Showing 23 items matching "switch plate"

-

Federation University Historical Collection

Federation University Historical CollectionElectrical Instrument, Analite Pty Ltd, Electric Switch Plate, c1905

... Electric Switch Plate...switch plate... copper brass connector variable selection analite switch plate ...Instrument probably for variable selection of power options from a solenoid, e.g. lift operation?; light dimming?Brass body with copper switch strips. 'Bakelite'? control buttons. Electric wire screw connector.Analite Pty Ltd, Sydney Melb underneath Numbers 1 to 4 electirc switch, copper, brass, connector, variable selection, analite, switch plate -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyTelephone Handset Field, early 1900s

... switches is a plate with "L (next to the top switch) and below... switches is a plate with "L (next to the top switch) and below ...This field telephone was developed primary for military purposes (World War I) and other wars/military interventions there after. It was the first "mobile" telephone which had a prime objective of providing isolated or "hard" to connect with locations instant communication links. Like a lot of "new" technologies it evolved from a war environment. This handset was used to connect offices and workshops, which due to their functions could not be co-located with their prime office(external workshops).The evolution from the early 1900s to the mid 1980s when mobile communication technology progressed in leaps and bounds from hard wire telephone communication to mobile digital receivers. This handset was manufactured by a subcontracted Australian company under the Australian Post Office mandate.This handset is significant in that it was donated by the Mount Beauty Timber yards and formed an integrated part of its communication system with its out lying work yards and buildings, before the mobile handset evolution. This handset was located in an environment which required a rugged and reliable day to day communications linkage as a vital part of its logistical (business) survival. As progress demands it, the faster that customers are satisfied with the service they obtain from suppliers the longer those services will be asked for and the longer and more profitable the supplier will be. This edict is as true for rural companies as it is for small or large city businesses. The customer is "always" right.This sturdy field telephone has a shell housing made in black bakelite material with a "U" form housing the major components (wiring, magneto and batteries). The main housing has two metal bells, with a central ringer between both, on the top part (to notify incoming calls). In front of the main structure is a box with the telephone hand piece (ear and mouth receptacles) nestled on two cradles. An on/off switch is activated when handset is removed from its cradle. On the front of the control box is a winder handle(to ring off) and in a field situation to activate/deactivate the magneto. To the left of the winder but on the the main body are two wind up connection buttons for the connection of operational wires (power)On the main right hand front body and next to two chrome switches is a plate with "L (next to the top switch) and below this "L2" and underneath this are "or" "EARTH". There is a plate fastened to the front of the handset and behind the winder with "REPLACE HANDSET WHEN FINISHED" and below the winder 'SERIAL NUMBER 5116"field telephone, world war ii field telephone f mk i -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Equipment - Train Departures Signal Device

... Metal plate with switches. Wooden box 1930s. Handset... railway stations trains railway signals Metal plate with switches ...Wooden box used to advise other stations - Box Hill and Ringwood when the Mitcham train was departing. Acquired when the Mitcham station was demolished in 2014. Handset altered c. 1970s.Metal plate with switches. Wooden box 1930s. Handset altered C.1970s as used by trains as they departed from Mitcham to Box Hill and Ringwood. Switches Black - Up to Box Hill and Down to Ringwood. Red "UP" Bell to Box Hill Red "Down" Bell To Ringwood To advise the train had left Mitchammitcham, box hill, ringwood, victorian railways, railway stations, trains, railway signals -

Bendigo Military Museum

Bendigo Military MuseumFunctional object - HEATER METERS, ONE SHILLING, Landis & GYRS.A, Pre 1970

... .1) On plate, "Remote Control Switch - for alternating... smirsl Shilling .1) On plate, "Remote Control Switch ....1) This one was used in the Writing room which later became a Meeting room then finally the RSL Building & History room. it was attached to the LH side of the Fire Place and ran an old Electric Heater on the Hearth. It was used up to about 2005. .2) This one was in the Old Kitchen built on the side of the Soldiers Memorial Institute in the mid 1960's This one ran the Electric stoves used by the Womens Auxiliary of the Bendigo RSL and to make the Rum & Coffee for the ANZAC Day Dawn service. The kitchen was removed as part of the Renovations in 2016 - 18..1) Heater meter, metal construction black coating, top face has a glass section with a "usage meter" saying "coins paid, unused", metal plate under with details re numbers, maker, coins per hour, on right side slot for "Shillings only" with knob, removeable lockable tray at bottom for coin storage and removing. .2)Same style as .1) but a different glass face style metering, it has 11 circular dials with one hand, these show "Coins paid, coins unused", this one shows the round meter going around when in use. The only differance between to two shapes is at the top re fixing to a wall..1) On plate, "Remote Control Switch - for alternating switch No 26 204 020 - Type Wik 36.1 - Adjustable 1-6 coins per hour, Adjusted for 1 coin per hour" On stickers, "insert 10 cents - Turn knob to right". .2) On glass section, "230/240 revs per KWH - 1200 - Serial No 8338380 - 5 - 50". On label stuck on, "10 c equals 1/2 hour"brsl, smirsl, shilling -

Glenelg Shire Council Cultural Collection

Glenelg Shire Council Cultural CollectionFunctional object - Light Sensitive Switch, n.d

Port of Portland CollectionFront: attached markers plate LIDINGO AGA SWEDEN VSAA - 10 413199 210 Nr 7628 Back: - -

4th/19th Prince of Wales's Light Horse Regiment Unit History Room

4th/19th Prince of Wales's Light Horse Regiment Unit History RoomTester, Dry Battery, 1957

Tester, Dry Battery, (Aust) No 1 Mk 1. Mounted in wooden hinged case. Meter, selector switch and terminals in one side of case, instruction plate in the other. Leather carrying strap missingCat No Z4/ZDA 0426, Defence Broad Arrow, 1366, FF2 stamped in case, Serial No 341, V1140 painted on casedry battery tester, -

Warrnambool RSL Sub Branch

Warrnambool RSL Sub BranchEquipment - Wireless Set, WW2 AWA (Australia) Wireless Set

tropical theatre WW2Radio Housed in Rectangular metal containerContainer outside on side reads 'Tropical Theatre'. Radio Set, Top- Switch Red plastic screw top, several 'plug-in' points, Metal plate which reads,"WIRELESS SET NO 11 (AUST) SUPPLY UNIT L.P. SERIAL NO 4451 MANUFACTURED IN AUSTRALIA BY A.W.A. LTD DDcommuniction -

Federation University Historical Collection

Federation University Historical CollectionObject, Synchronome Co. Ltd, Synchronome Frequency Checking Master Clock No. 2191, c1930

Information from Norman F. Dalton: Ballarat had a reticulated DC supply in the early part of last century and in 1905 had sufficient generating capacity to enable the trams to be changed from horse drawn to DC electricity. The use of electricity increased with the main power station located on Wendouree Parade, near Webster Street, under the ownership of The Electric Supply Company of Victoria. AC generating plant was installed in 1925 and conversion to AC proceeded. In 1934 the company was taken over by the State Electricity Commission Victoria (SECV) and more AC generation was installed and the changeover of customers was accelerated. This is around the time that the Synchronome Frequency Checking Mast Clock was installed at the Wendouree Parade Power Station. The SECV Annual Report of 1921 states: ::Section 11 of the act directed the COmmission to enquire into the question of securing the adoption of such standards of plant and equipment of a system, frequency and pressure for the generation and distribution of electricity as will admit of the efficient interconnection of undertakings throughout the State. In 1934 when the SECV took over the Ballarat operations the question of linking with the State grid had been a planned operation for some years but due to financial considerations had hindered it and in fact would continue to do so for a further 10 years. So while the need for close frequency control for interconnection was hardly an issue, the need to keep electric clocks correct was important, particularly as this item was a frequent sales point to cover the inconvenience and sometimes expense of converting from DC to AC. The clock is a very accurate pendulum clock with provision for varying effective length during operation for precise time regulation. There are two normal time dials and one is controlled by the pendulum and the other is operated by the system frequency. When the clock was in use it was installed by the MEter and Tests Laboratory and the time was checked daily by radio time signals. The two dials were repeated in the operators control panel in the Power Station. A maximum deviation between the two dials was set in the operating instructions (eg 5 seconds) and the operator would correct this when necessary by remote manual alteration of the turbine governor set point. The clock was used to drive and regulate a system of "slave" clocks which were used to display the time in various locations around the power station. A slave clock is a simple clock which is driven by a small electric motor, its accuracy is regulated by the master clock every 30 seconds to ensure that it and all the other slave clocks in the station are on exactly the right time; slave clocks were placed in various locations, from common rooms to workshops. A master clock could potentially run thousands of slave clocks at one plant. The clock also contains a rectifier. A rectifier is a device that is used to convert AC power to more stable DC current.Two clocks in a timber case. Both are electric, one is powered by the main pendulum mechanism, the other is a self contained electric clock. The main mechanism is of the gravity arm and roller type, which sends an impulse to the slave clocks every 30 seconds. The This Synchronome Frequency Checking Master Clock was used at the Ballarat Power Station. Below the main section of the case is a smaller cabinet containing a rectifier to provide consistent DC power for the clock. The rectifier was made by the Victorian company Hilco, which was located in Burwood. There is a high chance this is not the original rectifier from this clock as there appears to be brackets to hold a larger device in the space the rectifier occupies.Front below main clock face on front of case: "Patented Sychronome Brisbane" Lower left-hand clock face: "Frequency time" Lower right-hand clock face: "Standard Seconds" Synchronous electric clock mechanism on door (Frequency time clock): >200/250 V. 50~ >"Synchronomains" Made in England >Direction indicator for clock starting switch >"To start move lever in direction of arrow and release" >"Patent applied for" Mechanism for "standard seconds" clock: >"English Made" >"Patented" >Serial number "321" >0 above right-hand pillar on front-plate Mechanism for "standard seconds" clock: >"English Made" >"Patented" >Serial number "321" >0 above right-hand pillar on front-plate Mechanism for main clock face: >"English Made" >"Patented" >Serial number "8751" >0 above right-hand pillar on front-plate Inside case, back panel, top enamel plate: >Seconds Battery + Pos. > Battery Common or - Neg. >1/2 min dials Inside case, back panel, bottom enamel plate: external seconds dial Inside case, right hand side, electrical knobs: two switches, both "A.C. mains" Pendulum rod, below suspension spring: Serial number (?) 0000005 Rectifier in bottom cabinet: >"Hilco Rectifier" >"A.C. Volts 230/240" >"Model 1060/S" >"A.C. Amperes" >"Serial No. 1060/S >"Phases 1" >"D.C. Volts 6" >"C.P.S. 50" >"D.C. Amperes 1" >"Made in Australia by Hilco Transformers McIntyre St., Burwood, Victoria." Bakelite electrical plug: makers mark Lower cabinet, RH side panel, pressed tin plate: "AC" (upside down) Brass speed adjustment, outer right RH side: "S" and "F" Ivory and wood pendulum beat ruler: >Ruler, with 0 in centre and numbers 1-5 in ascending order from centre on left and right. > "Synchronome Patent." Steel plate, back panel, inside case, right hand side: >N R A" (descending) >"2191" serial number/part number Face of main clock: "Synchronome Electric" synchronome frequency checking master clock, electricity, state electricity commission, wendouree parade power station, secv, clock, time, pendulum, electric supply company of victoria, norman f. dalton, ballarat power station, rectifier, slave clock -

Federation University Historical Collection

Federation University Historical CollectionEquipment - Electrical Instrument, Moore Reed "Universal" Acoustic Coupler: Type TC301, c1980

The Universal Acoustic Coupler was made and would have been used to connect a telephone to dial a computer remotely. The control panel is under the wooden flap. There is a power switch, full duplex switch, 500 Ma Fuse, CCITT Port. When not in use it can be folded up into a small timber carry case with handle.Wooden box with two sections that open. Top section hinged and folds back. inside are controls and cables for connecting to a computer. Instructions for use are on the lid. Front section has clips and folds down to a phone to placed in "speakers". English maker's plate and Melbourne supplier's plate with A.P.O. Permit No. C74/8/903 Serial No. 775326 moore reed, universal acoustic coupler, telephone, remote connection, computer connection -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Domestic object - Kitchen Equipment, 'Smoothwell' electric flat iron c1935, c1935

c1881 Henry W Seely, of New Jersey, USA, designed and patented an electric sad iron for pressing and smoothing material. He continued to modify and improve his designs, with his partner Richard Dyer, and other electrical appliance firms, e.g Hotpoint, began producing these flat irons that could provide continuous heat by connecting via an electrical flex to a light socket and hence without the need for hot fires, ash, or burning hot handles. Women with access to an electricity supply were delighted and their ironing chore became much less arduous No heat was felt at all from the iron as it is all concentrated on the bottom surface. By the early 20th century enthusiasm was building for the new electric smoothing irons: clean, powerful, adjustable, and labour-saving. This c1935 Premier System 'Smoothwell' flat iron was used by a resident of City of Moorabbin and is an example of the progress made from the sad irons used by the pioneers that are displayed beside it.A "Premier Smoothwell" electric flat iron with switched control lead and original box, c 1935 On plate of handle attached to Iron ' HARRODS Ltd. / LONDON On attached plate at rear of iron ' The "SMOOTHWELL" / "Premier System" /......... Plate on cord Plug " PREMIER/ FLAT IRON CONNECTOR/ THIS SIDE OUTWARDS/ (2 columns) 1) FOR 100-125 VOLTS/ USE THREE TERMINALS/ THUS ..... 2) FOR 200 - 240 VOLTS/ USE TWO RIGHT/ HAND TERMINALS/ ONLY/ THUS......seely henry w., sad irons, electric flat irons, dyer richard, edison thomas, hotpoint pty ltd., premier electric company birmingham england, pioneers, early settlers, moorabbin, bentleigh, cheltenham, laundry, sewing, craftwork, table ware, irons -

Royal Australian and New Zealand College of Obstetricians & Gynaecologists (RANZCOG)

Royal Australian and New Zealand College of Obstetricians & Gynaecologists (RANZCOG)Incubator, neonatal, Australia/ tVictor Watson/Limited/ New Zealand”, late 1950s- early 1960s

This item was purchased at Leski's, Melbourne, Medical collection auction, 8 May 2013. The incubator was part of a rare collection of medical, dental and pharmaceutical objects belonging to a tourism business, Kryal Castle, near Ballarat, Victoria from 1974. At some point,apparently, an officer manager discarded the museum records, so the provenance of the neonatal incubator, and many other items in the Leski auction, has been lost.Neonatal incubator, "Glenleigh", made and used, late 1950s- early 1960s. The four side laminated panels as well as bottom panel are possibly made of asbestos fibreboard,. Each panel is sealed with polished aluminium strips, and has a metal handrail.The incubator is mounted on four castors made by "Shepherd USA'. On the front panel is a bakerlite dial and a bakerlite switch. The item is incomplete: the cover, probably glass, is missing. Inside the unit is an old calico infant's mattress.There are two name plates on the front panel; “Australia/ Victor Watson/Limited/ New Zealand” and "Glenleigh/ Baby Incubator/ Aeronautical & Industrial Lighting Co/ 677-9 North Road Carnegie”. Australia/ Victor Watson/Limited/ New Zealand” "Glenleigh/ Baby Incubator/ Aeronautical & Industrial Lighting Co/ 677-9 North Road Carnegie”. Castors::"Shepherd USA' -

National Wool Museum

National Wool MuseumMachine - Shearing Motor, Sunbeam, 1960-69

With more and more woolsheds being connected to power lines, the need for electric shearing gear markedly increased from the 1960s onwards. The greater economy made electric gear an attractive proposition to many graziers. Requiring only an electric shearing motor, for small and medium scale operations, electric shearing motors were a more economical way of shearing a wool clip. The other option for graziers was Overhead shearing gear, which also required an Engine to provide shared power to a row of shearing stations. Still working, this Sunbeam Electric Shearing Motor – Heavy Duty Model, features a slow speed motor totally enclosed for protection against dust and insects. The full bearing down tube is easily removed and stored to be out of the way when not in use (not pictured). Providing 0.5 hp, which is twice the power ever needed for shearing sheep, this buffer allows for fluctuations in voltages that can occur in rural districts. Inventor Frederick Wolseley made the world's first commercially successful power-shearing system in Australia in 1888. US company Cooper, which had been founded in 1843 as a maker of sheep dip, began selling Wolseley equipment in the USA in 1895. The Chicago Flexible Shaft Company successfully entered the power-shearing market a few years later and entered into a joint venture with Cooper. It set up a branch in Sydney and sold shearing sets, and engines to power them, into the Australian market. In 1921 the US parent company, realising it needed to make products whose sales were not as seasonal as those of shearing equipment, made its first household appliances and branded them Sunbeam. In 1933, changes in exchange rates and taxes led the company to manufacture engines and shearing equipment in Australia via subsidiary Cooper Engineering, which changed its name to Sunbeam in 1946. Although most Australians know of this company as a major manufacturer of household appliances, its rural division flourished and retained the Sunbeam name for shearing equipment even after it was taken over by New Zealand company Tru-Test in 2001. This 0.5 horsepower vertical brushed motor air-cooled engine was designed to drive a single shearing plant. From the central cylinder which features a yellow “Sunbeam” sticker, a grey 240v power lead can be found on the left-hand side. A blue capacitor is located next to this power lead. Below, two legs extend and meet to form a foot which is fastened to a wall. On the right-hand side of the engine, a specification plate is located on the central cylinder. A yellow directional arrow sticker is located on the rotating section of the engine below the specification plate (location for photography, this section is designed to rotate and hence this sticker is not fixed in this location). At the rear of the cylinder, a plastic cap with small air cut outs protects the air-cooled engine from contaminants. At the front of the engine, the location for securing the bearing down tube is located. On the right-hand side of the lock for the bearing down tube is the handle, to which a string is often attached for switching the motor on and off by a shearer bent at the waist (not pictured). Sticker. Gold writing. Front of shearing motor “Sunbeam” Plate. Inscribed. Side of shearing motor. “Sunbeam / SHEARING MOTOR / MADE IN AUSTRALIA / 0.5 H.P. / 220/240 V / 1 PHASE A.C. / 4.0 AMPS / 50 C/S. / CONT. RTG. / 1425 R.P.M. / CLASS A INSUL / NO. J244560 / TYPE: NSB5C2/49." sheep sheering, shearing equipment, sunbeam, electric shearing motor -

Moorabbin Air Museum

Moorabbin Air MuseumDrawing - Drawing Nos. 89692 - Gasket; 89693 - Plug Modified; 89694 - Element Outline; 89695 - Spacer; 89697 - Nut; 89698 - Washer; 89700 - Post; 89701 - Key; 89716 - Pin Threaded; 89717 - Connector Bracket; 89718 - Sliding Lock Retainer; 89719 - Block; 89720 - Straight Clamp; 89721 - Socket Modified; 89722 - Plate Mounting; 89723 - Plate Receptacle Mount; 89724 - Spring; 89u25 - Spring; 89726 - Spring; 89727 - Spring; 89728 - Bracket; 89729 - Clamp; 89730 - Pin Stop; 89731 - Button; 8o732 - Pin; 89733 - Nut; 89734 - Spring; 89735 - Cover Hinged; 89736 - Plate Hinge; 89737 - Washer; 89738 - Washer; 89739 - Washer; 89740 - Clamp Top; 89741 - Clamp Bottom; 89742 - Screw; 89743 - Mount; 89744 - Brake Sub Assembly; 89745 - Screw; 89746 - Sliding Lock Post; 89747 - Shaft; 89748 - Flange; 89749 - Brake; 89750 - Tappet; 89751 - Screw Top Plate; 89752 - Ring Retaining; 89753 - Locking Ring; 89754 - Knob; 89755 - Bearing Lower; 89756 - Plate; 89757 - Pin; 89758 - Hand Grip; 89759 - Pin Cam; 89760 - Insert; 80761 - Spacer; 89762 - Seal; 89763 - Bar Handle; 89764 - Key; 89765 - Ring Rotating; 89766 - Screw; 89767 - Support Ring; 89768 - Circlip; 89769 - Switch, Weapons Research Establishment

-

Ballarat Tramway Museum

Ballarat Tramway MuseumBook, Australian Commonwealth Engineering Standards Association, "Flame proof air break switches for Voltages Not Exceeding 600Volts"s", 1926-1932

.1 - Book - 20 pages + grey covers, side stapled, issued by the Australian Commonwealth Engineering Standards Association, Tentative Australian Standard - "Air-break knife switches and laminated brush switches for voltages not exceeding 660Volts" - C23 - 1926, August 1926" .2 - Book - 24 pages + grey covers, side stapled, issued by the Australian Commonwealth Engineering Standards Association, Tentative Australian Standard - "Flame proof air break switches for Voltages Not Exceeding 600Volts", C25-1926, October 1926. .3 - Book - 24 pages + grey covers, side stapled, issued by the Australian Commonwealth Engineering Standards Association, Tentative Australian Standard - "Flame proof air break circuit breakers for Voltages Not Exceeding 600Volts", C26-1926, October 1926. .4 - Book - 24 pages + grey covers, side stapled, issued by the Australian Commonwealth Engineering Standards Association, Tentative Australian Standard - "Totally Enclosed air-break Circuit Breakers for Voltages not exceeding 660 Volts" - C27 - 1926, September 1926. .5 - Book - 24 pages + grey covers, side stapled, issued by the Australian Commonwealth Engineering Standards Association, Tentative Australian Standard - "Totally Enclosed air-break Switches for Voltages not exceeding 660 Volts" - C28 - 1926, December 1926. .6 - Book - 24 pages + grey covers, side stapled, issued by the Australian Commonwealth Engineering Standards Association, Tentative Australian Standard "Metallic Resistance Materials for Electrical Purposes" - C29-1926, November 1926. .7 - Book - 28 pages + grey covers, side stapled, issued by the Australian Commonwealth Engineering Standards Association, Tentative Australian Standard - "Face Plate controllers and resistances for use therewith Electric Motors (DC and AC Slip ring)" - C31-1926 - December 1926. .8 - Book - 28 pages + grey covers, side stapled, issued by the Australian Commonwealth Engineering Standards Association, Australian Standard "Contactor Controllers and Resistances for use therewith Electric Motors (DC and AC Slip ring)" - C32-1926 - December 1926. .9 Book - 36 pages + grey covers, side stapled, issued by the Australian Commonwealth Engineering Standards Association, Tentative Australian Standard - "Electrical Performance of Industrial Electric Motors and Generators with class A insulation" - C34-1927, October 1927 with a green label dated September 1932 advised that the tentative standard has been endorsed as a Standard with amendment. .10 - Book - 56 pages + grey covers, side stapled, issued by the Australian Commonwealth Engineering Standards Association, Tentative Australian Standard - "Electrical Performance of Large Electric Generators and Motors - Rating permitting overloads" - C35-1927, April 1927 with a green label dated September 1932 advised that the tentative standard has been endorsed as a Standard with amendment. On top right hand corner has the date stamp of the "The Electric Supply Co. of Victoria Ltd Ballarat" trams, tramways, power station, standards, materials, electrical systems -

National Wool Museum

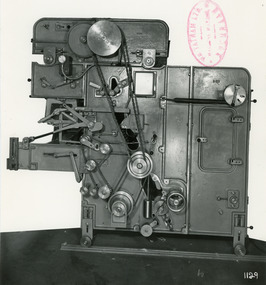

National Wool MuseumPhotograph - Product Photograph, Patent Automatic Feed Machine

These are sales photographs for William Tatham Ltd. of Rochdale. These photographs are taken in the fitting shop at William Tatham Ltd. where final assembly would have taken place. An Automatic Feeding Machine automatically and sequentially supplies uncarded wool to carding machines, The photographed machine was made by William Tatham Ltd, a textile engineering company based in Rochdale, UK. Established in 1866 Tatham developed innovative textile machinery and send their products to Australia and other countries around the world.A black and white photo of a Patent Automatic Feed Machine in a portrait format. Black wiritng on the rear, typed with a typewriter.Front - mid left corner - Wm. TATHAM Ltd. ROCHDALE. Machine Maker Front bottom right corner - 1129 Rear - Patent Automatic Feed with Extended Hopper fitted with balanced pressure plate which operates through Variable Speed Device to regulate speed of spiked lattice in accordance with material in Hopper. Electro-Magnetic Clutch Drive to spiked lattice controlled by Mercery Switch on scale arm. Diagonal Scale Pan with improved knife edge suspension. Dual Trap Doors over Pan actuated by Solenoid. Automatic device to slow spiked lattice just prior to weigh being obtained. Ball or roller bearings to main shaft, combs and other parts. Self-aligning bearing to timing shaft etc.textile machinery, tatham, wool manufacture, carding, automatic feeding machine, wool -

Vision Australia

Vision AustraliaEquipment - Object, Data Acquisition Ltd, Rain warning device

A battery operated device that is rectangular in shape with a sensor plate on top and an on/off switch on one end. At the other end is a round lid that screws off to allow a round 9 volt battery to be inserted. It was designed so that when placed outdoors would emit a noise at the first drop of rain, enabling vision impaired people to retrieve their washing from the line. 1 plastic box with metal plateRain warning device Made for the Royal National Institute for the Blind by Data Acquisition Ltd A price sticker reads: $49.assistive devices, royal national institute for the blind -

City of Greater Bendigo - Civic Collection

City of Greater Bendigo - Civic CollectionArtwork, other - Gold Chicko Roll, Simplot Australia, 2001

Commemorative object produced by Simplot Food Service and presented to the City of Greater Bendigo on the occasion of the 50th anniversary of the creation of the Chicko Roll by Bendigo born boiler maker, Frank McEncroe. The Chicko Roll has been an Australian icon since the 1960's and 70's. Inspired by the Chinese spring roll and first sold in 1951 as the "Chicken Roll" despite not actually containing chicken. The snack was designed to be easily eaten on the move without a plate or cutlery and is typically deep-fried in vegetable oil. By 1965 the ubiquitous Chicko Roll was sold in every fish and chip shop throughout the country and at the height of their popularity in the 1970s, 40 million Chiko Rolls were being sold Australia-wide each year and more than one million were exported to Japan.(Wikipedia https://en.wikipedia.org/wiki/Chiko_Roll). Advertised with the slogan 'Grab a Chiko', 'Hit the Hot Spot' and 'You Can't Knock the Roll' the marketing around the Chicko Roll was aimed towards the male population with women perched on Harley Davidson's prevocatively preparing to bite into a Chicko Roll. In 2008 with a push towards healthier eating, Chicko Roll reviewed its advertising and although it continues to target young men, it switched to using a 'fun, active' young women, riding a retro pushbike near the beach to improve its image. In 1995 J.R. Simplot, an American company who also own Leggo's, Birds Eye, Edgell and John Wes,t acquired Chicko Roll to sure up their foothold in the Australian market. Life size gold plated chicko roll in a hinged wooden presentation box with red lining. Double sided, printed letter accompanying the object explains its creation and significance.0365.1; CHICKOcity of greater bendigo commerce, mayor acherman -

Parks Victoria - Wilsons Promontory Lightstation

Parks Victoria - Wilsons Promontory LightstationPower board

The power board, which was the main power board for the lightstation between 1975 and 2007, retains a number of ceramic fuse parts and a wooden reel with fuse wire. The grey metal door has a plastic switch and a small metal plate is inscribed with ‘Custom styles by Thomson and Mackenzie’. Power board with ceramic fuse parts. Also wooden reel with fuse wire. ‘Custom styles by Thomson and Mackenzie’. -

Wodonga & District Historical Society Inc

Wodonga & District Historical Society IncFunctional object - Rail fish plate from Cudgewa Line, 1930 - 1960s

Cudgewa Line -The Cudgewa railway line opened in stages between 1889 and 1921. The first section from Wodonga to Huon opened on 10 September 1889. It was extended to Bolga on 18 July 1890, Tallangatta on 24 July 1891, Shelley on 13 June 1916 (the highest station in Victoria), Beetomba on 10 April 1919 and Cudgewa on 5 May 1921. The line had 1 in 30 grades and trestle bridges that have been heritage listed. In 1919, the line was used to carry materials for the construction of Hume Weir, and three years later a spur line connecting Ebden to the weir was opened. In the 1960s, Cudgewa became the railhead of materials for the Snowy Mountains Scheme. The last passenger service from Wodonga to Tallangatta ran on 30 September 1961. The turntable and passenger platform at Cudgewa were abolished in 1976. This fish plate came from the rails of the Cudgewa Line at Gordon Roy's hut which was situated behind Perry's Stump Hotel outside Wodonga. The hut was used as an office with the points lever outside to switch trucks to different tracks on the Bandiana and Cudgewa lines.This item is significant as it was part of the railway line to Cudgewa which played an important role in North east Victoria carrying freight during the construction of the Hume Weir and the Snowy Mountains Scheme.A section of flat plate. These plates were used in pairs to connect the ends of adjacent rails in railway track. victorian railways, cudgewa rail line, railway components -

Melbourne Tram Museum

Melbourne Tram MuseumDocument - Folder, William Pollock, "The Melbourne Cable Tramway System", c1940

Folder - heavy red covers with two screw sets containing a photocopy of a report by William Pollock, prepared after the closure of the cable tram system titled ""The Melbourne Cable Tramway System". Image numbers listed: Folder – htd4715i1 Inside of folder – htd4715i2.jpg Report –Photocopy of a 14 foolscap sheets, paper titled “The Melbourne Cable Tramway System” by William Pollock, describing the system in detail, listing 26 appendices. Has notes on each Power Station, including a table of opening, closing, power produced and cables, fuel, permanent way (track), cables, underground gear, tunnels, flooding and the grip. Image – htd4714i3.pdf Appendix 1 – Handwritten table “Cost the Melbourne Tramway System” – photocopied special size sheet folded. See image htd4715i4.jpg 2 – Drawing – Typical Power House layout - image htd4715i5.jpg 3 – Drawing – Head of Cable Driver – htd4715i6.jpg 4 – Drawing – Rope Drive – htd4715i7.jpg 5 – Photocopy of a Fuel and Water test sheet for the Esplanade Power House – two sheets – 14/5/1918 – htd4715i8.jpg and htd4715i9.jpg 6 – Section of Cable Tram track – htd4715i10.jpg 7 – Tar Burner used by MTOC 1893 – 1900 - htd4715i11.jpg 8 – Yoke Bracket for line drums – A1 Pulley – htd4715i12.jpg 9 – Tunnel Yoke – htd4715i13.jpg 10 – Elevating Wheel or Pulley with shield plate – htd4715i14.jpg 11 – Curve Pulleys, curve drum and rubbing bar – 2 sheets – htd4715i15.jpg and htd4715i16.jpg 12 – Curve or Conical drum – htd4715i17.jpg 13 – Cable Separating pulley or cone line drum – htd4715i18.jpg 14 – Yoke Pulley or General Pulley – htd4715i19.jpg 15 – Yoke Bracket for Drums – htd4715i20.jpg 16 – Automatic Switch Gear – htd4715i21.jpg 17 – Hand operated switch gear – htd4715i22.jpg 18 – Hand pickup – htd4715i23.jpg 19 & 20 – Photo of bunched strands and damaged cable – htd4715i24 21 – Diagram of Rope – Clarendon St Rope No. 41 – htd4715i25.jpg 22 – Strand Alarm – htd4715i26.jpg 23 – Rope History – two sheets – htd4715i27 and htd4715i28.jpg 24 – Rope Splice – htd4715i29.jpg 25 – Cable Grip – htd4715i30.jpg 26 – Crown Pulley – two sheets – htd4715i30 and htd4715i31trams, tramways, drawings, tramcars, cable trams, trackwork, mto co, reports -

Geoffrey Kaye Museum of Anaesthetic History

Geoffrey Kaye Museum of Anaesthetic HistoryTool - Laryngoscope, Magill, 1926

Ivan Magill (1888-1986) designer, this piece was designed in 1926 along with other anaesthetic equipment.Chrome plated straight complete Magill laryngoscope in medium size format, with attached light bulb. Cylindrical handle for battery deposit and with a wavy hand grip for easy handling. Serrated and screwed lids on top and base of the handle grip for insertion of batteries and checking of electrical contact stud. The handle also has a metallic switch without any instruction of use. The arm of the handle has a detachable screw to adjust extendable blade position and firmness. The light bulb is attached to a metallic tube connector to the handle arm which is just pressed to the contact point base. The blade has a oxidation spot under the blade. The piece in full has several scratches marks mostly founded in handle, arm and top blade areas. Two stamped inscriptions are present on the arm area, the manufacturer name and register number.Stamped on the arm of the handle lateral side, A.CHARLES KING Stamped on the arm of the handle opposite lateral side, REG. NO. 74901[9]magill, a. charles king ltd, regi. no. 749019, switch, laryngoscope -

Bendigo Military Museum

Bendigo Military MuseumMemorabilia - TRENCH ART, LAMP, Post WW2

Possibly made by the donor.This object is an example of trench art. .1 The lamp base consists of a chrome plated deactivated mortar bomb attached to a turned brown wooden base. A globe and switch socket are attached to the tip of the bomb. An electrical cord with power plug is threaded through the base of the bomb. .2 The lampshade is made of stiffened brown paper laced to a wire frame with dark brown cord. Handpainted coloured flowers decorate the outer surface of the shade. The shade is attached to the globe via a wire clamp.On the base of the mortar bomb: ' ?LB, IM, MF, 1940'ornaments, lighting - electrical, trench art, souvenir -

Wodonga & District Historical Society Inc

Wodonga & District Historical Society IncFunctional object - Ericsson Auto Flameproof Telephone from the Golden Fleece Depot, Wodonga, c. late 1930s

This British made type "N1087" and code "N1087" C Ericsson auto flameproof telephone was used in the drum filling platform of the Golden Fleece Depot, in Hovell St., Wodonga. The type "N1087" and code "N1087" C Ericsson flameproof telephone was introduced in 1937 and certified by the British Mines Department as flameproof for Petroleum and Acetone Vapours, in 1938. It was designed specifically for outdoor use in areas where there may be exposure to inflammable vapours and hazardous chemicals such as petroleum. Each contact or switch point is enclosed in its own flameproof chamber, to reduce the risk of ignition and the volume of gas.The Ericsson auto flameproof telephone has local significance due to its use in the Golden Fleece Depot in Wodonga, as well as national and international significance due to its date and the rarity and relatively complete condition.Black Ericsson auto flameproof rotary dial telephone secured in a hinged cast iron case painted black. Rubber tubing connected to the bakelite handset and an adjacent metal plate with the name "Ericsson", type "N1087" and code "N1087 C", and certification of the telephone as flameproof with the letters FLP. "Ericsson" on the top left corner of the metal plate. "AUTO TELEPHONE / TYPE N1087 / CERTIFIED FLAMEPROOF / FOR GROUPS II & III / CERTIFICATE FLP. 2378" / CODE N1087 C" on the main part of the metal plate.ericsson telephones, british telephones, flameproof telephones, mining telephones, golden fleece depot wodonga, wodonga