catalogue sixty years later. It was marketed as a device that not only ground meat, but also processed vegetables. The number 2 on the device referred to the size of the grinder, with the 3 model being the largest for heavy-duty use and the 00 model the smallest. This appliance was a common domestic item used throughout AustraliaA cast iron and wood domestic appliance. The food chopper has a large screw on the base which allowed it to be anchored to a table or work bench. Food items were placed in the the cavity at the top and the user wound the handle to force the food through the blade. Different attachments allowed adjustments to the size the food was chopped.On Side 1: Pat. Oct.12, 1897/ Apr. 18, 1899/ Re Sept. 5, 1899 On Side 2 : LF & Co. /New Britain / CONN USA / No 2/ UNIVERSAL FOOD CHOPPERfood chopper, kitchen appliances, food preparation -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Mincer, late 19th or early 20th Century

... way to process meat, and is a widely used piece of equipment... and vegetables. It is the best way to process meat, and is a widely used ...A meat grinder, commonly known as the meat mincer, is used for chopping meat into fine pieces. Alternatively, it can be used for the mixing of raw or cooked meat, fish and vegetables. It is the best way to process meat, and is a widely used piece of equipment by butchers and in the home.. Butchers have been known to use either mincing knives or meat cleavers in the kitchen for years to produce a quantity of minced meat. This was a slow and laborious process. The advent of the meat mincer has not only made the mincing process easier but also faster. The meat mincer has slowly evolved over the years into what it is today. The first meat mixer or meat mincer was invented in the 19th century by a German inventor named Baron Karl Drais. Although some versions of the device date back to much earlier. The oldest form of meat mincer was hand cranked which forced meat through a metal plate with several small holes in it, which resulted in long and thin strands of the meat. The meat was fed into the funnel that was placed at the top of the mixer. This meat would pass through a hand cranked screw conveyor that would squash and mix the meat before passing it through the metal plate. Needless to say, this was again a slow and laborious procedure to follow to produce large quantity of meat. With passage of time, this hand cracked machine became powered by electricity. The meat mincer has a great adaptability and efficiency now. The huge variety in mincer plates allows a butcher to produce different types of minced meat in any shape desired. However, traditional manual meat mincers have not really changed a lot. They are manually operated and made of cast iron, as earlier. They are similar to the original mincer designs, dating back to the early 1900s. Some butchers still prefer using a variety of mincer knives. Adapted from: https://brennan-group.com/blogs/news/history-of-the-meat-mincerThe development of the meat mincer enabled both butchers and home cooks to process and grind meat effectively.Clamp on meat mincer with handle for rotating the mincing apparatus inside.None.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, meat mincer -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Food Mincer, John Harper & Co, Early - Mid 20th Century

... way to process meat, and is a widely used piece of equipment... way to process meat, and is a widely used piece of equipment ...A meat grinder, commonly known as the meat mincer, is used for chopping meat into fine pieces. Alternatively, it can be used for the mixing of raw or cooked meat, fish and vegetables. It is the best way to process meat, and is a widely used piece of equipment by butchers and in the home.. Butchers have been known to use either mincing knives or meat cleavers in the kitchen for years to produce a quantity of minced meat. This was a slow and laborious process. The advent of the meat mincer has not only made the mincing process easier but also faster. The meat mincer has slowly evolved over the years into what it is today. The first meat mixer or meat mincer was invented in the 19th century by a German inventor named Baron Karl Drais. Although some versions of the device date back to much earlier. The oldest form of meat mincer was hand cranked which forced meat through a metal plate with several small holes in it, which resulted in long and thin strands of the meat. The meat was fed into the funnel that was placed at the top of the mixer. This meat would pass through a hand cranked screw conveyor that would squash and mix the meat before passing it through the metal plate. Needless to say, this was again a slow and laborious procedure to follow to produce large quantity of meat. With passage of time, this hand cracked machine became powered by electricity. The meat mincer has a great adaptability and efficiency now. The huge variety in mincer plates allows a butcher to produce different types of minced meat in any shape desired. However, traditional manual meat mincers have not really changed a lot. They are manually operated and made of cast iron, as earlier. They are similar to the original mincer designs, dating back to the early 1900s. Some butchers still prefer using a variety of mincer knives. Adapted from: https://brennan-group.com/blogs/news/history-of-the-meat-mincer This meat mincer belonged to the family of Dr.William Roy Angus, Surgeon and Oculist. It was donated to Flagstaff Hill Maritime Village by his daughter, Bernice McDade. It is part of the “W.R. Angus Collection” that includes historical medical equipment, surgical instruments and material once belonging to Dr Edward Ryan and Dr Thomas Francis Ryan, (both of Nhill, Victoria) as well as Dr Angus’ own belongings. The Collection’s history spans the medical practices of the two Doctors Ryan, from 1885-1926 plus that of Dr Angus, up until 1969. ABOUT THE “W.R.ANGUS COLLECTION” Doctor William Roy Angus M.B., B.S., Adel., 1923, F.R.C.S. Edin.,1928 (also known as Dr Roy Angus) was born in Murrumbeena, Victoria in 1901 and lived until 1970. He qualified as a doctor in 1923 at University of Adelaide, was Resident Medical Officer at the Royal Adelaide Hospital in 1924 and for a period was house surgeon to Sir (then Mr.) Henry Simpson Newland. Dr Angus was briefly an Assistant to Dr Riddell of Kapunda, then commenced private practice at Curramulka, Yorke Peninsula, SA, where he was physician, surgeon and chemist. In 1926, he was appointed as new Medical Assistant to Dr Thomas Francis Ryan (T.F. Ryan, or Tom), in Nhill, Victoria, where his experiences included radiology and pharmacy. In 1927 he was Acting House Surgeon in Dr Tom Ryan’s absence. Dr Angus had become engaged to Gladys Forsyth and they decided he would take time to further his studies overseas in the UK in 1927. He studied at London University College Hospital and at Edinburgh Royal Infirmary and in 1928, was awarded FRCS (Fellow from the Royal College of Surgeons), Edinburgh. He worked his passage back to Australia as a Ship’s Surgeon on the on the Australian Commonwealth Line’s T.S.S. Largs Bay. Dr Angus married Gladys in 1929, in Ballarat. (They went on to have one son (Graham 1932, born in SA) and two daughters (Helen (died 12/07/1996) and Berenice (Berry), both born at Mira, Nhill ) Dr Angus was a ‘flying doctor’ for the A.I.M. (Australian Inland Ministry) Aerial Medical Service in 1928 . The organisation began in South Australia through the Presbyterian Church in that year, with its first station being in the remote town of Oodnadatta, where Dr Angus was stationed. He was locum tenens there on North-South Railway at 21 Mile Camp. He took up this ‘flying doctor’ position in response to a call from Dr John Flynn; the organisation was later known as the Flying Doctor Service, then the Royal Flying Doctor Service. A lot of his work during this time involved dental surgery also. Between 1928-1932 he was surgeon at the Curramulka Hospital, Yorke Peninsula, South Australia. In 1933 Dr Angus returned to Nhill where he’d previously worked as Medical Assistant and purchased a share of the Nelson Street practice and Mira hospital from Dr Les Middleton one of the Middleton Brothers, the current owners of what was once Dr Tom Ryan’s practice. Dr L Middleton was House Surgeon to the Nhill Hospital 1926-1933, when he resigned. [Dr Tom Ryan’s practice had originally belonged to his older brother Dr Edward Ryan, who came to Nhill in 1885. Dr Edward saw patients at his rooms, firstly in Victoria Street and in 1886 in Nelson Street, until 1901. The Nelson Street practice also had a 2 bed ward, called Mira Private Hospital ). Dr Edward Ryan was House Surgeon at the Nhill Hospital 1884-1902 . He also had occasions where he successfully performed veterinary surgery for the local farmers too. Dr Tom Ryan then purchased the practice from his brother in 1901. Both Dr Edward and Dr Tom Ryan work as surgeons included eye surgery. Dr Tom Ryan performed many of his operations in the Mira private hospital on his premises. He too was House Surgeon at the Nhill Hospital 1902-1926. Dr Tom Ryan had one of the only two pieces of radiology equipment in Victoria during his practicing years – The Royal Melbourne Hospital had the other one. Over the years Dr Tom Ryan gradually set up what was effectively a training school for country general-practitioner-surgeons. Each patient was carefully examined, including using the X-ray machine, and any surgery was discussed and planned with Dr Ryan’s assistants several days in advance. Dr Angus gained experience in using the X-ray machine there during his time as assistant to Dr Ryan. Dr Tom Ryan moved from Nhill in 1926. He became a Fellow of the Royal Australasian College of Surgeons in 1927, soon after its formation, a rare accolade for a doctor outside any of the major cities. He remained a bachelor and died suddenly on 7th Dec 1955, aged 91, at his home in Ararat. Scholarships and prizes are still awarded to medical students in the honour of Dr T.F. Ryan and his father, Dr Michael Ryan, and brother, John Patrick Ryan. ] When Dr Angus bought into the Nelson Street premises in Nhill he was also appointed as the Nhill Hospital’s Honorary House Surgeon 1933-1938. His practitioner’s plate from his Nhill surgery states “HOURS Daily, except Tuesdays, Fridays and Saturday afternoons, 9-10am, 2-4pm, 7-8pm. Sundays by appointment”. This plate is now mounted on the doorway to the Port Medical Office at Flagstaff Hill Maritime Village, Warrnambool. Dr Edward Ryan and Dr Tom Ryan had an extensive collection of historical medical equipment and materials spanning 1884-1926 and when Dr Angus took up practice in their old premises he obtained this collection, a large part of which is now on display at the Port Medical Office at Flagstaff Hill Maritime Village in Warrnambool. During his time in Nhill Dr Angus was involved in the merging of the Mira Hospital and Nhill Public Hospital into one public hospital and the property titles passed on to Nhill Hospital in 1939. In 1939 Dr Angus and his family moved to Warrnambool where he purchased “Birchwood,” the 1852 home and medical practice of Dr John Hunter Henderson, at 214 Koroit Street. (This property was sold in1965 to the State Government and is now the site of the Warrnambool Police Station. ). The Angus family was able to afford gardeners, cooks and maids; their home was a popular place for visiting dignitaries to stay whilst visiting Warrnambool. Dr Angus had his own silk worm farm at home in a Mulberry tree. His young daughter used his centrifuge for spinning the silk. Dr Angus was appointed on a part-time basis as Port Medical Officer (Health Officer) in Warrnambool and held this position until the 1940’s when the government no longer required the service of a Port Medical Officer in Warrnambool; he was thus Warrnambool’s last serving Port Medical Officer. (The duties of a Port Medical Officer were outlined by the Colonial Secretary on 21st June, 1839 under the terms of the Quarantine Act. Masters of immigrant ships arriving in port reported incidents of diseases, illness and death and the Port Medical Officer made a decision on whether the ship required Quarantine and for how long, in this way preventing contagious illness from spreading from new immigrants to the residents already in the colony.) Dr Angus was a member of the Australian Medical Association, for 35 years and surgeon at the Warrnambool Base Hospital 1939-1942, He served as a Surgeon Captain during WWII1942-45, in Ballarat, Victoria, and in Bonegilla, N.S.W., completing his service just before the end of the war due to suffering from a heart attack. During his convalescence he carved an intricate and ‘most artistic’ chess set from the material that dentures were made from. He then studied ophthalmology at the Royal Melbourne Eye and Ear Hospital and created cosmetically superior artificial eyes by pioneering using the intrascleral cartilage. Angus received accolades from the Ophthalmological Society of Australasia for this work. He returned to Warrnambool to commence practice as an ophthalmologist, pioneering in artificial eye improvements. He was Honorary Consultant Ophthalmologist to Warrnambool Base Hospital for 31 years. He made monthly visits to Portland as a visiting surgeon, to perform eye surgery. He represented the Victorian South-West subdivision of the Australian Medical Association as its secretary between 1949 and 1956 and as chairman from 1956 to 1958. In 1968 Dr Angus was elected member of Spain’s Barraquer Institute of Barcelona after his research work in Intrasclearal cartilage grafting, becoming one of the few Australian ophthalmologists to receive this honour, and in the following year presented his final paper on Living Intrasclearal Cartilage Implants at the Inaugural Meeting of the Australian College of Ophthalmologists in Melbourne In his personal life Dr Angus was a Presbyterian and treated Sunday as a Sabbath, a day of rest. He would visit 3 or 4 country patients on a Sunday, taking his children along ‘for the ride’ and to visit with him. Sunday evenings he would play the pianola and sing Scottish songs to his family. One of Dr Angus’ patients was Margaret MacKenzie, author of a book on local shipwrecks that she’d seen as an eye witness from the late 1880’s in Peterborough, Victoria. In the early 1950’s Dr Angus, painted a picture of a shipwreck for the cover jacket of Margaret’s book, Shipwrecks and More Shipwrecks. She was blind in later life and her daughter wrote the actual book for her. Dr Angus and his wife Gladys were very involved in Warrnambool’s society with a strong interest in civic affairs. Their interests included organisations such as Red Cross, Rostrum, Warrnambool and District Historical Society (founding members), Wine and Food Society, Steering Committee for Tertiary Education in Warrnambool, Local National Trust, Good Neighbour Council, Housing Commission Advisory Board, United Services Institute, Legion of Ex-Servicemen, Olympic Pool Committee, Food for Britain Organisation, Warrnambool Hospital, Anti-Cancer Council, Boys’ Club, Charitable Council, National Fitness Council and Air Raid Precautions Group. He was also a member of the Steam Preservation Society and derived much pleasure from a steam traction engine on his farm. He had an interest in people and the community He and his wife Gladys were both involved in the creation of Flagstaff Hill, including the layout of the gardens. After his death (28th March 1970) his family requested his practitioner’s plate, medical instruments and some personal belongings be displayed in the Port Medical Office surgery at Flagstaff Hill Maritime Village, and be called the “W. R. Angus Collection”.The English-made food mincer is an example of kitchenware available to households from the early 20th century. The W.R. Angus Collection is significant for still being located at the site it is connected with, Doctor Angus being the last Port Medical Officer in Warrnambool. The collection of medical instruments and other items and equipment is culturally significant, being an historical example of medicine from late 19th to mid-20th century. Dr Angus assisted Dr Tom Ryan, a pioneer in the use of X-rays and in ocular surgery.Metal food mincer labelled Harper No. 3181, Beatrice. Made in England. The object is part of the W.R. Angus Collection. Harper. No 3181. Beatrice. Made in England. No 3 Fine. Also a leaflet of instructions headed up: 'Harper No.3181 "Beatrice" Food Mincer. Instuctions for Use.'flagstaff hill maritime museum and village, great ocean road, shipwreck coast, mincer, grinder, meat, cooking, beatrice, made in england, harper, no. 3181, w.r. angus -

Orbost & District Historical Society

Orbost & District Historical Societymeat mincer, mid 1900's

This mincer was donated to the Slab Hut (Visitor Information Centre) as a display item.This domestic kitchen appliance is typical of the period when food processing was done at home. It would have been before the time of mass food processing factories.A cast iron food mincer with a wooden handle. It has a funnel shaped cup at the top through which the pieces of meat are pushed to come out of the side. The wooden handle is turned to help this action. It has one blade. The mincer clamps to a flat surface by a hand operated vice/screw. MODEL No 2food-preparation mincer appliance kitchen domestic -

Orbost & District Historical Society

Orbost & District Historical Societymeat grinder, Late 19th century

This is one of many models of the Enterprise Tinned Meat Chopper No5This domestic kitchen appliance is typical of the period when food processing was done at home. It would have been before the time of mass food processing factoriesSmall black metal meat grinder with screw down grip for use on bench tops and tables. Still in working order. Carved wooden handle.Enterprise MFG.Co. PH'A, U.S.A. on clamp. Pat.Jan.30.83.June.5.88 on other side. Enterprise-Tinned-Meat-Chopper on barrel.grinder domestic food-preparation enterprise-mfc -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietySafe Coolgardie, circa early 1900s

The harsh summer temperatures and the isolated rural environment(of the 1890's) provided the inventor of the "Coolgardie safe" (Arthur Patrick McCormick) with an idea to cool perishable foods by using water soaked "hessian" cloth to provide the "coolant" for the evaporation process to cool the inside temperature of the "safe". Items such as meat,cream/milk/butter and cool "drinks" are a few perishables that need cool environments , especially in isolated "ice free" locations. Cities during this time period had large "ice works" which delivered block ice to all areas that required a form of refrigeration. These ice blocks where held in early refrigerators to keep perishables cool to cold. This "Coolardie" safe was the next best thing for isolated rural households and travellers/campers/stockmen to provide a cooler environment for foodstuff affected by heat. Ice filled "esky" coolers and ice boxes are a modern day off shoot to the original Coogardie safe however they still rely on ice or frozen coolant bricks for cooling.This "Coogardie" safe is very significant to the Kiewa Valley and the Bogong High Plains because it represents not only the initiative thinking of the early settlers and communities but also the "primitive" solution to an everyday (1800s to 1930s) problem (before gas and electric run refrigerators) of keeping "perishables" at a low temperature and thereby prolonging their "shelf" life. This was before electricity and gas was available to the inhabitants of the Kiewa Valley and Bogong High Plains. Another cooling method for food was to have "water tight" containers dipped into the very cold streams running from the "cooler" alpine mountains and the Bogong High Plains. This however could not be carried out in all situations eg. fast flowing currents and locations away from streams. This "Coolgardie safe" is made from a medium grade steel enclosure and its appearance is of a perforated box with a wire handle and one side (long side) being a hinged "door" with a clasp securing "lock". There are air holes grouped into a small "boxed" pattern. Each "box" is divided by a crossed pattern, dividing the "holed" sections(4) into a diamond configuration of 49 small holes each. There are four sides (long) which have the perforations except for the base which does not. The base has an indentation with a loose "catch" tray to catch water spills. When in use the "box" is covered with a water "soaked" cloth. The wet cloth is used as "coolant" ie. fibers in the cloth hold the water droplets seep out evaporating the area and thereby (in mass) cooling the air inside the container.domestic refrigeration cabinets, coolgardie "safe", insect and vermin proof food containers, electric and gas free cold storage containers -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyMincer Meat, early to mid 1900's

This cast iron kitchen appliance was made in England in the early 1900's and shipped to the "colony" Australia. This was before World War II and the "growing up" of a colony to an independent member of "the British Commonwealth". It was a period when most appliances (be they household) where manufactured in England and shipped to Australian ports. It was not until the late 1960's that the Asian manufacturing giant woke up and started to dominate the market palce.This domestic kitchen appliance is very significant to the Kiewa Valley because it highlights the "made at home" period when food processing was made "in house" due to inability to source food from specialised shops e.g. the butcher or slaughter houses. It was a period before mass food processing factories were established and roads constructed up to the standard for distribution to semi remote regions such as Kiewa Valley was in the beginning of the 1900's.This cast iron (malleable iron) mincer for meat products has a large "funnel" to direct "chunks" of meat to the grinding "wheels". These "star" shaped wheels with "teeth" of three different cutting surfaces (fine, medium and coarse) provide for texture types of the final meat product. The meat is placed into the "loading" funnel and push downwards(gravity feed) through the mincing chamber and out through the front side. There is a long "screw worm" which is rotated by turning the handle. The appliance is table mounted by a vice "G" screw on clamp (hand operated). "BEATRICE No. 3" and "MADE IN ENGLAND", "P 3181"household cast iron appliances, food processors -

Cheese World Museum

Cheese World MuseumThermometer, meat, 1911

... provides an insight into the manner early butchers processed meat ...This thermometer came from the Orr family at Addington. Archibald Orr, father and son, were butchers as well as farmers. B Heller & Co was founded in 1896 in Chicago and was well known for its sausage making and preservatives.The thermometer provides an insight into the manner early butchers processed meat.A cylindrical wooden case containing a bulb thermometer with markings for boiling various meats - hams, bacon, corned beef and pickled pork. The bulb at the contains balls of mercury.Certified correct/ tested in our laboratory/ Guaranteed accurate/ B HELLER & Co of Chicago USA/ reprints forbidden/ Copyright 1911.allansford, butchery, meat cooking, heller & co, thermometers -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Can Opener, Bottle Opener & Corkscrew

It took 15 years to invent the can. It took 100 more to invent a standard way to open it. In the 19th century, decades after the invention of canning, there were virtually no can openers. Canned food, such as sardines, came with its own "key" to peel back the tin lid. Birth of the can One of the oddest things about the can opener is that the can predates it by almost 150 years. Though common today, cans were once military-grade technology. In 1795, Napoleon, to whom the phrase "an army marches on its stomach" is attributed, offered 12,000 francs to anyone who could find a way to preserve food. Without any knowledge of bacteria or their role in food spoilage, scientists didn't even know where to begin. It took 15 years before a chef named Nicholas Appert claimed the prize after successfully jarring food. Soon after that, his countryman Philippe de Girard came up with a variant on Appert's method—metal tins—and sold the idea to the British. Spoiled food, and the sickness it caused, was a widespread problem. The public would have benefited from canned food, but for decades cans were almost exclusively for the army and the navy. The canning process, with its hours of boiling and steaming, its scrupulous cleanliness, its heated metal, and its need for a great deal of disposable material, made canned food far too expensive for anyone but the military. No can openers were needed or even possible. The metal of early cans was too thick to make openers practical. Soldiers and sailors had plenty of sharp objects on hand and made ample use of them when they wanted to eat. During the 19th century, the process of canning was refined and mechanised, and the metal wall of the average can slimmed down enough that a civilian could get it open—if that civilian had the right tool. No one had that tool yet, so early cans had to open themselves. In other words, they came with built-in openers. The result was a confusing but pleasing free-for-all, in terms of product engineering. Each type of food came with its own kind of can, and each kind of can came with its own kind of opener. Tinned fish and meat were often sold in rectangular cans. These cans were fitted with a "key" that would roll down the top of the can. Coffee, beans, and other types of meat were packaged in cylinders with metal strips that could be peeled back with their own kinds of built-in keys. Cans of milk, which didn't need to be completely opened, came with puncture devices. As tinned food became more common, its containers became more regular. A nice cylindrical can became the norm, and, as these cans filled kitchens, more engineers put their minds to finding a convenient way to open all of them. The first standalone can opener worked on a simple principle: point, stab, and pull. From the mid-19th century to the end of World War I, the typical can opener looked roughly like a wrench, if the lower 'jaw' of the wrench were replaced with a blade. People used the blade to puncture the top of the can near its edge, push the upper jaw against the side of the can, and drag the blade through the metal along the rim. Because meat was the first and most popular canned substance, these can openers were often shaped to look like cows and given the nickname 'bully beef can openers'. The bully beef can opener, popular in the mid-19th century, resulted in many lost fingers. Later, a corkscrew was added that was seated in the handle, and could be pulled out for use. Bully beef can openers were so common, effective, and sturdy that they are still frequently available on collectors' sites. Some are advertised as “still working,” and every last one of them is, without a doubt, soaked in the blood of our ancestors. Dragging a sharp blade along the edge of a can is certain to cause injury sooner or later. So once people got a reliable can shape and a reliable way to get the can open, the search was on for a reliable way to get a can open without the possibility of losing a finger. The answer came in 1925, from the Star Can Opener Company of San Francisco. This is probably the first can opener that resembles the one people have in their kitchens today. Instead of using a blade to pry open a metal can, buyers could clamp the edge of the can between two wheels and twist the handle of one of the wheels to move the blade around the lip. The Star can openers weren't perfect. Compared to the bully beef model, they were flimsy and breakable, but they probably prevented a few injuries. Six short years after the Star model came to market, the first electric can opener was invented. It was patented in 1931 by the Bunker Clancey Company of Kansas City, who had already been sued by the Star Can Opener Company for trying sell a double-wheeled can opener like the Star model (the case was dismissed). The electric can opener must have seemed like the wave of the future and a sure-fire seller, but it proved to be too far ahead of its time. In 1931 not that many households had electricity, and those that did weren't interested in buying can openers. The Bunker Clancey Company was subsequently bought by the Rival Company, which still makes small appliances like can openers today. It took another 25 years for electrically powered can openers to become practical. In the 1950s, Walter Hess Bodle and his daughter, Elizabeth Bodle, developed an electric can opener in the family garage. Walter came up with the opener's blades and motor, and Elizabeth sculpted the outside. Their can opener was a free-standing unit that could sit on the kitchen counter. The Udico brand of the Union Die Casting Company put it on the market in time for Christmas in 1956 and had great success with it. Over the next few years it came out in different styles and colours, and, like the bully beef can opener, has become a collector's item. Also like the bully beef model, Udico can openers often still work. They don't make 'em like they used to. Although there have been some design changes and refinements over the last sixty years, there have yet to be any more leaps forward in can opener technology. If you're resentfully opening a can, you are almost certainly doing it using the Star design, manually forcing the can between two wheels, or the Bodle design, clamping the can into a free-standing electrical opener. Whether or not you enjoy your holiday meals, at least you can be happy that you are not getting poisoned by your own food or cutting open your hand with the blade you use to get at it. That's something, right?The can opener, Bottle opener and the corkscrew are still very important and essential items in most kitchens.Metal can opener, chromed, with bottle opener, and a corkscrew seated in the handle.None.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, canning, can opener, corkscrew, bottle opener, kitchen equipment -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Can Opener

It took 15 years to invent the can. It took 100 more to invent a standard way to open it. In the 19th century, decades after the invention of canning, there were virtually no can openers. Canned food, such as sardines, came with its own "key" to peel back the tin lid. Birth of the can One of the oddest things about the can opener is that the can predates it by almost 150 years. Though common today, cans were once military-grade technology. In 1795, Napoleon, to whom the phrase "an army marches on its stomach" is attributed, offered 12,000 francs to anyone who could find a way to preserve food. Without any knowledge of bacteria or their role in food spoilage, scientists didn't even know where to begin. It took 15 years before a chef named Nicholas Appert claimed the prize after successfully jarring food. Soon after that, his countryman Philippe de Girard came up with a variant on Appert's method—metal tins—and sold the idea to the British. Spoiled food, and the sickness it caused, was a widespread problem. The public would have benefited from canned food, but for decades cans were almost exclusively for the army and the navy. The canning process, with its hours of boiling and steaming, its scrupulous cleanliness, its heated metal, and its need for a great deal of disposable material, made canned food far too expensive for anyone but the military. No can openers were needed or even possible. The metal of early cans was too thick to make openers practical. Soldiers and sailors had plenty of sharp objects on hand and made ample use of them when they wanted to eat. During the 19th century, the process of canning was refined and mechanised, and the metal wall of the average can slimmed down enough that a civilian could get it open—if that civilian had the right tool. No one had that tool yet, so early cans had to open themselves. In other words, they came with built-in openers. The result was a confusing but pleasing free-for-all, in terms of product engineering. Each type of food came with its own kind of can, and each kind of can came with its own kind of opener. Tinned fish and meat were often sold in rectangular cans. These cans were fitted with a "key" that would roll down the top of the can. Coffee, beans, and other types of meat were packaged in cylinders with metal strips that could be peeled back with their own kinds of built-in keys. Cans of milk, which didn't need to be completely opened, came with puncture devices. As tinned food became more common, its containers became more regular. A nice cylindrical can became the norm, and, as these cans filled kitchens, more engineers put their minds to finding a convenient way to open all of them. The first standalone can opener worked on a simple principle: point, stab, and pull. From the mid-19th century to the end of World War I, the typical can opener looked roughly like a wrench, if the lower 'jaw' of the wrench were replaced with a blade. People used the blade to puncture the top of the can near its edge, push the upper jaw against the side of the can, and drag the blade through the metal along the rim. Because meat was the first and most popular canned substance, these can openers were often shaped to look like cows and given the nickname 'bully beef can openers'. The bully beef can opener, popular in the mid-19th century, resulted in many lost fingers. Bully beef can openers were so common, effective, and sturdy that they are still frequently available on collectors' sites. Some are advertised as “still working,” and every last one of them is, without a doubt, soaked in the blood of our ancestors. Dragging a sharp blade along the edge of a can is certain to cause injury sooner or later. So once people got a reliable can shape and a reliable way to get the can open, the search was on for a reliable way to get a can open without the possibility of losing a finger. The answer came in 1925, from the Star Can Opener Company of San Francisco. This is probably the first can opener that resembles the one people have in their kitchens today. Instead of using a blade to pry open a metal can, buyers could clamp the edge of the can between two wheels and twist the handle of one of the wheels to move the blade around the lip. The Star can openers weren't perfect. Compared to the bully beef model, they were flimsy and breakable, but they probably prevented a few injuries. Six short years after the Star model came to market, the first electric can opener was invented. It was patented in 1931 by the Bunker Clancey Company of Kansas City, who had already been sued by the Star Can Opener Company for trying sell a double-wheeled can opener like the Star model (the case was dismissed). The electric can opener must have seemed like the wave of the future and a sure-fire seller, but it proved to be too far ahead of its time. In 1931 not that many households had electricity, and those that did weren't interested in buying can openers. The Bunker Clancey Company was subsequently bought by the Rival Company, which still makes small appliances like can openers today. It took another 25 years for electrically powered can openers to become practical. In the 1950s, Walter Hess Bodle and his daughter, Elizabeth Bodle, developed an electric can opener in the family garage. Walter came up with the opener's blades and motor, and Elizabeth sculpted the outside. Their can opener was a free-standing unit that could sit on the kitchen counter. The Udico brand of the Union Die Casting Company put it on the market in time for Christmas in 1956 and had great success with it. Over the next few years it came out in different styles and colours, and, like the bully beef can opener, has become a collector's item. Also like the bully beef model, Udico can openers often still work. They don't make 'em like they used to. Although there have been some design changes and refinements over the last sixty years, there have yet to be any more leaps forward in can opener technology. If you're resentfully opening a can, you are almost certainly doing it using the Star design, manually forcing the can between two wheels, or the Bodle design, clamping the can into a free-standing electrical opener. Whether or not you enjoy your holiday meals, at least you can be happy that you are not getting poisoned by your own food or cutting open your hand with the blade you use to get at it. That's something, right?The can opener is still a very important and essential item in most kitchens.Can opener, right handed, metal, upper blade section serrated, inscription 'Peerless Pat.Feb 11-90'.Peerless Pat.Feb 11-90flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, cannning, can opener, kitchen equipment -

Friends of Westgarthtown

Friends of WestgarthtownHanging bars

... melbourne food technology food processing smokehouse curing fire ...A single iron bar set into the fireplace near the top. At the centre of the circular bar is an attachment with a hook. From this attachment hangs a ring, through which two shaped bars overlap to forma cross. Each of these smaller, curved bars has an attachment at the end (two with flat, round rings, one with a V-shaped piece with upturned ends) for securing smoking items,No visible markingsfood technology, food processing, smokehouse, curing, fire, meat, hanging, iron -

Friends of Westgarthtown

Friends of WestgarthtownResting bars, parallel

... melbourne food technology food processing smokehouse curing fire ...A pair of iron resting bars built into the smokehouse fireplace. Each bar is cylindrical, and they are placed one behind the other near the base of the fireplace. They both have a large iron bolt which passes through the centre of the rod. The front bar is bent in the middle.No visible markingsfood technology, food processing, smokehouse, curing, fire, meat, iron -

Surrey Hills Historical Society Collection

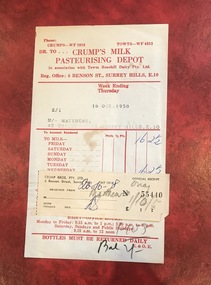

Surrey Hills Historical Society CollectionDocument - Account and receipt, Receipt signed (?) ES - possibly Eric Scanlan, Crump's Milk Pasteurising Depot account with attached receipt, 2 October 1958 /6 October 1958

Crumps Dairy (Milk Pasteurising Depot) was located at 6 Benson Street, Surrey Hills on the corner of Weybridge Street until c1973. It was demolished after it had been badly vandalised. The business closed after cartons replaced glassperishables including milk, bread, meat and fruit and vegetables bottles for sale of milk. It was one of many small local facilities for processing and delivering milk that existed from the early 1920s. Eric William Walker Crump (1903-1981) headed the family business. Also involved were Kevin Eric Crump, Eric William Scanlan. NB/ Also held in this collection is a copy of a project by Chatham Primary School student, Susanne Pascoe, dated 1956 which includes photos of the dairy's operations. An oral history by Dave Croft, a driver for the dairy, who lived close by, is also relevant. The account also mentions 'Towt'. Canterbury Oliver Towt (1890-1962) was another dairyman whose premises was on the corner of Chatham and Mont Albert Roads.This is material evidence of business practice c1920s-1960s when accounts for goods received, especially perishables, were often hand-delivered on a weekly basis, with monies owed collected at the door. A paper account printed red on cream (discoloured) paper with the details of the date, account holder and address typed in and the amount owed hand-written in blue ink. The attached receipt has been stuck onto the account and filled out in grey pencil and blue ink. The amounts are in pounds, shillings and pence.Typed: 2/1; 2 OCT. 1958 M/- MATTHEWS, 42 GUILDFROD RD. SURREY HILLS, E.10dairies, crumps dairy, crumps milk pasteurising depot, kevin eric crump, eric william scanlan, eric william walker crump, towt's dairy, canterbury oliver towt, accounts, receipts, guildford road, geoff matthews, ruth matthews, benson street, towts rosehill dairy -

Surrey Hills Historical Society Collection

Surrey Hills Historical Society CollectionDocument - Account and receipt, Receipt signed (?) ES - possibly Eric Scanlan, Crump's Milk Pasteurising Depot account with attached receipt, 16 October 1958 /20 October 1958

Crumps Dairy (Milk Pasteurising Depot) was located at 6 Benson Street, Surrey Hills on the corner of Weybridge Street until c1973. It was demolished after it had been badly vandalised. The business closed after cartons replaced glassperishables including milk, bread, meat and fruit and vegetables bottles for sale of milk. It was one of many small local facilities for processing and delivering milk that existed from the early 1920s. Eric William Walker Crump (1903-1981) headed the family business. Also involved were Kevin Eric Crump, Eric William Scanlan. NB/ Also held in this collection is a copy of a project by Chatham Primary School student, Susanne Pascoe, dated 1956 which includes photos of the dairy's operations. An oral history by Dave Croft, a driver for the dairy, who lived close by, is also relevant. The account also mentions 'Towt'. Canterbury Oliver Towt (1890-1962) was another dairyman whose premises was on the corner of Chatham and Mont Albert Roads.This is material evidence of business practice c1920s-1960s when accounts for goods received, especially perishables, were often hand-delivered on a weekly basis, with monies owed collected at the door. A paper account printed red on cream (discoloured) paper with the details of the date, account holder and address typed in and the amount owed hand-written in blue ink. The attached receipt has been stuck onto the account and filled out in grey pencil and blue ink. The amounts are in pounds, shillings and pence.Typed: 2/1; 16 OCT. 1958 M/- MATTHEWS, 42 GUILDFROD RD. SURREY HILLS, E.10dairies, crumps dairy, crumps milk pasteurising depot, kevin eric crump, eric william scanlan, eric william walker crump, towt's dairy, canterbury oliver towt, accounts, receipts, guildford road, geoff matthews, ruth matthews, benson street, towts rosehill dairy -

Surrey Hills Historical Society Collection

Surrey Hills Historical Society CollectionDocument - Account and receipt, Receipt signed (?) ES - possibly Eric Scanlan, Crump's Milk Pasteurising Depot account with attached receipt, 18 September 1958 /22 September 1958

Crumps Dairy (Milk Pasteurising Depot) was located at 6 Benson Street, Surrey Hills on the corner of Weybridge Street until c1973. It was demolished after it had been badly vandalised. The business closed after cartons replaced glassperishables including milk, bread, meat and fruit and vegetables bottles for sale of milk. It was one of many small local facilities for processing and delivering milk that existed from the early 1920s. Eric William Walker Crump (1903-1981) headed the family business. Also involved were Kevin Eric Crump, Eric William Scanlan. NB/ Also held in this collection is a copy of a project by Chatham Primary School student, Susanne Pascoe, dated 1956 which includes photos of the dairy's operations. An oral history by Dave Croft, a driver for the dairy, who lived close by, is also relevant. The account also mentions 'Towt'. Canterbury Oliver Towt (1890-1962) was another dairyman whose premises was on the corner of Chatham and Mont Albert Roads.This is material evidence of business practice c1920s-1960s when accounts for goods received, especially perishables, were often hand-delivered on a weekly basis, with monies owed collected at the door. A paper account printed red on cream (discoloured) paper with the details of the date, account holder and address typed in and the amount owed hand-written in blue ink. The attached receipt has been stuck onto the account and filled out in grey pencil and blue ink. The amounts are in pounds, shillings and pence.Typed: 2/1; 18 SEPT. 1958 M/- MATTHEWS, 42 GUILDFROD RD. SURREY HILLS, E.10dairies, crumps dairy, crumps milk pasteurising depot, kevin eric crump, eric william scanlan, eric william walker crump, towt's dairy, canterbury oliver towt, accounts, receipts, guildford road, geoff matthews, ruth matthews, benson street, towts rosehill dairy -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillagePrint - Vessel, Sailing Ship, Loch Vennacher, 1875

This print shows an image of the three-masted iron clipper Loch Vennachar. The ship was built by Thomson’s on the Clyde under the Glasgow Shipping Co in 1875 and named after a Scottish lake, as were other ships in the Loch Line’s fleet. Loch Vennachar made many journeys from Britain to Australia and was well-known in Australian ports. On one of its homeward-bound journeys from Australia, the ship sank in the River Thames. Its cargo included 850 tonnes of preserved canned rabbits from Warrnambool's Western Meat Preserving Company. The ship was raised and continued trading for another four years. On 14th June 1905, Loch Vennachar departed Glasgow for Adelaide and Melbourne. The last known sighting of it was on 6th September 1875 when overtaken by the SS Yongala; the captains exchanged the “all well” signals. After that, the ship disappeared with loss of all 27 lives, according to a list that was received by Fremantle through the English mail. The list indicated that there were no passengers on that voyage. Sadly, other Loch Line ships med with similar disasters. The list of lost crew on the Loch Vennachar included Thomas. W. Pearce, apprentice, Southampton. His father was Tom Pearce, one of the two survivors of the Loch Ard, wrecked in 1878. Also, Thomas’ grandfather, James Pearce, was the captain of SS Gothenburg at the time of her wrecking in 1875. Consequently, the wrecking of the Loch Vennachar and the Loc Sloy near the southwest point of Kangaroo Island, a lighthouse was erected, officially opening in June 1907. The northern headland of West Bay was named Vennachar Point in memory of the ship in 1908. The wreck was discovered in 1976 by divers from the Society for Underwater Historical Research, over seventy years after being lost off Kangaroo Island.The Loch Vennachar performed a significant role in Australia’s colonial trade, taking goods between Great Britain and Australia. These goods included locally preserved tinned rabbits processed at a factory in Warrnambool for overseas trade.Coloured print from a painting of the sailing ship Loch Vennachar in full sail on the sea. The ship was built in 1875 and wrecked in 1905 off Kangaroo Island.Text under print "Loch Vennacher" and "from 1875 this beautiful 1,400 ton ship was well-known in Australian ports, contributing much to this country's prosperity. Foundered near Kangaroo Island, S.A., in 1905." flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, loch vennachar, loch vennacher, loch line ship, glasgow shipping co, 1975 clipper ship, loch vennachar image., kangaroo island shipwreck, 1905 shipwreck, tinned rabbits, preserved rabbits, western meat preserving company, 1901, 1905 -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillagePrint - Vessel, Sailing Ship, Loch Vennachar, 1875-1905

This framed print of the Loch Vennachar has been framed as a gift given by McPherson's Ltd. of Melbourne Sydney Brisbane Perth, as per the inscription below the print. Loch Vennachar made many journeys from Britain to Australia and was well-known in Australian ports. On one of its homeward-bound journeys from Australia, the ship sank in the River Thames. Its cargo included 850 tonnes of preserved canned rabbits from Warrnambool's Western Meat Preserving Company. The ship was raised and continued trading for another four years. On 14th June 1905, Loch Vennachar departed Glasgow for Adelaide and Melbourne. The last known sighting of it was on 6th September 1875 when overtaken by the SS Yongala; the captains exchanged the “all well” signals. After that, the ship disappeared with loss of all 27 lives, according to a list that was received by Fremantle through the English mail. The list indicated that there were no passengers on that voyage. Sadly, other Loch Line ships med with similar disasters. The list of lost crew on the Loch Vennachar included Thomas. W. Pearce, apprentice, Southampton. His father was Tom Pearce, one of the two survivors of the Loch Ard, wrecked in 1878. Also, Thomas’ grandfather, James Pearce, was the captain of SS Gothenburg at the time of her wrecking in 1875. Consequently, the wrecking of the Loch Vennachar and the Loc Sloy near the southwest point of Kangaroo Island, a lighthouse was erected, officially opening in June 1907. The northern headland of West Bay was named Vennachar Point in memory of the ship in 1908. The wreck was discovered in 1976 by divers from the Society for Underwater Historical Research, over seventy years after being lost off Kangaroo Island. The Loch Vennachar performed a significant role in Australia’s colonial trade, taking goods between Great Britain and Australia. These goods included locally preserved tinned rabbits processed at a factory in Warrnambool for overseas trade.Print of painting clipper ship Loch Vennachar. (aka Loch Vennacher, as spelled on this print). Print is under glass in white painted timber frame. The vessel was wrecked on Kangaroo Island September 1905 with the loss of all hands. There is an inscription below the print"Loch Vannacher" on right below print, "Compliments from McPherson's Ltd. Melbourne,Sydney, Brisbane, Perth" on left below printflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, loch vennachar, loch vennacher, loch line ship, glasgow shipping co, mcpherson's ltd. melbourne sydney brisbane perth, loch vennachar image., kangaroo island shipwreck, 1905 shipwreck, mcpherson's ltd. melbourne sydney brisbane perth, canned rabbits, preserved rabbits, western meat preserving company -

Flagstaff Hill Maritime Museum and Village

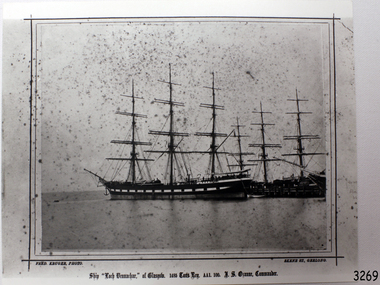

Flagstaff Hill Maritime Museum and VillagePhotograph - Vessel, Sailing Ship, Fred. Kruger, Loch Vennachar of Glasgow, 1875-1888

This is a photographic image of the three-masted iron clipper Loch Vennachar created by photographer Fred Kruger of Geelong. Fred Kruger was born in Germany in 1831 and migrated to Victoria before his wife, who arrived in 1863. He began working in photography in the 1850s. He was internationally recognised for his work, which covered a variety of subjects. He settled in Geelong in later years, registering his studio in Skene St, Newtown. He passed away in February 1888. The National Gallery of Victoria now holds much of his work. Loch Vennachar: - Loch Vennachar made many journeys from Britain to Australia and was well-known in Australian ports. On one of its homeward-bound journeys from Australia, the ship sank in the River Thames. Its cargo included 850 tonnes of preserved canned rabbits from Warrnambool's Western Meat Preserving Company. The ship was raised and continued trading for another four years. On 14th June 1905, Loch Vennachar departed Glasgow for Adelaide and Melbourne. The last known sighting of it was on 6th September 1875 when overtaken by the SS Yongala; the captains exchanged the “all well” signals. After that, the ship disappeared with loss of all 27 lives, according to a list that was received by Fremantle through the English mail. The list indicated that there were no passengers on that voyage. Sadly, other Loch Line ships med with similar disasters. The list of lost crew on the Loch Vennachar included Thomas. W. Pearce, apprentice, Southampton. His father was Tom Pearce, one of the two survivors of the Loch Ard, wrecked in 1878. Also, Thomas’ grandfather, James Pearce, was the captain of SS Gothenburg at the time of her wrecking in 1875. Consequently, the wrecking of the Loch Vennachar and the Loc Sloy near the southwest point of Kangaroo Island, a lighthouse was erected, officially opening in June 1907. The northern headland of West Bay was named Vennachar Point in memory of the ship in 1908. The wreck was discovered in 1976 by divers from the Society for Underwater Historical Research, over seventy years after being lost off Kangaroo Island.The Loch Vennachar performed a significant role in Australia’s colonial trade, taking goods between Great Britain and Australia. These goods included locally preserved tinned rabbits processed at a factory in Warrnambool for overseas trade.Black and white photograph of the Loch Vennachar at the dock, without sails. (aka Loch Vennacher). Printed below photo "Loch Vennachar of Glasgow, 1485 Tons Reg. AA1 100. T.S. Ozanne, Comander" and "Fred Kruger Photo / Skene Street, Geelong" Printed below photo "Loch Vennachar of Glasgow, 1485 Tons Reg. AA1 100. T.S. Ozanne, Comander" and "Fred Kruger Photo / Skene Street, Geelong" flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, loch vennachar, loch vennacher, loch line ship, glasgow shipping co, 1875 clipper ship, loch vennachar image., kangaroo island shipwreck, 1905 shipwreck, fred kruger photographer, photograph loch vennachar, preserved rabbits, canned rabbits, meat preserving company, western meat preserving company, 1901, 1905 -

Flagstaff Hill Maritime Museum and Village

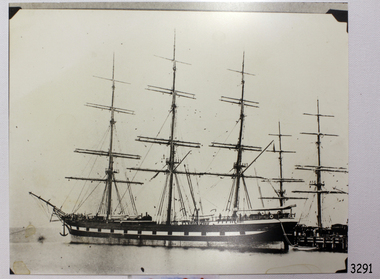

Flagstaff Hill Maritime Museum and VillagePhotograph - Vessel, Sailing Ship, 1875-1905

This photograph is an image of the Loch Vennacher, taken while she is docked. The photograph is very similar to another in our collection taken by Fred. Kruger, a renowned Victorian photographer, between 1875-1905 and possibly in the Port of Melbourne. Loch Vennachar made many journeys from Britain to Australia and was well-known in Australian ports. On one of its homeward-bound journeys from Australia, the ship sank in the River Thames. Its cargo included 850 tonnes of preserved canned rabbits from Warrnambool's Western Meat Preserving Company. The ship was raised and continued trading for another four years. On 14th June 1905, Loch Vennachar departed Glasgow for Adelaide and Melbourne. The last known sighting of it was on 6th September 1875 when overtaken by the SS Yongala; the captains exchanged the “all well” signals. After that, the ship disappeared with loss of all 27 lives, according to a list that was received by Fremantle through the English mail. The list indicated that there were no passengers on that voyage. Sadly, other Loch Line ships med with similar disasters. The list of lost crew on the Loch Vennachar included Thomas. W. Pearce, apprentice, Southampton. His father was Tom Pearce, one of the two survivors of the Loch Ard, wrecked in 1878. Also, Thomas’ grandfather, James Pearce, was the captain of SS Gothenburg at the time of her wrecking in 1875. Consequently, the wrecking of the Loch Vennachar and the Loc Sloy near the southwest point of Kangaroo Island, a lighthouse was erected, officially opening in June 1907. The northern headland of West Bay was named Vennachar Point in memory of the ship in 1908. The wreck was discovered in 1976 by divers from the Society for Underwater Historical Research, over seventy years after being lost off Kangaroo Island.The Loch Vennachar performed a significant role in Australia’s colonial trade, taking goods between Great Britain and Australia. These goods included locally preserved tinned rabbits processed at a factory in Warrnambool for overseas trade.Black and white photograph of Loch Vennachar (aka Loch Vennacher) at a wharf. There are photo mounts in each corner. The vessel was was built in 1875 and wrecked on Kangaroo Island with the loss of all hands; she was last seen September 6th 1905 flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, loch vennachar, loch vennacher, loch line ship, glasgow shipping co, 1875 clipper ship, loch vennachar image., kangaroo island shipwreck, 1905 shipwreck, photograph loch vennachar, fred kruger photographer, canned rabbits, preserved rabbits, western meat preserving company