Showing 50 items

matching pottery classes

-

Eltham District Historical Society Inc

Eltham District Historical Society IncPhotograph, Pottery Class, Eltham Living and Learning Centre, October 1988, 1988

... Pottery Class, Eltham Living and Learning Centre, October...pottery class... melbourne classes eltham living and learning centre pottery class ...Roll of 35mm colour negative film, 6 stripsFuji 100classes, eltham, living and learning centre, pottery class -

Federation University Historical Collection

Federation University Historical CollectionPhotograph - Photograph - black and white, Ballarat School of Mines Ceramics Class, early 1940s

Ceramics was taught at the Ballarat School of Mines Technical Arts School. A number of ceramics students work in the Ballarat School of Mines Technical Art School Ceramics Studio. Six students sit at a work bench undertake handbuilt pottery. Five students sit at pottery wheels, while tutor Neville Bunning stands and oversees (far right corner).ballarat school of mines, ballarat technical art school, art, ceramics, pottery, neville bunning, visual arts -

Federation University Historical Collection

Federation University Historical CollectionBook - Scrapbook, Ballarat School of Mines Scrap Book, 1916-1920, 1916-1920

Red hardcovered scrapbook with news clippings relating to the Ballarat School of Mines.ballarat school of mines, world war one, news clippings, scrapbook, william e. moon, john h. smyth, david l. thomas, clay, maurice copland, repatriation, g. buchanan, j.m. bickett, harrie wood, cliff garrad, harold c. cornell, f.g. marriott, technical education, classes for soldiers, w.h. middleton, e.j. cannon, ted cannon, ponsonby carew-smythe, boer war memorial, amalie feild, antarctica, fred middleton, richard vale obituary, rand, stephen richards, richard g. walker, world war one chemists, frank tate, free instruction for soldiers, ken moss, girls' preparatory, eureka stockade pageant commitee, fred g. middleton, shackelton relief party, aurora, emil gutheil obituary, henry james hall obituary, william elphick moon, arthur tandy, john mcwhae, harold bieske, james millhinch bickett obituary, wild flower show, technical schools conference, ballarat, allan t. perry, ballarat pottery clay, citizen soldiers' camp, george buchanan obituary, clifford garrard, james dyer woolcott obituary, frank penhalluriack, w.s> penhalluriack, annie whitla, ballarat school of mines jubilee, anniversary, university classes, maurice copland obituary, boot repairing, museum rennovation, bootmaking, f.g. marriott obituary, vocational training classes, j.d. woolcott obituary, ferdinand krause obituary, ferdinand krause, emil guthiel, cornell, spanish flu, pneumonic flu, pandemic -

Federation University Historical Collection

Federation University Historical CollectionBook, Victoria Education Gazette and Teachers' Aid, 1921-1930, 1921-1930

The Victoria Education Gazette and Teachers' Aid was published for Victoria's teachers and was sent to all school on the state. In 1920 The Ballarat School of Mines had donated 136 pounds 14 shillings and 10 pence to the Victorian Education Department's War Relief Account, and the Ballarat Junior Technical School had donated 10 pounds 6 shillings and 10 pence.Ten black hard covered volumes with red tape spine, covering 1921 to 1930. The gazettes include Education Department appointments, transfers, resignations and retirements, vacancies, notices, queries, notices of books, examination papers, original articles, lesson plans, suggestions for lessons, drawing, obituaries, notes on nature study, mathematics, music, sloyd woodwork, English grammar, Victorian State School Swimming Clubs, Geography, penmanship, science, History, Latin, Geography, The School Garden, horticulture, singing, World War One; ANZAC Day, lifesaving, Astronomy, Empire Day, ANZAC Buffet London, Victorian Education Department's War Relief Fund .1) 1928. Articles include: New Caledonia, Swimming and Lifesaving, School forestry, a visit to the pyramids, Exploration of Gippsland, paul de Strezelecki, Angus McMillan, Villers Bretonneux Memorial School, American Black Walnut, Red Gum, Messmate Stringybark, The Great Barrier Reef, retirement of Frank Tate, Stawell High School, Report on Some Aspects of Education in the United States, Jubilee Education Exhibition , New School Readers; measured Drawing Images include: Macarthur Street School's Plantation, Maryborough School Plantation, Pinus Insignis (Radiata) ready for Milling, Creswick State Forest, Metalwork, Daylesford Pine Plantation four years old, Henry Harvey (art Inspector); Omeo School Endowment Plantation; Frank Tate; Stawell High School Drawings From Casts; Lake Tyers School Endowment Plantation, measured drawing, Thomas H. Stuart, GEorge Swinburne. J.R. Tantham-Fryer, Cookery Class, John Edward Thomas. .3) War Savings Stampsm Swimming and Life-saving, Teh Rural School System of Victoria, Imaginative Composition, ANZAC Day, Retardation, Teh Bright Child Hudson Hard Obituary, Leeches, Relief for Distress in Europe, Dental, Teachers' Library, History of Portarlington, J.E. Stevens Obituary, Victorian Teachers in England Images: Swimming and Life-Saving Medallion .3) Swimming and Lifesaving, Bronze medallion, Victoria Leage of Victori, War Savings Stamps, Rural School Sytem of Victoria, .4) War Relief, Talbot Colony for Epileptics Masonmeadows, Discipline New and Old (Percy Samson), Soldier teachers, Preservation of Australian Birds, Arbor Day, Jubilee of Free Education, Teaching Geography, Poery in Schools, School Committees, Shelter Pavilion, Mysia Memorial School, Clovers, Jubilee Exhibition, Domestic Arts, Louis Pasteur, .5) Victoria League of Victoria, An Endowment Scheme (Pine Plantations), School Endowment Plantations, Protecting our trees by Owen Jones,. Victorian State Schools Horticultural Society, Sloyd Woodwork, School Forestry, Thomas Brodribb Obituary and portrait, Imperial Education Conference London, school Management and Method, School plantations, Eucalypt plantations in the Bendix and Heathcote District, Junior Red Cross, Jubilee Education Exhibition, Gould League Competitions, handwriting, The School Magazine, Frank Tate in London, Victorian beetles, Council of Public Education, Villers Bretonneux and its new School, Death of Samuel Summons, Woodwork Summer School, Swimming, Japanese Relief Fund, Retirement of John Cross, reminiscences of the Late Mr Albert Mattingley .6) Thomas H. Trengrove and the Villers Bretonneux School hall and pilaster carvings, forestry, visit of Maryborough teachers to Ballarat Water Reserves, noxious weeds, relief for Distressed Europe, The Dalton Plan, Empire Day, Retirement of Mr Fussell, Centenary of Hume and Hovell Expedition, League of Kindness, Effective Nature Study in a Rural School, Some Facts About Paper and their Bearing Upon School Plantations, Council of the Working Men's College Melbourne, Maria Montessori, University Vacation School, Horticulture in State Schools, An Informal Chat About French Schools (C.R. McRae), The Vacation School, Johann Heinrich Pestalozzi, Inspector's Report on a 5th-class School, Can Children Write Verse, John Adams, Victoria League of Victoria, R.F. Toutcher, Sir James Barbie's Address to High-School Girls, Impressions of a High School Teacher Abroad (R.D. Collman), The Spirit of the School Plantation Scheme, Monument of the Late Mr and Mrs A.T. Sharp at Box Hill Cemetery, The Teaching of Geography, The Treatment of Poetry in Class, Two Difficult Arithmetic Lessons, Location of Principal Australian Timbers, Dr John Smyth, Stammering and its Influence on Education, Wireless Broadcasting as an Educational Medium, Boys School at Villers Brettonneux, The New School at Villers Brettonneux, Bird Day, Messmate or Stringybark, What Every Woman Knows, Director's Report on Denmark .7)1925 . Includes: School Forestry, horticulture, J.H. Betheras retirement, Ivanhoe School, Coburg School, Moorabool Junior Technical School, Villers Bretonneux School hall and pilaster carvings, Francis Ormond, William Charles Kernot, Corsican Pnes at Creswick, Ballarat High School Plantation, Workin Men's College, RMIT, Naorrow LEafed Peppermint, Education and World Peace, Eucalypts of Victoria, John C. Eccles, Blue Gum. Manners, Giving the Poorly Nourished Boy A Chance, Native Ferns, Marybourough Technical School, Memorial School at Villers-Brettonneux .8) Experimental Plots in Country Schools (W.W. Gay), Villers Bretonneaux and its Memorial School. nominated classes for Art Teachers, The Teachers Act 1925, Horsham High School, Richmond Technical School, Farewell to Messrs C.R. Long and Ponsonby Carew-Smyth, Frank Tate, Phyiscal Training, Arbor Day, ANZAC Day, Shakespeare Day,Bendigo Junior Techncial School, Musical Appreciation, Motor Dental Unit, School Camps, Education Act of 1872: Mr Angus McKay's Part (George Mackay), A Bush Fire Experience (Irene Stable), Black Sunday, Californian Red Pine, Women's Education in America, Farewell to Lord and Lady Stradbroke, Grevilia Robusta, Silky Oak, Redwood, John E. Grant, The Need for Research (Donald Clark), Junior Drama, Ida D. Marshall, John Pounds, Australian Books, Fish Creek School, State Boundaries, History in the Curriculum, Ceramic Art in Australia (Percy E. Everett), Choice of School Songs, Tasmanian Beech, Should History be Taught on a National or an International Basis, Hydatid Disease, James Holland Obituary, Florrie Hodges, Queensland Maple, Post Bushfire Ruins at Fumina, Arbor Day at Fumina, Queensland Rosewood, Omeo Endowment Plantation, Bird Day, Junior Red Cross, Pioneers' Day, Edward Henty, Junior Technical Schools, Yellow Pine, History and Progress of Needlework, A.B.C. of Astronomy, Northumberland Mental tests, Queensland Red Cedar, Teh Globe Theatre, .9) 1927 includes The ABC of Astronomy, Atr Theatre, English Beech, Angus McMillan Art Pottery, School Singing, State Schools' Nursery, School endowment plantations, Making a Man, experimental proof of Charles's Law, John Smyth obituary and portrait, Linton Pine Planation, motivation of arithmetic, Women's Classes at Dookie, Swimming and Lifesaving, Pioneers Day, Drawing, Ballarat High School planation, biting fly, Tir-Na-N'og, John Byatt retirement and portrait, Technical Schools Conference at Daylesford, Ethel Osborne and portrait, library. Francis Thompson portrait, Adam Lindsay Gordon, Solar movement, motor transport, Liverpool Cathedral, Teh Story of the Cathedral, Bendigo School of Mines, Omeo School pine plantation, Egypt and the Nile, Self-Criticism Images include Ballarat High School Pine Plantation, Vale Park, Francis Ormond, Woking Men's College (RMIT), W.N. Kernot, A Stand of Corsican Pines at Creswick, Victoria .10) Some Remarks on the Relationship of the technical Schools to the University (Donald Clark) , Present Day Education in England , Memorial to Joseph Cornwall, Spelling, motivation, Singing, State Scholarships, Agriculture, T.W. Bothroyd, The Swimmer - A Summer School Sketch (H.H. Croll), Swimming woodwork, Farewell to Dr Sutton. ,Drowning, War Savings Movement, White Beech. George S. Browne , Example of School Honor Book, Blackwood, Optimistic teacher, Soldier settlement around Shapparton, Oral Hygiene, Cinema Machines, Basketball, Wakter M. Camble obituary, ANZAC day Pilgrimage in England, Froebel's System, Montessori Method, War Relief Fund, New Zealand Kauri Tree, Bat Tenis at a Bush School., Advice to Australian Girls, Chrysanthemums, Royal Visit, National Parks of Victoria, Maurice Copland Obituary, total eclipse of the Moon, School libraries, The teacher and the COmmunity (A.M. Barry), The Reading Lesson, Swimming and Life-saving, MElbourne Teachers' College War Memorial Windows Old Trainees War Memorial, Cultivating a Natinoal Art education gazette, school, education, teaching, teacher, world war one, school plantations, macarthur street pine plantation, school forestry, creswick state forest, anzac day, armistance celebrations, frank tate, frank tate retirement, drawing from cast, education department school readers, lake tyers pine plantation, w.n. kernot, rmit, working men's college, francis ormond, pine plantations, calenbeem park, creswick, villers-brettonneux school hall and carvings, thomas trengrove, corsican pines, creswick, pine endowment plantations, mccarthur st primary school pine plantation, ballarat high school pine plantation, vale park, mount pleasant primary school pine plantation, golden point pine plantation, angus macmillan, paul de strzelecki, gippsland, villers-bretonneaux memorial school, francis thompson, english ash, pestalozzi centenary, shakespeare day, swimming classes, clear pine, cinema in education, american black walnut, red gum, thomas wolliam bothroyd obituary, and portrait, physical training displays, teaching of spelling, ohm's law, blue gum -

Federation University Historical Collection

Federation University Historical CollectionDocument, Waller and Chester, Ballarat School of Mines and Industries Ballarat: The Art School, c1948, c1948

Entrance requirements for a full-course student was an Intermediate Certificate of equivalent. The Certificate of Art was a two year course of basic study to enable students to undertake a further two years of specialised training in a chosen field of art. The Diploma of Art was a two-year course of specialised training available to students, who have passed the Certificate of Art Examination or its equivalent. Candidates of the examination must be at least 19 years of age, must have completed two years' full -time training or not less than three years' part-time training, and must present for the Matriculation examination for English Expression. Part-Time classes at the Ballarat Technical Art School c1948 were: Day: Dressmaking, Weaving, Leatherwork, Pottery, Metalwork, Painting, Sculpture, Junior Art. Evening: Dressmaking, Weaving, Leatherwork, pottery, Metalwork, Painting, Sculpture, Ticket Writing, Lettering, Figure Drawing. Two fold, 6 page information flyer on classes held at the Ballarat Technical Art School. The Art school offered Diploma of Art, Certificate of Art and Part-time classes.ballarat technical art school, art, diploma of art, certificate of art, part-time classes, syllabus, design, scholarships, diploma of art in pottery, diploma of art in advertising, art education, dressmaking, weaving, leatherwork, pottery, metalwork, painting, sculpture, junior art, dressmaking, weaving, leatherwork, pottery, metalwork, painting, sculpture, ticket writing, lettering, figure drawing -

Federation University Historical Collection

Federation University Historical CollectionBook - Book - ledger, Ballarat School of Mines Council Minutes, 1946-1949, 1946-1949

SMB Library establishment - P.58 Former Ballarat Supreme Court House - p64 Red Cross Hut - p.69, p. 80 SMB Art Society, p.106 SMB Bicycle Shed - p. 109A larger quarter leather bound ledger with handwritten minutes of the Ballarat School of Mines Council. Pg. 8 - Retirement of Principal pg. 17 - Bicycle Accommodation Pg 24 - Visit of Minister of Public Instruction the Hon, F. Field pg. 32 - Interview with A.A. Robertson pg 46 - Congratulations to Ken Palmer for securing the commission for the execution of a bust for the Avenue Prime Ministers at the Ballarat Botanical Gardens. pg 64 - Former Ballarat Supreme Court pg 69 - Red Cross Hut pf 74 - Radio Mechanics pg 104 - Act of Remembrance for BevanA. John Pg 104 - Cobb & Co Coach pg 105 - Site for new Junior Technical School pg 109 - Dr Sydney Pern's collection to Native Weapons pg 120 - The late Bevan A. John pg 122 - Transfer of the Electrical Department to the former Ballarat Supreme Courthouse pg 129 - Pottery room pg 140 - The late D. Maxwell pg 145 - Dr Pound's Resignation pg 146 - Endowment Plantation pg 168 - Art School LIbrary pg 171 - Appointment of Principal - Richard W. Richards pg 237 - Farewell to Dr. J.R. Pound pg 241 - Architecture Course pg 270 - Appointment of E.J. Barker ballarat school of mines, ballarat school of mines minutes, e.j. tippett, m.g. beanland, k. sutton, a. heseltine, n. callow, m.b. john, d. maxwell, ballarat technical art school, bicycle accommodation, hollway, l. lederman, l.j. wilson, linotype machine, harry brew, dressmaking, reconstruction training, f. field, blacksmithing, gas heaters, d. taylor kellock, neville bunning, moulding class, a.a. robertson, gas fired kiln, d.i. johnston, entrance signboard, r.w. richards, kenpalmer, prime ministers avenue, e.g. savage appointment, r. calder resignation, brick class room, red cross hut, radio mechanics, cobb and co coach, a.m. wilkenson, b. bryan, beven a. john obituary, art society, d. maxwell resignation, pern collection of native weapons, ceramics, pottery, donald i. johnston, donald i johnston resignation -

Federation University Historical Collection

Federation University Historical CollectionBook, Ballarat Technical Art School Register, 1955-1971, 1955-1971

The Ballarat Technical Art School (No. 10) was a division of the Ballarat School of Mines. Green ledger with black spine. Lists Student Number, Name, Trade or Occupation, Age at Last Birthday, Address, Date of Joining the School, Course Work. Courses listed include dressmaking, Elementary Art, Ticket Writing, Shorthand, Drawing, Pottery and Drawing. Pottery, Millinery. Junior Art, Building Construction, Matriculation Art, Needlework, Painting, Life Class, Decorative Needlework, General Art Course, Sculptureballarat technical art school, art general register, student enrolments, alumni, art studies, ballarat school of mines -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Plate

The Process of Making Pottery Decorating, Firing, Glazing, Making, Technical There is a rhythm and flow to clay. It can’t be done all at once! Even the making process! It can take weeks to get everything done, especially if you can only work on your pottery once a week! Even though we have three hour classes, it’s often just not enough time! Here is an overview of some of the processes so you have a bit more grasp on some of the technical stuff! Step One – Design There are SO many ideas out there for making stuff in clay! From delicate porcelain jewellery, through to heavy sculptural work and everything in between. Deciding your direction is sometimes not that easy – when you first start, try everything, you will naturally gravitate to the style that you enjoy! The options and variations are endless and can get a wee bit overwhelming too! Check in with me before you start to ensure your ideas will work, what order you might do things, how you could achieve the look you are seeking and any other technical data required! Step Two – Making Clay is thixotropic. This means that as you work with it, the clay first gets sloppier and wetter, before is begins to dry in the atmosphere. For most things, you simply can’t do all parts of the project at once. An example of work order might look like: Get last weeks work out from the shelves Prepare clay for today’s work – roll your clay, prepare balls for throwing, make the first stage of a pinch pot) Clean up last week’s work and put it on the shelf for bisque firing Check that you have any glazing to do – and do enough of it that you will have time to finish your main project Do the next step of your next project – there might be a further step that can’t be complete immediately, in that case, wrap your work well and put onto the shelves. Letting your work rest for a while can really help keep your work clean and professional looking. Many things require bagging under plastic to keep it ready for work the next week – put your name on the outside of the bag so you can find your work easily. We have stickers and markers. Consider how you want to decorate your work – coloured slip can be applied at a fairly wet stage (remembering that it will make your work even wetter!). Trying to apply slip to dry clay won’t work! If you want to do sgraffito – you will need to keep the work leather hard (a state of dryness where you can still work the clay with a little effort and a little water and care). Step Three – Drying Most of the time your work can go into the rack uncovered to let it dry out for the following week. If you want to continue forming or shaping you will need to double bag your work – put your work on a suitable sized bat and put the bat in a bag so the base of the bag is under the bat, then put another bag over the top of the work and tuck the top of the bag under the bat. If you want to trim (or turn) your thrown work the following week, it should also be double bagged. If your work is large, delicate, or of uneven thicknesses, you should lightly cover your work for drying. When considering the drying process, bare in mind the weather, humidity and wind! The hotter and dryer, the faster things dry and work can dry unevenly in the shelves – this can lead to cracking – another time to lightly cover your work for drying. Step Four – Trimming and Cleaning Up Your work is dry! It is called greenware now and it is at it’s most fragile! Handle everything with two hands. I often refer to soft hands – keep everything gentle and with your fingers spread as much as possible. Try to not pick up things like plates too much, and always with both hands! Before your work can be bisque fired it should be “cleaned up”. You work won’t go into the kiln if it has sharp edges – when glazed, sharp edges turn into razor blades! Use a piece of fly wire to rub the work all over – this will scratch a little so be light handed. Use a knife or metal kidney to scrape any areas that require a bit more dynamic treatment than the fly wire offers! Finally, a very light wipe over with a slightly damp sponge can help soften and soothe all of your edges and dags! Trimming thrown work: If you are planning to trim (or turn) your thrown work (and you should be), make sure you bag it well – your work should be leather hard to almost dry for easiest trimming. Use this step to finish the work completely – use a metal kidney to polish the surface, or a slightly damp sponge to give a freshly thrown look. Wipe the sponge around the rim after trimming, and check the inside of the pot for dags! Trimming slip cast work: Usually I will trim the rims of your work on the wheel the following day to make that stage easier, however you will still need to check your work for lumps and bumps. Last but not least – check that your name is still clearly on the bottom of your work. Step Five – Bisque Firing When the work is completely dry it can go into the bisque kiln. The bisque kiln is fired to 1000°C. This process burns off the water in the clay as well as some of the chemically bound water. The structure of the clay is not altered that much at this temperature. Inside the bisque kiln, the work is stacked a little, small bowl inside a larger bowl and onto a heavy plate. Smaller items like decorations or drink coasters might get stacked several high. Consideration is paid to the weight of the stack and shape of the work. A bisque kiln can fire about one and a half times the amount of work that the glaze kiln can fire. The firing takes about 10 hours to complete the cycle and about two days to cool down. Once it has been emptied the work is placed in the glaze room ready for you to decorate! Step Six – Glazing Decorating your work with colour can be a lot of fun – and time consuming! There are three main options for surface treatment at this stage: Oxide Washes Underglazes Glazes Washes and underglazes do not “glaze” the work – It will still need a layer of glaze to fully seal the clay (washes don’t need glaze on surfaces not designed for food or liquid as they can gloss up a little on their own). Underglazes are stable colourants that turn out pretty much how they look in the jar. They can be mixed with each other to form other colours and can be used like water colours to paint onto your work. Mostly they should have a clear glaze on top to seal them. Oxides are a different species – the pink oxide (cobalt) wash turns out bright blue for instance. They don’t always need a glaze on top, and some glazes can change the colour of the wash! The glazes need no other “glaze” on top! Be careful of unknown glaze interactions – you can put any combination of glaze in a bowl or on a plate, but only a single glaze on the outside of any vertical surface! Glazes are a chemical reaction under heat. We don’t know the exact chemicals in the Mayco glazes we use. I can guess by the way they interact with each other, however, on the whole, you need to test every idea you have, and not run the test on a vertical surface! Simply put, glaze is a layer of glass like substance that bonds with the clay underneath. Clay is made of silica, alumina and water. Glaze is made of mostly silica. Silica has a melting point of 1700°C and we fire to 1240°C. The silica requires a “flux” to help it melt at the lower temperature. Fluxes can be all sorts of chemicals – a common one is calcium – calcium has a melting point of 2500°C, however, together they both melt at a much lower temperature! Colourants are metal oxides like cobalt (blue), chrome (green through black), copper (green, blue, even red!), manganese (black, purple and pink) iron (red brown), etc. Different chemicals in the glaze can have dramatic effects. for example, barium carbonate (which we don’t use) turns manganese bright pink! Other elements can turn manganese dioxide brown, blue, purple and reddish brown. Manganese dioxide is a flux in and of itself as well. So, glazes that get their black and purple colours, often interact with other glazes and RUN! Our mirror black is a good example – it mixes really well with many glazes because it fluxes them – causes them to melt faster. It will also bring out many beautiful colours in the glazes because it’s black colouring most definitely comes from manganese dioxide! Glaze chemistry is a whole subject on it’s own! We use commercial Mayco glazes on purpose – for their huge range of colour possibilities, stability, cool interactions, artistic freedom with the ability to easily brush the glazes on and ease of use. We currently have almost 50 glazes on hand! A major project is to test the interactions of all glazes with each other. That is 2,500 test tiles!!!! I’m going to make the wall behind the wheels the feature wall of pretty colours! Step Seven – Glaze (Gloss or sometimes called “Glost”) Firing Most of the time this is the final stage of making your creation (but not always!) The glaze kiln goes to 1240°C. This is called cone 6, or midrange. It is the low end of stoneware temperatures. Stoneware clays and glazes are typically fired at cone 8 – 10, that is 1260 – 1290°C. The energy requirement to go from 1240°C to 1280°C is almost a 30% more! Our clay is formulated to vitrify (mature, turn “glass-like”) at 1240°, as are our glazes. A glaze kiln take around 12 hours to reach temperature and two to three days to cool down. Sometimes a third firing process is required – this is for decoration that is added to work after the glaze firing. For example – adding precious metals and lustres. this firing temperature is usually around 600 – 800°C depending upon the techniques being used. There are many students interested in gold and silver trims – we will be doing this third type of firing soon! After firing your work will be in the student finished work shelves. Remember to pay for it before you head out the door! There is a small extra charge for using porcelain clay (it’s more than twice the price of regular clay), and for any third firing process! Once your work has been fired it can not turn back into clay for millennia – so don’t fire it if you don’t like it! Put it in the bucket for recycling. https://firebirdstudios.com.au/the-process-of-making-pottery/Ceramics have evolved over thousands of years.White earthenware dinner plate. Crazing evident all over.Backstamped ‘Made in England S LTD’flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, ceramics, tableware -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Plate, Johnson Bros

The Process of Making Pottery Decorating, Firing, Glazing, Making, Technical There is a rhythm and flow to clay. It can’t be done all at once! Even the making process! It can take weeks to get everything done, especially if you can only work on your pottery once a week! Even though we have three hour classes, it’s often just not enough time! Here is an overview of some of the processes so you have a bit more grasp on some of the technical stuff! Step One – Design There are SO many ideas out there for making stuff in clay! From delicate porcelain jewellery, through to heavy sculptural work and everything in between. Deciding your direction is sometimes not that easy – when you first start, try everything, you will naturally gravitate to the style that you enjoy! The options and variations are endless and can get a wee bit overwhelming too! Check in with me before you start to ensure your ideas will work, what order you might do things, how you could achieve the look you are seeking and any other technical data required! Step Two – Making Clay is thixotropic. This means that as you work with it, the clay first gets sloppier and wetter, before is begins to dry in the atmosphere. For most things, you simply can’t do all parts of the project at once. An example of work order might look like: Get last weeks work out from the shelves Prepare clay for today’s work – roll your clay, prepare balls for throwing, make the first stage of a pinch pot) Clean up last week’s work and put it on the shelf for bisque firing Check that you have any glazing to do – and do enough of it that you will have time to finish your main project Do the next step of your next project – there might be a further step that can’t be complete immediately, in that case, wrap your work well and put onto the shelves. Letting your work rest for a while can really help keep your work clean and professional looking. Many things require bagging under plastic to keep it ready for work the next week – put your name on the outside of the bag so you can find your work easily. We have stickers and markers. Consider how you want to decorate your work – coloured slip can be applied at a fairly wet stage (remembering that it will make your work even wetter!). Trying to apply slip to dry clay won’t work! If you want to do sgraffito – you will need to keep the work leather hard (a state of dryness where you can still work the clay with a little effort and a little water and care). Step Three – Drying Most of the time your work can go into the rack uncovered to let it dry out for the following week. If you want to continue forming or shaping you will need to double bag your work – put your work on a suitable sized bat and put the bat in a bag so the base of the bag is under the bat, then put another bag over the top of the work and tuck the top of the bag under the bat. If you want to trim (or turn) your thrown work the following week, it should also be double bagged. If your work is large, delicate, or of uneven thicknesses, you should lightly cover your work for drying. When considering the drying process, bare in mind the weather, humidity and wind! The hotter and dryer, the faster things dry and work can dry unevenly in the shelves – this can lead to cracking – another time to lightly cover your work for drying. Step Four – Trimming and Cleaning Up Your work is dry! It is called greenware now and it is at it’s most fragile! Handle everything with two hands. I often refer to soft hands – keep everything gentle and with your fingers spread as much as possible. Try to not pick up things like plates too much, and always with both hands! Before your work can be bisque fired it should be “cleaned up”. You work won’t go into the kiln if it has sharp edges – when glazed, sharp edges turn into razor blades! Use a piece of fly wire to rub the work all over – this will scratch a little so be light handed. Use a knife or metal kidney to scrape any areas that require a bit more dynamic treatment than the fly wire offers! Finally, a very light wipe over with a slightly damp sponge can help soften and soothe all of your edges and dags! Trimming thrown work: If you are planning to trim (or turn) your thrown work (and you should be), make sure you bag it well – your work should be leather hard to almost dry for easiest trimming. Use this step to finish the work completely – use a metal kidney to polish the surface, or a slightly damp sponge to give a freshly thrown look. Wipe the sponge around the rim after trimming, and check the inside of the pot for dags! Trimming slip cast work: Usually I will trim the rims of your work on the wheel the following day to make that stage easier, however you will still need to check your work for lumps and bumps. Last but not least – check that your name is still clearly on the bottom of your work. Step Five – Bisque Firing When the work is completely dry it can go into the bisque kiln. The bisque kiln is fired to 1000°C. This process burns off the water in the clay as well as some of the chemically bound water. The structure of the clay is not altered that much at this temperature. Inside the bisque kiln, the work is stacked a little, small bowl inside a larger bowl and onto a heavy plate. Smaller items like decorations or drink coasters might get stacked several high. Consideration is paid to the weight of the stack and shape of the work. A bisque kiln can fire about one and a half times the amount of work that the glaze kiln can fire. The firing takes about 10 hours to complete the cycle and about two days to cool down. Once it has been emptied the work is placed in the glaze room ready for you to decorate! Step Six – Glazing Decorating your work with colour can be a lot of fun – and time consuming! There are three main options for surface treatment at this stage: Oxide Washes Underglazes Glazes Washes and underglazes do not “glaze” the work – It will still need a layer of glaze to fully seal the clay (washes don’t need glaze on surfaces not designed for food or liquid as they can gloss up a little on their own). Underglazes are stable colourants that turn out pretty much how they look in the jar. They can be mixed with each other to form other colours and can be used like water colours to paint onto your work. Mostly they should have a clear glaze on top to seal them. Oxides are a different species – the pink oxide (cobalt) wash turns out bright blue for instance. They don’t always need a glaze on top, and some glazes can change the colour of the wash! The glazes need no other “glaze” on top! Be careful of unknown glaze interactions – you can put any combination of glaze in a bowl or on a plate, but only a single glaze on the outside of any vertical surface! Glazes are a chemical reaction under heat. We don’t know the exact chemicals in the Mayco glazes we use. I can guess by the way they interact with each other, however, on the whole, you need to test every idea you have, and not run the test on a vertical surface! Simply put, glaze is a layer of glass like substance that bonds with the clay underneath. Clay is made of silica, alumina and water. Glaze is made of mostly silica. Silica has a melting point of 1700°C and we fire to 1240°C. The silica requires a “flux” to help it melt at the lower temperature. Fluxes can be all sorts of chemicals – a common one is calcium – calcium has a melting point of 2500°C, however, together they both melt at a much lower temperature! Colourants are metal oxides like cobalt (blue), chrome (green through black), copper (green, blue, even red!), manganese (black, purple and pink) iron (red brown), etc. Different chemicals in the glaze can have dramatic effects. for example, barium carbonate (which we don’t use) turns manganese bright pink! Other elements can turn manganese dioxide brown, blue, purple and reddish brown. Manganese dioxide is a flux in and of itself as well. So, glazes that get their black and purple colours, often interact with other glazes and RUN! Our mirror black is a good example – it mixes really well with many glazes because it fluxes them – causes them to melt faster. It will also bring out many beautiful colours in the glazes because it’s black colouring most definitely comes from manganese dioxide! Glaze chemistry is a whole subject on it’s own! We use commercial Mayco glazes on purpose – for their huge range of colour possibilities, stability, cool interactions, artistic freedom with the ability to easily brush the glazes on and ease of use. We currently have almost 50 glazes on hand! A major project is to test the interactions of all glazes with each other. That is 2,500 test tiles!!!! I’m going to make the wall behind the wheels the feature wall of pretty colours! Step Seven – Glaze (Gloss or sometimes called “Glost”) Firing Most of the time this is the final stage of making your creation (but not always!) The glaze kiln goes to 1240°C. This is called cone 6, or midrange. It is the low end of stoneware temperatures. Stoneware clays and glazes are typically fired at cone 8 – 10, that is 1260 – 1290°C. The energy requirement to go from 1240°C to 1280°C is almost a 30% more! Our clay is formulated to vitrify (mature, turn “glass-like”) at 1240°, as are our glazes. A glaze kiln take around 12 hours to reach temperature and two to three days to cool down. Sometimes a third firing process is required – this is for decoration that is added to work after the glaze firing. For example – adding precious metals and lustres. this firing temperature is usually around 600 – 800°C depending upon the techniques being used. There are many students interested in gold and silver trims – we will be doing this third type of firing soon! After firing your work will be in the student finished work shelves. Remember to pay for it before you head out the door! There is a small extra charge for using porcelain clay (it’s more than twice the price of regular clay), and for any third firing process! Once your work has been fired it can not turn back into clay for millennia – so don’t fire it if you don’t like it! Put it in the bucket for recycling. https://firebirdstudios.com.au/the-process-of-making-pottery/Ceramics have evolved over thousands of years.A white earthenware side plate with a gadroon edge. Has water marks and chips on front.‘Johnson Bros England Reg No 15587’flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, johnson bros, ceramics, tableware -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Plate, Alfred Meakin

The Process of Making Pottery Decorating, Firing, Glazing, Making, Technical There is a rhythm and flow to clay. It can’t be done all at once! Even the making process! It can take weeks to get everything done, especially if you can only work on your pottery once a week! Even though we have three hour classes, it’s often just not enough time! Here is an overview of some of the processes so you have a bit more grasp on some of the technical stuff! Step One – Design There are SO many ideas out there for making stuff in clay! From delicate porcelain jewellery, through to heavy sculptural work and everything in between. Deciding your direction is sometimes not that easy – when you first start, try everything, you will naturally gravitate to the style that you enjoy! The options and variations are endless and can get a wee bit overwhelming too! Check in with me before you start to ensure your ideas will work, what order you might do things, how you could achieve the look you are seeking and any other technical data required! Step Two – Making Clay is thixotropic. This means that as you work with it, the clay first gets sloppier and wetter, before is begins to dry in the atmosphere. For most things, you simply can’t do all parts of the project at once. An example of work order might look like: Get last weeks work out from the shelves Prepare clay for today’s work – roll your clay, prepare balls for throwing, make the first stage of a pinch pot) Clean up last week’s work and put it on the shelf for bisque firing Check that you have any glazing to do – and do enough of it that you will have time to finish your main project Do the next step of your next project – there might be a further step that can’t be complete immediately, in that case, wrap your work well and put onto the shelves. Letting your work rest for a while can really help keep your work clean and professional looking. Many things require bagging under plastic to keep it ready for work the next week – put your name on the outside of the bag so you can find your work easily. We have stickers and markers. Consider how you want to decorate your work – coloured slip can be applied at a fairly wet stage (remembering that it will make your work even wetter!). Trying to apply slip to dry clay won’t work! If you want to do sgraffito – you will need to keep the work leather hard (a state of dryness where you can still work the clay with a little effort and a little water and care). Step Three – Drying Most of the time your work can go into the rack uncovered to let it dry out for the following week. If you want to continue forming or shaping you will need to double bag your work – put your work on a suitable sized bat and put the bat in a bag so the base of the bag is under the bat, then put another bag over the top of the work and tuck the top of the bag under the bat. If you want to trim (or turn) your thrown work the following week, it should also be double bagged. If your work is large, delicate, or of uneven thicknesses, you should lightly cover your work for drying. When considering the drying process, bare in mind the weather, humidity and wind! The hotter and dryer, the faster things dry and work can dry unevenly in the shelves – this can lead to cracking – another time to lightly cover your work for drying. Step Four – Trimming and Cleaning Up Your work is dry! It is called greenware now and it is at it’s most fragile! Handle everything with two hands. I often refer to soft hands – keep everything gentle and with your fingers spread as much as possible. Try to not pick up things like plates too much, and always with both hands! Before your work can be bisque fired it should be “cleaned up”. You work won’t go into the kiln if it has sharp edges – when glazed, sharp edges turn into razor blades! Use a piece of fly wire to rub the work all over – this will scratch a little so be light handed. Use a knife or metal kidney to scrape any areas that require a bit more dynamic treatment than the fly wire offers! Finally, a very light wipe over with a slightly damp sponge can help soften and soothe all of your edges and dags! Trimming thrown work: If you are planning to trim (or turn) your thrown work (and you should be), make sure you bag it well – your work should be leather hard to almost dry for easiest trimming. Use this step to finish the work completely – use a metal kidney to polish the surface, or a slightly damp sponge to give a freshly thrown look. Wipe the sponge around the rim after trimming, and check the inside of the pot for dags! Trimming slip cast work: Usually I will trim the rims of your work on the wheel the following day to make that stage easier, however you will still need to check your work for lumps and bumps. Last but not least – check that your name is still clearly on the bottom of your work. Step Five – Bisque Firing When the work is completely dry it can go into the bisque kiln. The bisque kiln is fired to 1000°C. This process burns off the water in the clay as well as some of the chemically bound water. The structure of the clay is not altered that much at this temperature. Inside the bisque kiln, the work is stacked a little, small bowl inside a larger bowl and onto a heavy plate. Smaller items like decorations or drink coasters might get stacked several high. Consideration is paid to the weight of the stack and shape of the work. A bisque kiln can fire about one and a half times the amount of work that the glaze kiln can fire. The firing takes about 10 hours to complete the cycle and about two days to cool down. Once it has been emptied the work is placed in the glaze room ready for you to decorate! Step Six – Glazing Decorating your work with colour can be a lot of fun – and time consuming! There are three main options for surface treatment at this stage: Oxide Washes Underglazes Glazes Washes and underglazes do not “glaze” the work – It will still need a layer of glaze to fully seal the clay (washes don’t need glaze on surfaces not designed for food or liquid as they can gloss up a little on their own). Underglazes are stable colourants that turn out pretty much how they look in the jar. They can be mixed with each other to form other colours and can be used like water colours to paint onto your work. Mostly they should have a clear glaze on top to seal them. Oxides are a different species – the pink oxide (cobalt) wash turns out bright blue for instance. They don’t always need a glaze on top, and some glazes can change the colour of the wash! The glazes need no other “glaze” on top! Be careful of unknown glaze interactions – you can put any combination of glaze in a bowl or on a plate, but only a single glaze on the outside of any vertical surface! Glazes are a chemical reaction under heat. We don’t know the exact chemicals in the Mayco glazes we use. I can guess by the way they interact with each other, however, on the whole, you need to test every idea you have, and not run the test on a vertical surface! Simply put, glaze is a layer of glass like substance that bonds with the clay underneath. Clay is made of silica, alumina and water. Glaze is made of mostly silica. Silica has a melting point of 1700°C and we fire to 1240°C. The silica requires a “flux” to help it melt at the lower temperature. Fluxes can be all sorts of chemicals – a common one is calcium – calcium has a melting point of 2500°C, however, together they both melt at a much lower temperature! Colourants are metal oxides like cobalt (blue), chrome (green through black), copper (green, blue, even red!), manganese (black, purple and pink) iron (red brown), etc. Different chemicals in the glaze can have dramatic effects. for example, barium carbonate (which we don’t use) turns manganese bright pink! Other elements can turn manganese dioxide brown, blue, purple and reddish brown. Manganese dioxide is a flux in and of itself as well. So, glazes that get their black and purple colours, often interact with other glazes and RUN! Our mirror black is a good example – it mixes really well with many glazes because it fluxes them – causes them to melt faster. It will also bring out many beautiful colours in the glazes because it’s black colouring most definitely comes from manganese dioxide! Glaze chemistry is a whole subject on it’s own! We use commercial Mayco glazes on purpose – for their huge range of colour possibilities, stability, cool interactions, artistic freedom with the ability to easily brush the glazes on and ease of use. We currently have almost 50 glazes on hand! A major project is to test the interactions of all glazes with each other. That is 2,500 test tiles!!!! I’m going to make the wall behind the wheels the feature wall of pretty colours! Step Seven – Glaze (Gloss or sometimes called “Glost”) Firing Most of the time this is the final stage of making your creation (but not always!) The glaze kiln goes to 1240°C. This is called cone 6, or midrange. It is the low end of stoneware temperatures. Stoneware clays and glazes are typically fired at cone 8 – 10, that is 1260 – 1290°C. The energy requirement to go from 1240°C to 1280°C is almost a 30% more! Our clay is formulated to vitrify (mature, turn “glass-like”) at 1240°, as are our glazes. A glaze kiln take around 12 hours to reach temperature and two to three days to cool down. Sometimes a third firing process is required – this is for decoration that is added to work after the glaze firing. For example – adding precious metals and lustres. this firing temperature is usually around 600 – 800°C depending upon the techniques being used. There are many students interested in gold and silver trims – we will be doing this third type of firing soon! After firing your work will be in the student finished work shelves. Remember to pay for it before you head out the door! There is a small extra charge for using porcelain clay (it’s more than twice the price of regular clay), and for any third firing process! Once your work has been fired it can not turn back into clay for millennia – so don’t fire it if you don’t like it! Put it in the bucket for recycling. https://firebirdstudios.com.au/the-process-of-making-pottery/Ceramics have evolved over thousands of years.Earthenware dessert plate, cream colour. Made by Alfred Meakin, England. Backstamped ‘Alfred Meakin England’. flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, alfred meakin, ceramics, earthenware, kitchenware -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Jug

The Process of Making Pottery Decorating, Firing, Glazing, Making, Technical There is a rhythm and flow to clay. It can’t be done all at once! Even the making process! It can take weeks to get everything done, especially if you can only work on your pottery once a week! Even though we have three hour classes, it’s often just not enough time! Here is an overview of some of the processes so you have a bit more grasp on some of the technical stuff! Step One – Design There are SO many ideas out there for making stuff in clay! From delicate porcelain jewellery, through to heavy sculptural work and everything in between. Deciding your direction is sometimes not that easy – when you first start, try everything, you will naturally gravitate to the style that you enjoy! The options and variations are endless and can get a wee bit overwhelming too! Check in with me before you start to ensure your ideas will work, what order you might do things, how you could achieve the look you are seeking and any other technical data required! Step Two – Making Clay is thixotropic. This means that as you work with it, the clay first gets sloppier and wetter, before is begins to dry in the atmosphere. For most things, you simply can’t do all parts of the project at once. An example of work order might look like: Get last weeks work out from the shelves Prepare clay for today’s work – roll your clay, prepare balls for throwing, make the first stage of a pinch pot) Clean up last week’s work and put it on the shelf for bisque firing Check that you have any glazing to do – and do enough of it that you will have time to finish your main project Do the next step of your next project – there might be a further step that can’t be complete immediately, in that case, wrap your work well and put onto the shelves. Letting your work rest for a while can really help keep your work clean and professional looking. Many things require bagging under plastic to keep it ready for work the next week – put your name on the outside of the bag so you can find your work easily. We have stickers and markers. Consider how you want to decorate your work – coloured slip can be applied at a fairly wet stage (remembering that it will make your work even wetter!). Trying to apply slip to dry clay won’t work! If you want to do sgraffito – you will need to keep the work leather hard (a state of dryness where you can still work the clay with a little effort and a little water and care). Step Three – Drying Most of the time your work can go into the rack uncovered to let it dry out for the following week. If you want to continue forming or shaping you will need to double bag your work – put your work on a suitable sized bat and put the bat in a bag so the base of the bag is under the bat, then put another bag over the top of the work and tuck the top of the bag under the bat. If you want to trim (or turn) your thrown work the following week, it should also be double bagged. If your work is large, delicate, or of uneven thicknesses, you should lightly cover your work for drying. When considering the drying process, bare in mind the weather, humidity and wind! The hotter and dryer, the faster things dry and work can dry unevenly in the shelves – this can lead to cracking – another time to lightly cover your work for drying. Step Four – Trimming and Cleaning Up Your work is dry! It is called greenware now and it is at it’s most fragile! Handle everything with two hands. I often refer to soft hands – keep everything gentle and with your fingers spread as much as possible. Try to not pick up things like plates too much, and always with both hands! Before your work can be bisque fired it should be “cleaned up”. You work won’t go into the kiln if it has sharp edges – when glazed, sharp edges turn into razor blades! Use a piece of fly wire to rub the work all over – this will scratch a little so be light handed. Use a knife or metal kidney to scrape any areas that require a bit more dynamic treatment than the fly wire offers! Finally, a very light wipe over with a slightly damp sponge can help soften and soothe all of your edges and dags! Trimming thrown work: If you are planning to trim (or turn) your thrown work (and you should be), make sure you bag it well – your work should be leather hard to almost dry for easiest trimming. Use this step to finish the work completely – use a metal kidney to polish the surface, or a slightly damp sponge to give a freshly thrown look. Wipe the sponge around the rim after trimming, and check the inside of the pot for dags! Trimming slip cast work: Usually I will trim the rims of your work on the wheel the following day to make that stage easier, however you will still need to check your work for lumps and bumps. Last but not least – check that your name is still clearly on the bottom of your work. Step Five – Bisque Firing When the work is completely dry it can go into the bisque kiln. The bisque kiln is fired to 1000°C. This process burns off the water in the clay as well as some of the chemically bound water. The structure of the clay is not altered that much at this temperature. Inside the bisque kiln, the work is stacked a little, small bowl inside a larger bowl and onto a heavy plate. Smaller items like decorations or drink coasters might get stacked several high. Consideration is paid to the weight of the stack and shape of the work. A bisque kiln can fire about one and a half times the amount of work that the glaze kiln can fire. The firing takes about 10 hours to complete the cycle and about two days to cool down. Once it has been emptied the work is placed in the glaze room ready for you to decorate! Step Six – Glazing Decorating your work with colour can be a lot of fun – and time consuming! There are three main options for surface treatment at this stage: Oxide Washes Underglazes Glazes Washes and underglazes do not “glaze” the work – It will still need a layer of glaze to fully seal the clay (washes don’t need glaze on surfaces not designed for food or liquid as they can gloss up a little on their own). Underglazes are stable colourants that turn out pretty much how they look in the jar. They can be mixed with each other to form other colours and can be used like water colours to paint onto your work. Mostly they should have a clear glaze on top to seal them. Oxides are a different species – the pink oxide (cobalt) wash turns out bright blue for instance. They don’t always need a glaze on top, and some glazes can change the colour of the wash! The glazes need no other “glaze” on top! Be careful of unknown glaze interactions – you can put any combination of glaze in a bowl or on a plate, but only a single glaze on the outside of any vertical surface! Glazes are a chemical reaction under heat. We don’t know the exact chemicals in the Mayco glazes we use. I can guess by the way they interact with each other, however, on the whole, you need to test every idea you have, and not run the test on a vertical surface! Simply put, glaze is a layer of glass like substance that bonds with the clay underneath. Clay is made of silica, alumina and water. Glaze is made of mostly silica. Silica has a melting point of 1700°C and we fire to 1240°C. The silica requires a “flux” to help it melt at the lower temperature. Fluxes can be all sorts of chemicals – a common one is calcium – calcium has a melting point of 2500°C, however, together they both melt at a much lower temperature! Colourants are metal oxides like cobalt (blue), chrome (green through black), copper (green, blue, even red!), manganese (black, purple and pink) iron (red brown), etc. Different chemicals in the glaze can have dramatic effects. for example, barium carbonate (which we don’t use) turns manganese bright pink! Other elements can turn manganese dioxide brown, blue, purple and reddish brown. Manganese dioxide is a flux in and of itself as well. So, glazes that get their black and purple colours, often interact with other glazes and RUN! Our mirror black is a good example – it mixes really well with many glazes because it fluxes them – causes them to melt faster. It will also bring out many beautiful colours in the glazes because it’s black colouring most definitely comes from manganese dioxide! Glaze chemistry is a whole subject on it’s own! We use commercial Mayco glazes on purpose – for their huge range of colour possibilities, stability, cool interactions, artistic freedom with the ability to easily brush the glazes on and ease of use. We currently have almost 50 glazes on hand! A major project is to test the interactions of all glazes with each other. That is 2,500 test tiles!!!! I’m going to make the wall behind the wheels the feature wall of pretty colours! Step Seven – Glaze (Gloss or sometimes called “Glost”) Firing Most of the time this is the final stage of making your creation (but not always!) The glaze kiln goes to 1240°C. This is called cone 6, or midrange. It is the low end of stoneware temperatures. Stoneware clays and glazes are typically fired at cone 8 – 10, that is 1260 – 1290°C. The energy requirement to go from 1240°C to 1280°C is almost a 30% more! Our clay is formulated to vitrify (mature, turn “glass-like”) at 1240°, as are our glazes. A glaze kiln take around 12 hours to reach temperature and two to three days to cool down. Sometimes a third firing process is required – this is for decoration that is added to work after the glaze firing. For example – adding precious metals and lustres. this firing temperature is usually around 600 – 800°C depending upon the techniques being used. There are many students interested in gold and silver trims – we will be doing this third type of firing soon! After firing your work will be in the student finished work shelves. Remember to pay for it before you head out the door! There is a small extra charge for using porcelain clay (it’s more than twice the price of regular clay), and for any third firing process! Once your work has been fired it can not turn back into clay for millennia – so don’t fire it if you don’t like it! Put it in the bucket for recycling. https://firebirdstudios.com.au/the-process-of-making-pottery/The form of the jug has been in use for many centuries.Stoneware jug. Two tone brown glaze with pierced lip behind spout. Spout chipped.None.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, jug, ceramic jug -

Federation University Historical Collection

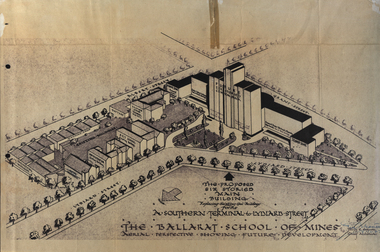

Federation University Historical CollectionPlan, Ballarat School of Mines Future Development: A Southern Terminal to Lydiard Street, 1947, 09/12/1947

In 1947 Percy Everett, Chief Architect for the Victorian Government, drew up plans to accomodate the growth in student numbers on the Ballarat School of Mines site. It was an era of government buildings surrounding the Ballarat School of Mines campus either being transfered to the school or foreshadowed for transfer. In 1947 two Red Cross huts were transferred from Victoria Park to the western side of the former Ballarat Supreme Court (later Courthouse Theatre) for use by Wool Classing and Motor Mechanics. In the same year additional facilities were provided for Pottery due to the increase in enrolments and a large brick classroom was built at the rear of the Ballarat Junior Technical School Building. In the annual report of 1947 the President said: "These transfers are, however, only temporary expedients and indicate the pressing need for more buildings of a permanent nature". By the end of the year the School Council decided to request the Education Department of Victoria to proceed with the implementation of the School's long-range plan whch had received approval earlier and to treat it as an urgent post-war requirement. After much communication a plan for a six-storied building, flanked by two three storied buildings was planned to be built on the site of the Ballarat Gaol was developed. The plan was sent to the Education Department for the Minister's Approval. It is not know if approval was granted, but the building did not proceed, possibly becausse the Ballarat Gaol was still very miuch in use. When a tertiary division of the Ballarat School of Mines was being developed in 1967 it corresponded with the closure of the Ballarat Gaol. It was determined that the Lydiard Street South site had no room for future growth so a new campus was sought. The new campus was purchased at Mt Helen, and was initially known as the Ballarat Insittute of Advanced Education. In 1976, when the Ballarat Teachers' College merged into the structure, the campus became known as the Ballarat College of Advanced Education and it was no longer a part of the Ballarat School of Mines. Plans for a proposed building to replace the Ballarat Gaol buildings. The proposed building was never built, the concept being replaced by a new teritary facility at Mt Helen. buildings, percy everett, ballarat school of mines battery, ballarat technical art school, engineering workshops, machine shop, ballarat junior technical school, architectural plans, ballarat school of mines, smb campus -

Federation University Historical Collection

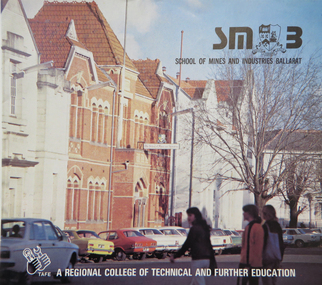

Federation University Historical CollectionBooklet - Brochure, School of Mines and Industries Ballarat: A Regional College of Technical and Further Education

A folded colour poster outlining the courses available at the Ballarat School of Mines, and a number of photographs of students and classes at the School.ballarat school of mines, tafe, library, audio visual, student centre, canteen, computer centre, counselling, typing, canoeing, pottery, ceramics, bricklaying, biology, woolclassing, welding, motor mechanics -

Federation University Historical Collection

Federation University Historical CollectionBook - Scrapbook, Ballarat School of Mines Scrapbook, 1936-1948, 1936-1948

The Ballarat School of Mines was the first school of mines in Australia.Exercise books of newspaper clippings relating to the Ballarat School of Mines. Clippings include: 12 Feb 1936 - State Scholarships 12 March 1936 - Dr J.R. Pound 19 March 1936 - MacRobertson Scholarship 23 March 1936 - gift to the museum - Wardle and Jermyn donate timber specimens 11 May 1935 - A.W. Steane 13 June 1936 - Frederick Longhurst appointed art instructor 27 July 1936 - Ballarat Junior Technical School Reunion 11 Sept 1936 - Wiltshire Poster Competition 30 Oct 1936 - Dressmaking classes 20 NOv 1936 - Nornie Gude NOvember 1936 - Ballarat School of Mines Reunion 16 March 1937 - Oval for Ballarat Junior Technical School - White Flat 11 Nov 1937 - Poster competition - Betty Brown and Albino Paganetti 08 Feb 1938 - Frederick J. Martell obituary 07 July 1938 - Henry Kum-Yuen 14 July 1938 - Red Cross Competition for Women 06 Aug 1938 - School Pine Plantation at Vale Park 19 Aug 1938 - Memorial trees planted at Ballarat Junior Technical School to the memory of Cliff Ellis and Ken Butler 06 March 1939 - Ballarat School of Mines Reunion 16 May 1939 - Ballarat School of Mines Battery 19 April 1940 - Progress of Technical Education - New Engineering workshop opended by Sir John Harris 03 June 1940 - W.H. Middleton obituary 16 July 1940 - Training munition workers 30 May 1941 - Lady Tracers 19 Oct 1942 - War Poster competition 24 February 1944 - Ballarat School of MInes Record Enrolments Feb 1944 - D.F.C. for Ballarat Airman H.J. Trevenen 11 Feb 1945 - Harold Herbert Obituary 14 Oct 1945 - Technical Schools in Wartime 23 Feb 1946 - Molasses and Chaff for SMB Initiates 06 June 1946 - Plans for Victory Ball 13 Sept 1946 - Ken Walker sculpts Prime Minister Chifey's bust 23 Aug 1946 - Edgar McConnon obituary 24 Oct 1946 0 Retirement of A.F. Heseltine 25 Nov 1946 - Army huts for classrooms 12 Dec 1946 - Proposed New Theatre for Ballarat by Geoff Richards 16 Dec 1946 - Ballarat Junior Technical School Old Boys who served in armed forces during World War Two 28 July 1947 - Pottery section at Ballarat School of Mines 31 July 1947 - Red Cross Hut removed to the Ballarat School of Mines 10 March 1948 - Guncotton Factory buildings to become nurses quarters 18 March 1948 - Samuel Mayo Obituary ballarat school of mines, ballarat techncial art school, swimming shield, ballarat school of mines museum, ballarat war museum, sydney pern, t.m. pescott, c.w. brazenor, victory ball, w. rowe, joan walker, graeme dowling, ken walker, prime ministers' avenue, ben chifley, amalie feild, amalie colquhoun, h.h. smith, portrait, girls' preparatory classes, world war two, w. williams, raaf, w.s. williams, william william, william williams, new workshops, herbert j. trevenen, harold herbert death, les crouch, swimming, ballarat city baths, heather scott, clunes hospital nurses' quarters, ballarat ladies' art association scholarships, samuel henry mayo, samuel mayo death, girls preparatory classes, w. william, pilot, killed in action, education reform, ballarat schoool of mines museum, h.j. trevenen, world war ii, world war 2, ballarat junior technical school war service, nurses quarters, guncotton factory building, s. mayo death, initiation, ballarat school of mines scrapbook, newsclippings, j.r. pound, macrobertson scholarship, a.w. steane, ballarat junior technical school, wiltshire's poster competition, ballarat junior technical school old boys' association, ballarat junior technical school old boys' reunion, nornie gude, a. nye, albino paganettu, betty brown, dorothy woolcock, jean coates, jack hewitt, hazel robinson, gilda gude, white flat oval, gauge tower demolition, a.f. hesiltine, darwin, victor greenhalgh, frederick martell, memorial trees, cliff ellis, valda king, pharmacy, reunion, engineering workshops, thomas k. sim, daylesford, battery, h.h. smith reunion, ballarat technical art school reunion, w.h. middleton obituary, munition makers, plumbers, pottery industry, girls education, munition trainees, lady tracers, waterloo prize money, war museum, art as vocation, art education, nine-inch telescope, returned soldiers' league, repatriation classes, pinkertson scholarship, amel robert gordon, projector, pethard cup, ballarat food appeal for britain, queen mary, ballarat swimming pool, ballarat school of mines initiation, swimming carneval, prime ministers avenue, edgar mcconnon, community theatre project, world war two service, john l. burt, hockey, pottery, ceramics, ballarat school of mines coat of arms, coat of arms, k. bremner, red cross hut, s.m.b. follies, ken palmer, s. mayo, chinese, albert steane, university women, a.f. heseltine, student activity, swimming sports, albino pagnetti, w.h. middleton death -

Ringwood and District Historical Society

Ringwood and District Historical SocietyLiterary work, Alice Milner's memories of CWA Ringwood Branch in 1995

Kindly scanned from Ringwood Branch archival collectionTranscript (kindly completed by Ken Briscoe using ChatGPT) RINGWOOD BRANCH COUNTRY WOMEN'S ASSOCIATION INC. February 13, 1946 in the Ringwood Town Hall, the Mayoress, Mrs. H.E. Parker, called the meeting and Ringwood Branch Country Women's Association was formed, and would be in the Yarra Valley Group. Speaker for the day was Mrs. Wray, Group President, Yarra Valley Group. Office bearers elected were: • Mrs. Greenshields (President) • Mrs. Shields (Secretary) • Mrs. Roberts (Treasurer) At the inaugural meeting, 93 ladies joined, and the first general meeting of the Ringwood Branch was held March 7, 1946, and by the end of August the membership grew to 160. In 1946 the joining fee was 4/- and you never attended a meeting unless you wore hat and gloves. The first year, meetings were held in the main Town Hall, then they were transferred to the small hall, which had a creche next door, at the baby health centre, where mothers could leave their little ones, while mum enjoyed the meetings, demonstrations or entertainment. The Branch had a very good Choir, conducted by Mrs. Dorrie Davidson, also a very talented theatrical group. Each birthday they put on excellent stage shows, some beautiful costumes being hired from well-known Melbourne theatrical company. The 1956 Olympic stage show had some well-trained, but out of form, athletes. Highlight of the year was the Annual Ball and two Debutante Balls. New branches were formed in the district, Everard, East Ringwood, Heathmont, South Warrandyte. There was also, Ringwood Younger set, a night branch (later years was renamed Marana). It was then that our membership dropped. As more and more branches were started in the district, Ringwood was then allocated to the newly formed Maroondah Highway Group. Craft classes and demonstrations were of a high standard, with some interesting things being made such as millinery, dressmaking, pottery, etc. In 1960 when Ringwood was made a City, a C.W.A. float was entered in the procession, this was a mammoth task, as hundreds of flowers were made and wired to the float, which was in green and gold C.W.A. colours. The time came when the Town Hall was to be demolished, and we moved to the Church of England Hall, Civic Place, but after a short time, this hall was also demolished. Meetings were then held at Ringwood Library until the library was no longer available. Our last move was to our present meeting room at Lionswood. Today you dress as you wish and membership is $12.00. The Ringwood Branch in 1995 has 2 life members and 21 members. Alice Milner March 15, 1995 As a matter of interest, of those 160 members who joined in the first year, only one active member is left with the Branch -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Book - BENDIGO: VICTORIA'S GOLDEN CITY

Coloured booklet of various scenes and buildings in and around Bendigo, titled Bendigo Victoria's Golden City. The front cover has a scene of Charing Cross looking towards Pall Mall. Inside the front cover is a very brief history and some Historical Buildings are mentioned. They are: Fortuna, Shamrock Hotel, Gold Mines Hotel, City Hall, Post Office, Law Courts, the Home for the Aged, Sacred Heart Cathedral, St. Paul's, Specimen Cottage, Log Lock-up and the Chinese Joss House. The coloured pictures inside are: The Central Deborah Gold Mine, Fortuna, Miner's Cottage, The Gold Mines Hotel, Victoria Hill, Bendigo Law Courts, Eaglehawk Log Lock-up, Look-out Tower Rosalind Park, Alexandra Fountain - Charing Cross, Conservatory Gardens with Law Courts in background, Inside the Conservatory, Bendigo Home & Hospital for the Aged - Victoria's 'White House', Sacred Heart Cathedral, Chinese Joss House, Chinese Joss House - Interior of the Main Temple, Bendigo Pottery - Potter at work, Bendigo Municipal Offices, Bendigo Institute of Technology at Flora Hill, Mt. Alvernia Hospital, Cobb & Co Coach, R Class Locomotive, Bendigo Tramcar, Lake Weeroona and Lake Eppalock Pumping Station. Some more attractions are mentioned inside the back cover. On the back cover is the Cenotaph - the only scale replica of the Whitehall Cenotaph - and Alexandra Fountain by night.Nucolorvue Productions Pty Ltdbendigo, tourism, photographs of bendigo icons, bendigo - victoria's golden city, fortuna, shamrock hotel, gold mines hotel, city hall, post office, law courts, home for the aged, victoria's 'white house', sacred heart cathedral, st paul's, specimen cottage, log lock-up, chinese joss house, charing cross, cenotaph, alexandra fountain, centra deborah gold mine, army cartographic unit, miner's cottage, harvey town, victoria hill, look-out tower rosalind park, conservatory gardens, conservatory, bendigo pottery, bendigo municipal offices, bendigo institute of technology, mt alvernia hospital, cobb & co coach, r class locomotive, bendigo railway station, bendigo tramcar, lake weeroona, lake eppalock pumping station, art gallery, historical museum eaglehawk, melville's caves, whitehall cenotaph, nucolorvue productins pty ltd, national library of australia -

Vision Australia

Vision AustraliaLetter - Text, Letter to The Trustees, Clubhouse, Recreation grounds for the Blind, 16/5/1957

... activities including a dance class, indoor bowling club, pottery... activities including a dance class, indoor bowling club, pottery ...Letter to the Trustees outlining the outcomes of a recent meeting, as the minute book was unable to be located. Below is a summary of the letter. The death of W.H. Paterson is mentioned and the recommendation to the Committee that the clubhouse by named in his honour was unanimously accepted, however requires the agreement of the Trustees. The remainder of the letter covers the past five years. The Victorian Association of Blind Cricketers are requesting the erection of a shelter shed and scoring boxes. Complaints have been received about horses using the park, which have been passed to Malvern Council who advise they have also received similar complaints from the general public. A fence is required but a lack of finance has delayed this action. The Clubhouse is being used for more activities including a dance class, indoor bowling club, pottery and craft work, therefore a new switchboard and rewiring were completed. In October 1955, the State Government offered funding through local councils, however despite a representation to the Minister, the Malvern Council were not willing to expend funds to the Association as they had committed to build an Elderly Citizens Club. A large signboard was repainted and a new signboard erected at the front entrance, along with a light controlled by a clock. The Clubhouse has also been used one night per month by the local branch of the RSL and occasional use by the Teachers College for inter College sports. There has been cooperation with the L.T.A.V. (Lawn Tennis Association of Victoria) during tennis championships, and although the Committee recognise the need to do more with the area, the impending homes been built at Ballarat and Bendigo have been a limited factor. Signed by J.W. Wilson3 pages of type letter on letterheadAssociation for the Advancement of the Blind, Under the Distinguished Patronage of His Excellency the Governor of Victoria and Lady Brooks Founded 1895 (image of shining lantern) Incorporated 1944 10-12 Queen Street, Melbourne, C.1. Phone: MU 4189 MU 1955 Homes at: Brighton Beach Windsor Ballarat Bendigo On the left hand side of the page: President: Bruce Small, Esq. Vice President: Hubert Opperman, O.B.E. Treasurer: W.J.S. Horsfall, F.C.A. Secretary: J.W. Wilson Objects: To promote the welfare of the Blind intellectually, physically and socially. To grant financial assistance in cases of necessity. To provide Homes and Hostels of an undenominational character for the Blind. To visit the Blind. To care for the adult Blind, especially the aged and infirm. Donations will be subject to the concessional allowances provided by the Income Tax Act. At the base of the page: Homes and help for aged blindassociation for the advancement of the blind, john wilson, kooyong club house -

Wodonga & District Historical Society Inc

Wodonga & District Historical Society IncDomestic object - Shallow Vegetable Serving bowl, Johnson Brothers England, 1913 - 1942

Johnson Bros. was founded by two brothers named Alfred and Frederick who purchased a pottery factory in Hanley, England, in 1883. They were grandsons of a renowned English potter, Alfred Meakin. They were later joined in the business by their brothers Henry and Robert. Their business grew rapidly, as they were one of the world's largest pottery factories by the turn of the 20th century. By 1970, Johnson Bros. obtained the Royal Charter to become the official provider of china for Her Majesty Queen Elizabeth II. More than 1,300 patterns have been created throughout Johnson Brothers' history. Due to their growing success, manufacturing plants were established overseas including the establishment of a tableware factory, Johnson Brothers Australia in 1957 in Croydon, Victoria operated through a company known as Sovereign Pottery Ltd. Due to rising competition, Johnson Brothers became part of the Wedgewood Group in 1968. In 2015, following the acquisition of Wedgewood by Finnish company Fiskars, the Johnson Brothers branding was discontinued. The trademark on this bowl was used by Johnson Brothers between 1913 and 1942. An item which reflects the changing market for tableware that was reasonably priced and serviceable. Their innovation of the pottery line called semi-porcelain changed the industry. This development allowed potteries to produce fashionable pottery items that were affordable to all social classes of the time. Their use became widespread in Australia, especially following their establishment of a tableware factory in Melbourne, Victoria. A shallow white bowl with gold trim, probably used for serving vegetables at the table. The underside of the bowl bears the mark of Johnson Bros England. The mark is composed of a green crown above the words "Johnson Bros England" also in green.On under side of bowl, beneath a green crown "Johnson Bros/England"johnson brothers ceramics, domestic utensils, kitchenware -

Federation University Historical Collection

Federation University Historical CollectionBook - Documents, Herbert Henry Smith, Ballarat Technical Art School, 1918-1929, 1918-1929