Showing 10 items matching "vertical feed"

-

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageBook - Instruction Manual, Illustrated Directions for using the New High Arm Davis Vertical Feed Sewing Machine, 1883-1885

... Vertical Feed Sewing Machine...Vertical Feed... with the Davis New High Arm Vertical Feed (VF) Sewing Machine. The first... Arm Vertical Feed Sewing Machine, a foot treadle machine made... DAVIS Vertical Feed Sewing Machine and its Accessories... was produced for use with the Davis New High Arm Vertical Feed (VF ...This book of Illustrated Directions was produced for use with the Davis New High Arm Vertical Feed (VF) Sewing Machine. The first model of the High Arm was produced in 1881, and the ‘New’ model, Model 2 VF, was introduced from 1883 and continued at least until 1885, when the Model 3 VF was manufactured. Job Davis, an inventor, showed his Davis Sewing Machine to two brothers in Watertown. The brothers, John and Joseph Shaldon, who founded the Davis Sewing Machine Company in February 1868 in Watertown, New York. The firm moved to Ohio in the 1890. Its early sewing machines were known as the Vertical Feed machines. These machines differed from others, in that there were two presser feet that moved and held the cloth as the needle went in and out of it. This type of action was also called ‘walking foot’ by makers of similar machines. Other machines used a feed dog below the machine’s bed to move the fabric. The Davis Company was awarded a Patents for its improvement to sewing machines. London offices were set up at 54, Queen Victoria Street, London in 1982. It was known as the Vertical Feed Sewing Machine Company. An article published in March 1885 states that the London Manager of the Vertical Feed Sewing Machine Company has 300,000 machines world-wide, including 4,000 in England alone. It claimed that the Auxiliary Forces Uniform and Equipment Company in Limerick, Ireland, was running its machines with steam power and could produce first-class work at the rate of 1,500 stitches per minute. The hand stitched binding of the manual is an example of early book binding processes. The is significant for its relationship to the Davis New High Arm Vertical Feed sewing machine, which was invented in 1866 and became popular in the domestic market. It was also used in industrial conditions as a labour-saving machine, one of the many machines that were part of the Industrial Revolution when steam power replaced manual power in many factories. Paper book with stitched binding. Printed text and illustrations contained within the 42-page booklet. The manual includes drawn diagrams and instructions for use of the Davis New High Arm Vertical Feed Sewing Machine, a foot treadle machine made in the 1880s. Front cover: "ILLUSTRATED DIRECTIIONS for the NEW HIGH ARM DAVIS Vertical Feed Sewing Machine and its Accessories and Attachments"flagstaff hill maritime museum and village, great ocean road, shipwreck coast, sewing machine manual, davis sewing machine, new high arm sewing machine, model 2 vf, vertical feed, sewing machine instructions, sewing machine directions, job davis, john sheldon, joseph sheldon, high arm sewing machine, watertown, new york, vertical feed sewing machine company, treadle, steam sewing machine, auxiliary forces uniform and equipment company, limerick, ireland -

Clunes Museum

Clunes MuseumPlan, CLUNES WATER SUPPLY

... CONTRACT NO. 740 2 HORIZONTAL SCALE FOUR CHAINS TO AN INCH VERTICAL... SCALE FOUR CHAINS TO AN INCH VERTICAL SCALE FORTY FEED ...DRAWINGS MADE TO SET UP A PERMENT PIPED WATER SUPPLY TO NEW NORTH MINE, CLUNES, VICTORIA, AUSTRALIA1 PAGE PLAN WITH DRAWING OF CLUNES WATER SUPPLY ON WAXED PAPER USING RED, BLACK AND BLUE INKCLUNES WATER SUPPLY LONGITUDINAL SECTION OF CENTRE LINE OF THE LOWER AWUEDECT FROM WEIR A TO SERVICE RESERVOIR DRAWING 420 5 CONTRACT NO. 740 2 HORIZONTAL SCALE FOUR CHAINS TO AN INCH VERTICAL SCALE FORTY FEED TO AN INCH SIGNED BY OCTAVIUS LANGTREE WORKS ENGINEER 13/12/1870octavius langtree, peter lalor, clunes water supply -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyMould Candle Making, Circa mid 1900's

... basin for vertical hollow tubes to feed off. The six tapered... holes in the top basin for vertical hollow tubes to feed off ...Candle stick manufacturing moulds were extensively used throughout the Kiewa Valley and its regions to provide rural homes and businesses with illumination during times of limited light e.g. night time. These candles were used before the Kiewa Valley was placed of the electrical grid. The candles were made from parrafin wax. Before the 1920"s electricity was in limited supply due to the inability of the private electricity suppliers to service isolated rural regions. It was not until the Victorian State Government passed legislation (1920) to improve electricity supplies by forming the State Electricity Commission of Victoria (S.E.C.V.) Isolated rural communities could not meet the higher costs to have electricity supplies connected and therefore it was not until the 1950's that adequate domestic electrical power could be supplied.The isolation that the Kiewa Valley provided was of a greater hindrance to any utility (power,roads & telephone) where the cost per instillation was beyond the rural population's ability to pay either directly or indirectly. One of the benefits that the "closed" community of Mount Beauty had, when it was administered by the SECV was that some utility costs were a lot lower than that of the other settlements in the Kiewa Valley. This disparity led to a conference in 1928 of the rural and regional councils to demand from the Government an equality of electricity tariffs. This equality did not take place until 1965. The demand and usage of cheaper and affordable lighting that wax candles provided was for some rural families a way of life until the mid 1900's.This candle making mould is made from mild rolled sheet steel(tin). The top basin is rectangular in shape with beveled edges(facing in on all sides. There are six holes in the top basin for vertical hollow tubes to feed off. The six tapered cyclindrical tubes running from the top basin to the bottom raised platform base. All connections are welded together. The bottom of each cylinder has an opening for the candle wick. The wick is positioned in place before the molten wax is poured into the cylinders. A positioning ring has been welded to one bottom ring for stability.parrafin wax, candles, domestic household ighting -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyBottle - Medical

This bottle was used in the Tawonga District General Hospital which was built in the 1950's specifically for the increase in population due to the Kiewa Hydro Scheme.Baby's feeding bottle. Small clear glass bottle with heavy embossing on the side and wide lip at the opening.On side vertically: Nestle / Lactogen / Regd and opposite: at the top 'MLS with a gauge underneath from 120, 100, 50 with horizontal lines every 10 ml baby's feeding bottle, nestle, lactogen, hospital -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Book - ERROL BOVAIRD COLLECTION: THE WEEKLY TIMES FARMERS HANDBOOK

Book with green cloth cover, black printing, black vertical and horizontal lines, and a black Logo of The Herald Press. It has a man on a rearing horse playing a trumpet. Livestock covered are horses, cattle, pigs, sheep, poultry, dogs, cats and ferrets. Also covered are fruits, vegetables, flowers General Information, Index to Advertisements, Clearing Out Rabbit Warrens, The Horse and Its Harness, Economical Feeding of Livestock and Good Fencing is a Wise Investment.john bovaird collection - the weekly times farmers handbook, farmers' information bureau, the herald press, the herald and weekly times ltd melbourne -

Royal Australian and New Zealand College of Obstetricians & Gynaecologists (RANZCOG)

Royal Australian and New Zealand College of Obstetricians & Gynaecologists (RANZCOG)Infant feeding bottle with thermometer, 'Kuwa', Germany, c. 1925

The neck of this bottle is quite wide and would have been fitted with quite a large teat. The use of an inbuilt thermometer on this bottle by the manufacturers, Kuwa, was quite innovative.Cylindrical glass feeding bottle, with calibrations for 1 to 8 (ounces) and 50 to 200 (mls). There is a vertical recess in centre front of the bottle, which contains a thermometer. There are two vertical seams in the glass, and a longitudinal bubble in the glass near the neck. Embossed on the neck of the bottle: "Kuwa" and "Made in Germany" on the lower front of bottle near the base."KUWA"; "MADE IN GERMANY"infant feeding -

Puffing Billy Railway

Puffing Billy RailwaySteam Driven Weir Pump, 1900s

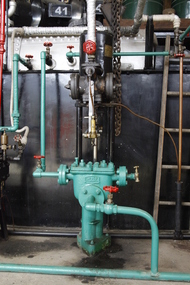

Weir Pumps - these types of vertical pumps were used extensively with both land and marine steam pumps. The pumps were also used for various duties from pumping oil fuel and feed water for boilers, to draining bilges on steam ship[s They are a single cylinder, double acting vertical pumps used by G. & J. Weir Ltd. , of Cathcart, Glasgow Historic - Weir Vertical PumpSteam Driven Weir Pump Green and Black with metal parts.No. B49717puffing billy, weir, steam pump -

Puffing Billy Railway

Puffing Billy RailwayVertical Pump, Weir, 1948

Weir Pumps - these types of vertical pumps were used extensively with both land and marine steam pumps. The pumps were also used for various duties from pumping oil fuel and feed water for boilers, to draining bilges on steam ship[s They are a single cylinder, double acting vertical pumps used by G. & J. Weir Ltd. , of Cathcart, Glasgow The large pump serial number 231703 was built in 1948 and worked at the old Victoria Brewery in East Melbourne before coming to the Museum in 1985. Historic - Weir Vertical Pump used at the old Victoria Brewery in East Melbourne The large pump serial number 231703 was built in 1948 and worked at the old Victoria Brewery in East Melbourne before coming to the Museum in 1985.Weir Vertical Pump - Large Steel PumpWeir puffing billy, weir vertical pump, victoria brewery -

Puffing Billy Railway

Puffing Billy RailwayWeir Pump ( no. 2 ), Vertical ( no. 2 )

Weir Vertical Pump Weir Pumps - these types of vertical pumps were used extensively with both land and marine steam pumps. The pumps were also used for various duties from pumping oil fuel and feed water for boilers, to draining bilges on steam ship[s single cylinder, double acting vertical pumps used by G. & J. Weir Ltd. , of Cathcart, Glasgow .Weir Vertical Pump ( no. 2 ) - Steel vertical pumpWeirpuffing billy, fluid pump, weir, vetical pump -

Harcourt Valley Heritage & Tourist Centre

Harcourt Valley Heritage & Tourist CentreCider Press, 1880s

... flywheel, wooden feed hopper in vertical arrangement, wooden frame... flywheel, wooden feed hopper in vertical arrangement, wooden frame ...A 'BUCKEYE" grape and cider press, manufactured by P.P. Mast & Co. of Springfield, Ohio, USA and distributed by P. Rohs, Sandhurst (Bendigo). The PP Mast Company was established in 1854. Their Buckeye drills, seeders and other implements played an important role in the development of American farm machinery, being sold in every American state, Europe and Australia. This press was used by the Gaasch family of Harcourt over several generations from 1898 to crush grapes for wine and vinegar making, subsequently to crush apples and then press the pulp to make apple vinegar and cider. The crushing was accompanied by lusty singing of songs and hymns such as 'Ein Feste Burg ist unter Gott'. The press was designed to be hand-operated but was later used by Harcourt Coolstores to press apples. It was then belt-driven by an electric motor. The press was restored (timber cleaned and varnished, metal shoes on base of wooden uprights, which had rotted ) by Mr. Howard Carr, 2001-An early application of mechanics to the crushing of grapes. Hand-driven, geared drive metal crushing parts, with metal flywheel, wooden feed hopper in vertical arrangement, wooden frame, tray and vat, with metal pressing screw installed in heavy metal yoke at front. Metal crushing section carries cast-in maker's name and patent details'BUCKEYE" manufactured by P.P. Mast & Co. of Springfield, Ohio, USA distributed by P. Rohs, Sandhurst (Bendigo).