Showing 11 items matching "roasting furnace"

-

Federation University Historical Collection

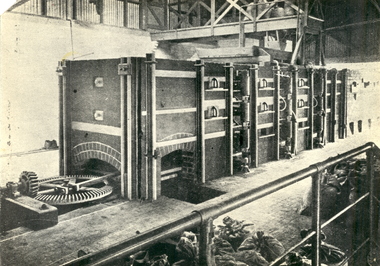

Federation University Historical CollectionPhotograph - Black and White Photograph, The Maddern Roasting Furnace in the Ballarat School of Mines Mining Laboratory, 1904

... The Maddern Roasting Furnace in the Ballarat School of...maddern roasting furnace...Interior view of the Maddern Roasting Furnace... roasting furnace ballarat school of mines model mine ballarat ...Interior view of the Maddern Roasting Furnace in the Ballarat School of Mines Model Minemaddern roasting furnace, ballarat school of mines model mine, ballarat school of mines battery -

Federation University Historical Collection

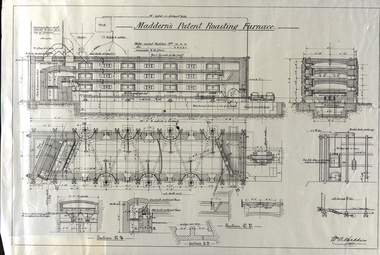

Federation University Historical CollectionEngineering drawings, Maddern's Patent Roasting Furnace, 1902

... Maddern's Patent Roasting Furnace...roasting furnace...Printed technical drawings of 'Maddern's Patent Roasting.... maddern roasting furnace assaying engineering drawings w.a ...Printed technical drawings of 'Maddern's Patent Roasting Furnace' .1) Assembly drawings with dimensions (4 copies) .2) Details for Maddern's roaster (3 copies)w. maddern, roasting furnace, assaying, engineering drawings, w.a. maddern, maddern's roasting furnace -

Federation University Historical Collection

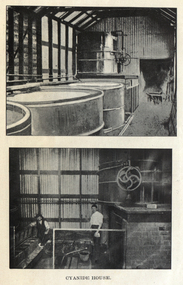

Federation University Historical CollectionPhotograph, Cyanide House and Maddern Roasting Furnace, 1908

... Cyanide House and Maddern Roasting Furnace... Cyanide House and the Maddern Roasting Furnace from the 1908 SMB... and the Maddern Roasting Furnace from the 1908 SMB Calendar. Cyanide House ...The Ballarat School of Mines had a functioning model mine.Two photographic images of the Ballarat School of Mines Cyanide House and the Maddern Roasting Furnace from the 1908 SMB Calendar.ballarat school of mines, maddern furnace, cyanide house, model mine -

Federation University Historical Collection

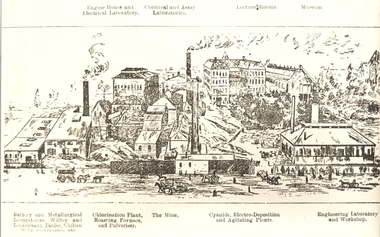

Federation University Historical CollectionImage, Ballarat School of Mines from Albert Street, Ballarat, c1904

... roasting furnace... laboratories, chlorination plant and roasting furnace, cyanide plant... chlorination plant roasting furnace cyanide plant engineering ...This image was reproduced in the Ballarat School of Mines Handbook and Prospectus, 1905.Copy of a line drawing of the Ballarat School of Mines from Albert Street, Ballarat, including the battery and metallurgical laboratories, chlorination plant and roasting furnace, cyanide plant, engineering laboratory and the Ballarat School of Mines Botanical Gardens. The original of this image is Cat. No. 4774.ballarat, school of mines, battery, metallurgy, chlorination plant, roasting furnace, cyanide plant, engineering, laboratory, museum, assay, mine, m3334, ballarat school of mines botanical gardens -

Federation University Historical Collection

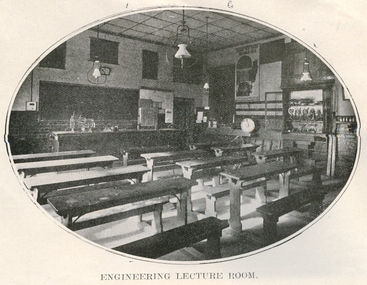

Federation University Historical CollectionBook, Ballarat School of Mines, Ballarat School of Mines Calendar, 1911, 1911

... of the Engineering Room, the Maddern Roasting Furnace, Museum, Junior... Roasting Furnace, Museum, Junior Chemical Laboratory, Plan ...In 1911 R. Maddern was President of the Ballarat School of Mines. Contents of this booklet are: Asssociateship, Calendar, Certificate Courses, Departmental Regulations, Discipline, Discipline Board, Examination Results, Fees, Full Certificates Issued, General Regulations, Introduction, Junior Technical School, Officer Bearers, Professors and Lecturers, Subjects of Instruction - Department of Chemistry and Metallurgy, Geological Department, Engineering Department, Electrical Engineering Department, Department of Mathematics and Physics, Practical, Plane and Solid Geometry, Photography, Subscriptions and Donations 1910. Plan of Buildings and Grounds Engineers with qualifications from the Ballarat School of Mines were sought by mines throughout the world. Blue soft covered book of 64 pages titled the Ballarat School of Mines Calendar. The book includes images of the Engineering Room, the Maddern Roasting Furnace, Museum, Junior Chemical Laboratory, Plan of Buildings and Ground, Chemical Laboratory, Concentration Floor, Linkenbach Table, Engineering Laboratory, Experimental Steam Engine, Chemical Lecture Room, Physics Instruction Room, Newtonian Telescopy, Ballarat Observatory, Instructor's Laoratory, Wilfrey Table, Chlorination plant, Cyanide House and R. Maddern. ballarat school of mines, scientific equipment, engineering, classroom, desks, gas lighting, calendar, r. maddern, j. m. bickett, w. h. middleton, j. d. woolcott, w. nixon, daniel. walker, fred j. martell, professor a. mica smith, hubert r. murphy, charles a. deane, arthur garrard, professor t. s. hart, professor a. d. gilchrist, a. e. c. kerr, j. brittain, e. j. a. mcconnon, john m. sutherland, bertram whitington, h. j. hall, e. gutheil, charles campbell, t. williams, d. e. mullins, sir redmond barry, judge rogers, r. m. sergeant, thomas bath, andrew anderson, general regulations, discipline, discipline board, associateship and final certificates, mining engineering, metallurgy, geology, electrical engineering, certificate courses, junior technical school, fees, subjects of instruction, chemistry, geological department, engineering department, electrical engineering department, department of mathematics and physics, practical, plane and solid geometry, photography, full certificates issued, supplementary examination results - may 1910, supplementary examination results - april 1908, subscriptions and donations 1910 -

Federation University Historical Collection

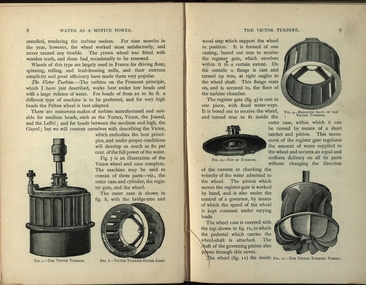

Federation University Historical CollectionBook, Machinery for Metalliferous Mines, 1894, 1894

... ; amalgamating plant; belt elevator;roasting furnace;splicing wire rope...; amalgamating plant; belt elevator;roasting furnace;splicing wire rope ...The 1st edition of this famous work, giving an excellent account of the machinery used in late 19th century metal mining in the UK and overseas is very rare. It covers a wide range of equipment - pumps, steam engines, drills, winding engines, stamps & concentration mills, aerial ropeways, tramways and early uses of electricity etc. Brown hard cloth covered book. xvi 564 pages with additional advertisements, with over 300 illustrations and drawings, some fold out. Chapters include Water as a motive power, Wind engines and ventilating machinery, Steam boilers/engines and oil engines, hoisting machinery, draining of Mines, pumping engines, rock drilling machinery, boring machinery, concentration machinery, sizing and classifications trommels, joggers and jigging, fine concentration, milling of gold ores, milling of silver ores, amalgamation plates and machinery, dry and roasting machinery, chlorination and cyandide processes for the extraction of gold, electricity as a motive power for mining, electric lighting and blasting, aerial wire ropeways, transport by rail and road. There a a number of lovely line illustrations in the book including: Poncelot's undershot waterwheel; Fromont furnace;Victor turbine; Pelton waterwheel; Root's positive blower;Cross section and front elevation of Lancashire boiler; Robey's Compound Mill Engine; Portable Winding Plant; Iron Pit Head Gear ; Loading Arrangement in an Incline Shaft; kibble; Worthington Pump; California Pump; Scram's Air Compressor; Rock drill Bits; Special Sharpening tools; Boring tools;Rotating Picking table; Ore Feeder; roller crusher; stamp battery; round buddle; slime table; vanner; amalgamating plant; belt elevator;roasting furnace;splicing wire rope; capel; tipping waggon;mining, cornish pump, linkenbach table, water wheel, ventilation, oil engine, california, america, water, steam boilers, steam engines, oil engines, pumpimg, rock drilling, boring, jiggers, milling, silver, gold, drying and roasting, chlorination, cyaniding, lead, zinc, copper, electricity, electric lighting, wire ropes, transport, wind engine, poppet head -

Federation University Historical Collection

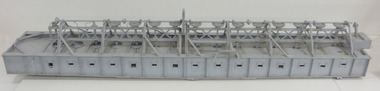

Federation University Historical CollectionUnknown - Model, Edwards' Ore Reduction Furnace Model, pre 1924

... , move the roasting ore in a zig-zag path through the furnace... This model of a mechanical ore roasting and chloridising furnace ...This model of a mechanical ore roasting and chloridising furnace was invented and patented by Thomas Edwards of the Edwards Pyrites Smelting and Ore Reduction Company. This new type of furnace produced a high standard of sulphur free ore known as ‘sweet roasted’. Edwards used this model for demonstrations in the USA. Of note is the central large vertical cogwheel (externally driven) which drives small vertical cogwheels via angled cogging drives. These in turn drive a horizontal wheel. Each side of the vertical wheel is set on an opposite side to the horizontal wheel of its neighbours, resulting in opposite direction rotation of neighbouring horizontal wheels. Each horizontal wheel turns a rabble (set of vertical iron paddles) within the furnace. These rabbles, each turning in opposite direction to its neighbours, move the roasting ore in a zig-zag path through the furnace. The elongated furnace with its line of rabbles produced a much ‘sweeter’ roasted ore than could be obtained from a typical tank-shaped furnace. In 1924, when the model was donated to the Ballarat School of Mines, Ballarat’s Courier newspaper reported, ‘Apart from its historical and education value, the gift should serve to stimulate the inventive faculties of the students who have to win fame for the school and for themselves in the metallurgical world.’ The furnace model was donated to Ballarat School of Mines and used as an educational prop from 1924. The model relates to the mining industry which is a significant part of Ballarat's history and heritage. Ballarat School of Mines is the oldest Technical School in Australia and is celebrating 150 years in 2020.Metal model of Edwards' Ore Reduction Furnace. The model includes cogwheels, rabbles and other details. Scale is thought to be around 1:20M259ballarat school of mines, edwards, pyrites, ore reducation, edward retallack, mining, model -

Federation University Historical Collection

Federation University Historical CollectionDocument, Indenture Between Robert M. Serjeant, Joseph Flude and the Trustees of the Ballarat School of Mines regarding Letters of Patents for the Benefit of the Ballarat School of Mines, 1877, 04/03/1875

R.M. Serjeant was listed as a mining manager and Joseph Flude as a metallurgist. In 1875 they were both living in Ballarat. The patent number is A.D.1875, 4th March. No 2031. According to the patent the hearth of the furnace is in the form of a cone revolving horizontally. The feed is supplied to the apex of the cone by an archimedian screw. The crown of the furnace comprises a double covering or roof with an intermediate chamber for receiving heated air. The inner covering is pierced to admit of the heated air being brought into contact with the pyrites on the face of the revolving hearth. The discharge of the roasted substance is affected by means of a scraper at the base of the cone. It was claimed that this was a new mode of introducing heated air, and the exclusion of flame during the operation of roasting pyrites. The self-acting charge and discharge of the furnace and the peculiar construction of the hot air chambers, and the use of perforated bricks through which the supply of air is affected were also new. (http://patentsvictoria.net/002031.html) From the Goulburn Herald, 14 September 1878 "A feature connected with the school of mines is the yet unfinished pyrites works. The extraction of the gold from pyrites and the utilization for commercial purposes of other substances connected with pyrites are peculiarly important to Ballarat, because were a simple and inexpensive method devised there are millions and millions of tons of quartz that would then be made remunerative. With this thought in their minds two scientific gentlemen invented the school of mines self-acting rotatory furnace. This, for lack of funds, has not been completed as yet, but the amount in hand for the purpose is daily increasing, and it will eventually be an accomplished fact. It is in contemplation also to erect machinery shops in connection with the school, and it is purposed to con struct a steam-engine to do at once the work of the pyrites treatment and the ma chine room. A model shaft and mine too are being prepared for on the reserve, so that practical mining of the most thorough character may be taught on the ground.'Large indenture on red bordered vellum. The indenture was regarding a patent for the benefit of the Ballarat School of Mines. Letters Patent for an Invention for Roasting Pyrites to be called 'the Ballarat School of Mines self-Acting Pyrites Furnace" to Robery Malachy Serjeant and Joseph Flude. The large document is on a vellum type paper complete with stamps and seal. The document is signed by Acting-Governor William Stawell. Inscriptions and Markings Written on verso: "Date of Patent 4th March 1875 No 2031 Letters Patent for An invention for roasting pyrities to be called "The Ballarat School of Mines Self-acting Pyrities Furnace" to Robert Malachy Serjeant and Joseph Flude Melbourne, Victoriaballarat school of mines, serjeant, r.m. serjeant, robert m. serjeant, flude, joseph flude, patent, barry, redmond barry, rogers, judge rogers, bland, rivett henry bland, john airy, warrington rogers, establishment, indenture, legal, cuthbert, ballarat school of mines trustees, william stawell, john warrington rogers -

Federation University Historical Collection

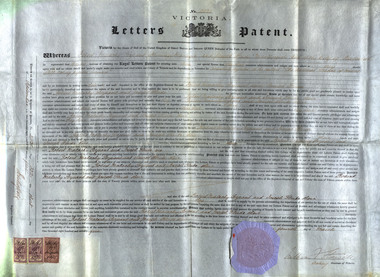

Federation University Historical CollectionDocument, Letters Patent for an Invention for Roasting Pyrites, 1875, 1875

R.M. Serjeant was listed as a mining manager and Joseph Flude as a metallurgist. In 1875 they were both living in Ballarat. The patent number is A.D.1875, 4th March. No 2031. According to the patent the hearth of the furnace is in the form of a cone revolving horizontally. The feed is supplied to the apex of the cone by an archimedian screw. The crown of the furnace comprises a double covering or roof with an intermediate chamber for receiving heated air. The inner covering is pierced to admit of the heated air being brought into contact with the pyrites on the face of the revolving hearth. The discharge of the roasted substance is affected by means of a scraper at the base of the cone. It was claimed that this was a new mode of introducing heated air, and the exclusion of flame during the operation of roasting pyrites. The self-acting charge and discharge of the furnace and the peculiar construction of the hot air chambers, and the use of perforated bricks through which the supply of air is affected were also new. (http://patentsvictoria.net/002031.html) From the Goulburn Herald, 14 September 1878 "A feature connected with the school of mines is the yet unfinished pyrites works. The extraction of the gold from pyrites and the utilization for commercial purposes of other substances connected with pyrites are peculiarly important to Ballarat, because were a simple and inexpensive method devised there are millions and millions of tons of quartz that would then be made remunerative. With this thought in their minds two scientific gentlemen invented the school of mines self-acting rotatory furnace. This, for lack of funds, has not been completed as yet, but the amount in hand for the purpose is daily increasing, and it will eventually be an accomplished fact. It is in contemplation also to erect machinery shops in connection with the school, and it is purposed to con struct a steam-engine to do at once the work of the pyrites treatment and the ma chine room. A model shaft and mine too are being prepared for on the reserve, so that practical mining of the most thorough character may be taught on the ground.'Letters Patent for an Invention for Roasting Pyrites to be called 'the Ballarat School of Mines Self-Acting Pyrites Furnace' to Robert Malachy Serjeant and Joseph Flude. The large document is on a vellum type paper complete with stamps and seal. The document is signed by Acting-Governor William Stawell.Written on verso: "Date of Patent 4th March 1875 No 2031 Letters Patent for An invention for roasting pyrities to be called "The Ballarat School of Mines Self-acting Pyrities Furnace" to Robert Malachy Serjeant and Joseph Flude Melbourne, Victoriaballarat school of mines, serjeant, r.m. serjeant, robert m. serjeant, flude, joseph flude, richard gibbs, stawell, william stawell, pyrities furnace, philately, statute stamp, seal (victoria), ballarat school of mines self-acting pyrities furnace, ballarat school of mines self-acting pyrites furnace -

Federation University Historical Collection

Federation University Historical CollectionLetter - Correspondence, Letter on Bendigo United Pyrites Company Letterhead, 1898, 1898

"The United Pyrites Company's Works are situated about three quarters of a mile from Spargo Brothers, and are on the northern side of the Marong road, in Pinch-gut Gully. Two processes are followed at these works, viz., the amalgamating process and the treatment by means of chlorine gas. The latter is called the Newbery-Vautin system, and the mode pursued is that laid down by Mr. Cosmo Newbery and Mr Vautin, whose names have been given to the process. Mr. Edwards manages these works. Three reverbatory furnaces are used to roast the pyrites, which is weighed in the truck before being put into the furnaces. At this weighbridge a sample of each lot is kept, and if the yield is not equal to expectation, the works are carefully gone over to see where the fault occurs. Care is taken at the furnace to regulate the heat, otherwise the pyrites might slag instead of roasting evenly right through. An immense revolving furnace (made of boiler iron) was used at these works. It was found to be suitable for treating blanket sand, but was not a success for roasting coarse pyrites. The process of amalgamating by means of Chilian mills is the same in these works as at the Western Works, but the United Works are on a larger scale, and eleven mills are utilised. It is the chlorine gas process which is most interesting here. The gas is made from sulphuric acid, black oxide of manganese, and common salt, and the gas is introduced into huge vats, where it works its way through a filter of pieces of quartz and then through the bed of roasted pyrites lying above. The action of the gas transforms the gold into chloride of gold. This is easily dissolved in water, and in that form is drawn off into huge delf jars, where the use of sulphate of iron precipitates the gold to the bottom. A small battery—eight head of stamps in two boxes—is in use here to crush small consignments of stone sent for trial. Test crushings come from all the Australasian colonies, and even from India. The jars used are manufactured at Epsom, and some of the salt used is also of home manufacture, from the Salt Lakes on the Northern plains. Mr. Edwards took us over a new building in course of erection, and in which the chlorine gas is to be generated in the midst of the pyrites— a still further advancement in the new process. There is some very good machinery in this new building, and the tailings from the ordinary pyrites works will also be treated by this chlorine gas system, which has been found to work well at Mount Morgan, in Queensland. The purest of gold is obtained by this process, the gold passing in solution into a charcoal filter, from which it emerges in the shape of metallic gold. We saw some nice cakes of retorted gold at the works. One of 26oz. was from some New Zealand pyrites (2½ tons), and assayed over 23 carats. There were also cakes of Avoca gold, of silver, and of the tremulous amalgam." (The Argus, 4 February 1887)Two handwritten letters to the Ballarat School of Mines on Bendigo United Pyrites Company Letterhead.bendigo united pyrites company, pyrites, ballarat school of mines, j.j. deeble, joel deeble, joel james deeble, a.m. dean, fred j. martell, martell, s.h. cowan, letterhead -

Federation University Historical Collection

Federation University Historical CollectionDocument - Document - Article, Edwards' Pyrites Works, Ballarat IN Australian Mining & Metallurgy, 1904, 1904

... furnace sebastopol roasting and chlorination kalgurli gold mines ...An online article downloaded. From the book 'Australian Mining & Metallurgy" by Donald Clark, special commissioner to the Australian Mining Standard. It includes images of the Ballarat works. It also includes an article on the Kalgurli Gold Mines, Limitededwards' pyrites works, edwards' mechanical ore roasing and chloridising furnace, sebastopol, roasting and chlorination, kalgurli gold mines