Showing 23 items matching "weft"

-

National Wool Museum

National Wool MuseumPamphlet, Krantz Weft Straightener

"Krantz Schussfadenrichter (weft straightener)" - H. Krantz Appreturmaschinen - Fabrik, Aachen, Germany.Pamphlet / catalogue for a Krantz Schussfadenrichter (weft straightener) by H. Krantz Appreturmaschinen - Fabrik, Aachen, Germany, c.1960s.textile machinery, h. krantz appreturmaschinen-fabrik -

National Wool Museum

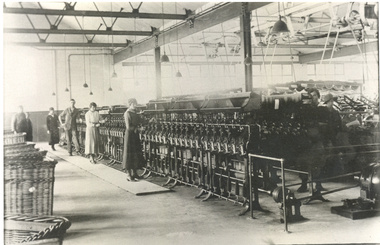

National Wool MuseumPhotograph, Federal Mill 1918: weft winding department

James Murgatroyd worked in textile mills in England, Victoria and NSW. His son Fred worked as a loom tuner at Yarra Falls, Tweedside and Collins mills in Victoria as well as in Sydney, and studied at Leeds University.The Murgatroyd CollectionFEDERAL MILL - 1918/ WEFT WINDING DEPT FILM No13textile machinery textile mills weaving mills textile mills - staff textile mills, federal woollen mills ltd tweedside woollen mills yarra falls mill collins bros mill pty ltd, winding, murgatroyd, mr fred murgatroyd, mr james, textile machinery, textile mills, weaving mills, textile mills - staff -

National Wool Museum

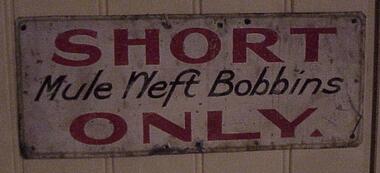

National Wool MuseumSign - Short Mule Weft Bobbins Only, Collins Bros Mill Pty Ltd

Taken from Collins Mill around 1984.Painted rectangular sheet metal sign reads "SHORT Mule Weft Bobbins ONLY". The sign is painted on one side and has a white background with a green strip around border.SHORT(red paint) Mule Weft Bobbins (black paint) ONLY (red paint)collins mill, signs, textile industry, wool, bobbins, weft -

National Wool Museum

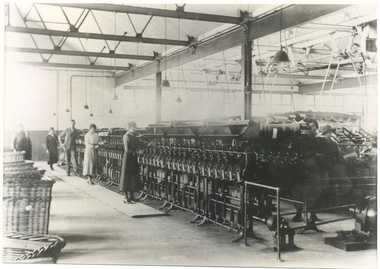

National Wool MuseumPhotograph, Federal Mill 1918: weft winding department

James Murgatroyd worked in textile mills in England, Victoria and NSW. His son Fred worked as a loom tuner at Yarra Falls, Tweedside and Collins mills in Victoria as well as in Sydney, and studied at Leeds University.The Murgatroyd Collectiontextile machinery textile mills weaving mills textile mills - staff textile mills, federal woollen mills ltd tweedside woollen mills yarra falls mill collins bros mill pty ltd, winding, murgatroyd, mr fred murgatroyd, mr james, textile machinery, textile mills, weaving mills, textile mills - staff -

Whitehorse Historical Society Inc.

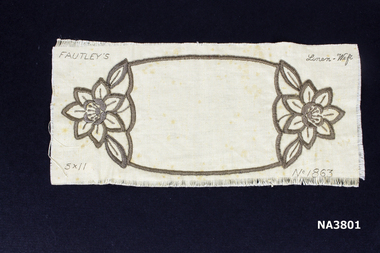

Whitehorse Historical Society Inc.Textile - Embroidered doiley

The doiley was worked by Betty Harrison, wife of Don Harrison. It is a sample of cutwork embroidery. The doiley was worked and when finished the pattern was cut out, leaving the centre uncutThe doiley is a part of a handcraft kit sold by Fautleys fancy work shops, and Needlework shops. Needle work such as embroidery was a very popular social activity during that era.Unfinished piece of cutwork in shape of oblong doiley. Brown cotton thread has been worked to shape star-shaped flowers at each end as well as the bordersFautley's Linen-Weft 5 x 11 No. 1863handcrafts, embroidery -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Caulking iron, Mid-to-late 20th century

Caulking is the use of cork or other substances to seal the seams and joints of the vessel to make them watertight. Caulking lasts for quite some time but eventually dries out and needs to be replaced. A hammer is often used with a caulking iron to drive it along the seams. The caulking iron’s blade is tapered to be narrower at the tip to make it easier to remove it from the joint. The shipwright’s tools on display in the Great Circle Gallery are connected to the maritime history of Victoria through their past owner, user and donor, Laurie Dilks. Laurie began his career as a shipwright in the mid-1900s, following in the wake of the skilled carpenters who have over many centuries used their craft to build and maintain marine vessels and their fittings. You can see Laurie’s inscription on the tool called a ‘bevel’. Laurie worked for Ports and Harbours, Melbourne, for over 50 years, beginning in the early 1960s. He and a fellow shipwright inscribed their names on a wheelhouse they built in 1965; the inscription was discovered many decades later during a repair of the plumbing. Many decades later Laurie worked on the Yarra moving barges up and down the river and was fondly given the title ‘Riverboat Man’ His interest in maritime history led him to volunteer with the Maritime Trust of Australia’s project to restore and preserve the historic WWII 1942 Corvette, the minesweeper HMAS Castlemaine, which is a sister ship to the HMAS Warrnambool J202. Laurie Dilks donated two handmade displays of some of his tools in the late 1970s to early-1980s. The varnished timber boards displayed the tools below together with brass plaques. During the upgrade of the Great Circle Gallery Laurie’s tools were transferred to the new display you see there today. He also donated tools to Queenscliffe Maritime Museum and Clunes Museum.The shipwright’s tools on display in the Great Circle Gallery are connected to the maritime history of Victoria through their past owner, user and donor, Laurie Dilks. Laurie began his career as a shipwright at Ports and Harbours in Melbourne in the mid-1900s, following in the wake of the skilled carpenters who have over many centuries used their craft to build and maintain marine vessels and their fittings.Caulking iron, or broad chisel, wooden handle with reinforcing on the ends, metal shaft that tapers down from the handle to the end of the blade. It has an inscription. It once belonged to shipwright Laurie Dinks.Stamped into metal " - - WARD /(image of crossed swords) WEFT / WARRANTED"flagstaff hill, warrnambool, great ocean road, shipwreck coast, maritime museum, maritime village, shipwright, carpenter, shipbuilding, ship repairs, hand tool, equipment, ship maintenance, cooper, tool, marine technology, caulking iron, jerry iron, broad chisel, caulking, sealing, laurie dilks, l dilks, port and harbours melbourne -

National Wool Museum

National Wool MuseumPhotograph

Fred Murgatroyd worked as a loom tuner at Yarra Falls, Tweedside and Collins mills in Victoria as well as in Sydney, and studied at Leeds University.Murgatroyd Photograph CollectionF Murgatroyd Federal/ Pirn - (weft) winder c 1918-1919textile machinery textile mills weaving mills textile mills, collins bros mill pty ltd tweedside woollen mills yarra falls mill federal woollen mills ltd, murgatroyd, mr fred murgatroyd, mr james, textile machinery, textile mills, weaving mills -

National Wool Museum

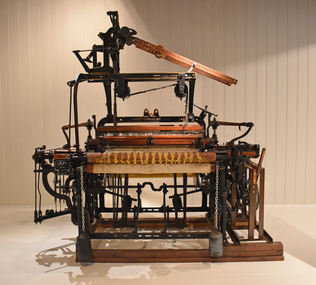

National Wool MuseumMachine - Loom, George Hattersley and Sons Ltd, 1920 - 1935

Weaving is the interlacing of two yarns, one at right angles to the other. Yarns that run the length of the fabric are called the warp. Yarns that run across the fabric are called the weft. Most woven fabrics are produced on a loom. The warp yarns are raised to form an opening - the shed. The weft carrier, usually the shuttle, shoots through the shed. Then the warp yarns change position up and down. Finally, the weft is pushed tight against the previous yarns, gradually building up the fabric. Hattersley dobby loom. In working order, black painted cast iron.weaving, george hattersley and sons ltd, weaving machinery, loom, wool processing, textile industry -

National Wool Museum

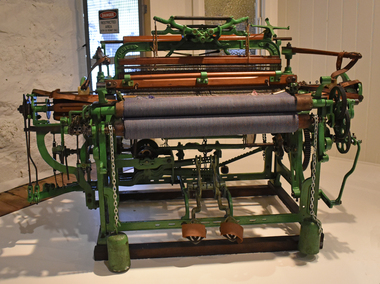

National Wool MuseumMachine - Loom, George Hattersley and Sons Ltd, 1920 - 1925

Weaving is the interlacing of two yarns, one at right angles to the other. Yarns that run the length of the fabric are called the warp. Yarns that run across the fabric are called the weft. Most woven fabrics are produced on a loom. The warp yarns are raised to form an opening - the shed. The weft carrier, usually the shuttle, shoots through the shed. Then the warp yarns change position up and down. Finally, the weft is pushed tight against the previous yarns, gradually building up the fabric. Hattersley treadle loom (revolving box hand loom). Beam of loom was removed and sent to Foster Valley Mill in 1989 to be returned via Tom Crocker. The National Wool Museum gratefully acknowledges the contribution of Mr Fred Murgatroyd & Mr Bernard Tolan in making this Hattersley Loom Operational. Green painted Hattersley treadle loom (revolving box hand loom).weaving, george hattersley and sons ltd, weaving machinery, wool processing, loom, restoration -

Kew Historical Society Inc

Kew Historical Society IncDecorative object - Silk table runner embroidered with silver bullion, c.1860

When donated by Mrs Docherty in 1991 it was described as a Scottish sideboard runner dating from the 1860s.Embroidered textile formerly used as a table runner. When donated by Mrs Docherty in 1991 it was described as a Scottish sideboard runner dating from the 1860. The design and construction of the fabric is probably Indian in origin. It includes an extensive use of silver bullion on a cream silk ground to define the areas of abstract floral patterning. The warp or weft of the cream silk ground has disintegrated in sections.textiles - international, embroidery, table runners -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Clothing - Lady's nightdress crepe de chine, floral c1950, c1950

Gladys Reed was a member of the Ormond Choral Society c 1950. who performed plays and musicals in the City of Moorabbin and she made this nightdress c1950 Crepe de Chine, also spelled Crêpe De Chine, (French: “crepe of China”), light and fine plain woven dress fabric in silk, wool, or synthetic fibre fabric with a distinctively crisp, crimped appearance produced either with all-silk warp and weft or else with a silk warp and hard-spun worsted weft. This material was easy to sew, wash and dry and required no ironing . . This crepe de chine nightdress is an example of the popular style worn by women in the post World War 11 Estates in the City of Moorabbin c1950 A lady's floral crepe de chine, full length, nightdress with shoulder straps and waist ties clothing, nightdress, crepe de chine, theatrical props, craftwork, sequins, beading, early settlers, moorabbin shire, mechanics institute cheltenham, ormond choral society, postworld war 11 settlers, housing estates moorabbin 1950, bentleigh, ormond, moorabbin, cheltenham, drama societies, musical society cheltenham, clark judy, reed gladys, reed george -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Clothing - Clothing, lady's Bombasine jacket, c1900

This lady's jacket would have been worn for special occasions by an early settler of the Moorabbin Shire c1900. Bombasine material was usually black and worn during the mourning time. It has a dull, twilled surface with a silk warp and worsted wool weftA lady's shiny black Bombasine dress jacket with embroidery at buttonsclothing, brighton, moorabbin, pioneers, sewing, dendy henry, early settlers, craftwork, jackets -

National Wool Museum

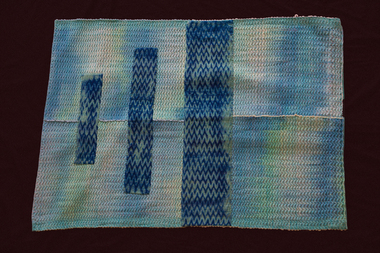

National Wool MuseumQuilt, Cross Currents

Expressions 2004 Quilt PrizeWeaving consisting of four panels sewn together to form the quilt. Consists of gradations of green to blue colours containing flecks of multicoloured wool through the weft. Weaving forms raised zigzag pattern running left to right through quilt. Three woven blue panels are sewn to the front of the quilt with dyed dark blue zigzags. The quilt is hung on a cardboard roll at the top. Satin square containing the artist's name and address sewn onto the back of the quilt in the right hand corner.'Cross Currents', Jean Inglis, 13 Park Street, Geelong, 52295131weaving, inglis, jean - geelong handweavers and spinners guild inc. -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Toiletries, steel, hair curling tongs, c1900

Hair curling tongs were used by women 1800 - 1950 to create appealing curls and ringlets in their hair. To achieve ringlets, the tongs were heated on a gas ring, stove top or flame and then thick weft of hair was wound around one side of the tongs. The tongs were then 'crimped' together and upon release a long ringlet of hair resulted . If the tongs were overheated the hair was singed producing a lingering malodour. A pair of lady’s steel tongs, with no clamp, for hair curling. toiletries, hairdressing, early settlers, market gardeners, moorabbin, bentleigh, cheltenham, marcel waves -

National Wool Museum

National Wool MuseumClothing - Dress, 1979

This dress was created by Jean Inglis for a competition of garments hosted by the Geelong Handweavers and Spinners Guild at a ski weekend in 1979. It was entered in the ‘evening wear’ category of hand spun and knitted garments. The Warp was commercially brought 2/24 wool. The Weft was hand spun black Corriedale wool. This wool was brought at a sale in Geelong and was hand dyed and spun by Jean. The patter is a ‘Ripple’ variation of a ‘Crackle’ weave completed on Jean’s own Dobby Loom (pictured). Long black dress stretching from the feet, reaching up to a hood at the neckline and down to the hands in the sleeve. The dress is black with a glossy silver pattern in the form of a band around the hood, hands and feet of the garment. In these bands is a wavy pattern of silver and black lines. There are multiple thick and thin lines of both the silver and black colours mirroring each other as the pattern stretches around the garment. wool, weaving, hand spun, corriedale -

National Wool Museum

National Wool MuseumClothing - Dress, 1993

This dress was made for the Melbourne Show in 1993 and won 3rd prize. It was designed by Jean Inglis who was inspired by the Blue Triangle Butterfly (Scientific name: Graphium sarpedon choredon). The Warp was 2/24 commercially brought black wool with a “tie down” thread of black polyester and Weft of the same 2/24 wool 2 ply. Jean utilised a twill technique devised by Theo Morgan in creating the dress. The dress was handwoven by Jean Inglis with the help of Ruth Rondell with some of the pattern and final sewing. Black dress stretching from below the knees, reaching up to the neckline and down to the hands in the sleeve. The dress has three butterflies attached to the front approximately 50mm in diameter going from right knee to left hip in a nonvisible diagonal line. Lower half of dress has ten thin blue & green lines of varying lengths, reaching a max height of the hip. The neck of dress has four frills of blue and green colour. The longest two frills are in the centre pointing diagonally outwards towards the hands. The second layer of frills is shorter and further around the neckline towards the shoulders. The dress is completed with a cape of blue and green colour with a thick black seam separating each segment of colour. The cape sits on the shoulders and droops to a height of the hips. At the rear, the cape reaches the height of the rump. The cape has two draw strings for tying to the shoulders. wool, butterflies, melbourne show, butterfly -

National Wool Museum

National Wool MuseumClothing - Suit, 1987

Hand spun, hand dyed, hand woven and hand sewn suit which won best garment in the 1987 Geelong show. Size 12 in a design by Chanel. It was spun with variegated natural greys on a Sheridan horizontal spinning wheel. It was then dyed pink using natural dyes. The jacket had commercially brought warp and hand spun weft in twill on a 24” loom. All spinning, dyeing and weaving was by Jean Inglis of Geelong. The suit was sewn by Caroline Mogic of Geelong, with iron on interfacing, commercially brought trim. It was worn only once in the parade at the Geelong show. The pink suit jacket has four pockets with gold buttons on front, size 12. The jacket has a checker-plate pattern in which the predominate pink is always present and is accompanied in areas which have grey or white showing through the pink. This checker plate pattern continues down the sleeves of the jacket. The edge of the jacket has a lighter pink trim. A pink skirt accompanies the suit jacket. It has horizontal lines with pink as the predominate colour and areas of grey and white showing through in sections. geelong show, hand spun, hand dyed, hand woven, hand sewn, channel -

Greensborough Historical Society

Greensborough Historical SocietyNewsletter, Greenhills and North Greensborough Progress Association, Community News: official journal of the Greenhills and Nth. Greensborough Progress Association and the Apollo Parkways Progress Association. 2nd November, 1976. Edition No. 10/76, 02/11/1976

This edition includes a report on the The Apollo Parkways Progress Association's October 1976 meeting, Arts & crafts issue, A local art/craft who's who, Keeping embroidery alive, Creation pangs, We're hooked!, Warp & weft, Road signs, symbols and your child's art, Hooking your own rug, Cameo of Ron Reynolds, Diamond Valley Arts Society, From the Council Chamber, Letter to the Editor, Nursing Mothers Association, Diamond Valle Repertory, Kinder news, Scout and Guide news. Supplement to "Community News" No. 10/76. Women's Recreational Program. A digital copy of this Newsletter is available from Greensborough Historical Society. Newsletter, 28 p., illus.greenhills and north greensborough progress association, greenhills, apollo parkways progress association -

National Wool Museum

National Wool MuseumClothing - Jacket, 1978

The wool for this jacket began on the back of two sheep many kilometres apart. The first fleece for the warp was shorn from a single Merino at Currotha in Moree, NSW. The wool was 21-22 micron and the bloodline is a cross between Bundemar, Rossmore and Eural. The second sheep that provided wool for the weft was shorn in Beaufort, Victoria. It was a single Corriedale fleece shorn at Niawanda. The distance between these two towns is approximately 1250kms; a 15-hour car ride between paddocks. The two fleeces were spun and weaved together by the donor’s mother, Marjorie Allnutt. A level of talent is required to spin Merino fleeces. It is easier to spin cross bred wool, such as Corriedale, because it is less dense and much easier to comb, card and then tease out for a spinning wheel. The donor Philip Allnutt had a suit tailored out of the completed fabric at Ravensdale J & Son, 37 Swanson Street, Melbourne. The tailor was then a member of the Master Tailors Federation of Victoria. The business closed around 1986. Adding to the jacket’s story is its relationship to the household board game “Squatter”. Marjorie Allnutt was the sister-in-law of Robert Crofton Lloyd, the inventor of the wool themed boardgame. With more than 500,000 games sold in Australia as of 2007, it is the most successful board game ever produced in the country. The original “Squatter” board game is located within the National Wool Museum’s Collection. Philip Allnutt donated the Jacket to the National Wool Museum Collection in 2021. Cream singled breasted jacket with a narrow overlap and one column of buttons for fastening. The jacket features notched lapels of a medium width and two buttons of a cream & brown marble. The jacket has three visible pockets. A jetted pocket with no flap is on the right breast. A further two jetted no flap pockets finish an inch above the hem, on either side of the opening. Internally, the jacket features a further two pockets and a white silk lining for comfort. At the cuffs, the jacket utilises another 2 buttons of the same cream & brown marble.merino, currotha, moree, nsw, niawanda, corriedale, beaufort, victoria, hand spun, hand weaved -

National Wool Museum

National Wool MuseumClothing - Jacket, Mrs Jean Inglis, 1988

This jacket is by the prolific spinner and weaver Jean Inglis. It has been woven with a warp of commercially brought wool & a weft of hand spun Corriedale. It is completed in a Swedish lace style of weaving. The highlight of the jacket is the blue section of fabric on the top left shoulder of the wearer, which works down to the bottom right hip. This pattern looks like long thin individual separate sections of fabric stitched to the jacket; however, only one section of fabric has been added. A dying technique has been utilised to give the appearance of multiple sections. This Japanese dyeing technique is called Shibori, “to wring, squeeze or press". It is a manual tie-dyeing technique, which produces several different patterns on fabric. The specific pattern on this fabric is known as Kumo Shibori. It utilises bound resistance. This technique involves folding sections of the cloth very finely and evenly. Then the cloth is bound in very close sections. The result is a very specific spider-like design. This design requires very precise technique. Specific to this jacket, the fabric for the dyed section was made with the same fabric as the rest of the jacket. A section of the excess fabric was concertina wrapped around a 100mm pipe and tied up before dying. This gives the consistent straight blue lines, with no bleed from the dye. The sections were then sewed into the jacket with the occasional sequin added for additional decoration and glamour. The jacket won 1st prize at the 1988 Geelong Show. Jean was assisted by the dress maker Ruth Randell with some of the design and sewing. Jean always found sewing “a bit of a bore”. The jacket also has an attached swing tag. It was added to provide information to the judges at the Melbourne Show on how the jacket was created. It comes complete with Jean’s self-proclaimed terrible handwriting. It was donated to the National Wool Museum in 2021.Cream singled breasted jacket with no overlap. The jacket has no column of buttons for fastening, or lapels. It is designed to be plain, to not draw attention. The jacket is highlighted by the Shibori dyed waves on the top left shoulder of the wearer, which works down to the bottom right hip. This blue dyed section of fabric is dotted with the occasional blue sequin. Internally, the jacket features a white silk lining for comfort. The jacket ends in a straight cut hem, including at the cuffs. The jacket has an attached swing tag. The swing tag is cream with a printed thin black boarder. Within the boarder, handwriting in black ink is found. It has a hole punch in the top left corner of the swing tag for attaching to the jacket.hand spun, hand weaving, textile design, textile production, shibori, kumo shibori -

National Wool Museum

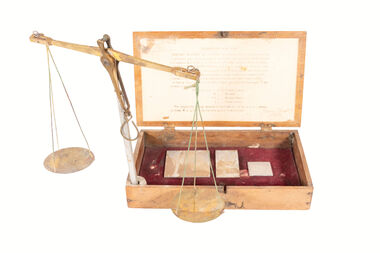

National Wool MuseumInstrument - Scales, 1880-1898

At the time of sale, the last of the Hirst family to work in the mill located in Geelong gave Donald (donor Bruce's father) Doherty a set of scales that had been used by several generations of Hirsts and adapted by them over time for specific use in their mill. These Scales were saved from waste and being thrown away at the time of sale to remain in use in the industry in the hands of someone who knew how to use them. The scales were used in calculating the weight of cloth and simultaneously calculating the amount of yarn required to weave it following the instructions printed within the box. The box bears the signatures of two Hirst family members, one being Lewis Hirst dated at 1898. The original brass pole has been replaced with a replica metal somewhere throughout the years after the brass pole broke through use. Hirst was brought by McKendrick in the 1960s and these scales sat for 12 months as part of the 12 month "cooling off" period. The scales were then handed to Donald rather than being disposed of.Scales used for weighing and calculating weight and thread count of textile samples. Originated from Godfrey Hirst Mills in Geelong. Writing describes how to utilise scales. Scales are made from brass, pole for holding scales once brass now replaced with metal pole. Scales held inside wooden box with black text in ink depicting use of scales on paper located inside and outside of box.Outside of box. Wording: APPARTUS for TESTING the WEIGHT per YARD of CLOTHS & COUNT of YARN from a small SAMPLE. -------------------------------------------------------------------------------------------------------------------------------------------------- Indispensable to Manufactures, Merchants & handling Woollen, Worsted, Cotton, Linen, Jute, Hemp, Flannel, Felt, Army, Navy, Police, Railway, Sail & other Cloths -------------------------------------------------------------------------------------------------------------------------------------------------- USED IN GOVERNMENT DEPARTMENTS -------------------------------------------------------------------------------------------------------------------------------------------------- The apparatus consists of Scales, Weights, 1, 2 & 4 sq. inch Cutting Templates & Book of Tables --------------------------------------------------------------------------------------------------------------------------------------------------By weighing a small Sample the accurate Weight in Ounces of a yard of Cloth any width from 18 to 64 inches, the Weight per Square Metre in Grams, the Counts* of Warp and Weft, and the approximate length of full & short ends of pieces of fabrics, [without unrolling and measuring for stocktaking & other purposes] can be ascertained without any Calculation --------------------------------------------------------------------------------------------------------------------------------------------------Price in United Kingdom, 25s., Carriage Paid. Price to Canada & U.S.A. $6.75 do. H. Lord. 10, And Place, Bradford, England. --------------------------------------------------------------------------------------------------------------------------------------------------*When ordering, state on what system you base your YARN COUNTS. Inside of box. Wording: DIRECTIONS FOR USE --------------------------------------------------------------------------------------------------------------------------------------------------TESTING WEIGHT OF CLOTHS. Place sample to be tested on a piece of cardboard, put a Cutting Template on it, cut card and cloth round template with scissors and weigh it according to instructions given in Book of Tables. TESTING FOR YARN COUNTS. Cut out 1 square inch of cloth, draw out wrap or weft threads, according to which is being tested, and the number of inches so drawn, that balance respective weight is the approximate Count. The same rule holds good when number of inches are drawn from a bobbin. In testing from the cloth, allowance has to be made for loss or gain in the process of manufacture. Weight marked C is for Cotton Counts " " W " " Worsted " " " WS " " Woollen Skeins " " L " " Linen Counts. The weights for testing samples of cloth are 20, 10, 10, 5, 3, 2, 1, grains in brass & '5, '3, '2, '1 [tenths of a grain] in aluminium. Inside of box. Signtures, handwritten: Bottom right: Lewis Hirst !898 Top Left (Smudge ?) W Hirst !935godfrey hirst, hirst family, textile design, textile creation -

National Wool Museum

National Wool MuseumClothing - 1984 Los Angeles Olympics Men's Opening Ceremony Shirt, c. 1984

On the 1984 Los Angeles Olympic Uniforms donator Doug wrote- During the 1980s the Australian wool industry was at its most prosperous times with record numbers of sheep producing wool receiving ever increasing values due to the success of the Reserve Price Scheme, and the overall guidance of the Australian Wool Corporation (AWC). As a humble technician, my role was a low profile newly created position of “Controller, Technical Marketing” where wool was to be marketed on its technical properties, as distinct from the “Product Marketing Group” which exploited trhe traditional high profile approach of marketing wool;s superior fashion attributes. The Woolmark was the tool central to this approach. When the forthcoming Los Angeles Olympic Games was announced, the Product Marketing Group seized upon the chance to show the world that we could make top fashion garments and display them on our elite athletes on the world stage. A concept was launched using a contemporary top designer, Adel Weiss, with the most exclusive fabrics and knits available, and all with a lot of hype. This launch failed dismally for the following reasons- - The designer did a wonderful job presenting an excellent fashion range on perfect skinny models. The AOC however wanted a uniform which had an obvious Australian appearance when fitted to elite, and frequently muscular, athletes. - The fabrics chosen did not reflect the performance required by travelling athletes, there was no recognition of the need for ‘easy care.’ - There was no recognition given to the problem of measuring, manufacturing and distribution of a range of articles when the selected athlete could be domiciled anywhere in Australia. - There was no appreciation of such historical facts as Fletcher Jones, who had been unofficial suppliers dating back to the 1954 Olympics in Melbourne, and the Fletcher Jones board member, who was also an AWC board member, and was not in favour of the change. The project passed from Product Marketing to Public Relations, a big spending off-shoot of the AWC Chairman David Asimus, and due to the day to day operations of the project was passed to me and PR took care of the financial matters. The first task was to meet with the AOC and find out exactly their requirements. This lead to the production of a design and manufacturing brief, cointaining exact time lines for each event required to ensure an appropriate uniform on every athlete chosen to represent his/her country on the date given for the Opening Ceremony in Los Angeles. Working backwards the timeline becomes- 1. Noted the exact date of the Opening Ceremony. 2. Estimated the date for distributing completed garments to each athlete. 3. Estimated the time span available for measuring each athlete and commence making each component of the ensemble to the individual measurements of each athlete. 4. Decided the date for making the final choice of uniform design concept. 5. Decided the date for distribution of the design brief to selected designers. These five steps were spread out over a two year period. The Commonwealth Games occur midway between each Olympic Games, work on the Olympic uniform commences the week after the Commonwealth Games closing ceremony and MUST be ready by the prescribed day two years hence. The project also had to remain cognisant of trade politics existing within the span of the task, as well as the temperament of designers in general. It is no overstatement to say that in the past every designer in Australia believed they could, and should, be chosen to design the Australian Uniform. The final choice of designer almost always faced criticism from the fashion press and any designer who had been overlooked. However, with the contenders receiving an exacting brief the numbers of serious contenders greatly reduced. The Los Angeles Olympic Uniforms. A further reason for the AWC bid failure to design the LA uniform was that the AOC had already chosen Prue Acton to design it. This was based on her proven performance during previous games as she had a talent for creating good taste Australiana. Her design concepts also considered the effect when they were viewed on a single athlete as well as the impact when viewed on a 400 strong team coming on to the arena. A blazer trouser/skirt uniform in bright gold was chosen for the formal uniform. It was my task to select a pure wool faille fabric from Foster Valley weaving mill and have sufficient woven and ready within the prescribed timeline. The trouser/skirt fabric selected was a 60/40 wool polyester plain weave fabric from Macquarie Worsted. This fabric had a small effect thread of linen that was most attractive when dyed to match some eucalyptus bark Prue had brought back from central Australia. For the Opening Ceremony uniform, Prue designed a series of native fauna, a kookaburra for the men’s shirt and a pleated skirt with a rural scene of kangaroos, hills and plants. This presented an insurmountable printing challenge to the local printing industry as it had an unacceptably large repeat size and the number required (50) was also commercially unacceptable. The solution was a DIY mock up at RMIT and the employment of four student designers. The fabric selected for this garment was a light weight 19 micron, pure wool with a very high twist yarn in alternating S and Z twist, warp and weft. This fabric proved to be the solution to a very difficult problem, finding a wool product which is universally acceptable when worn next to the sin by young athletes competing in the heat of a Los Angeles summer. Modifications to this fabric were developed to exploit its success when facing the same problem in future games. Garment Making- The most exacting garment in the ensemble is the tailored blazer, plus the related trouser/skirt. Unfortunately tailoring athletes that come in various shapes and sizes such as; - Weight lifters develop an enormous chest, arms and neck size. A shirt made to a neck size of 52 would produce a shirt with cuffs extending well beyond the wearer’s hands. - Basketball players are up to 7 feet tall and garments relying ona chest measurement grading would produce a shirt with cuffs extending only to elbow length. - Swimmers develop enormous shoulders and slim hips, cyclists by contrast develop thighs I liken to tree trunks and a uniform featuring tight trousers must be avoided at all cost. Suffice to say many ensembles require specialist ‘one off’ treatment for many athletes. Meanwhile there is a comfortable in between group who can accept regular sizes so you can cater for these by having back up stock with plenty of built in contingencies. Athletes may be domiciled anywhere in Australia, this creates a fundamental problem of taking their measurements. The Fletcher Jones organisation was key to answering this problem due to their presence in every capital city, as well as many provincial towns around Australia. Each athlete on being selected for the Olympic Team was simultaneously requested to visit their nearest Fletcher Jones shop. The standardised measurement data collected was shared with the other manufacturers, e.g. Pelaco Shirts, Holeproof Socks and Knitwear, Maddison Belts, and even Hush Puppy Shoes. As the time for the Games approached the AOC made arrangements for combining meeting of all. Selected available athletes at the Australian Institute of Sport, Canberra, where, among other things, they were fitted and supplied with their uniform. The method evolved as follows.Men’s cream coloured button up, collared shirt. Images of a kookaburra have been printed onto the shirt, a single kookaburra on the left breast and a pair of kookaburras on the reverse of the shirt. The kookaburras are printed in a brown tone to complement the cream colour of the fabric.On tag - FMaustralian wool corporation, 1984 los angeles olympics, olympic uniforms, men's uniforms, sport, athletes -

Nillumbik Shire Council

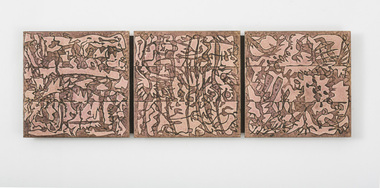

Nillumbik Shire CouncilCeramic (tiles): Tom SANDERS, Untitled, c. 1970s early

Sanders was a well-known local potter who worked for a time with David Boyd at the Martin Boyd Pottery, before returning to Melbourne where he had some association with Arthur Boyd, at the pottery in Murrumbeena. Sanders set up a studio in Eltham in the early 1950s and made the first of a series of architectural ceramic murals with painter and print maker Lawrence Daws in 1956. After returning from his travels in Europe to Australia in 1964, he began to work solely on creating ceramic murals. Murals created during the second half of the 1960s and into the 70s can/could previously be found at Southland Shopping Centre in Cheltenham, Melbourne (1968) - now demolished, the National Mutual Centre, Melbourne (1964-5) - now demolished, Dee Why Library, Sydney (1966), Woden Valley High School, ACT (1967), Tullamarine Airport, Melbourne (1969, 1970), Perth Concert Hall (1971) and University of Melbourne (1975) (with John Olsen). Sanders has worked with many of Australia’s pre-eminent painters and ceramicists including Fred Williams and John Olsen. In 2015 Nillumbik Shire Council will be installing a mural by Sanders, donated by Tom and his family before Tom passed away in 2009, for the redevelopment of the Eltham Town Square. During the 1970s Sanders produced a number of tapestry designs. Highly respected artist and one time local resident Hilary Jackman worked with Sanders developing and adapting his tile designs to be translated into silk tapestries that were made in Japanese Mills of Kawashima Orimono in Kyoto. They were displayed in the big Hall in the NGV. Sanders gave these tiles to Jackman as payment for her work. The tapestries are based on abstract designs and have a cotton warp, and silk weft. The tiles are similar to Sanders’ other mural works such as Wall of the Moon (Homage to Miro) and the mural located in the Perth Concert Hall. It’s clear that Sanders was inspired by the Spanish surrealist artist Joan Miro from the 1930s in both philosophy and style. Miro’s work is quite playful, symbolic and imaginative. Miro’s preference for painting like this was “to express contempt for conventional painting methods, which he saw was a way of supporting a bourgeois society”. He "famously declared an "assassination of painting" in favor of upsetting the visual elements of established painting.” Three earthenware tiles, embossed with an abstract linear design. N/A