Showing 20 items matching "retort"

-

Port Melbourne Historical & Preservation Society

Port Melbourne Historical & Preservation SocietyPostcard, Retort House and Coke Yards 1880s, 1880s

One from a set of six postcards related to the Gasworks and produced from early images by the City of Port Phillip: Retort House and Coke Yards 1880sCards have three logos: Gasworks Arts, City of Port Phillip, Gas and Fuel Corporationbuilt environment, industry, utilities - gas, south melbourne gasworks -

Stawell Historical Society Inc

Stawell Historical Society IncPhotograph, Stawell Gas Works -- Scrubbers, Purifier, Condensers, Washer, Retort house and Coke Plant

Gas Company – Stawell Ammonia Scrubber. Purifier. Condenser. Washer. Tower Scrubber with Retort house and Coke plant in the background.stawell -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

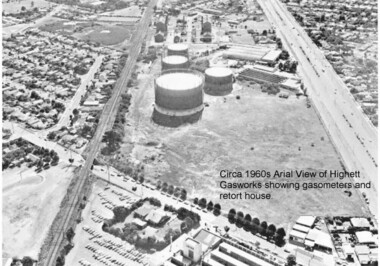

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Photograph - Photographs of Highett Gasworks, Gasometer, Retort House and Coal Store at Highett Gasworks, 1974 and 1960

Gasometers resulted from complex engineering design evolving from primitive gasholders first used in 1824 in England to power street lights. The 20th century gasometer, (as used at the Highett Gasworks), was comprised of a series of large interconnected, telescopic, cylindrical vessels or lifts, which rose and fell depending on the volume of gas stored. The gasholder operated on a basic principle of a gas-filled floating vessel, rising and falling in a seal of water. The Highett Gasworks had its beginning in 1939 but its beginnings commenced sixty-two years earlier when the privately owned Brighton Gas Company was floated in 1877. By 1880 the company was performing well and making excellent profits. The company was welcomed by residents wanting to replace the shadowy light of a kerosene lamp with the bright luminescence of "modern" gas lamps. The land developers of the day were also keen supporters. But by 1884 people became disgrunted because either the gas had not reached them yet or because the quality of the supply had diminished due to the increasing use. In 1885 a second private gas company, the Central Brighton and Moorabbin Gas Co, Chaired by "Tommy" Bent was floated and for many years the two gas companies enjoyed a shared monopoly in supplying gas from their New Street Works. In the 1930s the company expanded its gas production facilities to Highett where it had purchased 45 acres of land adjacent to the Melbourne-Frankston railway line. A gasholder with a capacity of 750,000 cubic feet was erected on the Highett land in 1927 and connected with high pressure mains to the Brighton works. Three years later the company directors decided to proceed with the construction of a vertical retort house and coal store. Following a "lull" during the Great Depression work recommenced in 1936 and by 1939 the first complete gas-making plant was completed, and gas making commenced. Over the next twenty one years other significant extensions occurred, including an amenities block to accomodate 100 workers. In 1969 Esso commenced the introduction of natural gas to residents homes and the gradual decommissioning of the Highett Gasworks commenced. Part of the old Highett Gasworks site is now a council owned parkThe photos of the Higett Gasworks, now demolished, recall their long history, that originated in the 1800s with the production of gas to supply homes with a new, much improved light source, and later it's other applications such as for stoves etc. The arrival of gas in the Shire of Moorabbin was a huge step forward that encouraged further building and development in the area.Three Photographs of the Highett Gasworks. Two are coloured photos taken in 1974, and one is black and white taken in the 1960s. All are in good conditionOn the back of the two coloured photographs "Highett Gasworks 1974" No inscription on the black and white aerial photograph.brighton, moorabbin, highett, bent thomas, gasometer, highett gasworks, engineering design, brighton gas company, central brighton and moorabbin gas company, great depression, lamp kerosene -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Tool - GOLD RETORT

Metal gold retort, it has a two parts circular container attached to crook shaped long handle. A caption reads Mr. G. Humphrey. An amalgam (gold and mercury) is placed inside and fire built around outside. Mercury vaporizes away leaving the gold. Diameter of retort 23 cm. Overall size 37x75 cm.mining, equipment, retort -

City of Kingston

City of KingstonPhotograph - Black and white, c. 1970

The Highett Gas Works were a landmark along the Nepean Highway for many years. With the cessation of the gasification of coal and the introduction of natural gas to Victoria, the gas holders were demolished and the Sir William Fry Reserve was developed on the southern end of the site. The Gas and Fuel redeveloped the northern end of the site with modern offices and laboratories for the organisation's scientific services. At this time, the chimney and retort house were retained.The Highett Gasworks had its beginning in 1939 operated by the Central Brighton and Moorabbin Gas Co Ltd. The company had expanded its gas production facilities to Highett where it had purchased 45 acres of land adjacent to the Melbourne-Frankston railway line. The first gasholder was erected on the Highett site in 1927 and connected with high pressure mains to the Brighton Gas Works. In 1939 the building program including gasometers, the vertical retort house and coal store was completed and gas making commenced. Its area of supply covered approximately 70 square miles and included the municipalities of Brighton, Sandringham, Moorabbin, Mordialloc, Chelsea and part of Dandenong. The Gas and Fuel Corporation eventually took over operations and with the disaggregation and privatisation of the organisation, the site was eventually closed c. 2002.Black and white aerial photograph featuring the Highett Gas Works with gasholders and retort house. In the top right-hand corner, a former Highett Primary School on Graham Road can be viewed. Photograph includes Bay Road, Royal Avenue, Princess Avenue and Jackson Road (Highett) and Alfred, Turner and Sandford Streets (Moorabbin).Handwritten in black ink: [indecipherable] in a circle Handwritten in red ink: 70% Four velcro display adhesivesgasification of coal, gas and fuel corporation of victoria, gasholders, highett, moorabbin, utilities -

University of Melbourne, School of Chemistry

University of Melbourne, School of ChemistrySwan Necked Glassware

Glass ware: Swan necked glass retorts Kavaliers Bohemian Glass -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Document - Digital, KEN BICE COLLECTION: NORTH DEBORAH MINING COMPANY NO LIABILITY TRIBUTERS INVOICE

Copy of document: tributers invoice showing tons crushed and retorted. Dated 28/3/1945. This is a digital only document.bendigo, mining, north deborah, bendigo , tribute, tributers, north deborah mining company, mining -

Bendigo Historical Society Inc.

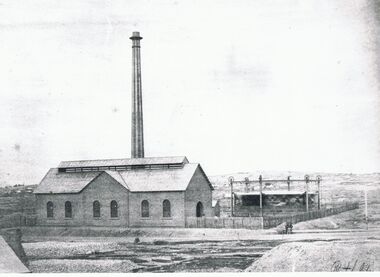

Bendigo Historical Society Inc.Photograph - GAS COMPANY: BENDIGO, approx.1861

Black and white photo: copy of an original by Batchelder held by State Library of Victoria. Depicting the retort house of the Bendigo Gas Company's works at Irish Town looking south east towards White Hills. The building was commissioned in 1860. The octagonal chimney behind the retort house was the tallest on Bendigo when constructed. Gas holder on the right of the building. Photographer Batchelder with structed gas holder on the right of the building. Photographer Batchelder with his handcart standing in front of the picket fence. No. 43 on observe side, signed by Photographer Batchelder, bottom right hand corner.atchelder, photographer, Pall Mall ( Sandhurst ) , Bendigobuildings, gas company -

Bendigo Historical Society Inc.

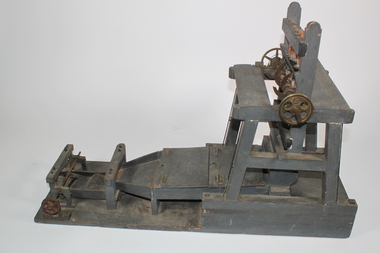

Bendigo Historical Society Inc.Model - MODEL of STAMPER

Gold bearing ore is pulverized by cast iron stampers (steam driven) and material then passes over a large copper plate covered in mercury causing the gold particles to combine with the mercury to form an amalgam which is scraped of and placed in a retort. The retort is heated causing the mercury to evaporate leaving the gold to be refined into ingots. The mercury is cooled as it leaves the retort and is reused. A second tray covered in what is called a blanket traps any fine gold that has passed the first plate. Finally the residue material goes over a vibrating table called a Wilfley Table which captures any iron pyrites which may contain about three percent gold. this is roasted and treated to recover any remaining gold at a special treatment plant.Wooden model of a five heads gold stamper battery. The gold stamper battery is a device for crushing ore. The parts of the battery are cams; dies; guides; kingposts; mortar box; shoes; stamps (or stampers); tappets. gold mining, mining equipment, gold stamper -

Federation University Historical Collection

Federation University Historical CollectionPhotograph, Val D'Angri, Former Clunes School of Mines, c2000, c2000

On 29 February 1892 'The Argus' reported on the first Annual Meeting of the Clunes School of Mines. "The annual meeting of the council of the Clunes School of Mines was held last evening at the town-hall. In place of members of the council retiring by effluxion of time the following were elected: — Rev. Elder Gray, Messrs. John Beveridge, R. Nichol, J. Bryant, W. T. Pitcher, J. H. Daley, and T. Gilbert. The first annual report, showing remarkable progress, was received and adopted. The following officers were elected for the ensuing year: — Rev. E. Grey, president; Rev. Father John Barrett and Dr. Gordon, vice- presidents; Mr. Joseph Bryant, hon. director; Mr. W. Y. Witherden, hon. treasurer, Mr. H. E. Sando retained the office of secretary, and the officers for the time being were appointed trustees." Great satisfaction was expressed with the success of the school, and the progress and extent of the classes. It was referred to a sub committee to make arrangements for allowing the free inclusion, in certain classes, of a limited number of boys and girls of 14 and upward, who on examination qualified themselves for the privilege. An offer by an anonymous resident to pay the fees for four miners for admission to any class in the school was announced by the president, and received with thanks.Two photographs showing the exterior of a weatherboard building known as the former Ballarat School of Mines Clunes campus. The Timber hall was erected as a School of Mines and later used by the Australian Natives Association. The retort furnace (indicated by the large chimney) is still located in the rear rooms.ballarat school of mines, assaying, clunes school of mines, john beveridge, r. nichol, j. bryant, w. t. pitcher, j. h. daley, t. gilbert, e. grey, john barret, joseph bryant, w. y. witherden, h. e. sando, schools of mines -

Stawell Historical Society Inc

Stawell Historical Society IncPhotograph, Magdala cum Moonlight Mine with two tailing dams c1900's. Same as 1386-13

Magdala cum Moonlight Mine c1900 Buildings include the mine managers office, change rooms, crushing battery, retorting room, blacksmith shop and cyanide vats. Fence advertises "Drink RoBur Tea"B/W Photo of Magdala Mine Works in middle distance with two tailing Dams. stawell gold mining -

Federation University Historical Collection

Federation University Historical CollectionBook, H.W. MacFarren, Practical Stamp milling and Amalgamation, 1910

Two yellow, cloth, hardcovered books. One is a first edition, and the other is a second edition. Contents include the Stamp mill, battery frame, mortar block, stem, finger jack, water supply, power, amalgamation, retorting, milling systems, millmen and mill crews, mill management, handling pulp and tailing. -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Functional object - Amalgam bucket

Ore bearing rock brought out of the mine was crushed at the battery by heavy metal stampers and the fine material passed over copper pates coated with mercury. Gold particles would combine with the mercury forming an amalgam which was then scrapped off the copper plates and put into the amalgam bucket ready for retorting too extract the gold. The amalgam of mercury and gold was placed into the retort which was heated to evaporate the mercury. The mercury cooled as it ran down the pipe which was recovered to be reused leaving the gold behind. The gold would later be put into a crucible and heated to burn of impurities and the molten pure gold poured into an ingot.A heavy cast iron bucket 20 centimetres high, 16 centimetres in diameter at its base and 22 centimetres diameter at the top. It has a spout five centimetres wide protruding two centimetres. There is a handle which is a semi- circular shape 19 centimetre wide extending 14 centimetres above the bucket The inside of the bucket has an enamel coating. amalgam bucket, bendigo gold, gold retort -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Photograph - MINE SITE, 1890's

Sepia print of board of workmen, perhaps at mine site. 56 males, large pipes on stand ( retort ? ) Crane ? In background ( possibly a gantry ) lengths of smaller pipes in foreground, also wooden posts ? RHSV Victoria, Bendigo Branch' in circular rubber stamp. On back in pencil 'R.A. Anderson /Bendigo' ' From J. Malloy 7/72'organization, business, mine site -

Rutherglen Historical Society

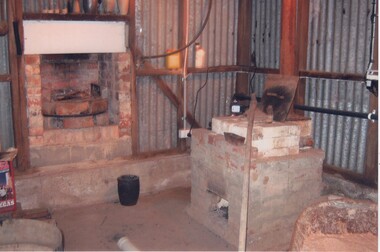

Rutherglen Historical SocietyImage, c1990

This photograph shows the pre-heater on the left and the furnace on the right. After clean up of stamper table, amalgam is placed in a retort, then placed in the furnace where mercury is condensed and runs down the small pipe into an enamel bucket and can be reused. This is one of a series of photographs of the Rutherglen Gold Battery. The battery's purpose was to crush quartz from nearby quartz reefs and extract gold from within. The battery was erected in 1908 and consists of a five-head battery, Wilfrey table, Bergin pan, portable steam engine and shed. The battery was restored in 2011/12 and can be viewed daily between 9.00am and 5.00pm. See website for details.Colour photograph of the interior of a room with corrugated iron walls, with a fireplace on the left and a furnace on the right.gold battery, gold processing -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Document - Mine Managers, a glimpse at a large subject. From Ballerstedt to Buerger

Mine managers had a variety of roles. They were a go-between for investors or shareholders and were responsible for the effective utilisation of human and physical resources above and underground. From the early 1870's the Bendigo school of mines held courses and exams leading to a Mine Manager's Certificate. These certificates were awarded in 3 classifications:- 1st class certificate holders could manage any mine where large and expensive machinery was used. They needed knowledge and competence in areas such as surveying, underground plan drawing, ventilation, amalgamation, retorting and smelting. They must also be literate and numerate. 2nd Class:- able to manage any mine where steam machinery was in use. 3rd Class:- for mines where there was no steam machinery . They needed to have a good knowledge of whim, whip or windlass work. Conversations continued through to the 1920's about whether the requirement for a Managers Certificate should be made compulsory under amendment to the Mines Act 1883. There were also discussions of the minimum amount of mine experience applicants should possess.A research paper detailing the history of managers and their role in the Bendigo gold fields. A short address prepared by James A. Lerk April/ May 2002. 8 pages.mine managers, ballerstedt, buerger -

Federation University Historical Collection

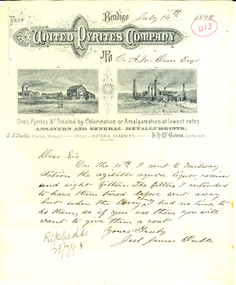

Federation University Historical CollectionLetter - Correspondence, Letter on Bendigo United Pyrites Company Letterhead, 1898, 1898

"The United Pyrites Company's Works are situated about three quarters of a mile from Spargo Brothers, and are on the northern side of the Marong road, in Pinch-gut Gully. Two processes are followed at these works, viz., the amalgamating process and the treatment by means of chlorine gas. The latter is called the Newbery-Vautin system, and the mode pursued is that laid down by Mr. Cosmo Newbery and Mr Vautin, whose names have been given to the process. Mr. Edwards manages these works. Three reverbatory furnaces are used to roast the pyrites, which is weighed in the truck before being put into the furnaces. At this weighbridge a sample of each lot is kept, and if the yield is not equal to expectation, the works are carefully gone over to see where the fault occurs. Care is taken at the furnace to regulate the heat, otherwise the pyrites might slag instead of roasting evenly right through. An immense revolving furnace (made of boiler iron) was used at these works. It was found to be suitable for treating blanket sand, but was not a success for roasting coarse pyrites. The process of amalgamating by means of Chilian mills is the same in these works as at the Western Works, but the United Works are on a larger scale, and eleven mills are utilised. It is the chlorine gas process which is most interesting here. The gas is made from sulphuric acid, black oxide of manganese, and common salt, and the gas is introduced into huge vats, where it works its way through a filter of pieces of quartz and then through the bed of roasted pyrites lying above. The action of the gas transforms the gold into chloride of gold. This is easily dissolved in water, and in that form is drawn off into huge delf jars, where the use of sulphate of iron precipitates the gold to the bottom. A small battery—eight head of stamps in two boxes—is in use here to crush small consignments of stone sent for trial. Test crushings come from all the Australasian colonies, and even from India. The jars used are manufactured at Epsom, and some of the salt used is also of home manufacture, from the Salt Lakes on the Northern plains. Mr. Edwards took us over a new building in course of erection, and in which the chlorine gas is to be generated in the midst of the pyrites— a still further advancement in the new process. There is some very good machinery in this new building, and the tailings from the ordinary pyrites works will also be treated by this chlorine gas system, which has been found to work well at Mount Morgan, in Queensland. The purest of gold is obtained by this process, the gold passing in solution into a charcoal filter, from which it emerges in the shape of metallic gold. We saw some nice cakes of retorted gold at the works. One of 26oz. was from some New Zealand pyrites (2½ tons), and assayed over 23 carats. There were also cakes of Avoca gold, of silver, and of the tremulous amalgam." (The Argus, 4 February 1887)Two handwritten letters to the Ballarat School of Mines on Bendigo United Pyrites Company Letterhead.bendigo united pyrites company, pyrites, ballarat school of mines, j.j. deeble, joel deeble, joel james deeble, a.m. dean, fred j. martell, martell, s.h. cowan, letterhead -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Tool - MERCURY BUCKET

Cast iron mercury bucket, used to hold mercury, potentially in the process of recovering minute pieces of gold mixed in soil and sediments. See research page for description of one process of using mercury to extract gold.gold mines, mining equipment, mercury bucket, miners used mercury in a number of ways to amalgamate gold, with each mill or battery operator having their preferred method depending on the nature of the ore. by the late 1850s the most common way of crushing goldbearing quartz ores or consolidated alluvial cements was in a stamp battery. the battery featured heavy iron stamp heads held in a frame, with each head often weighing up to 500 pounds (226 kg) or more (see msv 1880, page 45) (birrell 2005). stamp heads were lifted and dropped by a rotating overhead cam shaft driven by a steam engine or water wheel. ore was fed into a large cast-iron battery box, mixed with a steady stream of water, and pulverised by the stamp heads. in some batteries, mercury was placed in the base of the boxes to amalgamate with freed gold. the violent agitation of the mercury in the mortar box, however, could cause the mercury to break into myriad tiny globules that were carried away by the water with the tailings, thus losing a certain amount of gold in the process (thompson 1867; ritchie & hooker 1997). the water and sand slurry was splashed by the falling stamps from the box through fine mesh screens and onto inclined wooden tables below the mortar box (figure 2). the tables were covered with copper sheets or plates coated with mercury, which caught and amalgamated with a portion of the gold. the grey putty-like amalgam was periodically scraped off the sheets and retorted in a furnace to collect the gold and recover the mercury for reuse. mercury was inevitably lost from the plates, while poor maintenance resulted in further losses of gold and mercury in the tailings. mercury use and loss from gold mining in 19th century victoria. peter davies1, susan lawrence, and jodi turnbull, department of archaeology and history, la trobe university. -

The Ed Muirhead Physics Museum

The Ed Muirhead Physics MuseumEquipment - Adjustable Retort Stand, 20th Century

Heavy metal tripod stand with three knobs and two adjustable holders.On tripod base: 'MET. RES'retort stand, scientific apparatus, scientific equipment -

Clunes Museum

Clunes MuseumEquipment - RETORT FLASK

FROM THE OLD CLUNES HOSPITALROUND GLASS CONTAINER WITH A SHORT SPOUT OUT ONE SIDE. JUST IN BACK OF THE SHORT SPOUT IS A LONG TUBE-LIKE SPOUT WITH SMALL OPENINGlocal history, medicine, medical equipment, medical