Showing 21 items

matching wood splitting

-

Mont De Lancey

Mont De LanceyTool - Steel wedge

... Wood splitting wedges... Wood splitting wedges Woodworking tools A solid steel ...Used in the 19th century.A solid steel rectangular wedge fluted three quarters of the way down on both faces, used with a maul to split logs and timber, particularly hardwoods. It was used in the 19th Century.splitting wedges, steel, wood splitting wedges, woodworking tools -

Mont De Lancey

Mont De LanceyTool - Steel wedge

... Wood splitting wedges... Wood splitting wedges Woodworking tools A solid steel ...Used in the 19th century.A solid steel rectangular wedge fluted three quarters of the way down on both faces, used with a maul to split logs and timber, particularly hardwoods. It was used in the 19th Century.splitting wedges, steel, wood splitting wedges, woodworking tools -

Orbost & District Historical Society

Orbost & District Historical Societystud axe

... Used in wood splitting to split with the grain of the wood... gippsland Used in wood splitting to split with the grain of the wood ...Used in wood splitting to split with the grain of the wood. Splitting or stud axe bits are more wedge shaped. This shape causes the axe to rend the fibres of the wood apart, without having to cut through them. Possibly made by Kelly Axe Company after 1949.A wooden handled axe with a flat ended wedge shaped blade for hammering. There is a piece of orange cord threaded through the handle for hanging. Made in USA True temper flint edge.stud-axe tools -

Mont De Lancey

Mont De LanceyTool - Maul and Wedge, Unknown

... Wood Tools Splitting wedges wooden mallet Woodworking tools ...Used in the 19th CenturyA large handmade wooden barrel shaped headed maul with two steel bands at each end and a wooden handle. It was used to split logs or timber particularly hardwoods using a wedge as shown in the media photo. The rectangular steel wedge has a pointed end which is damaged. It was used in the late 19th Century. mauls, striking tools, steel, wood, tools, splitting wedges, wooden mallet, woodworking tools -

Mont De Lancey

Mont De LanceyTool - Maul and Wedge, Unknown

... handled heavy wooden mallet Steel Wood Tools Wedge Splitting tools ...Used in the 19th CenturyA large handmade wooden barrel shaped headed maul with two steel bands at each end. The handle is a metal pipe. It has a worn piece of a leather flap near the flanged join of the handle where it meets the head. A solid steel rectangular wedge which was used to split logs is displayed with the maul. It was used in the 19th Century.mauls, striking tools, long handled heavy wooden mallet, steel, wood, tools, wedge, splitting tools, splitting wedges, woodworking tools -

Mt Dandenong & District Historical Society Inc.

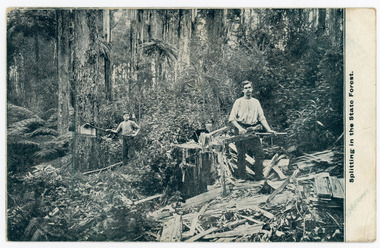

Mt Dandenong & District Historical Society Inc.Photograph, Splitting In The State Forest, Early 1900s

... Original postcard showing two men splitting wood... Original postcard showing two men splitting wood in the forest ...Original postcard showing two men splitting wood in the forest at Mt Dandenong. They are using axes. Early 1900s.On front of postcard: Splitting in the State Forestwood chop, splitters, wood splitters, forest, mt dandenong, axes -

Anglesea and District Historical Society

Anglesea and District Historical SocietyShingle Splitter - Wood Shingle Shaping Tool (FROE)

... by splitting it along the grain, then twisting the blade in the wood... by splitting it along the grain, then twisting the blade in the wood ...Froe (or shake axe) is a tool for cleaving wood by splitting it along the grain, then twisting the blade in the wood by rotating the handle (haft). The haft is a lever to multiply the force on the blade, allowing wood to be torn apart with little force applied to the haft.Noneaxehead shingle splitter, froe, shake axe -

Forests Commission Retired Personnel Association (FCRPA)

Forests Commission Retired Personnel Association (FCRPA)Shingle knife or paling splitter, Also known as a Froe

... , this tool is used for cleaving wood by splitting it along the grain... for cleaving wood by splitting it along the grain. The L-shaped tool ...Also known as a froe (or frow), shake axe or paling knife, this tool is used for cleaving wood by splitting it along the grain. The L-shaped tool is hammered on the top edge of its blade into the end of a piece of wood in the direction of the grain, then twisting the blade in the wood by rotating the haft (handle).Shingle knife or paling splitter Metal knife with short wooden handletimber tools -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Tools, 2x Gimlet, boring screw, c1900

... in wood, without splitting. A gimlet is always a small tool made... is a hand tool for drilling small holes, mainly in wood, without ...A gimlet is a hand tool for drilling small holes, mainly in wood, without splitting. A gimlet is always a small tool made of a piece of steel of a semi-cylindrical form, hollow on one side, having a cross handle at one end and a worm or screw at the other. A similar tool of larger size is called an auger. Early settlers in Moorabbin Shire had to be self reliant as they established their farms and built their homes using tools like this gimlet. 2 x small hand tool with a screw point, grooved shank, and cross handle for boring holes early settlers, pioneers, market gardeners, moorabbin, bentleigh, brighton, cheltenham, tools, blacksmiths -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageSnatch Block

... mechanism green & red paint evident on wood, which is splitting... & red paint evident on wood, which is splitting. Markings ...Snatch Block, 1 sheave wood block with hook and locking mechanism green & red paint evident on wood, which is splitting. Markings imprinted into mechanism near joining ring.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Mont De Lancey

Mont De LanceyTool - Paling knife, Unknown

... handle used for splitting wood along the grain. It is sometimes... for splitting wood along the grain. It is sometimes called a cleaving ...A forged steel headed paling knife or froe with a wooden handle used for splitting wood along the grain. It is sometimes called a cleaving tool. There is a large indented cross on the side of the head of the blade where the handle joins it.A large cross is indented on the head.cleaving tools, woodworking tools, froes, rending axes, cleaving irons -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Froe, Late 19th to Early 20th century

... A froe was used for splitting, or riving, wood in the early... for splitting wood. The froe was designed in many sizes and designs ...A froe was used for splitting, or riving, wood in the early days and was a skill practiced by craftsmen who made boards, shingles, c lapboards, fences, basket splints, chair parts, wagon spokes, lath, and more. Our ancestors used axes, gluts or wedges, froes, draw knives and spelk planes for splitting wood. The froe was designed in many sizes and designs for splitting timber. It is typically an L-shaped tool made up of a wedge-shaped blade with a dull, but not blunt, knife edge and a wood handle. Blades were usually straight with a socket forged at one end for a handle, but curved blades were also made. Most handles were round and tapered and were inserted up through this socket. But some froes had eyes similar to those on axes for handles that were wedged. The froe handle is held in an upright position in one hand while the other hand drives the top of the blade downward with a wood froe club or mallet. After a split is started, the froe is wiggled downward to lengthen it until the split is complete. Most old froes were hand forged, but they were also available in many catalogues. The 1873 D.R. Barton American catalogue offered straight froes at 12 1/2 cents per inch. You can still buy new froes from many tool manufacturers today.A tool that has not changed in design or use since its inception several hundred years ago to split timber for various uses.Froe, also called cooper's froe or stave froe, without handle.Noneflagstaff hill, warrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, froe, cooper's froe, stave froe, wood splitter, carpenders tools, coopers tool, splitting timber -

Forests Commission Retired Personnel Association (FCRPA)

Forests Commission Retired Personnel Association (FCRPA)Splitting Gun, Black Powder

... and difficulty of splitting the wood. The hole was stopped with a piece... size, species and difficulty of splitting the wood. The hole ...Black powder splitting guns were commonly used to split large logs into more manageable pieces before the advent of excavators and front-end loaders in bush logging operations. A typical splitting gun used in Victorian forests was a piece of high-grade steel about 1-1/2 to 2 inches in diameter and about 16 inches long, and slightly tapered at one end. They had a ¾ inch hole drilled about 9 inches deep into the centre of the shaft with a small pilot hole drilled from the outside to load the fuse. The tube was carefully loaded with an amount of black gunpowder using a funnel and spoon. Experience being the guide on how much powder to use, which depended on log size, species and difficulty of splitting the wood. The hole was stopped with a piece of wadded paper and the gun positioned at the end of a length of the log to be split. The splitting gun was then belted into the log with a large wooden maul or even the back of an axe to a depth of about 3 to 4 inches. There were often markings as a guide. This also had the effect of tamping the black powder inside the gun. Preferably the gun was backed up by another large log to absorb the shock and avoid it flying off in the bush somewhere. I have seen guns where a length of string and coloured flag could be attached to help find them. A length of fuse was then inserted in the small hole and lit. Kaboom !!!! Needless to say, the splitting gun was a dangerous implement.Commonly used to split pulpwood but now rareBlack Powder Splitting GunFive marking rings used to guide how far the gun was in the logforest harvesting -

Department of Energy, Environment and Climate Action

Department of Energy, Environment and Climate ActionLog Splitting Gun

... and difficulty of splitting the wood. The hole was stopped with a piece... and difficulty of splitting the wood. The hole was stopped with a piece ...Black powder splitting guns were commonly used to split large logs into more manageable pieces before the advent of excavators and front-end loaders in bush logging operations. A typical splitting gun used in Victorian forests was a piece of high-grade steel about 1-1/2 to 2 inches in diameter and about 16 inches long, and slightly tapered at one end. They had a ¾ inch hole drilled about 9 inches deep into the centre of the shaft with a small pilot hole drilled from the outside to load the fuse. The tube was carefully loaded with an amount of black gunpowder using a funnel and spoon. Experience being the guide on how much powder to use, which depended on log size, species and difficulty of splitting the wood. The hole was stopped with a piece of wadded paper and the gun positioned at the end of a length of the log to be split. The splitting gun was then belted into the log with a large wooden maul or even the back of an axe to a depth of about 3 to 4 inches. There were often markings as a guide. This also had the effect of tamping the black powder inside the gun. Preferably the gun was backed up by another large log to absorb the recoil shock and avoid it flying off in the bush somewhere. I have seen guns where a length of string and coloured flag could be attached to help find them. A length of fuse was then inserted in the small hole and lit. Kaboom !!!! Needless to say, the splitting gun was a dangerous implement.Log Splitting gun (large 50cm)forests commission victoria (fcv), hand tools -

Department of Energy, Environment and Climate Action

Department of Energy, Environment and Climate ActionLog Splitting Gun

... and difficulty of splitting the wood. The hole was stopped with a piece... and difficulty of splitting the wood. The hole was stopped with a piece ...Black powder splitting guns were commonly used to split large logs into more manageable pieces before the advent of excavators and front-end loaders in bush logging operations. A typical splitting gun used in Victorian forests was a piece of high-grade steel about 1-1/2 to 2 inches in diameter and about 16 inches long, and slightly tapered at one end. They had a ¾ inch hole drilled about 9 inches deep into the centre of the shaft with a small pilot hole drilled from the outside to load the fuse. The tube was carefully loaded with an amount of black gunpowder using a funnel and spoon. Experience being the guide on how much powder to use, which depended on log size, species and difficulty of splitting the wood. The hole was stopped with a piece of wadded paper and the gun positioned at the end of a length of the log to be split. The splitting gun was then belted into the log with a large wooden maul or even the back of an axe to a depth of about 3 to 4 inches. There were often markings as a guide. This also had the effect of tamping the black powder inside the gun. Preferably the gun was backed up by another large log to absorb the recoil shock and avoid it flying off in the bush somewhere. I have seen guns where a length of string and coloured flag could be attached to help find them. A length of fuse was then inserted in the small hole and lit. Kaboom !!!! Needless to say, the splitting gun was a dangerous implement.Log Splitting gun (large 45cm)forests commission victoria (fcv), hand tools -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageNail, 1855

... into timber across the grain in order to prevent the wood from... to be driven into timber across the grain in order to prevent the wood ...The artefact is the lower portion of a rectangular shanked ‘planking nail’ with a straight-edged ‘flat point’. The distinctive ‘point’ of a planking/skirting nail was designed to be driven into timber across the grain in order to prevent the wood from splitting. This relic is from the shipwreck of the SCHOMBERG, which ran aground near Peterborough in 1855. It was retrieved in 1875 from a large section of the ship’s bow which had been carried by ocean currents to the western coast of New Zealand’s South Island. The nail is still fixed in a fragment of the original timber that it secured in the SCHOMBERG. The top portion, or ‘head’ of the nail, has corroded away but the pronounced rectangular shank and its flat point indicate its likely purpose and position on the vessel. Most fastenings used in sailing ship construction were either wooden treenails or copper bolts, which were relatively resistant to seawater corrosion. In addition, the preferred hull-frame timber of British Oak has a high content of gallic acid which rapidly corrodes unprotected iron work. The ferrous composition of this planking nail suggests it came from an internal and upper portion of the ship’s bow (protected from exposure to the sea or oak). According to an 1855 edition of the Aberdeen Journal, the five outer layers, or ‘skins’, of the SCHOMBERG’s pine hull were “combined by means of patent screw treenails”. However the “beams of her two upper decks” were of “malleable iron”, and “part of the forecastle” was “fitted for the accommodation of the crew”. It is therefore possible that iron nails of this description were used by the ship’s builders to secure floor and wall planks in enclosed areas of the crew’s quarters. (The same reasoning would apply to officer and passenger accommodation amidships and at the stern of the vessel, but it was the bow that floated to New.Zealand.) The SCHOMBERG was a 2,000 ton clipper ship, specifically designed for the Australian immigration trade (back-loading wool for Britain’s mills), and constructed in Hall’s shipyard in Aberdeen, Scotland. She was owned by the Black Ball Line and launched in 1855. Alexander Hall & Son were renowned builders of sleek and fast 1,000 ton clippers for the China trade (opium in, tea out) and were keen to show they could also outclass the big North American ships built by Donald Mackay. Consequently the SCHOMBERG was ‘overbuilt’. Her hull featured five ‘skins’ of Scotch Larch and Pitch Pine overlaying each other in a diagonal pattern against a stout frame of British Oak. Oak has been favoured by builders of wooden ships for centuries. Its close, dense grain made it harder to work, but also gave it great strength and durability. In addition, the lateral spread of its branches supplied a natural curvature for the ribs of a vessel’s hull, as well as providing the small corner or curved pieces (‘knees’ and ‘elbows’) that fit them together. At the launch the SCHOMBERG’s 34 year old master, Captain ‘Bully’ Forbes, had promised Melbourne in 60 days, "with or without the help of God." James Nicol Forbes was born in Aberdeen in 1821 and rose to fame with his record-breaking voyages on the famous Black Ball Line ships; MARCO POLO and LIGHTNING. In 1852 in the MARCO POLO he made the record passage from London to Melbourne in 68 days. There were 53 deaths on the voyage but the great news was of the record passage by the master. In 1954 Captain Forbes took the clipper LIGHTNING to Melbourne in 76 days and back in 63 days, this was never beaten by a sailing ship. He often drove his crew and ship to breaking point to beat his own records. He cared little for the comfort of the passengers. On this, the SCHOMBERG’s maiden voyage, he was going to break records. SCHOMBERG departed Liverpool on her maiden voyage on 6 October 1855 flying the sign “Sixty Days to Melbourne”. She departed with 430 passengers and 3000 tons cargo including iron rails and equipment intended to build the Melbourne to Geelong Railway and a bridge over the Yarra from Melbourne to Hawthorn. She also carried a cow for fresh milk, pens for fowls and pigs, 90,000 gallons of water for washing and drinking. It also carried 17,000 letters and 31,800 newspapers. The ship and cargo was insured for $300,000, a fortune for the time. The winds were poor as she sailed across the equator, slowing SCHOMBERG’s journey considerably. Land was first sighted on Christmas Day, at Cape Bridgewater near Portland, and Captain Forbes followed the coastline towards Melbourne. Forbes was said to be playing cards when called by the Third Mate Henry Keen, who reported land about 3 miles off, Due in large part to the captain's regarding a card game as more important than his ship, it eventually ran aground on a sand spit near Curdie's Inlet (about 56 km west of Cape Otway) on 26 December 1855, 78 days after leaving Liverpool. The sand spit and the currents were not marked on Forbes’s map. Overnight, the crew launched a lifeboat to find a safe place to land the ship’s passengers. The scouting party returned to SCHOMBERG and advised Forbes that it was best to wait until morning because the rough seas could easily overturn the small lifeboats. The ship’s Chief Officer spotted SS QUEEN at dawn and signalled the steamer. The master of the SS QUEEN approached the stranded vessel and all of SCHOMBERG’s passengers and crew were able to disembark safely. The SCHOMBERG was lost and with her, Forbes’ reputation. The Black Ball Line’s Melbourne agent sent a steamer to retrieve the passengers’ baggage from the SCHOMBERG. Other steamers helped unload her cargo until the weather changed and prevented the salvage teams from accessing the ship. Later one plunderer found a case of Wellington boots, but alas, all were for the left foot! Local merchants Manifold & Bostock bought the wreck and cargo, but did not attempt to salvage the cargo still on board the ship. They eventually sold it on to a Melbourne businessman and two seafarers. In 1864 after two of the men drowned when they tried to reach SCHOMBERG, salvage efforts were abandoned. Parts of the SCHOMBERG were washed ashore on the south island of New Zealand in 1870, nearly 15 years after the wreck. The wreck now lies in 825 metres of water. Although the woodwork is mostly disintegrated the shape of the ship can still be seen due to the remaining railway irons, girders and the ship’s frame. A variety of goods and materials can be seen scattered about nearby. Flagstaff Hill holds many items salvaged from the SCHOMBERG including a ciborium (in which a diamond ring was concealed), communion set, ship fittings and equipment, personal effects, a lithograph, tickets and photograph from the SCHOMBERG. One of the SCHOMBERG bells is in the Warrnambool Library. This nail is a registered artefact from the wreck of the SCHOMBERG, Artefact Reg No S/35 and is significant because of its association with the SCHOMBERG. The SCHOMBERG collection as a whole is of historical and archaeological significance at a State level, listed on the Victorian Heritage Register VHR S612. Flagstaff Hill’s collection of artefacts from the SCHOMBERG is significant for its association with the Victorian Heritage Registered shipwreck. The collection is primarily significant because of the relationship between the objects, as together they have a high potential to interpret the story of the SCHOMBERG. The SCHOMBERG collection is archaeologically significant as the remains of an international passenger ship. The shipwreck collection is historically significant for representing aspects of Victoria’s shipping history and its potential to interpret sub-theme 1.5 of Victoria’s Framework of Historical Themes (living with natural processes). The collection is also historically significant for its association with the shipwreck and the ship, which was designed to be fastest and most luxurious of its day. The SCHOMBERG collection meets the following criteria for assessment: Criterion A: Importance to the course, or pattern, of Victoria’s cultural history. Criterion B: Possession of uncommon, rare or endangered aspects of Victoria’s cultural history. Criterion C: Potential to yield information that will contribute to an understanding of Victoria’s cultural history. The object is the bottom end of a slightly curved iron planking nail with remnant of timber still attached, recovered from the wreck of the SCHOMBERG (1855). The shank of the nail is rectangular and it narrows to a flat (chisel like) ‘point’. The ‘head’ is missing although there is a quantity of dark red corrosion within the top of the surrounding wood, suggesting where it might have been. The artefact is from the wreck of the SCHOMBERG (1855) and was retrieved from part of the ship’s bow which was carried by sea currents to the South Island of New Zealand. flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, schomberg, planking nail, rectangular ship’s nail, cast iron nail -

Whitehorse Historical Society Inc.

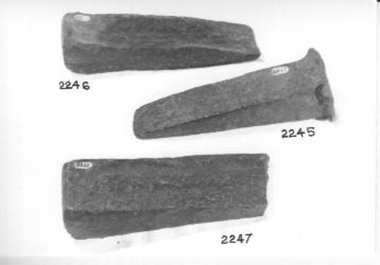

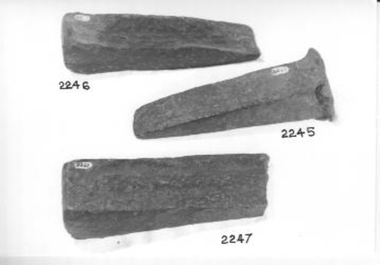

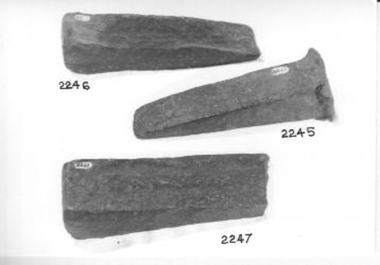

Whitehorse Historical Society Inc.Tool - Steel Wood Wedge, c1920

Used with wooden maul for splitting wooden logs etc.rural industry, farm machinery, trades, blacksmithing -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Tool - Steel Wood Wedge, c1920

Used with wooden maul for splitting wooden logs etcrural industry, farm machinery, trades, blacksmithing -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Tool - Steel Wood Wedge, c1920

Used with wooden Maul for splitting logs, etc.rural industry, farm machinery, trades, blacksmithing -

Mont De Lancey

Mont De LanceyTool - Shingle Splitter, Wolpin Wedge Mills, Unknown

Used in the late 19th century.A steel bladed wooden curved handled Shingle Splitter sometimes called a Paling Knife used for splitting or cleaving timber. It has two crossed hammer shape symbols stamped at the beginning and end of the inscription - Wolpin Wedge Mills. It was used in the late 19th century.Wolpin Wedge Millssteel, wood, froes, cleaving axes, axes, cutting tools, hand axes, woodworking tools -

Mont De Lancey

Mont De LanceyTool - Axe, Unknown

Used in the 19th century.A slightly curved wooden handled axe with a forged steel head. It is a multipurpose cutting tool used for felling and delimbing trees, splitting of logs for firewood and dressing of logs for timber conversion. It was used in the 19th century.woodworking tools, wood, steel, froes, cleaving axes, axes, cutting tools, hand axes