Showing 56 items

matching flywheels

-

Maldon Vintage Machinery Museum Inc

Maldon Vintage Machinery Museum IncHorizontal Oil Engine

Austral 8 HP oil engine on 4 wheeled steel chassis with wrought iron wheels. Two double flywheels and flat belt pulley. Water cooled exhaust system at the crank end of the engine. Galvanised iron fuel tank slung under the engine. Painted green and black with red wheels.On an oval brass plate on the side of the engine :- "The Austral Oil Engine / Ronaldson Bros / Makers / No 663 / & Tippett / Ballarat Victoria"machinery ... engine ... oil ... metalwork -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Leisure object - Toys, child's sewing machine, Circa 1940

The family of Mrs Nancy Maggs were early settlers in Moorabbin ShireCirca 1940/1950. Child's small tin-plate toy sewing machine. The body of the sewing machine is painted black with red and gold floral decoration - some loss of paintwork. The flywheel is cast, with a wooden handle. Some workings are made of steel. The manufacture is such that the machine could actually be used for sewing small articles. toys, sewing machines, early settlers, pioneers, moorabbin, bentleigh, cheltenham, ormond, market gardeners, maggs nancy, maggs geoff, f -

Maldon Vintage Machinery Museum Inc

Maldon Vintage Machinery Museum IncHorizontal Oil Engine, Early 20th century

Horizontal cylinder oil engine in working order. Mounted on a steel chassis with 4 cast iron wheels. Two flywheels and one flat belt pulley. Cylindrical cooling water tank and exhaust vertical exhaust pipe mounted at crankshaft end. Engine painted green with red wheels and red crankshaft balance weights. Oval brass plate on cylinder - "The Austral Oil Engine / Ronaldson Bros. / Makers / No. 1113 ? & Tippett / Ballarat Victoria" Thin oval metal transfer on cooling water tank with makers name and place of manufacture around Australian coat of arms.machinery; oil engine; metalwork -

Maldon Vintage Machinery Museum Inc

Maldon Vintage Machinery Museum IncPetrol Engine, Early 20th century

Single cylinder horizontal petrol engine mounted on a 4 wheeled trolley. Two flywheels, one either side, no pulley. Galvanised cylindrical fuel tank mounted on a wooden box in front. Box contains a battery and ignition coil. Trolley has cast iron wheels and is designed for pulling by hand. Painted red and grey. Probably a power source for farm machinery. On a brass plate fixed to the cylinder. "Waterloo Boy Gasoline Engine / No. 81491, HP 4 / Waterloo Gasoline Engine Co. / Waterloo Iowa / Patented / August 7 1900, Dec 3 1901, Oct 7 1907 / Other patents pending / Sold by Waterloo Gasoline Engine Co." On each side of the water tank is an oval white transfer with "Waterloo Boy" above an illustration of a small boy wearing a wide brimmed hat.machinery ... engine ... petrol ... metalwork -

Rutherglen Historical Society

Rutherglen Historical SocietyImage, c1990

This photograph is a view of the flywheel that drives the stampers. This is one of a series of photographs of the Rutherglen Gold Battery. The battery's purpose was to crush quartz from nearby quartz reefs and extract gold from within. The battery was erected in 1908 and consists of a five-head battery, Wilfrey table, Bergin pan, portable steam engine and shed. The battery was restored in 2011/12 and can be viewed daily between 9.00am and 5.00pm. See website for details. Colour photograph of a large piece of machinery inside a buildinggold battery, gold processing -

Yarrawonga and Mulwala Pioneer Museum

Yarrawonga and Mulwala Pioneer MuseumGrain Grister, 1925

grinding grainWooden delivery /storage box on top of metal Grister with three cogs and flywheel [approx. 30 cm diameter] and metal grinding cylinders [rollers] with horizontal grooved lines all around .This is bolted to a wooden stand [painted green] which has a wooden box to receive the crushed grain Rollers are adjustable .Machine driven by flat leather belt on a pulley from a small stationary engine Metal plaque attached to top of delivery box. J Buncle Parkside Ironworks North Melbournegrain, grister, farming, machinery -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Document - MINING ACCIDENTS - SHOCKING ACCIDENT AT WILSON'S REEF

Handwritten extract from the Bendigo Advertiser dated Friday 6th Feb. 1874 Page 2 when Thomas Bromley, engine driver at Wilson's Reef Coy, Marong was killed when he got caught in the flywheel. He had set the engine going pulling up a cage of mullock, then went away from the engine, One of the cages was pulled to the top of the poppet heads without him knowing. The wire rope broke and the cage fell down the shaft, no one was injured. The engine was still going, the braceman ran into the engine-room and told Bromley what had happened. Bromley stopped the engine to reverse the gear. He had loosened the screws and was rising from a stooping position when he was caught by the flywheel. It was thought that Bromley had started the engine, the rushed to the boiler to throw in a few pieces of wood and before he got back the cage had gone to the top of the poppet heads.document, gold, mining accidents, mining accidents, shocking accident at wilson's reef, bendigo advertiser 6/2/1874, thomas bromley -

Maldon Vintage Machinery Museum Inc

Maldon Vintage Machinery Museum IncSteam Engine, Estimated late 19th century

Large 4 wheeled single cylinder (horizontal) steam engine designed to be towed. Fire box painted black, boiler and steam cylinder green, wheels red. Boiler is not sound so engine is connected to an independent steam/air source to be operated for display purposes. 150 cm flywheel on LHS looking forward toward the front. Brass water drain tap on firebox. Also other brass fittings on firebox. Cast brass disc with red background fixed high on firebox :- "Marshal Sons & Co. / Made expressly / to the order / Shut, No. 45781, Open / of / Robison Bros / South Melbourne." "10017" raised in relief on firebox door. machinery; engines; steam power source -

Bendigo Historical Society Inc.

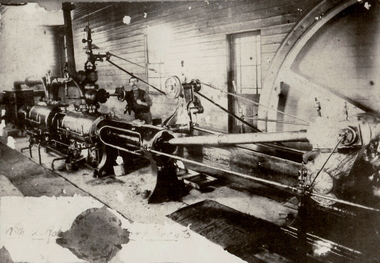

Bendigo Historical Society Inc.Photograph - COMPOUND AIR COMPRESSOR

Black and white photograph. One male with right hand on wheel of control valve in the compressed air pipe outlet of a two stage or compound air compressor with con rod and crank shaft to a large flywheel. Two belts to a vertical governor. Outgoing air pipe vertical to ceiling of enclosing building. Inscriptions: Nameplate or bed plate 'A Roberts and sons, Engineers, Bendigo' Lower left corner handwritten 'with A Rob. Compliments' On back - 'Compound Air Compressor'.machinery, compressors, compound air compressor, worker, male -

Maldon Vintage Machinery Museum Inc

Maldon Vintage Machinery Museum IncOil Engine, 1912

10 HP horizontal cylinder oil engine in working order. Mounted on a steel chassis with 4 wrought iron wheels. Two flywheels and one flat belt pulley. Rectangular cooling water tank and cast iron exhaust pot with vertical exhaust pipe mounted at crankshaft end. Engine painted green with pale yellow trim. Blow torch start on compression when hot bulb is of certain temperature. Mechanical water and fuel pumps. Oval brass plate fixed to cylinder "The "Blackstone" / Carter's Patent / 61892 / Quote this No. / When ordering parts / Oil Engine"engines horizontal cylinder -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Photograph - NEW MOON MINE - COPIES OF NEGATIVES OF THE NEW MOON MINE

Four copies of negatives, three showing mining machinery and the fourth, a table. (a) shows machinery driven by a large flywheel. A man is operating the machine. (b) shows the crushing machine and tables. They are driven by long belts being driven by a long overhead shaft. Two men are at the machine. A tub is in the foreground. (c - shows a view of the fitting shop at crushing machine. Picture is not very clear. There are four men in the picture. (d) shows a reverse image table of gross total of tons, gold, dividends and calls to June 30th, 1906. photo, new moon mine, copies of negatives of the new moon mine, mine machinery, crushing works, a richardson -

Glenelg Shire Council Cultural Collection

Glenelg Shire Council Cultural CollectionEquipment - Equipment - Divers air pump, 1900-1930

Port of Portland CollectionFront: C. E. Heinke/ Submarine Engineer 103 GI Portland St London (brass plate on side of pump)port of portland archives -

Federation University Historical Collection

Federation University Historical CollectionBook, William Ripper, Steam-Engine Theory and Practice, 1914

... flywheels ...Used at Ballarat School of MinesThe cover is a red brown colour with the title on the spine and the publisher Longmans & Co printed near base of the spine. The book has 496 illustrations throughout with some pull out plates. Pages 514.On the inside cover it is stamped with The School of Mines Ballarat and written in pencil is 1914 and E K.compound engines, thermodynamics of gases, properties of steam, temperature-entropy diagrams, superheated steam, steam-jacket, feed-water heaters, crank-shaft, flywheels, corliss engine, steam turbine, condensers, friction of engines, steam-engine, william ripper, steam -

Federation University Historical Collection

Federation University Historical CollectionBook, William J. Goudie, Ripper's Steam Engine Theory and Practice, 1932

... flywheels ...Formerly part of the Ballarat School of Mines libraryA blue book with the title printed in gold on the spine, and the publisher "Longmans" printed in gold at the base of the spine. It has 503 illustrations throughout. It has two loose pages of plates in a sleeve inside the back cover and some pull out plates throughout. 841 pagesIt is stamped with The School of Mines Ballarat near the front and back pages, as well as some throughout the book.steam engine, properties of steam, flywheels, condensers, thermodynamic principles, energy diagrams, engine cycles and efficiencies, brake horse-power, steam in the cylinder, multiple expansion engines, valve gears, governors, crank, corliss and drop-valve engines, steam turbines, turbine performance, steam -

Federation University Historical Collection

Federation University Historical CollectionDocument - Document - Design, E J Barker: University of Melbourne: Bachelor of Mechanical Engineering; Engineering Design Part II, 1946

Four folders containing an Engineering Design Part II Project. Each has detailed written information and drawings. No.1: To design an Extruder Addition to the hydraulic press in the plate shop to enable it to be used as an extruding press to operate on materials similar in behaviour to a wax. No. 2: To design a flywheel of uniform strength of not less than 25 feet. No 3: To design cams, valve gear and inlet and exhaust valves for a 6 cylinder truck engine. No 4: To design an experimental brown coal autoclave for drying brown coal in 10 kilogram lots. Jack chose to do Engineering while still at Footscray Technical School as it gave access to Diploma Courses and tertiary studies. This enabled him to enter the University of Melbourne and do a Bachelor in Mechanical Engineering - 1945, 1946, and 1947. In 1948 he did a Diploma in Education at Melbourne University. From this path he was able to follow a career in teaching and his first appointment was at the School of Mines in Ballarat, (SMB) 1949. He became the first Vice Principal of SMB in 1960 and then Principal in 1964 to 1976. From 1976 to his retirement in 1987, he was the Foundation Director of Ballarat College of Advanced Education (BCAE). The Library building at Mount Helen Campus is named after him.Four manila folders with design assessment in each. Each folder has written descriptions and detailed drawings.e j barker, jack barker, melbourne university, engineering, diploma of mechanical engineering, diploma of electrical engineering, school of mines ballarat, smb, diploma in education, vice principal, principal, foundation director, ballarat college of advanced education, bcae, bachelor of mechanical engineering, library, mount helen campus, engineering drawing, design, specifications, manufacture, extruder addition, hydraulic press, flywheel, cams, valve gear, inlet valve, exhaust valve, 6 cylinder truck engine, autoclave, brown coal -

Puffing Billy Railway

Puffing Billy RailwayBlackstone Oil Engine, 6 November 1908

8HP Blackstone Lamps Start Oil Engine engine number 71076 Engine Details Maximum operating RPM of 240. Fitted with a 3'9" Flywheel Tested on the 6th of November 1908. Shipped to Cluter buck South Australia for installation on concrete base. Recovered and restored during the 80's in South Australia Purchased privately in 2013 in Tailem Bend South Australia and transported to Victoria. Currently on loan to the Puffing Billy Museum at Menzies Creek as an operating exhibit. Blackstone & Co. was a farm implement maker at Stamford, Lincolnshire, United Kingdom. In 1896 they built lamp start oil engines. The Lamp or hot-bulb engine (also hotbulb or heavy-oil engine) is a type of internal combustion engine. It is an engine in which fuel is ignited by being brought into contact with a red-hot metal surface inside a bulb, followed by the introduction of air (oxygen) compressed into the hot-bulb chamber by the rising piston. There is some ignition when the fuel is introduced, but it quickly uses up the available oxygen in the bulb. Vigorous ignition takes place only when sufficient oxygen is supplied to the hot-bulb chamber on the compression stroke of the engine. Most hot-bulb engines were produced as one-cylinder, low-speed two-stroke crankcase scavenged units Historic - Industrial - single cylinder, horizontal, 4 stroke, hot-bulb ignition oil engine Blackstone 8HP Oil Engine made from steel, wrought iron and brassOval Plate with Black Stones and Clutter Buck Brass Plaque engine number 71076blackstone, oil engine, clutter buck, black stone, puffing billy, hit and miss, engine, blackstone & co -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Document - MARKS COLLECTION: HERCULES AND ENERGETIC GOLDMINING CO. SPECIFICATIONS

Handwritten document (15 pages) with two page blue document appended at back. On front of handwritten document : specifications for machinery and ironwork engineer and ironfounder for building plant for the Hercules & Energetic Goldmining Comp., Sandhurst. The contractor is to supply and deliver on the claim of the above Company the following machinery &c - and to get proper receipts for same from the Contractor for the erection of plant. Areas in specifications include: repairs to engine and boiler set-up & c., safety valve, whistle, cylinder, stop valve, piston, eccentric, crank shaft, feed pump & eccentric, flywheel very extensive descriptions of all areas, some with diagrams. Appended to back of document Ironfounders general conditions of contract work required in the making and delivery on the claim machinery &c for a winding plant for the Hercules & |Energetic Co., Drawings prepared by Wm Middleton, Engineer, Sandhurst. Agreement entered into this twelfth day of October, 1878, by and between Messrs Mitchell & Osborne and Hercules and Energetic GMC. Signed by Mitchell & Osborne, per ? Dobson., Wm Middleton ?.bendigo, mining, hercules & energetic mine -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Tilting Saw Bench, W F & John Barnes, 1874 to 1880

he subject item is a pedal-powered rip saw with a tilting table made in the USA by W.F. & John Barnes Co. of Rockford, Illinois, between 1874 and 1890. The saw's blade moves rapidly in a circular motion and is driven by a pedal that spins a heavy flywheel with a leather belt attached to a gear drive that in turn drives the circular saw blade. The operator holds a wood workpiece on the table and moves it forward so the blade cuts it to the desired width and length. Company History: WF & John Barnes Co. was established in 1869, by making a formal partnership between William F. Barnes and John Barnes in 1872, and then incorporating in 1884. This company was an early manufacturer of pedal-powered equipment. By 1881 they were also making powered machinery such as lathes and pedestal drills. Many companies were making lightweight foot-powered equipment, but Barnes and the Seneca Falls Co. were the only ones to also make professional-grade workshop machines. From the beginning of their existence, they focused on pedal-powered machinery and specialised in making scroll saws. By 1937 the company focus had completely shifted to automotive assembly machinery, and custom-built machinery, machine tools, electrical, hydraulic, and mechanical controls and systems, including nuclear hardware. their production of foot-powered machinery had ceased. In the intervening years, they have got out of manufacturing completely. After a series of ownership changes, their equipment parts and stock were purchased in 1998 by LeBlond Ltd. of Amelia, Ohio. An item that although incomplete gives a snapshot into the manufacture and use of early woodworking machinery before the introduction of electricity or electric motors to power machines.A Treadle powered tilting table saw benchWF & J Barnes, Rockford Ill USA flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDrill Press, 1920s-1950s

This drill once belonged to Goodall and Sons, who were blacksmiths in Terang. The smith was called upon to do a variety of work. In the early 1900s he was often the nearest person to be able to perform an engineer’s services for many miles around. The Dawn Ball-bearing Post Drill no. 611 is described in McPherson’s Catalogue as a “drilling machine with adjustable automatic feed, with improved Dawn coupler and ball-bearing thrust’. The heavy design of the flywheel enables it to maintain momentum” and is “fitted with pulleys for belt drive if desired” The hand crank drives an automatic feed to work off a cam-follow system opposite a large wheel. Made by Dawn Manufacturing Co. Australia 1920-1950. DAWN MANUFACTURING CO. Dawn Manufacturing Co. was founded in Coburg, Melbourne, in 1917 by the four Blake brothers, who were all engineers. After World War I Dawn was supplying drills Australia wide and the company was growing at a healthy rate. During the depression they remained busy, with employees working 60-80 hour weeks. Dawn was contracted to supply vices and clamps to the Australian Defence Department and munitions factory during the World War II. In 1959 the company was taken over by G.N. Raymond Group, then in 1973 the Siddons Ramset Limited acquired Dawn. In December 1991, Dawn became a unit of the United States owned Stanley Works Pty. Ltd. In November 1998 Dawn became 100 per cent Australian owned. HENRY GOODALL & SONS Henry Goodall (1870-1936) was proprietor of garages as H. Goodall & Sons Pty. Ltd., at both Terang (McKinnon and High Streets) and Mortlake (Dunlop Street). His business was in operation in at least in 1916 and perhaps well before, considering the date of the tyre bender and its use for wagons with wooden wheels. It was still in operation in 1953, chasing up debtors in Mount Gambier Court. Amongst the employees of H. Goodall & Sons Pty. Ltd. was Ernie Entwistle, a blacksmith (a soldier who died in 1916 ) and Alfred Hodgetts, radio expert (killed in a fatal accident in 1943, when he was in his early 30s ). Henry Goodall was involved in the community as a Justice of Peace, a deputy coroner, President of the Mortlake Hospital, trustee of the Soldiers’ Memorial Hall, and as a prominent Freemason. He and his wife had two sons (Charles and John) and one daughter (Mrs. Chas. Newton, of Skipton). The drill is locally significant as it was used by a local company in Terang and Mortlake in their blacksmith, wheelwright and garage business. It is an example of the tools of the blacksmiths’ trade in Victoria in the 1920s-1950s.Dawn Ball-bearing Post Drill no. 611, made by Dawn of Melbourne, model no 611. Hand operated drill press. Self-feeding blacksmiths’ drill-press. This drill once belonged to Harry Goodall & Sons, blacksmiths of Terang. Dated 1920s-1950s. Gear ratio 2:1 main drive, 6" diam, 3:1 reduction gear. "Dawn", "Melbourne"flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, h. goodall & sons of terang, terang blacksmith, h. goodall & sons pty ltd, mortlake, ernie entwistle blacksmith, alfred hodgetts radio expert, charles goodall, john goodall, mrs. chas. newton nee goodall, terang 1900s, warrnambool district 1900s, post drill, blacksmith’s drill, dawn post drill, dawn ball-bearing post drill no. 611, blacksmiths, dawn of melbourne -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Machine - Household Chopping Machine, Mechanical Chopper, c1886

Used in kitchen to cut carrots, cheese slices, onions. boiled eggs, etc.Painted black guillotine on a wooden stand. An iron pole keeps the guillotine in vertical position at one end of the block. Driven by two wheels when a handle is turned. A tilting beam moves the guillotine up and down to cut vegetables, etc. Blade 18cm long by 6.5cm wide. Metal plate missing under blade. A rotatable drum to contain the food to be chopped, which is rotated by a cog at the base (also missing) turns the container. The upright holding chopper blade e is a modification made because of the missing container.|The following description is from Ken Turner Booklet referred to under 'Reference'. ----|The Starrett food chopper would certainly have to be considered one of the more interesting inventions, which incidentally is now considered the ultimate in kitchen collectables. Laroy Starrett in later years' told of how the design of his food chopper was inspired by the action of the walking beam engine used on the Mississippi steam boats. When the crank handle of the chopper is turned, this sets in motion a mechanism which is just fascinating to watch. The crank activates a flywheel which in turn, by a series of cogs and levers, simultaneously rotates a food holding container and raises and lowers within the rotating container, a guillotine like 'chopping blade - the action does not only look like that of a beam steam engine, it even in a way sounds like one, although somewhat noisier. Starrett produced seven different models of these choppers, ranging in size appropriate for domestic use to heavy duty models for butchers, restaurants and for hotel use. The small model was capable of chopping 3lbs in three minutes, and the largest had a capacity for chopping something like 100 lbs in an hour. The mechanical chopper, which became affectionately known as the 'hasher', was the first of some one hundred of Starrett's inventions, and these include a washing machine patented in 1865 which had a similar action to his food chopper, a food press patented in 1873, and a device for lacing shoes he patented in 1886.domestic items, food preparation -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Dentist Drill, Late 19th century

The design of this and other similar treadle powered dental engine (or dentist drill) was in common use by dentists from the 1870’s into the 1920's. When electricity became accessible to most communities the electrically powered dental engines began to take over from the treadle power. Over the ages teeth were extracted using picks and scissors and other gouging instruments. Bow drills, hand drills and even a "bur thimble" drill were later used to prepare cavities for filling. Some drills were made bendable by attaching flexible shanks between the metal bur and the handle, giving access to the teeth at the back of the mouth. Other mechanical devices were introduced along the way, such as clockwork drills, but they were hard to handle and inefficient. Over the centuries “dentistry has been performed by priests, monks and other healers. This was followed by barbers; the barber’s chair may well have been the precursor to the dental chair. “(SA Medical Heritage Society Inc.) In 1871 James Morrison patented the first commercially manufactured 'foot treadle dental engine', the first practica dental engine although others had been introduced as early as 1790 (by John Greenwood). Handmade steel burs or drills were introduced for dental handpieces, taking advantage of the significant increase in the speed of the drill. In 1891 the first machine-made steel burs were in use. The treadle drill reduced the time to prepare a cavity from hours to less than ten minutes. In 1876 the Samuel S. White Catalogue of Dentist Instruments listed a 12 ½ inch wheel diameter dental engine, with 14 bright steel parts, for sale at US $55 In today’s market, this is the equivalent to US $1200 approx. The specifications of that dental engine are very similar to the this one in our Flagstaff Hill Maritime Village’s collection. It is interesting to note that workings of a similar treadle dentist drill were used and modified to power a treadle spinning wheel of one of the volunteer spinners at Flagstaff Hill Maritime Village. The foot treadle dental engine was a milestone in dental history. “Historic importance of treadle powered machines; they made use of human power in an optimal way” (Lowtech Magazine “Short history of early pedal powered machines”) The invention of a machine to speed up the process of excavation of a tooth lead to the invention of new burs and drills for the handpieces, improving speed and the surgical process of dentistry. They were the fore-runner of today’s electrically powered dental engines. This treadle-powered dentist drill, or dentist engine, is made of iron and steel and provides power for a mechanical dental handpiece that would be fitted with a dental tool. On the foot is painted lettering naming it "The Brentfield" and there is a fine line of light coloured paint creating a border around the name. The paint under the lettering is peeling off. The drill has a Y-shaped, three footed cast iron base, one foot being longer than the other two. A vertical frame is joined into the centre of the base, holding an axle that has a driving-wheel (or flywheel) and connecting to a crank. A slender, shoulder height post, made from adjustable telescoping pipes, joins into the top of this frame. On the post just above the frame is a short metal, horizontal bar (to hold the hand-piece when it is not in use). A narrow tubular arm is attached to the top of the stand at a right angle and can move up, down and around. There is a pulley each side of the joint of the arm and a short way along the arm is fitted a short metal pipe. A little further along the arm a frayed-ended cord hangs down from a hole. At the end of the arm is another pulley and a joint from which hangs a long, thin metal pipe with two pulleys and a fitting on the end. A treadle, or foot pedal, is joined to the long foot of the base, and joined at the toe to the crank that turns the driving-wheel. The metal driving-wheel has a wide rim. Touching the inside of the rim are four tubular rings that bulge towards the outside of the driving-wheel, away from the pole, and all meet at the hub of the axle. The axle fits between the inside of the driving-wheel and the frame then passes through the frame and is attached on the other side. The driving-wheel has a groove around which a belt would sit. The belt would also fit around a pulley on the arm, at the top of the post. The pulley is joined to a rod inside the arm and this spins the drill's hand-piece and dental tool holder. The foot pedal has a cross-hatch pattern on the heel and the ball of the foot has tread lines across it. The end of the toe and the instep areas have cut-out pattern in them. "The ____/ Brentfield / __ DE IN L___" (Made in London) painted on the long foot of the base. Marked on the drill connection is “Richter De Trey, Germany”flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, dentist, teeth, dental drill, dental engine, treadle drill, foot powered drill, treadle engine, orthodontics, dental surgery, james morrison, the brentfield, richter de trey, german dental fitting, london dental drill -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Dentist Drill, Late 19th century

The design of this and other similar treadle powered dental engine (or dentist drill) was in common use by dentists from the 1870’s into the 1920's. When electricity became accessible to most communities the electrically powered dental engines began to take over from the treadle power. Over the ages teeth were extracted using picks and scissors and other gouging instruments. Bow drills, hand drills and even a "bur thimble" drill were later used to prepare cavities for filling. Some drills were made bendable by attaching flexible shanks between the metal bur and the handle, giving access to the teeth at the back of the mouth. Other mechanical devices were introduced along the way, such as clockwork drills, but they were hard to handle and inefficient. Over the centuries “dentistry has been performed by priests, monks and other healers. This was followed by barbers; the barber’s chair may well have been the precursor to the dental chair. “(SA Medical Heritage Society Inc.) In 1871 James Morrison patented the first commercially manufactured 'foot treadle dental engine', the first practica dental engine although others had been introduced as early as 1790 (by John Greenwood). Handmade steel burs or drills were introduced for dental handpieces, taking advantage of the significant increase in the speed of the drill. In 1891 the first machine-made steel burs were in use. The treadle drill reduced the time to prepare a cavity from hours to less than ten minutes. In 1876 the Samuel S. White Catalogue of Dentist Instruments listed a 12 ½ inch wheel diameter dental engine, with 14 bright steel parts, for sale at US $55 In today’s market, this is the equivalent to US $1200 approx. The specifications of that dental engine are very similar to the this one in our Flagstaff Hill Maritime Village’s collection. It is interesting to note that workings of a similar treadle dentist drill were used and modified to power a treadle spinning wheel of one of the volunteer spinners at Flagstaff Hill Maritime Village. The foot treadle dental engine was a milestone in dental history. “Historic importance of treadle powered machines; they made use of human power in an optimal way” (Lowtech Magazine “Short history of early pedal powered machines”) The invention of a machine to speed up the process of excavation of a tooth lead to the invention of new burs and drills for the handpieces, improving speed and the surgical process of dentistry. They were the fore-runner of today’s electrically powered dental engines. This treadle-powered dentist drill, or dentist engine, is made of iron and steel and provides power for a mechanical dental hand-piece that would be fitted with a dental tool. The drill has a three footed cast iron base, one foot being longer than the other two. A vertical C shaped frame is joined into the centre of the base, holding an axle that has a driving-wheel (or flywheel) and connecting to a crank. A slender, shoulder height post, made from telescoping pipes, joins into the top of this frame and is height adjusted by a hand tightened screw with a round knob. On the post just above the frame is a short metal, horizontal bar (to hold the hand-piece when it is not in use). A narrow tubular arm is attached to the top of the stand at a right angle and can move up and down. At the end of the arm is a firmly fixed, flexible rubber hose protected for a short distance by a sheath of thin metal. At the end of the hose there is a fitting where the drill’s hand-piece would be attached; a small, silver coloured alligator clip is also at the end. A treadle, or foot pedal, is hinged to the heel to the long foot of the base, and joined at the toe to the crank that turns the driving-wheel. There is a spring under the toe of the treadle. The metal driving-wheel has a wide rim. Touching the inside of the rim are four tubular rings that bulge towards the outside of the driving-wheel, away from the pole, and all meet at the hub of the axle. The axle is bulbous between the inside of the driving-wheel and the frame then passes through the frame and is attached on the other side. The driving-wheel has a groove around which a belt would sit. The belt would also fit around a pulley on the arm, at the top of the post. The pulley is joined to a rod inside the arm and this spins the drill's hand-piece and dental tool holder. The two shorter feet of the base are made from a long metal bar that has been curved outwards, and its centre is bolted to the base of the pole. Under the ends of the curved legs of the base are wedge shaped feet. The driving-wheel is decorated in light coloured paint on both sides, each side having three sets of floral decals evenly spaced around them, and each about a sixth of the wheel's circumference. Similar decoration is along the sides of the frame. The foot pedal has decorative cutout patterns in the centre of the foot and at the toe. On the long foot of the stand is some lettering with a fine, light coloured border around it. The lettering is hard to read, being a dark colour and flaking off. There are also remnants of fine, light coloured flourishes. The foot pedal has lettering of the maker’s trade mark cast into the metal at the ball of the foot. Lettering on the base is peeling and difficult to read. The foot pedal has a trade mark cast into it that looks like a combination of ‘C’ , ‘S’ , ‘A’, ‘R’. flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, dentist, teeth, dental drill, dental engine, treadle drill, foot powered drill, treadle engine, orthodontics, dental surgery, james morrison -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Rod, Approx. 1871

This rod was salvaged from the American three-masted wooden clipper ship, Eric the Red, named after the Viking discoverer, Eric the Red. The ship first traded in coal between America and Britain and later traded in guano nitrates from South America. In 1879 its hull was re-metalled and the vessel was in first class condition. On 10th June 1880 Eric the Red departed New York under the command of Captain Z Allen, with 24 crew plus two passengers. It was heading for Melbourne and then Sydney. The ship was commissioned by American trade representatives to carry a special cargo of 500 American exhibits for the U.S.A. pavilion at Melbourne’s first International Exhibition. The items included furniture, ironmongery, wines, chemicals, dental and surgical instruments, paper, cages, bronze lamp trimmings, axles, stamped ware, astronomical and time globes, and samples of corn and the choicest of leaf tobacco. Also on board was general merchandise such as cases of kerosene and turpentine, brooms, Bristol's Sarsaparilla, Wheeler and Wilson sewing machines, Wheeler’s thresher machine, axe handles and tools, cases of silver plate, toys, pianos and organs, carriages and Yankee notions. The ship had been at sea for 85 days when, on 4th September 1880, it hit the Otway Reef on the southwest coast of Victoria and was quickly wrecked. Captain and crew ended up on floating parts, or in the long boat or the sea. He was amongst the 23 battered and injured men who were rescued by the steamer Dawn and later taken to Warrnambool, where they received great hospitality and care. Four men lost their lives; three crew and one passenger. Captain Allen took the train back to Melbourne and then returned to America. The captain and crew of the Dawn were recognised by the United States Government in July 1881 for their humane efforts, being thanked and presented with substantial monetary rewards, medals and gifts. The salvaging ship Pharos collected Wheeler and Wilson sewing machines, nests of boxes, bottles of Bristol’s sarsaparilla, pieces of common American chairs, axe handles, a Wheelers’ Patent thresher and a sailor’s trunk with the words “A. James” on the front. A ship’s flag board bearing the words “Eric the Red” was found on the deckhouse; finally, those on board the Pharos had found the name of the wrecked vessel. The government steamer Victoria and a steamer S.S. Otway picked up flotsam and wreckage. A whole side of the hull and three large pieces of the other side of the hull, with some of the copper sheathing stripped off, had floated onto Point Franklin. Some of the vessel's yards and portions of its masts were on shore with pieces of canvas attached, confirming that the vessel had been under sail. On shore were many cases of Diamond Oil kerosene labelled R. W. Cameron and Company, New York. large planks of red pine, portions of a small white boat and a large, well-used oar. There were sewing machines, some consigned to ‘Long and Co.”, and notions, axe and scythe handles, hay forks, wooden pegs, rolls of wire, some branded “T.S” and Co, Melbourne”, and kegs of nails branded “A.T. and Co.” from the factory of A. Field and Son, Taunton, Massachusetts. Other cargo remains included croquet balls and mallets, buggy fittings, rat traps, perfumery, cutlery and Douay Bibles, clocks, bicycles, chairs, a flywheel, a cooking stove, timber, boxes, pianos, organs, wooden clothes pegs and a ladder. There were three cases of goods meant for the Exhibition Other items salvaged from amongst the debris floating in the sea were chairs, doors, musical instruments, washing boards, nests of trunks and flycatchers. Most of the goods were saturated and smelt of kerosene. A section of the hull lies buried in the sand at Parker River Beach. An anchor with a chain is embedded in the rocks east of Point Franklin and a second anchor, thought to be from Eric the Red, is on display at the Cape Otway light station. A life belt was once on the veranda of Rivernook Guest House in Princetown with the words “ERIC THE RED / BOSTON”. Parts of the ship are on display at Bimbi Park Caravan Park and Apollo Bay Museum. Flagstaff Hill Maritime Village also has several artefacts from the wreck. There seemed to be no personal luggage or clothing. “The Eric the Red is historically significant as one of Victoria's major 19th century shipwrecks. (Heritage Victoria Eric the Red; HV ID 239) The wreck led to the provision of an additional warning light placed below the Cape Otway lighthouse to alert mariners to the location of Otway Reef. The site is archaeologically significant for its remains of a large and varied cargo and ship's fittings being scattered over a wide area. The site is recreationally and aesthetically significant as it is one of the few sites along this coast where tourists can visit identifiable remains of a large wooden shipwreck, and for its location set against the background of Cape Otway, Bass Strait, and the Cape Otway lighthouse.“ (Victorian Heritage Database Registration Number S239, Official Number 8745 USA)Iron rod with flat lugged washer. The rod is made of a heavy metal with encrustations and signs of rusting on the surface. It is stepped down in diameter mid-shaft and is slightly bowed on the narrower end. The narrow end flares out slightly in the last few centimetres with a burred foot and has a circular head on the wider end. The washer on the narrower end cannot move past the centre or the narrow end of the rod. The washer is a different metal from the rod and has a small lug jutting out along the circumference in one position. The rod was recovered from the wreck of the ship the Eric the Red.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, rod, iron-rod, eric the red, steamer dawn, cape otway reef, 1880, captain allen, usa pavillion, melbourne exhibition, melbourne international exhibition, captain jones, medal, united states government, pharos, a. james, flag board, steamer victoria, steamer otway, diamond oil, r w cameron and company, long and co., t s and co melbourne, a. field and son, taunton, massachusetts, ketch apollo, ship nail -

Geelong Naval and Maritime Museum

Geelong Naval and Maritime MuseumTeacup

The Orungal was originally built in Glasgow in 1923 for the Khedival Mail Steamship & Graving Dock Company of Egypt and named the S.S. Fezara. Due to the effects on steamship companies of the Great Depression including the steep costs of building new ships and increases in running costs and port charges, no new passenger ships had been ordered in Australia since before World War One. To meet demand for passenger berths, the Fezara (5826 tons) along with its sister ship the Famaka (5856 tons, renamed Ormiston), were chartered by the Australasian United Steam Navigation Company Ltd (A.U.S.N.Co.) in 1927. Both the A.U.S.N.Co and the Khedival Mail Steamship Co. were part of the P&O Group. The Orungal operated in this role as an interstate passenger and mail steamer between 1927 and 1940, being used mainly on the Melbourne to Queensland and Western Australian runs, with 240 single class berths. Following the outbreak of World War Two six of the nine large passenger liners servicing mainland Australian passenger and mail trades were requisitioned by the Government to ferry equipment, troops and supplies. Some of them were converted to armed merchant cruisers and used for patrol work and escort duties in the Indian and Pacific Oceans. The Orungal had originally been requisitioned by the government along with the Zealandia on 25 June 1940, to transport troops to Darwin, but was returned to commercial service because "of her unsuitability", perhaps too slow for the demands of the work. Despite being rejected for patrol and convoy duties the Orungal still had a vital role as one of only three passenger liners left to service the mainland Australian trade. Following its requisitioning by the Government shortly after war broke out, it had been fitted out with defensive armament. On its final voyage arriving at Port Phillip Heads from Sydney, Captain Gilling was attempting to enter the Heads ahead of a worsening south-westerly storm and, with a minefield known to have been laid in the area, had been warned by the Navy not to deviate from the swept channel. The captain and crew held fears that in the stormy seas a mine may have been carried away. In the worsening weather a blur of lights at Barwon Heads was mistaken for Port Lonsdale, and the Orungal steamed ashore onto Formby Reef, just east of the entrance of the Barwon River - instead of passing safely through the middle of the Rip. At the Marine Board Inquiry Capt. Gilling - who had been master of the Orungal since 1926 - stated that after becoming uneasy about his position and changing course to starboard one point: " At 10.21 pm I ordered the engine room to stand by and gave instructions for the patent log to be hauled in and for the sounding-gear to be got ready. Approximately two minutes later, in a flash of lightning, I saw land off the port beam. I immediately recognised it as Barwon Heads, and ordered the helm to be put hard to starboard, but the vessel struck before she had time to answer the helm" Barwon Heads and Ocean Grove residents were startled to hear the shrill blast of the ship's whistle, followed by the bright flares and explosions of signal rockets. The Queenscliff lifeboat crew, who had responded to the tragic collision between the Goorangai and another passenger liner the Duntroon in Port Phillip Bay less than 24 hours earlier, were later praised for their efforts in safely taking off all the passengers and crew. Most of the passengers were asleep at the time of the wreck, and were woken up by the commotion, the ship shaking "from stem to stern" and stewards ordering them to lifeboat stations in driving rain. It was a dramatic time with the ship siren wailing and distress rockets being fired. It was reported that "When it was found the ship was safe, the passengers all went to the music room. There they sang and danced for several hours. The ship's orchestra played merrily, and amateur performers among the passengers clowned, danced and sang to keep the laughter going. In the early hours of the morning passengers went to their cabins, most of them to sleep soundly while the keel grated on the rocks". At dawn the Queenscliff lifeboat arrived at the scene having been launched at 2.30am, and cautiously approached the ship which was being "battered by mountainous seas". By 5am oil from a burst oil line was helping to calm seas around the Orungal sufficiently enough for the lifeboat to approach, and all the passengers and crew were taken off in several trips by the lifeboat. A Court of Inquiry later found that the wreck was caused by an abnormal set of current to the north-west and cleared the officers and crew of neglect of duty. The sight of a huge liner almost on the beach saw an unprecedented amount of traffic as people drove an estimated 10,000 cars, using some 60,000 gallons of fuel in a time of strict petrol rationing, to see the spectacle. Salvage operations began in an attempt to refloat the vessel, scheduled for the high tide on 15 December 1940. However, during these operations, at 2.30 am on 13 December 1940, a major fire broke out, believed to have been caused by spontaneous combustion in the boiler room. The ship was soon ablaze, with smoke pouring from its hatches and ventilators, and at mid-morning the magazine exploded fiercely. Of the 60 men working aboard the vessel two were severely burned and had to be taken to Geelong Hospital. The gathered spectators witnessed the eerie sight of the ship's hull glowing red when night fell. The well-known building demolition contractor Whelan the Wrecker bought the salvage rights, and methodically proceeded to dismantle the ship and its fittings. The drama was not yet over for the wreckers when - without warning - the burnt-out hulk was 'attacked' by RAAF for strafing practice. Salvage rights were transferred to another private owner in 1963. By 1945 the combined effects of the exposed location, fire and salvage had seen what was left of the wreck disappear beneath the waves. The site today is marked by two of the four Scotch type boilers sitting upright and exposed at low tide, just north-east of the small boats channel at the entrance to Barwon Heads. Large sections of steel hull plating and framing, and impressively large pieces of ships structure and machinery including masts, booms, deck winches, propeller shaft, flywheel, and a thrust block lie scattered about and make the site an interesting shallow dive. It is interesting to compare the site of the Orungal with the intact remains of similar large passenger ships scuttled in deep water in the Ships' Graveyard, such as the Milora and Malaita. The site is subject to waves and surge, and is best dived on flat calm days The teacup originated from the SS Orungal and was likely used heavily in the ship's life as a passenger, mail and cargo carrier around Australia. The teacup is significant for its connections to SS Orungal and of this ships connected story of being sunk in extraordinary circumstances in the local region. A.U.S.N. Co. Ltd. Teacup salvaged from SS Orungal ss orungal, fezara, world war two, barwon heads, ocean grove -

Federation University Historical Collection

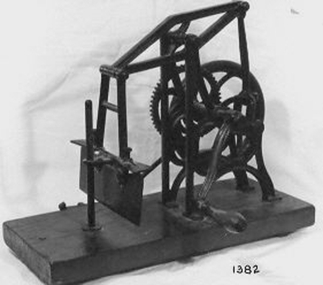

Federation University Historical CollectionEquipment - Model, 'Model Steam Engine' by Frederick Mitchell, 1886, c1892

Frederick Mitchell was born c1874 at Staffordshire Flat, Redcastle, near Heathcote. His father was an engineer from Cornwall, and had a quartz crushing battery at Staffordshire Flat from 1870 to at least the 1890s. Around 1886 Frederick Mitchell was an 18 year old "Engineer and Instrument Maker". He was awarded an 'Honorary Mention' at the Australian Juvenile Exhibition 1890-1. It was donated to the Ballarat School of Mines Museum in 1892. In the early 1960s the model was transferred to the Heat Engines Laboratory. All Heat Engines laboratory was moved from the Ballarat School of Mines to the Mt Helen Campus on October 1869. The model was accommodated in the thermodynamics laboratory. It was shown working during open days. The Ballarat School of Mines Calendar for 1893, page 66 refers to this item. There is correspondence between Frederick Mitchell's grandson, F.W. Mitchell; E.J. Barker, Director of the Ballarat College of Advanced Education; and Graham Beanland, Ballarat School of Mines.A working model of a vertical oscillating twin cylinder steam engine with fly wheel, mounted on a wood base board and covered in glass. Usually stored under a wood-framed glass cover. steam, model, engine, frederick mitchell, flywheel, ballarat school of mines museum -

Moorabbin Air Museum

Moorabbin Air MuseumPlan (item) - C.A.C Flywheel Power Unit

EX250012