Showing 15 items matching "noble comb"

-

National Wool Museum

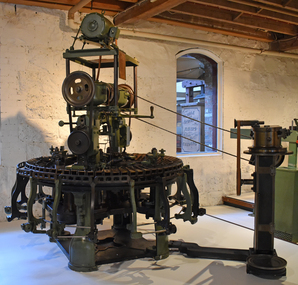

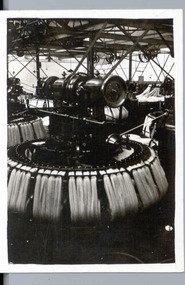

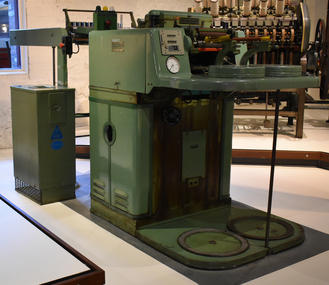

National Wool MuseumMachine - Noble Comb, Prince Smith & Sons, Burlington Shed, Keighley, 1915

... Noble Comb...Noble Comb... in Geelong, now the Little Creatures Brewery, ran 12 noble combs up...Noble Comb with plates - 'Prince Smith & Sons, Burlington... Creatures Brewery, ran 12 noble combs up until 1981. Gold plaque ...Combing removes the short or broken fibres and draws out the long fibres into even strands suitable for spinning. The process is necessary to produce long and soft strands needed for worsted yarn. These machines remove the short fibres and blend the remaining long fibres together to form the top. The short fibres that are removed, known as the noil, are used in the woollen system. The long fibres are drawn together, ready for spinning. To retain as many of the valuable long fibres as possible, a skilled operator always needed to be on duty in the factory to precisely set the machine. A Nobel Comb separates short (Noils) fibres while also blending long (Tops) fibres together. The long fibres are used for worsted materials while the short fibres are used for woollen fabrics. Woollen materials are soft, bulky and fuzzy, such as a picnic blanket; whereas worsted materials are fine, smooth and crisp, such as a suit jacket. The Valley Worsted Mills in Geelong, now the Little Creatures Brewery, ran 12 noble combs up until 1981. Gold plaque on display with machine until 2018 read: G.H. Mitchell & Son, Adelaide have celebrated 125 Years of involvement with the Australian Wool Processing Industry by contributing the funds necessary to restore The Carding Machine, Noble Comb & The Gill Box.Noble Comb with plates - 'Prince Smith & Sons, Burlington Shed, Keishley' (One plate located on each gear box). 'Prince Smith & Sons, Burlington Shed, Keishley' (One plate located on each gear box).wool manufacturing, noble comb, textile industry, geelong, little creatures brewery, valley worsted mills, fibres, wool, factory -

National Wool Museum

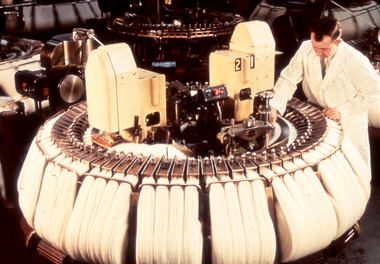

National Wool MuseumPhotograph - Slide, Stuart Ascough, Noble Comb, 1990s

... Noble Comb... combing machine inside a factory. Noble Comb Photograph Slide ...This slide is part of a collection of visual resources used by Stuart Ascough while conducting training and technical advice at mills in China, India, Russia and Australia. This item is part of a collection of books, manuals, photographs, letters and clothing relating to the working life of Stuart Ascough. Stuart's career in the wool industry spanned over 43 years from 1960 to 2003 in various roles including Topmaking Plant Manager at Courtaulds Ltd. in Spennymore, U.K., Operations Manager at Port Phillip Mills in Williamstown Victoria, Marketing Executive, Early Stage Wool Processing at the International Wool Secretariat Melbourne, Australia and General Manager of Victoria Wool Processors Pty. Ltd. in Laverton North, Victoria. Throughout his career Stuart travelled extensively, and in the 1990s worked at many topmaking mills in China on quality improvement projects. He also provided technical advice and training at mills in India, Ukraine, Lithuania, Kyrgyzstan, Russia, Latvia, Byelorussia and other parts of Europe and Asia.35mm colour transparency mounted in plastic slide mount showing a man in a white coat operating a wool combing machine inside a factory.wool, industry, australia, australian wool board international wool secretariat, factory, training, combing machine -

National Wool Museum

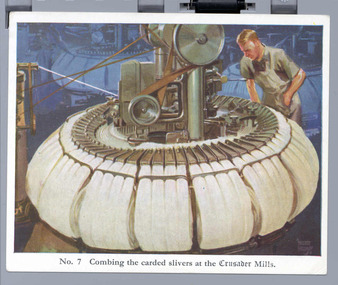

National Wool MuseumCard

... Noble Comb... and shows a Noble comb.... combing and shows a Noble comb. Australian Woollen Mills Pty Ltd ...This card is the seventh in a set of 16 information cards produced by the Stamina Clothing Company re: Australian Woollen Mills as give aways. It looks the process of wool combing and shows a Noble comb.Card no. 7 from the Crusader Mills information card set, c.1945-55. Verso of card no. 7 from the Crusader Mills information card set, c.1945-55.No. 7 Combing the carded slivers at the Crusader Mills.australian woollen mills pty ltd stamina clothing company, combing, noble comb -

National Wool Museum

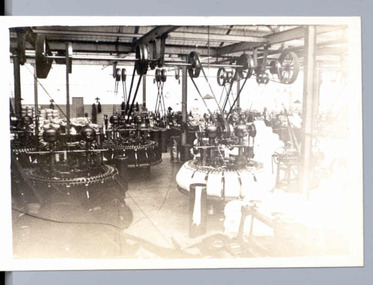

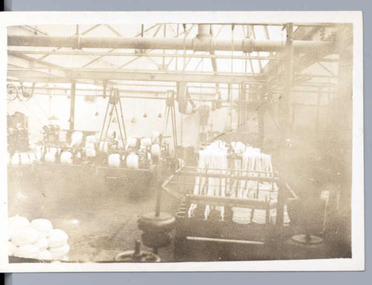

National Wool MuseumPhotograph - Noble Combs, Valley Worsted Mill, 1923

... Noble Comb... and shows several Noble combs. The donor worked at the Valley Mill... and shows several Noble combs. The donor worked at the Valley Mill ...This photograph shows the interior of the Valley Worsted Mill in 1923. The mill was first established at this time, and the photo shows the interior after tooling up but prior to the mill actually commencing operation. This photo is one of 31 in total and shows several Noble combs. The donor worked at the Valley Mill for many years. This mill still exists in Swanston Street, Geelong and is now being used by Melba Industries (an Austrim-Nylex company) to produce Jumbuck Nylon wool packs. "These 12 machines ended their working life in 1981 when the mill switched from the Bradford system of wool combing to the Continental system, the reason being was that the cost of maintaining them became too high, also the replacement rectilinear combs production rate was far greater and achieved higher yields although it could be argued that the Noble combs quality was superior". - Greg AldridgeBlack and white image showing the interior of a textile mill with machinery. Slightly overexposed on the right side.valley worsted mill, combing, noble comb, geelong -

National Wool Museum

National Wool MuseumPhotograph, Noble Combing Machine, Valley Worsted Mill

... Noble Comb... and shows several Noble combs. The donor worked at the Valley Mill... and shows several Noble combs. The donor worked at the Valley Mill ...This photograph shows the interior of the Valley Worsted Mill in 1923. The mill was first established at this time, and the photo shows the interior after tooling up but prior to the mill actually commencing operation. This photo is one of 31 in total and shows several Noble combs. The donor worked at the Valley Mill for many years. This mill still exists in Swanston Street, Geelong and is now being used by Melba Industries (an Austrim-Nylex company) to produce Jumbuck Nylon wool packs.Interior of Valley Worsted Mill, c.1923.textile mills, valley worsted mill foster valley mill pty ltd, combing, noble comb -

National Wool Museum

National Wool MuseumPhotograph

... Noble Comb... and shows several Noble combs. The donor worked at the Valley Mill... and shows several Noble combs. The donor worked at the Valley Mill ...This photograph shows the interior of the Valley Worsted Mill in 1923. The mill was first established at this time, and the photo shows the interior after tooling up but prior to the mill actually commencing operation. This photo is one of 31 in total and shows several Noble combs. The donor worked at the Valley Mill for many years. This mill still exists in Swanston Street, Geelong and is now being used by Melba Industries (an Austrim-Nylex company) to produce Jumbuck Nylon wool packs.Interior of Valley Worsted Mill, c.1923.valley worsted mill, combing, noble comb -

![Photograph, [Worsted room, Noble combing]](/media/collectors/510b3f7f023fd725b4cd52cc/items/54065f5a9821f50e3cc9f4da/item-media/54065f5a9821f50e3cc9f4db/item-fit-380x285.jpg) National Wool Museum

National Wool MuseumPhotograph, [Worsted room, Noble combing]

... Worsted room, Noble combing 10 P. HENDER O [...] R... Worsted room, Noble combing 10 P. HENDER O [...] R [Worsted room ...Acquired when "Classweave Industries" closed downWorsted room, Noble combing 10 P. HENDER O [...] Rtextile mills woollen mills, classweave industries pty ltd federal woollen mills ltd, combing, textile mills, woollen mills -

National Wool Museum

National Wool MuseumBook, Worsted Preparing and Spinning vol. II: wool combing

... Noble Comb... - worsted Combing Spinning Noble Comb Gilling Stanley Mr W. - Port ..."Worsted Preparing and Spinning vol. II: wool combing" - Fred Bradbury, 1923.FOR AND ON BEHALF OF / PORT PHILLIP MILLS PTY. LTD. / W. Stanley / Managing Director.port phillip mills pty ltd, cloth - worsted, combing, spinning, noble comb, gilling, stanley, mr w. - port phillip mills pty ltd -

National Wool Museum

National Wool MuseumSlide Folder, Wool Top Manufacturing

... Noble Comb... Noble Comb Noils 12 COLOUR SLIDES / WOOL TOP MANUFACTURING Wool ...Slide folder originally containing 12 slides and 4 wool samples depicting the wool top manufacturing process. Contains information about the slides.12 COLOUR SLIDES / WOOL TOP MANUFACTURINGwool tops, scouring, carding, noble comb, noils -

National Wool Museum

National Wool MuseumSlide

... Noble Comb...-and-the-bellarine-peninsula Wool Processing Top Making Combing Noble Comb ...wool processing, top making, combing, noble comb -

National Wool Museum

National Wool MuseumSlide

... Noble Comb...-and-the-bellarine-peninsula Wool Processing Top Making Combing Noble Comb ...wool processing, top making, combing, noble comb -

National Wool Museum

National Wool MuseumMachine - Windchest, Prince-Smith & Stells Ltd

... Used to collect the combed top from a noble comb. Consists...-and-the-bellarine-peninsula Used to collect the combed top from a noble comb ...Used to collect the combed top from a noble comb. Consists of a cast iron stand and base with steel pinch rollers and a rotating iron feed tube to empty the top into a receiving bin.combing, windchest, machine, wool processing, industry, wool, rollers, bin -

National Wool Museum

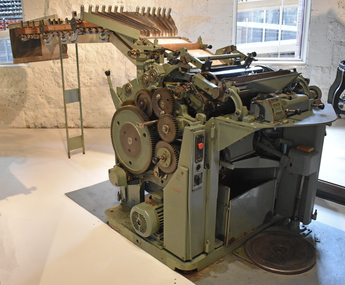

National Wool MuseumMachine - Gill Box, Deutscher Spinnereimaschinenbau Ingolstadt, 1963

... necessary to restore The Carding Machine, Noble Comb & The Gill Box.... necessary to restore The Carding Machine, Noble Comb & The Gill Box ...This machine uses a series of combs attached to bars that move with increasing speed away from a starting point. This draws-out and aligns the wool fibres to produce a gilled top. The gilling process is also used in other positions along the worsted production line. A gill box draws and combs the fibres prior to spinning. Gold plaque on display with machine until 2018 read: G.H. Mitchell & Son, Adelaide have celebrated 125 Years of involvement with the Australian Wool Processing Industry by contributing the funds necessary to restore The Carding Machine, Noble Comb & The Gill Box.Gill box. Green painted steel.Deutscher / Spinnereimaschinenbau / Ingolstadt / 1963deutscher spinnereimaschinenbau ingolstadt, gilling, gill box, textile industry, wool processing, factory, machine, mills, spinning, fibre, comb -

National Wool Museum

National Wool MuseumMachine - French Comb, Schlumberger & Cie, 1964

... of the Noble Comb, this machine separated long and short fibres... of the Noble Comb, this machine separated long and short fibres ...Combing removes the short or broken fibres and draws out the long fibres into even strands suitable for spinning. The process is necessary to produce long and soft strands needed for worsted yarn. These machines remove the short fibres and blend the remaining long fibres together to form the top. The short fibres that are removed, known as the noil, are used in the woollen system. The long fibres are drawn together, ready for spinning. To retain as many of the valuable long fibres as possible, a skilled operator always needed to be on duty in the factory to precisely set the machine. Machine has been completely rebuilt and set up by Nick Sokolov of Comb Research and Development with the help of Bruce Hill and others. NSC Schlumberger Comb PB25L machine No 3953, year of manufacture 1964. A rectilinear version of the Noble Comb, this machine separated long and short fibres. Donated to the National Wool Museum by Port Phillip Wool Processing Pty Ltd in 1993.French comb machine. 1962 Shlumberger and Co, France Model PB 251 NO. 3953.french comb, wool processing, textile industry, factory, machine, comb, restoration, fibres -

National Wool Museum

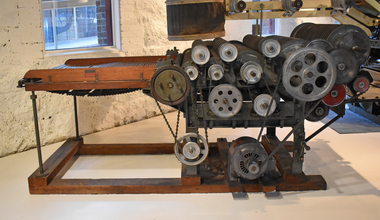

National Wool MuseumMachine - Carding Machine, CSIRO, 1960s

... necessary to restore The Carding Machine, Noble Comb & The Gill Box... necessary to restore The Carding Machine, Noble Comb & The Gill Box ...After scouring, the wool fibres are still tangled together. Carding untangles the fibres by brushing and straightening. The wool moves through a series of wire brush rollers that revolve at different speeds and in different directions to tease apart the wool. The fibres emerge from the machine as a continuous filmy web - called a sliver. The sliver must be thinned and divided into strands before the next process. Carding machines constantly require tuning. A highly skilled technician maintained and adjusted the speed of the rollers on the machine. This machine was developed by the CSIRO in the 1960s as a small-scale experimental machine. Industrial carding machines were four times the size of this one. Gold plaque on display with machine until 2018 read: G.H. Mitchell & Son, Adelaide have celebrated 125 Years of involvement with the Australian Wool Processing Industry by contributing the funds necessary to restore The Carding Machine, Noble Comb & The Gill Box. Also another gold plaque read: Experimental Carding Machine donated to The National Wool Museum by C.S.I.R.O Ryde has been rebuilt by Nick Sokolov of Comb Research & Development with the help of Bernard Tolan.Carder with small roller missing at coiling end. Driven by three horse power motor. Wooden slated feed table synchronised to overall gearing.carding machine, machines, wool industry, manufacturing, wool processing