Showing 9 items matching "pneumatic drill"

-

Federation University Historical Collection

Federation University Historical CollectionPhotograph - black and white, Miners at work underground with a pneumatic drill

... Miners at work underground with a pneumatic drill...pneumatic drill... pneumatic drill rail tracks hand pushed cart gold mining mining ...Photograph included in book "Victoria: Gold and Minerals" issued by Mines Department Victoria, 1935Photographvictoria, underground drilling, pneumatic drill, rail tracks, hand pushed cart, gold mining, mining, tools -

Lorne Historical Society

Lorne Historical SocietyPhotograph - Photograph of worker on rock face Great Ocean Road, Worker on rock face on Great Ocean Road

... G.O.R.; Big-Hill; Circa-1921; workmen; pneumatic-drill;...photograph of workmen using ropes for pneumatic drill...; workmen; pneumatic-drill; photograph of workmen using ropes ...photograph of workmen using ropes for pneumatic drill, ready to insert explosives into cliff face. Circa 1921g.o.r.; big-hill; circa-1921; workmen; pneumatic-drill; -

Federation University Historical Collection

Federation University Historical CollectionBook, Victoria: Gold and Minerals, 1935, 1935

... pneumatic drill... panning pneumatic drill puddling machine bendigo coal mine ...Hard cover book. Fold out map showing auriferous areas and mineral localities in Victoria, 1935victoria, gold, minerals, 1935, geological map, hydrolic sluicing, panning, pneumatic drill, puddling machine, bendigo, coal mine, wonthaggi, yallourn, jamieson valley, geological school, melbourne university, mount buffalo, electric power station, briquette factory, mines department, george brown, secretary of mines, e.j. hogan, minister of mines, mining -

RMIT Design Archives

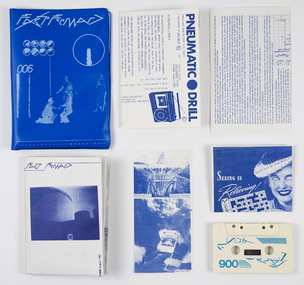

RMIT Design ArchivesMagazines, Fast Forward, number 6, August 1981

... , one newsletter titled 'Pneumatic Drill',and one 'Cassette... titled 'Pneumatic Drill',and one 'Cassette- It-Yourself' guide ...Cassette magazine in vinyl cover, Contents includes one magazine, one audio cassette, one crossword, one F.A.T.E entry form, one newsletter titled 'Pneumatic Drill',and one 'Cassette- It-Yourself' guide.ink, paper, plastic, vinyl -

Maldon Vintage Machinery Museum Inc

Maldon Vintage Machinery Museum IncRock Drill, Estimated second half to late 1800s

... Oswald pneumatic rock drill. What appears... / R. D. Oswald / Maldon". Oswald pneumatic rock drill. What ...This was the first rock drill to be made in Australia and was made in Maldon. It was used in the Carmen's Tunnel mine Maldon.Oswald pneumatic rock drill. What appears to be an operating lever extending to one side. Body only, no drill bits. Unpainted.Cast in relief on body "Late / R. D. Oswald / Maldon".tools, machinery, metalwork, mining -

Eltham District Historical Society Inc

Eltham District Historical Society IncPhotograph, Demolishing the Bini Shell at Diamond Creek, 1991, 1991

... holes. It was some days before pneumatic drills pecked out... holes. It was some days before pneumatic drills pecked out ...In 1978 Diamond Valley Shire recognised the need for a new public hall in Diamond Creek. Council considered the Bini shell form of construction which was in operation overseas and in use in New South Wales as libraries, gymnasiums, sports centres and multi-purpose centres. The Council gave the go-ahead. A site was chosen opposite the Hotel and close to the railway line. One day in - the following year, in 1979, activity stood still in Diamond Creek as school children and other excited spectators watched the one-hour inflation of the Bini Shell. This unusual method of construction was invented by Italian industrial designer and architect Dante Bini. The construction pneumatically raises a level of reinforced concrete from ground level which has not been set, using an internal balloon. The inner membrane inflates and compresses the mesh and concrete against the outer membrane. A net of flexible steel rods was laid on the building’s circular base, on the top of a fabric bladder. 300 tonnes of reinforced concrete were poured onto the mesh and a sealed cover laid over the concrete making a sandwich of cover, bladder and mesh. Compressed air was pumped into the bladder and the sandwich slowly began to rise and become a massive self-supporting dome. After inflation and removal of the outer membrane workmen filled in any holes. It was some days before pneumatic drills pecked out the first opening. The ceiling of the concrete dome was lined with fluffy insulating material. The dome was 36 metres in diameter at the base and 12 metres high in the centre with a usable floor space of 670 square metres. An opening night dinner was held to celebrate the new facility on March 12, 1980. Shire President Ron Pata made a speech and unveiled a plaque. It was the first public building in Victoria to be erected using the Bini Shell design method of construction The facility could cater for up to 400 people and in 1980 a fee for use was $100 for up to 200 people, $150 for up to 300 people and $200 for up to 400 people. For the next ten years or so, locals attended the hall for marital arts classes, basketball and netball games and school discoes and various other activities. After pieces of concrete fell off a Bini shell interstate due to a construction fault, the Council closed the centre. Demotion took place during the Diamond Creek Town Fair in 1991, as part of the annual Town Fair’s program. Research by L.P. Jan 2022This was the first public building in Victoria to be erected using the Bini Shell design method of construction.Colour photograph1991, diamond creek, bini shell, demolition, oval -

Eltham District Historical Society Inc

Eltham District Historical Society IncPhotograph, Fred Mitchell, Bini Shell at Diamond Creek, 1983, 1983

... holes. It was some days before pneumatic drills pecked out... holes. It was some days before pneumatic drills pecked out ...In 1978 Diamond Valley Shire recognised the need for a new public hall in Diamond Creek. Council considered the Bini shell form of construction which was in operation overseas and in use in New South Wales as libraries, gymnasiums, sports centres and multi-purpose centres. The Council gave the go-ahead. A site was chosen opposite the Hotel and close to the railway line. One day in - the following year, in 1979, activity stood still in Diamond Creek as school children and other excited spectators watched the one-hour inflation of the Bini Shell. This unusual method of construction was invented by Italian industrial designer and architect Dante Bini. The construction pneumatically raises a level of reinforced concrete from ground level which has not been set, using an internal balloon. The inner membrane inflates and compresses the mesh and concrete against the outer membrane. A net of flexible steel rods was laid on the building’s circular base, on the top of a fabric bladder. 300 tonnes of reinforced concrete were poured onto the mesh and a sealed cover laid over the concrete making a sandwich of cover, bladder and mesh. Compressed air was pumped into the bladder and the sandwich slowly began to rise and become a massive self-supporting dome. After inflation and removal of the outer membrane workmen filled in any holes. It was some days before pneumatic drills pecked out the first opening. The ceiling of the concrete dome was lined with fluffy insulating material. The dome was 36 metres in diameter at the base and 12 metres high in the centre with a usable floor space of 670 square metres. An opening night dinner was held to celebrate the new facility on March 12, 1980. Shire President Ron Pata made a speech and unveiled a plaque. It was the first public building in Victoria to be erected using the Bini Shell design method of construction The facility could cater for up to 400 people and in 1980 a fee for use was $100 for up to 200 people, $150 for up to 300 people and $200 for up to 400 people. For the next ten years or so, locals attended the hall for marital arts classes, basketball and netball games and school discoes and various other activities. After pieces of concrete fell off a Bini shell interstate due to a construction fault, the Council closed the centre. Demotion took place during the Diamond Creek Town Fair in 1991, as part of the annual Town Fair’s program. Research by LP January 2022This was the first public building in Victoria to be erected using the Bini Shell design method of construction.Digital copy of colour photographfred mitchell collection, 1983, bini shell, diamond creek -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyDrill Bit, Circa 1950

... powered by compressed air (Pneumatic). Rotary Air Blast Drilling... (Pneumatic). Rotary Air Blast Drilling. This drill bit was used ...This is the cutting bit on the end of a drilling rod. It would have been used to drill holes into rock for placing explosives, for installing steel rock anchors, etc. In hard rock the bits need to be replaced regularly. Compressed air is blown through the holes near the tip of the bit to blow rock fragments out of the drill hole. The main drilling unit would have been powered by compressed air (Pneumatic). Rotary Air Blast Drilling. This drill bit was used by workers in the SEC Vic. Kiewa Hydro Electricity Scheme. This type of bit although strong needed replacing frequently when the rock composition (type of rock) was extremely compact. The configuration of the tip bit (four star like pattern) was to provide the "teeth" to tear into the rock. This bit was manufactured in 1949 however drilling for rock cores, in the Kiewa Valley and the Victorian Alps, was carried out from the late 1920's.This particular drill bit would have been used by construction workers to drill holes into rock for either explosives or for installing steel anchor points into the rock. The use of compressed air was not only for waste extraction but also for running the main drilling unit.This four star rotary air balst (RAB) drill bit has a central "blow" hole (compressed air outlet to remove the ground rock particles through four extraction holes). There are four raised cutting/grinding lugs which allows the air compression hole(incoming) to always have a clear unblock opening. Extracted ground material is "blown" out from the drill head via the larger hole created by the steel bit.Stamped on the bottom outside shank "FAGERSTA SECO SWEDEN" and below this "102 7041 01 05 049".sec vic kiewa hydro scheme, alternate energy supplies, drilling into rocks in alpine regions -

Royal Australasian College of Surgeons Museum and Archives

Royal Australasian College of Surgeons Museum and ArchivesRadiological equipment, Stuart Morson's mechanical injector for angiography

Long term loan from Neurological Society of Australasia Museum of Neurosurgical Instruments , South Australia Catalogue with Historical Commentaries Second Edition January 2006 Copy located at RACS MuseumSTUART MORSON'S MECHANICAL INJECTOR FOR ANGIOGRAPHY. Stuart Morson(1913 - 1980) of Sydney had this injector constructed in or before 1952. It is said that it was not used much. The injector embodies two 10 ml and two 20 ml Record syringes coupled to a single delivery system. Each is operated by a piston. The pistons are driven from cylinders drilled in a metal block within the casing of the injector; the motive power must have been hydraulic or pneumatic pressure delivered through a manifold with taps allowing each syringe to be worked in isolation. The casing also contains two linked micro switches operated from a distance; it is unclear what was the role of these switches, and it is possible that a component of the unit is lost. JB Curtisl stated that a mechanical injector was devised in 1949 for serial angiography by his collaborator Schuster, but was not felt to be safe enough for use. For many years, neurosurgeons and neuroradiologists preferred to inject by hand.