Showing 111 items

matching machinery operation

-

Greensborough Historical Society

Greensborough Historical SocietyPhotograph - Digital Image, Mystery mine photographs: Building staff quarters with men outside, 1935c

This photograph shows the workers huts at the mine site, nearing completion, with men standing outside..An interesting collection of photographs, the connection to Greensborough remains a mystery. Digital copy of black and white photograph, one of 30 photos of mining operations. Photos have no markings or dates. Donor unknown.tasmania, mines and mining, mining machinery -

Greensborough Historical Society

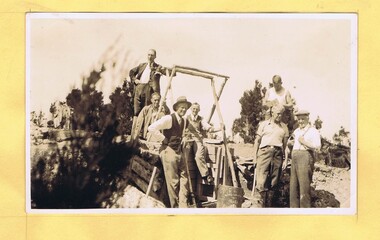

Greensborough Historical SocietyPhotograph - Digital Image, Mystery mine photographs: Workers at top of shaft, 1935c

This photograph shows workers at the mine site, at the top of the mine shaft. A ladder can be seen at centre of photo..An interesting collection of photographs, the connection to Greensborough remains a mystery. Digital copy of black and white photograph, one of 30 photos of mining operations. Photos have no markings or dates. Donor unknown.tasmania, mines and mining, mining machinery -

Greensborough Historical Society

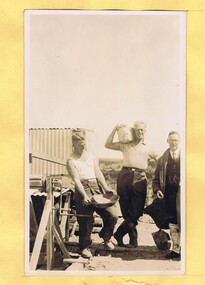

Greensborough Historical SocietyPhotograph - Digital Image, Mystery mine photographs: Workers posing for the camera, 1935c

This photograph shows workers posing for the camera - one with a pan and the other with a large rock on his shoulder..An interesting collection of photographs, the connection to Greensborough remains a mystery. Digital copy of black and white photograph, one of 30 photos of mining operations. Photos have no markings or dates. Donor unknown.tasmania, mines and mining, mining machinery -

Greensborough Historical Society

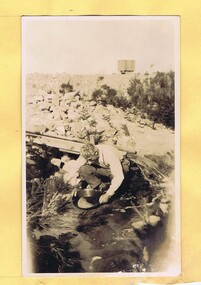

Greensborough Historical SocietyPhotograph - Digital Image, Mystery mine photographs: Panning, 1935c

This photograph shows a worker panning in the creek..An interesting collection of photographs, the connection to Greensborough remains a mystery. Digital copy of black and white photograph, one of 30 photos of mining operations. Photos have no markings or dates. Donor unknown.tasmania, mines and mining, mining machinery -

Greensborough Historical Society

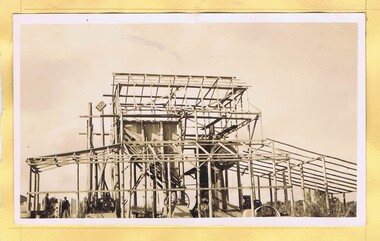

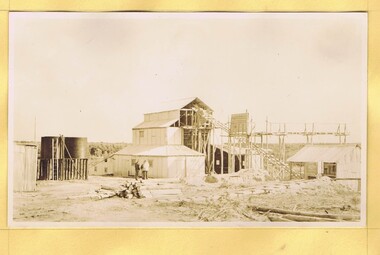

Greensborough Historical SocietyPhotograph - Digital Image, Mystery mine photographs: Builing the crusher plant, 1935c

Building the crusher plant (two angles). Hopper (centre left) to feed crusher..An interesting collection of photographs, the connection to Greensborough remains a mystery. Digital copy of 2 black and white photographs, two of 30 photos of mining operations.Photos have no markings or dates. Donor unknown.tasmania, mines and mining, mining machinery -

Greensborough Historical Society

Greensborough Historical SocietyPhotograph - Digital Image, Mystery mine photographs: Crusher plant with walls, 1935c

Crusher plant with walls and winch track right of centre to pull truck to hopper at top.An interesting collection of photographs, the connection to Greensborough remains a mystery. Digital copy of 2 black and white photographs, two of 30 photos of mining operations.Photos have no markings or dates. Donor unknown.tasmania, mines and mining, mining machinery -

Greensborough Historical Society

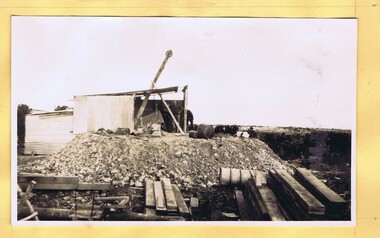

Greensborough Historical SocietyPhotograph - Digital Image, Mystery mine photographs: Shaft and pulley, 1935c

Shaft and pulley bring ore out of mine and tip into cart (two views).An interesting collection of photographs, the connection to Greensborough remains a mystery. Digital copy of 2 black and white photographs, two of 30 photos of mining operations.Photos have no markings or dates. Donor unknown.tasmania, mines and mining, mining machinery -

Greensborough Historical Society

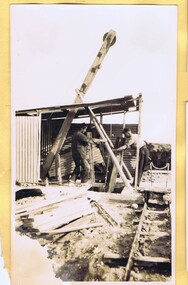

Greensborough Historical SocietyPhotograph - Digital Image, Mystery mine photographs: Shaft and pulley 2, 1935c

Shaft and pulley bring ore out of mine and tip into cart (two views).An interesting collection of photographs, the connection to Greensborough remains a mystery. Digital copy of 2 black and white photographs, two of 30 photos of mining operations.Photos have no markings or dates. Donor unknown.tasmania, mines and mining, mining machinery -

Greensborough Historical Society

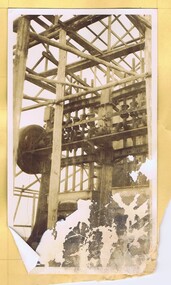

Greensborough Historical SocietyPhotograph - Digital Image, Mystery mine photographs: Inside the 10-head crushing plant, 1935c

This photograph shows inside the 10-head crushing plant.An interesting collection of photographs, the connection to Greensborough remains a mystery. Digital copy of black and white photograph, one of 30 photos of mining operations. Photos have no markings or dates. Donor unknown.tasmania, mines and mining, mining machinery -

Greensborough Historical Society

Greensborough Historical SocietyPhotograph - Digital Image, Mystery mine photographs: Dairy herd on the property, 1935c

This photograph shows a dairy herd on the property.An interesting collection of photographs, the connection to Greensborough remains a mystery. Digital copy of black and white photograph, one of 30 photos of mining operations. Photos have no markings or dates. Donor unknown.tasmania, mines and mining, mining machinery -

Cheese World Museum

Cheese World MuseumCheese press, Perfect Cheese company

Perfect Cheese Company was founded in 1930 by newly-arrived Italian migrant Natale Paquale Italiano. The company specialised in traditional Italian-style cheese but also produced Greek, Cypriot and Maltese origin cheeses. The cheeses were sold in Australia and Italy with all products being matured and non-processed. The company remained in operation until the early 2000s.This cheese press is significant as it represents the machinery used by an early cheese production company.Stainless cheese press machine with three steel supports and two threaded rods will spring tension wheels to screw down to pressurise the hoops containing cheese.J & T YOUNG AYR UKallansford, perfect cheese company, avery, cheese manufacturing, dairy industry -

Cheese World Museum

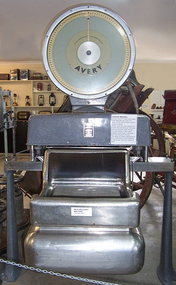

Cheese World MuseumMilk weighing machine, Perfect Cheese company weighing machine

Perfect Cheese Company was founded in 1930 by newly-arrived Italian migrant Natale Paquale Italiano. The company specialised in traditional Italian-style cheese but also produced Greek, Cypriot and Maltese origin cheeses. The cheeses were sold in Australia and Italy with all products being matured and non-processed. The company remained in operation until the early 2000s.This weighing machine is significant as it represents the machinery used by an early cheese production company.Large metal machine with cast iron with a cast iron frame and a stainless steel rectangular bowl in a cradle. The round weighing scale at the top shows a weight scale up to 1100 pounds. A mesh stainless steel baffle strains the milk.Made in England Birmingham - AVERY SOLE AGENTSallansford, perfect cheese company, avery, cheese manufacturing, dairy industry -

Cheese World Museum

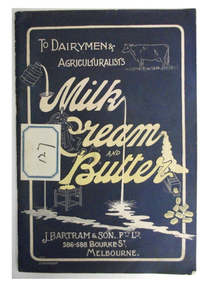

Cheese World MuseumCatalogue, To Dairymen & Agriculturalists: Milk Cream and Butter

This catalogue belonged to Alderdice Brass Foundry in Warrnambool. It was donated to the museum by John Downing from the foundry. The catalogue is for the firm of J Bartram & Son who were suppliers of dairy equipment. They were one of the earliest suppliers of mechanical milking machines in Victoria.The catalogue is significant as it is from an early dairy supplier and shows early dairy equipment. The Alderdice Brass Foundry has been in operation since the 19th century.Blue covered catalogue booklet with white text and illustrations of a cow, separator, butter maker and butter slicer machines.To Dairymen &/Agriculturalists/Milk/Cream/and/Butter J.BARTRAM & SON. PTY. LTD./586-588 BOURKE ST./MELBOURNEcatalogues, dairy industry, j bartram & son pty ltd, dairy machinery, milk, cream, butter -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageRangefinder, E R Watts & Sons, 1930-1945

E. R. Watts and Son, makers of theodolites and other surveying instruments, of 123 Camberwell Road, London. The company was established in 1856 by Edwin Watts at twenty-three he had saved £100 from his earnings to start the business with his staff consisting of one boy and later Alexander Clarkson as an apprentice with the workshop a small room over a Bemondsey stable. Watts' first order was from Negretti and Zambra for a mining dial Alexander Clarkson In the early days the firm worked mainly on marine compasses. Edwin Watts would go down to the Docks to adjust the compasses once they had been installed on the ships. In May 1873 the business moved to larger premises a house with a garden. The workshop was also the home of Mr and Mrs Watts and their five sons and three daughters. By now there were fifteen to twenty men employed by the firm. The company were commissioned to supply the Theodolites and Levels for the construction to the Canadian Pacific Railway in 1881. Towards the end of the century, the firm began to make heliographs continuing to produce them for the government until just before the Second World War when by agreement assigned their manufacture to another firm. 1904 The first dividing engine was completed by George William Watts. It was so remarkable an instrument at the time and for years afterwards, In 1907 Arthur Ames went to Canada and started an organisation in Winnipeg in 1909 this became a separate company called E. R. Watts and Son Ltd. of Ottawa. This firm developed considerably and was eventually with the co-operation of three other instrument companies (Cambridge Instrument Co, Ross, and Negretti and Zambra), were reconstituted as ”Instruments Ltd” of Ottawa and Toronto. During the next ten years, the firm expanded greatly to include glass grinding, leather work, dividing and engraving, testing, adjusting and packing. This expansion was continued during the First World War when workshops were completed and the machinery installed and running within eleven weeks from the start of construction. During the war, a Sergeant Coles, among the rats, lice and mud of the trenches, fitted various bits of scrap into his cocoa tin and made the first Flash Spotter for plotting the positions of enemy guns. Coles was rushed home to the firm's factory where he and George William Watts designed a spotter not made out of a cocoa tin and as a result, the Watts Vertical Force Variometer was developed during WWI. Other Watts instruments made in the First World War included the Light Mountain Theodolites which were taken on Mt Everest expeditions. In 1919 ER Watts and Sons was incorporated as a limited company and in 1939 G. A. Whipple joined the Board of Directors. Shortly afterwards, Frank Charles Watts died having been Chairman of the firm for over 37 years and seen it through the First World War with all its expansions and difficulties. He was succeeded by his brother George William Watts with the vacant post of Managing Director being filled by G. A. Whipple. During the Second World War, the company expanded further and the number of employees rose to well over 1,300. In 1946 Watts acquired 78% of Adam Hilger and the microscope maker James Swift and Son Who were Manufacturers of Theodolites, Levels, Alidades, Meteorological Instruments, Variometers, and many other types of scientific instruments Then in 1948 the company amalgamated with Adam Hilger as Hilger and Watts which was then incorporated as a public company.Naval Rangefinder with a vertical wooden handle, and an arrangement of optical lenses. Three reversible brass inserts calibrated on both sides in yards, correspond to various base heights, (20 and 25 feet, 30 and 35 feet and 40 and 50 feet). They are fitted along the axis of the instrument. When the scale for the appropriate base height is selected and inserted, the carriage can be slid for coincidence and the distance read at the index mark on the sliding carriage.inscribed "Rangefinder Cotton Type Mk II" Calibrated scale up to 5000 yds (50 ft), 5000 yds (35 ft), 4000 yds (25 ft) made by E. R. Watts & Son.flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, rangefinder, cotton type, e r watts & sons, naval range finder, marine equipment -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageMachine - Guillotine, c. 1880's

This guillotine is a hand operated machine specifically designed to cut through multiple sheets of paper or card. It has a very heavy and sharp single blade knife mounted between vertical guides or runners. The main users of a machine like this is in by the printing and publication binding industry. Book binding companies use a guillotine to evenly trim the pages of a book after it has been bound. The way the guillotine is used is - paper or card is stacked squarely on the flat table and pushed firmly against the back guide - the handle below the table at the front of the machine is wound around, which brings the back guide forward, pushing the paper stack forward and positioning the centre of the stack below the vertical frame - the upper wheel is wound around, which brings the clamp and firmly in position on top of the paper, to hold it very firmly - the large wheel on the side of the machine is turned around to lower the long sharp blade down onto the pages and cut them through. The sharp edge of the blade is protected somewhat from becoming blunt; a block of wood sits in the table under the stack of paper An early model of a guillotine was patented in 1837 by Thirault, who built a model with a fixed blade. Guillotines similar in principal to this one were patented by Guillaume Massiquot in 1844 and 1852. Over the years many improvements have been made and operation has moved from man power to electricity. Oscar Friedheim Ltd. was the importer and wholesaler of a large range of machinery and equipment for the printing and bookbinding industry. He sold most of his equipment under his own name. On this guillotine or paper cutter he refers to the origin of the guillotine’s manufacture only as “German Manufacrure”. A reference book “Commercial Bookbinding: a description of the processes and the various machines used" by Geo. Stephen, 1910, recommends Oscar Friedheim, amongst others, for the supply of “reliable cutting machines for hand or power”. It also recommends Oscar Friedheim’s for a wide range of other printing machinery and processes. OSCAR FRIEDHEIM LIMITED, LONDON Oscar Friedheim Ltd. was established in 1884 and operated from Ludgate in London. The company was an importer and wholesale supplier in the 1880’s, offering machinery and equipment for the printing and packaging industry for the UK and Ireland. The company became incorporated in 1913. An advertisement of 1913 includes a telegraphic code plus two telephone numbers for Oscar Friedheim Ltd and invites readers to call at the Ludgate, London, showrooms to see the machines working. The company later became Friedheim International Ltd. The book titled “Friedheim, A Century of Service 1884-1984 by Roy Brewer, celebrates Oscar Friedheim’s achievements. Friedheim International currently operates from Hemel Hempstead, on the northern outskirts of London UK. It promotes itself as “… the leading supplier of finishing, converting and packaging machinery to the printing, graphic arts, and highly varied packaging industries in the UK and Ireland. The company’s policy is simple – “employ the best people, work with the best equipment manufacturers in the world, and treat our customers as partners!” The company still sells guillotines. The guillotine is significant for its ability to represent aspects of the printing trade in Warrnambool and in a typical port town circa 1850 to 1910. It represents communication methods and processes used in the time before electrically powered equipment became common in industry.Guillotine (or paper cutter), hand operated. Metal framework with vertical guides, stand and metal mechanical parts including wheels and gears. Table with back guide; handle below front of table winds to move the back guide. A wheel at top of machine winds to adjust pressure of the clamp on the work on the table below it. The cutting blade fits between vertical guides; a timber insert in the table below the blade helps minimise the loss of sharpness of the blade. A handle on the side of the machine turns a large spoked wheel, which rotates a large gear, causing the blade to move up and down. Makers details are on a small oval plaque with embossed maker’s details is screwed onto main body. Maker is O Friedheim, London, and the machine is of German manufacture, circa late 1880’s.Maker’s plaque inscribed "O. FRIEDHEIM / London / German Manufacture"flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, printing machinery, printer’s guillotine, paper guillotine, paper cutter machine, oscar friedheim ltd london, friedheim international ltd, bookbinding industry, printing industry -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageCeramic - Jug, Baker & Co, 1891 to 1893

W Baker and Co-produced many different types of pottery at their Fenton Potteries, Stoke-on-Trent, Staffordshire England. The company was established in 1790 by Ralph Bourne and William Baker the company was working at capacity by the end of the century. By the late 1820's Bourne and Baker, in partnership with John Bourne, had acquired additional works opposite the first in 1833. With the deaths of John Bourne and William Baker, the partnership was dissolved, and then for a short time, the business was carried on by Ralph Bourne and William Baker junior and John Baker. By the early 1840s, William Baker was running it alone and was then using 'machinery for the potteries manufacturing operations in addition to the mill that was producing the raw clay. The business was subsequently carried on by William Baker and Company that were known for the making of printed, sponged, and pearl-white granite ware for export in the early 1880s at the Fenton works between Manor and Fountain Streets. The original works on the south side of City Road were by then an en-caustic tile works, apparently still in the hands of the Baker family. The pottery works flourished under William Baker’s management and by the middle of the nineteenth century with almost 500 employees was the biggest firm in Fenton. An early piece of ironstone Staffordshire pottery now a collector's item showing the types of domestic items that were exported from England to its colonies towards the end of the nineteenth century and into the beginning of the twentieth.Water pitcher ironstone ceramic white with raised embossed Lilly of the valley decoration around handle and lip sections. Marked on bottom, "Royal stone china, Baker and Co, England" with emblem of lion, crown and unicornflagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, jug, kitchen utensil, kitchen ware, water pitcher -

Federation University Historical Collection

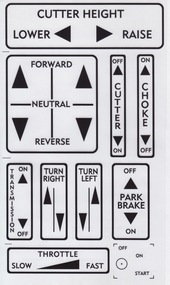

Federation University Historical CollectionArticle - Article - Decal designs for machinery, ZILLES COLLECTION: Decal stencils for parts of a cutting machine

Zilles Printers was begun by Lewis Zilles in the early 1930s. It was in McKenzie Street Ballarat. His son Jeffrey also became a printer - letterpress, offset and screen printer. The business became Zilles Printers/Graphics and was in Armstrong Street and later Bell Street Ballarat. Stencil has sections relating to various parts and functions of a cutting machine. These labels / decals would be placed at appropriate parts for the safe operation of the machine.Frosted sheet with black labelled sectionszilles printers, ballarat, machine, labels, decals, cutter height, choke, cutter, park brake, transmission, throttle, turn right, turn left -

Federation University Historical Collection

Federation University Historical CollectionPhotograph - Photograph - Digital, Geoff Little, Ballarat Gaol Under Demolition, 1968, 1968

The Ballarat Gaol was one of the earliest gaols. Building commenced in 1856 and was completed in 1862. It provided accommodation for 74 prisoners - male and female. The materials use to build the gaol were locally quarried basalt combined with local bricks. At that time there were about 14 brick making plants in Ballarat. 1870 saw the opening of the School of Mines, Australia's third oldest tertiary institution. The purpose of the school was "to impart instruction in the various branches of science relating to mining engineering. It is proposed, as soon as practicable, to extend the operation of the school so as to impart instruction in those branches of technical science which may be considered most likely to exert a beneficial influence on the prosperity of Victoria." School was in a disused Circuit Court House in Lydiard Street South. Sir Redmond Barry was first President of the School of Mines Council.Seven black and white and sepia photographs of the Ballarat Gaol under demolition. Progressive demolition showing rubble and machinery used. Gift of photographer. ballarat gaol, ballarat school of mines, gaol, basalt, local bricks, prisoners, circuit court house, mining engineering, sir redmond barry, lydiard street, tertiary institution, geoff little -

Federation University Historical Collection

Federation University Historical CollectionBook, Stanley B. Hunter, Memoirs of the Geological Survey of Victoria No 7., The Deep Leads of Victoria, 1909

Pink paper covered book by Stanley Hunter, Engineer in Charge of Boring Operations. Contents include tunnelling, deep sinking, the Chiltern Method, the Ballarat Method, Stawell, Ararat, Moyston, Raglan, Wimmera, Landsborough, Avoca, Ballarat West Leads, Berry-Moolort-Loddon Lead System, Clunes, Creswick, Bullarook Affluent, Corinella, Daylesford-Castlemaine Tributary, Majorca-Carisbrook tributary, Huntly, Coliban, Campaspe, Rutherglen., Smythesdale, Durham Lead, Tanjil, Evolution of Mining Machinery, size of claims, Definition of a Deep Lead, Discovery of Gold in Victoria, Geographical Position of Deep Leads, Water in Deep Leads, Methods of Deep Lead Mining, Cost of Deep Lead Mining, Stawell, Ararat, Moyston, Raglan, Wimmera, Landsborough, Avoca, Ballarat West, Berry, Springs Hill, Loddon Valley, Charlotte Plains, , Timor, Burn Creek, Huntly, Colinan, Goulburn, Ovens Valley, Chiltern, Indigo, Morrison's Lead, Plans include: geological Map of Stawell, ararat, Raglan and Landsborough; Kempson's Freehold Mine, Stawell; Geological Map of Beaufort, Avoca, Maryborough, Ballarat west, Berry-Moolort, Loddon, Creswick, Marong, &c; Cardigan Propriety Gold Mine; Working Miners United Gold Mine, Homebush; Hepburn Deep Lead Plan; Madame Berry West Mine; West Berry Consols Mine; Spring Hill and Central Leads; Berry Consols Extended Mine; Loddon Valley Goldfields; Chalk's No 3 Mine; Charlotte Plains Considated Mine; Duke United Mine; Geological Map of Bendigo, Huntley, Campaspe, Malmsbury, Kyneton, trentham, &c; Geological Map of Chiltern, Rutherglan, Eldorado, Beechworth, &c; Chiltern Valley Gold Mine; Wallace Chiltern Valley Consols Mine; great Southern and Chiltern Valley United Mine; great Northern extended Consols; Prentice and Southern deep Leads; Glenfine South Gold Mine; Geological map of Pitfield, Rokewood, Mt Mercer, Ballark, Meredith, &c.; McEvoy Mine; Dargo . . . . . . . . . . . . . . . . . . . . . . . mining, deep leads, squire, tools, gold panning, gold cradle, cradling, puddling, tubbing, mining shaft, shaft sinking, whip, horse whip, whim, horse whim, chalk's no. 1 mine, maryborough, mining cage, shaft, mining trucks, maryborough, washdirt, puddler, tunnelling, deep sinking, chiltern method of working, ballarat method of working, sampling washdirt. gravels, balmoral, mt william, stawell, moyston, great western, ararat, raglan, wimmera valley, landsborough, cardigan, haddon, beaufort, waterloo, avoca, lamplough, caralulup, ballarat west, ballarat, smythesdale, glenfine, illabarook, durham lead, morrison's lead, bullengarook, berry-moolort-loddon system, clunes, creswick, spring hill, bullarook, castlemaine - daylesford, majorca, carisbrook, timor, burnt creek tributary, tarnagulla, marong, rheola, inglewood, huntly, coliban, campaspe, goulburn lead system, ovens valley system, mitta mitta, kiewa valley, tarago, tanjil, moondarra, bogong, dargo high plains -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Company seal embosser, Unknown

The former Albion (West) Woollen and Worsted Mills is a functional structure which has been built in stages, possibly dating from the 1880s, with the earliest sections near to the Barwon River.The Worsted mill operated for about 50 years and at its peak employed around 500 people. In 1973 the mill merged with the British John Foster and Sons Company under some controversial stock and shareholding issues. The mill continued for a short period before closing at a time when much of the Australian textile industry was finding it difficult to compete with overseas operations. In the 30 plus years after the closure, the site was used for several ventures, including the Mill Vintage Markets and a vehicle trim manufacturing operation. In 2011 the site was purchased by Little Creatures of Western Australia to become their main brewery for the eastern states of Australia. Now owned by the Lion Group, Little Creatures started their 60 million dollar transformation of the old mill in 2012. Finally, in 2013 these former walls of industry were soon rattling away to the sounds of a different type of industry, as the first bottles of beer made their way out of the Geelong Little Creatures Brewery. The remaining building of the former Albion Woollen and Worsted Mills has historical significance as one of Geelong's major woollen mills. The venture has operated on the same site for more than a century. The Albion Woollen Mill was one of the four key sites along with Victoria, Barwon and Union Mills that was established in the late 1860s to mid-1870s. These mills were in constant operation on the west side of the Barwon Bridge over the last century and led to Geelong's fame as milling and scouring locality. The Albion Mill was probably the most successful survivor of the early private company operations. It was regarded as a model mill in the late 1880s and was, from all accounts, well-planned and organised with machinery on a par with the great mills of England. It produced high-quality tweeds. Together with the (now demolished) Union Mill it was regarded as the borough's principal industry over the 1870-1900 period and was one of Australia's most significant producers of tweed by 1900. These two mills were more successful, competitive and long-lived than the Barwon and Victoria Mills. The remaining building form is an important reminder of the private ventures of both the Albion and Union Mills and represents a key site of spinning, carding and finishing as well as scouring and dying that occurred in the lower section near to the river. The loss of the adjacent former Union Mill is unfortunate because the complex, together with the former Collins Union Mill office building, was an important reminder of the success of these industries and the reputation they earned for the Geelong region as a centre for quality textile products. Company seal embosser hand operated matte black & brass colour Western District Worsted Mills emblem on frontflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Hand operated embossing document press, 1910

The woollen mill was a vital part of Warrnambool for all but 22 years of the town’s history since it's the establishment in 1847 when the first land sales were held and white settlement began. In 1869 the Warrnambool Meat Preserving Company began operations on the mill site, in 1875, shareholders of the then defunct Warrnambool Meat Preserving Company happily sold the land and buildings on the Merri river to Warrnambool Woollen Mill Company Ltd for £5,000. The site was sold again in 1876 to grazer Robert Hood of Sherwood, who was chairman of directors of the failed company, which couldn’t raise sufficient capital to keep the works operating. The entrepreneurial Hood then used the existing plant to turn his own wool into tweed cloth. But just as the mill was starting to show a profit, a fire destroyed the building and plant on the night of 25 March 1882. So again, the mill was operational for six short years. Insurers only paid a fraction over 10% of the damage, Hood couldn't raise sufficient capital to rebuild on his own, and so the site lay unused until 1910. In 1908 Marcus Saltau and Peter John McGennan convinced the Warrnambool Chamber of Commerce to invest in a secondary industry with local capital. A public meeting in September 1908 agreed to raise £40,000, electing Saltau chairman of directors, a post he held for 34 years. A year later, using mostly local money, the Warrnambool Woollen Mill Company dispatched its first manager, John E. Bennett, to buy a plant and recruit 20 experienced staff from the Yorkshire woollen industry in December 1909. Another year more, the new mill was officially opened on 14 November 1910 by Marcus Saltau as company chairman and town mayor. Eighteen months on, in May 1912, the mill paid its first half-yearly dividend of 2 ½%. It was now working two shifts, with a year's orders to fill. In 1914 the mill ordered its own generator, providing the town with electricity and effectively doubling its plant size by October 1915, six months after Gallipoli. Thereafter, government orders for cloth and military supplies assured the mill’s success right through the First World War and on until 1923. A plant upgrade in 1922 for machinery to make worsted fabric drained profits, which, with a fall in demand, led to a loss in 1925. Profits were restored by the 1930s, despite the Depression, mostly due to tight management and robust marketing. Production boomed again during the Second World War, but soon foreign competition bit into profits, forcing the company to consolidate operations. The ‘50s and ‘60s were golden years for the mill. Security and growth gave the company confidence to trial Australia’s first electric blanket in 1958 and to install Swiss Sulzer looms in 1965. Over time, the building facades took on the modern look that the mill presented until it closed. The Dunlop company bought the mill in 1968, fending off a challenge from Onkaparinga in South Australia, and continued to expand by adding Wendouree Woollen Mill in the same year and Dream-spun Textiles a decade later, in 1979. Soon after that purchase, however, the mill began its slippery slide into decline. Dunlop sold to its former rival bidder Onkaparinga Woollen Co. Ltd in 1982, which in turn was taken over by Macquarie Worsted's only a year later, in 1983. Operations remained stable for a decade until 1994 when the Macquarie Group signaled that its newly rationalised operations left no room for the Warrnambool investment. The final operator of the mill was The Smith Family charity group, which ran the site by agreement with the Warrnambool City Council and a state government grant in that same year, 1994. The mill became more of a fabric recycler than a manufacturer. The site was sold to private operators in February 2003 and rezoned four months later to allow for the mixed housing development. The embossing press is significant for its association with the Warrnambool Woollen Mills 1910-1968, a major employer in the Warrnambool district. The press is also significant as an example of commercial office equipment used in the 19th and 20th century.Press, metal, for Company seal of Warrnambool Woollen Mill, stamping their brand as Western District Worsted Mills Pty Ltd. Metal is black with red and gold floral markings. Inscription of stamp reads "WESTERN DISTRICT WORSTED MILLS PROPRIETRY LIMITED" flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, warrnambool woollen mills, western district worsted mills proprietry limited, worsted fabric, printing press, logo printing press, stamp printing press, shipwreck-coast, flagstaff-hill-maritime-village -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Document - CENTRAL DEBORAH GOLD MINE POSTER

Poster of central Deborah Gold Mine, Bendigo Victoria showing in black and white poppet head. Advertising: Bendigo goldmine open for inspection daily 10am - 5 pm guided tours by appointment phone 438070 or 436401. The Central Deborah gold mine, the last to close on the Bendigo field, was purchased early in 1970m by the Bendigo City Council for restoration and preservation as a typical Bendigo gold mine equipped with machinery , most of which was made in Bendigo. The Central Deborah Company was formed in 1939 to deepen an existing shaft sunk in 1912. Underground operations ceased in 1954. from 1942 to 1954 29,460 ounces of gold was won from 63,962 tons of ore.mine, gold, central deborah gold mine -

Monbulk RSL Sub Branch

Monbulk RSL Sub BranchBook, Salamander Books, Suicide squads: the men and machines of World War II special operations, 1981

An examination of the machinery and motives of self sacrifice during World War TwoIndex, bibliography, ill, diagrams, p.281.non-fictionAn examination of the machinery and motives of self sacrifice during World War Twoworld war 1939 – 1945 – aerial operations - japan, kamikaze attacks -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Leisure object - WOODEN MODEL CYANIDE PLANT

Wooden model of a cyanide plant. A cyanide plant was used for dissolving gold from finely divided ores by means of dilute solutions of sodium or potassium cyanides. The model has five metal bins, there is some rust on the bins and scorch mark on the wooden base.mining, equipment, cyanide plant, gold cyanidation (also known as the cyanide process or the macarthur-forrest process) is a hydrometallurgical technique for extracting gold from low-grade ore by converting the gold to a water-soluble coordination complex. it is the most commonly used leaching process for gold extraction. the ore is comminuted using grinding machinery. depending on the ore, it is sometimes further concentrated by froth flotation or by centrifugal (gravity) concentration. water is added to produce a slurry or pulp. the basic ore slurry can be combined with a solution of sodium cyanide or potassium cyanide, however many operations utilize calcium cyanide, which is more cost effective. to prevent the creation of toxic hydrogen cyanide during processing, slaked lime (calcium hydroxide) or soda (sodium hydroxide) is added to the extracting solution to ensure that the acidity during cyanidation is maintained over ph 10.5 - strongly basic. lead nitrate can improve gold leaching speed and quantity recovered, particularly in processing partially oxidized ores. -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Book - ALBERT RICHARDSON COLLECTION: WANNANS ENGINE DRIVERS GUIDE

Book: red covered book, written on front in gold 'Wannan's Engine-Drivers' Guide'. Written in pencil inside front cover : H.R. Attwood, Alice St., Sunshine and in blue pen 'Hrm Grauz' On further page, Hilliaue Grauz, Gibson Street, Warrnambool. Book contains chapters relating to boilers, operation and accidents.A.C. Wannan, Consulting Engineermachinery, engines- steam, wannan's engine-drivers' guide, richardson, wannan, boilers, mining, mines, engine driver, engineman -

Victorian Interpretive Projects Inc.

Victorian Interpretive Projects Inc.Photograph-colour, LJ Gervasoni, Jubilee Mine Scarsdale Victoria, 19/03/2011

The Jubilee Mine at Scarsdale was started by Thomas Greenwood of Italian Gully.Jubilee Company Quartz Gold Mine has one of the most comprehensive range of quartz mining foundations in the State. The brick and concrete foundations cover pumping, winding and crushing operations, as well as cyaniding of mine tailings. The machinery foundations are the remnants of large scale quartz mining operations carried on at the site between 1899 to 1912. During this time the mine produced over 125,000 ounces of gold and was the district's most important gold mine. (Source Victorian Heritage Register http://vhd.heritage.vic.gov.au/vhd/heritagevic/?timeout=yes#detail_places;5517)colour photograph in digital format showing the brick foundations of the stamping plant at the Jubilee Mine in Scarsdale, Victoria.gold mine mining scarsdale -

National Vietnam Veterans Museum (NVVM)

National Vietnam Veterans Museum (NVVM)Book, Bosiljevac TL, Seals: UDT/SEAL Operations In Vietnam (Copy 2)

When technology and machinery can;t doe the job, it's tine to call in a small group of men.When technology and machinery can;t doe the job, it's tine to call in a small group of men.united states. navy. seals, vietnam -

Puffing Billy Railway

Puffing Billy RailwayV. R. Krupp 1888. IV. Rail, 1888

60lbs rail that was used throughout the Victorian rail network. In 1887 Gibbs, Bright and Co. had a contract with Victorian Railways for railway and canal construction and supply of Krupp Rails. Gibbs, Bright and Co were merchant bankers and shipping agents and merchants who where also Directors of the GWR ( Great Western Railway ) and the Ship The "Great Britain" in England Gibbs, Bright and Company had principally been involved in shipping and trading, mainly in the West Indies, but following the discovery of gold in Victoria they established an office in Melbourne and soon became one of the leading shipping agents and merchants in the Colony. They expanded into passenger shipping and soon established offices in Brisbane, Sydney, Newcastle, Adelaide and Perth as well as launching passenger services between England, Mauritius and New Zealand. Gibbs, Bright also held a number of financial agencies from British mortgage, finance and investment companies as well as representing several British insurance companies in Australia. In addition they conducted a growing import business as well as an export business that included livestock, dairy produce, wool and flour. Also the company played a substantial part in the development of Australia's mineral resources, starting with lead in 1895, and later venturing into tin, gold, copper, cement and super phosphates. In Australia, after WWI, many of the larger companies were managing their own import and export so Gibbs, Bright and Company tended to focus its Agency business on smaller companies while expanding their interest into other markets such as timber, wire netting, zinc, stevedoring, road transport, marine salvage, gold mining as well as mechanical, structural, electrical and marine engineering. The Company's shipping interests continued to grow as well and still formed a major part of its business. In 1948 the parent company in England took the major step from tradition when they changed the business from a partnership into a private limited company. The name was the same, Antony Gibbs and Sons Limited, and in practice the effect of the change was very little. Some of the firm's branches and departments had already become limited companies and the formation of a parent company simplified the structure. The Australian operation was in time changed to Gibbs Bright & Co Pty Ltd in 1963. In 1848 Alfred Krupp becomes the sole proprietor of the company which from 1850 experiences its first major growth surge. In 1849 his equally talented brother Hermann (1814 - 1879) takes over the hardware factory Metallwarenfabrik in Berndorf near Vienna, which Krupp had established together with Alexander Schöller six years earlier. The factory manufactures cutlery in a rolling process developed by the brothers. Krupp's main products are machinery and machine components made of high-quality cast steel, especially equipment for the railroads, most notably the seamless wheel tire, and from 1859 to an increased extent artillery. To secure raw materials and feedstock for his production, Krupp acquires ore deposits, coal mines and iron works. On Alfred Krupp's death in 1887 the company employs 20,200 people. His great business success is based on the quality of the products, systematic measures to secure sales, the use of new cost-effective steel-making techniques, good organization within the company, and the cultivation of a loyal and highly qualified workforce among other things through an extensive company welfare system. From 1878 August Thyssen starts to get involved in processing the products manufactured by Thyssen & Co., including the fabrication of pipes for gas lines. In 1882 he starts rolling sheet at Styrum, for which two years later he sets up a galvanizing shop. The foundation stone for Maschinenfabrik Thyssen & Co. is laid in 1883 with the purchase of a neighboring mechanical engineering company. In 1891 August Thyssen takes the first step toward creating a vertical company at the Gewerkschaft Deutscher Kaiser coal mine in [Duisburg-]Hamborn, which he expands to an integrated iron and steelmaking plant on the River Rhine. Just before the First World War he starts to expand his group internationally (Netherlands, UK, France, Russia, Mediterranean region, Argentina). info from The company thyssenkrupp - History https://www.thyssenkrupp.com/en/company/history/the-founding-families/alfred-krupp.htmlHistoric - Victorian Railways - Track Rail - made by Krupp in 1888Section of VR Krupp 1888 Rail mounted on a piece of varnished wood. Rail made of ironpuffing billy, krupp, rail, victorian railways -

El Dorado Museum Association Inc.

El Dorado Museum Association Inc.Photograph (item) - Digital Image

Cocks Pioneer Engine c1930s. Cocks Pioneer Electric Gold & Tin Mine Company was formed in 1899. The company's first power station, located at the eastern end of the valley began operating with its 340 Kilowatt steam-powered generator. By 1909, from 2,500,000 cubic yards worked, reported recovery was 17,284 ounces of gold and 224 tons of tin ore. By 1909, Cocks Pioneer’s power plant had become inadequate and uneconomical. The barge was floated downstream about a mile, but lost time caused the operations to cease. Following testing, a new mine was established by diverting Reid's Creek at a cost of £25 000. Settling dams were built, one of which held 1,,935,900 cubic feet. Sold earth banks, built against a wall of stringy bark saplings constructed and laced with vertical props, were built. In 1914, the company was reformed as Cock’s Pioneer Gold and Tin Mines NL, another power station was constructed at the western end of the township, near the junction of Clear and Reid's Creeks. From 6,800,000 cubic yards of material processed, the returns were 64,397 ounces of gold and 855 ton of tin. Cocks Pioneer mine then moved the barge downs stream and continued sluicing. In 1929 Cocks Pioneer Electric Gold and Tin Mining Company ceased operations due to a drop in values. Cock’s Pioneer Gold and Tin Mines NL carried on large-scale hydraulic sluicing operations until 1941. mining, gold, tin, gold mining, tin mining, machinery, engines, men, cocks pioneer, el dorado, eldorado -

National Wool Museum

National Wool MuseumFolder, Northrop

Folder containing sheets of information on parts, and instruction sheets for the operation of the different facets of the Northrop loom.Folder containing sheets of information on parts, and instruction sheets for the operation of the different facets of the Northrop loom.Northroptextile machinery, british northrop loom co. limited, weaving looms, weaving machinery