Historical information

Bushfire behaviour is influenced by many things including temperature, relative humidity, forest type, fuel quantity and fuel dryness, topography and even slope. Wind has a dominant effect on the Rate of Spread (ROS), and also bushfire size, shape and direction.

Fuel arrangement is as important as fuel quantity (tonnes/ha). Fibrous and ribbon bark, together with elevated and near-surface scrub fuels act as ladders which lead flames into the tree canopy.

But the availability of fuel to burn depends largely on its moisture content. When it exceeds 20-25% not much will burn, whereas 12-15% is generally ideal for fuel reduction burning, but if the moisture content drops as low as 7-10% virtually everything will ignite, and fire behaviour becomes extreme. During the afternoon of the Ash Wednesday bushfires on 16 February 1983 fuel moisture contents were recorded at Stawell as low as 2.7%.

Fine fuels like leaves and bark can rapidly absorb moisture after a shower of rain, or from the air when the Relative Humidity (RH) is high, and the temperature is low. Conversely, they can also dry out very quickly.

So even though the overall fuel quantity in the forest doesn’t change, the fine fuel availability can increase rapidly from zero after rain to many tonnes per hectare as the fuel dries out. This can happen over a few hours on hot and windy days. Heavy fuels like logs on the ground take longer to dry out.

Since the 1930s foresters, firefighters and researchers have been working to develop quick and reliable techniques for measuring fuel moisture content.

One of the most accurate methods is slowly drying a sample of fuel in a conventional oven for 24-48 hours to remove all the moisture and measuring the weight difference, but this takes time and is not practical in the field when rapid measurements are needed. But oven drying is often used as a benchmark to compare other methods.

Microwave ovens are faster but can cause uneven drying and even char the fuel. They are also not very practical for use in the field.

Some mathematical models rely on weather records such as rainfall, wind speed, evaporation, cloud cover, shading, relative humidity, slope, aspect and season of the year to predict soil and fuel moisture. The Keetch-Byram Drought Index of soil dryness is the most common. But complex fuels with leaves, twigs, grass etc make the predictive models often inadequate for fine fuels.

The most common technique in Victorian forests until recently was the trusty Speedy Moisture Meter. Originally developed in England during the 1920s for measuring moisture in wheat and other grains it was adapted for Australian forest fuels in the 1950s (I think).

Fuel was first ground using a Spong mincer, often attached to the bullbar of a vehicle, and a small sample placed into the Speedy together with a measure of calcium carbide and then sealed. A chemical reaction created gas pressure which was read on the external dial.

There were important techniques with cleaning, mincing and using the chemicals with the Speedy to give reliable readings, but it was quick, inexpensive, robust, portable and practical in the field. It was used routinely before igniting a fuel reduction burn or measuring fuel moisture differentials on slash burns.

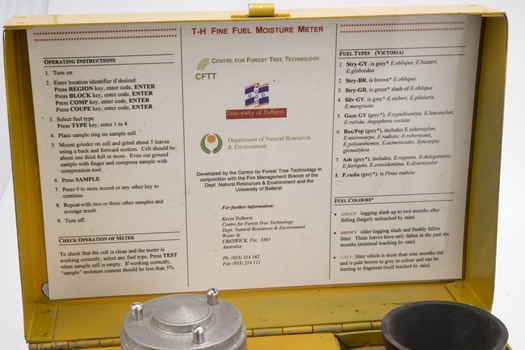

But in about 1996, Karen Chatto and Kevin Tolhurst from the Department’s Creswick Research Station developed the Wiltronics Fuel Moisture meter which measured electrical resistance. Wiltronics is an Australian owned company operating from Ballarat.

The final result was a kit that was portable, accurate and could reliably measure fuel moisture contents between 3% and 200%. Although expensive, it is now widely used by fire agencies around the world which has virtually relegated the Speedy to the back cupboard.

Physical description

Prototype Fuel moisture meter

Inscriptions & markings

T-H Fine Fuel Meter