Showing 51 items matching "crushing machinery"

-

Rutherglen Historical Society

Rutherglen Historical SocietyImage, c1990

This photograph is a general view of the machinery of the Gold Battery. The Bergin Pan is on the left, Stamper Box and in foreground concrete bed for Wilfrey table which has been removed. This is one of a series of photographs of the Rutherglen Gold Battery. The battery's purpose was to crush quartz from nearby quartz reefs and extract gold from within. The battery was erected in 1908 and consists of a five-head battery, Wilfrey table, Bergin pan, portable steam engine and shed. The battery was restored in 2011/12 and can be viewed daily between 9.00am and 5.00pm. See website for details.Colour photograph of a number of large pieces of machinery inside a buildinggold battery, gold processing -

Rutherglen Historical Society

Rutherglen Historical SocietyImage, c1990

This photograph is of machinery in the yard of the Gold Battery. The Baler Bucket is at the rear, the cage in the centre and the skip at the front. This is one of a series of photographs of the Rutherglen Gold Battery. The battery's purpose was to crush quartz from nearby quartz reefs and extract gold from within. The battery was erected in 1908 and consists of a five-head battery, Wilfrey table, Bergin pan, portable steam engine and shed. The battery was restored in 2011/12 and can be viewed daily between 9.00am and 5.00pm. See website for details.Colour photograph of a pieces of machinery in the yard of the Gold Batterygold battery, gold processing -

Rutherglen Historical Society

Rutherglen Historical SocietyImage, c1990

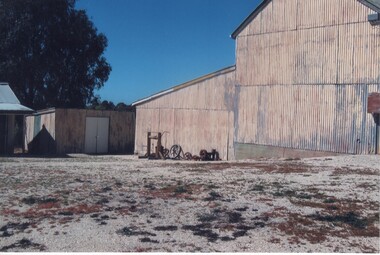

This photograph is of the side of the main building of the Gold Battery with workshop at rear (now demolished). Beside building is a hand windlass, along with some old pulleys and various parts. This is one of a series of photographs of the Rutherglen Gold Battery. The battery's purpose was to crush quartz from nearby quartz reefs and extract gold from within. The battery was erected in 1908 and consists of a five-head battery, Wilfrey table, Bergin pan, portable steam engine and shed. The battery was restored in 2011/12 and can be viewed daily between 9.00am and 5.00pm. See website for details.Colour photograph of the side of a corrugated iron building with a smaller building at the left, and a number of pieces of machinery next to the buildinggold battery, gold processing -

Rutherglen Historical Society

Rutherglen Historical SocietyImage, c1990

This photograph is of the back end of the side of the main building of the Gold Battery with workshop at rear (now demolished). Beside building is a hand windlass, along with some old pulleys and various parts. This is one of a series of photographs of the Rutherglen Gold Battery. The battery's purpose was to crush quartz from nearby quartz reefs and extract gold from within. The battery was erected in 1908 and consists of a five-head battery, Wilfrey table, Bergin pan, portable steam engine and shed. The battery was restored in 2011/12 and can be viewed daily between 9.00am and 5.00pm. See website for details.Colour photograph of the side of a corrugated iron building with a smaller building at the left, and a number of pieces of machinery next to the buildinggold battery, gold processing -

Bendigo Historical Society Inc.

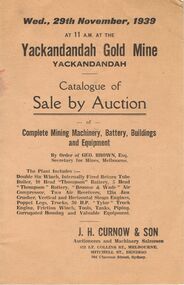

Bendigo Historical Society Inc.Document - IAN DYETT COLLECTION: AUCTION CATALOGUE - YACKANDANDAH GOLD MINE

Light tan coloured auction catalogue for a sale at the Yackandandah Gold Mine, Yackandandah on 29th November, 1939 of Complete Mining Machinery, Battery, Buildings and Equipment, By Order of Geo. Brown, Esq, Secretary for Mines, Melbourne. The Plant Includes:- Double 8in Winch, Internally Fired Return Tube Boiler, 10 Head Thompson Battery, 5 Head Thompson Battery, 'Broome & Wade' air Compressor, two Air Receivers, 12in Jaw Crusher, Vertical and Horizontal Steam Engines, Poppet Legs, Trucks, 30 H.P. 'Tylor' Truck Engine, Friction Winch, Tools, Tanks, Piping, Corrugated Housing and Valuable Equipment.J.; H. Curnow & Son were the auctioneers. Catalogue printed by The Cambridge Press.business, auctioneers, j h curnow & son pty ltd, ian dyett collection - auction catalogue - yackandandah gold mine, geo brown esq, j h curnow & son, the cambridge press -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Document - IAN DYETT COLLECTION: AUCTION CATALOGUE - COSTERFIELD SMELTING AND REFINING CO WORKS

Three Auction catalogues with greenish covers for a sale on 3rd July, 1941 at the Costerfield Smelting and Refining Co. Works, Costerfield of Machinery, Plant & Equipment comprising - 4 Diesel Engines, Jaques Crusher, 2 Boilers, Chilian Mill, Huntington Mill, 2 Steam Engines, Blast and other Furnaces, Exhaust Fan, Lighting Plant, Cyanide Plant, Pumps, Buildings, Piping, Tools, etc. One copy has 'Marked Catalogue' written across the top of the front cover. Some of the lots have the price written beside them, some have a note and some prices are written on the right side of the page. Signed at the end - J. H. Curnow & Son 21/7/41. J. H. Curnow & Son were the auctioneers and the Cambridge Press were the printers of the catalogue.business, auctioneers, j h curnow & son pty ltd, ian dyett collection - auction catalogue - costerfield smelting and refining co works, j h curnow & son, j l jamieson, the cambridge press -

Maldon Vintage Machinery Museum Inc

Maldon Vintage Machinery Museum IncTip Dray, Late 19th century

Used for carting rock to crushing batteries, road making, railway track building.Single horse drawn tip dray, restored by G & S Little in 1999. Made of timber with metal fittings and wheel rims. Enclosed sides with hinged front and rear panels. Chassis and wheels painted dark red, body in dark blue.Rectangular brass plaque on LHS looking forward detailing restoration and possible usage.transport ..... horse-drawn -

Tarnagulla History Archive

Tarnagulla History ArchivePhotograph - Photograph: Company's Dam and Flour Mill, Tarnagulla, c. 1880 - 1920

Williams Family Collection. On the 20th December 1873 it was reported in the Tarnagulla Courier that arrangements were being made for the erection of a steam flour mill at Tarnagulla. Mr Bristol had purchased the necessary plant which would be erected with as little delay as possible. The site chosen was the premises occupied previously by Mr John Pierce, grocer and wine and spirit merchant, at the corner of King and Commercial Road. These premises were incorporated in the mill building. Suitable buildings for receiving and storing grain and flour had been erected already. On 10th January, 1874 an advertisement in the Courier called for tenders from masons, bricklayers and carpenters for the erection of a flour mill at Tarnagulla for H. C. Bristol, Esq. with all enquiries to be made from G. Minto, Engineer. In December 1881 the proprietors made a request to the Tarnagulla Borough Council for permission to lay pipes to the Municipal Dam, which was generally known as the Company's Dam, and to obtain water from the dam for milling purposes. This was granted. Steam was got up for the first time on 30th of March, 1882. A large quantity of wheat was stored ready for milling. Just prior to 29th of April 1882 the boiler at the mill burst, as the result of which two men, J. H. Smith and W. Hargreaves died and H. Joyce Bousfield, senior and junior, were seriously injured. The mill commenced operations on 13th June, 1882 with Mr W Fitzgerald as manager. The price offered for wheat was thirty-seven pence per bushell. It operated with grinding stones until considerable renovations were done in the early part of 1899 when new rollers and more up to date equipment installed. The mill was then known as the Tarnagulla Flour Mill Co., with Thos. Comrie as proprietor, Mr Fitzgerald was still manager, and Mr T. Leonard was the traveller. Much new equipment was put in and each of the three floors had different processes. The rollers were on the ground floor, the purifiers and elevators reel were on the second floor, plus the clean wheat bin directly over the Ganz rollers. On the top floor was the chop reel, bran reel, inter-elevator reels, brush machine cyclone sack hoist, dirty wheat shaker, clean wheat bin, dust rooms and also double damping rooms. A plant was also erected for the making of an improved quality of wheaten meal, for which purpose special machinery was procured and a pair of stones was left for grinding the meal. A complete plant for the crushing of oats etc was also erected. The driving power of the mill was supplied by a new engine complete with 16 inch cylinder, manufactured and erected by Bousfield & Co. of Eaglehawk. It was fitted with Pickering governors, connected with the cylinder was a super heater. The boiler was tested and all connections etc. overhauled, with much of it being completely renewed. There was a complete network of belts, spouts, elevators etc. all over the building, all conveniently placed. The plans etc for the new plant were drawn up by Mr J. Kilborn, manager of the firm of Bodington & Co., engineers and millwrights of Carlton, which supplied the whole of the machinery, excepting the engine. The work of erection was carried out by Mr Kilborn and his assistants to the entire satisfaction of Mr Comrie, who had gone to considerable expense to bring the mill to a completely up-todate machine, fitted with all of the most modern appliances available. An advertisement on May 6th, 1899 read: "Tarnagulla Flour Mill Co., Patent Roller Flour. Also their Digestive Wheaten Meal specially prepared for Porridge or Bread." In January 1901, 6000 bags of wheat were received weekly at the mill and it was a common sight to see the streets lined with wagons. In May 1902 the mill was lighted by gas and in July 1906 an application was made to the Tarnagulla Borough Council for permission to lay a tram track from the mill to the Railways Station. Council was agreeable to this provided suitable plans were submitted. In 1913, 15,000 bags of wheat were bought at three shillings and four pence per bushell. In January 1914 the mill was renovated. At this time 1500 bags of wheat were coming in daily, with 20,000 bags in storage. On 15th December, 1917 the mill was advertised for sale, to be sold on Friday, 21st December,.1917, on behalf of the Estate of the Late Thomas Comrie, who had died on 4th August, 1910. The Courier at that time recorded him as being responsible for the building of the mill and with being the sole proprietor. The mill was closed, apparently, for a short period. The Courier reported on 13th of September, 1918 that the mill had been sold to Mr O. Albert of Talbot and that it would re-open. An advertisement read: ALBERT. O. & SON, MILLERS. During 1920 the mill was closed and pulled down. It was later re-erected at Mildura where it operated for many years. (by Donald Clark)Monochrome photograph depicting view of Company's Dam and the flour mill in Tarnagulla. Handwritten on reverse: 'J. Caldwell and photographer's stamp 'C. Bock Photo Tarnagulla'.tarnagulla -

Tarnagulla History Archive

Tarnagulla History ArchivePostcard - Photographic postcard: Company's Dam and Flour Mill, Tarnagulla, c. 1880 - 1920

Williams Family Collection. On the 20th December 1873 it was reported in the Tarnagulla Courier that arrangements were being made for the erection of a steam flour mill at Tarnagulla. Mr Bristol had purchased the necessary plant which would be erected with as little delay as possible. The site chosen was the premises occupied previously by Mr John Pierce, grocer and wine and spirit merchant, at the corner of King and Commercial Road. These premises were incorporated in the mill building. Suitable buildings for receiving and storing grain and flour had been erected already. On 10th January, 1874 an advertisement in the Courier called for tenders from masons, bricklayers and carpenters for the erection of a flour mill at Tarnagulla for H. C. Bristol, Esq. with all enquiries to be made from G. Minto, Engineer. In December 1881 the proprietors made a request to the Tarnagulla Borough Council for permission to lay pipes to the Municipal Dam, which was generally known as the Company's Dam, and to obtain water from the dam for milling purposes. This was granted. Steam was got up for the first time on 30th of March, 1882. A large quantity of wheat was stored ready for milling. Just prior to 29th of April 1882 the boiler at the mill burst, as the result of which two men, J. H. Smith and W. Hargreaves died and H. Joyce Bousfield, senior and junior, were seriously injured. The mill commenced operations on 13th June, 1882 with Mr W Fitzgerald as manager. The price offered for wheat was thirty-seven pence per bushell. It operated with grinding stones until considerable renovations were done in the early part of 1899 when new rollers and more up to date equipment installed. The mill was then known as the Tarnagulla Flour Mill Co., with Thos. Comrie as proprietor, Mr Fitzgerald was still manager, and Mr T. Leonard was the traveller. Much new equipment was put in and each of the three floors had different processes. The rollers were on the ground floor, the purifiers and elevators reel were on the second floor, plus the clean wheat bin directly over the Ganz rollers. On the top floor was the chop reel, bran reel, inter-elevator reels, brush machine cyclone sack hoist, dirty wheat shaker, clean wheat bin, dust rooms and also double damping rooms. A plant was also erected for the making of an improved quality of wheaten meal, for which purpose special machinery was procured and a pair of stones was left for grinding the meal. A complete plant for the crushing of oats etc was also erected. The driving power of the mill was supplied by a new engine complete with 16 inch cylinder, manufactured and erected by Bousfield & Co. of Eaglehawk. It was fitted with Pickering governors, connected with the cylinder was a super heater. The boiler was tested and all connections etc. overhauled, with much of it being completely renewed. There was a complete network of belts, spouts, elevators etc. all over the building, all conveniently placed. The plans etc for the new plant were drawn up by Mr J. Kilborn, manager of the firm of Bodington & Co., engineers and millwrights of Carlton, which supplied the whole of the machinery, excepting the engine. The work of erection was carried out by Mr Kilborn and his assistants to the entire satisfaction of Mr Comrie, who had gone to considerable expense to bring the mill to a completely up-todate machine, fitted with all of the most modern appliances available. An advertisement on May 6th, 1899 read: "Tarnagulla Flour Mill Co., Patent Roller Flour. Also their Digestive Wheaten Meal specially prepared for Porridge or Bread." In January 1901, 6000 bags of wheat were received weekly at the mill and it was a common sight to see the streets lined with wagons. In May 1902 the mill was lighted by gas and in July 1906 an application was made to the Tarnagulla Borough Council for permission to lay a tram track from the mill to the Railways Station. Council was agreeable to this provided suitable plans were submitted. In 1913, 15,000 bags of wheat were bought at three shillings and four pence per bushell. In January 1914 the mill was renovated. At this time 1500 bags of wheat were coming in daily, with 20,000 bags in storage. On 15th December, 1917 the mill was advertised for sale, to be sold on Friday, 21st December,.1917, on behalf of the Estate of the Late Thomas Comrie, who had died on 4th August, 1910. The Courier at that time recorded him as being responsible for the building of the mill and with being the sole proprietor. The mill was closed, apparently, for a short period. The Courier reported on 13th of September, 1918 that the mill had been sold to Mr O. Albert of Talbot and that it would re-open. An advertisement read: ALBERT. O. & SON, MILLERS. During 1920 the mill was closed and pulled down. It was later re-erected at Mildura where it operated for many years. (by Donald Clark)Photographic postcard, front image depicting view of Company's Dam and the flour mill in Tarnagulla. Handwritten on reverse: 'A Merry Christmas and a Happy New Year, E. Bool' and photographer's stamp 'C. Bock Photo Tarnagulla'.tarnagulla -

Harcourt Valley Heritage & Tourist Centre

Harcourt Valley Heritage & Tourist CentreCider Press, 1880s

A 'BUCKEYE" grape and cider press, manufactured by P.P. Mast & Co. of Springfield, Ohio, USA and distributed by P. Rohs, Sandhurst (Bendigo). The PP Mast Company was established in 1854. Their Buckeye drills, seeders and other implements played an important role in the development of American farm machinery, being sold in every American state, Europe and Australia. This press was used by the Gaasch family of Harcourt over several generations from 1898 to crush grapes for wine and vinegar making, subsequently to crush apples and then press the pulp to make apple vinegar and cider. The crushing was accompanied by lusty singing of songs and hymns such as 'Ein Feste Burg ist unter Gott'. The press was designed to be hand-operated but was later used by Harcourt Coolstores to press apples. It was then belt-driven by an electric motor. The press was restored (timber cleaned and varnished, metal shoes on base of wooden uprights, which had rotted ) by Mr. Howard Carr, 2001-An early application of mechanics to the crushing of grapes. Hand-driven, geared drive metal crushing parts, with metal flywheel, wooden feed hopper in vertical arrangement, wooden frame, tray and vat, with metal pressing screw installed in heavy metal yoke at front. Metal crushing section carries cast-in maker's name and patent details'BUCKEYE" manufactured by P.P. Mast & Co. of Springfield, Ohio, USA distributed by P. Rohs, Sandhurst (Bendigo). -

Eltham District Historical Society Inc

Eltham District Historical Society IncPhotograph - Digital Photograph, Alan King, Yarrambat Heritage Museum, 23 January 2008

Original Yarrambat Primary School building at the Yarrambat Heritage Museum, Yarrambat Park. At the museum, visitors can gain an insight into Yarrambat’s past since non-Aboriginal settlement. The museum includes the original Yarrambat Primary School, which was moved to the site in 2000 and now serves as the Yarrambat Historical Society headquarters.The museum also includes a fully operational battery (gold-bearing ore crusher) driven by a McDonald 30HP diesel engine built in Richmond in 1938. The battery was relocated from the Golden King Mine in North Oatlands Road, Yarrambat, where it operated until 1984.1 Other exhibits include farming implements and machinery from the Yarrambat district. Published: Nillumbik Now and Then / Marguerite Marshall 2008; photographs Alan King with Marguerite Marshall.; p25This collection of almost 130 photos about places and people within the Shire of Nillumbik, an urban and rural municipality in Melbourne's north, contributes to an understanding of the history of the Shire. Published in 2008 immediately prior to the Black Saturday bushfires of February 7, 2009, it documents sites that were impacted, and in some cases destroyed by the fires. It includes photographs taken especially for the publication, creating a unique time capsule representing the Shire in the early 21st century. It remains the most recent comprehenesive publication devoted to the Shire's history connecting local residents to the past. nillumbik now and then (marshall-king) collection, yarrambat heritage museum, yarrambat historical society, yarrambat primary school -

National Vietnam Veterans Museum (NVVM)

National Vietnam Veterans Museum (NVVM)Photograph, Gibbons, Denis, Mobile Crusher 2

Denis Gibbons (1937 – 2011) Trained with the Australian Army, before travelling to Vietnam in January 1966, Denis stayed with the 1st Australian Task Force in Nui Dat working as a photographer. For almost five years Gibbons toured with nine Australian infantry battalions, posting compelling war images from within many combat zones before being flown out in late November 1970 after sustaining injuries. The images held within the National Vietnam Veterans Museum make up the Gibbons Collection.A black and white photograph of Engineers, from 17 Construction Squadron, use a front end loader to deliver rock into a mobile crusher used to prepare fine rock material for all types of foundation work, used in construction projects throughout Phuoc Tuy Province, South Vietnam.photograph, engineers, 17 const sqn, phuoc tuy province, gibbons collection catalogue, photographer, vietnam war, denis gibbons, front end loader, machinery -

Eltham District Historical Society Inc

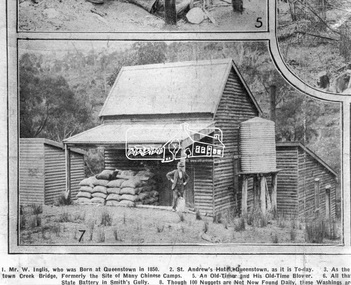

Eltham District Historical Society IncPhotograph, Queenstown - St. Andrews District. "Quartz awaiting crushing at the State Battery in Smith's Gully.", c.1929

"The State Battery was the central component in the gold mining of this area from the 1920s. The battery crushed the gold bearing quartz extracted from the mines and was a sizeable weatherboard building enclosing the engine and stampers. All that now remains are the bases for the machinery that comprised the battery, one timber and a couple of concrete bases and the nearby dam, which supplied water. However the historic significance of the site remains and is enhanced by the Queenstown Cemetery on the other side of Smiths Gully Road". - Bick Study 1922 This site is now the Peter Franke Reserve and is managed by Parks Victoria Photo Source: The Leader, Nov. 2nd, 1929This photo forms part of a collection of photographs gathered by the Shire of Eltham for their centenary project book,"Pioneers and Painters: 100 years of the Shire of Eltham" by Alan Marshall (1971). The collection of over 500 images is held in partnership between Eltham District Historical Society and Yarra Plenty Regional Library (Eltham Library) and is now formally known as the 'The Shire of Eltham Pioneers Photograph Collection.' It is significant in being the first community sourced collection representing the places and people of the Shire's first one hundred years.Digital imagesepp, shire of eltham pioneers photograph collection, queenstown, st andrews, gold mining, smiths gully -

Bendigo Historical Society Inc.

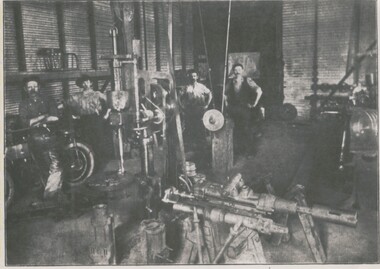

Bendigo Historical Society Inc.Photograph - New Moon Mine Battery

black and white photo - copy. Workshop in corrugated iron walls, 4 adult males standing amongst machinery. At bottom of image printed ' view showing fitting shop at crushing machine' New Moom Mine ? ( J. Lerk 26.11.1999 ).W.H. Robinson ?organization, business, new moon mine ? -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Document - VICTORIA HILL - MINING EQUIPMENT, MACHINERY, ETC

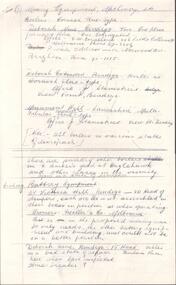

BHS CollectionHandwritten, carbon copy of a list of boilers, crushing equipment, burners, Cyanide plants and rails at various locations.Locations include: Deborah Mine, Deborah Extended, Monument Hill, R. Barker's Yard, Victoria Hill, Maldon State Battery, Liddle's Bendigo, Devonshire Sands, North Deborah, The Great Southern, South Deborah, North Hustlers and Wattle Gully. Notes prepared by Albert Richardson.mine, gold, victoria hill, victoria hill, mining equipment machinery etc, deborah mine, deborah extended, monument hill, r barker's yard, victoria hill, miller & co melb, maldon state battery, john cocks, mr l picken, liddle's bendigo, g holt, devonshire sands, graham bedford, central deborah, north deborah, great southern, south deborah, north hustlers, wattle gully -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Document - MINING REPORTS - CATHERINE REEF UNITED MINE MANAGERS REPORTS

Handwritten notes, with typed transcript of same, on Catherine Reef United Mine Manager, J. M. Eyre Report 20/5/'72. Recommends the purchase of a new boiler. S. Jackson killed in a boiler explosion which the jury said was due to an error of judgement on his part. Recommendations, re New Winding Engine and Poppet Legs by Rbt. Coakes 18th May, 1905. Truck road from the shaft to the battery. Recommendation to call for tenders for a new changing house and a blacksmith shop. Reports about boilers, ropes, cleaning of machinery, testing of brakes, slack coal from the Powlett North Woolamai Collieries, crushings, number of batteries, low wood supply and a visit to the New Moon & South New Moon which are burning the Powlett slack coal. Albert Richardson Collectiondocument, gold, mining reports, mining reports, catherine reef united mine managers reports, j m eyre, myrtle creek coy, s jackman, rbt coakes, great northern co, virginia co, mr roberts, mr harkness, mr mcgrath, ernest mueller, roberts & sons, mr bennett, mr abrahams, mr sluyterman, j langdon, electrical supply coy, smiths, powlett north woolamai collieries, m j gwatkins, new moon, south new moon -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Document - VICTORIA HILL - QUESTION 5 ON VICTORIA HILL

Handwritten notes and carbon copy titled Question 5. Notes refer to Victoria Hill being opened up by Theodore Ballerstedt and his son early in 1854. Theodore Ballerstedt left for Germany having sold his home, crushing battery and mine to Mr. Geo Lansell. He called the mine the '180'. Next mine north to the '180' was the Victoria Quartz. Also contains notes on machinery, geological formations and earning from the mines.document, gold, victoria hill, victoria hill, question 5 on victoria hill, theodore ballerstedt, mr geo lansell, fortuna villa, commonwealth survey regiment, the 180, ballerstedt's original open cut, bendigo south rotary club, john wybrandt, north old chum coy, victoria quartz, victoria reef quartz company, mr william rae, a roberts & sons united ironworks, australian mining standard special edition 1899, bendigo advertiser 10/2/1897, a harkness & coy, bendigo advertiser 30/6/1910 page 5, rae's open cut, e j dunn, bendigo saddle reefs, wittscheibe's 'jeweller's shop', roberts & frost, ashley noy & coy, grant & co, woodward & son, couth allen and co, taylor gould and co, crawshaw & co, roberts & co -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Document - MINING REPORTS - EXTRACTS IRONBARK SOUTH MINE MANAGER'S REPORTS

Handwritten extracts from the Manager's Reports Ironbark South Mine on the Sheepshead Line for the Hlaf-Year ended Feb. 4th, 1936. Report mentions work carried on the mine,crushings, gold yield and development work carried out. H. E. Jones, Gen. Manager and P. I. Wellington, Mine Manager. Also a profit and loss account 1/2 year to 31st Dec. 1935. Details expenses such as wages firewood, etc. Value of gold and plant and machinery. Aslo for the 1/2 year ending 19/1/1937, crushing and gold yield. H. E. Jones. M. Manager.document, gold, mining reports, ironbark south mine, h e jones, p i wellington -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Document - VICTORIA HILL - RECOMMENDATIONS FOR VICTORIA HILL

BHS CollectionHandwritten notes on recommendations for cleaning up and signposting Victoria Hill. Also contains list of photos from the Bendigonian of 1899. List of photos: Shamrock Mine, Undershot Water Wheel at Diamond Hill for Phillips Crushing Battery. Mr. Ballerstedt's Crushing Battery at Victoria Hill, Thompson's Foundry at Castlemaine, Machinery made for Bendigo Mines, Air Compressor at Shenandoah Mine, Winding Engine at Koch's Pioneer Mine, Poppet Legs at Koch's Pioneer Mine, Air Compressor at New Chum Railway Mine, Fortune Hustlers G M Co Bendigo View of Mine, Winding Plant and Afternoon Shift and Underground Work in the New Chum Railway. Also mentioned are notes on Machinery made by Thompsons. Also, a carbon copy of Annual Report to Bendigo Branch Royal Historical Society, Victoria 1/7/71. Mentioned in the Report are: Historical Ball, The Central Deborah, Victoria Hill, Tours and Society Business. Albert Richardson document?document, victoria hill, recommendations for victoria hill, north old chum, ballerstedt's rich 24 yard claim, floyds battery lansell's big 180, the bendigonian 26/1/1899, 2/2/1899, 20/4/1899, 11/5/1899, 10/8/1899, 14/9/1899, shamrock mine, undershot waterwheel at diamond hill, phillips crushing battery, mr ballerstedt's crushing battery, thompson's foundry, shenandoah mine, koch's pioneer mine, new chum railway mine, fortuna hustlers g m co bendigo, new chum railway, st mungo lady barkly, catherine reef, new moon, rae's open cut, old court house eaglehawk, police barracks, vic wodetzki, joss house, central deborah, central nell gwynne, mr harold curnow, bendigo branch royal historical society victoria, mrs kingerlee, felicity kingerlee, mr h biggs, city council, rotary club of bendigo south, white hills cemetry, chinese joss house, bendigo pottery, mr derham, reservoir high, princess theatre, a n a hall, mr hattam, col. sprenger, survey corps, a richardson -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Document - NEW CHUM & VICTORIA LINES OF REEF - MINING MACHINERY, NEW CHUM LINE, EAGLEHAWK

Handwritten notes on mining machinery sold at auction. South St Mungo - Winding Engine. Pair of 15 ? Cyl. Winding Engines. 7 ft Winding Gear. Also, Jackass Boiler. Feed Pump, Trucks, Rails, Flat Sheets, Poppet Heads, Housing, etc. Sold for 270 pounds. Purchaser H Ralph for Austral Drill Co. Lady Barkly Company - 12-inch Cylinder Winding Engine. 8 ft Winding Gear. Cornish Flue Boiler, Feed Pump, Rails, Poppet Heads, Housing, etc. Sold for 162 pound 10 shillings. Purchaser W. J. Sever, Mining Merchants, Melb. Crushing Battery - Complete 40 Head Battery. Tandem Compound Engine. 11 in & 22 in Cylinders. High Press, Boilers, Electric Lighting Plant. 6 in Cyl. High Speed Engine, Fire-proof, Feed Pump, Rails, Flat Sheets, Tools & Sundries. 1000 pound to R. Ralph. These three mining plants, complete. Sold by Messrs. Bell, Lambert and Nixon - Auctioneers. Ref; Bendigo Advertiser. July 14th, 1910, Page 2.document, gold, new chum & victoria lines of reef, mining machinery new chum line eaglehawk, south st mungo, h ralph, austral drill co, lady barkly company, w j sever, crushing battery, messrs bell, lambert and nixon -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Document - MINING REPORTS - MINE MANAGERS REPORT

... . Report mentions machinery and equipment, crushing, firewood... mentions machinery and equipment, crushing, firewood and winding ...BHS CollectionHandwritten extracts from the Mine Manager's Report, John Veale from the North Johnsons Shaft No 216, dated Jan 16th 1908 and the Koch's Pioneer Shaft No 224, Manager C. Rowe dated 26 /4/1899. Report mentions machinery and equipment, crushing, firewood and winding engine.document, gold, mining reports, mine manager's report, north johnsons, john veale, koch's pioneer, c rowe, cornish united co, central windmill coy, windmill hill coy, mr mcgrath