Showing 99 items

matching air cooling

-

Moorabbin Air Museum

Moorabbin Air MuseumMachine - ADC Cirrus II 60Hp Air Cooled Inline 4 Cylinder

... an upright 4 cylinder air cooled inline engine. The engine powered... engine to produce an upright 4 cylinder air cooled inline engine ...Historical Details: . Description: The ADC Cirrus engine was developed in Britain for the de Havilland Moth aircraft and was produced by cutting in half an Airdisco V8 aero engine to produce an upright 4 cylinder air cooled inline engine. The engine powered many aircraft including the. Level of Importance: State -

Moorabbin Air Museum

Moorabbin Air MuseumMachine - Bristol Hercules 734 - 1700 Hp Air Cooled Twin Row 18 Cylinder Radial

... in 1938 the Bristol Hercules sleeve valve 18 cylinder twin row air... row air cooled radial engine was one of the most powerful ...Historical Details: . Description: Developed in Britain in 1938 the Bristol Hercules sleeve valve 18 cylinder twin row air cooled radial engine was one of the most powerful British aero engines of the day. It powered the Beaufighter and Bristol Freighter amongst other aircraft. Donated. Level of Importance: State -

National Wool Museum

National Wool MuseumMachine - Shearing Motor, Sunbeam, 1960-69

... This 0.5 horsepower vertical brushed motor air-cooled...: NSB5C2/49." This 0.5 horsepower vertical brushed motor air-cooled ...With more and more woolsheds being connected to power lines, the need for electric shearing gear markedly increased from the 1960s onwards. The greater economy made electric gear an attractive proposition to many graziers. Requiring only an electric shearing motor, for small and medium scale operations, electric shearing motors were a more economical way of shearing a wool clip. The other option for graziers was Overhead shearing gear, which also required an Engine to provide shared power to a row of shearing stations. Still working, this Sunbeam Electric Shearing Motor – Heavy Duty Model, features a slow speed motor totally enclosed for protection against dust and insects. The full bearing down tube is easily removed and stored to be out of the way when not in use (not pictured). Providing 0.5 hp, which is twice the power ever needed for shearing sheep, this buffer allows for fluctuations in voltages that can occur in rural districts. Inventor Frederick Wolseley made the world's first commercially successful power-shearing system in Australia in 1888. US company Cooper, which had been founded in 1843 as a maker of sheep dip, began selling Wolseley equipment in the USA in 1895. The Chicago Flexible Shaft Company successfully entered the power-shearing market a few years later and entered into a joint venture with Cooper. It set up a branch in Sydney and sold shearing sets, and engines to power them, into the Australian market. In 1921 the US parent company, realising it needed to make products whose sales were not as seasonal as those of shearing equipment, made its first household appliances and branded them Sunbeam. In 1933, changes in exchange rates and taxes led the company to manufacture engines and shearing equipment in Australia via subsidiary Cooper Engineering, which changed its name to Sunbeam in 1946. Although most Australians know of this company as a major manufacturer of household appliances, its rural division flourished and retained the Sunbeam name for shearing equipment even after it was taken over by New Zealand company Tru-Test in 2001. This 0.5 horsepower vertical brushed motor air-cooled engine was designed to drive a single shearing plant. From the central cylinder which features a yellow “Sunbeam” sticker, a grey 240v power lead can be found on the left-hand side. A blue capacitor is located next to this power lead. Below, two legs extend and meet to form a foot which is fastened to a wall. On the right-hand side of the engine, a specification plate is located on the central cylinder. A yellow directional arrow sticker is located on the rotating section of the engine below the specification plate (location for photography, this section is designed to rotate and hence this sticker is not fixed in this location). At the rear of the cylinder, a plastic cap with small air cut outs protects the air-cooled engine from contaminants. At the front of the engine, the location for securing the bearing down tube is located. On the right-hand side of the lock for the bearing down tube is the handle, to which a string is often attached for switching the motor on and off by a shearer bent at the waist (not pictured). Sticker. Gold writing. Front of shearing motor “Sunbeam” Plate. Inscribed. Side of shearing motor. “Sunbeam / SHEARING MOTOR / MADE IN AUSTRALIA / 0.5 H.P. / 220/240 V / 1 PHASE A.C. / 4.0 AMPS / 50 C/S. / CONT. RTG. / 1425 R.P.M. / CLASS A INSUL / NO. J244560 / TYPE: NSB5C2/49." sheep sheering, shearing equipment, sunbeam, electric shearing motor -

Federation University Historical Collection

Federation University Historical CollectionBook, The Institution of Engineers, Australia Victoria Division Country Convention 1981, 1981

... of Producer gas in a 24kW Air-Cooled Diesel Engine (J. Stephenson... in a 24kW Air-Cooled Diesel Engine (J. Stephenson and R.R. Raine ...The conference was held at Ballarat.Yellow soft covered book of conference papers for the "New Generation Transport Fuels". Papers include * Vegetable Oils as Diesel Fuel (G. Stecher) * University of Melbourne's Hydrogen Fuelled Spark Ignition Engine (J. Edsell and E. Milkins) * Use of Producer gas in a 24kW Air-Cooled Diesel Engine (J. Stephenson and R.R. Raine) * Small Scale Liquid Fuel Production (G. Tippett, Horsham) * New Generation transport Fuels (L. Cubitt, Ballarat College of Advanced Education) * Hydrogen as Fuel for Motor Vehicles (Mercedes Benz Australia) Loose advertising material, letters and associated material is included.engineers, engineering, fuel, transport, institution of engineers, australia, e.j. barker, jack barker -

Dandenong/Cranbourne RSL Sub Branch

Dandenong/Cranbourne RSL Sub BranchPainting - Large wooden framed painting

... by a pair of Bristol Mercury V111 air cooled radial engines capable... by a pair of Bristol Mercury V111 air cooled radial engines capable ...Michael Turner born in 1934 is a British painter and illustrator specialising in motoring and aviation paintings. After leaving school he attended Art College followed by National Service with the Royal Electrical and Mechanical Engineers for 2 years. On leaving National Service he worked with a London advertising studio before turning freelance in1957. The Bristol Blenheim depicted in the painting was a British light bomber used extensively for 2 years of the Second World War. It was powered by a pair of Bristol Mercury V111 air cooled radial engines capable of developing 860 bhp. armament was a combination of Vickers, Browning and Lewis machine guns in .303 ( 7.7mm ). A 1000lb (450kg ) could be carried in the internal bomb bay in the centre section of the fuselage. The 114 Squadron was a Squadron of the British Royal Air Force formed in India during the First World War. The Squadron was disbanded in 1971.Large wooden framed painting of an RAF WW2 bomber in flight.Below the painting is the wording " A 114 Squadron Blenheim 1V on a low level bombing run over the power station at Knapsack Cologne, in August 1941 - donated by Laurie Pillar". -

Flagstaff Hill Maritime Museum and Village

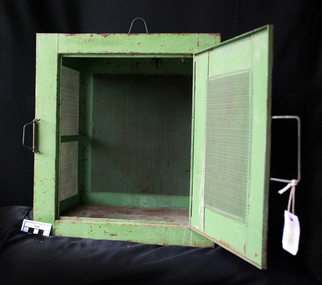

Flagstaff Hill Maritime Museum and VillageFunctional object - Food Safe, 1890 to 1925

... refrigerator was sold in America in 1913. It had an air-cooled... refrigerator was sold in America in 1913. It had an air-cooled ...The first commercially available, Australian-made domestic refrigerator to operate without ice was produced by Edward Hallstrom in 1923. It used kerosene as a power source and was promoted as ideal for outback stations where ice was not available. According to Museum Victoria, Hallstrom introduced the 'Silent Night' which ran on electricity or gas in 1935. However, Hailstorm's great-grandson, stated that the Silent Night refrigerator was introduced in 1928. Although Australians were among the pioneers of refrigeration in the 1850s, the technology wasn't adapted for domestic use until many decades later. The first domestic electric refrigerator was sold in America in 1913. It had an air-cooled refrigeration unit mounted on top of an ice box. The Frigidaire and Kelvinator brands date from 1918 when the first self-contained fridges were sold. Before this food safes were used as well to keep food away from flies and to keep items cool.A significant item used from the late Victorian era until around 1940 when people were beginning to be able to afford domestic refrigerators. After the second world war, most households had replaced their food storage cupboards or safes with refrigerators. The subject item gives a snapshot of domestic life from this time.Wooden kitchen safe with 3 metal perforated panels & 2 shelves inside. Was painted light Green but has been restoredflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, refrigeration, refrigerator, food storage, food safes, edward hallstrom -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Food Safe, 1920s

... refrigerator was sold in America in 1913. It had an air-cooled... refrigerator was sold in America in 1913. It had an air-cooled ...The first commercially available, Australian-made domestic refrigerator to operate without ice was produced by Edward Hallstrom in 1923. It used kerosene as a power source and was promoted as ideal for outback stations where ice was not available. According to Museum Victoria, Hallstrom introduced the 'Silent Night' which ran on electricity or gas in 1935. However, Hailstorm's great-grandson, stated that the Silent Night refrigerator was introduced in 1928. Although Australians were among the pioneers of refrigeration in the 1850s, the technology wasn't adapted for domestic use until many decades later. The first domestic electric refrigerator was sold in America in 1913. It had an air-cooled refrigeration unit mounted on top of an ice box. The Frigidaire and Kelvinator brands date from 1918 when the first self-contained fridges were sold. Before this food safes were used as well to keep food away from flies and to keep items cool.A significant item used from the late Victorian era until around 1940 when people were beginning to be able to afford domestic refrigerators. After the second world war, most households had replaced their food storage cupboards or safes with refrigerators. The subject item gives a snapshot of domestic life from this time.Wooden kitchen food safe, 2 door with wire mesh at sides. Raised back panel has shaped edges and includes a shelf above bench area that has turned legs. The safe has 4 plain legs.Noneflagstaff hill, warrnambool, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, food safe, kitchen safe, kitchen furniture, food storage -

Lara RSL Sub Branch

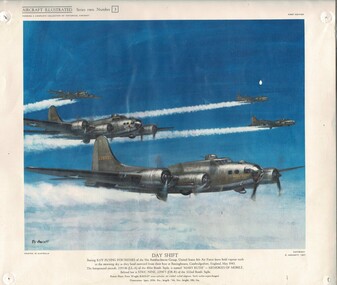

Lara RSL Sub BranchColoured Print of Boeing B.17F Flying Fortress, Day Shift

... Plant: Four Wright R1820-97 nine cylinder air cooled radial...: Four Wright R1820-97 nine cylinder air cooled radial engines ...A rectangular Coloured Print of a group of Boeing B.17F's Boeing B.17F Flying Fortresses of the 91st Bombardment Group, United States 8th Air Force leave vapour trails in the morning sky as they head eastward from their base at Bassingbourn, Cambridgeshire, England, May 1943. The foreground aircraft, 229536 (LL-A) of the 401st Bomb SQN. is named "Mary Ruth"- Memories of mobile. Behind her is "Stric Nine, 229475 (OR-R) of the 322nd Bomb SQN. Power Plant: Four Wright R1820-97 nine cylinder air cooled radial engines. Each turbo-supercharged. Dimensions: Span 103ft 9in, Length: 74ft 9in, Height: 19ft 1in. -

Puffing Billy Railway

Puffing Billy RailwayLister Auto Truck

... . The engines were single-cylinder and air-cooled. Ignition.... The engines were single-cylinder and air-cooled. Ignition ...The Lister Auto-Truck was a small monowheel tractor built for moving light loads around factories, railway yards and similar sites. They were built by R A Lister and Company of Dursley, Gloucestershire, well known for their range of small stationary engines The Auto-Truck was one of several monowheel tractors to appear in the 1920s and '30s, with the availability of small, reliable petrol engines, as developed for motorcycles and the stationary engines for which Lister were already known. These were tricycle vehicles, with the single leading wheel used for both drive and steering. Their simple construction carried most of the mechanism on this wheel as a single unit, the chassis with the trailing wheels being little more than a trailer for balance. Simplicity was a key feature. The engines were single-cylinder and air-cooled. Ignition was by magneto, rather than requiring a battery and electrical system. One of these designs was produced in the 1920s by George Grist of the Auto Mower Co., Norton St Philip, Somerset. The engine was a JAP 600 cc four-stroke air-cooled sidevalve, a typical small engine of the time. The Auto Mower Co. were Lister agents and when Lister heard of this 'Auto-Truck' they bought one for use in their own factory. It was used to carry heavy engine castings from the foundry to the machine shop. Lister customers saw them and there was such interest in wanting to buy them that Lister negotiated with Auto Mower to build them under licence. Although Lister were already well known for their small petrol stationary engines, these were heavy cast-iron engines with water hopper cooling and unsuitable for vehicle use. Lister remained with the JAP engine for the Auto-Truck. The Auto-Truck was designed for use in factories or other places with smooth surfaces of concrete or tarmac. This allowed the use of small solid-tyred wheels with only simple suspension, making the vehicle simple, cheap and lightweight. They had little ability on soft surfaces though and could even topple over if driven carelessly across slopes. Their design was a compromise between the top-heavy nature of the tall engine grouping above its wheel and a well thought-out chassis for stability. The bearing between them was a large diameter ring roller bearing, mounted at the lowest part of the chassis. This gave rigidity and stability, even after long wear. A ring of rolled channel girder was attached to the engine group and rollers on the chassis carried the load upon this. On early Auto-Trucks this bearing is set very low, in line with the chassis members, and is covered by thin steel plates. The front panel of the engine cover is distinctive with large ventilation holes and a Lister signature cut through it. Strangely this panel is made of thick cast iron, providing substantial weight high on the engine and only adding to its top heaviness. To improve visibility of moving vehicles in noisy factories, this panel was often painted white, the rest of the vehicle being Lister's usual brunswick green. The driver was seated on a Brooks bicycle saddle, which in recognition of the lack of vehicle suspension, was carried on the end of a cantilevered bar that acted as a leaf spring. A wide handlebar on the engine group was used for steering. A squeeze bar the width of this handlebar engaged the clutch. Controls included a hand throttle, a gear lever with two forward and one reverse gears, and a large handbrake lever. The engine unit rotated freely for a full 360° rotation. When used in reverse, the Auto-Truck could either be driven from the saddle, looking backwards over the driver's shoulder; or they could dismount, swivel the engine unit around and control it as a pedestrian-controlled truck from behind. Under the engine cover were two equal diameter tanks, a fuel tank for petrol and a shorter oil tank. Engine and chain-drive lubrication used a total-loss oil system, controlled by a small pump and needle valve. Info Ref: Lister Auto-Truck - Wikipedia https://en.wikipedia.org/wiki/Lister_Auto-TruckHistoric - Industrial monowheel tractor for moving light loads around factories, railway yards and similar sites.The Lister Auto-Truck - small monowheel tractor Made of steel with three wheels. Powered by a J.A.P single cylinder petrol motor which is Hand Cranked to start.Lister puffing billy, lister, lister auto truck, monowheel tractor -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Ice Chest, 1927

... would cool the air and the cool air would flow downwards through... iron stand. The ice would cool the air and the cool air would ...This particular small ice chest was once part of the domestic furniture of Dr W.R. Angus and his young family in 1927 when they lived in the Nhill and Ballarat districts. The family relocated to Warrnambool in 1939 and brought the ice chest with them. An ice chest, also called an icebox or refrigerator, was invented by Thomas Moore in 1802 and had become a common home appliance from the mid-1800s until around the 1930s, when electric refrigerators became affordable and safe. The non-mechanical ice chest allowed perishable food to be kept fresh for longer than the food-safe or ‘Coolgardie’ used in colonial days in Australia. It required the use of ice blocks, which were delivered to households by the ‘iceman' and his horse and cart. The ice man would use an ice pick to cut the blocks into the right size for the buyer’s ice chest. The ice came from an ‘ice house’, a factory where the ice was made. The ice chest required a block of ice to be placed into the insulated top section on top of the corrugated iron stand. The ice would cool the air and the cool air would flow downwards through the oval hole under the stand and into the refrigerator compartment below. The water from the melted ice would drain from the sloping floor of the top compartment and into the hooded pipe. The pipe went through the refrigerator and ended below its floor, where the drained water would be collected in the metal bowl placed there for that purpose. The lip on the bowl allowed it to be easily removed and emptied at regular intervals before it overflowed. W.R. Angus Collection- The W R Angus Collection spans from 1885 to the mid-1900s and includes historical medical and surgical equipment and instruments from the doctors Edward and Thomas Ryan of Nhill, Victoria. Dr Angus married Gladys in 1927 at Ballarat, the nearest big city to Nhill where he began as a Medical Assistant. He was also Acting House surgeon at the Nhill hospital where their two daughters were born. He and his family moved to Warrnambool in 1939, where Dr Angus operated his own medical practice. He later added the part-time Port Medical Officer responsibility and was the last person appointed to that position. Dr Angus and his wife were very involved in the local community, including the early planning stages of the new Flagstaff Hill, where they contributed to the layout of the gardens. Dr Angus passed away in March 1970.This ice chest is significant for representing a method of refrigeration and food preservation used in the 19th to mid-20th centuries when people were beginning to afford powered domestic refrigerators. After the second world war, most households replaced their food storage cupboards and ice chests with refrigerator appliances. The ice chest is also significant for its connection with the domestic furniture of Dr W.R. Angus and his family, and its inclusion in the W.R. Angus Collection.Ice chest; single front wooden cabinet with two doors and a flap, and three accessories. The top door is a lid with a metal handle at the front and two metal hinges along the back. The front door has two metal hinges on the right-hand side and has a metal lever catch. A hinged flap fits between the front legs at bottom of the ice chest and swings upwards. The front legs have wheels. The insulated top compartment has a metal lining and its floor slopes towards the centre of the back wall. In the floor are a formed oval air-flow hole and the open end of a pipe that has a hood partly covering it. The front compartment is an insulated metal-lined cupboard with a vertical pipe down the centre of the back wall and horizontal rails in the centre of each side wall. The accessories are a rectangular corrugated iron stand, a rectangular wire grid shelf and a round aluminium bowl with a lip and two sides pushed in. The ice chest was made circa 1927 and is part of the W.R. Angus Collection.flagstaff hill, warrnambool, maritime village, maritime museum, shipwreck coast, great ocean road, dr w r angus, dr roy angus, dr ryan, doctor angus, dr angus, ice chest, ice box, antique, food preservation, refrigeration, domestic equipment, kitchen appliance, refrigerator, non-electric refrigerator, non-mechanical refrigerator, w.r. angus collection -

Geoffrey Kaye Museum of Anaesthetic History

Geoffrey Kaye Museum of Anaesthetic HistoryMachine - Scarificator

... the cuts. As the air inside the cup cools, it creates a vacuum... the cuts. As the air inside the cup cools, it creates a vacuum ...Scarifiers were traditionally used for blood letting, and in folk medicine for the practice of cupping. Spring loaded knives cut the skin, then a warmed metal or glass cup is placed over the cuts. As the air inside the cup cools, it creates a vacuum drawing out the "bad" blood. The process is also related to the ancient medical theory of "humors". This theory dates back to the Hippocratic tradition and persisted through to the mid-19th Century. According to this theory, the body had four "humors", "airs" or "elements" which neeed to be kept in balance. Any imbalance could cause illness and this was often explained in terms of excess fluids. One prescribed treatment was to remove the excess blood which would restore the balance.Square, solid brass object with lever to release blades underneath.Etched on side: Mundy / Londonmetal, blades, bloodletting -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietySafe Coolgardie, circa early 1900s

... (in mass) cooling the air inside the container.... (in mass) cooling the air inside the container. Safe Coolgardie ...The harsh summer temperatures and the isolated rural environment(of the 1890's) provided the inventor of the "Coolgardie safe" (Arthur Patrick McCormick) with an idea to cool perishable foods by using water soaked "hessian" cloth to provide the "coolant" for the evaporation process to cool the inside temperature of the "safe". Items such as meat,cream/milk/butter and cool "drinks" are a few perishables that need cool environments , especially in isolated "ice free" locations. Cities during this time period had large "ice works" which delivered block ice to all areas that required a form of refrigeration. These ice blocks where held in early refrigerators to keep perishables cool to cold. This "Coolardie" safe was the next best thing for isolated rural households and travellers/campers/stockmen to provide a cooler environment for foodstuff affected by heat. Ice filled "esky" coolers and ice boxes are a modern day off shoot to the original Coogardie safe however they still rely on ice or frozen coolant bricks for cooling.This "Coogardie" safe is very significant to the Kiewa Valley and the Bogong High Plains because it represents not only the initiative thinking of the early settlers and communities but also the "primitive" solution to an everyday (1800s to 1930s) problem (before gas and electric run refrigerators) of keeping "perishables" at a low temperature and thereby prolonging their "shelf" life. This was before electricity and gas was available to the inhabitants of the Kiewa Valley and Bogong High Plains. Another cooling method for food was to have "water tight" containers dipped into the very cold streams running from the "cooler" alpine mountains and the Bogong High Plains. This however could not be carried out in all situations eg. fast flowing currents and locations away from streams. This "Coolgardie safe" is made from a medium grade steel enclosure and its appearance is of a perforated box with a wire handle and one side (long side) being a hinged "door" with a clasp securing "lock". There are air holes grouped into a small "boxed" pattern. Each "box" is divided by a crossed pattern, dividing the "holed" sections(4) into a diamond configuration of 49 small holes each. There are four sides (long) which have the perforations except for the base which does not. The base has an indentation with a loose "catch" tray to catch water spills. When in use the "box" is covered with a water "soaked" cloth. The wet cloth is used as "coolant" ie. fibers in the cloth hold the water droplets seep out evaporating the area and thereby (in mass) cooling the air inside the container.domestic refrigeration cabinets, coolgardie "safe", insect and vermin proof food containers, electric and gas free cold storage containers -

Melton City Libraries

Melton City LibrariesPhotograph, The Cairn- Jimmy Melrose's plane crash site, 1988

... inverted in-line air-cooled engine. Six Phoenix were built; five... inverted in-line air-cooled engine. Six Phoenix were built; five ...Edna Barrie at the cairn, photo received from Graeme Minns in 1988. The cairn marks the site of Jimmy Melrose's plane crash in Melton South. The accident which happened on July 5th 1936. In 1934 Melrose made headlines with a series of spectacular flights. In July of that year, he set around Australia record and in that year established a new solo Australia England record when he flew to England to compete in the MacRoberston race with a De Havilland Puss Moth VH- YQO. The only Australian and the only solo pilot to complete the course within the time limit. He was seventh in finishing order and third in the handicap section making news again during the race with a dramatic landing in Darwin with empty fuel tanks. Late in 1935 Melrose imported the Phoenix for his “Adelaide to Anywhere” Charter Service. The previous year the Heston Aircraft Company had taken over the interests of the well known Comper Aircraft Company, and the first production of the new firm was the Phoenix, a single-engined all wooden five seater machine of sesquiplane configuration. The forward half of the fuselage was a streamlined rectangular section and the rear portion was a monocogue shell; the whole was of plywood fabric covered. The wing was built up of spruce box spars and lattice ribs, ply covered from the leading edge to the front spar and the fabric covered over the remainder. The tail surfaces were of similar construction. The most notable feature of the design was the lower stub wing which ran right across the fuselage embodying two box spars, plywood covered it housed the main undercarriage wheels when retracted and provided a substantial anchorage for the Nu form wing struts. The Dowty undercarriage retracted inwards, operated manually by hydraulic packs, Dual control fitted, with side by side seating for the pilots and three passenger seats behind. Power was a 200 h.p. De Havilland Gipsy VI 6 cylinder inverted in-line air-cooled engine. Six Phoenix were built; five of them registered in Great Britain and one of those was later sold abroad the remaining four were impressed into the R.A.F. in 1940. Specifications were: 40 feet 4 inches length 30 ft 2 ins height, 9ft 7ins, wing area 270 sq ft, Tare weight 2,600lbs loaded weight 3,300lbs; cruising speed 360 m.p.h. landing 50mph ceiling 14,000 ft range 700 miles. Melrose’s machine the first production aircraft was built early in 1936 and test flown of the 24th March. Painted green it carries the words “South Australian Centenary 1936” in silver of the fuselage and the name “Billing on the engine cowling in honor of Melrose’s uncle Noel Pemberton Billing, pioneer designer and founder of the Supermarine Aviation Company. The delivery flight was planned as a goodwill mission to publicise the forthcoming South Australian Centenary celebrations. Melrose left Dympne on the 9th April 1936, and flying via Marseilles, Naples, Athens, Baghdad, Basra, Karachi, Jodphur, Calcutta, Akyab, Penang, Singapore, Lombok, Darwin, Newcastle Waters and Alice Springs reached Adelaide on the 25th of April. Continuing the goodwill flight to other States, he visited Melbourne, Sydney, Newcastle, Grafton, Brisbane, Coff’s Harbour, Sydney again, Launceston, Hobart and Mount Gambier before returning to Adelaide on the 13th May. During June Jimmy made some charter flights and early in July was engaged by Mr. A.J. Campbell a director of several mining companies from Melbourne to Darwin to commence at Essendon on the4th July. However on that day low cloud and steady rain caused the postponement. There was little improvement and Melrose was advised to delay the departure again. However he wished to reach Oodnadatta that night, and when he observed the break in the clouds decided to leave. He planned to climb above the cloud and fly to Adelaide at 3,000 feet. The aircraft was airborne about 8.10 a.m. and was last seen from Essendon climbing above the clouds. At 8.45 people at Melton (30 miles West of Melbourne) heard an approaching aircraft. The engine noise increased abnormally and eye witnesses saw the machine fall out of control from the cloud base about 800 feet and then disintegrate, fragments were scattered for 1½ miles and both occupants were killed. Hand written carbon copy by Edna Barrie.Typed by Wendy Barrie March 2014 Last Flight of Jimmy Melrose by John Burke Parade Magazine July 1972 Page 2 –4 This article gives the take off time of 7.50 am from Essendon Airport Eyewitness account at the time Maisie Arthur’s description. Newspaper article. Edna Barrie at the site of the 'Cairn'local identities, local significant events -

Melton City Libraries

Melton City LibrariesPhotograph, Edna and Bon's family camp trip at Apollo Bay, 1948

... the hairpin bends and breathing in the cool fresh air of the forest... in the cool fresh air of the forest, and keeping an eye out of the log ...Wendy Barrie's memories of Apollo Bay The camping trips were a yearly event after the harvest had finished. The trip down to the beach was a much-anticipated event heading out through Parwan and to Geelong leaving behind the hot and dusty plains and our parents relieved to have the hard work of harvesting left behind. The Otways in the distance were reached with great anticipation, Mum in the car and Dad in the Truck ahead of us anxiously winding through the narrow roads and negotiating the hairpin bends and breathing in the cool fresh air of the forest, and keeping an eye out of the log trucks that might come sweeping the corner. The tree ferns with their dripping moisture and the giant trees and the unmistakeable small of the eucalypts. Great excitement was when we caught our first view of the sea from the highest point of the road and then is was the cautious drive the sea level to the sight of the blue ocean with the white of the waves crashing on the rocks and the pristine sand. The water from the Wild Dog and Skenes creek trickling onto the ocean. The tree ferns with their dripping moisture and the giant trees and the unmistakeable smell of the eucalypts. The return journey was usually taken on the Great Ocean Road, it was considered safer to be on the inside of the road. In the early days it was very narrow and passing oncoming cars was taken very cautiously. Landslides and floods sometimes meant we would take the inland route. One year the bridges were washed away and bailey bridges were erected to keep the road open. Rock falls off the cliffs were common Stops on the way home gave us our last chance for our feet in the sand and a swim in the ocean. By the time we reached the hill at Angle Sea the vast blue ocean was behind us and we trekked back through Geelong- Bacchus road and the plains of stubble and the dry grass, and sometimes evidence of burnt patches from a bush fire. The closest we came to a pool at home was the concrete sheep trough at the gate to the work sheds. It was filled with bore water pumped from the nearby windmill. Edna, Bon and their family members at their camp site in Apollo Baylocal identities -

Orbost & District Historical Society

Orbost & District Historical Societycabinet

Food safes / cabinets are used principally to keep food safe (from flies and other pests), clean and cool. They have been used to store perishable foodstuffs for centuries, and are still made and used today. They are usually placed in a well ventilated area to allow for air flow, thus ensuring the produce is kept cool. This was a normal household item before iceboxes came into regular use.This was a normal household item before iceboxes came into regular use.A wooden cabinet / safe. It has two doors and zinc mesh insets on the sides and front. Inside are two shelves. The back and top are closed. The knob fittings are brass. It has four turned wooden legs and the doors are hinged.furniture-domestic cabinet food-safe -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyFan - S.E.C.V

... Electric fans were used for cooling rooms prior to air... fans were used for cooling rooms prior to air conditioning ...Electric fans were used for cooling rooms prior to air conditioning.This fan was used by S.E.C.V. office workers working on the Kiewa Hydro Electric Scheme. Small electric swivel fan. This heavy black metal fan has 4 curved 'wings' covered by protecting wire consisting of 2 wire rings joined by 6 curved pieces of wire covering the sides and front. Attached to the motor that can swivel and to the base is a black rubber covered electric cord. The base forms a stand with a control knob for speed and swivel options. On a plaque: Menominee / Fan Motor / 55182591 Serial No. 200 volts / ACC current 6 cycles / Menominee Electric Mfg. Co. / Menominee ..? Control knob: 0,1,2,3 along slotelectric fan; state electricity commission of victoria; kiewa hydro electric scheme; office furniture -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyFan - S.E.C.V

... Electric fans were used for cooling rooms prior to air... fans were used for cooling rooms prior to air conditioning ...Electric fans were used for cooling rooms prior to air conditioning.This portable fan was used on the Kiewa Hydro Electric Scheme by office workers.Green metal swivel fan with base, motor and 4 cream angled 'wings' covered by 3 wire rings connected by 6 pieces of curved wire that cover the blades at the side and front. An electric grey rubber cord is attached. There is a lever in the base for moving from 'off to 1.2.or 3' (but no marks to indicate these positions.)Base: "Elcon Fan / Made in Australia"electric fan; state electricity commission of victoria; office equipment; kiewa hydro electric scheme; -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Kitchen Equipment, tin mesh, meat safe, c1900

This is a common small 'meat safe' used in most homes prior to the arrival of Refrigerators. Food, such as milk, butter, cooked meat would be stored for a short time in this safe. It would be suspended from the ceiling / roof in a cool place - Dairy - and the mesh sides allowed air circulation while providing protection from insects and vermin.A green, tin meat safe with mesh sides and a hinged door with a latch lock. early settlers, pioneers, food preservation, meat safe, kalgoolie safe, moorabbin, bentleigh, cheltenham, ormond, dairy products, diseases, vermin -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyJar/ Demi John Stone Ware, Circa 1860

This kiln glazed container for liquid's, was the type used in the 1700's to mid 1900's to contain fluids mainly for human consumption which needed to retain liquid that could be affected by sunlight and or required to be maintained at a cooler temperatures. Ginger beer and other "brews" for human consumption were the prime target. The ability to refill these vessels were of the utmost importance to the consumer. Over time these containers were reduced in size and produced for "special" liquids e.g. alcoholic Port. This Demi John stone ware was manufactured in Tamworth (England) and imported into Australia during a period when the majority of "quality" domestic items were sourced from "the Mother Country" and the ties between the still "colonial" outpost were very strong. This bondage remained longer in rural communities than in the cities. The "multi-culturalism of the post World War II era resulted in the lessening of the earlier ties. The growing of nationalism, the Aussie evolution, was brought about by the increased social and business/commercial interactions between Australia and the United States of America, post World War II.This container(jug) is very significant to the Kiewa Valley, a rural region that required these type of liquid storage vessels, especially in the late 1800's to the mid 1900's. These were times when household refrigeration, if available, would be from the "block ice" coolers or "cool" storage nooks and crannies within farmhouse locations.This large "stone ware" glazed Demi John, alias Carboy has a capacity of over 20 litres. It has a conical smooth lipped neck top with a wide, flat(three to four finger) carry and poring handle. The top third portion of the jug is caramel in colour and the bottom a darker cream. It has a manufacturer's seal stamped into the surface before glazing. This item would have been corked and then sealed (air tight) with wax.manufacturer's seal "GEORGE SKEY WILNECOTE TAMWORTH"household liquid jar container, 1800's food storage, kiln fired glazed pottery -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyBag Canvas Water, Circa 1950

This extract from an advertisement in the Sydney Morning Herald newspaper of 1/12/1959 places the era in which this water bag was prolific throughout rural Australia. " ABERDEEN CANVAS GOODS for the man on the land here is Australia's most useful, convenient and hygienic water bag. Its special unbreakable plastic nozzle is fitted with a perforated filter strainer. Made from long flax canvas, its universal handle enables it to be hung on bumper bar, wire fence or on hook or nail" The availability of clean cool drinking water in remote rural locations was essential for survival under the blistering Australian summer sun. This was in a pioneer era when transport, roads and convenience stores were ,in a lot of "outback" Australia, in short supply and survival was dependent upon what could be carried by vehicle or pack horse.When the Kiewa Hydro Electricity Scheme became a reality, the use of the water bag was one of the essential personal items of survival given to each person working in the forests and on and in the high plains environment. Even in an outside stationary work place the availability of cool clean water was a prerequisite. The canvas water bag allowed any wind or airflow to cool down the water, even on very hot days, to provide a refreshing and throat quenching supply of water. These bags could be fastened onto the front of vehicles or hanging from shady tree branches thereby permitting air flow around the bag. During the "wearing in" period the residual taste from the canvas was fairly strong, this became considerably less as time and a half moved on. This "Aberdeen" long flax canvas water bag is held together on two sides and the top by strong heavy cotton stitching. The iron fashioned carrying handle has, protruding from its top elevation ,a very strong hook (well in excess of the bags' weight requirement). At the top, of the bag, and on one side only, is a brown coloured bakelite spout (with an inbuilt filter) protruding upwards. This spout has its matching , screw on, lid complete with attachment chain (not fixed at the handle end)On the front of the bad and stenciled in bold lettering, "ABERDEEN" and directly below "Travellers" and below this "FILTER BAG". Below this are two parallel black lines enclosing an ochre coloured band(12mm wide) running around the bottom section of the bag. Below this band is stenciled the number 14 in black (25mm high) figures. The spout lid has stamped on the top surface and within the outline of Australia, "ABERDEEN FILTER WATER BAG". Above this and close to the edge of the lid is pressed "PAT. No 9149/32 and down at the bottom rim is stamped "RD. No. 9870". canvas, water bag, water container, camping equipment, survival pack -

Orbost & District Historical Society

Orbost & District Historical SocietyCoolgardie safe, first half 20th century

Without refrigeration, storage of meat was difficult. Flies were a problem, and it was important to keep meat cool and out of the way of pests. One way of doing this was to use a meat safe: a kind of cupboard designed to store meat and keep it fresh enough to eat. Meat safes are ventilated. They were sometimes made with sides of wire mesh or perforated metal, so that air could circulate around the meat while keeping flies and other animals out.The Coolgardie safe was invented in the late 1890s by Arthur Patrick McCormick, who used the same principle as explorers and travelers in the Outback used to cool their canvas water bags Originally they were handmade using materials to hand. In the early 20th century, Coolgardie Safes were manufactured commercially across Australia, and found their way into homes in both rural and urban areas. These safes incorporated shelving and a door, had metal or wooden frames and Hessian bodies. The feet of the safe were usually placed in a tray of water to keep ants away. (refs ABC-Home; Museum Victoria)The Coolgardie safe was an Australian invention used especially in country areas from the 1890s until the mid 20th century. It began to be replaced by ice chests from the turn of the twentieth century in cities and country towns which had ice works. This item is an example of a domestic appliance commonly used before electricity was widely available for domestic use.A cube-shaped metal Coolgardie safe painted blue. It has a triangular hook on the top for hanging or lifting. There are small feet at bottom . The sides are perforated in a Above the door; Inside a rhomboid shape "WILLOW"food-storage coolgardie-safe domestic -

Orbost & District Historical Society

Orbost & District Historical SocietyCoolgardie safe, first half 20th century

Without refrigeration, storage of meat was difficult. Flies were a problem, and it was important to keep meat cool and out of the way of pests. One way of doing this was to use a meat safe: a kind of cupboard designed to store meat and keep it fresh enough to eat. Meat safes are ventilated. They were sometimes made with sides of wire mesh or perforated metal, so that air could circulate around the meat while keeping flies and other animals out.The Coolgardie safe was invented in the late 1890's by Arthur Patrick McCormick, who used the same principle as explorers and travelers in the Outback used to cool their canvas water bags Originally they were handmade using materials to hand. In the early 20th century, Coolgardie Safes were manufactured commercially across Australia, and found their way into homes in both rural and urban areas. These safes incorporated shelving and a door, had metal or wooden frames and Hessian bodies. The feet of the safe were usually placed in a tray of water to keep ants away. (refs ABC-Home; Museum Victoria)This item is an example of a common domestic appliance used before the widespread connection of electricity to homes and refrigeration. The Coolgardie meat safe is an Australian invention used widely in rural areas from the 1890's until the mid 20th century.A metal meat safe, painted white. It has a shelf inside. The door has two perforated rectangular sections metal framed in solid metal. The base is flat.storage domestic coolgardie-safe -

Cheese World Museum

Cheese World MuseumSafe, food, Coolgardie safe

Coolgardie safes were invented in the 1890s by Patrick McCormick in the Western Australian town of Coolgardie. Coolgardie safes were usually placed in a draughty areas, often under verandas. The hessian was placed in the water and draped around the sides and the draft cooled the contents of the safe. The legs could be stood in another tray of water to deter ants. This safe was bought at an auction at Orford by Laurie Gunnulson.Coolgardie safe has a box-shaped frame with wire mesh on the sides for air circulation. A four-legged tray for water is at the bottom. A piece of hessian hangs on one side (for demonstration purposes). The safe opens by a hinged door with a wire handle and there is a maker's name on the front. Inside it has a shelf in the middle. The safe is painted with Silvafros.Simpsonallansford, food storage, simpson, coolgardie safes, food safes, orford -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageContainer - Bottle, 1880s to 1910’s

This handmade green glass bottle was made using the turn-moulded or rotated-moulded method, a variation of the mould-blown process. The bottle has the remnants of a cork seal in its mouth. It possibly contained ginger beer, soda or mineral water, flavoured drinks, liquor or wine. The bottle’s shine has been worn from around 3/4 of its body, indicating that it has been resting horizontally on an abrasive surface, perhaps in the ground or on a river or sea bed. TURN-MOULDED BOTTLE production method This bottle was handmade using the ‘turn-moulded’ process, one of a variety of mould-blown processes that followed the earlier mouth-blown method. The maker would add a portion of hot soft glass to the end of his blowpipe then blow air through the pipe while placing the end inside a bottle mould. The mould was then turned and twisted, giving the bottle a round, seamless body, and usually a round indented base. The cooled body of the bottle would then be finished with the addition of an applied top. A small amount of soft glass would be applied to the top of the bottle and a lip would be formed using a tooling implement. A concentric ring would also form below the lip, caused by the rotated lipping tool. The bases of bottles made with the turn-moulded method were generally not embossed but would commonly have a mamelon or ‘dot’ in the centre of the base. SEALING THE BOTTLE After filling this type of bottle with its contents it is then sealed with a straight, cylindrical cork with the aid of a hand operated tool called a bottle corker. The bottle corker compresses the cork as it is driven into the bottle. Once inside the bottle the cork expands evenly into the opening to tightly seal the contents – the denser the cork the better the seal. Brown, brown glass. Handmade turn-moulded bottle with seamless body and tooled lip. Deeply indented base has push-up mark with a ‘mamelon’ nipple-liker bump in the centre. Bottle is straight from base to half height then tapers to a shoulder over the next quarter, than almost straight up to the mouth. Produced in 1880s to 1910’s. flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, brown glass bottle, handmade glass bottle, bottle with indented base, turn-moulded bottle, rotate-moulded bottle, tooled lip on bottle mouth, applied lip bottle, bottle corker, ginger beer bottle -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageContainer - Bottle, 1880s to 1910s

This handmade green glass bottle was made using the turn-moulded or rotated-moulded method, a variation of the mould-blown process. The bottle has the remnants of a cork seal in its mouth. It possibly contained ginger beer, soda or mineral water, flavoured drinks, liquor or wine. TURN-MOULDED BOTTLE production method This bottle was handmade using the ‘turn-moulded’ process, one of a variety of mould-blown processes that followed the earlier mouth-blown method. The maker would add a portion of hot soft glass to the end of his blowpipe then blow air through the pipe while placing the end inside a bottle mould. The mould was then turned and twisted, giving the bottle a round, seamless body, and usually a round indented base. The cooled body of the bottle would then be finished with the addition of an applied top. A small amount of soft glass would be applied to the top of the bottle and a lip would be formed using a tooling implement. A concentric ring would also form below the lip, caused by the rotated lipping tool. The bases of bottles made with the turn-moulded method were generally not embossed but would commonly have a mamelon or ‘dot’ in the centre of the base. SEALING THE BOTTLE After filling this type of bottle with its contents it is then sealed with a straight, cylindrical cork with the aid of a hand operated tool called a bottle corker. The bottle corker compresses the cork as it is driven into the bottle. Once inside the bottle the cork expands evenly into the opening to tightly seal the contents – the denser the cork the better the seal. This turn-moulded glass bottle is made distinctive due to its round seamless body and indented base.Bottle, dark green glass. Handmade turn-moulded bottle with seamless body and tooled lip. Deeply indented base has push-up mark with a ‘mamelon’ bump in the centre. Bottle is straight from base to half height, then tapers to a shoulder over the next quarter, than almost straight up to the mouth. There is a portion of cork in the bottle’s mouth and dry remnants in the bottle’s base. Possibly used for ginger beer. Produced in 1880s to 1910’s. flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, green glass bottle, handmade glass bottle, bottle with indented base, turn-moulded bottle, rotate-moulded bottle, tooled lip on bottle mouth, applied lip bottle, bottle corker -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageContainer - Bottle, 1880s to 1910s

This handmade green glass bottle was made using the turn-moulded or rotated-moulded method, a variation of the mould-blown process. The bottle has the remnants of a cork seal in its mouth. It possibly contained ginger beer, soda or mineral water, flavoured drinks, liquor or wine. TURN-MOULDED BOTTLE production method This bottle was handmade using the ‘turn-moulded’ process, one of a variety of mould-blown processes that followed the earlier mouth-blown method. The maker would add a portion of hot soft glass to the end of his blowpipe then blow air through the pipe while placing the end inside a bottle mould. The mould was then turned and twisted, giving the bottle a round, seamless body, and usually a round indented base. The cooled body of the bottle would then be finished with the addition of an applied top. A small amount of soft glass would be applied to the top of the bottle and a lip would be formed using a tooling implement. A concentric ring would also form below the lip, caused by the rotated lipping tool. The bases of bottles made with the turn-moulded method were generally not embossed but would commonly have a mamelon or ‘dot’ in the centre of the base. SEALING THE BOTTLE After filling this type of bottle with its contents it is then sealed with a straight, cylindrical cork with the aid of a hand operated tool called a bottle corker. The bottle corker compresses the cork as it is driven into the bottle. Once inside the bottle the cork expands evenly into the opening to tightly seal the contents – the denser the cork the better the seal. This hand made, green glass bottle is representative of bottle making before mass production and is made distinctive due to its round seamless body and indented base.Bottle, dark green glass. Handmade turn-moulded bottle with seamless body and tooled lip. Deeply indented base has push-up mark with a ‘mamelon’ bump in the centre. Bottle is straight from base to half height, then tapers to a shoulder over the next quarter, than almost straight up to the mouth. There is a portion of cork in the bottle’s mouth and dry remnants in the bottle’s base. Possibly used for ginger beer. Produced in 1880s to 1910’s. flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, green glass bottle, handmade glass bottle, bottle with indented base, turn-moulded bottle, rotate-moulded bottle, tooled lip on bottle mouth, applied lip bottle, bottle corker -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageContainer - Bottle, 1880s to 1910s

This handmade green glass bottle was made using the turn-moulded or rotated-moulded method, a variation of the mould-blown process. The bottle has the remnants of a cork seal in its mouth. It possibly contained ginger beer, soda or mineral water, flavoured drinks, liquor or wine. The bottle’s shine has been worn from around 3/4 of its body, indicating that it has been resting horizontally on an abrasive surface, perhaps in the ground or on a river or sea bed. TURN-MOULDED BOTTLE production method This bottle was handmade using the ‘turn-moulded’ process, one of a variety of mould-blown processes that followed the earlier mouth-blown method. The maker would add a portion of hot soft glass to the end of his blowpipe then blow air through the pipe while placing the end inside a bottle mould. The mould was then turned and twisted, giving the bottle a round, seamless body, and usually a round indented base. The cooled body of the bottle would then be finished with the addition of an applied top. A small amount of soft glass would be applied to the top of the bottle and a lip would be formed using a tooling implement. A concentric ring would also form below the lip, caused by the rotated lipping tool. The bases of bottles made with the turn-moulded method were generally not embossed but would commonly have a mamelon or ‘dot’ in the centre of the base. SEALING THE BOTTLE After filling this type of bottle with its contents it is then sealed with a straight, cylindrical cork with the aid of a hand operated tool called a bottle corker. The bottle corker compresses the cork as it is driven into the bottle. Once inside the bottle the cork expands evenly into the opening to tightly seal the contents – the denser the cork the better the seal. This turn-moulded glass bottle is made distinctive due to its round seamless body and indented base.Bottle, dark green glass. Handmade turn-moulded bottle with seamless body and tooled lip. Deeply indented base has push-up mark with a ‘mamelon’ bump in the centre. Bottle is straight from base to half height, then tapers to a shoulder over the next quarter, than almost straight up to the mouth. The shine has been worn from three-quarters of the body of the bottle. There are particles adhered to the inside of the bottle. Possibly used for ginger beer. Produced in 1880s to 1910’s. flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, green glass bottle, handmade glass bottle, bottle with indented base, turn-moulded bottle, rotate-moulded bottle, tooled lip on bottle mouth, applied lip bottle, bottle corker -

Moorabbin Air Museum

Moorabbin Air MuseumDrawing (item) - C.A.C Refrigerated Cooling Red Cross Bus 20V0006

-

Moorabbin Air Museum

Moorabbin Air MuseumBooklet (item) - A Cooling Calibration Of An R2800-31 Wasp Engine In Ventura Aircraft A59-4 -0 Report E.39

-

Moorabbin Air Museum

Moorabbin Air MuseumBook (item) - Napier-Halford "Dagger" Air-Cooled Aero Engine Specification

... "Dagger" Air-Cooled Aero Engine Specification Book Napier-Halford ...Series II, Series III, Series VI