Showing 57 items

matching electrical appliance

-

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Can Opener, Bottle Opener & Corkscrew

It took 15 years to invent the can. It took 100 more to invent a standard way to open it. In the 19th century, decades after the invention of canning, there were virtually no can openers. Canned food, such as sardines, came with its own "key" to peel back the tin lid. Birth of the can One of the oddest things about the can opener is that the can predates it by almost 150 years. Though common today, cans were once military-grade technology. In 1795, Napoleon, to whom the phrase "an army marches on its stomach" is attributed, offered 12,000 francs to anyone who could find a way to preserve food. Without any knowledge of bacteria or their role in food spoilage, scientists didn't even know where to begin. It took 15 years before a chef named Nicholas Appert claimed the prize after successfully jarring food. Soon after that, his countryman Philippe de Girard came up with a variant on Appert's method—metal tins—and sold the idea to the British. Spoiled food, and the sickness it caused, was a widespread problem. The public would have benefited from canned food, but for decades cans were almost exclusively for the army and the navy. The canning process, with its hours of boiling and steaming, its scrupulous cleanliness, its heated metal, and its need for a great deal of disposable material, made canned food far too expensive for anyone but the military. No can openers were needed or even possible. The metal of early cans was too thick to make openers practical. Soldiers and sailors had plenty of sharp objects on hand and made ample use of them when they wanted to eat. During the 19th century, the process of canning was refined and mechanised, and the metal wall of the average can slimmed down enough that a civilian could get it open—if that civilian had the right tool. No one had that tool yet, so early cans had to open themselves. In other words, they came with built-in openers. The result was a confusing but pleasing free-for-all, in terms of product engineering. Each type of food came with its own kind of can, and each kind of can came with its own kind of opener. Tinned fish and meat were often sold in rectangular cans. These cans were fitted with a "key" that would roll down the top of the can. Coffee, beans, and other types of meat were packaged in cylinders with metal strips that could be peeled back with their own kinds of built-in keys. Cans of milk, which didn't need to be completely opened, came with puncture devices. As tinned food became more common, its containers became more regular. A nice cylindrical can became the norm, and, as these cans filled kitchens, more engineers put their minds to finding a convenient way to open all of them. The first standalone can opener worked on a simple principle: point, stab, and pull. From the mid-19th century to the end of World War I, the typical can opener looked roughly like a wrench, if the lower 'jaw' of the wrench were replaced with a blade. People used the blade to puncture the top of the can near its edge, push the upper jaw against the side of the can, and drag the blade through the metal along the rim. Because meat was the first and most popular canned substance, these can openers were often shaped to look like cows and given the nickname 'bully beef can openers'. The bully beef can opener, popular in the mid-19th century, resulted in many lost fingers. Later, a corkscrew was added that was seated in the handle, and could be pulled out for use. Bully beef can openers were so common, effective, and sturdy that they are still frequently available on collectors' sites. Some are advertised as “still working,” and every last one of them is, without a doubt, soaked in the blood of our ancestors. Dragging a sharp blade along the edge of a can is certain to cause injury sooner or later. So once people got a reliable can shape and a reliable way to get the can open, the search was on for a reliable way to get a can open without the possibility of losing a finger. The answer came in 1925, from the Star Can Opener Company of San Francisco. This is probably the first can opener that resembles the one people have in their kitchens today. Instead of using a blade to pry open a metal can, buyers could clamp the edge of the can between two wheels and twist the handle of one of the wheels to move the blade around the lip. The Star can openers weren't perfect. Compared to the bully beef model, they were flimsy and breakable, but they probably prevented a few injuries. Six short years after the Star model came to market, the first electric can opener was invented. It was patented in 1931 by the Bunker Clancey Company of Kansas City, who had already been sued by the Star Can Opener Company for trying sell a double-wheeled can opener like the Star model (the case was dismissed). The electric can opener must have seemed like the wave of the future and a sure-fire seller, but it proved to be too far ahead of its time. In 1931 not that many households had electricity, and those that did weren't interested in buying can openers. The Bunker Clancey Company was subsequently bought by the Rival Company, which still makes small appliances like can openers today. It took another 25 years for electrically powered can openers to become practical. In the 1950s, Walter Hess Bodle and his daughter, Elizabeth Bodle, developed an electric can opener in the family garage. Walter came up with the opener's blades and motor, and Elizabeth sculpted the outside. Their can opener was a free-standing unit that could sit on the kitchen counter. The Udico brand of the Union Die Casting Company put it on the market in time for Christmas in 1956 and had great success with it. Over the next few years it came out in different styles and colours, and, like the bully beef can opener, has become a collector's item. Also like the bully beef model, Udico can openers often still work. They don't make 'em like they used to. Although there have been some design changes and refinements over the last sixty years, there have yet to be any more leaps forward in can opener technology. If you're resentfully opening a can, you are almost certainly doing it using the Star design, manually forcing the can between two wheels, or the Bodle design, clamping the can into a free-standing electrical opener. Whether or not you enjoy your holiday meals, at least you can be happy that you are not getting poisoned by your own food or cutting open your hand with the blade you use to get at it. That's something, right?The can opener, Bottle opener and the corkscrew are still very important and essential items in most kitchens.Metal can opener, chromed, with bottle opener, and a corkscrew seated in the handle.None.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, canning, can opener, corkscrew, bottle opener, kitchen equipment -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Can Opener

It took 15 years to invent the can. It took 100 more to invent a standard way to open it. In the 19th century, decades after the invention of canning, there were virtually no can openers. Canned food, such as sardines, came with its own "key" to peel back the tin lid. Birth of the can One of the oddest things about the can opener is that the can predates it by almost 150 years. Though common today, cans were once military-grade technology. In 1795, Napoleon, to whom the phrase "an army marches on its stomach" is attributed, offered 12,000 francs to anyone who could find a way to preserve food. Without any knowledge of bacteria or their role in food spoilage, scientists didn't even know where to begin. It took 15 years before a chef named Nicholas Appert claimed the prize after successfully jarring food. Soon after that, his countryman Philippe de Girard came up with a variant on Appert's method—metal tins—and sold the idea to the British. Spoiled food, and the sickness it caused, was a widespread problem. The public would have benefited from canned food, but for decades cans were almost exclusively for the army and the navy. The canning process, with its hours of boiling and steaming, its scrupulous cleanliness, its heated metal, and its need for a great deal of disposable material, made canned food far too expensive for anyone but the military. No can openers were needed or even possible. The metal of early cans was too thick to make openers practical. Soldiers and sailors had plenty of sharp objects on hand and made ample use of them when they wanted to eat. During the 19th century, the process of canning was refined and mechanised, and the metal wall of the average can slimmed down enough that a civilian could get it open—if that civilian had the right tool. No one had that tool yet, so early cans had to open themselves. In other words, they came with built-in openers. The result was a confusing but pleasing free-for-all, in terms of product engineering. Each type of food came with its own kind of can, and each kind of can came with its own kind of opener. Tinned fish and meat were often sold in rectangular cans. These cans were fitted with a "key" that would roll down the top of the can. Coffee, beans, and other types of meat were packaged in cylinders with metal strips that could be peeled back with their own kinds of built-in keys. Cans of milk, which didn't need to be completely opened, came with puncture devices. As tinned food became more common, its containers became more regular. A nice cylindrical can became the norm, and, as these cans filled kitchens, more engineers put their minds to finding a convenient way to open all of them. The first standalone can opener worked on a simple principle: point, stab, and pull. From the mid-19th century to the end of World War I, the typical can opener looked roughly like a wrench, if the lower 'jaw' of the wrench were replaced with a blade. People used the blade to puncture the top of the can near its edge, push the upper jaw against the side of the can, and drag the blade through the metal along the rim. Because meat was the first and most popular canned substance, these can openers were often shaped to look like cows and given the nickname 'bully beef can openers'. The bully beef can opener, popular in the mid-19th century, resulted in many lost fingers. Bully beef can openers were so common, effective, and sturdy that they are still frequently available on collectors' sites. Some are advertised as “still working,” and every last one of them is, without a doubt, soaked in the blood of our ancestors. Dragging a sharp blade along the edge of a can is certain to cause injury sooner or later. So once people got a reliable can shape and a reliable way to get the can open, the search was on for a reliable way to get a can open without the possibility of losing a finger. The answer came in 1925, from the Star Can Opener Company of San Francisco. This is probably the first can opener that resembles the one people have in their kitchens today. Instead of using a blade to pry open a metal can, buyers could clamp the edge of the can between two wheels and twist the handle of one of the wheels to move the blade around the lip. The Star can openers weren't perfect. Compared to the bully beef model, they were flimsy and breakable, but they probably prevented a few injuries. Six short years after the Star model came to market, the first electric can opener was invented. It was patented in 1931 by the Bunker Clancey Company of Kansas City, who had already been sued by the Star Can Opener Company for trying sell a double-wheeled can opener like the Star model (the case was dismissed). The electric can opener must have seemed like the wave of the future and a sure-fire seller, but it proved to be too far ahead of its time. In 1931 not that many households had electricity, and those that did weren't interested in buying can openers. The Bunker Clancey Company was subsequently bought by the Rival Company, which still makes small appliances like can openers today. It took another 25 years for electrically powered can openers to become practical. In the 1950s, Walter Hess Bodle and his daughter, Elizabeth Bodle, developed an electric can opener in the family garage. Walter came up with the opener's blades and motor, and Elizabeth sculpted the outside. Their can opener was a free-standing unit that could sit on the kitchen counter. The Udico brand of the Union Die Casting Company put it on the market in time for Christmas in 1956 and had great success with it. Over the next few years it came out in different styles and colours, and, like the bully beef can opener, has become a collector's item. Also like the bully beef model, Udico can openers often still work. They don't make 'em like they used to. Although there have been some design changes and refinements over the last sixty years, there have yet to be any more leaps forward in can opener technology. If you're resentfully opening a can, you are almost certainly doing it using the Star design, manually forcing the can between two wheels, or the Bodle design, clamping the can into a free-standing electrical opener. Whether or not you enjoy your holiday meals, at least you can be happy that you are not getting poisoned by your own food or cutting open your hand with the blade you use to get at it. That's something, right?The can opener is still a very important and essential item in most kitchens.Can opener, right handed, metal, upper blade section serrated, inscription 'Peerless Pat.Feb 11-90'.Peerless Pat.Feb 11-90flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, cannning, can opener, kitchen equipment -

Federation University Historical Collection

Federation University Historical CollectionBook, Ballarat School of Mines Apprentices' Handbook, 1953, 1953

... equivalents power consumption of electrical appliances horse power ...Apprentices' Handbook, Issued with the compliments of The Council and Staff of The Ballarat School of Mines and Industries. It contains a foreword from the Principal to apprentices. It states how they are taking the first step towards becoming a first class craftsman in their chosen field. The course is set down by the Victorian Apprenticeship Commission and consists of the practical experience obtained while on the job together with the subjects studied at this school. Page 26 gives the date the book was produced. From the diary of a service man dated January 25, 1913:- "Been filing crank pins all day. Hard to get a good job if they are much out of round, but it is the only practical way at present." That is 40 years ago and contrasts with today. (1953)Sixty-two page handbook with illustrations. .1: E J Tippett in blue ink on inside of front cover. Printer's name and emblem on last page. "John Fraser & Son Printers - Albert Street, Ballarat"ballarat school of mines, trades, apprenticeship, apprentice, electrical mechanics, motor mechanics, turning and fitting, plumbing and gasfitting, blacksmithing, printing, useful tables, mechanical and electrical unit equivalents, power consumption of electrical appliances, horse power to drive machinery, breakdown troubles of cars, pre-war post-war, table of chemical elements, screw gauges, welding tips -

Federation University Historical Collection

Federation University Historical CollectionBooklet, Berry Anderson & Co, The Ballarat School of Mines, Calendar and Annual Report 1894, 1894

The Ballarat School of Mines Calendar and Annual Report 1894. Associateship of The School, Calendar for 1894, Certificates Granted by the Council 1893, Comparative Statement of Receipts and Expenditure, Departmental Expenditure, Examiners, Examination Papers, Examination Fees, Fees, Honorary Correspondents, Life Governors, Meteorological Observations, Mining Engineering Scholarship, Number of Certificates Granted since Inception, Number of Students attended The School of Mines, Office Bearers, Plant and Appliances, Practical Treatment of Ores, Professors and Lecturers, Report of the Professor of Mineralogy and Geology and Curator of the Museum, Report of the Superintendent of Laboratories, Report of the Lecturer on Engineering and Surveying, Report of the Lecturer on Mathematics, Report of the Instructor in Mechanical Drawing and Machine Construction and Design, Report of the Lecturer on Electrical Engineering and Telegraphy, Report of the Lecturer on Geometrical Model and Perspective Drawing, Report of the Lecturer on Botany, Report of the Lecturer on Biology, Pharmacy, Materia Medica, Scale of Charges for Assays and Analyses, State School Science Classes, Statement of Receipts and Expenditure for year 1893 and Serjeant Scholarship Fund, Statistics - Student attending Lectures, Subscriptions and Donations, Syllabus of Lecture Courses, Time TableThe Ballarat School of Mines Calendar and Annual Report, 1894. Green soft cover, 116 pages. ballarat school of mines, annual report, andrew anderson j.p. - president, f. j. martell - vice president, r. denham pinnock - vice president, rivett henry bland - trustee, the hon. sir w. j. clarke - trustee, the hon. john warrington rogers - trustee, james oddie - trustee, the hon. henry cuthbert - honorary solicitor, r. g. middleton - honorary treasurer, charles kent - auditor, andrew berry - registrar, professor alf. mica smith - chemistry, metallurgy, natural philosophy, professor krause - geology, mineralogy, principles of mining, professor j. h. horwood - mine and land surveying, mining mechanics, hydraulics, civil engineering, applied mechanics, j. a. dawson - electrical engineering, d. walker - chemistry and natural philosophy, w. e. bennetts - mathematics, henry j. hall - freehand and perspective drawing, a. e. c. kerr - mechanical drawing, george p. day - botany, e. gutheil - paleontology, zoology, materia medica, w. d. snowball - veterinary science -

Anglesea and District Historical Society

Anglesea and District Historical SocietyCassette Recorder, GAC, Not known

Six key portable cassette recorder/player with rotary volume control. It can be operated directly from batteries or AC power (cord included). Also has Automatic Recording Level Control Circuitry (ALC), thus no need to adjust volume while recording. In original box with instructions and power cord. (Purchased at Waltons for 29.99).Auto Stop / GAC - logo Top: Condenser mic Rec / Play / Rewind / FF / Eject Left side: Ear O / Remote Mike 00 / Volume Bottom markings: Model No. SW-201 AC: 240V 50HZ 6W DC: 6V (UM - 2x4) Made in Hong Kong Warning: To prevent fire or electrical shock hazard, do not expose this appliance to rain or moisture, do not remove cover, no user serviceable parts inside, refer servicing to qualified service personnel. cassette recorder, gac -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Machine - Washing Machine, c. 1960

... Volunteers domestic items laundering electrical technology appliances ...This was donated by the Eastern Emergency VolunteersHOOVER TWIN TUB WASHING MACHINE MODEL 1116 The twin tub machine appears to have been developed to assist in the washing of clothes by including a spin dryer. One tub had an agitator in the side wall to wash clothes which were then lifted into the spin dryer.Hoovermatic GZ046916domestic items, laundering, electrical technology, appliances & accessories -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Machine - Washing Machine, c.1970

... laundering electrical technology appliances & accessories Simpson ...Was used by owner until concerned that children may have hurt themselves on the wringerSimpson electric washing machine with wringer attached above bowl. White, round with removable lid. Front lever: Wash/Stop; three buttons on front: Empty-Wash-Off indicated. Appliance on castors attached wringer with metal drip tray and two rubber rollers. Wringer will pivot.Simpsondomestic items, laundering, electrical technology, appliances & accessories -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Audio - Clock Radio

Purchased in 1973 with a group of fellow office workers. Used by Ted Arrowsmith for 33 years as a bedside alarm and later as a clock in our back room.1973 Clock Radio FM - AM. Cream attached casing - black face - electrical - Peak DC 12|It worked through a ratchet arrangement which enabled the time disc to drop after each minute and then hourly. It was a 24 hour clock.'Peak DC 12'audio-visual technology, audio appliances -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Domestic object - Wall Clock, 1945s

... Mitcham melbourne Unknown horology clocks electrical technology ...UnknownClock square with rounded corners cream bakelite electric wall clock with art deco style corners. Silver edged clock face with black numbers on silver edge with cream centre. Black filigree hands with a red minute hand. Black adjustment knob at bottom. Made in Great Britain by Smiths Sectric is marked on face. Back is black bakelite 'Smiths English Clocks' 200/250V 50SFC - Reg Trade Mark. Made in England. Instructions to set hands, press and turn knob. Made under one or moe Brit. Patents 366710 369 336 374 713 384441 484222. Back is cream with black book and white electric cord with black ring-grip plug 250V - 10amp. Made in Australiahorology, clocks, electrical technology, appliances & accessories -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Audio - Portable Radio, 1960's (probably 1964)

... Mitcham melbourne Designer was John Holt electrical technology ...Designer was John HoltPortable Radio A.W.A. Radiola in brown PVC case with handle. H11cm x L21cm x D5cm. No 9 Battery. The radio will handle short and medium wave reception. AWA Radiolaelectrical technology, appliances & accessories -

Whitehorse Historical Society Inc.

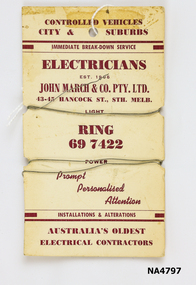

Whitehorse Historical Society Inc.Tool - Fuse wire, c1950

... Mitcham melbourne ELECTRICAL TECHNOLOGY Appliances & Accessories ...Fuse wire loops on cardboard card which has John March & Con P/L Electricians, marked.Fuse wire card - Controlled vehicles, City and suburbs/ Immediate breakdown service, Electricians, Est 1906. John March & Co P/L, 43-45 Hancock St. Sth Melb. Light, ring 697422, Power, Prompt Personalised Attention. Installations & alterations, Australia's Oldest Electrical Contractors.electrical technology, appliances & accessories -

Whitehorse Historical Society Inc.

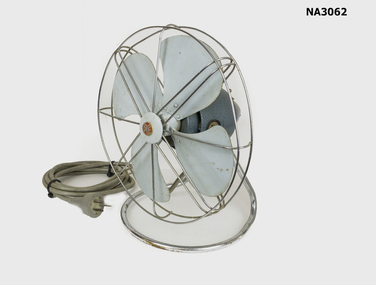

Whitehorse Historical Society Inc.Domestic object - Fan

... Mitcham melbourne DOMESTIC ITEMS Cooling ELECTRICAL TECHNOLOGY ...Four blade electric fan. Grey blades enclosed in chrome guard. Connection grey electric cord and connectionPyedomestic items, cooling, electrical technology, appliances & accessories -

Whitehorse Historical Society Inc.

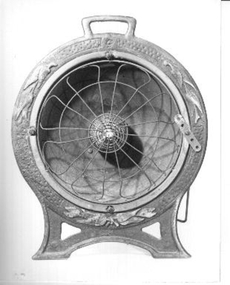

Whitehorse Historical Society Inc.Domestic object - Electric Fan

... the 1930s DOMESTIC ITEMS Cooling ELECTRICAL TECHNOLOGY Appliances ...Fan was used by Robert Gardiner,s father during the 1930sElectric fan with four blades enclosed in wire guard. Round metal disk on front of guard. Round base supporting electrical connection. Three metre cord and fittings attached to base.G.E.C.domestic items, cooling, electrical technology, appliances & accessories -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Functional object - Electric Heater

... Mitcham melbourne domestic items heating electrical technology ...Circular bowl shaped reflector with wire framed cover. Element wound on central core. Brown frame decorated with birds. Handle at top. Wire stand at rear'Laing' scratched on backdomestic items, heating, electrical technology, appliances & accessories -

Lakes Entrance Historical Society

Lakes Entrance Historical SocietyEquipment - Simrad sonar

... Entrance gippsland ELECTRICAL TECHNOLOGY Appliances & Accessories ...Simrad Asdic Sounderelectrical technology, appliances & accessories -

Kew Historical Society Inc

Kew Historical Society IncEquipment - Travel iron, Birko, 1960s

Birko is an Australian brand, manufacturing and retailing appliances since before the Second World War.Birko travel iron with its original electrical fittings and vinyl case.Birko iron birko, travel irons -

Wodonga & District Historical Society Inc

Wodonga & District Historical Society IncDomestic object - Electric Toaster, Hecla Electrics Pty Ltd, c1940s

... by a pioneering Australian company. Electrical appliances HECLA ...Hecla produced a wide range of appliances for domestic use, beginning with heaters and later branching out to a wider range of kitchen appliances Hecla was established by Clarence William Marriott, a young Melbourne metal worker. He began manufacturing Australia's first carbon filament electric radiators in 1899. He originally worked for his father James Marriott who commenced business in Melbourne as an art metal worker in 1872 and was, in 1907, appointed as the official art metal worker to the Victorian Government producing items including the ornate iron gates and gas lamp standards outside Melbourne's Parliament House. With the invention of nickel chromium wire after 1900, C.W. Marriott began making more efficient heating elements using this new material in 1916. After being influenced by the eruption of Mount Hekla in Iceland, on 19 December 1918, Clarence registered the brand name "HECLA" with an erupting volcano as its logo. The company Hecla Electrics Pty Ltd was officially registered in 1922. In 1928 the company adopted the advertising slogan, 'By Hecla, it's Good'. The Hecla range rapidly expanded to include electric heaters and radiators, electric foot warmers, electric kettles, ceramic & metal electric jugs, immersion hot water elements, electric fans, electric coffee percolators, electric toasters, electric grillers and stoves, electric irons and electric frypans, clocks and curling wands. Electric blankets were introduced shortly after WWII.In 1930, a controlling interest in Hecla Electrics Pty Ltd was acquired by General Electric Corporation. Clarence William Marriott died in June 1967 in Melbourne, Victoria.This item is representative of a common domestic appliance used throughout Australia. It was manufactured by a pioneering Australian company.A small chrome steel toaster manufactured by Hecla Australia. It has a door on either side which flips down to insert or remove a slice of bread on each side, Each door has two black Bakelite knobs. The electric element is placed down the centre of the cavity. A detachable electric cord is included.240 Volts, 600 Watts. Cat. No. T4 Submitted to Electrical Approval Board Ref Application A1/AD01 SECV 240 Volt 600 Watt MANFED. IN AUSTRALIA SOLID BRASSelectrical appliances, hecla corporation australia, clarence william marriott, domestic appliances -

Wodonga & District Historical Society Inc

Wodonga & District Historical Society IncDomestic object - Food vitamiser, Semak, c1950

Semak is an Australian company, manufacturing Australian-Made equipment for the Foodservice Industry. It was established in 1948. The most famous Semak appliance is the 'Vitamizer'. Designed in 1948 it quickly became the standard for blending. An updated version was relaunched in 2012. The Semak vitamiser was advertised as a wonder machine which every housewife should have.Advertising claimed that the Semak could whip cream, grind coffee, blend jam, makes soups and sauces, makes cakes, sandwich spreads, ice-cream, special diets, puree fruit drinks, supper snacks, mayonnaise and dessert. It sold for £21. Demonstrations were conducted in electrical stores across the nation. A recipe book and full instructions for operation was included.This item is representative of a popular Australian-made kitchen appliance used across the country. A food vitamiser in 2 sections. Top section is detachable for cleaning. Has electrical cord attached.Surrounding power control: Semak Vitamiser Under base: CAT No. S2/ 230 - 25 V / 240W / 40 - 60kitchen appliances, food vitamisers, semak industries -

Wodonga & District Historical Society Inc

Wodonga & District Historical Society IncDomestic object - Floor Polisher, Hoover Ltd. Great Britain, 1950

The history of Hoover dates back to the early 1900s and directly to Mr. James M. Spangler, an American janitor who invented the first vacuum cleaner to assist in dealing with his asthma. Originally founded in Ohio in 1908, Hoover Limited became a registered company in the United Kingdom in 1919. The first factory, in Perivale, Middlesex, England, opened in 1932. Hoover became the undisputed leader in the floor-cleaning market, so much so that in USA vacuuming became referred to as “hoovering”. This model was widely advertised in Australia from 1952 to 1958. Advertisements referred to it as “The Wonderful Hoover Floor Polisher”. It came complete with Scrubbers, Felt Pads, Lambswool Pads and Built - in Head Light and in 1952 sold for £32/8/-, or could be purchased with a deposit of £8 and weekly payments of 15/-. They claimed that the Hoover Polisher would take the drudgery out a woman’s work and appealed to men by saying the lambswool pads could be used to perfectly polish the headlights and duco of cars.This item is represented of domestic appliances used throughout Australia in the 1950s and 1960sAn upright Hoover electric polisher made from die-cast aluminium with Bakelite outer casing and electrical components.On plate attached to back: THE HOOVER ELECTRIC POLISHER MODEL 0212A./TRADE MARK D.C. OR A.C. 0-60) CYCLES VOLTS / 300 WATTS RATING SERIAL NOPF 533695 PROTECTED BY PATENTS, REGISTERED DESIGNS AND TRADE MARKS IN GREAT BRITAIN AND THE PRINCIPAL COUNTRIES OF THE WORLD MADE BY HOOVER LTD. GREAT BRITAINhoover appliances, domestic appliances -

Wodonga & District Historical Society Inc

Wodonga & District Historical Society IncFunctional object - Hotpoint Electric Iron, Hotpoint under Licence to Edison Elelectric Appliance Co. Inc, c1930s

... of early electrical appliances manufactured under licence ...Hotpoint Irons were first developed in 1903 in California. The invention was named Hotpoint, after the heating elements that converged in the iron's tip, allowing it to be used to press around buttonholes and in and around ruffles and pleats on clothing and curtains. 'Hotpoint' electric irons were first sold in Australia around 1914 and remained a popular product for many decades. From the late 1920s they were manufactured in Australia by the Australian General Electric Co. Ltd.This iron is representative of early electrical appliances manufactured under licence in Australia from the late 1920s onwards.Early electric iron manufactured under license by Hotpoint Australia. The iron has a metal base into which a power cord is plugged. The iron has a wooden handle.Label: " Hotpoint. Made in Australia. Licensed by Edison Elelectric Appliance Co. Inc. Chicago, U.S.A. Cat.915 F61. W.575, W200."domestic appliances, early electric appliances, hotpoint australia -

Wodonga & District Historical Society Inc

Wodonga & District Historical Society IncFunctional object - Light 'N Easy Electric Iron, General Electric Housewares Pty Ltd, c1950s

... of electrical appliances developed under licence in Australia from ...From the late 1920s several brands of irons, including Hotpoint and Light' N Easy were manufactured in Australia by the Australian General Electric Co. Ltd. Light' N Easy irons were marketed as a versatile iron, small and light enough to be taken with you if you needed to travel away from home.This iron is representative of electrical appliances developed under licence in Australia from the late 1920s onwards.Small yellow steam iron. There are controls and a water level indicator on the side of the iron. There are 25 steam vents in the base. Steam and dry iron with surge of steam. A 3 metre electrical cord is attached.Label: " General Electric Housewares Pty Ltd. Vic/ Nottinghill Melbourne 3166/ 700 Watts/ APP NO. V79008 Cat 04/06 240 Voltsdomestic appliances, light 'easy irons -

Wodonga & District Historical Society Inc

Wodonga & District Historical Society IncFunctional object - Kerosene Lamp, Aladdin Industries Ltd, 1953-1963

Kerosene lamps were used as a main source of lighting throughout Australia prior to the supply of domestic electrical services. This was obviously later in many rural areas. This lamp was used in the home of Mrs. Gina Elizabeth Harris of Bethanga in Northeast Victoria where electricity was connected on 23 March 1959.This lamp is representative of the lamps used throughout Australia prior to the introduction of domestic electricity supplies. This vintage kerosene lamp is model No. 21 which was manufactured by Aladdin Industries in Greenford, Middlesex, England in the 1950s. Base stems were mostly made from wood, turned into several different patterns. More expensive table lamp stems were of metal. Bases were mostly steel filled with sand as a weight. When Bakelite became available it was used extensively in three different colours, although collectors say that white bases were used primarily in hospitals and churches and are more rare. On wick knob: "21/Aladdin Industries Ltd/GREENFORD" Inscribed around burner: "GB Patent No 9. 69-4273-4"kerosene lamp, bakelite, domestic appliances -

Wodonga & District Historical Society Inc

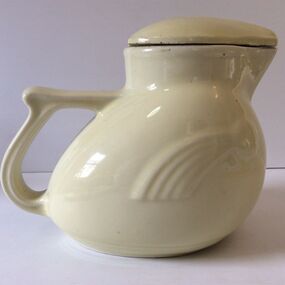

Wodonga & District Historical Society IncDomestic object - Ceramic KOOKABURRA Electric Jug, Nilsen Porcelain Australia, 1930s

Electric kettles were invented by the English to speed up tea preparation. In Australia fancy ceramic electric jugs quickly became a status symbol. During the Great Depression era anyone who could offer you a cuppa from a beautiful Electric Kookaburra Jug was considered to be doing well. Made by Nilsen Porcelain Australia in the 193Os, these kettles were unique for their charming art deco bird shape. Nilsen Electric Kookaburra Jugs are now regarded as a classic Australian icon prized by collectors. Oliver John Nilsen was born in Collingwood, Victoria in 1894. In 1916 he began his own electrical business, Oliver J. Nilsen & Co. (later Oliver J. Nilsen (Australia) Ltd). Nilsen's manufactured goods included such diverse products as transformers, bearings, battery chargers, bells, buzzers and gongs, porcelain ware, fuses, insulators and neon signs. Nilsen Porcelain Australia was a smaller company within the Nilsen group. Nilsen still operates as an electro-technology company operating throughout AustraliaThis jug is an excellent example of art deco ceramic appliances of the 1930s to 1950s on both a local and national level. It is also representative of products developed by a major Australian manufacturer. Earthernware ceramic jug, moulded in art deco style to represent an Australian kookaburra.vintage electric kettles, kitchen appliances, nilsen australia -

Wodonga & District Historical Society Inc

Wodonga & District Historical Society IncFunctional object - Early Electric Table Top Fan, Elcon Australia, 1920s to 1950s

This desk or table-top electric fan marked is typical of the fans popular in the 1930s through to the 1950s. The fans were made for use in the home, office or factory and were produced in a variety of sizes. They were available in both fixed and oscillating models with different speeds. The fans cost several weeks of a man's average wage at the time and were promoted not only as improving comfort in the home but also increasing efficiency at work. With the development of air-conditioning from the 1960s and its increasing use in the workplace and then into the home, fans declined in popularity. This fan was manufactured by the Engineering & Construction Company (ELCON) an Australian owned and patented company originally based in Melbourne, Victoria in the late 1920s. The company became a subsidiary of the Electricity Meter & Allied Industries Ltd (EMAIL) in 1939. Then in 1946 they were decentralised to Orange, New South Wales. EMAIL brands included Email, Emailair, Westinghouse, Carmichael, Elcon, Metters and Weatherall. Electrolux purchased the major appliance division of Email in 2001.This item is representative of early electric fans manufactured in Australia in the early to mid 20th century. They were widely used throughout Australian homes and workplaces prrior to the development of airconditioning.This early electric table fan has four metal blades attached to an egg shaped enclosed motor. Each blade is attached with three rivets. The fan has a wire safety guard surrounding the blades. This is attached to a circular metal base.There is a switch in the centre of the base to adjust speed. A knob at the back of the fan enables its position to be adjusted. There is no longer any branding visible on the fan but it has been identified as an ELCON fan manufacured in Australia. The electrical cord is not the original which has been replaced.electric fans, home appliances, elcon fans -

Wodonga & District Historical Society Inc

Wodonga & District Historical Society IncDomestic object - Kerosene Lamp, early 20th Century

Kerosene lamps were used as a main source of lighting throughout Australia prior to the supply of domestic electrical services. This was obviously later in many rural areas. This lamp was used in the home of Mrs. Laura Flower nee Sommer wife of Mr. Stanley Flower of Wodonga.This lamp is representative of the lamps used throughout Australia prior to the introduction of domestic electricity supplies. It was used in the home of a Wodonga resident.This item has a cast iron base in a pyramidal shape with the four sides having an identical leaf and flower design. A piece of brass attaches the base to a clear glass bowl. The bowl contains a white wick. The brass wick holder has an external knob for regulating the light intensity. There is more brass between the bowl and the mantle which is made of plain glass.Inside the base of the lamp: an Rd No which is uncleardomestic appliances, kerosene lamp -

Wodonga & District Historical Society Inc

Wodonga & District Historical Society IncDomestic object - Portable Steam Iron, Breville

... innovations in the electrical appliance industry. Domestic appliances ...The Breville company was established in Sydney in 1932, by Bill O’Brien and Harry Norville, who combined their two surnames to form the company name. The company originally manufactured radios. During World War II, it made mine detectors. By 1953, the radio business had been taken over by A.W. Jackson Industries Pty. Ltd., which manufactured radiograms and, later, television sets under the Breville brand. In the 1960s, Breville turned its attention to manufacturing kitchen appliances and other domestic appliances. With more people owning cars, caravans and becoming more mobile, a range of lighter appliances were also developed. This included the Breville Travel Light Steam Iron. Breville has now become a global brand which delivers kitchen products to more than 70 countries.This item is representative of an Australian company established in 1962 and its innovations in the electrical appliance industry.A small foldable steam iron manufactured by Breville in Honk KongBreville Travel Light Steam Iron Model details on metal platedomestic appliances, breville irons, travel irons -

Whitehorse Historical Society Inc.

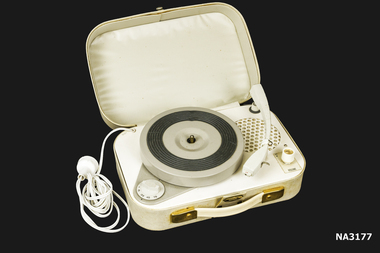

Whitehorse Historical Society Inc.Functional object - Portable Record Player, c1970

Bought at a church fete by donor and used at her beach house at Philip island.A small vinyl covered case containing a turntable and tone arm, volume control and speed controls, with an electrical cord and plug. Case is cream with a beige contrast.audio-visual technology, audio appliances, musical instruments, accessories