Showing 62 items

matching food packaging

-

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Can Opener

It took 15 years to invent the can. It took 100 more to invent a standard way to open it. In the 19th century, decades after the invention of canning, there were virtually no can openers. Canned food, such as sardines, came with its own "key" to peel back the tin lid. Birth of the can One of the oddest things about the can opener is that the can predates it by almost 150 years. Though common today, cans were once military-grade technology. In 1795, Napoleon, to whom the phrase "an army marches on its stomach" is attributed, offered 12,000 francs to anyone who could find a way to preserve food. Without any knowledge of bacteria or their role in food spoilage, scientists didn't even know where to begin. It took 15 years before a chef named Nicholas Appert claimed the prize after successfully jarring food. Soon after that, his countryman Philippe de Girard came up with a variant on Appert's method—metal tins—and sold the idea to the British. Spoiled food, and the sickness it caused, was a widespread problem. The public would have benefited from canned food, but for decades cans were almost exclusively for the army and the navy. The canning process, with its hours of boiling and steaming, its scrupulous cleanliness, its heated metal, and its need for a great deal of disposable material, made canned food far too expensive for anyone but the military. No can openers were needed or even possible. The metal of early cans was too thick to make openers practical. Soldiers and sailors had plenty of sharp objects on hand and made ample use of them when they wanted to eat. During the 19th century, the process of canning was refined and mechanised, and the metal wall of the average can slimmed down enough that a civilian could get it open—if that civilian had the right tool. No one had that tool yet, so early cans had to open themselves. In other words, they came with built-in openers. The result was a confusing but pleasing free-for-all, in terms of product engineering. Each type of food came with its own kind of can, and each kind of can came with its own kind of opener. Tinned fish and meat were often sold in rectangular cans. These cans were fitted with a "key" that would roll down the top of the can. Coffee, beans, and other types of meat were packaged in cylinders with metal strips that could be peeled back with their own kinds of built-in keys. Cans of milk, which didn't need to be completely opened, came with puncture devices. As tinned food became more common, its containers became more regular. A nice cylindrical can became the norm, and, as these cans filled kitchens, more engineers put their minds to finding a convenient way to open all of them. The first standalone can opener worked on a simple principle: point, stab, and pull. From the mid-19th century to the end of World War I, the typical can opener looked roughly like a wrench, if the lower 'jaw' of the wrench were replaced with a blade. People used the blade to puncture the top of the can near its edge, push the upper jaw against the side of the can, and drag the blade through the metal along the rim. Because meat was the first and most popular canned substance, these can openers were often shaped to look like cows and given the nickname 'bully beef can openers'. The bully beef can opener, popular in the mid-19th century, resulted in many lost fingers. Bully beef can openers were so common, effective, and sturdy that they are still frequently available on collectors' sites. Some are advertised as “still working,” and every last one of them is, without a doubt, soaked in the blood of our ancestors. Dragging a sharp blade along the edge of a can is certain to cause injury sooner or later. So once people got a reliable can shape and a reliable way to get the can open, the search was on for a reliable way to get a can open without the possibility of losing a finger. The answer came in 1925, from the Star Can Opener Company of San Francisco. This is probably the first can opener that resembles the one people have in their kitchens today. Instead of using a blade to pry open a metal can, buyers could clamp the edge of the can between two wheels and twist the handle of one of the wheels to move the blade around the lip. The Star can openers weren't perfect. Compared to the bully beef model, they were flimsy and breakable, but they probably prevented a few injuries. Six short years after the Star model came to market, the first electric can opener was invented. It was patented in 1931 by the Bunker Clancey Company of Kansas City, who had already been sued by the Star Can Opener Company for trying sell a double-wheeled can opener like the Star model (the case was dismissed). The electric can opener must have seemed like the wave of the future and a sure-fire seller, but it proved to be too far ahead of its time. In 1931 not that many households had electricity, and those that did weren't interested in buying can openers. The Bunker Clancey Company was subsequently bought by the Rival Company, which still makes small appliances like can openers today. It took another 25 years for electrically powered can openers to become practical. In the 1950s, Walter Hess Bodle and his daughter, Elizabeth Bodle, developed an electric can opener in the family garage. Walter came up with the opener's blades and motor, and Elizabeth sculpted the outside. Their can opener was a free-standing unit that could sit on the kitchen counter. The Udico brand of the Union Die Casting Company put it on the market in time for Christmas in 1956 and had great success with it. Over the next few years it came out in different styles and colours, and, like the bully beef can opener, has become a collector's item. Also like the bully beef model, Udico can openers often still work. They don't make 'em like they used to. Although there have been some design changes and refinements over the last sixty years, there have yet to be any more leaps forward in can opener technology. If you're resentfully opening a can, you are almost certainly doing it using the Star design, manually forcing the can between two wheels, or the Bodle design, clamping the can into a free-standing electrical opener. Whether or not you enjoy your holiday meals, at least you can be happy that you are not getting poisoned by your own food or cutting open your hand with the blade you use to get at it. That's something, right?The can opener is still a very important and essential item in most kitchens.Can opener, right handed, metal, upper blade section serrated, inscription 'Peerless Pat.Feb 11-90'.Peerless Pat.Feb 11-90flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, cannning, can opener, kitchen equipment -

Blacksmith's Cottage and Forge

Blacksmith's Cottage and ForgeBiscuit Forcer

... of packaged biscuits. domestic kitchen food technology biscuit forcer ...Dough was put in forcer/case/cylinder and wooden pin pressed down to force dough out as a star-shaped biscuit. In use in a working-class home in the mid 20th century.Representative of kitchen utensils in common use in working class kitchens in 20th century prior to the common availability of packaged biscuits. Tin/metal outer cylinder/case/open one end, lid other end, with star pattern (can be removed for washing). Inner wooden pin or forcer, knob on end to be pushed into metal cylinder to force dough out through patterned disc.domestic, kitchen, food, technology, biscuit, forcer, baking, woman s, work, appliances -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageContainer - Tea Tin, First half of 20th Century

The history of metal packaging began in Bohemia in the 1200s. Metal has been produced for a very long time. But the first metal used for packaging was tin. In particular, it was the process of tin plating that was invented in Bohemia. Before this no other metal was economically able to be used for packaging. Later, in 1667 Andrew Yarranton, and English engineer, and Ambrose Crowley brought the method to England. Here it was improved by ironmasters including Philip Foley. Then by 1697, John Hanbury had a rolling mill at Pontypool in South Wales. The method they developed involved rolling iron plates using cylinders. This process enabled more uniform blank plates to be produced than was possible by just hammering the tin. https://www.shilohplastics.com.au/history-of-metal-packaging/The use of tin to protect and store food and other items, revolutionised the world.Tin container painted yellow with printed crosses and circles,. The lid is labelled "Robur Cross Stitch Company" and "R" imprinted in the centre although the lid is badly corroded. ‘Cross – Stitch’ (printed green in small crosses and circles) followed by ‘Nett Weight ¾ lb. (printed beige in crosses and circles). Pure Blended Tea. Robur Tea Co Ltd’ flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, robur tea co ltd, tea, tea caddy, tin, tin plating, food containers -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Food Safe, Willow Ware Pty Ltd, 1920s -1950

Willow started business in 1887 as a metal working company based in Melbourne Australia, making tinned biscuit and tea canisters. The outbreak of the First World War saw their manufacturing change to making armaments and essential packaging for the war effort. In the early 1920’s, the Willow brand was established. Making tin plated canisters and baking pans with the well-known Willow pattern, imprinted on them. Some other items in production at this time include billies, boilers, basins and Coolgardie safes. In the late 1950’s, the company ventured into plastics production. Stepping away from its very successful tin plating industry of more than 50 years. In 1965, the company name changed to Willow Ware Pty Ltd, to be more closely linked to its Willow brand. Willow Ware is still in business today. A food safe known as a “Coolgardie” meat storage made by an emerging Australian company no longer in bushiness. This item gives a snapshot into early Australian manufacturing specifically aimed at the Australian market.Safe metal kitchen food safe with 2 shelves, a hinged door and latch and a small swivel wire handle at the top. Painted light green, rusting.Willowwarrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, safe, food safe, meat safe, coolgardie safe, domestic object, kitchen object, willow ware, food preservation, kitchen safe -

Glenelg Shire Council Cultural Collection

Glenelg Shire Council Cultural CollectionPhotograph - Photograph - Frozen meat for loading onto ship, n.d

Port of Portland Authority archivesFront: (no inscriptions) Back: (no inscriptions)port of portland archives, cargo, frozen food -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Manufactured Glass, bottle PURA Cream 4oz, 20thC

There are two distinct types of milk consumption: a natural source of nutrition for all infant mammals and a food product for humans of all ages that is derived from other animals. Milk is a key contributor to improving nutrition and food security particularly in developing countries. Improvements in livestock and dairy technology offer significant promise in reducing poverty and malnutrition in the world. Pasteurization is used to kill harmful micro-organisms by heating the milk for a short time and then immediately cooling it. In the past, milk was always packaged in glass milk bottles The first glass bottle packaging for milk was used in the 1870s. The first company to do so may have been the New York Dairy Company in 1877 with a small glass lid and a tin clip. Lewis P. Whiteman holds the first patent for a glass milk bottle c1884,which was sealed with a waxed paper disk. The Express Dairy Company in England began glass bottle production in 1880. Melbourne Glass Bottle Works Spotswood 1880 - 1990. Milk cartons first came to Australia in 1958, when the Model Dairy in Melbourne began packaging milk in 150 ml and 500 ml cartons. At the time, 160,000 new glass bottles were needed in Melbourne alone every week to keep up the delivery of 1.3 million bottles of milk a day. n 1970, the blow-moulded disposable plastic milk bottle was introduced. In 1987, only about 2% of milk was still being sold in glass bottles. Glass milk bottles are now rare .Melbourne Glass Bottle Works Co Pty Ltd (1903 - 1915) Registered in Victoria in 1903 the company amalgamated with the Waterloo Glass Bottle Works Ltd in 1915 to form Australian Glass Manufacturers Company, Limited. Melbourne Glass bottle works Spotswood 1872- 1915 The Melbourne Glass Bottle Works (former), comprising a complex of buildings constructed between 1880 and 1940, at Booker Street, Douglas Parade, 2-38 Hudson Road, Raleigh Street and Simcock Avenue, Spotswood. The former glassworks was established in 1890 and originally made bottles for pharmacists Felton Grimwade before it was sold to the state government by US multinational, OI glass manufacturers A clear glass 4 oz bottle for PURA Creamery Carnegie. . A waxed cardboard disc lid from Devonshire Dairy Hepburn Springs is not related to this bottle but is an example of the typical lid used during this period Bottle : PURA / CREAMERY / CARNEGIE / CONTENTS 4 OZS Base : 120 Lid circumference : DEVONSHIRE DAIRY HEPBURN SPRINGS:/ Lid centre: PURE MILK/ T.B. TESTED COWS / PHONE 223 melbourne glass bottle works, spotswood melbourne, milk, dairy, dairy produce, dairy farmers, market gardeners, pioneers, early settlers, moorabbin, cheltenham, pasteur louis, pasteurization, pura creamery carnegie, devonshire dairy, hepburn springs, waxed paper milk bottle lids, felton grimwade co ltd, -

National Vietnam Veterans Museum (NVVM)

National Vietnam Veterans Museum (NVVM)Equipment - Equipment, Army, Stove Hexamine

Small folding hinged metal portable stove with unopened packet of Hexamine tablets inside stove. used by one man for heating food or waterDetailed directions on tablet packagehexamine stove, cooking, sas -

Port Melbourne Historical & Preservation Society

Port Melbourne Historical & Preservation SocietyPhotograph - Lagoon Confectioners, Peter Parrington, 24 Feb 1999

When Lagoon announced their imminent departure from Port Melbourne, PMH&PS arranged a farewell display for the 1999 Festival. Anne CALLAGHAN and Peter PARRINGTON went to the factory to collect information and memorabilia, and to take these photos.From a group of colour photos taken at Lagoon Confectioners February 1999 prior to their leaving Port Melbourne: Phyl SPOTKEIFF nee CAMILLERI and Pat AQUINILA nee MOIRER, employees for 40 years (ref 963.01), packaging sherbet bombsindustry - food, business and traders - confectioners, phyl spotkeiff nee camilleri, pat aquilina nee morier, lagoon confectionery pty ltd, bob mcquade, dean mcquade, lorraine mcquade -

Port Melbourne Historical & Preservation Society

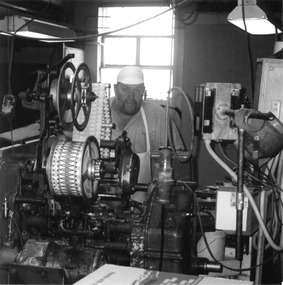

Port Melbourne Historical & Preservation SocietyPhotograph - Lagoon Confectioners, Peter Parrington, 24 Feb 1999

When Lagoon announced their imminent departure from Port Melbourne, PMH&PS arranged a farewell display for the 1999 Festival. Anne Callaghan and Peter Parrington went to the factory to collect information and memorabilia, and to take these photos.From a group of colour photos taken at Lagoon Confectioners February 1999 prior to their leaving Port Melbourne: Pat AQUILINA nee MORIER packaging sherbet bombsindustry - food, lagoon confectionery pty ltd, business and traders - confectioners, pat aquilina nee morier, bob mcquade, dean mcquade, lorraine mcquade -

Port Melbourne Historical & Preservation Society

Port Melbourne Historical & Preservation SocietyPhotograph - Lagoon Confectioners, Peter Parrington, 24 Feb 1999

When Lagoon announced their imminent departure from Port Melbourne, PMH&PS arranged a farewell display for the 1999 Festival. Anne CALLAGHAN and Peter PARRINGTON went to the factory to collect information and memorabilia, and to take these photos.From a group of colour photos taken at Lagoon Confectioners February 1999 prior to their leaving Port Melbourne: Male employee at packaging machineryindustry - food, business and traders - confectioners, lagoon confectionery pty ltd, bob mcquade, dean mcquade, lorraine mcquade -

Port Melbourne Historical & Preservation Society

Port Melbourne Historical & Preservation SocietyDocument - Robert Harper & Co, Jenny Bell, unknown

A three page document about Robert Harper and his company, including a 1920's black & white photograph of the packaging and 13 colour photographs of labels of products including coffee, rice, tea, oatmeal and safety matches.industry-manufacturing, industry - food, manufacturing, robert harper & co ltd -

Wangaratta RSL Sub Branch

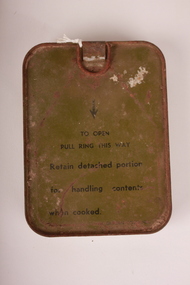

Wangaratta RSL Sub BranchArmy Field Ration

A field ration, combat ration or ration pack is a canned or pre-packaged meal, easily prepared and eaten, transported by military troops on the battlefield. They are distinguished from regular military rations by virtue of being designed for minimal preparation in the field, using canned, pre-cooked or freeze-dried foods, powdered beverage mixes and concentrated food bars, as well as for long shelf life.Most armies in the world today now field some form of pre-packaged combat ration, suitably tailored to meet national or ethnic tastes.AMF Emergency Ration Pack ContainerOn front: To open pull ring this way. Retain portion for handling contents when cooked. Gadden container On back: AMF Emergency Ration. To be consumed only when no other rations of any kind are procurable. Consumption of this ration must be reported at first opportunity. Instructions for use are printed under cover of container and also on paper slip within can. Gadden container.ration, container, food, ring pull, emergency -

Robin Boyd Foundation

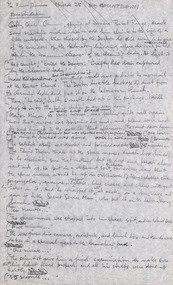

Robin Boyd FoundationDocument - Script, Robin Boyd, The Flying Dogtor. Episode 25 The Countdown, 1963

Major Minor, the space mouse, was feeling well again now that no-one was poisoning his food and plans were made to send him up in the satellite that afternoon. The countdown began. Major Minor was strapped in and given his camera, notebook and cheese lunch packages for seven orbits. The Flying Dogtor thought his work in Woomera had been completed when he realised they’d given the space mouse the wrong package. The Dogtor and the Secret Service Man looked at each other in horror because that meant that Crafty was onboard the rocket!The Flying Dogtor" series was broadcast on Australian Television Network (later becoming the Seven Network) between February and April 1964 (see item D254 for schedule).Handwritten, foolscap, 2 pagesThe title is crossed out. Many edits.the flying dogtor, robin boyd, crawford productions, manuscript -

Hume City Civic Collection

Hume City Civic CollectionContainer - Treacle Tin, Treacle

The tins were used by the Colonial Sugar Refining Co. to store and sell treacle which is a by-product of cane sugar and molasses. The tin is labelled with the imperial pound measurement so it preceded metric weights and measures.A green, red and gold tin used to sell and store treacle. Two stick of sugar cane decorate the front and the back of the round tin. The tin lid on the top of the tin needs to be levered open. The tin's capacity is 2 pounds. The word 'treacle' is written in bold red capital letters.THE COLONIAL SUGAR REFINING CO. LTD / TREACLE / 2 LB NET / MADE FROM CANE SUGAR ONLYcolonial sugar refining co., treacle, sugar cane, food, canning, sugar mills, george evans collection, commercial packaging -

Hume City Civic Collection

Hume City Civic CollectionContainer - Golden Syrup Tin, Golden Syrup

The tin was designed and used by the Colonial Sugar Refining Co. to store and sell golden syrup which is a by-product of cane sugar, molasses and treacle. The tin was used after the introduction of metric weights and measures.A yellow, red, brown, white and black tin used to sell and store golden syrup. The kilogram tin has the words 'golden syrup' printed in large red letters. There is a recipe and picture for caramel sauce on the back of the tin.MADE FROM AUSTRALIAN GROWN SUGAR CANE / CSR / Golden / Syrup / Net 1 kg / The COLONIAL SUGAR REFINING CO LTD / MELBOURNEcolonial sugar refining co., golden syrup, sugar cane, food, recipes, sugar mills, canning, george evans collection, commercial packaging -

Hume City Civic Collection

Hume City Civic CollectionContainer - Tin, Golden Syrup

These tins held the golden syrup which was made from sugar cane. The golden syrup was manufactured by the Colonial Sugar Refining Co. Ltd later known a CSR who had refineries in Brisbane, Sydney, Melbourne and Adelaide. A tin of golden syrup was found in many households and used to spread on bread or crumpets to be eaten and was also used in cooking. This particular tin once empty looks as if may have been used to store possibly nuts and screws. Many of these tins once empty were put to other uses.A round red and gold colour with gold and red print around the side of the tin. It has a lid on the top with black writing.THE COLONIAL SUGAR REFINING CO.LTD/GOLDEN SYRUP/MADE FROM CANE SUGAR ONLYfood technology, golden syrup, households, george evans collection, commercial packaging -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Document - Instructions for Superba Skin Food

The Bendigo based Sander family business Sander and Sons, were producers of eucalyptus oil/extract in the 19th and 20th centuries. Carl Sandner established Sander and Sons Eucalyptus Distillery in 1875. It operated until 1967Instructions included in a box of Superba Skin Food. One page with black printing included claims made after use of product and directions for use. Notes that an application for Registration of the distinctive label was made on January 18 1907. Instructions originally folded tightly to fit inside packaging with tin. Two copies.advertising, sander, sandner -

Ararat Gallery TAMA

Ararat Gallery TAMAFunctional object, Preserved shrimp, c. 1900s

‘The Art of the Japanese Package’ was an exhibition that toured to 10 Australian and 11 New Zealand public galleries in 1979 and 1980. The touring exhibition comprised 221 objects of traditional Japanese packaging which extended from ceramics, wood and paper to woven fibre containers. At the conclusion of the tour, The Japan Foundation and the Crafts Board of the Australia Council donated the vast majority of the exhibition to the Ararat Gallery for its permanent collection. Combining the natural qualities of bamboo, paper and straw with delicate craftsmanship, these unique objects express Japanese aesthetics as applied through fibre crafts. In Japan, the qualities and traits of natural materials are exploited rather than hidden. The texture of straw, the septa of bamboo are not concealed but lovingly incorporated into the whole. In 1979 Hideyuki Oka, curator of ‘The Art of the Japanese Package’ wrote: “In no way self-conscious or assertive, these wrappings have an artless and obedient air that greatly moves the modern viewer. They are whispered evidence of the Japanese ability to create beauty from the simplest products of nature. They also teach us that wisdom and feeling are especially important in packaging because these qualities, or the lack of them, are almost immediately apparent. What is the use of a package if it shows no feeling?” The descriptions of the featured objects were written by Hideyuki Oka, curator of ‘The Art of the Japanese Package’, 1979.Gift of the Japan-Australia Foundation and the Crafts Board of the Australia Council, 1981Shrimp and fish were often preserved by drying them and stringing them together with straw. The age-old technique is also used for other foods, including fish, peppers, and giant white radishes known as daikon. The shrimp here are likely to be from Kagoshima, the southernmost prefecture of Kyushu. - Professor Hideyuki Oka, curator.japanese art, japanese packaging, tsutsumi, gift giving -

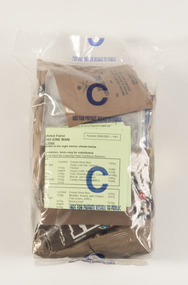

Beechworth RSL Sub-Branch

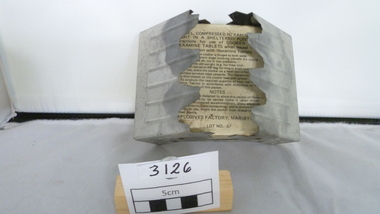

Beechworth RSL Sub-BranchEquipment - Combat Ration One Man (24 Hour), c.2006

Common every day items food used by the ADF in combat situations. This shows the combat ration one man that has been used by the ADF since the Vietnam War era. The CR1M consists of two main meals, various light snacks, sundry and beverage items. The CR1M is designed to provide the daily nutritional value to sustain a soldier over a 24 hour period. Failure to consume all food items with this period will impact upon functional energy levels due to an unbalanced nutrition intake. Excluding tea and coffee aal food items are consumable either hot or cold. It is advised to fill one cup canteen with water, immerse one 250g main meal pouch and heat for 10 - 15 minutes. For heat source use use issued hexamine stove and tablets. residual boiled water is safe and may be used for hot beverage makingCombat Ration One Man (24 hour). Sealed in a clear plastic bag with the letter 'C' printed in blue on the front (indicating that contents are menu 'C'). This pack includes small packages of supplies in various shapes and sizes, including: M and M's chocolate, potato with onion powder, sweetened condensed milk, cream spread, tea bags, safety matches and toilet paper. Front - Blue text - C / NOT FOR PRIVATE RESALE TO PUBLIC ration pack, consumables, supplies -

Melton City Libraries

Melton City LibrariesNewspaper, Crosses lay out pledge to remember, 2015

"The outbreak of World War I in August 1914 had an immediate impact on communities across Australia, and it was no different in Melton. Young men began enlisting immediately, and Australia’s initial offer of 20,000 troops was soon exceeded by Victorian enlistments alone. Over the four years of the war, approximately 114,000 Victorians enlisted and around 91,000 servicemen and women were sent overseas. They came not just from Melbourne, but from all over the state; from farms, small towns and suburban areas. They included locals, newly arrived migrants and Indigenous people. The Australian home front was a hive of activity throughout the war, and the Melton community played its part. Following the announcement that Australia was joining the war with Great Britain and its allies on 5 August 1914, the Melton community lost no time in launching into action. A meeting ‘to assist the Red Cross fund’ was held in the Melton Mechanics’ Institute hall on 18 August – just days after the outbreak of the war. Collectors were appointed for each corner of the shire and individual donations were made. A Melton branch of the Australian Red Cross Society was formed in June 1915 and focused its energies on raising funds to purchase material that was used to make clothes for sick and wounded soldiers. A depot was established in Melton to collect clothing and other ‘comfort’ items for the soldiers – including reading material, tobacco, linen, canned foods and soap – and to coordinate the branch’s work and activities. Local cab driver Percival Stubbs volunteered to transport all the packages to the Melton railway station, until he enlisted and departed for the front in 1916. Such were the numbers of people getting involved that branches were also established in Toolern Vale and Rockbank. Regular community events were held to farewell soldiers who were leaving on active service and to welcome those who returned home. Gunner Robert (Bob) Wynne, whose uncle’s family ran the general store in Toolern Vale, was presented with a pair of field glasses (binoculars), a gold watch, inscribed locket and autographed letter by the Toolern Vale community before he set sail for the front in 1916. His mother noted that he ‘sailed away in good spirits with a smile till out of sight’. From June 1915 to June 1919, the Melton Red Cross branch donated 2,156 pairs of socks, 1,357 shirts, 425 kit bags, 251 pillowslips, 224 towels and 121 pairs of pajamas. Countless fundraising events were held, including jumble fairs, concerts and gift evenings. Local schools also encouraged students to contribute through fund-raising and making and collecting comforts for the soldiers. People across the country engaged in similar activities, but Victoria’s rural communities found unique ways of contributing. In Melton, people were encouraged to send rabbits and hares ‘in good condition’ to an exporter in Spencer Street, for export to Belgium ‘for the relief of those suffering". Special Anzac Memorial article featured in the Star Weeklylocal identities, war -

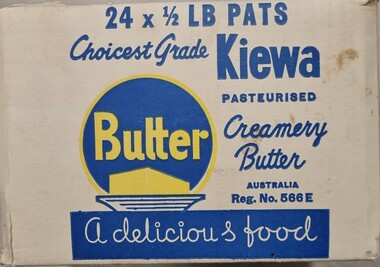

Wodonga & District Historical Society Inc

Wodonga & District Historical Society IncFunctional object - Kiewa Dairy Box

The Kiewa Butter Factory began in 1893, named after the Kiewa River on which it is located. By 1905, butter shipped from Kiewa was receiving a top price of 114 s per cwt at the London market. It continued to prosper until 1959 when it merged with Tallangatta Butter Factory and Creamery Co. Ltd to become the North Eastern Dairy Company. In 1985 this organisation was taken over by the Murray Goulburn Co-operative.This package is representative of an important industry in Wodonga and the surrounding district.A packing box for butter from the Kiewa North Eastern Dairy. Made from heavy cardboard with blue and yellow design.On Front: 24 x 1/2 lb PATS / Choicest grade Kiewa/ Pasteurised / Creamery Butter/ AUSTRALIA / Reg. No. 566E/ BUTTER A delicious food On sides: 24 x 1/2 lb PATS / Choicest grade Kiewa/ Pasteurised / Creamery Butter/ AUSTRALIA / Reg. No. 566E/ North Eastern Dairy Co. Ltd. / KIewa Australianortheastern dairy co, dairies and butter factories, dairy industry victoria -

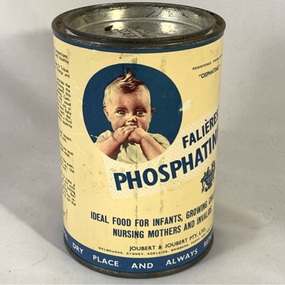

The Royal Women's Hospital

The Royal Women's HospitalTool - Packaging, Faliere's Phosphatine container

Phosphatine Falieres was invented by pharmacist Émile Falières in the 1880s and marketed as a fortifying cereal or "farine" [flour] for infants, enriched with calcium. Said to be easily mixed and easily digestible, the cereal was added to an infant’s milk. It was made in Australia and distributed by a number of pharmaceutical companies, in the 1950s by Joubert & Joubert. The Phosphatine Falieres company advertised extensively, marketing to doctors, nurses, and mothers always using pictures of rosy-cheeked children. Falières created charming three-dimensional chromolithography pop-up/pop-out/moveable images many of which had a little tab. When the tab was pulled, these colourful sales props showed happy and healthy children opening a tureen of food that was fortified with Falieres cereal. The collection of Nurse Florence Green RWHA_2018_069 contains one such item of ephemera. Green was a graduate of the Women’s Hospital’s midwifery nurse training scheme in 1914. She lived at Hawthorn. The container is a cardboard cylinder with a printed label (stained) covering the entire surface. It has a metal (rusted) lid. The word "BORAX" has been written on the side. -

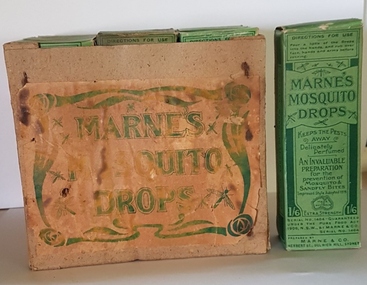

Linton and District Historical Society Inc

Linton and District Historical Society IncMosquito drops, Marne & Co. Herbert St., Dulwich Hill, Sydney, N.S.W, Marne's Mosquito Drops, 1919

Found in the cellar of the former Barr's drapery shop, Sussex Street, Linton, which at one time had a doctor's consulting room. Bob Albert (who found them) assumed they were something to do with the medical practice. He gave the box of mosquito drops to Joan and Alan Giles. Information in newspaper advertising (found via Trove) shows the drops were marketed in New South Wales, Queensland and South Australia between about 1915 and 1927. The address on the packaging suggests these particular bottles were manufactured after 1918.Twelve green boxes labelled 'Marne's Mosquito Drops', stored in a strong cardboard box bearing a green label, also reading 'Marne's Mosquito Drops'. Information on individual cardboard packaging: "Marne & Co., Herbert St, Dulwich Hill, NSW / Registered under the Pure Food Act 1908 / Improved Formula 1919".marne's mosquito drops, pest control, mosquito drops -

Flagstaff Hill Maritime Museum and Village

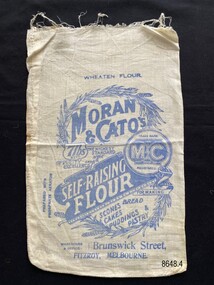

Flagstaff Hill Maritime Museum and VillageTextile - Flour bag - Moran & Cato's

The flour bag is an example of packaging from the grocery store, Moran & Cato's. Moran & Cato's were a large chain of grocery stores operating from the late nineteenth century to the mid twentieth century across Victoria, Tasmania and New South Wales. The address on the flour bag is for the warehouse (wholesale depot) of the business which was a significant building in Brunswick St, Fitzroy.The flour bag provides a snapshot of packaging for a well known grocery store of the early twentieth century. The advertisement on the back for 'Cleaned Fruits' is an example of advertising that highlighted important facts relevant to that time (e.g. "latest Special Machinery" and "with running water").Small calico flour bag for self-raising flour (7lb) supplied from Moran & Cato's in Brunswick Street, Fitzroy, Melbourne. The front of the bag includes not only the detail of the business but ideas for baking, images of wheat and claims as to its excellence. The back of the bag has a written advertisement for 'Cleaned Fruits' another product of the company.Front - Wheaten Flour, Moran & Cato's, Trade mark The M & C Brand Registered, 7lbs Nett, The Highest Standard of Purity and Excellence, prepared with phosphate aerator, Self-raising Flour, For making scones bread cakes puddings & pastry, Warehouse & Office- Brunswick Street, Fitzroy, Melbourne Back - Moran & Cato's, Cleaned Fruits are Perfection, (advertising text), The Same High Quality, The Same Prices at all our Branches.flagstaff hill maritime museum and village, great ocean road, shipwreck coast, calico, domestic object, textile, food storage, moran & cato's, flour bag, self-raising flour -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTextile - Parsons' Oatmeal Bags

Dry foods such as oats were packaged in cloth bags from the late 19th century to the mid 20th century. Parsons' Brothers and Company were involved in packaging a variety of produce for the Australian market including oatmeal for porridge.The oat bags provide a snapshot of a well-known Australian food company and how the bags were used to advertise other items available from the business.A set of two Oatmeal Bags from the Parsons' company. Each bag is made from calico with ornate writing and images on the front that relate to the product and company. The back of each bag is used to advertise a different product from the company – Saline Powder (8649.1) and Mustard (8649.2).Front (both): 7-lbs. Net, PARSONS', TRADE MARK, THE ORIGINAL FLAKED OATMEAL, DELICIOUS PORRIDGE, WITH ONLY TEN MINUTES BOILING, PARSONS BROS & COY., PROPY. LTD., MELBOURNE Back 8649.1 : TRY Parsons', PARSONS' SALINE POWDER, NET ? LB, SALINE POWDER, A COOL, REFRESHING AND HEALTHFUL DRINK Back 8649.2 : UNSURPASSED in Quality and Price, PARSONS' MUSTARD, (further writing is faded)flagstaff hill maritime museum and village, great ocean road, shipwreck coast, warrnambool, calico, domestic object, textile, food storage, parsons' bros, oatmeal, porridge -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTextile - Flour bag - Golden Crust

Flour bags were used when purchasing flour from the late 19th century to the mid 20th century. They were able to be reused for bulk storage of dry goods or sewn into domestic objects such as tea towels, pillowcases or waggas.The flour bag provides an example of a useful domestic packaging product, from the early 20th century.Calico flour bag for Golden Crust Self-raising flour, 25lb. The stencil on the bag includes the manufacturer’s address and images of heads of wheat and a plate of scones. 25lbs, Golden Crust, Self-raising Flour, Blended with Phosphate Aerator, Hancock’s Golden Crust Pty.Ltd. South Yarra, Vicflagstaff hill maritime museum and village, great ocean road, shipwreck coast, calico, domestic object, textile, food storage, flour bag, golden crust -

Flagstaff Hill Maritime Museum and Village

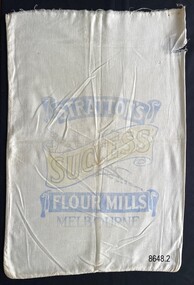

Flagstaff Hill Maritime Museum and VillageTextile - Flour bag - Stratton's, Melbourne

Flour bags were used when purchasing flour from the late 19th century to the mid 20th century. They were able to be reused for bulk storage of dry goods or sewn into domestic objects such as tea towels, pillowcases or waggas.The flour bag provides an example of a useful domestic packaging product, from the early 20th century.Calico flour bag for 'Success Flour' from Stratton’s flour mill in Melbourne. The stencil on the front of the bag includes the image of a wheat stalk overlaid with the written information in scroll format.Stratton's, Success, Flour Mills, Melbourneflagstaff hill maritime museum and village, great ocean road, shipwreck coast, calico, domestic object, textile, food storage, stratton's, flour bag -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTextile - Flour Bags (5)

Flour bags were used when purchasing flour from the late 19th century to the mid 20th century. They were able to be reused for bulk storage of dry goods or sewn into domestic objects such as tea towels, pillowcases or waggas.The flour bags provide both a snapshot of different producers and stockists of flour in Victoria and an example of a useful domestic packaging product, from the early 20th century.A set of five flour bags originating from different Victorian places. Stratton's in Melbourne, McAlpin's in Melbourne / Ballarat, Moran & Cato's in Fitzroy, Golden Crust from South Yarra and W.C. Thomas from Warracknabeal. Each bag is made from calico with an image on the front that relates to the company.flagstaff hill maritime museum and village, great ocean road, shipwreck coast, flour bags, calico, domestic object, textile, food storage -

Flagstaff Hill Maritime Museum and Village

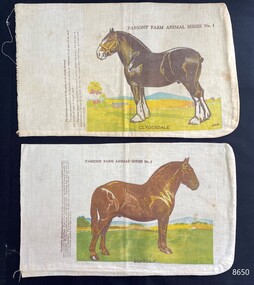

Flagstaff Hill Maritime Museum and VillageTextile - Parsons' Farm Animal Series Oat Bags

Dry foods for domestic use were packaged in cloth bags from the late 19th century to the mid 20th century. As the bags contain the name Parsons' it could be presumed that they were oat bags as the Parsons Company packaged a variety of groceries for the Australian market including oats. The bags provide an example of calico bags used to store dry goods. Being presented as a ‘Farm Animal Series’ gives them added value as a collectable item and may have been an advertising ploy used by the company.A set of two calico bags from the Parsons' company - most likely bought as oat bags. The two are: No 1. (Clydesdale) and No 3. (Suffolk) from the Parsons' Farm Animal Series. Each bag has a multicoloured ink picture and written information about the horse described on the bag.8650.1 PARSONS' FARM ANIMAL SERIES No. 1, CLYDESDALE, The Clydesdale originated in the valley of the Clyde, Scotland. The main characteristics of the Clydesdale are ability to acclimatise in all parts of the world and perform all types of draught work. Clydesdale breeders lay emphasis upon bone, quality, weight, and action. The feet must be proportionate to the size of the horse, the hoof-head should have a full crown, with heels wide and quarters strong. 8650.2 PARSONS' FARM ANIMAL SERIES No. 3, SUFFOLK, The Suffolk, often known as the Suffolk Punch, originated in the County of Suffolk, England and is noted for its hardiness. From 15 to 16 hands in height, the Suffolk in general is smaller than the Clydesdale. The head is rather coarse, with the neck short. The body long, deep and wide with a round full appearance. The croup is straight, the legs short and free from feather. The invariable colour is chestnut, varying from light to dark.flagstaff hill maritime museum and village, great ocean road, shipwreck coast, warrnambool, calico, domestic object, textile, food storage, parsons' farm animal series, oats, clydesdale, suffolk -

Wangaratta RSL Sub Branch

Wangaratta RSL Sub BranchMemorabilia - Australian Defence Force Ration Pack

A field ration, combat ration or ration pack is a canned or pre-packaged meal, easily prepared and eaten, transported by military troops on the battlefield. They are distinguished from regular military rations by virtue of being designed for minimal preparation in the field, using canned, pre-cooked or freeze-dried foods, powdered beverage mixes and concentrated food bars, as well as for long shelf life.Australian Defence Force Combat Ration pack for one man. Contains 30 items: tomato soup, processed cheddar cheese, blackberry fruits spread, sweetened condensed milk, cream cracker buscuits, scotch finger biscuits, instant coffee x2, chocolate drinking powder, sugar x8, mixed berry beverage powder, Cottee's cordial powder, tropical fruit grains, salt, pepper, sweet chilli sauce, tabasco sauce, arrowmint chewing gum, tangerine lemon lollies, toothpicks, scourer, napkins, bottle opener.Australian Defence Force Combat Ration (One Man) contents list.ration pack, australian army ration pack