Showing 68 items

matching drill bits

-

Hand Tool Preservation Association of Australia Inc

Hand Tool Preservation Association of Australia IncBrace bit

... brace bit, drill... of Australia. brace bit, drill Brace bit ...This item is part of the Thomas Caine Tool Collection, owned by The National Trust of Australia (Victoria) and curated by the Hand Tools Preservation Association of Australia.brace bit, drill -

Anglesea and District Historical Society

Anglesea and District Historical SocietyBrace and Drill Bit

... Brace and Drill Bit... and tear on the hands. A drill bit is in the chuck.... the hands without producing wear and tear on the hands. A drill bit ...Iron and wooden brace for drilling holes. The U-shaped crank has a wooden spindle on it and along with the top spindle is allowed to freely turn under the hands without producing wear and tear on the hands. A drill bit is in the chuck.brace and bit -

Hand Tool Preservation Association of Australia Inc

Hand Tool Preservation Association of Australia IncBrace bit

... brace bit, twist drill... of Australia. brace bit, twist drill Brace bit ...This item is part of the Thomas Caine Tool Collection, owned by The National Trust of Australia (Victoria) and curated by the Hand Tools Preservation Association of Australia.brace bit, twist drill -

Nillumbik Historical Society Incorporated

Nillumbik Historical Society IncorporatedTool - Portable Sleeper Drill, Early 20th century

... be engaged to raise and lower the mechanism and drill bit. Mechanism... be engaged to raise and lower the mechanism and drill bit. Mechanism ...This drill was used in the construction of the Eltham-Hurstbridge Railway extension in 1911. The device was placed over the wooden sleeper to drill holes for the iron spikes which held the rail down. Example of tools needed to build railway in early 20th Century in the Diamond Valley.Drill mechanism mounted on wooden frame. Mechanism tilts to enable holes to be drilled vertically (normal) or at angles up to 45 degrees using double hand cranks and gears. A rack can be engaged to raise and lower the mechanism and drill bit. Mechanism appears original. Base frame replaced recently. #drill, #railwayconstruction, #sleepers, #tilting, #handoperated -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Pamphlet, Stanley-Titan Pty Ltd, 1960s?

... Wood chisels, auger bits, eyed augers, machine bits..., machine bits, masonry drills, linoleum or leather knives, handsaws... bits, masonry drills, linoleum or leather knives, handsaws ...Hand tool catalogue.Hand tool catalogue: wood chisels, auger bits, eyed augers, machine bits, masonry drills, linoleum or leather knives, handsaws, plane irons, woos screw pilot bits and flat power bits.Hand tool catalogue.stanley-titan pty ltd, woodworking tools -

Kiewa Valley Historical Society

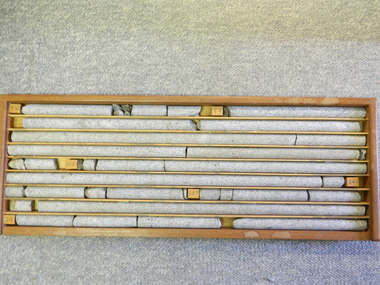

Kiewa Valley Historical SocietyCore Rock Samples

... and replenishment of diamond drill bits(the strongest available, see KVHS... drill bits(the strongest available, see KVHS 0280) was dependent ...The core samples in the display cabinet were obtained from the various sites at which drilling into the rock surface was carried out (under the control of design and structural engineers of the SEC Kiewa Hydro Scheme - late 1940's). This function was a precursor to the decision where to locate, in this case, the McKay Creek Power Station. The information gained by structural engineers from the core samples would be used also for the placements of underground tunnels entry and exit points and the overall effective size of the generator plant. This would have included drill and blast techniques (rock characteristics play an import part of explosion control), requirements for support structures and reinforcing cement/steel forms. The use and replenishment of diamond drill bits(the strongest available, see KVHS 0280) was dependent on the "type" of rock found (harder rock required greater numbers of drill bits). Support beams for reinforced ceilings and floors was also a necessity.These rock core samples are very significant in the formulation and placement of the underground Power Stations and their maze of tunnels (in and out) for a successful implementation of the Hydro Scheme. The amount of pre-planning and engineering studies required for such a large scheme must be undertaken to ensure that a "white elephant" was not the result.There are nine columns of rock cores, each 30mm in diameter, set in a wooden display rack. A clear plastic (slide out) protective panel is installed to the front section. Within each column are block details of the depth from which that section was brought from. See KVHS for the appropriate sketch details.Depth levels (retrieved from) are shown for each section on wooden Blocks: 1st Block: "7'10" (seven feet, ten inches), 2nd Block:"9'4" (nine feet, four inches), 3rd Block: "19'3" (nineteen feet, three inches), 4th Block: "24'2" (twenty four feet, two inches), 5th Block: "25'7"( twenty five feet, seven inches) and last block: "30' (thirty feet)"alternate energy supplies, alpine feasibility studies temperature, rainfall, sec, kiewa hydro scheme, electricity -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyBraces for Hand Drilling x4

... a drilling motion. A brace is a hand tool used with a bit (drill bit... by woodworkers in the Kiewa Valley. brace and bit woodwork hand drilling ...Very old. Ref. Pages 6 and 7 Tools for all Trades Catalogue. The braces vary in quality (strength) depending on what materials are used to make them.The brace is a hand operated tool for boring holes in wood, consisting of a crank-shaped turning device. The brace that grips and rotates the hole-cutting tool, the bit.Used by woodworkers in the Kiewa Valley.Vintage hand drill braces. All different and not all complete. Made of cast iron, steel with wooden handles. The drills fit into one end of the brace which is turned to make a drilling motion. A brace is a hand tool used with a bit (drill bit or auger) to drill holes, usually in wood. Pressure is applied to the top while the handle is rotated.brace and bit, woodwork, hand drilling -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Tool - Carpentry Brace and Bits, c 1878

... . Into this block are inserted the various drill bits . Bits are of various.... Into this block are inserted the various drill bits . Bits are of various ...Brace and bits are believed to be 120 years old.|Tools used by Mrs Duncan's grandfather, when he was a carpenter on the clipper ship of the 1870's between England and Australia.'U-shaped brace with wooden handle at one end, a wooden ball in centre and a rectangular metal block at the other end. Into this block are inserted the various drill bits . Bits are of various sizes shaped with a start screw and then the cutting edge. Rest of the drill is like a corkscrew. End of bit has a four-sided tapered section which is inserted into the metal block on the brace.trades, carpentry -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Tool - PITTOCK COLLECTION: ASSORTED ITEMS

... brackets * one drill bit 65 mm L Items stored in Pittock coach... slide bolt, 202 mm L x 30 mm W * two U-bolt brackets * one drill ...Pittock collection: assorted metal items * brass hose spray, 85 mm L * three corner squares, 35 x 35 x20 mm D * one large steel slide bolt, 202 mm L x 30 mm W * two U-bolt brackets * one drill bit 65 mm L Items stored in Pittock coach builder's box, reference 13000.1. -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Drill Brace, 1800s

... . Later designs had a catch to secure drilling bits. This type... secure the bit. Later designs had a catch to secure drilling bits ...The subject item is an early Victorian Scotch Brace with a 10-inch sweep. They were also known as a six penny or "gentleman's" brace and were designed to accept tapered square shank bits, early designs have a thumb screw to help secure the bit. Later designs had a catch to secure drilling bits. This type of brace was used in wagon making for boring & drilling holes into the wood for a variety of purposes, including driving screws. The subject item is unmarked but could have been made in Glasgow Scotland by John Fray in the 1800s A significant early example of a drill brace made in the UK during the 1800s demonstrates the evolution of this type of tool from this time that today is a rare and collectable example of woodworking tools.Drill Brace metal with socket and thumbscrew, varnished wooden head and handleNoneflagstaff hill, warrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, brace, carpenders wheel brace, cabinet makers tools, drilling tool, wagon makers drill -

Stawell Historical Society Inc

Stawell Historical Society IncMemorabilia - Realia

... Metal Brace and Bits for drilling holes with simple chuck... grampians Stawell Metal Brace and Bits for drilling holes ...Metal Brace and Bits for drilling holes with simple chuck and mushroom headstawell -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDrill Press, early to mid-20th century

... in the centre, a chuck, for the drill bit and has two metal handles...-village blacksmiths blacksmith’s drill blacksmith tools dawn drill ...This post drill press has been made by Melbourne business, Dawn Manufacturing Company. It can be operated manually or by a pulley driven flywheel, with the aid of an engine connected to a power supply. In the late 1800s early 1900s a drill press like this would have been driven by steam from a boiler, the main power source for manufacturer’s power at that time. Dawn’s Golden Anniversary 1917-1967 Catalogue describes this model 611 drill as … “Ruggedly constructed with accurately reamed bearings. The coupling between the main spindle and feed screw engages the full circumference of the spindle, and embraces a ball-bearing thrust race. The pillar, as in all “Dawn Drilling Machines” is a solid bright steel bar, in place of the usual light tubing. Adjustable automatic feed.” And “F. & l. Pulleys extra, if required”. DAWN MANUFACTURING CO. The Dawn Manufacturing Co. was founded in Coburg, Melbourne, in 1917 by the four Blake brothers, who were all engineers. After World War I Dawn was supplying drills Australia wide and the company was growing at a healthy rate. During the depression they remained busy, with employees working 60-80 hour weeks. Dawn was contracted to supply vices and clamps to the Australian Defence Department and munitions factory during the World War II. - 1959 the company was taken over by G.N. Raymond Group. - 1967 the Dawn Manufacturing Co. had distributors in Australia and overseas, including USA, Canada, New Zealand, Asia and the Middle East. - 1973 the Siddons Ramset Limited acquired Dawn. - December 1991, Dawn became a unit of the United States owned Stanley Works Pty. Ltd. - November 1998 Dawn became 100 per cent Australian owned. The drill is a typical tool of a blacksmith, cart wright, wheelwright and garage business. It is an example of the tools of the blacksmiths’ trade in Victoria in the early to mid-20th century.Post type drill press machine with gear driven flywheel. Drill press is attached to a post and is fitted with a pulley belt and will run at a speed of maxim 200 r.p.m. The machine can also be manually operated. It has an aperture in the centre, a chuck, for the drill bit and has two metal handles at the centre, on the right hand side. Gear ratio 2:1 main drive, 6" diam, 3:1 reduction gear. Made by Dawn of Melbourne, Australia. Model No. 611, Code No. 9157"DAWN MFG COY”, “MELB. AUSTRALIA", " 611"flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, blacksmiths, blacksmith’s drill, blacksmith tools, dawn drill model no. 611, dawn drill code no. 9157, dawn manufacturing coy melbourne, dawn manufacturing coy coburg, dawn post drill, drilling machine, drill with gear driven flywheel, forging tool, metal working tool, post drill, steam powered drill, trade tool, warrnambool district 1900s -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Drill Brace, 1800s

... . Later designs had a catch to secure drilling bits. This type... secure the bit. Later designs had a catch to secure drilling bits ...The subject item is an early Victorian Scotch Brace with a 10-inch sweep. They were also known as a six penny or "gentleman's" brace and were designed to accept tapered square shank bits, early designs have a thumb screw to help secure the bit. Later designs had a catch to secure drilling bits. This type of brace was used in wagon making for boring & drilling holes into the wood for a variety of purposes, including driving screws. The subject item is unmarked but could have been made in Glasgow Scotland by John Fray in the 1800s, early drill braces of this type were often unmarked by their makers. A significant early example of a drill brace made in the UK during the 1800s demonstrates the evolution of this type of tool from this time that today is a rare and collectable example of woodworking tools.Brace metal with wooden handle. Has a screw in the holding socket item also has an auger bit. Noneflagstaff hill, warrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, brace, carpenders wheel brace, cabinet makers tools, drilling tool, wagon makers drill -

Kiewa Valley Historical Society

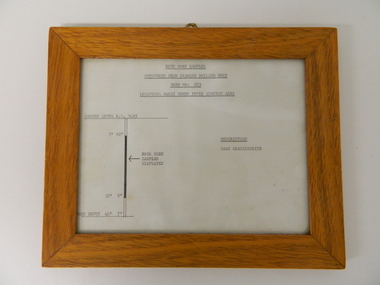

Kiewa Valley Historical SocietySketch Rock Core Display, circa mid to late 1900's

... drill bits(the strongest available, see KVHS 0280) was dependent... in the display cabinet were removed. The drilling was a precursor ...This framed sketch details, in graphic form, where the core samples in the display cabinet were removed. The drilling was a precursor to the decision where to locate, in this case, the McKay Creek Power Station. The information gained by structural engineers from the core samples would be used also for the placements of underground tunnels entry and exit points and the overall effective size of the plant. This would have included drill and blast techniques(rock characteristics play an import part of explosion control), requirements for support structures and reinforcing cement/steel forms. The use and replenishment of diamond drill bits(the strongest available, see KVHS 0280) was dependent on the "type" of rock found. Support beams for reinforced ceilings and floors was also a necessity.The visual derails of where the rock core samples were removed is very significant in the formulation and placement of the underground Power Stations and their maze of tunnels(in and out) for a successful implementation of the Hydro Scheme. The amount of pre-planning and scientific studies required for such a large scheme must be undertaken to ensure that a "white elephant" was not the result.This framed and glass front rock core display sketch has type written information of the rock samples displayed in KVHS 0279 (A). It has a softwood stained and glossed frame with a fixed(nailed) back board and a brass fixture for mounting onto a wall.The paper and type are slighted faded (sunlight affected). The sign heading "ROCK CORE SAMPLES RECOVERED FROM DIAMOND DRILLED BORE" underneath this "BORE NO: 883" and below this "LOCATION: McKAY CREEK POWER STATION AREA" to the left a sketch incorporating the ground level point "GROUND LEVEL R.L.3493", and the core depth point "CORE DEPTH 40' 7". In between and representing( in visual form) the core location areain question.alternate energy supplies, alpine feasibility studies temperature, rainfall, sec, kiewa hydro scheme, electricity -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Screwdriver Set, 1930-1955's

... drill’ or hand drill. 9 parts, Yankee brand, No. 31 set. Made... for use are on label. Ratchet screwdriver plus 6 drill bits ...This Yankee spiral-ratchet Screw Driver (screwdriver) set was a hand tool with drills, used in the making of components for the ship model Sovereign of the Seas. It is part of a collection of objects used by Jim Williams, maker of fine ship models from about 1930-1955. Most of the components for the models, as well as many of the tools, were handmade by Jim Williams. Jim’s family has donated the ship model “Sovereign of the Seas” and many tools, accessories and documents used in the making of this and other ship models have been donated to Flagstaff Hill Maritime Village. Ship model of HMS Sovereign of the Seas, scale model of 17th Century English war ship, was handmade and carved from plans, enclosed in airtight glass case. All components of that model, including even the smallest pulleys, were hand crafted using tools designed and made by Jim. Outstanding details include functional rigging and moving cannons. Please see our record 3732 of the mode Sovereign of the Seas for further details of the ship and the maker. This set is connected with the hobby and skill of ship model making that has been crafted as a leisure activity for many generations. The hobby is often chosen by serving and retired mariners who appreciate the connection with maritime history. This set was used by local Warrnambool man, Jim Williams, who was employed at Cramond and Dickson clothing store, and then at Fletcher Jones menswear for 27 years. It was used in making components for the model of the historic ship, the Sovereign of the Seas. The Sovereign of the Seas was a historic 17th century English war ship with important maritime heritage. Spiral-Ratchet Screw Driver set, also called an ‘American drill’ or hand drill. 9 parts, Yankee brand, No. 31 set. Made by North Bros. Mfc Co. Philadelphia, Pennsylvania, U.S.A.. Instructions for use are on label. Ratchet screwdriver plus 6 drill bits - sizes 1/16th to 11/64th - contained in a small round wooden tube with lid, label on outside. This Screw Driver set is part of a collection of tools and accessories once used by Jim Williams, maker of a series of ship models 1930-1955 including “HMS Sovereign of the Seas”. “WITH 6 DRILL POINTS / SIZES, 1/16 TO 11/64 includes - - with - - / “Yankee” Spiral-Ratchet Screw Driver No. 31 / Made by NORTH BROS. MFG. CO. PHILADELPHIA P [A?]- / Directions for use – First Insert Drill Point In - / Drill Chuck, and turn the – in Chuck of Screwdriver U.S.A.”flagstaff hill, warrnambool, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, jim williams, james bernard williams, ship model hobby, ship model tools, ship model making equipment, ship model making accessories, wood working tool, model making tool, screwdriver set, spiral ratchet screwdriver set, yankee screwdriver set, spiral-ratchet screw driver set, american drill, ratchet drill set, ratchet hand drill, ratchet screwdriverset, north bros. mfc co philadelphia pa, tool, sovereign of the sea, ship model, hobby, ship model tool -

Tatura Irrigation & Wartime Camps Museum

Tatura Irrigation & Wartime Camps MuseumDrill bit

... Drill bit...bit - drill...Metal bit for drilling holes. Spiral end used... - drill hoefer family camp 3 tatura ww2 trades tools Metal bit ...Made and used by internees at Camp 3Metal bit for drilling holes. Spiral end used in conjunction with handle (C7200). Located in Tool kit (C7199)bit - drill, hoefer family, camp 3, tatura, ww2, trades, tools -

Southern Sherbrooke Historical Society Inc.

Southern Sherbrooke Historical Society Inc.Drill brace

... A hand tool used with a bit to drill holes, usually in wood... is No,144 10in. A hand tool used with a bit to drill holes, usually ...A hand tool used with a bit to drill holes, usually in wood. Pressure is applied to the top and the tool is rotated with a U-shaped grip. This example has two wooden handles.On the metal pipe says "Stanley". On other side is No,144 10in.carpentry, tool -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Tools, steel spiral bit Auger, c1900

... . Spiral-bit augers were precursors to modern drills, whose bits... augers were precursors to modern drills, whose bits cleared ...Before drills and braces, T-shaped augers were used to poke holes into wood, while smaller gimlets were used to start them. Auger handles were usually made of a piece of hardwood that was sanded, rounded, or even contoured to give the user a firm grip. Bits on spoon augers essentially carved a hole in the piece of wood, and had to be periodically removed to clear the chips. Spiral-bit augers were precursors to modern drills, whose bits cleared the hole of chips as the user drilled. A significant advance on the auger was the brace, which was originally designed with a single, permanently fixed bit at its end. Eventually, though, braces were designed with sophisticated chucks to accommodate replacement bits, as well as bits of different sizes and for various purposes A steel spiral bit Auger* pioneers, early settlers, market gardeners, moorabbin, bentleigh, cheltenham, brighton, tools, craftsman, carpenters, , blacksmiths, builders, farmers, metalwork, woodwork, drills, augers, gimlets -

Federation University Historical Collection

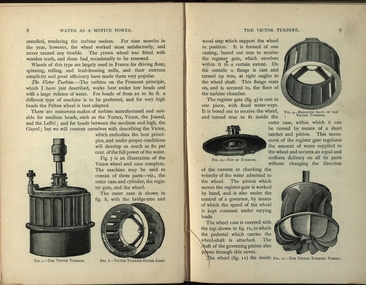

Federation University Historical CollectionBook, Machinery for Metalliferous Mines, 1894, 1894

... ; California Pump; Scram's Air Compressor; Rock drill Bits; Special...; California Pump; Scram's Air Compressor; Rock drill Bits; Special ...The 1st edition of this famous work, giving an excellent account of the machinery used in late 19th century metal mining in the UK and overseas is very rare. It covers a wide range of equipment - pumps, steam engines, drills, winding engines, stamps & concentration mills, aerial ropeways, tramways and early uses of electricity etc. Brown hard cloth covered book. xvi 564 pages with additional advertisements, with over 300 illustrations and drawings, some fold out. Chapters include Water as a motive power, Wind engines and ventilating machinery, Steam boilers/engines and oil engines, hoisting machinery, draining of Mines, pumping engines, rock drilling machinery, boring machinery, concentration machinery, sizing and classifications trommels, joggers and jigging, fine concentration, milling of gold ores, milling of silver ores, amalgamation plates and machinery, dry and roasting machinery, chlorination and cyandide processes for the extraction of gold, electricity as a motive power for mining, electric lighting and blasting, aerial wire ropeways, transport by rail and road. There a a number of lovely line illustrations in the book including: Poncelot's undershot waterwheel; Fromont furnace;Victor turbine; Pelton waterwheel; Root's positive blower;Cross section and front elevation of Lancashire boiler; Robey's Compound Mill Engine; Portable Winding Plant; Iron Pit Head Gear ; Loading Arrangement in an Incline Shaft; kibble; Worthington Pump; California Pump; Scram's Air Compressor; Rock drill Bits; Special Sharpening tools; Boring tools;Rotating Picking table; Ore Feeder; roller crusher; stamp battery; round buddle; slime table; vanner; amalgamating plant; belt elevator;roasting furnace;splicing wire rope; capel; tipping waggon;mining, cornish pump, linkenbach table, water wheel, ventilation, oil engine, california, america, water, steam boilers, steam engines, oil engines, pumpimg, rock drilling, boring, jiggers, milling, silver, gold, drying and roasting, chlorination, cyaniding, lead, zinc, copper, electricity, electric lighting, wire ropes, transport, wind engine, poppet head -

Warrnambool and District Historical Society Inc.

Warrnambool and District Historical Society Inc.Hand Drill, Late 19th century

... end for the insertion of a bit or drill. In the middle... for the insertion of a bit or drill. In the middle is a circular turning ...This tool is one of a collection of tools which are believed to have belonged to Henry Phillips. English-born carpenter, Henry Phillips (1821-1896) came to Australia with his wife Elizabeth in 1849. They lived for some time in Port Fairy before coming to Warrnambool where Henry formed a partnership with Christopher Beattie and established the undertaking firm of Beattie and Phillips in 1865. This firm continued on after the death of the two founders and lasted until the year 2000. In Warrnambool Henry Phillips was involved in the management of the Mechanics’ Institute. This tool is of interest, firstly as an example of a vintage tool and secondly as a memento of the Warrnambool carpenter and businessman, Henry Phillips. This is a hand drill with a composite material handle at one end (for one hand) and a tubular metal piece at the other end for the insertion of a bit or drill. In the middle is a circular turning piece with metal spokes and a metal handle (for the other hand). The circular piece is held together and attached to the main body of the tool with several screws. vintage tools, henry phillips, history of warrnambool -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Brace & Bit, John S Fray, 1883 - 1906

... Context: A brace is a hand tool used with a bit (drill bit... with a bit (drill bit or auger) to drill holes, usually in wood ...Context: A brace is a hand tool used with a bit (drill bit or auger) to drill holes, usually in wood. The pressure is applied to the top and the tool is rotated with a U-shaped grip. Bits used to come in a variety of types but today the more commonly used Ridgeway and Irwin pattern bits also rely on a snail point (called the snail), which is a tapered screw point shaped the same as a wood screw thread, which helps to pull the bit into the wood as the user turns the brace handle and applies pressure. The designs used today come from an original idea and pattern invented by John S Fray. Company History: John S. Fray (1833 ) immigrated to Bridgeport Connecticut USA from England in the 1850s and established a working relationship with Nelson Spofford, who held an 1858 patent for a bit brace (the tool could be augured in a continuous circular motion by hand). He established the John S. Fray Co. around the same time and immediately began producing the Spofford bit brace. Fray himself held at least two patents: one awarded in 1869 for a boring brace attachment, and another awarded in 1883 for a tool handle. By 1889, the firm was located at the industrial complex that sits between the former International Silver Company and the former Bridgeport Chain Company on Crescent Avenue and is identified on the Sanborn Insurance Atlas as a manufacturer of Spofford bit braces, hollow handle awl, and toolsets. The company was in competition with Peck Stow and Wilcox Co. of Southington, and in 1898 was enjoined from making a ratchet bit brace for which the latter company held a patent. By the 1920s, the factory had been purchased by the Stanley Company of New Britain and leased to the American Tube and Stamping Company, a manufacturer of brass, copper, seamless, and bicycle tubing, which also ran a rolling mill to the south on Stafford Avenue (now demolished). The Stanley Company bought both mills in 1926, perhaps as a strategic move to be located along the Bridgeport Harbour, through which much of the raw material used in its operations throughout the state came. By the 1950s, the Crescent Avenue operations had been moved to other sites in Connecticut, and Stanley again leased the building to a company called Cornwall and Patterson, a manufacturer of piano hardware. Today the building appears to be vacant. An early carpenters tool made by a well known early manufacturer from America who instigated many innovations to the making of tools. His early pattern for the improvement of a tool that could be used for the boring of holes in wood was a significant step forward. His design for a boring brace attachment and later a specific handle is still in use today and his original brace and bit is now sought after by collectors of antique tools. Spofford Carpenter's Bit Brace metal has bit attached. Wing nut holds bit in place but nut missing. holds bit in place. 285mm long x 160mm Noneflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Tool - Brace and Bit hand drill, 20thC

... Brace and Bit hand drill.... Spiral-bit augers were precursors to modern drills, whose bits... augers were precursors to modern drills, whose bits cleared ...Before drills and braces, T-shaped augers were used to poke holes into wood, while smaller gimlets were used to start them. Auger handles were usually made of a piece of hardwood that was sanded, rounded, or even contoured to give the user a firm grip. Bits on spoon augers essentially carved a hole in the piece of wood, and had to be periodically removed to clear the chips. Spiral-bit augers were precursors to modern drills, whose bits cleared the hole of chips as the user drilled. A significant advance on the auger was the brace, which was originally designed with a single, permanently fixed bit at its end. Eventually, though, braces were designed with sophisticated chucks to accommodate replacement bits, as well as bits of different sizes and for various purposes. Chucks were patented as vigorously as the braces themselves The braces themselves also evolved for particular trades, from furniture makers to surgeons. The operator holds the ‘head’ in one hand, positions the drill in the wood , applies pressure and rotates the ‘centre piece’ to cause the drill to pierce the wood. A steel revolving hand tool for boring and screw-driving with wood handles * pioneers, early settlers, market gardeners, moorabbin, bentleigh, cheltenham, brighton, tools, craftsman, carpenters, , blacksmiths, builders, farmers, metalwork, woodwork, screws -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Chain Drill Attachment, Millers Falls Co, 1900-1931

... An auxiliary tool for use with a breast drill or bit brace... drill or bit brace, when extra power is needed, or where ...An auxiliary tool for use with a breast drill or bit brace, when extra power is needed, or where pressure cannot be easily applied. The drill is automatically fed into the work by an adjustable friction feed which is automatically regulated by the resistance the drill encounters. These were made to fit on breast drills, and used for drilling metal, particularly round sections like a pipe. The chain is run around the object being drilled and gradually tightens as the hole is drilled, maintaining pressure while being a bit easier on the operator. Millers Falls Co. is a tool manufacturing company originally based in Millers Falls, Massachusetts, USA. It was established in Greenfield, Massachusetts in 1868 as Gunn & Amidon by Levi J. Gunn and Charles H. Amidon. Gunn and Amidon, along with a third partner, Henry L. Pratt built a factory in the north of Greenfield. After the Greenfield factory burned down, the company was reorganized as the Millers Falls Manufacturing Co. It merged with Backus Vise Co. in 1872 to form Millers Falls Co. In 1931 Millers Falls tools purchased the majority of the shares of Goodell-Pratt tools and merged with that manufacturer in 1932. In 1962 the company was acquired by Ingersoll Rand. In 1982, Ingersoll Rand sold the Millers Falls business to the newly created Millers Falls Tool Co. The company was head quartered in Alpha, New Jersey. Since 2002 the company trademark has belonged to Hangzhou Great Star Industrial, of Hangzhou, China. The item is associated with a tool manufacturing company established in the mid-19th century that pioneered the development of many types of tools used in many differing trades. The company grew to become a major supplier of tools around the world and today its tools that were produced during the mid-19th and early 20th centuries are now collectable items. Drill attachment with chain No 717 from 1925 catalogue 1/2 socket hole Millers Falls, Massachusettsflagstaff hill, warrnambool, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, chain drill, mast drill, millers falls, drilling attachment, drilling tools -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyDrill Auger, Circa early 1900s

This item wasused before diesel, electric and battery drilling apparatus were used by farmers, and other trades requiring a portable yet reliable method of drilling holes. As this item is a 3/4 inch hole drill it would be suitable for fencing and providing holes for structural studs. As with all outdoor farm equipment, man power was required (be it the farmer or farm hands). Fitness of the operator was at a high standard but protective gloves were not highly thought of as it was before occupational, health and safety regulations became mandatory over all manual handling activities, be they on rural properties or town/city factories. This period was one where the male ego was at its pinnacle i.e. the harder the tasks the more of a man was required. Hard manual work was not only the "way to go" but also a necessity. Evolution of cheap portable electric/battery powered tools opened up a more efficient method available, especially to those with less muscle strength. This item personifies the rugged environment of the rural workplace. The Kiewa Valley with its main emphasis on farming and grazing provided ample opportunity to use this construction implement. The manufacturer being a Scottish tool company is very significant in the era when this hole maker was in high demand. British steel products were of high grade and had a good record of reliability. The reliability of any tool was a solid factor for farmers and tradesmen in this semi-isolated region (Circa early 1900s) within the Kiewa Valley and its regional area. This factor,although not as crucial, post 1960s, when Asian manufacturers entered the market place and produced cheaper tools and transportation and supplies was more frequent and reliable, the need for the more expensive British made tools diminished considerably. After the influx of tradesmen from war torn Europe (post 1945) and the increased availability of tradesmen in the Kiewa Valley and its region the price of tools was and still is not as crucial and the cost of all required tools has become a minimal part of the equation. It is only with the emerging younger trades person, farmer and grazier, who have more, "one eye on production costs" and no "old ties to the motherland" inert mind set that quality tools such as this auger and other hand tools "must be made to last a life time" is no longer part of the modern work environment.This cast iron, hand operated Auger has a short barrel shaped cylinder at one end (known as the "Eye") and at the other end a Helical screw blade (screws the cutting edge into wooden material, thereby creating a hole 3/4 inch diameter in the wood) . The barrel section at the top permits a metal or wooden leverage plank to be inserted. The main rod has a 180mm long cutting/screw blade running from the bottom up towards the "eye" end. From the end of the screw blade to the handle is 380mm and cylindrical, but this changes at 550mm from the "eye" end to a 14mm x 10mm rectangular shape shaft.This shaft end is welded to the "Eye".On the shaft below the "eye" is stamped " MATHESON GLASGOW" on the front side and a spade (cards) symbol on the back.auger, hand drill, fencing, tool, rural trades, brace & bit -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyDrill Auger, Circa early 1900's

This item was before diesel, electric and battery drilling apparatus were used by farmers, and other trades requiring a portable yet reliable method of drilling holes. As this item is a 3/4 inch hole drill it would be suitable for fencing and providing holes for structural studs. As with all outdoor farm equipment, man power was required (be it the farmer or farm hands). Fitness of the operator was at a high standard but protective gloves were not highly thought of as it was before occupational, health and safety regulations became mandatory over all manual handling activities, be they on rural properties or town/city factories. This period was one where the male ego was at its pinnacle i.e. the harder the tasks the more of a man was required. Hard manual work was not only the "way to go" but also a necessity. Evolution of cheap portable electric/battery powered tools opened up a more efficient method available, especially to those with less muscle strength.This item personifies the rugged environment of the rural workplace. The Kiewa Valley with its main emphasis on farming and grazing provided ample opportunity to use this construction implement. The manufacturer being a Scottish tool company is very significant in the era when this hole maker was in high demand. British steel products were of high grade and had a good record of reliability. The reliability of any tool was a solid factor for farmers and tradesmen in this semi-isolated region (Circa early 1900s) of the Kiewa Valley and its regional area. This factor,although not as crucial, post 1960s, when Asian manufacturers entered the market place and produced cheaper tools and transportation and supplies was more frequent and reliable, the need for the more expensive British made tools diminished considerably. After the influx of tradesmen from war torn Europe (post 1945) and the increased availability of tradesmen in the Kiewa Valley and its region the price of tools is not as crucial and the cost of all required tools has become a minimal part of the equation. It is only with the emerging younger trades person, farmer and grazier, who have more, "one eye on production costs" and no "old ties to the motherland" inert mind set that quality tools such as this auger and other hand tools "must be made to last a life time" is no longer part of the modern work environment.This cast iron hand operated drill, has a short barrel-shaped cylinder, known as "the eye" welded across the main rod and is 30mm in circumference. It also has a hole drilled to allow a screw to be fastened onto the hand stock ( not available).The main rod is solid for 400mm and then has been flattened and coiled (Helical screw blade) for another 200mm. At the end of the larger screw blade there is a smaller gauged starter blade with a pointer thread 15mm long. This Auger produces a 1/8th inch hole (metric measurement not used at time of manufacture) See KVHS 0469 for 3/4 inch hole and KVHS 0471 for another 1/8th inch hole.A number 5 stamped on the flat sideauger, hand drill, fencing, tool, rural trades, brace & bit -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyDrill Auger, Circa early 1900's

This item was before diesel, electric and battery drilling apparatus were used by farmers, and other trades requiring a portable yet reliable method of drilling holes. As this item is a 3/4 inch hole drill it would be suitable for fencing and providing holes for structural studs. As with all outdoor farm equipment, man power was required (be it the farmer or farm hands). Fitness of the operator was at a high standard but protective gloves were not highly thought of as it was before occupational, health and safety regulations became mandatory over all manual handling activities, be they on rural properties or town/city factories. This period was one where the male ego was at its pinnacle i.e. the harder the tasks the more of a man was required. Hard manual work was not only the "way to go" but also a necessity. Evolution of cheap portable electric/battery powered tools opened up a more efficient method available, especially to those with less muscle strength.This item personifies the rugged environment of the rural workplace. The Kiewa Valley with its main emphasis on farming and grazing provided ample opportunity to use this construction implement. The manufacturer being a Scottish tool company is very significant in the era when this hole maker was in high demand. British steel products were of high grade and had a good record of reliability. The reliability of any tool was a solid factor for farmers and tradesmen in this semi-isolated region (Circa early 1900s) of the Kiewa Valley and its regional area. This factor,although not as crucial, post 1960s, when Asian manufacturers entered the market place and produced cheaper tools and transportation and supplies was more frequent and reliable, the need for the more expensive British made tools diminished considerably. After the influx of tradesmen from war torn Europe (post 1945) and the increased availability of tradesmen in the Kiewa Valley and its region the price of tools is not as crucial and the cost of all required tools has become a minimal part of the equation. It is only with the emerging younger trades person, farmer and grazier, who have more, "one eye on production costs" and no "old ties to the motherland" inert mind set that quality tools such as this auger and other hand tools "must be made to last a life time" is no longer part of the modern work environment.This cast iron hand operated drill, has a short barrel-shaped cylinder, known as "the eye" welded across the main rod and is 30mm in circumference. It also has a hole drilled to allow a screw to be fastened onto the hand stock ( not available).The main rod is solid for 400mm and then has been flattened and coiled (Helical screw blade) for another 200mm. At the end of the larger screw blade there is a smaller gauged starter blade with a pointer thread 15mm long. This Auger produces a 1/8th inch hole (metric measurement not used at time of manufacture) See KVHS 0469 for 3/4 inch hole and KVHS 0470 for another 1/8th inch hole.auger, hand drill, fencing, tool, rural trades, brace & bit -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageAngle Bit stock

... Adjustable Angle Bit-stock. Used for drilling in difficult...-stock Adjustable Angle Bit-stock. Used for drilling in difficult ...Adjustable Angle Bit-stock. Used for drilling in difficult places. Is fully adjustable and pivots around a universal jointflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, angle bit-stock -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Scotch Eye Beam Auger, W M Ridgway, 1930s

William Ridgway and Sons company of Sheffield, manufacturers of augers, bits, wood-boring, and motorising tools, was founded in 1878 and became a Private company in 1909, their factory was founded in the 1930s. William Ridgway Tools merged first with Record Tools in 1974 to form Record Ridgway Tools Ltd. Record was another Sheffield company that was renowned for the quality of their vices and industrial clamps. Following the merger Record, Ridgway Tools Ltd was made up of fourteen UK Companies and five overseas companies. A later merger with a woodwork tools company called Marple (which was part-owned by Record and Ridgway respectively before their original merger) led to the company becoming known as Record Marples Tools. Record Marples was taken over by the Swedish hardware manufacturer AB Bahco in 1982. Despite a management buyout leading to the company reverting to British ownership in 1985 the company struggled financially and the following administration was acquired by U.S.-based Irwin Tools in 1998 who has since moved production to China in recent years. A vintage tool made in the 1930s when Ridgway began mass producing augers and other tools for export and sale. This item would have probably been used in Australia on a farm for drilling fence posts for wire to pass through or other tasks where a hole was required to be bored in timber. Scotch eye beam auger, with double twist and Lead screw. Ridgway Sheffield warrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, wood boring tool, scotch auger, carpenters tools, shipwrights tools, coopers tools, ridgway & sons, auger bits -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Scotch Eye Beam Auger, W M Ridgway, 1930s

William Ridgway and Sons company of Sheffield, manufacturers of augers, bits, wood-boring, and motorising tools, was founded in 1878 and became a Private company in 1909, their factory was founded in the 1930s. William Ridgway Tools merged first with Record Tools in 1974 to form Record Ridgway Tools Ltd. Record was another Sheffield company that was renowned for the quality of their vices and industrial clamps. Following the merger Record, Ridgway Tools Ltd was made up of fourteen UK Companies and five overseas companies. A later merger with a woodwork tools company called Marple (which was part-owned by Record and Ridgway respectively before their original merger) led to the company becoming known as Record Marples Tools. Record Marples was taken over by the Swedish hardware manufacturer AB Bahco in 1982. Despite a management buyout leading to the company reverting to British ownership in 1985 the company struggled financially and the following administration was acquired by U.S.-based Irwin Tools in 1998 who has since moved production to China in recent years. A vintage tool made in the 1930s when Ridgway began mass producing augers and other tools for export and sale. This item would have probably been used in Australia on a farm for drilling fence posts for wire to pass through or other tasks where a hole was required to be bored in timber. Ring Auger, Double Twist with Lead Screw, square shaft (which has had a welded repair), socket set at right angle. Broad arrow mark Ridgway Sheffield and DO stamped. warrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, wood boring tool, scotch auger, carpenters tools, shipwrights tools, coopers tools, ridgway & sons, auger bits -

Coal Creek Community Park & Museum

Coal Creek Community Park & MuseumHollow drill bit

... Hollow drill bit... is approximately 5cm shorter than the object itself Hollow drill bit ...8416.1 - Long hollow cylindrical tube capped at one end with a pointed bit and a flat ring with two short cylindrical projections sticking out. The central hollow is approximately 5cm shorter than the object itself