Showing 135 items matching "steel manufacturer"

-

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Education kit - Wood shaft writing pens and nibs, Steel Nib Manufacturer, mid 20thC

... Steel Nib Manufacturer... kit Wood shaft writing pens and nibs Steel Nib Manufacturer ...A dip pen usually consists of a metal nib with capillary channels like those of fountain pen nibs, mounted in a handle or holder, often made of wood. Dip pens have no ink reservoir, so the user must recharge the ink from an ink bowl or bottle to continue drawing or writing. Dip pens emerged in the early 19th century, when they replaced quill pens and were generally used before the development of fountain pens in the later 19th centuryThe pioneer settlers in the Moorabbin Shire area valued education and established schools for their children in Cheltenham and East Brighton c1860's These wood shaft pens and steel nibs are typical of the type used up to the mid 20th Century in school classes.3 wood shaft writing dip pens with steel nibs schools, education, writing equipment, victoria melbourne, market gardeners, pioneer, settlers, cheltenham state school no. 84., bentleigh east state school no. 2083, st stephens c of e school tucker road east brighton, pen steel nibs -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Manufactured Objects, bottle opener 'Lukey Mufflers', mid 20thC

... steel manufacturer... cheltenham early settlers bottle openers steel manufacturer brabham ...Len Lukey was a Victorian Racing Car Driver in the 1950s & 1960s and established his Car Exhaust Muffler business in his backyard in Highett c 1970. In 1964 he purchased the site and then developed and operated the Phillip Island Car Racing Track until his death 1978. He designed the Lukey Racing Car Museum and Gardens at that site. The 1959 Australian Drivers Championship was a CAMS sanctioned motor racing title for drivers of Formula Libre cars. The championship winner was awarded the 1959 CAMS Gold Star. The series was won by Victorian racer Len Lukey driving his Cooper T45 Climax and in the opening round of the series his own much modified Cooper T23 which was known as the Lukey-Bristol. Lukey was one of only a few drivers who attempted to complete the gruelling twelve race schedule, the longest in ADC history. Lukey finished just two points ahead of his season long rival, Alec Mildren from the ACT [1] (Cooper-Climax). Stan Jones, the father of F1 World Champion Alan Jones, was third in the championship, using four different cars over the course of the series. Race victories were shared around with Mildren taking three wins. Lukey, Jones and Bill Patterson each took two wins, with single victories going to Jack Brabham, Bib Stillwell and New Zealand Maserati 250F racer Ross Jensen. Jack Brabham later became F1 World Champion 3 times. A steel bottle opener with engraved advertising for Lukey Mufflers Pty Ltd HighettAlong Shaft : LUKEY MUFFLERS / HIGHETT VICTORIA / XL 3641car part manufacturers, lukey mufflers pty ltd, highett, moorabbin, bentleigh, cheltenham, early settlers, bottle openers, steel manufacturer, brabham jack, formula one grand prix champions, jones alan, phillip island car racing track. -

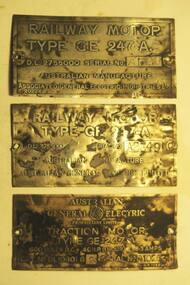

Ballarat Tramway Museum

Ballarat Tramway MuseumSign - Manufacturers plate - GE 247 tram motors, Australian General Electric

... Set of three metal (brass or steel) manufacturers plates... Australian made Set of three metal (brass or steel) manufacturers ...Set of three manufacturer's serial plates from GE 247-A motors used in tramcars. Manufactured in Australia under licence from General Electric of the USA. Known as "railway motors" in the USA. Used extensively in Australian tramway systems. The company changed its name a number of times. 1 - Associated General Electric Industries - Serial Number A1307 2 - Australian General Electric Limited - A2349 3 - Australian General Electric Pty Ltd - A10253 - has the GE logo.Yields information about the Australian Company who made tramway motors in SydneySet of three metal (brass or steel) manufacturers plates for GE 247-A motorsge 247 motors, tramways, trams, motors, general electric, australian made -

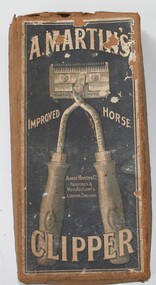

Trafalgar Holden Museum

Trafalgar Holden MuseumFunctional object - Martins Horse Clippers

... On clipper steel arm manufacturers A Martin & co... Improved Horse Clipper Picture of clipper on lid On clipper steel ...Used in the grooming of horses c1900imported and retailed by Holden and FrostHorse clippers inside cardboard presentation box. clipper has wooden handles A Martins Improved Horse Clipper Picture of clipper on lid On clipper steel arm manufacturers A Martin & coequine agricultural, equine civilian -

Wodonga & District Historical Society Inc

Wodonga & District Historical Society IncFunctional object - German Hairclippers, Alcoso Company, c1900 - 1950

... started as steel manufacturers by Alexander Coppel in 1821. Alcoso... as steel manufacturers by Alexander Coppel in 1821. Alcoso ...Hair and beard clipping was frequently carried out at home prior to WW11 and often much later in rural areas. Manual hair clippers were readily available for purchase. The Alcoso company started as steel manufacturers by Alexander Coppel in 1821. Alcoso is an acronym for Alexander Coppel Solingen. They were very successful and opened a second manufacturing facility sometime in the 1850s. They manufactured pipes, rolled steel, wire, tableware, daggers, swords, knives and razors. They started manufacturing razors in the 1850s. The company is most famous for their swords. The Coppel family that Alexander donated millions of marks to charity including building an orphanage, a school for the disadvantaged, and a recreation centre. They headed various social rights groups. They were leading citizens of Solingen. The family was Jewish and the company was Aryanized in 1936. Alexander Coppel and his family were sent to a concentration camp in 1941 along with the remaining Solingen Jews. He died there of starvation in 1942 at the age of 77.This kind of hair clippers were a common household item in the early 20th century. They are representative of an important Jewish company prior to WW2.2 sets of hairclippers made from steel alloy. The arms of the clippers are hinged and can be adjusted with a wing screw. The arms are squeezed together and released. like scissors to operate,On box lid: "Haarschneide-Maschine/ Hairclipper/ "Alcoso"/ Solingen / Tondeuse/ Maquina para cortar el pelo" Translation hair cutting machinehair clippers, alcoso company, alexander coppe, personal items -

Anglesea and District Historical Society

Anglesea and District Historical SocietyHorse Clipper and Box, Albert Martin & Co, Estimated 20th century

... / Manufacturers on steel: A Martin & Co / Manufacturers on blade... on steel: A Martin & Co / Manufacturers on blade: A. Martin's ...1. Clippers, manual: Steel handles with wooden grips, attached by brass fitments. On wood: Albert Martin & Co / London / Manufacturers on steel: A Martin & Co / Manufacturers on blade: A. Martin's / Improved. 2. Box: Cardboard with blue and black printing: A. Martin's / Improved Horse / Clipper. 3. Label on box printed by Johnson Riddle & Co, London. 6/- (handwritten on edge of box).albert martin & co, animal husbandry, johnson riddle & co -

Coal Creek Community Park & Museum

Coal Creek Community Park & MuseumInk bottle, Simpson's Ink Pty Ltd

... and with steel nibs. Sole manufacturer Simpson's Ink Pty Ltd. Australia.... and with steel nibs. Sole manufacturer Simpson's Ink Pty Ltd. Australia ...Square bottle of red ink with screw in cork lid and red, blue and yellow label.Simpson's Celebrated Writing Ink. This is made specially to flow freely with all standard makes of fountain pen and with steel nibs. Sole manufacturer Simpson's Ink Pty Ltd. Australia. -

Coal Creek Community Park & Museum

Coal Creek Community Park & MuseumInk bottle, Simpson's Ink Pty Ltd

... and with steel nibs. Sole manufacturer Simpson's Ink Pty Ltd. Australia.... of fountain pen and with steel nibs. Sole manufacturer Simpson's Ink ...Square shaped glass bottle with brown plastic lid and blue, red and white label.Simpson's Celebrated Green Writing Ink. This is made specially to flow freely with all standard makes of fountain pen and with steel nibs. Sole manufacturer Simpson's Ink Pty Ltd. Australia. -

Coal Creek Community Park & Museum

Coal Creek Community Park & MuseumInk bottle, Simpson's Ink Pty Ltd

... and with steel nibs. Sole manufacturer Simpson's Ink Pty Ltd. Australia.... of fountain pen and with steel nibs. Sole manufacturer Simpson's Ink ...Square glass bottle containing ink with an aluminium screw top.Simpson's Celebrated Violet Writing Ink. This is made specially to flow freely with all standard makes of fountain pen and with steel nibs. Sole manufacturer Simpson's Ink Pty Ltd. Australia. -

Coal Creek Community Park & Museum

Coal Creek Community Park & MuseumInk bottle, Simpson's Ink Pty Ltd

... of fountain pen and with steel nibs. Sole manufacturer Simpson's Ink... standard makes of fountain pen and with steel nibs. Sole ...Square glass bottle with pouring spout containing red ink, with a red, blue and cream label.20 oz. Established 1894. Simpson's Celebrated Writing Ink. This is made specially to flow freely with all standard makes of fountain pen and with steel nibs. Sole manufacturer Simpson's Ink Pty Ltd. Australia. -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Sharpening Steel

... ; manufacturers replaced steels with ceramic (and later, manufactured... steel are able to remove small amounts of metal via adhesive ...A honing steel, sometimes referred to as a sharpening steel, whet steel, sharpening stick, sharpening rod, butcher's steel, and chef's steel, is a rod of steel, ceramic or diamond-coated steel used to restore keenness to dulled blade edges. They are flat, oval, or round in cross-section and up to 30 centimetres (1 ft) long. The steel and ceramic honing steels may have longitudinal ridges, whereas the diamond-coated steels are smooth but embedded with abrasive diamond particles. Non-abrasive honing rods such as smooth ceramic or ribbed steel are able to remove small amounts of metal via adhesive wear. In normal use, the rod is applied to the blade at a slightly higher angle than that of the bevel, resulting in the formation of a micro-bevel. The term "hone" is associated with light maintenance performed on a blade without the effort and precision normally associated with sharpening, so the name "hone" was borrowed. In the 1980s, ceramic abrasives became increasingly popular and proved an equal, if not superior, method for accomplishing the same daily maintenance tasks; manufacturers replaced steels with ceramic (and later, manufactured diamond abrasive) sharpening "steels" that were actually hones. Use Honing steels are used by lightly placing the near edge of the blade against the base of the steel, then sliding the blade away from yourself along the steel while moving it down – the blade moves diagonally, while the steel remains stationary. This should be done with the blade held at an angle to the steel, usually about 20°, and repeating on the opposite side at the same angle. This is repeated five to ten times per side. Steeling It is often recommended that steeling be performed immediately before or after using a knife and can be done daily. By contrast, knives are generally sharpened much less frequently. A traditional smooth honing steel is of no use if the edge is blunt, because it removes no material; instead it fixes deformations along the edge of a sharp blade, technically known as burnishing. There has long been speculation about the efficacy of steeling (re-aligning the edge) vs honing (removing minor deformation with abrasives); studies tend to favour abrasives for daily maintenance, especially in high-carbide-volume "stainless" steels (such as the popular CPM S30V steel, which tends to "tear out" when steeled rather than re-forming an edge.) Small honing steel for outdoor activities Usage trends Steels have traditionally been used in the West, especially in heavy-use scenarios (e.g. butchering, where the edge deforms due to forceful contact with bone). These scenarios also lead Western trends toward blades tempered to a lower level of hardness (and thus lower brittleness). In East Asia, notably Japan, harder knives are preferred, so there is little need for steeling intra-day, as the edge does not deform as much. Instead, the blade is honed as needed on a waterstone. While tradition has kept the practice of steeling alive in Western kitchens, the majority of honing steels sold are abrasive rather than smooth, and knives are harder and more frequently made of stainless steel, which does not respond to traditional steeling techniques as well as high-carbon/low alloy tool steels.The sharpening steel is essential to maintain the sharpness of carving and other knives.Steel knife sharpener with bone handle. Part of a carving set.None.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, sharpening steel, carving set, kitchen equipment -

Orbost & District Historical Society

Orbost & District Historical Societybutton accordion, 1930's

This instrument was given to Allan White on 24.8.1935 by his grandfather. Allan White came to Orbost in 1946. He was firstly a share fvarmer on 3 farms then in business - saddler and bike shop with his brother Eric. Then withG.P. Motors as the RACV man. Allan was a "ham radio" operator and involved with Rotary, Rifle and Bowling clubs, also with the Presbyterian Church.A Mezon button accordion with a tan coloured canite carrying case. it has 3 bass valves and 10 treble valves.On front of case : MEZON Superior Manufacturer On accordion : MEZON accordion Made in Germany On end : steel reeds Hand engraved : 24.8.35 Corner pieces : MEZON Trade mark Made in Saxony musical-instrument button-accordion white-allan -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Leg Vice, Mid 19th Century

The blacksmith leg vise is also called the "solid box vise" and is one of the most important tools in the blacksmith's shop. It firmly holds hot iron while it is hammered, chiseled, or twisted. These are the only vises that are designed to take this kind of use day in and day out. A small 30-pound blacksmith's vise can survive pounding that would wreck a much heavier cast iron bench model. Three things make a blacksmith's vice special. One is that they are forgings, not cast iron or ductile iron. The second is the leg that provides support to the floor or from a sunken post. The last is the hinge, while not a perfect way to construct a vice the pin joint is durable and can take a considerable beating. If sheared it is easy to replace. These things all combine into a tool that can take decades of heavy use and abuse. Most in use is one to two hundred years old.Some of these vises were made by specialists such as Atwood of Stourbridge England, Steel City and Columbian in the U.S. and others were made in anvil manufacturing plants such as "Mousehole Forge" and "Peter Wright" in England and "Fisher-Norris" and others in North America. The design of these vises right down to the last chamfer seems to have been perfected in the 1600s and remained more or less the same until the 20th century. The bodies are forged wrought iron or mild steel and they have hard steel surfaces welded into the jaws. The jaws have little or very shallow serrations which are generally worn off.Around the turn of the 20th Century during the hey-day of the blacksmith shop in North America, these tools were considered so standard a commodity that they were sold without reference to the manufacturer. Very few were even marked with the maker's name. Size is best defined by weight as there is some variation in jaw size from manufacturer to manufacturer. They were sold by the pound and are still best judged by the pound.A vintage tool used in a Blacksmiths shop during the early 19th century to the beginning of the 20th century. Regarded as a significant into social history of the time.Leg Vice attached with screws to bench via a block of wood. Has large metal pole which practically reaches the floor. Also has a metal device to either tighten or slacken vice.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDrill Press, early to mid-20th century

This post drill press has been made by Melbourne business, Dawn Manufacturing Company. It can be operated manually or by a pulley driven flywheel, with the aid of an engine connected to a power supply. In the late 1800s early 1900s a drill press like this would have been driven by steam from a boiler, the main power source for manufacturer’s power at that time. Dawn’s Golden Anniversary 1917-1967 Catalogue describes this model 611 drill as … “Ruggedly constructed with accurately reamed bearings. The coupling between the main spindle and feed screw engages the full circumference of the spindle, and embraces a ball-bearing thrust race. The pillar, as in all “Dawn Drilling Machines” is a solid bright steel bar, in place of the usual light tubing. Adjustable automatic feed.” And “F. & l. Pulleys extra, if required”. DAWN MANUFACTURING CO. The Dawn Manufacturing Co. was founded in Coburg, Melbourne, in 1917 by the four Blake brothers, who were all engineers. After World War I Dawn was supplying drills Australia wide and the company was growing at a healthy rate. During the depression they remained busy, with employees working 60-80 hour weeks. Dawn was contracted to supply vices and clamps to the Australian Defence Department and munitions factory during the World War II. - 1959 the company was taken over by G.N. Raymond Group. - 1967 the Dawn Manufacturing Co. had distributors in Australia and overseas, including USA, Canada, New Zealand, Asia and the Middle East. - 1973 the Siddons Ramset Limited acquired Dawn. - December 1991, Dawn became a unit of the United States owned Stanley Works Pty. Ltd. - November 1998 Dawn became 100 per cent Australian owned. The drill is a typical tool of a blacksmith, cart wright, wheelwright and garage business. It is an example of the tools of the blacksmiths’ trade in Victoria in the early to mid-20th century.Post type drill press machine with gear driven flywheel. Drill press is attached to a post and is fitted with a pulley belt and will run at a speed of maxim 200 r.p.m. The machine can also be manually operated. It has an aperture in the centre, a chuck, for the drill bit and has two metal handles at the centre, on the right hand side. Gear ratio 2:1 main drive, 6" diam, 3:1 reduction gear. Made by Dawn of Melbourne, Australia. Model No. 611, Code No. 9157"DAWN MFG COY”, “MELB. AUSTRALIA", " 611"flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, blacksmiths, blacksmith’s drill, blacksmith tools, dawn drill model no. 611, dawn drill code no. 9157, dawn manufacturing coy melbourne, dawn manufacturing coy coburg, dawn post drill, drilling machine, drill with gear driven flywheel, forging tool, metal working tool, post drill, steam powered drill, trade tool, warrnambool district 1900s -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Wood moulding Plane, Auburn Tool Company, 1870 to 1893

Moulding Plane: A moulding plane is a specialised plane used for making the complex shapes found in wooden mouldings that are used to decorate furniture or other wooden object. Traditionally, moulding planes were blocks of wear resistant hardwood, often beech or maple, which were worked to the shape of the intended moulding. The blade, or iron was likewise formed to the intended moulding profile and secured in the body of the plane with a wooden wedge. A traditional cabinetmakers shop might have many, perhaps hundreds, of moulding planes for the full range of work to be performed. Large crown mouldings required planes of six or more inches in width, which demanded great strength to push and often had additional peg handles on the sides, allowing the craftsman's apprentice or other worker to pull the plane ahead of the master who guided it. Auburn Tool Company: The Auburn Tool Company is known to exist from 1864 to 1893. George Casey reorganized the firm of Casey, Clark and Company as a joint-stock company in 1864, under the company name of Auburn Tool Company. The 1865 New York State Census noted the firm as a manufacturer of the plane, plane irons, and skates. The production that year was listed as 30,000 pairs of skates and 35,000 planes along with 25,000 dozen plane irons. The plane irons carried the trademark "Thistle". Both skates and plane irons were made from welded wrought iron and cast steel. The Auburn Tool Company was among the five leading plane manufacturing firms existing in the mid to late 19th century USA. Others were: H. Chapin's Son; Greenfield Tool Company; and Sandusky Tool Company. Auburn Tool Company, with these others, was also a founding member of the Plane Makers Association, organized around 1858 to fix prices. Most of the companies tools were manufactured by prisoners and in 1866 the firm was outbid for prison labour by J M Easterly and Co. After losing the contract with the prison authority they constructed a new building and continued in the plane manufacturing business with private labour. The 1870 US Census reported the firm had 21 machines, driven by water power, employing 66 males, producing annual products valued at us$70, 000. After A. Howland and Company was dissolved in 1874, the Auburn Tool Company again resumed using contract labour at the State Prison until 1877. The Auburn Tool Company merged with the Ohio Tool Company of Columbus, Ohio, on Nov 14, 1893. Although plane manufacturing was continued at Auburn until after 1907, after this merger the firm went under the name of the Ohio Tool Company. A significant item from the mid to late 19th century that today is quite rare and sought after by collectors. It gives us a snapshot of how furniture was made predominately by hand and with tools that were themselves hand made shows the craftsmanship used to make such a unique item. It also gives an insight into how many manufacturing companies bid for the rights to use prison labour to make their products at this time in our history. Decorative wood Moulding, plane Round type Auburn New York. Owner A Neudt Size 14 flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageBinnacle, Early to mid 20th Century

Mr John Wilson Gillie was born on the 31st of March 1864. On the 31st of July 1880 he was apprenticed for four years to J.J. Wilson and Sons, Nautical Instrument Makers of Sunderland. Following the apprenticeship he spent six months to a year as an ‘improver’ in Glasgow, and then started a new company ‘Wilson and Gillie’ in North Shields. At this time sail had just given way to steam and wooden ships to steel, and the railways were competing with colliers for the carrying of coal from the North East of England to London and the South. In 1858 only seven out of 44 shipyards on the Tyne were using iron, but by 1862 there were ten, employing around 4,000 men. These changes had a significant effect on nautical instrument manufacturers, as the magnetic compass for a wooden sailing vessel was very simple and required little in the way of compensation. For steel vessels much more was required and this was a period of great development, both in the compass bowl and the binnacle in which it was housed. In 1870 Sir William Thomson (later Lord Kelvin) designed his dry card standard compass, which completely replaced all previous designs. Wilson and Gillie started as agents for the Thomson compass, but later J.W. Gillie, using similar principles, redesigned the compass suspension and patented the ‘UNIT’ standard compass. It became popular with local shipowners and shipbuilders. In 1910 the firm of John Lilley and Son (which had been established in London in 1812), found themselves in financial difficulties and were saved with the help of John Wilson Gillie, who established, on the 8th of August 1911, a new firm of John Lilley and Son Limited. John Lilley and Son had been the sole London agents for Sir William Thomson, a very enviable position during this period, when the Thomson compass led the field. Unfortunately, Mr. Lilley had quarreled with the Glasgow company, who withdrew the agency and established their own branch in London (later to become Kelvin White and Hutton). On November 7th 1913, the firm of John Lilley and Son Limited of London amalgamated with Wilson and Gillie of North Shields, and after this date instruments manufactured by the two companies bore the name John Lilley and Son Limited of London and North Shields. During the 1930s many of the London nautical instrument makers were in difficulties, including John Lilley and Son Limited and Reynolds and Son, Dobbie and Clyde Limited, and Mr. J.W. Gillie arranged an amalgamation between these two companies. The new firm became Lilley and Reynolds Limited. In 1943, with estate duties in mind, the North Shields company was reconstituted and took the name of John Lilley and Gillie Limited, although the shareholders, directors and personnel remained unchanged In the early 1970s Lilley and Gillie developed close links with Observator in Rotterdam, who manufactured one of the first fully reliable transmitting magnetic compass systems. The Observator shareholders, Holland America Line, bought the share capital of John Lilley and Gillie Limited., but retained all the personnel and the directors. (See Links for more information)A significant item of early 20th century marine navigational equipment made by a leading manufacturer in the field from a company that is still producing marine navigational instruments today. John Lilleys company began in 1812 growing at a time when the transition of compasses from timber ships, to steel vessels. Compasses at this time required a method of compensation to allow their inclusion in steel vessels without magnetic deviation. This therefore was a period of great development, both in the compass bowl and the binnacle in which it was housed and the Lilley company were leaders in the field. Ships binnacle, wood with brass fittings, consists of 2 brass lamp holders, place for compass, Also has an inclinometer with a scale 40 to 0 to 40, one red and one green iron Kelvin compensation balls, one on each side of binnacle denoting port and starboard, a brass cylinder attached perpendicular at the rear for storing a Flinders Bar, 2 hinged cupboards containing adjustable wooden racks with drilled holes in them to hold iron Heeling error magnets.Textured brass plate attached to front stating "JOHN LILLEY & SON LTD (WILSON & GILLIE), NAUTICAL INSTRUMENT MAKERS, NORTH SHIELDS" . Inclinometer has "JOHN LILLEY & SON LTD (Wilson & Gillie) LONDON & NORTH SHIELDS" engraved. flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, binnacle, john lillie & son ltd, compass -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageContainer - Medical container, Late 19th century or early 20th century

THE DISCOVERY OF STAINLESS STEEL Harry Brearley Since the dawn of man colonies have raced against each other to uncover new technologies, to be the first to stamp their names on a discovery, and although we’ve evolved over millions of years, the urge to be the first remains at the very core of our nature. This sense of passion and pride can lead some of the more unscrupulous humans to claim others discoveries as their own. Of course many breakthroughs are genuinely made in tandem, or are simultaneously occurring, but unless you can categorically prove that you were the pioneer of these incredible findings, then the other party involved will always dispute the fact. And so we come to stainless steel. The first point to note is that ‘inventor’ is a very ambiguous term. Is this the first person to think, to document, to patent, or to produce? The second point is that stainless steel wasn’t truly defined until 1911, so are we to cast aside those chromium-iron alloys that don’t quite meet the minimum requirement of 10.5% chromium? It seems like anyone and everyone has a different claim to being labelled the ‘inventor’ of stainless steel; from Britain, Germany, France, Poland, the U.S.A., and even Sweden. The cogs were set in motion by Englishmen Stoddart and Faraday circa 1820 and Frenchman Pierre Berthier in 1821. These scientists, among others, noted that iron-chromium alloys were more resistant to attack by certain acids, but tests were only carried out on low chromium content alloys. Attempts to produce higher chromium alloys failed primarily because of scientists not understanding the importance of low carbon content. In 1872 another pair of Englishmen, Woods and Clark, filed for patent of an acid and weather resistant iron alloy containing 30-35% chromium and 2% tungsten, effectively the first ever patent on what would now be considered a stainless steel. However, the real development came in 1875 when a Frenchman named Brustlein detailed the importance of low carbon content in successfully making stainless steel. Brustlein pointed out that in order to create an alloy with a high percentage of chromium, the carbon content must remain below around 0.15%. Thus ensued two decades of stagnation for the development of stainless steel, and while many scientists attempted to create a low carbon stainless steel, none succeeded. Hans Goldschmidt It wasn’t until 1895, when Hans Goldschmidt of Germany developed the aluminothermic reduction process for producing carbon-free chromium, that development of stainless steels became a reality. In 1904 French Scientist Leon Guillet undertook extensive research on many iron-chromium alloys. Guillet’s work included studies on the composition of what would now be known as 410, 420, 442, 446 and 440-C. In 1906 Guillet went on to analyse iron-nickel-chrome alloys, which would now be considered the basics of the 300 series. However, while noting the chemical composition of his alloys, Guillet failed to acknowledge the potential corrosion resistance of his materials. Albert Portevin In 1909 Englishman Giesen published an in-depth work regarding chromium-nickel steels, while the French national, Portevin, studied what is now regarded as 430 stainless steel. However, it wasn’t until 1911 that the importance of a minimum chromium content was discovered by Germans P. Monnartz and W. Borchers. Monnartz and Borchers discovered the correlation between chromium content and corrosion resistance, stating that there was a significant boost in corrosion resistance when at least 10.5% chromium was present. The pair also published detailed works on the effects of molybdenum on corrosion resistance. It is at this point we introduce Harry Brearley, born in Sheffield, England in 1871, he was appointed lead researcher at Brown Firth Laboratories in 1908. In 1912 Brearley was given a task by a small arms manufacturer who wished to prolong the life of their gun barrels which were eroding away too quickly. Brearley set out to create an erosion resistant steel, not a corrosion resistant one, and began experimenting with steel alloys containing chromium. During these experiments Brearley made several variations of his alloys, ranging from 6% to 15% chromium with differing levels of carbon. On the 13th August 1913 Brearley created a steel with 12.8% chromium and 0.24% carbon, argued to be the first ever stainless steel. The circumstances in which Brearley discovered stainless steel are covered in myth; some enchanted tales of Brearley recite him tossing his steel into the rubbish, only to notice later that the steel hadn’t rusted to the extent of its counterparts, much like Alexander Fleming’s experience 15 years later. Other more plausible, (but less attractive), accounts claim it was necessary for Brearley to etch his steels with nitric acid and examine them under a microscope in order to analyse their potential resistance to chemical attack. Brearley found that his new steel resisted these chemical attacks and proceeded to test the sample with other agents, including lemon juice and vinegar. Brearley was astounded to find that his alloys were still highly resistant, and immediately recognised the potential for his steel within the cutlery industry. The Half Moon Brearley struggled to win the support of his employers, instead choosing to produce his new steel at local cutler R. F. Mosley. He found difficulty producing knife blades in the new steel that did not rust or stain and turned to his old school friend, Ernest Stuart, Cutlery Manager at Mosley’s Portland Works, for help. Within 3 weeks, Stuart had perfected the hardening process for knives. Brearley had initially decided to name his invention ‘Rustless Steel’, but Stuart, dubbed it ‘Stainless Steel’ after testing the material in a vinegar solution, and the name stuck. And that’s how Harry Brearley discovered stainless steel…. well, not quite… During the 5 year period between 1908 and Brearley’s discovery in 1913 many other scientists and metallurgists have potential claims to Brearley’s title. In 1908 the Germans entered the fray, the Krupp Iron Works in Germany produced a chrome-nickel steel for the hull of the Germania yacht. The Half Moon, as the yacht is now known, has a rich history and currently lies on the seabed off the east coast of Florida. Whether the steel contains the minimum 10.5% chromium content remains inconclusive. Employees of the Krupp works, Eduard Maurer and Benno Strauss, also worked from 1912-1914 on developing austenitic steels using <1% carbon, <20% nickel and 15-40% chromium. Not happy with Europe hogging the glory, the USA got in on the act. Firstly, Elwood Haynes, after becoming disenchanted at his rusty razor, set out to create a corrosion resistant steel, which he supposedly succeeded in doing during 1911. Two other Americans, Becket and Dantsizen, worked on ferritic stainless steels, containing 14-16% chromium and 0.07-0.15% carbon, in the years 1911-1914. Elwood Haynes During 1912 Max Mauermann of Poland is rumoured to have created the first stainless steel, which he later presented to the public during the Adria exhibition in Vienna, 1913. Finally, a recently discovered article, which was published in a Swedish hunting and fishing magazine in 1913, discusses a steel used for gun barrels, (sound familiar?), which seems to resemble stainless steel. Although this is purely speculation, the Swedes have still made an audacious claim that they were in fact responsible for the first practical application for stainless steel. That concludes the shambolic discovery of stainless steel! Although there is much mystery and speculation behind the discovery of this wonderful material, there is no question that without the combined effort of all the above scientists and metallurgists, (and all the many more that were not mentioned), we would not have such a rich and versatile metal at our fingertips. https://bssa.org.uk/bssa_articles/the-discovery-of-stainless-steel/#:~:text=On%20the%2013th%20August%201913,the%20first%20ever%20stainless%20steel. This stainless steel container was donated to Flagstaff Hill Maritime Village by the family of Doctor William Roy Angus, Surgeon and Oculist. It is part of the “W.R. Angus Collection” that includes historical medical equipment, surgical instruments and material once belonging to Dr Edward Ryan and Dr Thomas Francis Ryan, (both of Nhill, Victoria) as well as Dr Angus’ own belongings. The Collection’s history spans the medical practices of the two Doctors Ryan, from 1885-1926 plus that of Dr Angus, up until 1969. ABOUT THE “W.R.ANGUS COLLECTION” Doctor William Roy Angus M.B., B.S., Adel., 1923, F.R.C.S. Edin.,1928 (also known as Dr Roy Angus) was born in Murrumbeena, Victoria in 1901 and lived until 1970. He qualified as a doctor in 1923 at University of Adelaide, was Resident Medical Officer at the Royal Adelaide Hospital in 1924 and for a period was house surgeon to Sir (then Mr.) Henry Simpson Newland. Dr Angus was briefly an Assistant to Dr Riddell of Kapunda, then commenced private practice at Curramulka, Yorke Peninsula, SA, where he was physician, surgeon and chemist. In 1926, he was appointed as new Medical Assistant to Dr Thomas Francis Ryan (T.F. Ryan, or Tom), in Nhill, Victoria, where his experiences included radiology and pharmacy. In 1927 he was Acting House Surgeon in Dr Tom Ryan’s absence. Dr Angus had become engaged to Gladys Forsyth and they decided he would take time to further his studies overseas in the UK in 1927. He studied at London University College Hospital and at Edinburgh Royal Infirmary and in 1928, was awarded FRCS (Fellow from the Royal College of Surgeons), Edinburgh. He worked his passage back to Australia as a Ship’s Surgeon on the on the Australian Commonwealth Line’s T.S.S. Largs Bay. Dr Angus married Gladys in 1929, in Ballarat. (They went on to have one son (Graham 1932, born in SA) and two daughters (Helen (died 12/07/1996) and Berenice (Berry), both born at Mira, Nhill ) Dr Angus was a ‘flying doctor’ for the A.I.M. (Australian Inland Ministry) Aerial Medical Service in 1928 . The organisation began in South Australia through the Presbyterian Church in that year, with its first station being in the remote town of Oodnadatta, where Dr Angus was stationed. He was locum tenens there on North-South Railway at 21 Mile Camp. He took up this ‘flying doctor’ position in response to a call from Dr John Flynn; the organisation was later known as the Flying Doctor Service, then the Royal Flying Doctor Service. A lot of his work during this time involved dental surgery also. Between 1928-1932 he was surgeon at the Curramulka Hospital, Yorke Peninsula, South Australia. In 1933 Dr Angus returned to Nhill where he’d previously worked as Medical Assistant and purchased a share of the Nelson Street practice and Mira hospital from Dr Les Middleton one of the Middleton Brothers, the current owners of what was once Dr Tom Ryan’s practice. Dr L Middleton was House Surgeon to the Nhill Hospital 1926-1933, when he resigned. [Dr Tom Ryan’s practice had originally belonged to his older brother Dr Edward Ryan, who came to Nhill in 1885. Dr Edward saw patients at his rooms, firstly in Victoria Street and in 1886 in Nelson Street, until 1901. The Nelson Street practice also had a 2 bed ward, called Mira Private Hospital ). Dr Edward Ryan was House Surgeon at the Nhill Hospital 1884-1902 . He also had occasions where he successfully performed veterinary surgery for the local farmers too. Dr Tom Ryan then purchased the practice from his brother in 1901. Both Dr Edward and Dr Tom Ryan work as surgeons included eye surgery. Dr Tom Ryan performed many of his operations in the Mira private hospital on his premises. He too was House Surgeon at the Nhill Hospital 1902-1926. Dr Tom Ryan had one of the only two pieces of radiology equipment in Victoria during his practicing years – The Royal Melbourne Hospital had the other one. Over the years Dr Tom Ryan gradually set up what was effectively a training school for country general-practitioner-surgeons. Each patient was carefully examined, including using the X-ray machine, and any surgery was discussed and planned with Dr Ryan’s assistants several days in advance. Dr Angus gained experience in using the X-ray machine there during his time as assistant to Dr Ryan. Dr Tom Ryan moved from Nhill in 1926. He became a Fellow of the Royal Australasian College of Surgeons in 1927, soon after its formation, a rare accolade for a doctor outside any of the major cities. He remained a bachelor and died suddenly on 7th Dec 1955, aged 91, at his home in Ararat. Scholarships and prizes are still awarded to medical students in the honour of Dr T.F. Ryan and his father, Dr Michael Ryan, and brother, John Patrick Ryan. ] When Dr Angus bought into the Nelson Street premises in Nhill he was also appointed as the Nhill Hospital’s Honorary House Surgeon 1933-1938. His practitioner’s plate from his Nhill surgery states “HOURS Daily, except Tuesdays, Fridays and Saturday afternoons, 9-10am, 2-4pm, 7-8pm. Sundays by appointment”. This plate is now mounted on the doorway to the Port Medical Office at Flagstaff Hill Maritime Village, Warrnambool. Dr Edward Ryan and Dr Tom Ryan had an extensive collection of historical medical equipment and materials spanning 1884-1926 and when Dr Angus took up practice in their old premises he obtained this collection, a large part of which is now on display at the Port Medical Office at Flagstaff Hill Maritime Village in Warrnambool. During his time in Nhill Dr Angus was involved in the merging of the Mira Hospital and Nhill Public Hospital into one public hospital and the property titles passed on to Nhill Hospital in 1939. In 1939 Dr Angus and his family moved to Warrnambool where he purchased “Birchwood,” the 1852 home and medical practice of Dr John Hunter Henderson, at 214 Koroit Street. (This property was sold in1965 to the State Government and is now the site of the Warrnambool Police Station. ). The Angus family was able to afford gardeners, cooks and maids; their home was a popular place for visiting dignitaries to stay whilst visiting Warrnambool. Dr Angus had his own silk worm farm at home in a Mulberry tree. His young daughter used his centrifuge for spinning the silk. Dr Angus was appointed on a part-time basis as Port Medical Officer (Health Officer) in Warrnambool and held this position until the 1940’s when the government no longer required the service of a Port Medical Officer in Warrnambool; he was thus Warrnambool’s last serving Port Medical Officer. (The duties of a Port Medical Officer were outlined by the Colonial Secretary on 21st June, 1839 under the terms of the Quarantine Act. Masters of immigrant ships arriving in port reported incidents of diseases, illness and death and the Port Medical Officer made a decision on whether the ship required Quarantine and for how long, in this way preventing contagious illness from spreading from new immigrants to the residents already in the colony.) Dr Angus was a member of the Australian Medical Association, for 35 years and surgeon at the Warrnambool Base Hospital 1939-1942, He served as a Surgeon Captain during WWII1942-45, in Ballarat, Victoria, and in Bonegilla, N.S.W., completing his service just before the end of the war due to suffering from a heart attack. During his convalescence he carved an intricate and ‘most artistic’ chess set from the material that dentures were made from. He then studied ophthalmology at the Royal Melbourne Eye and Ear Hospital and created cosmetically superior artificial eyes by pioneering using the intrascleral cartilage. Angus received accolades from the Ophthalmological Society of Australasia for this work. He returned to Warrnambool to commence practice as an ophthalmologist, pioneering in artificial eye improvements. He was Honorary Consultant Ophthalmologist to Warrnambool Base Hospital for 31 years. He made monthly visits to Portland as a visiting surgeon, to perform eye surgery. He represented the Victorian South-West subdivision of the Australian Medical Association as its secretary between 1949 and 1956 and as chairman from 1956 to 1958. In 1968 Dr Angus was elected member of Spain’s Barraquer Institute of Barcelona after his research work in Intrasclearal cartilage grafting, becoming one of the few Australian ophthalmologists to receive this honour, and in the following year presented his final paper on Living Intrasclearal Cartilage Implants at the Inaugural Meeting of the Australian College of Ophthalmologists in Melbourne In his personal life Dr Angus was a Presbyterian and treated Sunday as a Sabbath, a day of rest. He would visit 3 or 4 country patients on a Sunday, taking his children along ‘for the ride’ and to visit with him. Sunday evenings he would play the pianola and sing Scottish songs to his family. One of Dr Angus’ patients was Margaret MacKenzie, author of a book on local shipwrecks that she’d seen as an eye witness from the late 1880’s in Peterborough, Victoria. In the early 1950’s Dr Angus, painted a picture of a shipwreck for the cover jacket of Margaret’s book, Shipwrecks and More Shipwrecks. She was blind in later life and her daughter wrote the actual book for her. Dr Angus and his wife Gladys were very involved in Warrnambool’s society with a strong interest in civic affairs. Their interests included organisations such as Red Cross, Rostrum, Warrnambool and District Historical Society (founding members), Wine and Food Society, Steering Committee for Tertiary Education in Warrnambool, Local National Trust, Good Neighbour Council, Housing Commission Advisory Board, United Services Institute, Legion of Ex-Servicemen, Olympic Pool Committee, Food for Britain Organisation, Warrnambool Hospital, Anti-Cancer Council, Boys’ Club, Charitable Council, National Fitness Council and Air Raid Precautions Group. He was also a member of the Steam Preservation Society and derived much pleasure from a steam traction engine on his farm. He had an interest in people and the community He and his wife Gladys were both involved in the creation of Flagstaff Hill, including the layout of the gardens. After his death (28th March 1970) his family requested his practitioner’s plate, medical instruments and some personal belongings be displayed in the Port Medical Office surgery at Flagstaff Hill Maritime Village, and be called the “W. R. Angus Collection”. The W.R. Angus Collection is significant for still being located at the site it is connected with, Doctor Angus being the last Port Medical Officer in Warrnambool. The collection of medical instruments and other equipment is culturally significant, being an historical example of medicine from late 19th to mid-20th century. Dr Angus assisted Dr Tom Ryan, a pioneer in the use of X-rays and in ocular surgery. Medical box; rectangular stainless steel base and separate lid, from the W.R. Angus Collection.warrnambool, flagstaff hill maritime museum, great ocean road, dr w r angus, dr ryan, surgical instrument, t.s.s. largs bay, warrnambool base hospital, nhill base hospital, mira hospital, flying doctor, medical treatment, stainless steel medical container, medical container, stainless steel -

Bendigo Military Museum

Bendigo Military MuseumAccessory - WHEEL CHAIR MOBILITY AID, Webster Brothers, C.Post WW1

This mobility aid was housed under the old stage area of the Soldiers Memorial Institute building in Pall Mall Bendigo. When the renovations to the building began in late 2016 the Aid was removed and restored by the Bendigo District RSL Men in Sheds program and is now on display in the same building now called Bendigo Military Museum. The Soldiers Memorial was the HQ of the Bendigo RSL Sub Branch. It is not known the origin of the Aid but it was most likely used by disabled Bendigo RSL members post WW1.Three wheeled Mobility Aid. Front wheel is 41cm dia pneumatic, 32mm wide, rear wheel 68cm dia, width 52mm wide. The right wheel axle has a sprocket & chain assembly, the left is free wheeling, both have mud guards. Frame is tubular steel painted reddish colour, the seat and back rest are brown leather, seat sides are timber, there are two timber platforms in front, the top one is adjustable the bottom one is fixed. The chair is steered via a long metal handle fixed to the wheel frame. The right hand side has the sprocket and chain assembly and motion is controlled by turning the handle in a circular motion, only one speed.on the front wheel stem is a transfer. “Webster Brothers Cycle Manufacturers Mitchell Street Bendigo”mobility, aid, wheel chair, brsl, smirsl -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyPortable Resuscitator Electric Therapy Unit

A shock of different voltages was delivered to a person using the two metal handles or two heavy soft wire combs (missing but known of) were moved across the skin. Perhaps this was an early TENS Unit. The unit came to the donor's grandfather (Roy F. Leibig - Chief Electrical Inspector of the Brunswick (Melbourne) Electric Supply) for repair and returned to his keeping once it had become obsolete (upgraded by newer machine). Donor often helped his Pa repair electrical equipment.Historical: The Resuscitator or Electric Therapy Unit was used in hospitals, possibly Mental hospitals. Provenance: The donor worked at Mt Beauty in the Kiewa Hydro Electric Scheme with the State Electric Commission of Victoria as an electrician. Black wooden smooth box with clip fastener which is screwed on - 3 screws for the base and 2 for the lid. On top of the box is a leather strap for the handle fastened by steel screwed into the box. Inside: A mask with attached strap. Tap fitting loosely into steel box. Metal cylinders and a Cardboard box. A wooden lockable case, housing electrical equipment suitable for issuing high voltage shocks.In red, middle of the side with fastener - "SPARKLETS RESUSCITATOR" Scruff marks inside the lid. A cream plastic tag is screwed on and inscribed"Manufacturers:- / SPARKLETS LIMITED / EDMONTON, LONDON, N.18 / Made in ENGLANDmedical, hospital equipment, resuscitator, tawonga district hospital, doctor -

Warrnambool and District Historical Society Inc.

Warrnambool and District Historical Society Inc.Functional object - Portable cycle carbide lamp, Powell & Hanmer, Birmingham, c 1920

This is a removable bicycle lantern probably dating from the first half of the 20th Century. It is a carbide lamp which was a popular form of lighting, particularly in rural areas. This item has no known local provenance but is retained as it is a good example of an early bicycle lamp.This is a brass and steel bicycle lamp. It has a circular glass front, a mechanism for attaching the lamp to the bicycle, a lighting adjustable wick and two glass panels on the side, one green and one red. There is a label with the manufacturer's name on the side. POWELL & HANMER "KINGFISHER" MAKERS, BIRMINGHAMvintage lighting, powell and hanmer -

Warrnambool and District Historical Society Inc.

Warrnambool and District Historical Society Inc.Woodwork, Wood plane, Early 20th century

This hand tool would have been used either in the home for making small items of furniture or small building projects or it could have been used by a tradesman working on small jobs in the building industry – window sills, doors, cupboards etc. Planes are still used today to whittle down wood. This tool has no known local provenance but it is a good example of hand tools of the past and will be useful for display. This is a metal plane used for shaving wood. It has a rectangular base curved at the ends and the end of a steel blade is visible near one end of the base. The handle is dome-shaped and attached to the handle by a screw is a ridged metal wheel that rests on the blade which has been inserted on an angle. This wheel can be turned to adjust the blade, keep it in place or remove it for replacement. The plane is much rusted (it may have been painted black) and no manufacturer’s marks are visiblhousehold tools, wood plane -

Bendigo Military Museum

Bendigo Military MuseumUniform - GAITERS, USA PATTERN, Johnson, Stephens and (Illegible) Shoe Coy. Jeffersonville QM Depot, 1938

This is one pair of 1938 USA Pattern gaiters. They are made of canvas and have a webbing strap that goes under the boot. The buckle fitting is black painted steel. One edge of the gaiter has black printed etelets, the other edge has black metal hoops, There is a cotton bootlace tied to the gaiter. The colour is jungle green. Printed outside - leggings, canvas dismanted M-1938 2R. Plus manufacturers details.ww2, usa gaiters -

J. Ward Museum Complex

J. Ward Museum ComplexEquipment - 'Electroshock Therapy' Machine, Konvulsator 2077, Post 1930's

Electroconvulsive therapy (ECT) was invented in Italy in the late 1930s. ECT is a medical treatment most commonly used in patients with severe major depression or bipolar disorder that has not responded to other treatments. Psychiatrists had already discovered that inducing seizures could relieve symptoms of mental illness. Before ECT, this was done with the use of chemicals, usually one called Metrazol. More can be read here: http://theconversation.com/electroconvulsive-therapy-a-history-of-controversy-but-also-of-help-70938 This machine was used both at Aradale Mental Hospital and J Ward. The object is significant because it is a well preserved instrument that illustrates the medical apparatus used at both Ararat Mental Hospital and J Ward for the treatment of mental illness.A metal instrument. The front contains three knobs, two switches, and power button. Two fully intact electrical cords - One leads to the paddles used on the patient: One used to attach to the electric source [power point]. Paddles are made of hard plastic and stainless steel metal. The back has a compartment where the paddles can be stored. The top has a carry handle.Manufacturer: Siemens Power supply: 220V 85AC, 50Hzmentalhealth, psychiatrichealth, depression, #bipolardisorder -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Pliers, Early 20th Century

In 1887 the long established steel toy business of Richard Timmins and Sons of Pershore Street Birmingham was sold to W C Wynn & sons, of Commercial Street Birmingham. They proceeded to extend their works and eventually concentrated on the amalgamation of both businesses under the name of Wynn and Timmins at the one address in Commercial Street. In 1892 they were incorporated as a Limited Company and by 1914 were known as the manufacturers of hand tools for all trades, iron and steel stampers, die sinker, and in the process of press working in sheet and metal for various items. The company around this time employed 200 people and the directors of the company in 1914 were W. H. Wynn, H. S. Wynn, W. L. Wynn. In 1929 they were producing tools under the heart brand until in 1969 the company was taken over by Balfour and Darwins of Sheffield, and the manufacturing facility in Birmingham was closed.An early manufacture of tradesman's tools, from 1900 into the late 1960s the company was a major suppler of tools to various industries and pioneered a number of improvements for individual hand tools for specific industries.Steel snub nosed pliers designed for a specific use unidentified at this time."WYNN & TIMMINS" stamped into the steel handle tools, pliers, metal pliers, wynn & timmins, birmingham manufacturer, tool manufacturer, richard timmins, sheet metal manufactures -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Cooking pot and lid, T & C Clarke and Co Ltd, 1880 to1910

T & C Clark & Company Limited, based at Shakespeare Foundry, was founded in 1795 by Thomas and Charles Clark and grew to be one of the largest iron foundries in Wolverhampton. The firm was the pioneers of Enamelled Cast ironware and the founder Charles Clerk went on to became mayor of Wolverhampton in 1860 after also serving as a Councilor, Alderman, and later Chief Magistrate. The company exhibited many products at the International Exhibition of 1862 at South Kensington, alongside the gardens of the Royal Horticultural Society. The company was also awarded the silver medal for its products at the International Paris Exhibition in 1878. The company's product range included thousands of items, both domestic and industrial. T & C Clark pioneered the use of enamelled cast ironware, after taking out a patent in 1839 guaranteed to be free of lead or arsenic. In the late 1940s and 1950s the company produced acid-resisting enamelled cast iron boiling pans; steam-jacketed pans; stills; square and rectangular tanks; open and closed mixing vessels; flanged pipes; bends and tees; laboratory equipment; small scale plant; evaporating bowls; beakers; sulphonates; and glass-lined mild steel tanks for beer, mineral water, and food. The company is listed as enamelled chemical plant manufacturers in Kelly's 1962 Wolverhampton Directory, but within a few years, the company had ceased trading. The cooking pot is significant because it demonstrates one of the social norms founded by early settlers to this region. That close ties to "Mother England" and the "establishment" was still very strong. The social and family values from the British way of life was ingrained in colonial society until well past Australian Federation in July of 1900. It was not until the friendly "American soldier" invasion during World War II that the Empire mindset was slowly being eroded away. This change was the slowest in semi remote rural areas such as the Warrnambool district. Cast iron open fire cooking pot with lidCLARK & Co. PATENT", Below this a six star triangle with the letter "C" in the middleflagstaff hill museum, cooking appliance, camp fire pot, cast iron, t & c clark & co, drovers cooking pot -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillagePen Nibs, 1920's

The two cards of nibs are retail display cards of the dip pen nibs that William Mitchell Calligraphy produced, dating back to around the 1920’s, which was the time of the Great Exhibition in the UK. At that time dip pens with steel nibs were the main writing instruments. British Pens Ltd. had recently formed as a company and its subsidiaries included the the company William Mitchell, which is why British Pens Ltd. is named on the cards as well. One card (1) has the Round Hand nib, which is widely used today for calligraphy scripts. The other card (2) has the Script nib that has round upturned points for monocline or unshaded lettering that is also used for calligraphy. The nibs also have a detachable reservoir. The pen nibs are shaped to fit into a slot in the base of a wooden or Bakelite pen holder. The hole at the front of the nib is for collecting ink from a well, which is then stored in a reservoir at the back of the nib. The nibsare stamped with their nib size and Pedigree (what type of nib it is) and maker’s details. William Mitchell Calligraphy still makes these nibs today with a slightly difference finish. (ref: Sales and Marketing Director of William Mitchell Calligraphy in 2016). HISTORY of the Ink Pen Quills and ink were common writing tools until the early 19th century when the pen trade began mass producing steel nibs and pens. The steel nibs each have a hole in the middle that acts like a well for the ink. When the nib is dipped into the ink well the writer needs to ensure that it is dipped to only just past that well. India Ink was one of the most popular inks used with the nib pens, notable for its satin-like smooth flow. This ink is composed of a particularly fine carbon mixed with water; it can also be obtained as a dry stick that is then crushed and mixed with water as required. The Jewellery Quarter of Birmingham had the largest concentration of independent jewellers in Europe. Birmingham became the centre of the world’s pen trade for many years -, during the 1800’s over 100 factories, employing 1000s of skilled workers, manufactured the ‘Birmingham Pen’. ABOUT WILLIAM MITCHELL CALLIGRAPHY LTD.* (*The following text is quoted from the William Mitchell Calligraphy website) British based William Mitchell Calligraphy has been designing and manufacturing exceptional pens for almost 200 years. The William Mitchell heritage in making pen nibs began whilst working with his brother John Mitchell in the early 1820s. William Mitchell established his own business in 1825 to become one of the leading nib manufacturers and famous for lettering pens. Almost 100 years later William Mitchell merged with Hinks, Wells & Co, another pen manufacturer, to form British Pens, employing around 1000 people in the Bearwood Road area of Birmingham. During the early 1960s British Pens acquired the pen business of other pen manufacturers Perry & Co and John Mitchell, once again reuniting the two brothers. Joseph Gillott, who were famous for their artist drawing and mapping nibs, amalgamated with British pens in 1969. William Mitchell and Joseph Gillott established in Birmingham during the early part of the nineteenth century and [their products] are still proudly made here. British Pens were subsequently purchased by its current owner Byron Head, the owner of William Mitchell (Sinkers) in 1982, and was subsequently renamed William Mitchell (calligraphy) Ltd. Established in 1827 Joseph Gillott was one of the pioneers of mass steel pen nib manufacturing. The company was particularly strong in the American market, prompting Elihu Burrit, the American consul, to write “In ten thousand school houses across the American continent between two oceans, a million children are as familiarly acquainted with Joseph Gillott as with Noah Webster” (The compiler of the famous American dictionary). The company consequently received visits from many notable Americans, including president Ulysses S Grant. The early 19th century invention and mass production of pen nibs such these in our collection had a large impact on education and literacy because the nibs could be produced in great numbers and affordable prices.Pen nibs; 2 cards of steel dip pen nibs from the 1920’s. The steel nibs are attached to cards by 2 rows of entwined cotton cord. Reverse sides of cards have some hand written marks. Manufacturer; William Mitchell, Birmingham, England. Card issued by British Pens Ltd. Nibs have shaped ends, a hole in the centre with a well on the underside, and the tops are shaped approximately quarter circle. Inscriptions are pressed into each nib. The script pens have detachable reservoirs made of a metal different to the nib. (Card 1) Round Hand Pens, 11 nibs remain from card of 12. Printed on card “Round Hand Pens for Beautiful Writing, Twelve degrees of point, Square points. William Mitchell, Birmingham, England. This card is issued by British Pens Ltd. MADE IN ENGLAND” Also printed on top left of card is a pen drawing of a person writing at a desk, background of decorative 3-paned window in brick wall. (Card 2) Script Pens; 11 nibs remain from card of 12. “Script pens fitted with detachable reservoir. William Mitchell, Birmingham, England. This card is issued by British Pens Ltd. MADE IN ENGLAND” Also printed on top right of card is a pen drawing of a person writing at a desk, background of decorative 3-paned window in brick wall. On Card 1, - each nib is stamped with its size, and “Wm MITCHELLS / PEDIGREE / ROUND HAND / ENGLAND” - hand written on front bottom of card in ball point pen “Lettering 5 times size of nib” - hand drawn on back of card in red and blue ball point pen are scribbled lines On Card 2 - each nib is stamped with its size, and “WILLIAM / MITCHELLS / SCRIPT PEN / ENGLAND” - a black circle corresponding to the nib is printed on the card above each nib. - hand written on back of card in black felt tip pen are numerals - hand drawn on back, 4 parallel lines in red ball point pen with the numbers “10” between 2 of the lines flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, great ocean road, william mitchell calligraphy ltd, british pens ltd., pen nib, writing implement, dip pen, round hand nib, script nib, birmingham manufacturer, communication in writing, mass produced pen nibs -

Mission to Seafarers Victoria

Mission to Seafarers VictoriaFunctional object - Cigarette Lighter, c. 1950

Possibly acquired by seafarer Mr Arthur Dixon who served in WW2 merchant vessels. The origin of the lighters appears to be Austria and could have been acquired either during or post his war service. Initial research indicates an approximate date of 1950s for date of manufacture.See Donor details 1727-1737.2 Small, cylindrical, fluted, polished, stainless steel cigarette lighters, with flint action. Includes a flint gauge in the ignition unit. Runs on lighter fuel, with inbuilt wick. Accompanying bronze coloured metal case of flints. Manufacturer name embossed on body. Lid incised with cylindrical grip of 4 ridges. Lighter1: PATENT/BORA/EXTRA/MADE IN/AUSTRIA (stamped alongside body of lighter) Lighter2: PATENT/Made/in/Austria/902. At right angles at base of lighter, REL Flints: Thorens (stamped in brand name logo style on body at right angle to lid)cigarette lighters, smoking accessories, arthur dixon, bora cigarette lighter, arthur oswald dixon, sailors, seafarers, seamen, officers, smoking, lighters, bora -

Montmorency–Eltham RSL Sub Branch

Montmorency–Eltham RSL Sub BranchUniform - Helmet, Duperite, 1942

Owned by Sig. L. W. Hanger who enlisted in February 1942 at Caulfield and was discharged in December 1945. Last posting was with 5 Aust. Jungle Trunk Line Maintenance Section with rank of Lance Corporal. Note: Although these helmets were designed for Motorcycle Despatch Riders, they were also widely used by the 1st Australian Parachute Battalion from 1943-1945 due to a lack of available British Steel Airborne Helmets. Despatch rider's helmet made of Duperite (similar to Bakelite) with leather wraparound side and back below helmet. Cloth webbing inside for firm fitting. (See photos for detail of leather wrap and internal webbing). Chinstrap buckle and tongue attached to leather wrap.External front of helmet: ink-stamped Despatch Rider insignia Name (Inside on webbing support): Sig. L.W. Hanger Service Number (Inside on webbing support): VX74482 Manufacturer's Label (inside): Duperite 1942 Made In Australia THIS HELMET IS SUITABLE FOR HEAD SIZES 6 3/4 TO 7 MODEL No. 2200/2 (See photos for more detail of Label) -

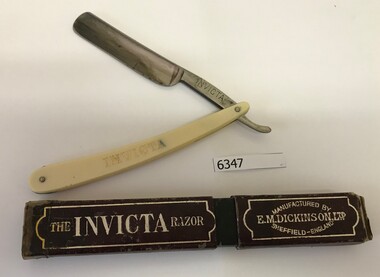

Greensborough Historical Society

Greensborough Historical SocietyCut-throat razor, Invicta Razor, 1900c

This "Invicta" cut-throat razor was owned and used by Osborne (Ozz) Daniel John Hawkins Abbott of Albury, N.S.W."Cut-throat" razor, stainless steel with cream plastic handle in brown cardboard case"Invicta" inscribed on handle and razor; "The Invicta Razor, manufactured by E. M. Dickinson Ltd., Sheffield England" printed in silver on case; Manufacturer's name inscribed on razorrazors, cutthroat razors -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Personal Effects, Cut-throat razor ‘Bengal’, early 20thC

... , steel manufacturers, ‘Bengal’ trade mark, early settlers, market ...Bengal’ THOMAS RADLEY CADMAN & SONS St. Mary's Road, Sheffield In business at least 1892-1919 Originally a trademark of Luke Cadman, Sheffield, England from ca. 1748-1906. From ca. 1906 - 1953, used by: Thomas Radley Cadman & Sons St. Mary's Road, Sheffield. In business at least between 1892 and 1965. The Cadman family originally came from Derbyshire and settled in the village of Eckington, to the south of Sheffield. Luke Cadman (1727-1788) moved to Sheffield in 1740 and became apprenticed into the cutlery trade. He became a freeman of the Cutlers' Company of Hallamshire in 1748 and was granted the trademark "BENGALL". (Another branch of the family was granted the trademark "SENEGALL"). Two of Cadman's sons followed him into the business. The Cadmans' business was located at various addresses in Sheffield over the years. In the early 1870s Thomas Radley Cadman (1833-1917) took over the firm. By 1933 the firm had diversified into safety razor and pocket knife manufacture. T.R.Cadman & Sons, Ltd. ceased trading in 1965. A man's cut-throat razor that folds to protect the blade inside the handle , 'Bengal'on blade 'BENGAL'cut-throat razors, straight razors, shaving equipment, steel blades, sheffield steel, england, thomas radley cadman & sons ltd., cutlers, steel manufacturers, ‘bengal’ trade mark, early settlers, market gardeners, moorabbin, bentleigh, cheltenham,