Showing 54 items matching "metalworking tools"

-

University of Melbourne, Burnley Campus Archives

University of Melbourne, Burnley Campus ArchivesTool - Metalworking, Anvil

... Small cast iron metalworking tool (very rusty). "A relic...) metalworking principal tool Burnley College artifact Small cast iron ...A relic from the principal's garage area near the house (Burnley College Principal's house was demolished in 1980)Small cast iron metalworking tool (very rusty). "A relic from the Principals' garage."metalworking, principal, tool, burnley college, artifact -

Mont De Lancey

Mont De LanceyTool - Blacksmith Tongs, Unknown

... Metalworking tools...-and-dandenong-ranges Blacksmithing tools Forging tools Metalworking ...A pair of vintage handmade blacksmith tongs with two handles called reins, which are riveted together to form a hinge joint for the long 90 degree right angled flat edged tongs. The blacksmith opens and closes the tongs using the handles. They are made of flat mild steel. They were used for holding steel in position and turning it over during forging operations.blacksmithing tools, forging tools, metalworking tools, furnace tools, tools -

Mont De Lancey

Mont De LanceyTool - Blacksmith Tongs, Unknown

... Metalworking tools...-and-dandenong-ranges Blacksmithing tools Forging tools Metalworking ...A pair of small vintage handmade blacksmith tongs with two handles called reins, which are riveted together to form a hinge joint for the flat edged tongs. The blacksmith opens and closes the tongs using the handles. They are made of flat mild steel. They were used for holding steel in position and turning it over during forging operations.blacksmithing tools, forging tools, metalworking tools, furnace tongs, tools -

Mont De Lancey

Mont De LanceyTool - Blacksmith Tongs, Unknown

... Metalworking tools...-and-dandenong-ranges Blacksmithing tools Forging tools Metalworking ...A pair of long handled vintage handmade blacksmith tongs with two handles called reins, which are riveted together to form a hinge joint for the flat edged tongs. The blacksmith opens and closes the tongs using the handles. They are made of flat mild steel. They were used for holding steel in position and turning it over during forging operations.blacksmithing tools, forging tools, metalworking tools, furnace tongs, tools -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageAnvil, early to mid-1900s

... Anvil, single horn, used as a tool by blacksmiths... Blacksmith tools Metalworking tool Forging tool Terang 1900s ...This anvil once belonged to Goodall and Sons, who were blacksmiths in Terang. The smith was called upon to do a variety of work. In the early 1900s he was often the nearest person to be able to perform an engineer’s services for many miles around. An anvil is used by blacksmiths to forge and shape his work pieces. The conical horn is used for hammering curved work pieces. The anvil is a common tool of the blacksmiths (‘smithies’) and other metalworkers. There has been very little change in the basic design of the anvil since Greek and Roman times. Henry Goodall (1870-1936) Henry Goodall was proprietor of garages as H. Goodall & Sons Pty. Ltd., at both Terang (McKinnon and High Streets) and Mortlake (Dunlop Street). His business was in operation in at least in 1916 and perhaps well before, considering the date of the tyre bender and its use for wagons with wooden wheels. It was still in operation in 1953, chasing up debtors in Mount Gambier Court. Amongst the employees of H. Goodall & Sons Pty. Ltd. was Ernie Entwistle, a blacksmith (a soldier who died in 1916 ) and Alfred Hodgetts, radio expert (killed in a fatal accident in 1943, when he was in his early 30s ). Henry Goodall was involved in the community as a Justice of Peace, a deputy coroner, President of the Mortlake Hospital, trustee of the Soldiers’ Memorial Hall, and as a prominent Freemason. He and his wife had two sons (Charles and John) and one daughter (Mrs. Chas. Newton, of Skipton). The anvil is locally significant as it was used by a local company in Terang and Mortlake in their blacksmith, wheelwright and garage business. It is an example of the tools of the blacksmiths’ trade in Victoria in the early to mid-1900s. Anvil, single horn, used as a tool by blacksmiths and metalworkers. Large block of metal with a flat top face, a conical horn on one side and a ‘v’ shape on the other. The anvil’s base has a squat stand and sides that are a variety of shapes. This anvil once belonged to Harry Goodall & Sons, blacksmiths of Terang. C. early to mid-1900s.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, h. goodall & sons of terang, terang blacksmith, h. goodall & sons pty ltd, mortlake, ernie entwistle blacksmith, alfred hodgetts radio expert, charles goodall, john goodall, mrs. chas. newton nee goodall, trade tools, blacksmith tools, metalworking tool, forging tool, terang 1900s, warrnambool district 1900s, anvil, blacksmith’s anvil, single horn anvil -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Tool - Post Drill Set

... . trades tools metalworking Buffalo Forge Co, Buffalo N.Y. No 151 ...Used by donor's father, John Palmer, on his parents dairy farm at Mupunga East and later on his own dairy farm at Allansford. From 1966 until 1992 used in Mitcham and Blackburn.A post mounted drill stand with a gearing arrangement driven by a handle. The depth of drill is adjusted by a large red wheel which raises or lowers the drill. There are other adjusting devices on the drill.Buffalo Forge Co, Buffalo N.Y. No 151 (on both sides of main casting)trades, tools, metalworking -

The Beechworth Burke Museum

The Beechworth Burke MuseumPhotograph, c1900

... Metalwork Farming and agriculture Tools Mining workmen Reverse ...The Beechworth Foundry was vital to the industry of the town and surrounding district in the early years of the town’s development. Originally opened as the New Ford Street Foundry by A. Roger in 1858, J Duncan and M Straughair amalgamated and established the Beechworth Foundry in 1867. The business was extensive and operated out of many buildings, each with their own specialisation. All of the buildings pictured in this image are part of the larger Beechworth Foundry. In the late 1860s it employed 16 men. The foundry was fundamental to the running of the town and surrounding district, as it manufactured all manner of items, including tools and machinery for the mining and agricultural industries. The foundry business collapsed in 1896 after the death of it’s founder, John Duncan, the same year (Straughair had died in 1882). The foundry was reopened by W H Phillips in 1905 and taken over by H Delora in 1906 This image is significant as it shows some of the many buildings of the Beechworth Foundry, which was a fundamental business to the running of the town and surrounding district, and supplied many of the tools and machines required for the mining and agricultural industries, as well as other aspects of life between the 1850s and early 1900sSepia rectangular photograph printed on paper. It has rough, torn-looking edgesReverse 97.2321 / BMM A03115duncan, john duncan, j duncan, m straughair, straughair, foundry, beechworth foundry, industry, factory, newtown, new ford street foundry, a roger, roger, w h phillips, phillips, w phillips, h delora, delora, metalwork, farming and agriculture, tools, mining, workmen -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Marking Gauge, Prior to 1950

A marking gauge, also known as a scratch gauge, and] is used in woodworking and metalworking to mark out lines for cutting or other operations. The purpose of the gauge is to scribe a line parallel to a reference edge or surface. It is used in joinery and sheet metal operations. The gauge consists of a beam, a headstock, and a scribing or marking implement, typically a pin, knife, pen or wheel. The headstock slides along the beam, and is locked in place by various means: a locking screw, cam lever, or a wedge. The marking implement is fixed to one end of the beam.A tool that has been in use since woodworking began for hundreds if not thousands of years without much change to the design or how the tool is used. Its use to scribe a line in various material as a cutting guide and is still in use today by many trades. Wooden marking Gauge, smallNonewarrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, marking gauge, woodworking, carpenters tools, tool -

Federation University Historical Collection

Federation University Historical CollectionBook - Book - Scrapbook, Ballarat School of MInes: Scrapbook of Newspaper Cuttings, Book 47, March 1991 to May 1991

... - roger keen - jamie walker metalworks finals tools to help ...Collection of newspaper articles related to Ballarat School Of Mines.They cover activities and advertisements for staff. The papers concerned are The Courier, Ballarat, The Australian, The Age over the period of 2 March 1991 to 24 May 1991.Book with yellow cover, front, spiral bound. teaching positions advertised, pre-employment courses, courses available, enrolment for smb courses, education under threat in country, apprenticeship system threatened, students work for community and industry, jason williams - roger keen - jamie walker, metalworks finals, tools to help disabled, neville french local potter, wayne strong new inskill manager, smb music program for children, jean read and helen fairhall, students plant an elm, austin mccallum special development school, heather horrocks and bruce stalley, adult literacy resource centre, motivation is the key, catherine mccann, autumn music in the gardens, bradley slater and lana zylan, adam fleming plumbing and gas fitting award, meg and rosalie barry, native garden honors former apprentice, ballarat library use increased, adam lindsay gordon cottage, extensions to child care centre, jack barker, smb director praises staff, damian smith top apprentice, trimathon planned, christopher sanders potter, jill simmons and john o'laughlin ceramics students, alfred mica smith -

Glenelg Shire Council Cultural Collection

Glenelg Shire Council Cultural CollectionTool - Anvil, Bradford and Kendall, n.d

Port of Portland Collection Bradken, originally Bradford and Kendall, began as a steel foundry in Sydney in 1920 and produced BK anvils at its factories in Alexandria and Mascot NSW. Leslie Bradford (General Manager) and Jim Kendall (Chief Mechanical Engineer), two BHP steelworks employees, got lucky at the races one day in 1920 and pledged their £15,000 winnings to start a steel foundry business. The horse they backed, ‘Jack Findlay’ completed a remarkable sequence of five wins during 1919 and 1920. With each win Leslie Bradford, Jim Kendall and a group of friends rolled-over their bets. By January 24, 1920 they had won a small fortune. On April 28 1920, the group used their winnings to establish the Alloy Steel Syndicate and build a steel foundry in Alexandria, Sydney to take advantage of what they saw as an untapped potential for industrial growth. Bradford Kendall Ltd was incorporated on 20th March 1922.Metal blacksmiths anvil. An anvil is used by blacksmiths to forge and shape his work pieces. The conical horn is used for hammering curved work pieces. The anvil is a common tool of the blacksmiths (‘smithies’) and other metalworkers. There has been very little change in the basic design of the anvil since Greek and Roman times. Blacksmith anvil, 5CWT, iron BK Sydney Australia.Front: 'BK SYDNEY AUST. 5CWT' Back: -port of portland, anvil, blacksmith, industry, bk anvil, bradken, brandford and kendall -

Glenelg Shire Council Cultural Collection

Glenelg Shire Council Cultural CollectionTool - Blacksmith Tongs, n.d

PORT OF PORTLAND COLLECTIONBlacksmith's tongs, hand forgedport of portland, blacksmith, tongs, trade, industry, metalwork -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Tools, steel spiral bit Auger, c1900

Before drills and braces, T-shaped augers were used to poke holes into wood, while smaller gimlets were used to start them. Auger handles were usually made of a piece of hardwood that was sanded, rounded, or even contoured to give the user a firm grip. Bits on spoon augers essentially carved a hole in the piece of wood, and had to be periodically removed to clear the chips. Spiral-bit augers were precursors to modern drills, whose bits cleared the hole of chips as the user drilled. A significant advance on the auger was the brace, which was originally designed with a single, permanently fixed bit at its end. Eventually, though, braces were designed with sophisticated chucks to accommodate replacement bits, as well as bits of different sizes and for various purposes A steel spiral bit Auger* pioneers, early settlers, market gardeners, moorabbin, bentleigh, cheltenham, brighton, tools, craftsman, carpenters, , blacksmiths, builders, farmers, metalwork, woodwork, drills, augers, gimlets -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Tools, Screwdriver large, c1900

A screwdriver is a tool, manual or powered, for turning (driving or removing) screws. A typical simple screwdriver has a handle and a shaft, and a tip that the user inserts into the screw head to turn it. The shaft is usually made of tough steel to resist bending or twisting. The tip may be hardened to resist wear, treated with a dark tip coating for improved visual contrast between tip and screw—or ridged or treated for additional 'grip'. Handle are typically wood, metal, or plastic and usually hexagonal, square, or oval in cross-section to improve grip and prevent the tool from rolling when set down. The handle and shaft of screwdrivers have changed considerably over time. The "Perfect Pattern Handle’ screwdriver was first manufactured by HD Smith & Company, which operated from 1850 to 1900. Screwdrivers were probably invented in the late 15th century, either in Germany or France when Screws were used to construct screw-cutting lathes, for securing breastplates, backplates, and helmets on medieval jousting armor—and eventually for multiple parts of the emerging firearms, particularly the matchlock. The jaws that hold the pyrites inside medieval guns were secured with screws, and the need to constantly replace the pyrites resulted in considerable refinement of the screwdriver. The screwdriver depended entirely on the screw, and it took several advances to make the screw easy enough to produce to become popular and widespread Canadian P.L. Robertson, though he was not the first person to patent the idea of socket-head screws, was the first to successfully commercialize them, starting in 1908. In Portland, Oregon, Henry F. Phillips patented his own invention, an improved version of a deep socket with a cruciform slot, today known as the Phillips Screw. Phillips offered his screw to the American Screw Company, and after a successful trial on the 1936 Cadillac, it quickly swept through the American auto industry. A main attraction for the screw was that conventional slotted screwdrivers could also be used on them, which was not possible with the Robertson Screw. A large steel screwdriver with worn wooden handlepioneers, early settlers, market gardeners, moorabbin, bentleigh, cheltenham, brighton, tools, craftsman, carpenters, , blacksmiths, builders, farmers, metalwork, woodwork, screws, philllips head screwdrivers, h.d.smith & co usa, p.l. robertson, henry f.phillips , oregon, canada, american screw company, -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Tool - Brace and Bit hand drill, 20thC

Before drills and braces, T-shaped augers were used to poke holes into wood, while smaller gimlets were used to start them. Auger handles were usually made of a piece of hardwood that was sanded, rounded, or even contoured to give the user a firm grip. Bits on spoon augers essentially carved a hole in the piece of wood, and had to be periodically removed to clear the chips. Spiral-bit augers were precursors to modern drills, whose bits cleared the hole of chips as the user drilled. A significant advance on the auger was the brace, which was originally designed with a single, permanently fixed bit at its end. Eventually, though, braces were designed with sophisticated chucks to accommodate replacement bits, as well as bits of different sizes and for various purposes. Chucks were patented as vigorously as the braces themselves The braces themselves also evolved for particular trades, from furniture makers to surgeons. The operator holds the ‘head’ in one hand, positions the drill in the wood , applies pressure and rotates the ‘centre piece’ to cause the drill to pierce the wood. A steel revolving hand tool for boring and screw-driving with wood handles * pioneers, early settlers, market gardeners, moorabbin, bentleigh, cheltenham, brighton, tools, craftsman, carpenters, , blacksmiths, builders, farmers, metalwork, woodwork, screws -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyReamer

... A reamer is a type of rotary cutting tool used... is a type of rotary cutting tool used in metalworking. Precision ...A reamer is a type of rotary cutting tool used in metalworking. Precision reamers are designed to enlarge the size of a previously formed hole by a small amount but with a high degree of accuracy to leave smooth sides. Very oldUsed by metal workers in the Kiewa ValleyThis reamer is made of steel and is not tapered. It has a handle end and a serrated end. It has a three quarter inch diameter. reamer, metalworking tool -

Federation University Historical Collection

Federation University Historical CollectionPlan, New Workshop Block Ballarat School of Mines

It is not known which building these plans belong to. Since there is a Heat Treatment Room and a number of vices it may be a metalwork room, and may be related to Repatriation classes after World War One. Blueprint of plans for a new workshop at the Ballarat School of Mines. The plan includes a lecture room, bulk store, tool store, heat treatment room, office and two machine shops. Around the machine shops are work benches and vyces (sic)new workshop block, ballarat school of mines, repatriation, buildings -

Federation University Historical Collection

Federation University Historical CollectionBook, B.T. Batesford, Handcraft in Wood and Metal, c1913

... library library catalogue cards and date stamps tools metalwork ...Green/brown hard covered book of 240 pages.handcraft, woodcraft, metalcraft, models, ballarat technical art school library, library catalogue cards and date stamps, tools, metalwork, lettering, design -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Tool - Tools, blacksmith's tongs, c1900

Whilst each town's blacksmiths played an essential part in the colony of Victoria, the early settlers frequently had their own small forge and a few blacksmith's tools to attend to smaller day to day repairs. A long-handled pair of blacksmith tongs were essential for handling red-hot metal that was being repaired.As only a handful of settlers were present in the Moorabbin district from the 1840s. These early colonists were required to use their ingenuity and skill to undertake the "running repairs", including some basic blacksmithing, required around their property or leasehold.Circa 19th century. Large pair of forge-made blacksmith's tongs. Nilblacksmiths, forges, metalwork, craftwork, fireplaces, early settlers, pioneers, moorabbin, bentleigh, cheltenham, market gardeners colonists, 1840s -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Tools, Blacksmith tongs, c1880

... mend wheel bands, tools, farm equipment and also fine tune ...The Blacksmith used these tongs to make repairs at his forge. He could mend wheel bands, tools, farm equipment and also fine tune generic sized horseshoes on site. He needed tongs to work on any heated metal as required at his forge A Blacksmith was an essential person for the maintenance and making of farm and household equipment, and shoeing horses, in the pioneer settlements of Brighton, Moorabbin, Cheltenham c1900 A pair of forged steel blacksmith tongsmarket gardeners, pioneers, early settlers, moorabbin, brighton, cheltenham, blacksmith, tools, metalwork, forges, ploughs, horse-drawn carts -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Tools, Blow-torch brass, 20thC

A blowtorch is a fuel-burning tool used for applying flame and heat to various applications, usually metalworking. Early blowlamps used liquid fuel, carried in a refillable reservoir attached to the lamp. Modern blowtorches are mostly gas-fuelled. Their fuel reservoir is disposable or refillable by exchange. The term "blowlamp" usually refers to liquid-fuelled torches still used in the UK. Liquid-fuelled torches are pressurized by a piston hand pump, while gas torches are self-pressurized by the fuel evaporation. In 1882, a new vaporizing technique was developed by C. R. Nyberg in Sweden, and the year after, the production of the Nyberg blow lamp started. It was quickly copied or licensed by many other manufacturers. The US blowlamp was independently developed with a distinctive flared base and was fuelled by gasoline, whereas the European versions used kerosene for safety and low cost.The family of Mr Howcroft were early settlers in Moorabbin ShireA brass blow-torch B.A. HJOP Co. STOCKHOLM SWEDENblowtorch, stockholm sweden, welding, moorabbin, cheltenham, bentleigh, early settlers -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Tools, steel 'C' or 'G' clamp, c1900

... flat edges. tools, woodwork, metalwork, welding, carpentry ...A clamp is a fastening device to hold or secure objects tightly together to prevent movement or separation through the application of inward pressure. The tool is for temporary use for positioning components during construction and wood working. There are many types of clamps available for many different purposes. Some are temporary, as used to position components while fixing them together, others are intended to be permanent. A C-clamp or G-clamp is a type of clamp device typically used to hold a wood or metal work piece, and often used in carpentry and welding. C-clamps or G-clamps are typically made of steel or cast iron, though smaller clamps may be made of pot metal. At the top of the "C" is usually a small flat edge. At the bottom is a threaded hole through which a large threaded screw protrudes. One end of this screw contains a flat edge of similar size to the one at the top of the frame, and the other end usually a small metal bar, perpendicular to the screw itself, which is used to gain leverage when tightening the clamp. When the clamp is completely closed, the flat end of the screw is in contact with the flat end on the frame. When the clamp is actually used, it is very rare that this occurs. Generally some other object or objects will be contained between the top and bottom flat edges. A steel ‘C’ or ‘G’ Clamp used to hold a wood or metal work piece, used in carpentry and welding.L.W.BANKtools, woodwork, metalwork, welding, carpentry, pioneers, market gardeners, early settlers, bank w.l., moorabbin, cheltenham, bentleigh, ormond -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Tools, steel hacksaw 'Marples', 20thC

... used over 100 years ago. tools, woodwork, metalwork, carpentry ...A hacksaw is a fine-toothed saw, originally and principally for cutting metal. They can also cut various other materials, such as plastic and wood; for example, plumbers and electricians often cut plastic pipe and plastic conduit with them. On hacksaws, as with most frame saws, the blade can be mounted with the teeth facing toward or away from the handle, resulting in cutting action on either the push or pull stroke. In normal use, cutting vertically downwards with work held in a bench vice, hacksaw blades should be set to be facing forwards. Joseph Marples & Son Pty Ltd Traditional Craftsmans Hand Tools made in Sheffield. The finest quality hand made tools, backed by over 170 years of manufacturing heritage. .In the 1840’s Joseph Marples was one of several ‘Marples’ (most of which were related) in Sheffield manufacturing joiners tools, such as brass inlaid rosewood & ebony braces, boxwood spokeshaves, beech planes, gauges and squares. The business has remained within the family to this date, and has been based in Sheffield since those early days. Although modern technology has been used in some instances, many of the traditions of manufacturing fine hand tools has remained the same using selected materials and hand finishing, indeed the same threads are used in the gauges as were used over 100 years ago. A steel hacksaw. 'Marples' with bladeMARPLEStools, woodwork, metalwork, carpentry, pioneers, market gardeners, early settlers, moorabbin, cheltenham, bentleigh, ormond, joseph marples & son pty ltd, sheffield , england, -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Tools, Blowtorch 'Sievert', 20thC

A blowtorch or blowlamp is a fuel-burning tool used for applying flame and heat to various applications, usually metalworking. Early blowlamps used liquid fuel, carried in a refillable reservoir attached to the lamp. Modern blowtorches are mostly gas-fuelled. The blowlamp is of ancient origin and was used as a tool by gold and silversmiths. They began literally as a "blown lamp", a wick oil lamp with a mouth-blown tube alongside the flame. This type of lamp, with spirit fuel, continued to be in use for such small tasks into the late 20th century. In 1882, a new vaporizing technique was developed by Carl Richard Nyberg in Sweden, and the year after, the production of the Nyberg blow lamp started. It was quickly copied or licensed by many other manufacturers. Carl Richard Nyberg (May 28, 1858, – 1939) was the founder of Max Sievert’s Lödlampfabrik, then one of the largest industries in Sundbyberg, Sweden. After school he started working for a jeweller and later he moved to Stockholm and worked with various metalworks. 1882 and set up a workshop at Luntmakargatan in Stockholm making blowtorches. However the business didn't work well because it took too long to both manufacture and sell them. In 1886 he met Max Sievert (1849 - 1913) at a country fair and Sievert became interested in Nyberg's blowtorch and started selling it. In 1922 the company was sold to Max Sievert who continued to own it until 1964 when it was bought by Esso. The blowtorch is commonly used where a diffuse high temperature naked flame heat is required but not so hot as to cause combustion or welding: soldering, brazing, softening paint for removal, melting roof tar, or pre-heating large castings before welding such as for repairing. It is also common for use in weed control by controlled burn methods, melting snow and ice from pavements and driveways in cold climate areas, road repair crews may use a blowtorch to heat asphalt or bitumen for repairing cracks in preventive maintenance. It is also used in cooking; one common use is for the creation of the layer of hard caramelised sugar in a crème brûlée. A brass blowtorch, 'Sievert' with a wooden handleSIEVERTtools, blow torches, blow lamps, welding, brazing, jewellery, cookery, soldering, nyberg carl, sievert max, stockholm, sweden, spirit fuel, kerosene, gas fuel, moorabbin, bentleigh, cheltenham, market gardeners, pioneers, early settlers, plumbing, carpenters, -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Tool - Bow saw with blade, 20thC

... their market gardens and farms. tools woodwork metalwork carpentry ...Traditionally, a bow saw is a woodworking tool used for straight or curved cuts. A bow saw is a type of frame saw. Its thin blade is held in tension by a frame. In English and American vocabulary it denotes a toothed blade suspended between two long narrow handles called "cheeks" that are supported and separated by a thin stretcher in the centre of the handles, making a wide H shape (the cheeks form the uprights of the H, the stretcher the crossbar of the H). The blade is kept in tension with a turnbuckle or a twisted cord that runs parallel to the blade between the two cheeks but on the opposite side of the stretcher. If a cord is used, the cord is twisted with a toggle attached to one loop of the cord, adding tension. The toggle hits the stretcher, which keeps the cord from untwisting. A finer version of the saw uses a narrow blade (1/4" or less) with handles that allow the user to hold the saw and turn the blade. In this context it is also known as a turning saw[2] which is larger than a coping saw.Early settlers in Moorabbin Shire had to be self reliant and made their own clothes, tools and equipment as they established their market gardens and farms. A wooden Bow saw with tensioning string, toggle and bladetools, woodwork, metalwork, carpentry, pioneers, market gardeners, early settlers, moorabbin, cheltenham, bentleigh, ormond -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Tools, steel 'G' Clamp, early 20thC

A C-clamp or G- clamp is a type of clamp device typically used to hold a wood or metal work-piece, and often used in, but are not limited to, carpentry and welding. These clamps are called "C" clamps because of their C shaped frame, but are otherwise often called G-clamps or G-cramps because including the screw part they are shaped like an uppercase letter G. The fixed end is not adjustable so size is not variable. G-clamps are typically made of steel or cast iron, though smaller clamps may be made of pot metal. At the top of the "G" is usually a small flat edge. At the bottom is a threaded hole through which a large threaded screw protrudes. One end of this screw contains a flat edge of similar size to the one at the top of the frame, and the other end usually a small metal bar, perpendicular to the screw itself, which is used to gain leverage when tightening the clamp. When the clamp is completely closed, the flat end of the screw is in contact with the flat end on the frame When used some other object or objects will be contained between the top and bottom flat edges. A steel 'G' Clamp tools, g clamp, screws, steel, clamps, metalwork, woodwork, carpentry, early settlers, pioneers, market gardeners, moorabin, bentleigh, cheltenham -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Tools, Coping saw, c1900

... while continuing to cut steadily. tools, saws, steel , clamps ...A coping saw is a type of hand saw used to cut intricate external shapes and interior cutouts in woodworking or carpentry. It is widely used to cut mouldings to create coped rather than miter joints. It is occasionally used to create fretwork though it is not able to match a fretsaw in intricacy of cut, particularly in thin materials. Coping saw blades are always thicker and much coarser cutting than typical fretsaw blades. A coping saw consists of a thin, hardened steel blade, stretched between the ends of a square, c-shaped, springy-iron frame to which a handle is attached. The blade is easily removed from the frame so that the blade can be passed through a drilled hole in the middle of a piece of wood. The frame is then re-attached to the blade and the cut starts from the middle of the piece. Long cuts perpendicular to the edge of the material are possible but the shallow depth of the frame rather limits how far from the edge one may cut. The much deeper frame of the fretsaw is more useful for cutting well away from the edge but conversely cannot manage the thicker materials commonly cut by the coping saws. The coping saw blade is installed with the teeth pointing towards the handle. Unlike a hacksaw, which has the teeth pointed away from the handle, the coping saw cuts on the pull stroke. The coping saw blade is removable by partially unscrewing the handle. The blade is prevented from rotating by means of the short, steady bar provided where the blade is attached. Loosening the handle also allows the blade to be rotated relative to the frame as desired. Carefully aligning the finger steady bars at the top and bottom of the blade ensures that the thin blade is straight and not twisted along its length. Re-tightening the handle tensions the blade and locks it at the desired angle relative to the frame. The short steady bar nearest the handle is held securely between finger and thumb while the handle is tightened to ensure the blade remains at the desired angle. Unlike the fretsaw the coping saw blade has holding pins which lock securely into the angled slots of the rotatable blade holders. Gentle curves are achieved by slowly turning the whole frame by means of the handle while continuing to cut steadily. A coping saw with wooden handle but no bladetools, saws, steel , clamps, metalwork, woodwork, carpentry, early settlers, pioneers, market gardeners, moorabbin, bentleigh, cheltenham, fretsaw, coping saw, bowsaw, blacksmiths, -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Tools, steel vice, c1900

... to a bench . tools, vice, steel , clamps, metalwork, woodwork ...Perak or State of Perak one of the 13 states of Malaysia, is the second largest state in Peninsular Malaysia. It borders Kedah and the Thai Yala Province to the north; Penang to the northwest; Kelantan and Pahang to the east; Selangor to the south, and the Straits of Malacca to the west. The state's administrative capital of Ipoh was known historically for tin-mining activities until the price of the metal dropped, severely affecting the state's economy. A vice is a tool with 2 jaws between which an object is gripped, usually by tightening a screw, so as to leave the hands free for working upon it. The vice is usually firmly attached to a bench . A steel vice THE PERAK TIN MINING COMPANYtools, vice, steel , clamps, metalwork, woodwork, carpentry, early settlers, pioneers, market gardeners, moorabbin, bentleigh, cheltenham, blacksmiths, perak tin mining co. -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Tool - Hammer, Ball & Peen , metal wood c1900, c1900

Among the early settlers in Moorabbin Shire were blacksmiths who made tools for the other settlers who were establishing the homes, market gardens, farms, orchards and various businesses. Early settlers were self reliant and repaired their own equipment for kitchen,dairy, farm, horses, carts using various tools . Besides for peening (surface hardening by impact), the ball-peen hammer is useful for many tasks, such as striking punches and chisels - usually performed with the flat face of the hammer. The peening face is useful for rounding off edges of metal pins and fasteners, such as rivets. The ball face of the hammer can also be used to make gaskets for mating surfaces. A suitable gasket material is held over the surface where a corresponding gasket is desired, and the operator will lightly tap around the edges of the mating surface to perforate the gasket materialThis hammer is typical of the type used by early settlers in Moorabbin Shire c1900A hard faced ball & peen hammer, also known as a machinist's hammer,[ is a type of peening hammer used in metalworking. It has two heads, one flat and the other, called the peen, rounded.early settlers, market gardeners, blacksmiths, tools, building equipment, hammers, moorabbin shire, bentleigh, mckinnon, highett, cheltenham,mcewan james pty ltd, melbourne, bunnings pty ltd, -

Tatura Irrigation & Wartime Camps Museum

Tatura Irrigation & Wartime Camps MuseumTools, 1940's

... . tatura camp 3 faig p kaltenbach g hermann w trades metalworking ...Sent from Germany by Elfriede & Paul Faig.Tools belonging to W. Hermann / G. Kaltenbach - 1. Small metal handle|2. Drilling device, made of metal and possibly made on lathe (no. 7955).|3. Metal thread cutting tool (originally Australian).tatura, camp 3, faig, p, kaltenbach, g, hermann, w, trades, metalworking, handcrafts, woodturning -

Tatura Irrigation & Wartime Camps Museum

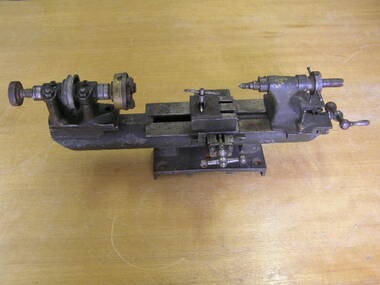

Tatura Irrigation & Wartime Camps MuseumTool - Lathe, Metal Lathe

Made at a forge outside the camp 3 perimeter by Gotthilf Kaltenbach & Manuel Kaltenbach. It is made from British Army scrap metal. Used for fine metal turning. The Witworth gauges were not used in Central Europe after 1918. The motor that was on it was a small electric sewing machine motor which was discarded about ten years ago in Germany. Sent from Germany by Elfriede & Paul Faig.Handmade metal turning lathe, 600mls long and weighing 16 kg. Made at a forge site outside the camp perimeter. All dimensions are in imperial inches, all threads are Witworth gauges. Painted in British Army colours.tatura, camp 3, lathe, metalworking, paul faig, gotthilf kaltenbach, manuel kaltenbach