Showing 525 items

matching use of machinery

-

Eltham District Historical Society Inc

Eltham District Historical Society IncNegative - Photograph, Eltham Shire Council display, 1987 Eltham Community Festival, Alistair Knox Park, 7 Nov. 1987

... of and services provided by Council and various equipment and machinery... and machinery used. aerial photographs alistair knox park displays ...Regular display by Council at the Eltham Festival providing ratepayers and visitors some insight into the daily operations of and services provided by Council and various equipment and machinery used.Roll of 35mm colour negative film, 4 stripsKodak GB 200 5096aerial photographs, alistair knox park, displays, eltham festival, eltham shire council, infrastructure, shire of eltham, briar hill, eltham, montmorency -

Eltham District Historical Society Inc

Eltham District Historical Society IncNegative - Photograph, Eltham Shire Council display, 1987 Eltham Community Festival, Alistair Knox Park, 7 Nov. 1987

... of and services provided by Council and various equipment and machinery... and machinery used. aerial photographs alistair knox park displays ...Regular display by Council at the Eltham Festival providing ratepayers and visitors some insight into the daily operations of and services provided by Council and various equipment and machinery used.Roll of 35mm colour negative film, 4 stripsKodak GB 200 5096aerial photographs, alistair knox park, displays, eltham festival, eltham shire council, infrastructure, shire of eltham, montmorency, lower plenty -

Eltham District Historical Society Inc

Eltham District Historical Society IncNegative - Photograph, Eltham Shire Council display, 1987 Eltham Community Festival, Alistair Knox Park, 7 Nov. 1987

... of and services provided by Council and various equipment and machinery... and machinery used. eltham festival eltham shire council infrastructure ...Regular display by Council at the Eltham Festival providing ratepayers and visitors some insight into the daily operations of and services provided by Council and various equipment and machinery used.Roll of 35mm colour negative film, 4 stripsKodak GB 200 5096eltham festival, eltham shire council, infrastructure, shire of eltham, alistair knox park, displays, surveying equipment, theodolite -

Eltham District Historical Society Inc

Eltham District Historical Society IncNegative - Photograph, Eltham Shire Council display, 1987 Eltham Community Festival, Alistair Knox Park, 7 Nov. 1987

... of and services provided by Council and various equipment and machinery... and machinery used. eltham festival eltham shire council infrastructure ...Regular display by Council at the Eltham Festival providing ratepayers and visitors some insight into the daily operations of and services provided by Council and various equipment and machinery used.Roll of 35mm colour negative film, 4 stripsKodak GB 200 5096eltham festival, eltham shire council, infrastructure, shire of eltham, alistair knox park, displays, surveying equipment, theodolite -

Eltham District Historical Society Inc

Eltham District Historical Society IncNegative - Photograph, Eltham Shire Council display, 1987 Eltham Community Festival, Alistair Knox Park, 7 Nov. 1987

... of and services provided by Council and various equipment and machinery... and machinery used. infrastructure shire of eltham displays alistair ...Regular display by Council at the Eltham Festival providing ratepayers and visitors some insight into the daily operations of and services provided by Council and various equipment and machinery used.Roll of 35mm colour negative film, 4 stripsKodak GB 200 5096infrastructure, shire of eltham, displays, alistair knox park, building construction, eltham festival, eltham shire council, houses -

Phillip Island and District Historical Society Inc.

Phillip Island and District Historical Society Inc.Photographs/Slides, Laurie Dixon, 1961

... are of the machinery used to clear the land for the reservoir constructed...). The photographs are of the machinery used to clear the land ...Five of a collection of slides donated by Laurie Dixon. Water was pumped from Candowie Reservoir to nearby Almurta Basin and gravity fed to Wimbledon Heights Storage Basin. These open water basins were two main components of the water distribution of the day and supplied the area from 1964 to 1989. The Almurta and Wimbledon Heights Storage Basins were decommissioned in 1999 when the San Remo Basin was improved an now is the vital link in the transfer of water from Candowie via the Purification Plant.Five of a collection of slides taken by Laurie Dixon. (Photographs scanned by E Alexander). The photographs are of the machinery used to clear the land for the reservoir constructed at Wimbledon Heights in September 1961 273-08 Robert Cleeland on TractorInscriptions of slides 273-09. Tourerpull & crawler at reservoir Sep. 61 273-10. Reservoir Sep 61 273-11. Reservoir Sep 61 273-12. Building reservoir Sep 61wimbledon heights reservoir, laurie dixon -

Vision Australia

Vision AustraliaPoster - Object, Congratulations poster, 1985

... clients playing cricket, using machinery and learning to walk... clients playing cricket, using machinery and learning to walk ..."Congratulations ... and sincere thanks from the R.V.I.B. to the management and patrons of all hotels who contributed so magnificently in 1985. Fred Berry" Hotels were involved in fundraising for the RVIB through the placement of Lucky Envelopes machines. To honour this establishments and those which had raised the most funds, a poster was produced listing each hotel and the amount that was collected throughout 1985. The United Kingdom Hotel in Clifton Hill reached first place and a photograph of hotel management and RVIB staff was taken. Other pictures on the poster include RVIB clients playing cricket, using machinery and learning to walk with a white cane.1 rectangular white poster with red and black text with black and white illustrationsroyal victorian institution for the blind, fundraising, fred berry -

Bendigo Historical Society Inc.

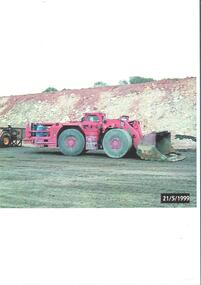

Bendigo Historical Society Inc.Photograph - Kangaroo Flat Gold Mine Collection: mining equipment, 21st May 1999

... operator is an individual who controls the machinery used... operator is an individual who controls the machinery used ...A bogger is a heavy-duty piece of equipment used in underground mining to transport rocks, ore, and other materials from the digging face to processing facilities or loading areas. A bogger operator is an individual who controls the machinery used to transport materials.Colour photocopy of original photo. Image shows red load haul dump loader, pictured parked on a mine road at the Kangaroo Flat Gold Mine site. Date stamp on bottom RH corner: 21/5/1999.western mining corporation, goldmining, capping, shaft, mining regulations, kangaroo flat gold mine, 1999 -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Document - IAN DYETT COLLECTION: HISTORY OF THE FIRM OF W D MASON PTY LTD

... /99. this version mentions machinery used, glass handling...: Original Revised Version 29/2/99. this version mentions machinery ...Six copies of the History of the firm of W D Mason Pty Ltd Glass Merchants of Bendigo 1894 - 1998. Note paper clipped to one copy and written in red ink: Original Revised Version 29/2/99. this version mentions machinery used, glass handling, making of mirrors, sandblasting and shopfronts.business, auctioneers, j h curnow & son pty ltd, ian dyett collection - history of the firm of w d mason pty ltd 1894 - 1998, owen walter williams, evening mail newspaper, henry brooks & company of england, brooks robinson & co pty ltd of melbourne, shaw savill & albion company limited line, arawa (5026 tons), capt'n snooze, coles new world supermarket, susan rebecca lawson, walter williams, samuel thomas williams, owen mostyn williams, ann (annie) mckenzie, wavertree ellen williams, reed smart & tappin, bendigo cathedral (sacred heart), alan walter mason, walter david mason, melva joan mason, wavertree ellen mason (nee williams), j b young, taylor family, australian window glass company -

Kew Historical Society Inc

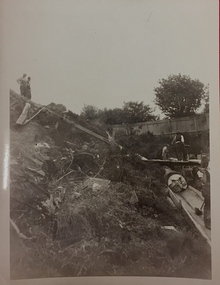

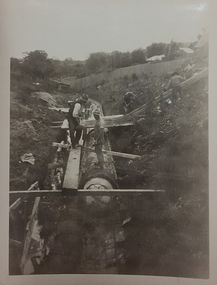

Kew Historical Society IncPhotograph, City of Kew, City of Kew, Cecil Street Drain, 1936

... , the techniques used and the equipment and machinery in the possession.... They reveal they types of labour conducted, the techniques used ...An original photograph donated to the Kew Historical Society by the City's Engineering Department preceding the amalgamation of Kew into the City of Boroondara. While not all of the photographs are of Studley Park, Kew or East Kew, each photo provides a fine snapshot of the work of local government engineering departments of the period. They reveal they types of labour conducted, the techniques used and the equipment and machinery in the possession of the local government authority. Historic and rare photograph of major public works in Kew in the 1930sPublic works. Men at work in the creek bed of Connor's Creek in Kew, while constructing the underground barrel drain. Connors Creek was one of the two main tributaries of the Yarra River in Kew. It originated somewhere near the grounds of Genazzano FCJ College. The barrel drain was finally completed in 1941 at a cost of £14,000. Inscription on reverse: "City of Kew / Cecil st drain / November 1936". public works (kew), roadmaking, engineering, city of kew (engineering department), connor's creek (kew), cecil street drain -

Kew Historical Society Inc

Kew Historical Society IncPhotograph, City of Kew, City of Kew, Cecil Street Drain, 1936

... , the techniques used and the equipment and machinery in the possession.... They reveal they types of labour conducted, the techniques used ...An original photograph donated to the Kew Historical Society by the City's Engineering Department following the amalgamation of Kew into the City of Boroondara. While not all of the photographs are of Studley Park, Kew or East Kew, each photo provides a fine snapshot of the work of local government engineering departments of the period. They reveal they types of labour conducted, the techniques used and the equipment and machinery in the possession of the local government authority. Historic and rare photograph of major public works in Kew in the 1930s.Public works. Men at work in the creek bed of Connor's Creek in Kew, while constructing the underground drain. Connor's Creek was one of the two main tributaries of the Yarra River in Kew. It originated somewhere near the grounds of Genazzano FCJ College. The barrel drain was finally completed in 1941 at a cost of £14,000. Inscription on reverse: "City of Kew / Cecil st drain / November 1936". city of kew, city of kew (engineering department), engineering, connor's creek (kew) -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageCeramic - Jug, Baker & Co, 1891 to 1893

... and was then using 'machinery for the potteries manufacturing operations... and was then using 'machinery for the potteries manufacturing operations ...W Baker and Co-produced many different types of pottery at their Fenton Potteries, Stoke-on-Trent, Staffordshire England. The company was established in 1790 by Ralph Bourne and William Baker the company was working at capacity by the end of the century. By the late 1820's Bourne and Baker, in partnership with John Bourne, had acquired additional works opposite the first in 1833. With the deaths of John Bourne and William Baker, the partnership was dissolved, and then for a short time, the business was carried on by Ralph Bourne and William Baker junior and John Baker. By the early 1840s, William Baker was running it alone and was then using 'machinery for the potteries manufacturing operations in addition to the mill that was producing the raw clay. The business was subsequently carried on by William Baker and Company that were known for the making of printed, sponged, and pearl-white granite ware for export in the early 1880s at the Fenton works between Manor and Fountain Streets. The original works on the south side of City Road were by then an en-caustic tile works, apparently still in the hands of the Baker family. The pottery works flourished under William Baker’s management and by the middle of the nineteenth century with almost 500 employees was the biggest firm in Fenton. An early piece of ironstone Staffordshire pottery now a collector's item showing the types of domestic items that were exported from England to its colonies towards the end of the nineteenth century and into the beginning of the twentieth.Water pitcher ironstone ceramic white with raised embossed Lilly of the valley decoration around handle and lip sections. Marked on bottom, "Royal stone china, Baker and Co, England" with emblem of lion, crown and unicornflagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, jug, kitchen utensil, kitchen ware, water pitcher -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Document - VICTORIA HILL - THE BENDIGO DIGGINGS, PRELIMINARY DRAFT FOR BROCHURE

... in the places they were used, e.g. quartz mining machinery exhibited... exhibits in the places they were used, e.g. quartz mining machinery ...BHS CollectionNine typed pages of notes on a preliminary draft for a brochure on the Bendigo Diggings. First part is the objective which is to preserve the mining history and to have exhibits in the places they were used, e.g. quartz mining machinery exhibited in a quartz mining area, not on an alluvial field. Part B is historical notes on the area. Part C is the Site - Victoria Hill area. Part D is Stage One which consists of carpark area, technological museum, restaurant, mineral haulage line, picnic ground, earthworks and planting over the area. Part E is Stage Two which will consist of the open-air exhibits, in the area surrounded by the mineral haulage line, and the Central Nell Gwynne mine on the west side of the site. Part F is Stage Three which will consist of the winery, the steam tram track, the lake, the wildlife sanctuary and various buildings associated with gold mining. Part G is Costing with the prices to be filled in. Parts H and I are the Appeal and the Committee. Details to be filled in. Notes prepared by Albert Richardson.mining, marketing, victoria hill, victoria hill, the bendigo diggings - preliminary draft for brochure, aust national travel association, tullamarine jetport, emu bottom homestead, kyneton historical museum, chinese joss house, eaglehawk museum, whipstick scrub, cairn curran reservoir, castelmaine historical museum and market hall, national trust, ballarat hiatorical park, echuca's hopwood gardens, swan hill folk museum, gibson's mount alexander no 2 squatting run, captain brown, chief commissioner wright, hustler's reef, thomas hustler, mining board, drainage of reefs act 1862, first world war, bendigo amalgamated goldfields, second world war, sandhurst, w c vahland, battery trams, horse trams, steam trams, electric trams, central nell gwynne mine, theodore ballerstadt, george lansell, new chum hill, ballerstadt's open cut, 180 mine, new chum syncline battery, william rae, victoria quartz, wittscheibe's 'jeweller's shop', luffsman and sterry, gold mines hotel, adventure, bendigo and district tourist association, bendigo city council, bendigo branch of the royal historical society of victoria, professor brian lewis, school of architecture and building at the university of melbourne, taylor horsfield, lord robert cecil, south australian gold commissioner -

Kiewa Valley Historical Society

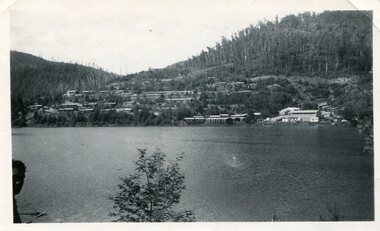

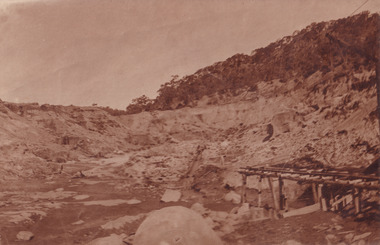

Kiewa Valley Historical SocietyPhotographs x 2 1. Lake Guy & Bogong Village 2. Bulldozer moving rocks

... of heavy machinery used in clearing and building of Lake Guy... of heavy machinery used in clearing and building of Lake Guy ...1. In 1940 Field Headquarters for the Kiewa Scheme were established at Bogong with office, workshop facilities and accommodation for workmen, staff and some families constructed. (There had been a 'tent camp' on this site in 1939 but was destroyed by bushfires) Construction of accommodation continued until 1947. A total of 40 houses plus a hostel for single staff, post office, police station, medical centre and primary school all with water and sewerage and electricity supply. The staff hostel was known as Kiewa House and is now occupied by the Education Department. Lake Guy was named after Mr. L.T. Guy who was the Resident Engineer in charge of construction work and associated activities on the Kiewa area. He held this position from 1939 to November 1946 when he was transferred to Head Office. 2. Example of the type of heavy machinery used in clearing and building of Lake Guy, Bogong Village and Clover Dam 1. The Bogong Township was developed firstly as an accommodation centre (base camp) for construction workers employed under the Kiewa Hydroelectric Scheme. At the completion of the scheme, in the 1960's, the village was opened to public/tourism use. Strict environmental control has not allowed for any extensive redevelopment in tourist accommodation and basically restricted it to the accommodation initially built for the construction workers. Lake Guy is one of the many water storage reservoirs used to supply the power stations their main power to run the huge turbines generating the final product, electricity 2. Pictorial record of the types of machinery used in the development of Bogong Village and the Hydro-electricity scheme including the Clover Dam. Note the lack of safety equipment worn by construction workers of the period. 2 black and white photographs taken at Bogong 1. Lake Guy with Bogong Village in the background 2. Workman in bulldozer clearing rocks, possibly for construction at Bogong1. Handwritten in blue ink on back of photo 'Lake Guy showing Bogong Village' 2. No markingslake guy, bogong village, secv -

Cheese World Museum

Cheese World MuseumPetrol bowser, Super Plume, c1927

... re-used, recycled and repaired items and examples can be seen... on-farm. The bowser was used to refuel farm machinery. Mobil's ...The Uebergang family came from Silesia to Australia in 1848 and were early settlers in the Allansford area. The sons and other descendants also purchased farms in the area. The Percy Uebergang family lived at Tooram Park, Allansford from 1912 until 1992. Percy and Myrtle Uebergang's children were twins, Ray and Joyce born in 1926 who lived at Tooram Park until their deaths, Ray in 1986 and Joyce in 1992 after which the property was sold. Neither Ray nor Joyce married and following the death of her brother Joyce set up the Ray and Joyce Uebergang Foundation which supports the local community. The collection of items from their property was put into store for a number of years before being given into the care of the Cheese World Museum. The family often re-used, recycled and repaired items and examples can be seen in the museum. This petrol pump is part of the collection of items given into the care of the Cheese World Museum. As with many rural families the Uebergangs had bulk fuel supplies on-farm. The bowser was used to refuel farm machinery. Mobil's Super Plume petrol was one of the many brands of petrol available from the late 1920s. No electricity was required to work this bowser as it was gravity fed. The amount of petrol was selected by the position of the front lever. Petrol was then pumped into the bowl by the handle on the side of the bowser and gravity=fed to the vehicle. This petrol bowser is an example of a 1920s petrol bowser.allansford, uebergang, vacuum oil company, super plume petrol bowser, petrol bowsers, farm machinery -

The Beechworth Burke Museum

The Beechworth Burke MuseumPhotograph, 1907-8

... the use of heavy machinery.... the use of heavy machinery. The search for gold is ingrained ...The photo from 1907-8 is a sepia print, depicting a small valley with building at base. There are flumes visible above areas of water, trees on hills and a few small cottages on the hillside. Cock's Pioneer Gold & Tin Sluicing Co NZ No 2 Site. The photo was taken of Matthews Gully looking west. Sluicing was undertaken in the area from 1900 to 1942 with some short breaks between these periods. The image depicts a location mined by Cocks Pioneer Gold and Tin Sluicing Company (as recorded on the annotation on the card mount) The Cocks Pioneer Gold and Tin Mines N.L was one of El Dorado's two largest open cut sluicing mines of the 20th Century. The other was named the Cocks El Dorado Gold Dredging Company. The Cocks Pioneer Mines operated from 1901 until 1941 and found a total of 117,378 ounces of Gold and 1,673 tones of tin concentrates over these years. The Cocks company was formed in 1898 and operated until 1941. Open cut sluicing involved the use of high-powered hoses which used the centrifugal sand pump system (known as hydraulic sluicing) which broke down the soil which was then processed for gold and other precious metals. From 1914 , four years after this image was captured, the company reformed to Cocks Pioneer Gold and Tin Mines NL (previously it was known as Cocks Pioneer Sluicing Co) and undertook large scale sluicing operations until 1929 and then 1934-1941. El Dorado is located on Reedy Creek and is surrounded by forested country to the north and east. It is 20 km east of Wangaratta in Victoria's regional north-east. John Cock was the son of a Cornish minor who arrived in El Dorado in 1858. Cock founded his gold and tin mining company which ran successfully for many years in the El Dorado region. It was an open cut sluicing company because of the abandonment of underground mining after this was deemed too dangerous. In 1935 Cock's El Dorado Company commissioned the floating dredge which is still visible in El Dorado today. The dredge was built by the Thompson engineering works, Castlemaine, and weighed over 2,000 tones and today has a place on the Victorian Registers of historic buildings. Interestingly, the name El Dorado does not derive from the gold in the region, but from the Barambogie pastoral run completed by William Baker in 1840-1841. Gold was discovered in El Dorado 1854 but the gold was too deep for individual prospectors to find, it required the use of heavy machinery.The search for gold is ingrained into the history of Victoria and therefore, images like this one which portray an open cut sluicing site can reveal important information for society and technology for the date when the photograph was taken. This image is of important historical significance for its ability to convey information about sluicing and the methods used to find gold in 1910. It also shows a location where sluicing was undertook which provides insight into the impact of sluicing on the environment at a time when it was done. This image is important for current research into the history of El Dorado, a small regional location near Wangaratta in Victoria's North East. Therefore, this image has the capacity to be beneficial for research into society and the motivations of those living and working in this region during this period and therefore, has social significance. The Beechworth Burke Museum has additional images relating to gold sluicing and El Dorado which can be analysed and studied alongside images like this one.Sepia coloured rectangle photograph printed on gloss photographic paper Reverse: 1997. 2613/ A02613/ No2 site/ Matthews Gully/ Cocks Pioneer G&T. ?? Co NZ/ No2 Site looking West/ 1907-8/ (7)sluicing, hydraulic sluicing, 1907, 1908, mining, cock's pioneer gold & tin sluicing co nz, nz, site no 2, matthews gully, west, valley, building, cottages, hillside, trees, water, gold and tin mine -

The Beechworth Burke Museum

The Beechworth Burke MuseumPhotograph, 1910 - 1911

... , it required the use of heavy machinery...., it required the use of heavy machinery. The search for gold ...This photograph depicts Cock's Pioneer G & T Sluicing site No. 4 in El Dorado. Looking eastwards, the photo captures a wooden and tin building with various mining equipment strewn in the foreground. Underneath the verandah, figures can be seen. These are believed to be a Mr. Hollister (left), Mrs. Breustedt (4th from left), children Min and Chris Breustedt, and Kate Timmons holding a girl's hand. The Cocks Pioneer Gold and Tin Mines N.L was one of El Dorado's two largest open-cut sluicing mines of the 20th Century. The other was named the Cocks El Dorado Gold Dredging Company. The Cocks Pioneer Mines operated from 1901 until 1941 and found a total of 117,378 ounces of Gold and 1,673 tones of tin concentrates over these years. The Cocks company was formed in 1898 and operated until 1941. Open cut sluicing involved the use of high-powered hoses which used the centrifugal sand pump system (known as hydraulic sluicing) which broke down the soil which was then processed for gold and other precious metals. From 1914, four years after this image was captured, the company reformed to Cocks Pioneer Gold and Tin Mines NL (previously it was known as Cocks Pioneer Sluicing Co) and undertook large-scale sluicing operations until 1929 and then 1934-1941. The Cocks Pioneer was an extremely successful mining company during the 20th century. In the Annual Report of the Secretary for Mines for the year 1915, the Cocks Pioneer was the largest producer of gold and tin collecting 5,535 ozs. of gold and £7,500 of tin. Twenty years later in 1935, Cocks Pioneer was still one of the most profitable mines in Victoria, ranking as the second-highest dividend paying mine. The company produced a total of 3,650 kg of gold. El Dorado is located on Reedy Creek and is surrounded by forested country to the north and east. It is 20 km east of Wangaratta in Victoria's regional northeast. John Cock was the son of a Cornish miner who arrived in El Dorado in 1858. Cock founded his gold and tin mining company which ran successfully for many years in the El Dorado region. It was an open-cut sluicing company because of the abandonment of underground mining after this was deemed too dangerous. In 1935 Cock's El Dorado Company commissioned the floating dredge which is still visible in El Dorado today. The dredge was built by the Thompson engineering works, Castlemaine, and weighed over 2,000 tones and today has a place on the Victorian Registers of historic buildings. Interestingly, the name El Dorado does not derive from the gold in the region, but from the Barambogie pastoral run completed by William Baker in 1840-1841. Gold was discovered in El Dorado in 1854 but the gold was too deep for individual prospectors to find, it required the use of heavy machinery.The search for gold is ingrained into the history of Victoria and therefore, images like this one which portray an open cut sluicing site can reveal important information for society and technology for the date when the photograph was taken. This image is of important historical significance for its ability to convey information about sluicing and the methods used to find gold in 1910. It also shows a location where sluicing was undertook which provides insight into the impact of sluicing on the environment at a time when it was done. This image is important for current research into the history of El Dorado, a small regional location near Wangaratta in Victoria's North East. Therefore, this image has the capacity to be beneficial for research into society and the motivations of those living and working in this region during this period and therefore, has social significance. The Beechworth Burke Museum has additional images relating to gold sluicing and El Dorado which can be analysed and studied alongside images like this one.A black and white copy of a sepia coloured rectangular photograph printed on matte photographic paper mounted on boardObverse: COCKS PIONEER G + T SL CO, N.L. / 1910 - 11 / NO 4 SITE LOOKING EAST / 4 Reverse: 1997.2508 / AUG 29 1909cocks pioneer gold and tin sluicing company, el dorado, mining, sluicing, hydraulic mining, hollister, breustedt, timmons, gold, tin, gold rush, victoria -

The Beechworth Burke Museum

The Beechworth Burke MuseumPhotograph, 1910

... the use of heavy machinery.... the use of heavy machinery. The search for gold is ingrained ...This photograph dating to 1910 depicts an open cut sluicing site located in El Dorado captured looking east up the open cut from the number 3 Barge site. Sluicing was undertaken in the area from 1900 to 1942 with some short breaks between these periods. The image depicts a location mined by Cocks Pioneer Gold and Tin Sluicing Company (as recorded on the annotation on the card mount). It portrays open cut rocks with a crevice in the center of the image where the sluicing was being undertaken. There is a small timber structure on the right of the image which could be an entrance to a mine or supports made of wood to prevent a cave in at the open cut site and above the cut rock there is bush. The timber structure has rail tracks on top of the bridge which could suggest the identification of this structure as a mine entrance. The rail tracks were used for little carts which hauled soil from the mine. The Cocks Pioneer Gold and Tin Mines N.L was one of El Dorado's two largest open cut sluicing mines of the 20th Century. The other was named the Cocks El Dorado Gold Dredging Company. The Cocks Pioneer Mines operated from 1901 until 1941 and found a total of 117,378 ounces of Gold and 1,673 tones of tin concentrates over these years. The Cocks company was formed in 1898 and operated until 1941. Open cut sluicing involved the use of high-powered hoses which used the centrifugal sand pump system (known as hydraulic sluicing) which broke down the soil which was then processed for gold and other precious metals. From 1914 , four years after this image was captured, the company reformed to Cocks Pioneer Gold and Tin Mines NL (previously it was known as Cocks Pioneer Sluicing Co) and undertook large scale sluicing operations until 1929 and then 1934-1941. El Dorado is located on Reedy Creek and is surrounded by forested country to the north and east. It is 20 km east of Wangaratta in Victoria's regional north-east. John Cock was the son of a Cornish minor who arrived in El Dorado in 1858. Cock founded his gold and tin mining company which ran successfully for many years in the El Dorado region. It was an open cut sluicing company because of the abandonment of underground mining after this was deemed too dangerous. In 1935 Cock's El Dorado Company commissioned the floating dredge which is still visible in El Dorado today. The dredge was built by the Thompson engineering works, Castlemaine, and weighed over 2,000 tones and today has a place on the Victorian Registers of historic buildings. Interestingly, the name El Dorado does not derive from the gold in the region, but from the Barambogie pastoral run completed by William Baker in 1840-1841. Gold was discovered in El Dorado 1854 but the gold was too deep for individual prospectors to find, it required the use of heavy machinery.The search for gold is ingrained into the history of Victoria and therefore, images like this one which portray an open cut sluicing site can reveal important information for society and technology for the date when the photograph was taken. This image is of important historical significance for its ability to convey information about sluicing and the methods used to find gold in 1910. It also shows a location where sluicing was undertook which provides insight into the impact of sluicing on the environment at a time when it was done. This image is important for current research into the history of El Dorado, a small regional location near Wangaratta in Victoria's North East. Therefore, this image has the capacity to be beneficial for research into society and the motivations of those living and working in this region during this period and therefore, has social significance. The Beechworth Burke Museum has additional images relating to gold sluicing and El Dorado which can be analysed and studied alongside images like this one.Sepia coloured rectangular photograph printed on gloss photographic paper mounted on board.Obverse: COCKS PIONEER Q + T SL CO, N.L. / 1910 / LOOKING EAST UP OPEN CUT / FROM NO3 BARGE SITE / Reverse: 1997 . 2611 / A02611el dorado, north east gold, sluicing, gold sluicing, hydraulic sluicing, 1910, gold and tin mine, open cut mining, mining, gold mining, north-east victoria, beechworth, burke museum -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageClock, 1867-1870

... ," learning how to make previously handmade cases using machinery... previously handmade cases using machinery. Deciding to go ...Chauncey Jerome (1793–1868) was an American clock maker in the early to mid 19th century. He made a fortune selling his clocks, and his business grew quickly. Jerome was born in Canaan USA in 1793 son of a blacksmith and nail-maker. He began his career in Plymouth, making dials for long-case clocks where he learned all he could about clocks, particularly clock cases, and then went to New Jersey to make seven-foot cases for clocks mechanisms. In 1816 he went to work for Eli Terry making "Patent Shelf Clocks," learning how to make previously handmade cases using machinery. Deciding to go into business for himself, Jerome began to make cases, trading them to Terry for wooden movements. In 1822 Jerome moved his business to Bristol New Haven, opening a small shop with his brother Noble and began to produce a 30-hour and eight-day wooden clocks. By 1837 Jerome's company was selling more clocks than any of his competitors. A one-day wood-cased clock, which sold for six dollars had helped put the company on the map. A year later his company was selling that same clock for four dollars. The company also sold one line of clocks at a wholesale price of 75 cents and by 1841 the company was showing an annual profit of a whopping $35,000, primarily from the sale of its brass movements. In 1842 Jerome moved his clock-case manufacturing operation to St. John Street in New Haven. Three years later, following a fire that destroyed the Bristol plant, Jerome relocated the entire operation to Elm City factory. Enlarging the plant, the company soon became the largest industrial employer in the city, producing 150,000 clocks annually. In 1850 Jerome formed the Jerome Manufacturing Co. as a joint-stock company with Benedict & Burnham, brass manufacturers of Waterbury. In 1853 the company then became known as the New Haven Clock Co, producing 444,000 clocks and timepieces annually, then the largest clock maker in the world. Jerome's future should have been secure but in 1855 he bought out a failed Bridgeport clock company controlled by P.T. Barnum, which wiped him out financially, leaving the Jerome Manufacturing Co. bankrupt. Jerome never recovered from the loss. By his admission, he was a better inventor than a businessman. When Jerome went bankrupt in 1856 the New Haven Clock Company purchased the company. One of the primary benefits of Jerome purchasing New Haven in the first place was the good reputation of the Jerome brand and the network of companies that remained interested in selling its clocks. In England, Jerome & Co. Ltd. sold Jerome clocks for the New Haven company until 1904, when New Haven purchased the English firm outright. After his involvement with the New Haven Company in 1856, Jerome traveled from town to town, taking jobs where he could, often working for clock companies that had learned the business of clock making using Jerome's inventions. On returning to New Haven near the end of his life, he died, penniless, in 1868 at the age of 74. The company struggled on after Jerome's bankruptcy until after World War II, when the company endeavored to continue through disruptions caused by a takeover along with poor sales, finally having to fold its operations in 1960 a little more than 100 years after it had been founded. The item is significant as it is associated with Chauncey Jerome who had made a historic contribution to the clock making industry during the 19th century when he began to substitute brass mechanisms for wooden mechanisms in his clocks. This was said to be the greatest and most far-reaching contribution to the clock industry. Because of his discovery of stamping out clockwork gears rather than using castings, Jerome was producing the lowest-priced clocks in the world. That can only add to his significance as the major clock manufacture of the 19th century. Jerome may have made and lost, a fortune selling his clocks but was perhaps the most influential and creative person associated with the American clock business during the mid-19th century. Also, he had served his community as a legislator in 1834, a Presidential elector in 1852 and mayor of New Haven, Connecticut from 1854 to 1855.Eight day movement wall clock with Roman numerals, octagonal shaped rosewood veneered casing, hinged face with locking clip. Wound from front. Face has adjustment for Fast-to-Slow.Part paper label on back of case can just make out "Jerome" and "ight and One" probable meaning is "Eight and One Day" describing the movements operational time between winding the mechanism.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, clock maker, jerome & co, new haven, chauncey jerome, canaan -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageClock, 1867-1870

... ," learning how to make previously handmade cases using machinery... previously handmade cases using machinery. Deciding to go ...Chauncey Jerome (1793–1868) was an American clock maker in the early to mid 19th century. He made a fortune selling his clocks, and his business grew quickly. Jerome was born in Canaan USA in 1793 son of a blacksmith and nail-maker. He began his career in Plymouth, making dials for long-case clocks where he learned all he could about clocks, particularly clock cases, and then went to New Jersey to make seven-foot cases for clocks mechanisms. In 1816 he went to work for Eli Terry making "Patent Shelf Clocks," learning how to make previously handmade cases using machinery. Deciding to go into business for himself, Jerome began to make cases, trading them to Terry for wooden movements. In 1822 Jerome moved his business to Bristol New Haven, opening a small shop with his brother Noble and began to produce a 30-hour and eight-day wooden clocks. By 1837 Jerome's company was selling more clocks than any of his competitors. A one-day wood-cased clock, which sold for six dollars had helped put the company on the map. A year later his company was selling that same clock for four dollars. The company also sold one line of clocks at a wholesale price of 75 cents and by 1841 the company was showing an annual profit of a whopping $35,000, primarily from the sale of its brass movements. In 1842 Jerome moved his clock-case manufacturing operation to St. John Street in New Haven. Three years later, following a fire that destroyed the Bristol plant, Jerome relocated the entire operation to Elm City factory. Enlarging the plant, the company soon became the largest industrial employer in the city, producing 150,000 clocks annually. In 1850 Jerome formed the Jerome Manufacturing Co. as a joint-stock company with Benedict & Burnham, brass manufacturers of Waterbury. In 1853 the company then became known as the New Haven Clock Co, producing 444,000 clocks and timepieces annually, then the largest clock maker in the world. Jerome's future should have been secure but in 1855 he bought out a failed Bridgeport clock company controlled by P.T. Barnum, which wiped him out financially, leaving the Jerome Manufacturing Co. bankrupt. Jerome never recovered from the loss. By his admission, he was a better inventor than a businessman. When Jerome went bankrupt in 1856 the New Haven Clock Company purchased the company. One of the primary benefits of Jerome purchasing New Haven in the first place was the good reputation of the Jerome brand and the network of companies that remained interested in selling its clocks. In England, Jerome & Co. Ltd. sold Jerome clocks for the New Haven company until 1904, when New Haven purchased the English firm outright. After his involvement with the New Haven Company in 1856, Jerome traveled from town to town, taking jobs where he could, often working for clock companies that had learned the business of clock making using Jerome's inventions. On returning to New Haven near the end of his life, he died, penniless, in 1868 at the age of 74. The company struggled on after Jerome's bankruptcy until after World War II, when the company endeavored to continue through disruptions caused by a takeover along with poor sales, finally having to fold its operations in 1960 a little more than 100 years after it had been founded. The item is significant as it is associated with Chauncey Jerome who had made a historic contribution to the clock making industry during the 19th century when he began to substitute brass mechanisms for wooden mechanisms in his clocks. This was said to be the greatest and most far-reaching contribution to the clock industry. Because of his discovery of stamping out clockwork gears rather than using castings, Jerome was producing the lowest-priced clocks in the world. That can only add to his significance as the major clock manufacture of the 19th century. Jerome may have made and lost, a fortune selling his clocks but was perhaps the most influential and creative person associated with the American clock business during the mid-19th century. Also, he had served his community as a legislator in 1834, a Presidential elector in 1852 and mayor of New Haven, Connecticut from 1854 to 1855.Clock, marine, in octagonal rosewood veneer case. Roman numerals to dial, has a seconds dial. 2 key-winding holes slow-to-Fast adjustment pin through dial. Small lever in lower edge of case activates a chime. "8 day, 8 inch, Lever Striking escarpment " Paper label on the back of the clock "Jerome & Co, New Haven, Conn" "Manufacturers of every variety of Office and Home Clocks and Time Pieces".flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, clock, jerome & co, new haven, clock maker, chauncey jerome -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageAnimal specimen - Whale bone, Undetermined

... , was used to make a wide variety of consumer goods. In short, whales... from whales, and it was used to lubricate machinery ...Prior to carrying out a detailed condition report of the cetacean skeletons, it is useful to have an understanding of the materials we are likely to encounter, in terms of structure and chemistry. This entry invites you to join in learning about the composition of whale bone and oil. Whale bone (Cetacean) bone is comprised of a composite structure of both an inorganic matrix of mainly hydroxylapatite (a calcium phosphate mineral), providing strength and rigidity, as well as an organic protein ‘scaffolding’ of mainly collagen, facilitating growth and repair (O’Connor 2008, CCI 2010). Collagen is also the structural protein component in cartilage between the whale vertebrae and attached to the fins of both the Killer Whale and the Dolphin. Relative proportions in the bone composition (affecting density), are linked with the feeding habits and mechanical stresses typically endured by bones of particular whale types. A Sperm Whale (Physeter macrocephalus Linnaeus, 1758) skeleton (toothed) thus has a higher mineral value (~67%) than a Fin Whale (Balaenoptera physalus Linnaeus, 1758) (baleen) (~60%) (Turner Walker 2012). The internal structure of bone can be divided into compact and cancellous bone. In whales, load-bearing structures such as mandibles and upper limb bones (e.g. humerus, sternum) are largely composed of compact bone (Turner Walker 2012). This consists of lamella concentrically deposited around the longitudinal axis and is permeated by fluid carrying channels (O’Connor 2008). Cancellous (spongy) bone, with a highly porous angular network of trabeculae, is less stiff and thus found in whale ribs and vertebrae (Turner Walker 2012). Whale oil Whales not only carry a thick layer of fat (blubber) in the soft tissue of their body for heat insulation and as a food store while they are alive, but also hold large oil (lipid) reserves in their porous bones. Following maceration of the whale skeleton after death to remove the soft tissue, the bones retain a high lipid content (Higgs et. al 2010). Particularly bones with a spongy (porous) structure have a high capacity to hold oil-rich marrow. Comparative data of various whale species suggests the skull, particularly the cranium and mandible bones are particularly oil rich. Along the vertebral column, the lipid content is reduced, particularly in the thoracic vertebrae (~10-25%), yet greatly increases from the lumbar to the caudal vertebrae (~40-55%). The chest area (scapula, sternum and ribs) show a mid-range lipid content (~15-30%), with vertically orientated ribs being more heavily soaked lower down (Turner Walker 2012, Higgs et. al 2010). Whale oil is largely composed of triglycerides (molecules of fatty acids attached to a glycerol molecule). In Arctic whales a higher proportion of unsaturated, versus saturated fatty acids make up the lipid. Unsaturated fatty acids (with double or triple carbon bonds causing chain kinks, preventing close packing (solidifying) of molecules), are more likely to be liquid (oil), versus solid (fat) at room temperature (Smith and March 2007). Objects Made From the Whaling Industry We all know that men set forth in sailing ships and risked their lives to harpoon whales on the open seas throughout the 1800s. And while Moby Dick and other tales have made whaling stories immortal, people today generally don't appreciate that the whalers were part of a well-organized industry. The ships that set out from ports in New England roamed as far as the Pacific in hunt of specific species of whales. Adventure may have been the draw for some whalers, but for the captains who owned whaling ships, and the investors which financed voyages, there was a considerable monetary payoff. The gigantic carcasses of whales were chopped and boiled down and turned into products such as the fine oil needed to lubricate increasing advanced machine tools. And beyond the oil derived from whales, even their bones, in an era before the invention of plastic, was used to make a wide variety of consumer goods. In short, whales were a valuable natural resource the same as wood, minerals, or petroleum we now pump from the ground. Oil From Whale’s Blubber Oil was the main product sought from whales, and it was used to lubricate machinery and to provide illumination by burning it in lamps. When a whale was killed, it was towed to the ship and its blubber, the thick insulating fat under its skin, would be peeled and cut from its carcass in a process known as “flensing.” The blubber was minced into chunks and boiled in large vats on board the whaling ship, producing oil. The oil taken from whale blubber was packaged in casks and transported back to the whaling ship’s home port (such as New Bedford, Massachusetts, the busiest American whaling port in the mid-1800s). From the ports it would be sold and transported across the country and would find its way into a huge variety of products. Whale oil, in addition to be used for lubrication and illumination, was also used to manufacture soaps, paint, and varnish. Whale oil was also utilized in some processes used to manufacture textiles and rope. Spermaceti, a Highly Regarded Oil A peculiar oil found in the head of the sperm whale, spermaceti, was highly prized. The oil was waxy, and was commonly used in making candles. In fact, candles made of spermaceti were considered the best in the world, producing a bright clear flame without an excess of smoke. Spermaceti was also used, distilled in liquid form, as an oil to fuel lamps. The main American whaling port, New Bedford, Massachusetts, was thus known as "The City That Lit the World." When John Adams was the ambassador to Great Britain before serving as president he recorded in his diary a conversation about spermaceti he had with the British Prime Minister William Pitt. Adams, keen to promote the New England whaling industry, was trying to convince the British to import spermaceti sold by American whalers, which the British could use to fuel street lamps. The British were not interested. In his diary, Adams wrote that he told Pitt, “the fat of the spermaceti whale gives the clearest and most beautiful flame of any substance that is known in nature, and we are surprised you prefer darkness, and consequent robberies, burglaries, and murders in your streets to receiving as a remittance our spermaceti oil.” Despite the failed sales pitch John Adams made in the late 1700s, the American whaling industry boomed in the early to mid-1800s. And spermaceti was a major component of that success. Spermaceti could be refined into a lubricant that was ideal for precision machinery. The machine tools that made the growth of industry possible in the United States were lubricated, and essentially made possible, by oil derived from spermaceti. Baleen, or "Whalebone" The bones and teeth of various species of whales were used in a number of products, many of them common implements in a 19th century household. Whales are said to have produced “the plastic of the 1800s.” The "bone" of the whale which was most commonly used wasn’t technically a bone, it was baleen, a hard material arrayed in large plates, like gigantic combs, in the mouths of some species of whales. The purpose of the baleen is to act as a sieve, catching tiny organisms in sea water, which the whale consumes as food. As baleen was tough yet flexible, it could be used in a number of practical applications. And it became commonly known as "whalebone." Perhaps the most common use of whalebone was in the manufacture of corsets, which fashionable ladies in the 1800s wore to compress their waistlines. One typical corset advertisement from the 1800s proudly proclaims, “Real Whalebone Only Used.” Whalebone was also used for collar stays, buggy whips, and toys. Its remarkable flexibility even caused it to be used as the springs in early typewriters. The comparison to plastic is apt. Think of common items which today might be made of plastic, and it's likely that similar items in the 1800s would have been made of whalebone. Baleen whales do not have teeth. But the teeth of other whales, such as the sperm whale, would be used as ivory in such products as chess pieces, piano keys, or the handles of walking sticks. Pieces of scrimshaw, or carved whale's teeth, would probably be the best remembered use of whale's teeth. However, the carved teeth were created to pass the time on whaling voyages and were never a mass production item. Their relative rarity, of course, is why genuine pieces of 19th century scrimshaw are considered to be valuable collectibles today. Reference: McNamara, Robert. "Objects Made From the Whaling Industry." ThoughtCo, Jul. 31, 2021, thoughtco.com/products-produced-from-whales-1774070.Whale bone was an important commodity, used in corsets, collar stays, buggy whips, and toys.Whale bone in two pieces. Advanced stage of calcification as indicated by deep pitting. Off white to grey.None.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, whale bones, whale skeleton, whales, whale bone, corsets, toys, whips -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageAnimal specimen - Whale bone, Undetermined

... , was used to make a wide variety of consumer goods. In short, whales... from whales, and it was used to lubricate machinery ...Prior to carrying out a detailed condition report of the cetacean skeletons, it is useful to have an understanding of the materials we are likely to encounter, in terms of structure and chemistry. This entry invites you to join in learning about the composition of whale bone and oil. Whale bone (Cetacean) bone is comprised of a composite structure of both an inorganic matrix of mainly hydroxylapatite (a calcium phosphate mineral), providing strength and rigidity, as well as an organic protein ‘scaffolding’ of mainly collagen, facilitating growth and repair (O’Connor 2008, CCI 2010). Collagen is also the structural protein component in cartilage between the whale vertebrae and attached to the fins of both the Killer Whale and the Dolphin. Relative proportions in the bone composition (affecting density), are linked with the feeding habits and mechanical stresses typically endured by bones of particular whale types. A Sperm Whale (Physeter macrocephalus Linnaeus, 1758) skeleton (toothed) thus has a higher mineral value (~67%) than a Fin Whale (Balaenoptera physalus Linnaeus, 1758) (baleen) (~60%) (Turner Walker 2012). The internal structure of bone can be divided into compact and cancellous bone. In whales, load-bearing structures such as mandibles and upper limb bones (e.g. humerus, sternum) are largely composed of compact bone (Turner Walker 2012). This consists of lamella concentrically deposited around the longitudinal axis and is permeated by fluid carrying channels (O’Connor 2008). Cancellous (spongy) bone, with a highly porous angular network of trabeculae, is less stiff and thus found in whale ribs and vertebrae (Turner Walker 2012). Whale oil Whales not only carry a thick layer of fat (blubber) in the soft tissue of their body for heat insulation and as a food store while they are alive, but also hold large oil (lipid) reserves in their porous bones. Following maceration of the whale skeleton after death to remove the soft tissue, the bones retain a high lipid content (Higgs et. al 2010). Particularly bones with a spongy (porous) structure have a high capacity to hold oil-rich marrow. Comparative data of various whale species suggests the skull, particularly the cranium and mandible bones are particularly oil rich. Along the vertebral column, the lipid content is reduced, particularly in the thoracic vertebrae (~10-25%), yet greatly increases from the lumbar to the caudal vertebrae (~40-55%). The chest area (scapula, sternum and ribs) show a mid-range lipid content (~15-30%), with vertically orientated ribs being more heavily soaked lower down (Turner Walker 2012, Higgs et. al 2010). Whale oil is largely composed of triglycerides (molecules of fatty acids attached to a glycerol molecule). In Arctic whales a higher proportion of unsaturated, versus saturated fatty acids make up the lipid. Unsaturated fatty acids (with double or triple carbon bonds causing chain kinks, preventing close packing (solidifying) of molecules), are more likely to be liquid (oil), versus solid (fat) at room temperature (Smith and March 2007). Objects Made From the Whaling Industry We all know that men set forth in sailing ships and risked their lives to harpoon whales on the open seas throughout the 1800s. And while Moby Dick and other tales have made whaling stories immortal, people today generally don't appreciate that the whalers were part of a well-organized industry. The ships that set out from ports in New England roamed as far as the Pacific in hunt of specific species of whales. Adventure may have been the draw for some whalers, but for the captains who owned whaling ships, and the investors which financed voyages, there was a considerable monetary payoff. The gigantic carcasses of whales were chopped and boiled down and turned into products such as the fine oil needed to lubricate increasing advanced machine tools. And beyond the oil derived from whales, even their bones, in an era before the invention of plastic, was used to make a wide variety of consumer goods. In short, whales were a valuable natural resource the same as wood, minerals, or petroleum we now pump from the ground. Oil From Whale’s Blubber Oil was the main product sought from whales, and it was used to lubricate machinery and to provide illumination by burning it in lamps. When a whale was killed, it was towed to the ship and its blubber, the thick insulating fat under its skin, would be peeled and cut from its carcass in a process known as “flensing.” The blubber was minced into chunks and boiled in large vats on board the whaling ship, producing oil. The oil taken from whale blubber was packaged in casks and transported back to the whaling ship’s home port (such as New Bedford, Massachusetts, the busiest American whaling port in the mid-1800s). From the ports it would be sold and transported across the country and would find its way into a huge variety of products. Whale oil, in addition to be used for lubrication and illumination, was also used to manufacture soaps, paint, and varnish. Whale oil was also utilized in some processes used to manufacture textiles and rope. Spermaceti, a Highly Regarded Oil A peculiar oil found in the head of the sperm whale, spermaceti, was highly prized. The oil was waxy, and was commonly used in making candles. In fact, candles made of spermaceti were considered the best in the world, producing a bright clear flame without an excess of smoke. Spermaceti was also used, distilled in liquid form, as an oil to fuel lamps. The main American whaling port, New Bedford, Massachusetts, was thus known as "The City That Lit the World." When John Adams was the ambassador to Great Britain before serving as president he recorded in his diary a conversation about spermaceti he had with the British Prime Minister William Pitt. Adams, keen to promote the New England whaling industry, was trying to convince the British to import spermaceti sold by American whalers, which the British could use to fuel street lamps. The British were not interested. In his diary, Adams wrote that he told Pitt, “the fat of the spermaceti whale gives the clearest and most beautiful flame of any substance that is known in nature, and we are surprised you prefer darkness, and consequent robberies, burglaries, and murders in your streets to receiving as a remittance our spermaceti oil.” Despite the failed sales pitch John Adams made in the late 1700s, the American whaling industry boomed in the early to mid-1800s. And spermaceti was a major component of that success. Spermaceti could be refined into a lubricant that was ideal for precision machinery. The machine tools that made the growth of industry possible in the United States were lubricated, and essentially made possible, by oil derived from spermaceti. Baleen, or "Whalebone" The bones and teeth of various species of whales were used in a number of products, many of them common implements in a 19th century household. Whales are said to have produced “the plastic of the 1800s.” The "bone" of the whale which was most commonly used wasn’t technically a bone, it was baleen, a hard material arrayed in large plates, like gigantic combs, in the mouths of some species of whales. The purpose of the baleen is to act as a sieve, catching tiny organisms in sea water, which the whale consumes as food. As baleen was tough yet flexible, it could be used in a number of practical applications. And it became commonly known as "whalebone." Perhaps the most common use of whalebone was in the manufacture of corsets, which fashionable ladies in the 1800s wore to compress their waistlines. One typical corset advertisement from the 1800s proudly proclaims, “Real Whalebone Only Used.” Whalebone was also used for collar stays, buggy whips, and toys. Its remarkable flexibility even caused it to be used as the springs in early typewriters. The comparison to plastic is apt. Think of common items which today might be made of plastic, and it's likely that similar items in the 1800s would have been made of whalebone. Baleen whales do not have teeth. But the teeth of other whales, such as the sperm whale, would be used as ivory in such products as chess pieces, piano keys, or the handles of walking sticks. Pieces of scrimshaw, or carved whale's teeth, would probably be the best remembered use of whale's teeth. However, the carved teeth were created to pass the time on whaling voyages and were never a mass production item. Their relative rarity, of course, is why genuine pieces of 19th century scrimshaw are considered to be valuable collectibles today. Reference: McNamara, Robert. "Objects Made From the Whaling Industry." ThoughtCo, Jul. 31, 2021, thoughtco.com/products-produced-from-whales-1774070.Whale bone was an important commodity, used in corsets, collar stays, buggy whips, and toys.Whale bone piece. Advanced stage of calcification as indicated by deep pitting. Off white to grey.None.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, whales, whale bone, corsets, toys, whips -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageAnimal specimen - Whale bone, Undetermined

... , was used to make a wide variety of consumer goods. In short, whales... from whales, and it was used to lubricate machinery ...Prior to carrying out a detailed condition report of the cetacean skeletons, it is useful to have an understanding of the materials we are likely to encounter, in terms of structure and chemistry. This entry invites you to join in learning about the composition of whale bone and oil. Whale bone (Cetacean) bone is comprised of a composite structure of both an inorganic matrix of mainly hydroxylapatite (a calcium phosphate mineral), providing strength and rigidity, as well as an organic protein ‘scaffolding’ of mainly collagen, facilitating growth and repair (O’Connor 2008, CCI 2010). Collagen is also the structural protein component in cartilage between the whale vertebrae and attached to the fins of both the Killer Whale and the Dolphin. Relative proportions in the bone composition (affecting density), are linked with the feeding habits and mechanical stresses typically endured by bones of particular whale types. A Sperm Whale (Physeter macrocephalus Linnaeus, 1758) skeleton (toothed) thus has a higher mineral value (~67%) than a Fin Whale (Balaenoptera physalus Linnaeus, 1758) (baleen) (~60%) (Turner Walker 2012). The internal structure of bone can be divided into compact and cancellous bone. In whales, load-bearing structures such as mandibles and upper limb bones (e.g. humerus, sternum) are largely composed of compact bone (Turner Walker 2012). This consists of lamella concentrically deposited around the longitudinal axis and is permeated by fluid carrying channels (O’Connor 2008). Cancellous (spongy) bone, with a highly porous angular network of trabeculae, is less stiff and thus found in whale ribs and vertebrae (Turner Walker 2012). Whale oil Whales not only carry a thick layer of fat (blubber) in the soft tissue of their body for heat insulation and as a food store while they are alive, but also hold large oil (lipid) reserves in their porous bones. Following maceration of the whale skeleton after death to remove the soft tissue, the bones retain a high lipid content (Higgs et. al 2010). Particularly bones with a spongy (porous) structure have a high capacity to hold oil-rich marrow. Comparative data of various whale species suggests the skull, particularly the cranium and mandible bones are particularly oil rich. Along the vertebral column, the lipid content is reduced, particularly in the thoracic vertebrae (~10-25%), yet greatly increases from the lumbar to the caudal vertebrae (~40-55%). The chest area (scapula, sternum and ribs) show a mid-range lipid content (~15-30%), with vertically orientated ribs being more heavily soaked lower down (Turner Walker 2012, Higgs et. al 2010). Whale oil is largely composed of triglycerides (molecules of fatty acids attached to a glycerol molecule). In Arctic whales a higher proportion of unsaturated, versus saturated fatty acids make up the lipid. Unsaturated fatty acids (with double or triple carbon bonds causing chain kinks, preventing close packing (solidifying) of molecules), are more likely to be liquid (oil), versus solid (fat) at room temperature (Smith and March 2007). Objects Made From the Whaling Industry We all know that men set forth in sailing ships and risked their lives to harpoon whales on the open seas throughout the 1800s. And while Moby Dick and other tales have made whaling stories immortal, people today generally don't appreciate that the whalers were part of a well-organized industry. The ships that set out from ports in New England roamed as far as the Pacific in hunt of specific species of whales. Adventure may have been the draw for some whalers, but for the captains who owned whaling ships, and the investors which financed voyages, there was a considerable monetary payoff. The gigantic carcasses of whales were chopped and boiled down and turned into products such as the fine oil needed to lubricate increasing advanced machine tools. And beyond the oil derived from whales, even their bones, in an era before the invention of plastic, was used to make a wide variety of consumer goods. In short, whales were a valuable natural resource the same as wood, minerals, or petroleum we now pump from the ground. Oil From Whale’s Blubber Oil was the main product sought from whales, and it was used to lubricate machinery and to provide illumination by burning it in lamps. When a whale was killed, it was towed to the ship and its blubber, the thick insulating fat under its skin, would be peeled and cut from its carcass in a process known as “flensing.” The blubber was minced into chunks and boiled in large vats on board the whaling ship, producing oil. The oil taken from whale blubber was packaged in casks and transported back to the whaling ship’s home port (such as New Bedford, Massachusetts, the busiest American whaling port in the mid-1800s). From the ports it would be sold and transported across the country and would find its way into a huge variety of products. Whale oil, in addition to be used for lubrication and illumination, was also used to manufacture soaps, paint, and varnish. Whale oil was also utilized in some processes used to manufacture textiles and rope. Spermaceti, a Highly Regarded Oil A peculiar oil found in the head of the sperm whale, spermaceti, was highly prized. The oil was waxy, and was commonly used in making candles. In fact, candles made of spermaceti were considered the best in the world, producing a bright clear flame without an excess of smoke. Spermaceti was also used, distilled in liquid form, as an oil to fuel lamps. The main American whaling port, New Bedford, Massachusetts, was thus known as "The City That Lit the World." When John Adams was the ambassador to Great Britain before serving as president he recorded in his diary a conversation about spermaceti he had with the British Prime Minister William Pitt. Adams, keen to promote the New England whaling industry, was trying to convince the British to import spermaceti sold by American whalers, which the British could use to fuel street lamps. The British were not interested. In his diary, Adams wrote that he told Pitt, “the fat of the spermaceti whale gives the clearest and most beautiful flame of any substance that is known in nature, and we are surprised you prefer darkness, and consequent robberies, burglaries, and murders in your streets to receiving as a remittance our spermaceti oil.” Despite the failed sales pitch John Adams made in the late 1700s, the American whaling industry boomed in the early to mid-1800s. And spermaceti was a major component of that success. Spermaceti could be refined into a lubricant that was ideal for precision machinery. The machine tools that made the growth of industry possible in the United States were lubricated, and essentially made possible, by oil derived from spermaceti. Baleen, or "Whalebone" The bones and teeth of various species of whales were used in a number of products, many of them common implements in a 19th century household. Whales are said to have produced “the plastic of the 1800s.” The "bone" of the whale which was most commonly used wasn’t technically a bone, it was baleen, a hard material arrayed in large plates, like gigantic combs, in the mouths of some species of whales. The purpose of the baleen is to act as a sieve, catching tiny organisms in sea water, which the whale consumes as food. As baleen was tough yet flexible, it could be used in a number of practical applications. And it became commonly known as "whalebone." Perhaps the most common use of whalebone was in the manufacture of corsets, which fashionable ladies in the 1800s wore to compress their waistlines. One typical corset advertisement from the 1800s proudly proclaims, “Real Whalebone Only Used.” Whalebone was also used for collar stays, buggy whips, and toys. Its remarkable flexibility even caused it to be used as the springs in early typewriters. The comparison to plastic is apt. Think of common items which today might be made of plastic, and it's likely that similar items in the 1800s would have been made of whalebone. Baleen whales do not have teeth. But the teeth of other whales, such as the sperm whale, would be used as ivory in such products as chess pieces, piano keys, or the handles of walking sticks. Pieces of scrimshaw, or carved whale's teeth, would probably be the best remembered use of whale's teeth. However, the carved teeth were created to pass the time on whaling voyages and were never a mass production item. Their relative rarity, of course, is why genuine pieces of 19th century scrimshaw are considered to be valuable collectibles today. Reference: McNamara, Robert. "Objects Made From the Whaling Industry." ThoughtCo, Jul. 31, 2021, thoughtco.com/products-produced-from-whales-1774070. Whale bone was an important commodity, used in corsets, collar stays, buggy whips, and toys.Whale bone vertebrae. Advanced stage of calcification as indicated by deep pitting. Off white to grey.None.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, whales, whale bone, corsets, toys, whips -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageAnimal specimen - Whale bone, Undetermined