Showing 14 items matching "wool work equipment"

-

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Tool - WOOL WINDER

... Wool work equipment... HANDCRAFTS Wool work equipment wool winder Wooden instrument ...Wooden instrument for winding wool with circular base, a detachable top section which spins with four concertina arms.handcrafts, wool work equipment, wool winder -

Federation University Historical Collection

Federation University Historical CollectionBook - Book - Scrapbook, Ballarat School of MInes: Scrapbook of Newspaper Cuttings, Book 34, January 1988 to April 1988

Collection of newspaper articles related to Ballarat School Of Mines.They cover activities and advertisements for staff. The papers concerned are The Courier, Ballarat, The Australian, The Age over the period of 22 July to 3 October 1987.Book with green cover, front, spiral bound. teaching positions advertised, pre-employment courses, courses available, ricky hains receives highest state mark, draftsman, enrolment for smb courses, tafe state conference, next wave festival, sec pupils at smb, women's trade progam to continue, $60000grant for aboriginal studies, neville french pottery, latest equipment installed - catering, smb staff stop work, intellectually disabled stand on their own, gary bell appointed as music teacher, field work for students, the smeaton painting studio complex, small business course for women, wool prices, enriched life in twilight years, calligraphy course, eddie goodson american calligrapher, smb's heritage -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyPlough Yoke - Swingletree

Bullock drays were commonly used to transport heavy loads, such as the wool clip from a large property, across long distances.In the 19th century. The yoke is worn on the neck of the bullocks and is secured by a belt around the neck. The bullocks push the yoke with their shoulders, hump and neck; therefore, the work is performed.This yoke seems to be handmade on a farm. It was used in the Kiewa ValleyA wooden bar behind a harnessed horse. It is used to balance the pull of a draught horse or other draft animal (bullock) when pulling a vehicle like a plough. A yoke is an interface between bullock power and actual work to be performed.This yoke is timber with a shape to form curved depressions that allow it to rest across the necks of two bullocks to keep them together.The bullocks were chained to the steel oblong ring - one at each end of the yoke. The middle ring was attached to the bullock or vehicle in front of them.bullock yoke, swingletree, farm equipment, plough -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Kitchen Equipment, curved sad iron, c1880

Sad-irons or "solid" irons were made by blacksmiths and used to smooth out material by pressing the hot iron over it. A piece of sheet -iron was placed over the kitchen fire and the irons placed on it could be heated whilst remaining clean of ash.. The women used 2 irons - one heating while the other was used. Thick cloth or gloves protected their hands from the hot irons. The handle was removed from the cool iron and re- attached to remove the hot iron from the fire. The cool iron was replaced on the fire or stove to heat again. These irons were cleaned with steel wool to prevent them marking the material. If the iron was too hot the material would scorch. Most homes set aside one day for ironing and some large households had an ironing room with a special stove designed to heat irons. However, most women had to work with a heavy, hot iron close to the fireplace even in summer.The Curtis family were early settlers in Moorabbin Shire c1880 and used sad ironsA small, curved, flat iron, with attached handle, used for cuffs, collars and frillsSILVESTER'S/ PATENT/ SALTERS / No 3 with the pretzel & a arrow going through the centresad iron, kitchen equipment, pioneers, early settlers, market gardeners, sewing, craftwork, clothing, moorabbin, brighton, bentleigh, fireplaces, stoves -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Craft - Craft equipment, wool winder, c1860

Pioneers migrating to Moorabbin Shire brought items they thought would assist them in the new Country. They had to be self reliant and made their own clothing and utensils while establishing their market gardens and farms. A wooden wool winder, with extending arms for winding hanks of wool into balls prior to knitting. For ease of use the winder also rotates. Circa 1860s this winder was made in Ireland.The pioneer settlers and market gardeners of Moorabbin Shire had to be self reliant and made their own clothing and utensils. This is one of many items used to exhibit the skill and craftsmanship of the women in these families. Phillip Jones migrated from Ireland c1852 and his son, James Jones 1857 – 1940 was born in East Brighton , married Mary Ann Moore and raised his family in Bentleigh, as the area became known. A wooden wool winder, with extending arms for winding hanks of wool into balls prior to knitting. For ease of use the winder also rotates. Circa 1860s this winder was made in Ireland.brighton, moorabbin, pioneers, bentleigh, market gardeners, wool, craft work, early settlers, knitting, craft equipment, jones mary ann, jones james, jones phillip, herron john -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Domestic object - Kitchen equipment, sad iron, c1880

Sad-irons or "solid" irons were made by blacksmiths and used to smooth out material by pressing the hot iron over it. A piece of sheet -iron was placed over the kitchen fire and the irons placed on it could be heated whilst remaining clean of ash.. The women used 2 irons - one heating while the other was used. Thick cloth or gloves protected their hands from the hot irons. The handle was removed from the cool iron and re- attached to remove the hot iron from the fire. The cool iron was replaced on the fire or stove to heat again. These irons were cleaned with steel wool to prevent them marking the material. If the iron was too hot the material would scorch. Most homes set aside one day for ironing and some large households had an ironing room with a special stove designed to heat irons. However, most women had to work with a heavy, hot iron close to the fireplace even in summer.These sad irons remind us of the difficult circumstances experienced in their daily routines by the pioneers and early settlers of Moorabbin Shire. The family of Miss M Curtis were early settlers in Moorabbin Shire. Sad-iron, domestic, flat, cast iron, Silvester's Patent, No 6, Salter, England, c. 1890-1900s A sad iron made from cast iron was heated over a fire or on a stove and used for pressing clothing and table wareSILVESTER'S/ PATENT/ SALTERS / No 6 with the pretzel & a arrow going through the centresad iron, kitchen equipment, pioneers, early settlers, market gardeners, sewing, craftwork, clothing, moorabbin, brighton, bentleigh, fireplaces, stoves -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Domestic object - Kitchen Equipment, flat iron with trivet stand, c1880

Sad-irons or "solid" irons were made by blacksmiths and used to smooth out material by pressing the hot iron over it. A piece of sheet -iron was placed over the kitchen fire and the irons placed on it could be heated whilst remaining clean of ash.. The women used 2 irons - one heating while the other was used. Thick cloth or gloves protected their hands from the hot irons. The handle was removed from the cool iron and re- attached to remove the hot iron from the fire. The cool iron was replaced on the fire or stove to heat again. These irons were cleaned with steel wool to prevent them marking the material. If the iron was too hot the material would scorch. Most homes set aside one day for ironing and some large households had an ironing room with a special stove designed to heat irons. However, most women had to work with a heavy, hot iron close to the fireplace even in summer. These sad irons remind us of the difficult circumstances experienced in their daily routines by the pioneers and early settlers of Moorabbin Shire The family of Miss M Curtis were early settlers in Moorabbin Shire. A) A heavy cast iron, flat iron with B) horseshoe shaped trivet stand c1880 The trivet can be attached to a table by an adjustable clamp.A) 5 on tip of ironsad iron, kitchen equipment, pioneers, early settlers, market gardeners, sewing, craftwork, clothing, moorabbin, brighton, bentleigh, fireplaces, stoves -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Domestic object - Kitchen Equipment, sad iron with lifter, c1900

Sad-irons or "solid" irons were made by blacksmiths and used to smooth out material by pressing the hot iron over it. A piece of sheet -iron was placed over the kitchen fire and the irons placed on it could be heated whilst remaining clean of ash.. The women used 2 irons - one heating while the other was used. Thick cloth or gloves protected their hands from the hot irons. The handle was removed from the cool iron and using the lifter the cool iron was replaced on the fire or stove to heat again. These irons were cleaned with steel wool to prevent them marking the material. If the iron was too hot the material would scorch. Most homes set aside one day for ironing and some large households had an ironing room with a special stove designed to heat irons. However, most women had to work with a heavy, hot iron close to the fireplace even in summer.These sad irons remind us of the difficult circumstances experienced in their daily routines by the pioneers and early settlers of Moorabbin Shire. The Curtis family were early settlers in Moorabbin ShireA) This heavy sad iron, made from cast iron, was heated over a fire or on a stove and used for pressing clothing and haberdashery. B) The separate tapered handle was used to lift the hot iron from the fire and when a "Potts" Handle was attached the ironing commenced. sad iron, kitchen equipment, fireplaces, stoves, pioneers, early settlers, market gardeners, sewing, craftwork, clothing, moorabbin, brighton, bentleigh -

National Wool Museum

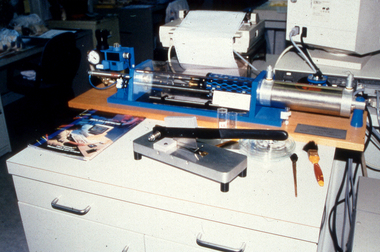

National Wool MuseumPhotograph - Slide, Stuart Ascough, Tops Used in Laboratory, 1990s

This slide is part of a collection of visual resources used by Stuart Ascough while conducting training, seminars, conferences and lectures in China, Australia, India, Russia and Taiwan. This item is part of a collection of books, manuals, photographs, letters and clothing relating to the working life of Stuart Ascough. Stuart's career in the wool industry spanned over 43 years from 1960 to 2003 in various roles including Topmaking Plant Manager at Courtaulds Ltd. in Spennymore, U.K., Operations Manager at Port Phillip Mills in Williamstown Victoria, Marketing Executive, Early Stage Wool Processing at the International Wool Secretariat Melbourne, Australia and General Manager of Victoria Wool Processors Pty. Ltd. in Laverton North, Victoria. Throughout his career Stuart travelled extensively, and in the 1990s worked at many topmaking mills in China on quality improvement projects. He also provided technical advice and training at mills in India, Ukraine, Lithuania, Kyrgyzstan, Russia, Latvia, Byelorussia and other parts of Europe and Asia.35mm colour transparency mounted in plastic slide mount showing interior view of scientific equipment in a laboratory.wool, industry, australia, australian wool board international wool secretariat, topmaking, carding, factory, training, gill box -

National Wool Museum

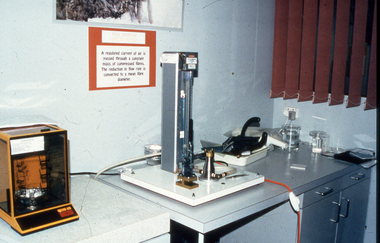

National Wool MuseumPhotograph - Slide, Stuart Ascough, Tops Used in Laboratory, 1990s

This slide is part of a collection of visual resources used by Stuart Ascough while conducting training, seminars, conferences and lectures in China, Australia, India, Russia and Taiwan. This item is part of a collection of books, manuals, photographs, letters and clothing relating to the working life of Stuart Ascough. Stuart's career in the wool industry spanned over 43 years from 1960 to 2003 in various roles including Topmaking Plant Manager at Courtaulds Ltd. in Spennymore, U.K., Operations Manager at Port Phillip Mills in Williamstown Victoria, Marketing Executive, Early Stage Wool Processing at the International Wool Secretariat Melbourne, Australia and General Manager of Victoria Wool Processors Pty. Ltd. in Laverton North, Victoria. Throughout his career Stuart travelled extensively, and in the 1990s worked at many topmaking mills in China on quality improvement projects. He also provided technical advice and training at mills in India, Ukraine, Lithuania, Kyrgyzstan, Russia, Latvia, Byelorussia and other parts of Europe and Asia.35mm colour transparency mounted in plastic slide mount showing interior view of scientific equipment and a computer on a bench top in a laboratory.wool, industry, australia, australian wool board international wool secretariat, topmaking, carding, factory, training, gill box -

National Wool Museum

National Wool MuseumPhotograph - Slide, Stuart Ascough, Tops Used in Laboratory, 1990s

This slide is part of a collection of visual resources used by Stuart Ascough while conducting training, seminars, conferences and lectures in China, Australia, India, Russia and Taiwan. This item is part of a collection of books, manuals, photographs, letters and clothing relating to the working life of Stuart Ascough. Stuart's career in the wool industry spanned over 43 years from 1960 to 2003 in various roles including Topmaking Plant Manager at Courtaulds Ltd. in Spennymore, U.K., Operations Manager at Port Phillip Mills in Williamstown Victoria, Marketing Executive, Early Stage Wool Processing at the International Wool Secretariat Melbourne, Australia and General Manager of Victoria Wool Processors Pty. Ltd. in Laverton North, Victoria. Throughout his career Stuart travelled extensively, and in the 1990s worked at many topmaking mills in China on quality improvement projects. He also provided technical advice and training at mills in India, Ukraine, Lithuania, Kyrgyzstan, Russia, Latvia, Byelorussia and other parts of Europe and Asia.35mm colour transparency mounted in plastic slide mount showing interior view of scientific equipment on a bench top in a laboratory.wool, industry, australia, australian wool board international wool secretariat, topmaking, carding, factory, training, gill box -

Wodonga & District Historical Society Inc

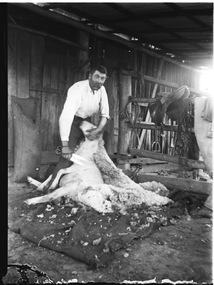

Wodonga & District Historical Society IncNegative - Haeusler Glass Negatives Collection - Harry Schuster blade shearing

The Wodonga Historical Society Haeusler Collection provides invaluable insight into life in late nineteenth and early twentieth century north east Victoria. The collection comprises manuscripts, personal artefacts used by the Haeusler family on their farm in Wodonga, and a set of glass negatives which offer a unique visual snapshot of the domestic and social lives of the Haeusler family and local Wodonga community. The Haeusler family migrated from Prussia (Germany) to South Australia in the 1840s and 1850s, before purchasing 100 acres of Crown Land made available under the Victorian Lands Act 1862 (also known as ‘Duffy’s Land Act’) in 1866 in what is now Wodonga West. The Haeusler family were one of several German families to migrate from South Australia to Wodonga in the 1860s. The Schuster family were also of German migrant background. Johannes Edward Schuster was born in Hoyles Plains, South Australia and with his wife Johanna and young family moved to Victoria circa 1882. He took up farming land in Wodonga West. The St John’s Lutheran Church Sunday school hall was erected from part of the proceeds of the sale of some 41 acres of land at Wodonga West, which had been bequeathed to the Wodonga congregation by the late Johannes Edward Schuster. This land was the original home site of the Schuster family on arrival from South Australia. Shearing - Although the first mechanised sheep shearing machine was created by James Higham, from Melbourne in 1868, the use of blade shears were more common well into the early 20th century. Pastoralists on smaller holdings continued to either shear their own sheep or employ blade shearers rather than outlay the cost of machines. In large sheds, professional shearers worked as they travelled the country. They would earn around 17 to 20 shillings per day in the early days of the wool industry. However mechanisation continued and by 1915 most sheep shearing sheds in Australia contained sheep shearing machines. The original machines were powered by steam and later combustion engines were used. This digital image was produced from one of the glass negatives that form part of the collection, probably taken by Louis Haeusler (b.1887) with the photographic equipment in the Wodonga Historical Society Haeusler Collection.This item is unique and has well documented provenance and a known owner. It forms part of a significant and representative historical collection which reflects the local history of Wodonga. It contributes to our understanding of domestic and family life in early twentieth century Wodonga, as well as providing interpretative capacity for themes including local history and social history.Digital image created from the Haeusler Glass negative collection. Harry Schuster shearing sheep using blade shears. wodonga pioneers, haeusler family, glass negatives, dry plate photography, blade shearing, schuster family -

City of Greater Bendigo - Civic Collection

City of Greater Bendigo - Civic CollectionUniform - Department of Supply Cap, 1971

Established in 1950, the Department of Supply headquarters transferred to Canberra in January 1968 and was dissolved in 1974. It was superseded by the Department of Manufacturing Industry and Department of the Special Minister of State. The Department was a Commonwealth Public Service department, staffed by officials who were responsible to the Minister for Supply. The department's main function was to support Australia's Navy, Army and Air Force in defence production, research and development, purchasing, transport and storage. The Department was also the Commonwealth Disposals Authority. Finally, the Department was responsible for the Australian Antarctic program. Bendigo was the site of an Ordnance Factory and manufactured and reconditioned naval guns and mountings, turbine gears for large ships, general heavy engineering work, large fabricated structure and missile handling equipment. The factory was managed in 1970 by R.I.M Moss. The department may have had an office in the former Bendigo Post Office now the Bendigo Visitor Information Centre.Blue, felt or wool peaked service cap with woven band and plastic strap. Small brass buttons. The cap has a synthetic lining around the crown and on the roof of the cap. Marked on the inside with the maker's details.bendigo post office, city of greater bendigo uniform -

Mont De Lancey

Mont De LanceyContainer - Lidded Container, c1920

Used for storing various threads for mending in the home - cotton, silk, wool nylon.A decorated brown lidded round container coated inside with black and brown type lacquer. The outside of the container and lid has patterns painted by hand in yellow and red of a bird, ying and yang symbols and oriental script all surrounded in black lined sections. It appears to be made from papier-mache which is layers of cardboard glued together and tightly compressed. This can be seen by the damage sections which grey cardboard shows though. It would have been lacquered over and painted. The container has a variety of sewing items and mending threads for stockings, socks and other work. Some pearl buttons included.As mentioned above, the container has various patterns painted on it. The sewing items include brands of threads for sewing work - Darneezi, Eagley, Rite Tone, Clark's Filosheen,Chadwick's Wool and Nylon, Nylusta.sewingcontainer, threads, containers, sewing equipment, gibson collection