Showing 192 items matching "trade tool"

-

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDrill Press, early to mid-20th century

... trade tool... business. It is an example of the tools of the blacksmiths’ trade ...This post drill press has been made by Melbourne business, Dawn Manufacturing Company. It can be operated manually or by a pulley driven flywheel, with the aid of an engine connected to a power supply. In the late 1800s early 1900s a drill press like this would have been driven by steam from a boiler, the main power source for manufacturer’s power at that time. Dawn’s Golden Anniversary 1917-1967 Catalogue describes this model 611 drill as … “Ruggedly constructed with accurately reamed bearings. The coupling between the main spindle and feed screw engages the full circumference of the spindle, and embraces a ball-bearing thrust race. The pillar, as in all “Dawn Drilling Machines” is a solid bright steel bar, in place of the usual light tubing. Adjustable automatic feed.” And “F. & l. Pulleys extra, if required”. DAWN MANUFACTURING CO. The Dawn Manufacturing Co. was founded in Coburg, Melbourne, in 1917 by the four Blake brothers, who were all engineers. After World War I Dawn was supplying drills Australia wide and the company was growing at a healthy rate. During the depression they remained busy, with employees working 60-80 hour weeks. Dawn was contracted to supply vices and clamps to the Australian Defence Department and munitions factory during the World War II. - 1959 the company was taken over by G.N. Raymond Group. - 1967 the Dawn Manufacturing Co. had distributors in Australia and overseas, including USA, Canada, New Zealand, Asia and the Middle East. - 1973 the Siddons Ramset Limited acquired Dawn. - December 1991, Dawn became a unit of the United States owned Stanley Works Pty. Ltd. - November 1998 Dawn became 100 per cent Australian owned. The drill is a typical tool of a blacksmith, cart wright, wheelwright and garage business. It is an example of the tools of the blacksmiths’ trade in Victoria in the early to mid-20th century.Post type drill press machine with gear driven flywheel. Drill press is attached to a post and is fitted with a pulley belt and will run at a speed of maxim 200 r.p.m. The machine can also be manually operated. It has an aperture in the centre, a chuck, for the drill bit and has two metal handles at the centre, on the right hand side. Gear ratio 2:1 main drive, 6" diam, 3:1 reduction gear. Made by Dawn of Melbourne, Australia. Model No. 611, Code No. 9157"DAWN MFG COY”, “MELB. AUSTRALIA", " 611"flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, blacksmiths, blacksmith’s drill, blacksmith tools, dawn drill model no. 611, dawn drill code no. 9157, dawn manufacturing coy melbourne, dawn manufacturing coy coburg, dawn post drill, drilling machine, drill with gear driven flywheel, forging tool, metal working tool, post drill, steam powered drill, trade tool, warrnambool district 1900s -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Article, Old trades museum, 1978

... Dolph Slykuis has started a museum of old Australian trade... of old Australian trade tools. Dolph Slykuis has started a museum ...Dolph Slykuis has started a museum of old Australian trade tools.Dolph Slykuis has started a museum of old Australian trade tools he has gathered from the Riverina and Victoria. 'Arbuthnot Cottage' is situated in Blackburn. He is researching the items with the help of historical societies.Dolph Slykuis has started a museum of old Australian trade tools. museums, tools, slykhuis, dolph, slykhuis, anne, arbuthnot cottage, alfred street, blackburn, no 8, tools -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - File, Early 20th century

... Road file woodworking carpentry tool trade Large file ...This file would be used by a tradesperson or home handyman to smooth the edges of the wooden piece he or she was working on. The surfaces of the file would be of different abrasiveness to suit different stages of the job. A file would be part of a woodworker's tool kit.The design of a file hasn't altered significantly over the last century. This file is an example of an early 20th century file but would be at home in the workshop today.Large file with wooden handle. Brass collar sits between handle and file.flagstaff hill, warrnambool, maritime village, maritime museum, flagstaff hill maritime museum & village, shipwreck coast, great ocean road, file, woodworking, carpentry, tool, trade -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Netting Shuttle, Early-to-mid 20th century

... making tool maritime trade darning shuttle tool 20th century W.R ...Maritime trades included making and mending nets. Netcraft skills have been taught and applied for centuries and are ongoing. Shuttles, or net needles, are used in the netting process, along with twine or cord, and a sharp knife or scissors. The twine is wound onto the shuttle and dispensed as the shuttle knots and weaves the cord to make the net. These shuttles are lightweight, compact and portable too. Nets were used on sailing ships for the crew's safety, often saving the sailor's lives in stormy seas Examples are the ship mast nets or shrouds that are wide at the base on the deck and taper to a point at the top of the mast, and railing nets that encircle the rails around the deck and prevent people and objects from rolling or falling into the sea. The shuttles were donated to Flagstaff Hill Maritime Village by the family of Doctor William Roy Angus, Surgeon and Oculist. It is part of the “W.R. Angus Collection” that includes historical medical equipment, surgical instruments and material belonging to Dr Edward Ryan and Dr Thomas Francis Ryan, (both of Nhill, Victoria) and Dr Angus’ own belongings. The Collection’s history spans the medical practices of the two Doctors Ryan, from 1885-1926 plus that of Dr Angus, until 1969. Nets were an essential part of the life-saving safety equipment on sailing vessels. The set of netting shuttles is an example of net-making tools used in the 18th to 20th centuries and continues into modern times to create and repair safety equipment. The shuttles are part of the W.R. Angus Collection, which is significant for still being located at the site it is connected with, Doctor Angus being the last Port Medical Officer in Warrnambool. Shuttles, set of three; wooden slats, one end pointed, the other a concave shape. The centre is cut-out, leaving a straight tab in the centre lengthwise. The set is part of the W.R. Angus Collection. warrnambool, shipwreck coast, flagstaff hill, flagstaff hill maritime museum, flagstaff hill maritime village, net making, net mending, net shuttle, net making tool, maritime trade, darning, shuttle, tool, 20th century, w.r. angus, weaving, netting shuttle, net craft, net needles, safety nets, safety equipment -

Federation University Historical Collection

Federation University Historical CollectionObject, Brown and Sharpe Manufacturing Co, Universal Surface Gauge

... slot. gauge tool trade Brown and Sharp Manufacturing Company ...Used to lay out Machine work, or to set up pieces on a planer, radial drill, milling machine or boring machine. To set the Scriber the spindle swivels down or up into any position where it is clamped by the knurled nut. There is a fine screw adjustment for the Scriber point (note: this is not original Scriber supplied with this instrument). The base on this Surface Gauge can be set on cylindrical work, using the ‘V’ groove in the base, or by pushing down the two gauge pins. It can be brought square with an edge or T slot. Metal gauge toolgauge, tool, trade, brown and sharp manufacturing company -

Clunes Museum

Clunes MuseumTool - BROAD AXE

... HARVEY USED THIS BROAD AXE BRIDGE BUILDING LOCAL HISTORY TOOL ...MR. TOM HARVEY USED THIS BROAD AXE BRIDGE BUILDINGAN AXE LIKE IMPLEMENT WITH LARGE SHAPED CUTTING EDGE WITH WOODEN HANDLE USED IN BRIDGE BUILDING.local history, tool, trade -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Auger, Stanley Rule & Level Co, 1922-1935

... Stamped on shank "AA" trade mark (Stanley Tools)... Stamped on shank "AA" trade mark (Stanley Tools) Nose bit auger ...The Stanley Works was founded by Frederick Trent Stanley in 1843, originally a bolt and door hardware manufacturing company located in New Britain, Connecticut, USA. The Stanley Rule and Level Company was founded in 1857 by Henry Stanley in New Britain, Connecticut. In 1920, this company was independent from Trent Stanley's works but they merged with the separate but related Stanley Works, that was founded by Henry Stanley's cousin Frederick Trent Stanley, and continued operating as its hand tools division. At this time after the merger the “Sweetheart” Trademark was adopted for tools made between 1922 to 1935 with augers manufactured during this time having the “AA” trademark and this is when the Stanley company we know today came into being. Around 1937, Stanley acquired the British J. A. Chapman company, a British manufacturer of carpentry tools and other items (including bayonets during World War I) formerly located in Sheffield, from Norman Neill. This helped Stanley to enter the British market.A early tool manufactured by an emerging company that today produces tools for sale in just about every country in the world. The subject items trademark shows the item was produced between 1922-1935 at a time when the company had just merged and was transitioning into Stanley Tools Ltd.Nose bit auger. Similar to shell bit except the nose turned inwards to form a cutting lip. Stamped on shank "AA" trade mark (Stanley Tools)flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Stawell Historical Society Inc

Stawell Historical Society IncPhotograph, School of Mines Students 1907 with Mr W. W. Telford in the rear, second from the right

... standing, four seated. Six of the men are holding tools of trade... of the men are holding tools of trade used in training - mortar ...School of Mines Students 1907 with mortar and Pestle and Forge Tongs. Rear second from right is W.W. Telford.Black and white photograph of eight young males, four standing, four seated. Six of the men are holding tools of trade used in training - mortar and pestle, tongs etcOn the back: Stawell School of Mines Skene Street Stawell Rear, 2nd from right Mr. W.W. TELFORDstawell education -

Federation University Historical Collection

Federation University Historical CollectionBook - Booklet, The Institute of Physics Handbook: Exhibition of Scientific Instruments and Apparatus, 08/1960

... was set up to show the professional scientist the latest tools... the professional scientist the latest tools of trade and glimpses of future ...The Exhibition of Scientific Instruments and apparatus was set up to show the professional scientist the latest tools of trade and glimpses of future developments in the field of instrumentation .Cream soft covered book of 198 pages relating to an exhibition of scientific instruments and apparatus held at the School of Chemistry, University of Sydney. Exhibitors in the exhibition include: Advance components, Airmec, Akashi, Aladdin Industries, Amalgamated Wireless, Applied Physics Corporation, Ardente, Austral Engineering Supplies Pty Ltd, Avo Limited, Baird Atomic, Baker, Baldwin Instrument Co., B. and Relays, Barnstead Still and Steriliser Co., Beckman, Bender, Boonton Radio Corporation, Bosch, British Electric Resistence, British Physical Laboratories, Buccho, Bundenberg, Buehler, Bureau of Analysed Samples Ltd, Business Equipment Pty Ltd, Cambridge Instrument Co, Casella, Chamberlain and Hookham, Cossar, Cooke Troughton, Counting Instruments Co, CSIRO, Dawe Instruments, Difco, Duff and Macintosh, Dumont, Dupree, Dynatron Rodio Ltd, East Lancashire Chemical Co., Edwards High Vacuum Ltd, Eletircal Equipment Australia, Electronic Industries, Electroscientific Industries, Electrothermal Heating, Elema Schonanda, EMI, Englehard, Epprect, ERD Engineering, Ericsson Telephones, Esdaile, Ether Ltd, Evershed and Vignoles, Faraday Electronic Instruments, Federal Products, Filtron, Fischer, Fluke, Foot, Fortiphone, PX Fox, Foxall Instruments, Gambrell Bros, Gardener and Salmon, Garlick, Gelman , Gossen, Griffen and george, Gurr, Guthrie. Hasler, Headland Engineering Developments, Heraeus, Hersey Sparling Meter Co, Hewlett Packard, Heyneco, Hilger and Watts, Instron Engineering, Institute of Physics, Intermetal, Internation Resistance Corporation, Jacoby Mitchell and Co, Janke and Kinkel, JENA-er Glasswerke Schott and Gen, Keithly Instruments, Kelvin and Hughes, Kent, Kipp and Zonene, Kovo, Krautkramer, Kruss, Lambrecht, Land Pyrometers Leeds and Northrup, Leeds Meter Co, Leybold, Liddle and Epstein, Long Industrial Equipment, macdougall, McKinlay Fletcher, McLellan, Marconi Instruments, Masruements, Metrimpex, Metrohn, Metron, Mettler, Mica Corporation, Minneapolis Honeywell Regulator Company, Moisture Regulator, Morganite, Morris, Moseley, Muirhead, Mullard- Australia, Nagard, National Instrument Co, National Standards Laboratory, Negretti and Zamba, Nira, Northeastern Engineering, Nuclear Equipment Ltd, Ronald payne, Philbrick, Philips, Physik Instruments, Pincombe, Precision Tools and Instrument Co., Printed Electronics, Pye, Quicfit, Radion Corporation of Amerixa, Radio Frequency Laboratories, Radiometer, Rank Cintel, record Electric Co., Reichert Optische Werke, Rhode and Schwarz, Ridsdales and Co, Rocol, Rotameter, Rototherm, Rowe, George Sample, Santon, Sanders, Sartorious-Werke, Sauter August, Schneider, Scruttons, SEFRAM, Selby, Sensitive Research, Servomax Controls, shckman, Shimadzu, Siemens, Simpson, Sodeco, Soiltest, Solartorn, Southern Instruments, Albert Speck, Stanford X-Ray, Sunvic Controls, Sweda, Sydney County Council, Tamson, techne Cambridge, Tektronix, Telefunken, Telequipment, Andrew Thom, Thompson J, Langha,, Thronethwaite, Tinsley, Tokyo Opptical co., Townsen and Mercer, Treacerlab, Tylors, Unicam, Union OPtical Co, Varian Associated, Venner Electronics, Vidler Thornethwaite Engineering, Crosweller, Wandel and Golterman, Watson Victor Limited, Wayne Kerr Laboratories, waveforms, West Instruments, Herman Wetzer, Wild Instrument Supply Co, Yokagawa Electrical Works, Carl Seiss, Zwick.science, instruments, apparatus, scientific objects -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Document - PEARCE COLLECTION: ACCOUNTS MAURICE MORAN & CO

... in trade, re itemized Tinsmiths tools, Fittings, Sundries etc sold..., Auctioneers Account of Sales of stock in trade, re itemized Tinsmiths ...Maurice Moran & Co, Auctioneers Account of Sales of stock in trade, re itemized Tinsmiths tools, Fittings, Sundries etc sold at Mundy St on a/c of Messrs Eldridge & Burnet. Five pages of listed sale items with prices obtained; Includes cost of advertising in Bendigo papers and commission. Dated 21st December 1911.business, auctioneers, bendigo, maurice moran & co -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageLap Skiver, J Dixon, 1900s

... of the Walsall leather industry. Many companies supplied this trade... of the Walsall leather industry. Many companies supplied this trade ...Walsall in England was regarded as the world`s greatest centre of the saddlery trade. The town's craftsmen began to specialise in making bits, stirrups and spurs in the Middle Ages, developing into fully-fledged makers of saddlery and harness, by the end of the nineteenth century. As a result, over a hundred firms were exporting their products throughout the British Empire and beyond. The Walsall firms flourished as horses were so vital to everyday life in Victorian Britain and the colonies. The Walsall area emerged as a major supplier of military saddlery and harnesses, with one company supplying an astonishing 100,000 saddles for the British army in the First World War. The twentieth century saw the rise of light leather goods, such as handbags, cases and gloves. With the coming of the motor car, these products became the mainstay of the Walsall leather industry. Many companies supplied this trade and Dixon tools was one, as a commercial and industrial equipment supplier to the trade. The company started in 1843 and has continued to produce tools for the leather industries up and till August 2017 when the company was dissolved.A vintage item used in the leather working industries see additional notes at end of document for clarity on how the item was used and it's importance in making leather goods.Lap Skiver has a roller missing. Painted reddish brown J Dixonflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, lap skiver, leather industries, leather making tools, tools, j dixon -

Forests Commission Retired Personnel Association (FCRPA)

Forests Commission Retired Personnel Association (FCRPA)Branding Hammer issued to FCV overseer Jim Browning at Beechworth

... and were an important, and closely guarded tool-of-trade. They were... and were an important, and closely guarded tool-of-trade. They were ...Metal branding hammers were the most common way to control the sale and movement of hardwood timber produce like logs, railway sleepers, fence posts, and poles from Victorian State forests. Royalty was also paid on this basis. The hammer has a crown stamp on one end with a unique number in the middle (453) which identified its owner, and a crows foot or broad arrow on the other. The broad arrow was a symbol traditionally used in Britain and its colonies to mark government property. Forest regulations state that an authorised officer may use the crown mark to identify produce which has been sold and may be removed from the forest, whereas the broad arrow can be used to brand and mark trees which are not to be felled, or to indicate forest produce which has been seized. Hammers were traditionally only ever issued to forest officers and were an important, and closely guarded tool-of-trade. They were not transferred between staff and lending hammers was not permitted. But it was an onerous task for staff to hammer and tally hundreds of logs, or thousands of fence posts each week, so in about 1990 a system was introduced whereby hammers were allocated to logging contractors to grade logs and tally them instead. But there was still spot checking by authorised officers. A register was kept, and contractors paid a substantial deposit to make sure they didn't lose them, but they occasionally turn up by fossickers with metal detectors. While branding hammers are still used in some smaller locations, plastic tags and barcodes are now more common.Metal log branding hammer with a crown stamp on one end with a unique number (453) in the middle which identified its owner, and a crows foot or broad arrow on the other. The unusual bent metal handle was designed to protect user from banging their fingers on the log. It was also fitted with a rubber hand grip. Most FCV branding hammers were issued with wooden handles. The branding hammer 453 was initially issued to Wally Cowell at Beechworth. It was reissued to Jim Browning upon Wally’s retirement The hammer still had a wooden handle, but the it broke and became loose inside hammer head. Russel Pritchard from the Beechworth Depot replaced the handle with a new metal one and put a dog leg in it It mainly branded forest produce cut in Mt. Pilot and Reedy Creek areas. The main logging contractors were Gordon Habeck from Chiltern and Steven Goldsworthy from BeechworthCrown mark one end (453) and Crows foot other endforest harvesting, forests commission victoria (fcv) -

Department of Energy, Environment and Climate Action

Department of Energy, Environment and Climate ActionLog Branding Hammers (various)

... , and closely guarded tool-of-trade. They were not transferred between..., and closely guarded tool-of-trade. They were not transferred between ...Metal branding hammers were the most common way to control the sale and movement of hardwood timber produce like logs, railway sleepers, fence posts, and poles from Victorian State forests. Royalty was also paid on this basis. Hammers most commonly had a crown stamp on one end with a unique number in the middle which identified its owner, and a crows foot or broad arrow on the other. The broad arrow was a symbol traditionally used in Britain and its colonies to mark government property. Other local configurations were used by sawmillers, post cutters and pulpwood contactors. Forest regulations state that an authorised officer may use the crown mark to identify produce which has been sold and may be removed from the forest, whereas the broad arrow can be used to brand and mark trees which are not to be felled, or to indicate forest produce which has been seized. Hammers were traditionally only ever issued to forest officers and were an important, and closely guarded tool-of-trade. They were not transferred between staff and lending hammers was not permitted. But it was an onerous task for staff to hammer and tally hundreds of logs, or thousands of fence posts each week, so in about 1990 a system was introduced whereby hammers were allocated to logging contractors to grade logs and tally them instead. But there was still spot checking by authorised officers. A register was kept, and contractors paid a substantial deposit to make sure they didn't lose them, but they occasionally turn up by fossickers with metal detectors. While branding hammers are still used in some smaller locations, plastic tags and barcodes are now more common.Log Grading hammersforests commission victoria (fcv), hand tools, forest harvesting -

Department of Energy, Environment and Climate Action

Department of Energy, Environment and Climate ActionLog Branding Hammer

... , and closely guarded tool-of-trade. They were not transferred between..., and closely guarded tool-of-trade. They were not transferred between ...Metal branding hammers were the most common way to control the sale and movement of hardwood timber produce like logs, railway sleepers, fence posts, and poles from Victorian State forests. Royalty was also paid on this basis. Hammers most commonly had a crown stamp on one end with a unique number in the middle which identified its owner, and a crows foot or broad arrow on the other. The broad arrow was a symbol traditionally used in Britain and its colonies to mark government property. Other local configurations were used by sawmillers, post cutters and pulpwood contactors. Forest regulations state that an authorised officer may use the crown mark to identify produce which has been sold and may be removed from the forest, whereas the broad arrow can be used to brand and mark trees which are not to be felled, or to indicate forest produce which has been seized. Hammers were traditionally only ever issued to forest officers and were an important, and closely guarded tool-of-trade. They were not transferred between staff and lending hammers was not permitted. But it was an onerous task for staff to hammer and tally hundreds of logs, or thousands of fence posts each week, so in about 1990 a system was introduced whereby hammers were allocated to logging contractors to grade logs and tally them instead. But there was still spot checking by authorised officers. A register was kept, and contractors paid a substantial deposit to make sure they didn't lose them, but they occasionally turn up by fossickers with metal detectors. While branding hammers are still used in some smaller locations, plastic tags and barcodes are now more common.Log Grading hammersforests commission victoria (fcv), hand tools, forest harvesting -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Wood moulding Plane, Edward Preston & Sons, Early 20th century

... following a batch process. Not all Preston tools are trade-marked... following a batch process. Not all Preston tools are trade-marked ...By the end of the nineteenth century, the firm of Edward Preston & Sons was founded in 1825, becoming one of England's leading makers of hand tools and in many ways a British counterpart to America's "Stanley" for its wide range of quality utilitarian tools at affordable prices. Edward Preston Sr. (1798–1883) was first listed as a plane-maker at 77 Lichfield Street in the Birmingham Directory of 1833, but later listings and advertisements assert that the business was started in 1825. Preston is likewise recorded as a plane-maker living with his family in Lichfield Street in the 1841 census, at which time his younger son Edward was 6 years old. Around 1850, his son Edward left school to join his father's business and is recorded in the 1851 census as a plane-maker at his father's address. He appears to have been quite a talented and resourceful young man, as he had later been able to start up his own "wood and brass spirit level manufacturing business at 97½ Lichfield Street by 1864. By 1866, Edward Jnr had added planes, routers, joiners, coach, gun, cabinet, and carpenters tools to his line, and the following year he moved his shop from his father's address and relocated to 26 Newton Street, before moving again to much larger premises at 22–24 Whittall Street. This location became known as the Whittall Works and later was the office and factory of Edward Preston & Sons, Ltd. In 1889 Edward Preston Jnr and his three sons were brought into the firm and the name was changed to Edward Preston & Sons, becoming Edward Preston & Sons Ltd on incorporation in 1898. Part of the firm's output was a healthy line of malleable and gun-metal planes and patent adjustable iron smoothers, shoulder planes, bull-nose, and block planes - a range that was expanded in later years. The 1901 catalog shows several styles of planes that were unique to the Preston brand, along with the usual styles which had already been set by other makers. The death of Edward Preston Jnr was reported in the Lichfield Mercury of 26 September 1913. "Mr. Preston was decided of an innovative turn of mind," the newspaper wrote, "as many of the machines in use at his works, as well as of the tools produced were the invention of himself and his three sons, who now manage the business." The report noted that at the time of his death, the business was carried on at Whittall Works, Cheston Street, Aston, Birmingham. Falling on hard times, the firm of Edward Preston & Sons was sold to the Birmingham firm of John Rabone & Sons in 1932, and shortly thereafter manufacturing rights to some of the Preston range of planes were sold to the Sheffield firm of C. & J. Hampton, who would later merge with the Record Tool Company. Some of the Preston planes were directly added to the Record line by the Hampton firm, while others were modified or discontinued altogether. Generally, all Preston wooden planes are stamped on the front of the plane, the shape, size, and character type of the stamp indicating the age of the plane. On some metal planes, all the parts were stamped with a number or symbol during manufacture. This number was used to re-assemble the parts following a batch process. Not all Preston tools are trade-marked clearly. Early shoulder, rebate, chariot planes, and chamfer rebates commonly appear without trademarks but may have assembly numbers. The "E P" trade-mark was already in use by 1882. The trade-mark "Preston" also appears on some later tools that were manufactured in Sheffield, England. These are generally smoothing planes and appear modern and very similar in construction to other modern manufacturers' planes.The item gives a snapshot of one of England's premier tool manufacturing companies at a time when significant industrial changes were occurring in manufacturing and business structures in the World that were beginning to affect social changes.Ogee moulding Plane Maker E Preston & Sons sticker with date 1904 -1931flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Wood moulding Plane, Edward Preston & Sons, Early 20th century

... following a batch process. Not all Preston tools are trade-marked... following a batch process. Not all Preston tools are trade-marked ...By the end of the nineteenth century, the firm of Edward Preston & Sons was founded in 1825, becoming one of England's leading makers of hand tools and in many ways a British counterpart to America's "Stanley" for its wide range of quality utilitarian tools at affordable prices. Edward Preston Sr. (1798–1883) was first listed as a plane-maker at 77 Lichfield Street in the Birmingham Directory of 1833, but later listings and advertisements assert that the business was started in 1825. Preston is likewise recorded as a plane-maker living with his family in Lichfield Street in the 1841 census, at which time his younger son Edward was 6 years old. Around 1850, his son Edward left school to join his father's business and is recorded in the 1851 census as a plane-maker at his father's address. He appears to have been quite a talented and resourceful young man, as he had later been able to start up his own "wood and brass spirit level manufacturing business at 97½ Lichfield Street by 1864. By 1866, Edward Jnr had added planes, routers, joiners, coach, gun, cabinet, and carpenters tools to his line, and the following year he moved his shop from his father's address and relocated to 26 Newton Street, before moving again to much larger premises at 22–24 Whittall Street. This location became known as the Whittall Works and later was the office and factory of Edward Preston & Sons, Ltd. In 1889 Edward Preston Jnr and his three sons were brought into the firm and the name was changed to Edward Preston & Sons, becoming Edward Preston & Sons Ltd on incorporation in 1898. Part of the firm's output was a healthy line of malleable and gun-metal planes and patent adjustable iron smoothers, shoulder planes, bull-nose, and block planes - a range that was expanded in later years. The 1901 catalog shows several styles of planes that were unique to the Preston brand, along with the usual styles which had already been set by other makers. The death of Edward Preston Jnr was reported in the Lichfield Mercury of 26 September 1913. "Mr. Preston was decided of an innovative turn of mind," the newspaper wrote, "as many of the machines in use at his works, as well as of the tools produced were the invention of himself and his three sons, who now manage the business." The report noted that at the time of his death, the business was carried on at Whittall Works, Cheston Street, Aston, Birmingham. Falling on hard times, the firm of Edward Preston & Sons was sold to the Birmingham firm of John Rabone & Sons in 1932, and shortly thereafter manufacturing rights to some of the Preston range of planes were sold to the Sheffield firm of C. & J. Hampton, who would later merge with the Record Tool Company. Some of the Preston planes were directly added to the Record line by the Hampton firm, while others were modified or discontinued altogether. Generally, all Preston wooden planes are stamped on the front of the plane, the shape, size, and character type of the stamp indicating the age of the plane. On some metal planes, all the parts were stamped with a number or symbol during manufacture. This number was used to re-assemble the parts following a batch process. Not all Preston tools are trade-marked clearly. Early shoulder, rebate, chariot planes, and chamfer rebates commonly appear without trademarks but may have assembly numbers. The "E P" trade-mark was already in use by 1882. The trade-mark "Preston" also appears on some later tools that were manufactured in Sheffield, England. These are generally smoothing planes and appear modern and very similar in construction to other modern manufacturers' planes.The item gives a snapshot of one of England's premier tool manufacturing companies at a time when significant industrial changes were occurring in manufacturing and business structures in the World that were beginning to affect social changes.Ogee wood moulding plane Maker E Preston & Sons No 5 (Owner A T Nipe) also has A's stamped on ends and the No 7flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Orbost & District Historical Society

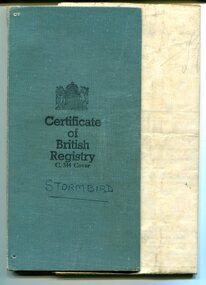

Orbost & District Historical Societycertificate, 23.2.1911

The Stormbird was built in Southport Tasmania in 1874 and was originally a steamer registered in Hobart. 1876. It was re-registered many times with different owners: William Fergusson & S.Reeves, reg. Port Adelaide; 1878: G.McKay, C.Heath & J.Yeo; 1883: G.S.Simmonds. It made regular voyages from Port Victoria. In 1893 on November14 Stormbird sank at her wharf, near Honey Street, after being struck by the Tenterden. It was raised (29 Nov) & repaired.In 1902. It was registered to A.Le Messurier. In 1904 it was registered to J.& A.Tainsh. This certificate is the record of registration for George Tainsh, a master mariner, Alice Thompson, a widow and John Tainsh, master mariner. 1922. The Stormbird was eventually lost on a voyage Madang to Wewak with the loss of two lives. This was after 1968. It had been changed to a sailing ship with an auxiliary engine in 1938.This certificate is a useful research tool and is a valuable source of information on maritime history.A small, blue folder containing a certificate of British Registry for the ship "Stormbird". Black text with additional hand-written details in red added in 1938. The certificate gives details of size, tonnage and engine. The owners are listed and it is dated 24th May, 1922 and signed by the Registrar of Shipping, Ernest Hall.stormbird-registration tainsh -

Orbost & District Historical Society

Orbost & District Historical Societytrade axe, Early 20th -mid 20th century

... axe trade-axe timber farming tool... trade-axe timber farming tool A wooden handled axe. The top edge ...This axe is fitted with a smaller head and handle than a felling axe and is probably for one-handed use. It would be used for trimming limbs and for small chopping jobs.This is an example of a tool commonly used by early generations of Orbost settlers.A wooden handled axe. The top edge of the iron blade is straight and the shape is a right-angled triangle. A yellow cord is threaded through the handleaxe trade-axe timber farming tool -

Orbost & District Historical Society

Orbost & District Historical Societyaxe head

Inspected by Joanna Freslov, archaeologist 2/6/2008. Genuine Aboriginal axe head up to 2000 years old. Possibly came through trading from western district. Stone tools were used for a variety of purposes, in ways similar to those of the steel knives, axes, hammers and chisels. Ground-edge tools are made from fracture-resistant stone, such as basalt.This stone is able to withstand repeated impact, and and wqas generall used for stone axes. The stone was dug or found and then roughly shaped into a tool blank with blows from a hammerstone. The edges were then sharpened and refined by grinding the tool against a coarse, gritty rock. The necessary tools and equipment for hunting, fishing and warfare were one of the very few items that Aboriginals carried with them from place to place. Most were used for a multiplicity of purposes. Because many were made from raw natural materials, such as wood, generally only partial remains are found today. This axe head is an example of an early stone tool used by the Indigenous people of Victoria.Small grey oval-shaped axe head.axehead stone-artifact aboriginal tool -

The Beechworth Burke Museum

The Beechworth Burke MuseumCeremonial object - Ushabti of Taweret-Khaiti, Circa 1292 BC

Ushabti are tiny anthropoid (human-shaped) figures placed in the tombs of wealthy Egyptians. They were intended to do the work of the deceased in the afterlife. This purpose is implied through their name, which may have derived from the Egyptian word “to answer”. The Burke Museum in Beechworth is home to a particular ancient Egyptian Ushabti figure. This artefact was donated to the Museum in 1875. No details about how it left Egypt, arrived in Australia, and where it was located before this donation are known. The Nineteenth Century, when this artefact was donated, was a period when many museums acquired items of ancient Egyptian heritage. Many of these items were procured in less than desirable circumstances, having often been looted from ancient tombs and sold to tourists without documentation as to their original location and/or accompanying grave goods. These artefacts were also divested through partage (the trading of artefacts for funds); however, the latter is unlikely to have been the case for this artefact. Since the Ushabti was donated by an unknown donor, it is likely to have been in a private collection rather than an institution. Ushabti can be dated using iconographic analysis which is non-invasive and provides a comprehensive study of the artefact. The later period of the 18th Dynasty marked the beginning of an increase in both the inclusion of Ushabti as essential funerary items and the creation of Ushabti with tools. From this period, they are no longer depicted without tools. Depictions of tools including gardening hoes are frequently depicted grasped in the Ushabti’s hands whilst items like the seed-bag are depicted hanging on the back rather than in an alternative position. This Ushabti figure grasps a gardening hoe and a mattock and a small seed bag surrounded by a yoke bearing water jars are depicted on the upper back of the Ushabti. These features are essential in helping narrow this dating to the late 18th and before the early 20th Dynasty. The position of this seed bag also provides dating information. In the early 18th Dynasty this bag was consistently drawn on the front of the figurine; however, by the reign of Seti I, this feature moved to the back. Thus, since the seed bag is located on the back of this Ushabti, it cannot date to the early 18th Dynasty. By the 19th Dynasty, Ushabti’s were increasingly made from either faience or terracotta. The availability of these materials in Egypt resulted in the increase of Ushabti production with tombs containing many more figurines than previously seen. The Ushabti held by the Burke collections is made from terracotta. Terracotta was rarely used for Ushabti before and during the early 18th Dynasty with only the odd appearance until the late 18th Dynasty and becoming common through that period until the late Third Intermediate Period. Whilst the face has been damaged, there is no evidence for the Ushabti having been provided with an Osirian false beard. This omission rules out a dating of later than the 25th Dynasty when beards became prominent. The inscriptions also date the Ushabti to the New Kingdom. This is because of the use of sḥḏ (“to illuminate”) with Wsjr (“Osiris”) which only occurs in these periods. Therefore, considering all these elements, the Ushabti can be confidently be dated to between the late 18th to early 19th dynasty.Artefacts like this Ushabti are no longer exclusively representative of their origins in burial assemblages and significance in the mythology of the Egyptian afterlife but are also significant for the accumulated histories they have gained through travel. The movement of this artefact from Egypt to Australia allows insight into the collecting habits of the 19th century, and in particular, the reception of ancient Egyptian artefacts in small rural museums. The procurement of Egyptian artefacts was a social trend around the late 1800s to early 1900s. Egyptian artefacts were considered curiosities and recognised for their ability to attract public attention to museums. They were also utilised in Australian museums, like the Burke Museum, to connect the collection to one of the oldest civilisations known to man and since Australia was considered a “young” country by European settlers, this was vital and derived from an interest in Darwin’s “Origin of the Species” 1859. Furthermore, there was a culture of collecting in the 1800s amongst the affluent in English society which led to the appearance of many Egyptian artefacts in private collections. The acquisition of this Ushabti figure is not certain, but it was likely donated from a private collection rather than an institution. This particular artefact is significant as an example of a high-quality Ushabti representative of those produced during the late 18th or early 19th century. It provides insight into the individualism of an Ushabti and the mythology of ancient Egypt. It also provides an example of the types of items required in the tomb assemblages of this period and reinforces the importance of ensuring the successful afterlife of the deceased through art. This Ushabti belonged to a woman named Taweret-Khaiti, Chantress of Amun, in the late 18th Dynasty or early 19th Dynasty (c.1292 BC) of the Egyptian New Kingdom. It likely comes from an undetermined tomb in the locality of Thebes. This figure is made from Nile silt clay (a polyester terracotta; clay sourced from the banks of the Nile River) which was a popular material for Ushabti construction in the early 19th Dynasty. It is in a fair state of preservation (with the exception of a break through the centre) and originally made to a high quality. The face has been damaged but the eyes and eyebrows are clearly marked with black ink and the sclera painted white. The Ushabti is painted a light brown/yellow colour and features a vertical line of inscription down the lower front. The Ushabti wears a large wig and and a schematic collar. The arms are painted light brown and depicted crossed with bracelets around the wrists. It grasps a hoe and mattock. A yellow seed-basket is depicted on the Ushabti’s back. These features represent the likelihood that this particular Ushabti was intended to complete farm work for the deceased in the next life. There would have been additional Ushabti of similar design within the tomb who worked under the supervision of a foreman Ushabti. The foreman Ushabti would be depicted dressed in the clothing of the living. The inscriptions are painted freehand in black ink and written in a vertical column from the base of the collar to the foot pedestal on the front of the Ushabti. The owner of the Ushabti could elect to have the figures inscribed with their name, the Ushabti spell and any other details they deemed necessary. In the case of this example, the Ushabti is inscribed with the owner’s details and is an abbreviated version of the standard Ushabti formula. This formula ensured that the Ushabti would complete the desired task in the afterlife when called upon by the deceased. Ushabti which were not inscribed would represent their intended purpose through design; however, this Ushabti, like most made in the late 18th Dynasty, conveys its purpose both through both design and inscription. The inscription is as follows: sHD wsir nbt pr Smayt imn tA-wr(t)-xai(ti) mAa xrw which translates to: "The illuminated one, the Osiris (the deceased), the mistress of the household, Chantress of Amun, Taweret-Khaiti, true of voice (justified)"ancient egypt -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Hand Adze, A Mathieson and Son, First quarter of the 20th Century

An adze is an ancient and versatile cutting tool similar to an axe but with the cutting edge perpendicular to the handle rather than parallel. Adzes are used for smoothing or carving wood in hand woodworking, and as a hoe for agriculture and horticulture. Two basic forms of an adze are the hand adze (short hoe) a short handled tool swung with one hand and the foot adze (hoe) a long handled tool capable of powerful swings using both hands, the cutting edge usually striking at foot or shin level. Mathieson & Sons Maker: In 1792 John Manners had set up a workshop making woodworking planes at 14 Saracens Lane Glasgow. He also had employed an apprentice Alexander Mathieson (1773-1851). But in the following year at Saracen's Lane, the 1841 census describes Alexander Mathieson as a master plane-maker now at 38 Saracen Lane with his son Thomas Adam working with him as a journeyman plane-maker. Presumably, Alexander must have taken over the premises and business of John Manners. Now that the business had Thomas Adam Mathieson working with his father it gradually grew and became more diversified, and it is recorded at the time by the Post-Office Glasgow Annual Directory that by 1847-1848 Alexander Mathieson was a “plane, brace, bit, auger & edge tool maker” In 1849 the firm of James & William Stewart at 65 Nicolson Street, Edinburgh was taken over and Thomas was put in charge of the business, trading under the name Thomas A. Mathieson & Co. as plane and edge-tool makers. Thomas's company went on to acquire the Edinburgh edge-tool makers “Charles & Hugh McPherson” and took over their premises in Gilmore Street. In the Edinburgh directory of 1856/7, the business is recorded as being Alexander Mathieson & Son, plane and edge-tool makers at 48 Nicolson Street and Paul's Work, Gilmore Street Edinburgh. The 1851 census Alexander is recorded as working as a tool and plane-maker employing eight men. Later that year Alexander died and his son Thomas took over the business. Under the heading of an edge-tool maker in the 1852/3 Post-Office Glasgow Annual Directory the firm is now listed as Alexander Mathieson & Son, with further entries as "turning-lathe and vice manufacturers". By the early 1850s, the business had moved to 24 Saracen Lane. The directory for 1857/8 records that the firm had moved again only a few years later to East Campbell Street, off the Gallowgate area, and that through further diversification was also manufacturing coopers' and tinmen's tools. The ten-yearly censuses report the firm's growth in 1861 stating that Thomas was a tool manufacturer employing 95 men and 30 boys; in 1871 he had 200 men working for him and in 1881 300 men. By 1899 the firm had been incorporated as Alexander Mathieson & Sons Ltd, even though only Alexander's son Thomas appears ever to have joined the firm so the company was still in his fathers' name. In September 1868 Thomas Mathieson put a notice in the newspapers of the Sheffield & Rotherham Independent and the Sheffield Daily Telegraph stating that his firm had used the trade-mark of a crescent and star "for some time" and that "using or imitating the Mark would be proceeded against for infringement". The firm had acquired its interest in the crescent-and-star mark from the heirs of Charles Pickslay, the Sheffield cutler who had registered it with the Cutlers' Company in 1833 and had died in 1852. The year 1868 seems also to be the one in which the name Saracen Tool Works was first adopted; not only does it figure at the foot of the notice in the Sheffield press, it also makes its first appearance in the firm's entry in the Post-Office Glasgow Annual Directory in the 1868/9 edition. As Thomas Mathieson's business grew, so too did his involvement in local public life and philanthropy. One of the representatives of the third ward on the town council of Glasgow, he became a river bailie in 1868, a magistrate in 1870 and a preceptor of Hutcheson's Hospital in 1878. He had a passion for books and was an "ardent Ruskinian". He served on the committee handling the bequest for the setting up of the Mitchell Library in Glasgow. When he died at Coulter Maynes near Biggar in 1899, he left an estate worth £142,764. The firm of Alexander Mathieson & Sons was one of the leading makers of hand tools in Scotland. Its success went hand in hand with the growth of the shipbuilding industries on the Firth of Clyde in the nineteenth century and the emergence of Glasgow as the "second city of the Empire". It also reflected the firm's skill in responding to an unprecedented demand for quality tools by shipyards, cooperages and other industries, both locally and far and wide.Hand Adze or Cooper's adze No 4 A Mathieson & Sons Glasgowflagstaff hill, warrnambool, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, adze mathieson & sons, cooperage tools, woodworking, barrel making, working timber, joiners tools, carpenters tools -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Coopers Croze, Prior to 1950

A Croze is a tool used by a cooper for cutting a groove of a barrel, cask, etc., into which the edge of both the heads of a barrel fits. The cooper uses a Croze to cut a groove into either end of the inside of the staves of the bucket or barrel so the lid or bottom would fit securely against the wood. The cooper had to make sure the pieces of wood fit tightly together so none of the contents, such as beer, milk or grain, would seep out.A tool of the cooper that is specific to his trade, this wood grooving plane has been in use since the making of barrels and wooden buckets for hundreds of years without much change to the design or how the tool is used.Croze, has 2 Lance teeth and 1 Hawk tooth.Noneflagstaff hill, warrnambool, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, croze, coopers tools, barrel making -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Mortice Machine, Mathieson and Son, 1910-1940

In 1792 John Manners had set up a workshop making woodworking planes at 14 Saracens Lane Glasgow. He also had employed an apprentice Alexander Mathieson (1773-1851). But in the following year at Saracen's Lane, the 1841 census describes Alexander Mathieson as a master plane-maker now at 38 Saracen Lane with his son Thomas Adam working with him as a journeyman plane-maker. Presumably, Alexander must have taken over the premises and business of John Manners. Now that the business had Thomas Adam Mathieson working with his father it gradually grew and became more diversified, and it is recorded at the time by the Post-Office Glasgow Annual Directory that by 1847-1848 Alexander Mathieson was a “plane, brace, bit, auger & edge tool maker” In 1849 the firm of James & William Stewart at 65 Nicolson Street, Edinburgh was taken over and Thomas was put in charge of the business, trading under the name Thomas A. Mathieson & Co. as plane and edge-tool makers. Thomas's company went on to acquire the Edinburgh edge-tool makers “Charles & Hugh McPherson” and took over their premises in Gilmore Street. In the Edinburgh directory of 1856/7, the business is recorded as being Alexander Mathieson & Son, plane and edge-tool makers at 48 Nicolson Street and Paul's Work, Gilmore Street Edinburgh. In the 1851 census, Alexander is recorded as working as a tool and plane-maker employing eight men. Later that year Alexander died and his son Thomas took over the business. Under the heading of an edge-tool maker in the 1852/3 Post-Office Glasgow Annual Directory the firm is now listed as Alexander Mathieson & Son, with further entries as "turning-lathe and vice manufacturers". By the early 1850s, the business had moved to 24 Saracen Lane. The directory for 1857/8 records that the firm had moved again only a few years later to East Campbell Street, off the Gallowgate area, and that through further diversification was also manufacturing coopers' and tinmen's tools. The ten-yearly censuses report the firm's growth in 1861 stating that Thomas was a tool manufacturer employing 95 men and 30 boys; in 1871 he had 200 men working for him and in 1881 300 men. By 1899 the firm had been incorporated as Alexander Mathieson & Sons Ltd, even though only Alexander's son Thomas appears ever to have joined the firm so the company was still in his fathers' name. In September 1868 Thomas Mathieson put a notice in the newspapers of the Sheffield & Rotherham Independent and the Sheffield Daily Telegraph stating that his firm had used the trade-mark of a crescent and star "for some time" and that "using or imitating the Mark would be proceeded against for infringement". The firm had acquired its interest in the crescent-and-star mark from the heirs of Charles Pickslay, the Sheffield cutler who had registered it with the Cutlers' Company in 1833 and had died in 1852. The year 1868 seems also to be the one in which the name Saracen Tool Works was first adopted; not only does it figure at the foot of the notice in the Sheffield press, it also makes its first appearance in the firm's entry in the Post-Office Glasgow Annual Directory in the 1868/9 edition. As Thomas Mathieson's business grew, so too did his involvement in local public life and philanthropy. One of the representatives of the third ward on the town council of Glasgow, he became a river bailie in 1868, a magistrate in 1870, and a preceptor of Hutcheson's Hospital in 1878. He had a passion for books and was an "ardent Ruskinian". He served on the committee handling the bequest for the setting up of the Mitchell Library in Glasgow. When he died at Coulter Maynes near Biggar in 1899, he left an estate worth £142,764. Company's later years: Both Thomas's sons, James Harper and Thomas Ogilvie were involved in the continuing life of the firm. James followed in his father's footsteps in becoming a local public figure. He was appointed Deputy Lieutenant of the County of the City of Glasgow and was made a deacon of the Incorporation of the Hammermen of Glasgow in 1919. His brother Thomas Ogilvie was recorded as a tool manufacturer and employer in the 1911 census. Thomas Ogilvie's son Thomas Alastair Sutherland Ogilvie Mathieson was born in 1908 took a rather different approach to engineering, however, by becoming a racing driver. In 1947 he wed the French film actress Mila Parély. The firm had won many awards at world fairs for their goods. At the Great Exhibition, London, 1851. Prize medal for joiners' tools in the class of Cutlery & Edge Tools, Great London Exposition, 1862. Prize medal honoris causa. International Exhibition, Melbourne, 1880. Gold medal International Exhibition of Industry, Science and Art, Edinburgh, 1886 Prize medal. See note section for Thomas McPherson Australian Retailer information: The firm of Alexander Mathieson & Sons was one of the leading makers of hand tools and later woodworking machines in Scotland. Its success went hand in hand with the growth of the shipbuilding industries on the Firth of Clyde in the nineteenth century and the emergence of Glasgow regarded as the "second city of the Empire". It also reflected the firm's skill in responding to an unprecedented demand for quality tools by shipyards, cooperages, and other industries, both locally and throughout the world. McPherson's started as an Australian retailer of hardware products in Melbourne going on to become a company that supplied machinery and other items for the establishment of major infrastructure projects in Australia during the early days of the colony that assisted in linking the various states and territories which became a precursor of Federation. From a humble beginning McPherson's became one of Australia's leading retail, and later manufacturing businesses that is still in existence today.Mortice machine metal with long metal lever handle with counter weight & 3 adjustment wheels & metal crank with wood end. Has 4 feet that can be bolted to floor & vertical moving piece that a cutting bit would fit into.Imprinted Alex Mathieson & Son Trademark Saracen Tool works Glasgow' also a brass plate "Thomas McPherson & Son Machinery Importer Melbourne"flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageLeg Vice, c. early 1900s

... of the tools of the blacksmiths’ trade in Victoria in the early to mid ...This leg (post) vice once belonged to Goodall and Sons, who were blacksmiths in Terang. The leg vice is a common tool of the ‘smithies’ (blacksmiths). It is also an engineer's tool but in the early 1900s the smith was often the nearest approach to an engineer’s services for many miles around. The smith was called upon to do a variety of work. The leg vice is used to hold hot iron while the metal is pounded, heated and beaten again and again until it is the required shape. Henry Goodall (1870-1936) Henry Goodall was the proprietor of garages as H. Goodall & Sons Pty. Ltd., at both Terang (McKinnon and High Streets) and Mortlake (Dunlop Street). His business was in operation in at least in 1916 and perhaps well before, considering the date of the tyre bender and its use for wagons with wooden wheels. It was still in operation in 1953, chasing up debtors in Mount Gambier Court. Amongst the employees of H. Goodall & Sons Pty. Ltd. was Ernie Entwistle, a blacksmith (a soldier who died in 1916 ) and Alfred Hodgetts, radio expert (killed in a fatal accident in 1943, when he was in his early 30s ). Henry Goodall was involved in the community as a Justice of Peace, a deputy coroner, President of the Mortlake Hospital, trustee of the Soldiers’ Memorial Hall, and as a prominent Freemason. He and his wife had two sons (Charles and John) and one daughter (Mrs. Chas. Newton, of Skipton). The leg vice is locally significant as it was used by a local company in Terang and Mortlake in their blacksmith, wheelwright and garage business. It is an example of the tools of the blacksmiths’ trade in Victoria in the early to mid-1900s.Leg vice, also called a post vice. The large iron vice stands on a post on the floor and post brackets attach it firmly to a solid object such as a workbench. The sliding metal handle winds the screw spindle in and out to change the grip of the jaws that hold the workpiece. This leg vice once belonged to Harry Goodall & Sons, blacksmiths of Terang.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, h. goodall & sons of terang, terang blacksmith, h. goodall & sons pty ltd, mortlake, ernie entwistle blacksmith, alfred hodgetts radio expert, charles goodall, john goodall, mrs. chas. newton nee goodall, trade tools, blacksmith tools, leg vice, leg vise, pose vice, post vise, terang 1900s, warrnambool district 1900s -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageAnvil, early to mid-1900s

... of the tools of the blacksmiths’ trade in Victoria in the early to mid ...This anvil once belonged to Goodall and Sons, who were blacksmiths in Terang. The smith was called upon to do a variety of work. In the early 1900s he was often the nearest person to be able to perform an engineer’s services for many miles around. An anvil is used by blacksmiths to forge and shape his work pieces. The conical horn is used for hammering curved work pieces. The anvil is a common tool of the blacksmiths (‘smithies’) and other metalworkers. There has been very little change in the basic design of the anvil since Greek and Roman times. Henry Goodall (1870-1936) Henry Goodall was proprietor of garages as H. Goodall & Sons Pty. Ltd., at both Terang (McKinnon and High Streets) and Mortlake (Dunlop Street). His business was in operation in at least in 1916 and perhaps well before, considering the date of the tyre bender and its use for wagons with wooden wheels. It was still in operation in 1953, chasing up debtors in Mount Gambier Court. Amongst the employees of H. Goodall & Sons Pty. Ltd. was Ernie Entwistle, a blacksmith (a soldier who died in 1916 ) and Alfred Hodgetts, radio expert (killed in a fatal accident in 1943, when he was in his early 30s ). Henry Goodall was involved in the community as a Justice of Peace, a deputy coroner, President of the Mortlake Hospital, trustee of the Soldiers’ Memorial Hall, and as a prominent Freemason. He and his wife had two sons (Charles and John) and one daughter (Mrs. Chas. Newton, of Skipton). The anvil is locally significant as it was used by a local company in Terang and Mortlake in their blacksmith, wheelwright and garage business. It is an example of the tools of the blacksmiths’ trade in Victoria in the early to mid-1900s. Anvil, single horn, used as a tool by blacksmiths and metalworkers. Large block of metal with a flat top face, a conical horn on one side and a ‘v’ shape on the other. The anvil’s base has a squat stand and sides that are a variety of shapes. This anvil once belonged to Harry Goodall & Sons, blacksmiths of Terang. C. early to mid-1900s.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, h. goodall & sons of terang, terang blacksmith, h. goodall & sons pty ltd, mortlake, ernie entwistle blacksmith, alfred hodgetts radio expert, charles goodall, john goodall, mrs. chas. newton nee goodall, trade tools, blacksmith tools, metalworking tool, forging tool, terang 1900s, warrnambool district 1900s, anvil, blacksmith’s anvil, single horn anvil -

Flagstaff Hill Maritime Museum and Village

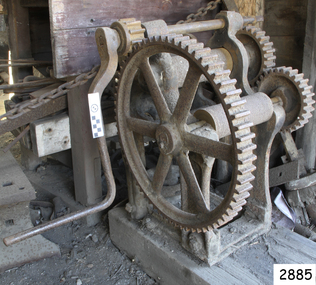

Flagstaff Hill Maritime Museum and VillageDrill Press, 1920s-1950s

... of the tools of the blacksmiths’ trade in Victoria in the 1920s-1950s ...This drill once belonged to Goodall and Sons, who were blacksmiths in Terang. The smith was called upon to do a variety of work. In the early 1900s he was often the nearest person to be able to perform an engineer’s services for many miles around. The Dawn Ball-bearing Post Drill no. 611 is described in McPherson’s Catalogue as a “drilling machine with adjustable automatic feed, with improved Dawn coupler and ball-bearing thrust’. The heavy design of the flywheel enables it to maintain momentum” and is “fitted with pulleys for belt drive if desired” The hand crank drives an automatic feed to work off a cam-follow system opposite a large wheel. Made by Dawn Manufacturing Co. Australia 1920-1950. DAWN MANUFACTURING CO. Dawn Manufacturing Co. was founded in Coburg, Melbourne, in 1917 by the four Blake brothers, who were all engineers. After World War I Dawn was supplying drills Australia wide and the company was growing at a healthy rate. During the depression they remained busy, with employees working 60-80 hour weeks. Dawn was contracted to supply vices and clamps to the Australian Defence Department and munitions factory during the World War II. In 1959 the company was taken over by G.N. Raymond Group, then in 1973 the Siddons Ramset Limited acquired Dawn. In December 1991, Dawn became a unit of the United States owned Stanley Works Pty. Ltd. In November 1998 Dawn became 100 per cent Australian owned. HENRY GOODALL & SONS Henry Goodall (1870-1936) was proprietor of garages as H. Goodall & Sons Pty. Ltd., at both Terang (McKinnon and High Streets) and Mortlake (Dunlop Street). His business was in operation in at least in 1916 and perhaps well before, considering the date of the tyre bender and its use for wagons with wooden wheels. It was still in operation in 1953, chasing up debtors in Mount Gambier Court. Amongst the employees of H. Goodall & Sons Pty. Ltd. was Ernie Entwistle, a blacksmith (a soldier who died in 1916 ) and Alfred Hodgetts, radio expert (killed in a fatal accident in 1943, when he was in his early 30s ). Henry Goodall was involved in the community as a Justice of Peace, a deputy coroner, President of the Mortlake Hospital, trustee of the Soldiers’ Memorial Hall, and as a prominent Freemason. He and his wife had two sons (Charles and John) and one daughter (Mrs. Chas. Newton, of Skipton). The drill is locally significant as it was used by a local company in Terang and Mortlake in their blacksmith, wheelwright and garage business. It is an example of the tools of the blacksmiths’ trade in Victoria in the 1920s-1950s.Dawn Ball-bearing Post Drill no. 611, made by Dawn of Melbourne, model no 611. Hand operated drill press. Self-feeding blacksmiths’ drill-press. This drill once belonged to Harry Goodall & Sons, blacksmiths of Terang. Dated 1920s-1950s. Gear ratio 2:1 main drive, 6" diam, 3:1 reduction gear. "Dawn", "Melbourne"flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, h. goodall & sons of terang, terang blacksmith, h. goodall & sons pty ltd, mortlake, ernie entwistle blacksmith, alfred hodgetts radio expert, charles goodall, john goodall, mrs. chas. newton nee goodall, terang 1900s, warrnambool district 1900s, post drill, blacksmith’s drill, dawn post drill, dawn ball-bearing post drill no. 611, blacksmiths, dawn of melbourne -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTyre Bender, 1884

... wheelwright tool blacksmith trade blacksmithing equipment and supplies ...A tyre bender is used to bend and shape metal rims for wooden wagon wheels. This tyre bender’s model first appeared in the Day Bros catalogue in 1884 as the “Giant” model. The catalogue of 1883 only showed a lighter duty model called the “Lion”. It can be assumed that this later “Giant” model was a heavy duty improvement over the 1883 "Lion" and other smaller models which were still being advertised for sale in 1884. The Day Bros foundry, makers of this tyre bender, was operating as the manufacture of wheel right and blacksmith tools and general machinery in the 19th century in the USA and successfully exported their goods all over the world. Wagon tyre benders would have been very common circa 1850-1920, so there were probably many makers over the years. Early on, it would have become clear to the blacksmiths about which designs worked best so, eventually, the various makers would have made similar products to each other. This tyre bender was once used by Harry Goodall of H. Goodall & Sons Pty. Ltd. corner of McKinnon and High Streets, Terang. Victoria. Henry Goodall & Sons Henry Goodall (1870-1936) was proprietor of garages as H. Goodall & Sons Pty. Ltd., at both Terang (McKinnon and High Streets) and Mortlake (Dunlop Street). His business was in operation in at least in 1916 and perhaps well before, considering the date of the tyre bender and its use for wagons with wooden wheels. It was still in operation in 1953, chasing up debtors in Mount Gambier Court. Amongst the employees of H. Goodall & Sons Pty. Ltd. was Ernie Entwistle, a blacksmith (a soldier who died in 1916 ) and Alfred Hodgetts, radio expert (killed in a fatal accident in 1943, when he was in his early 30s ). Henry Goodall was involved in the community as a Justice of Peace, a deputy coroner, President of the Mortlake Hospital, trustee of the Soldiers’ Memorial Hall, and as a prominent Freemason. He and his wife had two sons (Charles and John) and one daughter (Mrs. Chas. Newton, of Skipton). The tyre bender is significant as it demonstrates how blacksmiths or wheelwrights could make new metal rims for wagon wheels for carts, wagons, stage coaches and carriages over a 135 years ago. The machine is a part of our social history as it demonstrates part of the process of making wagon wheels, which played an important part in aiding the continuation of daily transport needs that people had at the time, such as farming, personal transport and commercial activities. The machine or tool is locally significant as it was used by a local company in Terang and Mortlake in their blacksmith, wheelwright and garage business. Steel tyre bender mounted on timber base, used for wagon wheel steel rims. Made from cast iron and steel, double geared with four cogs to unite the upper and lower steel rollers. There are adjustable guide collars to keep the iron in line while it is being bent. It can also be used with two cranks for heavy duty work utilising the use to two operators. It is the Giant model, made in 1884 by Day Bros. of Philadelphia. This tyre bender once belonged to Harry Goodall & Sons, blacksmith's of Terang. Victoria. “DAY BROS. PHILAP. PA” cast into the side of machineflagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, machinery, wagon wheel, wheelwrights, blacksmith, steel rim wheels, tyre bender, tire bender, the giant tyre bender, henry goodall (1870-1936), terang, wheelwright tool, blacksmith trade, blacksmithing equipment and supplies, wagon tyre bender, day bros. philadelphia pennsylvania, h. goodall & sons of terang, terang blacksmith, h. goodall & sons pty ltd, mortlake, ernie entwistle blacksmith, alfred hodgetts radio expert, charles goodall, john goodall, mrs. chas. newton nee goodall -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageVice, 1800s

... ) terang wheelwright tool blacksmith trade blacksmithing equipment ...A wheelwright’s spoke vice was used to hold the wheel hub firmly while the spokes were hammered into the wheel hub, then the spokes would be joined to the wooden wheel felloe before finally the metal flat tyre, or later the rubber tyre, would be attached to the felloe. A wheelwright’s spoke vice would have been very necessary for blacksmiths circa 1800s-1920s as it would have been used in the manufacture and repair of carts, wagons, coaches and other horse-drawn vehicles. This wheelwright’s spoke vice was once used by Harry Goodall of H. Goodall & Sons Pty. Ltd. corner of McKinnon and High Streets, Terang. Victoria. Henry Goodall & Sons Henry Goodall (1870-1936) was proprietor of garages as H. Goodall & Sons Pty. Ltd., at both Terang (McKinnon and High Streets) and Mortlake (Dunlop Street). His business was in operation in at least in 1916 and perhaps well before, considering the date of the tyre bender and its use for wagons with wooden wheels. It was still in operation in 1953, chasing up debtors in Mount Gambier Court. Amongst the employees of H. Goodall & Sons Pty. Ltd. was Ernie Entwistle, a blacksmith (a soldier who died in 1916) and Alfred Hodgetts, radio expert (killed in a fatal accident in 1943, when he was in his early 30s). Henry Goodall was involved in the community as a Justice of Peace, a deputy coroner, President of the Mortlake Hospital, trustee of the Soldiers’ Memorial Hall, and as a prominent Freemason. He and his wife had two sons (Charles and John) and one daughter (Mrs. Chas. Newton, of Skipton). The wheelwright’s spoke vice is significant as it demonstrates how blacksmiths or wheelwrights could make new metal rims for wagon wheels for carts, wagons, stage coaches and carriages over a 135 years ago. The machine is a part of our social history as it demonstrates part of the process of making wagon wheels, which played an important part in aiding the continuation of daily transport needs that people had at the time, such as farming, personal transport and commercial activities. The tool is locally significant as it was used by a local company in Terang and Mortlake in their blacksmith, wheelwright and garage business. Vice; wheelwright’s wheel spoke vice. Manufactured in 1800s. This was once belonged to Harry Goodall & Sons, blacksmith's of Terang. Victoria.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, machinery, wagon wheel, steel rim wheels, henry goodall (1870-1936), terang, wheelwright tool, blacksmith trade, blacksmithing equipment and supplies, h. goodall & sons of terang, terang blacksmith, h. goodall & sons pty ltd, mortlake, ernie entwistle blacksmith, alfred hodgetts radio expert, charles goodall, john goodall, wheel hub, wheel spoke, wheel felloe, wheel tyre, wheel tire -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageInstrument - Clock, 1900's

In August 1884, Alfred Hirst who had started his trade as a watch repairer and was described as a watchmaker extraordinaire established Hirst Brothers and Company, on Union Street in Oldham Manchester. He took his two stepbrothers into the business and the company was set up to produce timepieces and jewellery as well as importing “Limit company” Swiss watches and precision machine tools for the watch and clock trade. By 1902 Hirst Brothers. had become a limited company and was still growing, adding other businesses in Manchester in 1904 and at Birmingham in 1907. The quality of the clocks and watches was such that Alfred Hirst realised his greatest ambition in 1912 with a range of watches which carried the "Limit" trademark. These watch movements had originally been made in Switzerland and shipped to Hirst Bros. to be put into British made “Dennison” cases. This trade brought even more growth with additional sales offices opening in London and Glasgow. At the outbreak of the First World War in 1914 found them manufacturing aircraft parts including revolution counters and optical instruments. The firm had been tasked by the Ministry of Munitions to solve the problem of pilots dropping bombs by hand and as a result, they effectively created the first bomb rack. After the war, the company once again began to prosper and with the demand for their products increasing they looked to build a new purpose-built factory to manufacture their products. In 1917 they purchased a seven-acre field site at Tame Side Dobcross, the designing of the new factory was passed onto local architect AJ Howcroft. His brief for the design of the clockworks would have been prompted by Alfred Hirst who having visited modern factories in the United States was inspired by the latest factory designs providing as much daylight as possible during working hours. The factory was eventually completed in 1920, by the mid-1920s there were cheap clock imports from Germany and production turned to radio sets and other components as well as counter and gas meters for the "Parkinson and Cowan" company who was later to take over the business. In 1926 came the cotton crash and the District Bank who had loans with the company foreclosed on the Hirst loan. The company did survive and throughout the second World, War II were involved in munitions work at the factory as well as making instruments for various aircraft. In the 1950’s they were producing meters and high grade measuring equipment but by the 1970's the business had closed and the factory was demolished in the mid-1980 "s The item is a good example of the later use of an early mechanism “Fusee” that was originally invented around 1525 in Prague. This type of clock mechanism was replaced as watchmakers looked for mechanisms that could reduce the size of clocks and watches, it appears England was the only country to continue making clocks with a Fusee device until around 1900,s of which our clock is an example. The use of a Fusee movement eventually became obsolete in 1970,s. The item is significant for the collection as it is a clock with a movement that has long since been made obsolete. Fusee type gallery wall clock made by Tame Side with an 8-day mechanical fusee movement. The white enamel dial is a little crazed and some of the Roman Numeral numbers are fading due to over-cleaning. The movement has a hexagonal iron pendulum bob hooking onto a pendulum rod with a spring-wound anchor escapement.Only mark is stamped on the movement believed to be a production number "13490" and made in Tame Side. (If the clock had been made after 1912 it would have had a trade mark "Limit")flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, clock, wall clock, fusee, gallery clock, alfred hirst, tame side -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageLead Beater Balls, 19th to 20th century

... or mallet. These lead beater balls are a good example of the tools ...These lead beater balls were used be plumbers to shape metal. The balls would be held in a sling and the lead was formed around them by being beaten with a hammer or mallet.These lead beater balls are a good example of the tools of trade for plumbers.Lead Beater Balls, quantity of 47, rounded solid wooden balls with domed ends, various sizes. Balls were used by plumbers for beating lead into different shapes and sizes, spheroid in shape and ranging in size. Balls were placed in a sling and lead was formed around them by beating with a Bossing mallet e.g. Item No 1449.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, plumbers tools, lead beater balls, plumber's balls