Showing 72 items matching "welded metal"

-

Montmorency–Eltham RSL Sub Branch

Montmorency–Eltham RSL Sub BranchEquipment - Canteen, Water, Circa 1960s

Used by Australian Army circa 1960s.Used by Australian Army circa 1960sUnpainted US style aluminium canteen formed by two seam welded halves (front and back sides) with an aluminium threaded top for attaching a top to the water canteen. The water canteen has a black plastic screw top lid attached to the neck by a metal link chain. The front of the water canteen is bowed outwards with the back being flat with a curved top doorway shaped indentation.australian army, water canteen, aluminium -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyBelt Linesman Pole, circa mid to late 1900's

This linesman belt was used under the 1947 Electricity Regulations and before tighter Occupation and Health regulations (late 1990's early 2000's) were introduced that mechanical lifting platforms(wherever possible) replaced the belt up the pole method.The safety concern was that it required that tools needed by the linesman had to be placed in a large canvas bag and attached to the belt (extra weight) then the linesman had to climb the ladder. Ladders had to be at the correct angle and not able to "slip" from their initial footings. A full harness and a secondary fall belt is now mandatory for pole linesmen. The safety of fellow workers could be compromised if they were required to assist or recover the first linesman if needed. In 2006 an additional 269 registered lineworkers were employed. Please note that the terminology of linesman has become unisex. The linesman's belt enabled the linesman to place his feet against the pole adjust the belt (if needed) and lean back securely allowing both hands to be free to work with. This linesman belt is very significant to the Kiewa Valley due to the numerous poles and high voltage overhead power structures that needed maintenance for the extensive "mushroom" installation of electrical power polls(wood and metal). On high poles (steel) climbing pegs were welded on, however in the Alpine areas snow in winter caused an OH&S problem which were hard to overcome. The safety of a linesman when maintenance of electricity line on poles can be highlighted by the New Zealand linesman who survived an 11,000 volt shock when carrying out maintenance. For the record 11,000 volts is four times more powerful than execution by "the electric chair". The maintenance of the linesman's belt was his responsibility (keeping it clean and in "good" condition). Labour laws change this initial responsibility, from the linesman, to the employer. Climbing pegs were installed on higher poles that extended beyond the reach of ladders.This thick leather linesman belt is made from two lengths of heavy lengths of leather straps sewn together to make up 80% of the belt. The remaining 20% is "the belt tonge" which has eleven holes for three (solid steel tang) buckle connections.kiewa hydro electricity scheme, victorian state electricity commission, relays, generators, electrical pole maintenance -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyDrill Auger, Circa early 1900s

This item wasused before diesel, electric and battery drilling apparatus were used by farmers, and other trades requiring a portable yet reliable method of drilling holes. As this item is a 3/4 inch hole drill it would be suitable for fencing and providing holes for structural studs. As with all outdoor farm equipment, man power was required (be it the farmer or farm hands). Fitness of the operator was at a high standard but protective gloves were not highly thought of as it was before occupational, health and safety regulations became mandatory over all manual handling activities, be they on rural properties or town/city factories. This period was one where the male ego was at its pinnacle i.e. the harder the tasks the more of a man was required. Hard manual work was not only the "way to go" but also a necessity. Evolution of cheap portable electric/battery powered tools opened up a more efficient method available, especially to those with less muscle strength. This item personifies the rugged environment of the rural workplace. The Kiewa Valley with its main emphasis on farming and grazing provided ample opportunity to use this construction implement. The manufacturer being a Scottish tool company is very significant in the era when this hole maker was in high demand. British steel products were of high grade and had a good record of reliability. The reliability of any tool was a solid factor for farmers and tradesmen in this semi-isolated region (Circa early 1900s) within the Kiewa Valley and its regional area. This factor,although not as crucial, post 1960s, when Asian manufacturers entered the market place and produced cheaper tools and transportation and supplies was more frequent and reliable, the need for the more expensive British made tools diminished considerably. After the influx of tradesmen from war torn Europe (post 1945) and the increased availability of tradesmen in the Kiewa Valley and its region the price of tools was and still is not as crucial and the cost of all required tools has become a minimal part of the equation. It is only with the emerging younger trades person, farmer and grazier, who have more, "one eye on production costs" and no "old ties to the motherland" inert mind set that quality tools such as this auger and other hand tools "must be made to last a life time" is no longer part of the modern work environment.This cast iron, hand operated Auger has a short barrel shaped cylinder at one end (known as the "Eye") and at the other end a Helical screw blade (screws the cutting edge into wooden material, thereby creating a hole 3/4 inch diameter in the wood) . The barrel section at the top permits a metal or wooden leverage plank to be inserted. The main rod has a 180mm long cutting/screw blade running from the bottom up towards the "eye" end. From the end of the screw blade to the handle is 380mm and cylindrical, but this changes at 550mm from the "eye" end to a 14mm x 10mm rectangular shape shaft.This shaft end is welded to the "Eye".On the shaft below the "eye" is stamped " MATHESON GLASGOW" on the front side and a spade (cards) symbol on the back.auger, hand drill, fencing, tool, rural trades, brace & bit -

Victoria Police Museum

Victoria Police MuseumArmour (Dan Kelly), 1880

Armour worn by Dan Kelly, Kelly Gang member and brother to Ned Kelly, during the Glenrowan Siege, August 1880.Armour worn by bushranger Dan Kelly including helmet (VPM1799.1); chest plate (VPM1799.2); back plate (VPM1799.3) and groin plate (1799.4). Armour constructed from heavy metal plough plates, bolted and welded together.Painted on inside of armour : 'Dan Kelly', 'Police Exhibition', 'E. Kelly' Impressed on plough VPM1799.3 'Huntly Crucible Cast'ned kelly, bushranger, kelly gang, dan kelly, glenrowan, victoria police -

Warrnambool RSL Sub Branch

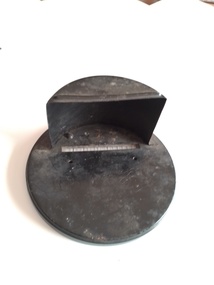

Warrnambool RSL Sub BranchEquipment - Headlight Cover, WW2

... to headligh, with with metal hood attached (welded/soldered?). Light... for attachment to headligh, with with metal hood attached (welded ...Metal, flat round plate with flange for attachment to headligh, with with metal hood attached (welded/soldered?). Light slot attached from backnone -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Colander, 1900-1920

... handle, plated metal construction with welded or folded seams... or colander, metal, with concave base and wood handle, plated metal ...A colander, sieve or cullender is a kitchen utensil used to strain foods such as pasta or to rinse vegetables. The perforated nature of the bowl allows liquid to drain through while retaining the solids inside it is sometimes also called a pasta strainer or kitchen sieve. Conventionally, colanders are made of a light metal, such as aluminum or thinly rolled stainless or plated steel, colanders are also made of plastic, silicone, ceramic, and enamelware. The word colander comes from the Latin Colum meaning sieve.Early 20th century kitchen item possibly of French manufacture due to the design and shape of the bowl this design appears to have been favoured by the French around 1910 for smaller Colanders. This item gives a snapshot into domestic life around the late 19th and early 20th centuries and the types of kitchen equipment in use.Strainer or colander, metal, with concave base and wood handle, plated metal construction with welded or folded seams. Handle painted black, perforated base.Noneflagstaff hill, warrnambool, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, strainer, food strainer, seive, food preparation, kitchen ware -

Federation University Historical Collection

Federation University Historical CollectionTool, British Oxygen Company Ltd, Oxy-cutting and Welding Blow Pipes, c 1904

In 1903 the oxyacetylene welding process was developed. Around the same time, new cryogenic air separation processes, based on work undertaken by Carl von Linde and others, replaced the barium oxide process. This paved the way for larger scale and more efficient production. British Oxygen Company, [1905 to 1969] was formally BRIN'S Oxygen Company Ltd from 1886 to 1905. In 1969 it became BOC. These Blowpipes were used at the Ballarat School of Mine c1916 Interesting article = 1917. https://trove.nla.gov.au/newspaper/article/1629321Boxed Universal Blow Pipe, presented under a perspex top. Pipes mounted by metal bar and hooks to polished wooden board. Display case is 69.0cm x 12.0cm x 25.0cmBoth pipes have metal plates indicating information of maker.blowpipes, ocyacetylene, ballarat school of mines, welding, cutting, commonwealth industrial gases, boc, brin's oxygen company, british oxygen company -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageAnchor, Before 1831

Historical Information: The anchor is from the wooden sailing ship CHILDREN, which was wrecked at Childers Cove east of Warrnambool on the 15th of January 1839 with the loss of 16 lives. The Children anchor was raised from the wreck site by Flagstaff Hill Divers; Peter Ronald, Garry Hayden (Terang, still), Tim Goodall (now Warrnambool), and Colin Goodall (now Warrnambool), on Sunday 3rd January 1974. A week or so later it was dragged up the cliffs and taken to Warrnambool. It is now on display near the entrance to the Maritime Village and Museum. It appears to be a Pering’s Improved Anchor, developed at Portsmouth after 1813. The addition of broad curvature to the anchor arms provided a stronger purchase than the pre-existing Admiralty Old Pattern Long Shanked Anchor with straight arms. However, the evidence of hammer-welding the separate pieces of the arms and palms to the central shank (peaked crown and flat palms) suggests the manufacture is before the 1831 Rodger’s Anchor design, (which cast both arms and their flukes as one piece that was then attached to the shank by a bolt through the crown). This identification seems consistent with the date of the CHILDREN’s construction in 1824. The CHILDREN was a three masted barque with a wooden hull built at Liverpool in England. She was bought by the Henty family of Portland (Australia Felix) in 1837 for regular coastal trading between Van Diemens Land, the Port Phillip District of New South Wales and South Australia. Only 255 tons burden (92 feet in length, with a beam of 25 feet and depth of 17 feet), she sailed from Launceston bound for Adelaide in late December1838, on her first Australian voyage and under the English master who had brought her out – Captain H. Browne. On board the CHILDREN were 24 passengers, including 9 children; the captain and 14 crew; livestock of 1500 sheep, 8 bullocks and 7 horses; general cargo of beef, pork, tobacco, tripe, butter, limejuice, horse hair, currants, lead shot, beer and spirits; 5,000 house bricks from London; and six whaling boats with associated whaling gear. The vessel was battered by gale force north-westerly winds shortly after setting out from Launceston on 11 January 1839 and adverse sailing conditions persisted for the next four days. At 11 pm on the 15th of January 1839, and many miles north and east of the captain’s navigated position, the CHILDREN struck the Pinnacle, a limestone stack off Childers Cove. Within half an hour the ship was completely destroyed. As well as the loss of livestock and cargo, 16 passengers and crew perished, including the captain, six men, one woman and eight children. In 1931 shifting sands at Childers Cove uncovered the skeleton of an adult male. In 1951 another two skeletons were exposed by storms, an adult male and a child. In 1963 some district scuba divers retrieved a small signal-cannon from the site. And in 1974 Flagstaff Hill recovered the anchor and some house bricks. The shipwreck of the CHILDREN is of state significance – Victorian Heritage Register No. S116.A large forged-wrought iron anchor from the wreck of the CHILDREN. Flat hammer-welded flukes on opposing curved arms and a peaked crown. It has a metal (elbowed) stock or cross-bar and a heavy duty pinned shackle (not ring) for the anchor chain. It is in fair condition but extensively corroded after 135 years on seabed (supported on display) .warrnambool, shipwreck coast, flagstaff hill, shipwrecked coast, flagstaff hill maritime village, flagstaff hill maritime museum, shipwreck artefact, maritime museum, the children, childers cove, anchor, pering’s improved anchor, 1839 shipwreck. -

Federation University Historical Collection

Federation University Historical CollectionBooklet - Printed Programme, Ballarat School of Mines Prize Night Programs, 1961-1975, 1960-1975

The Ballarat School of Mines Prize Night was held at the Ballarat Town Hall Trench Room from 1960-1971, the Lower Civic Hall 1972, Wendouree Municipal Hall 1973-1975. The prizes awarded were for the work done in the previous year. Guest speakers: 1960 J. Lonsdale, Production Manager, M.B. John & Hattesley Ltd. 1961 E.J. Neale, Manager Ballaarat Gas Company 1962 W.G. Smith, Director, Myer Empirium (Ballarat) Pty Limited and Member of the School of Mines Council 1963 K.C. Webb, Member of the School of Mines Council 1964 A.E. Stohr Vice-President of the School of Mines Council 1965 B.J. Nicholson, Factory Manager, Australian Timken Pty Ltd and Chairman of the Ballarat PRoductivity Group 1966 L.C. Yandell, District Inspector of Schools 1967 J.L. Trevenen, Vice-President, Victorian Automobile Chamber of Commerce 1968 A.C. Eldridge, Assistant Director of Technical Commission of Victoria 1969 W.J. Anderson, General Manager, Bendix Mintex Pty LtdS. Martin-Brown, Managing Director, Firth Cleveland Pty Ltd 1971 S.F. Newman, Manager Director, Engineering Products Pty Ltd, Employer Representative, Metal Trades Division, Apprenticeship Commission 1972 R.J. Dobell, Regional Directorof Education, Ballarat 1973 B.J. McCulloch, Manager, ELectrical Supply, Mid-Western Regions, State Electricty Commission. 1974 W.J.C. North, Managing Director, Australian Timken Pty Ltd 1975 I.D. McCoy, Managing Director, James Selkirk Pty Ltd Four page booklets listing students who won a trade prize at the Ballarat School of Mines. From 1960 to 1971 the awards were held at the Ballarat Town Hall Trench Room, in 1972 it was held at the Lower Civic Hall, and from 1973 to 1975 it was held at the Wendouree Municipal Hall. ballarat school of mines, prize night, ballarat town hall, trench room, lower civic hall, wendouree municipal hall, commercial, awards, dressmaking, woolclassing, turning and fitting, tool and die-making, oxywelding, electric welding, boiler making, panel beeting, motor mechanics, electrical mechanics, arpentry and joinery, plumbing and gasftting, m.b. john, h.e. arblaster, harry arblaster, w.g. smith, a.e. stohr, ken webb -

Federation University Historical Collection

Federation University Historical CollectionBooks, H.E. Daw Government Printer, Ballarat School of Mines and Industries Departmental Papers, 1914-1950, 1914-1950

Used at the Ballarat School of Mines and the Ballarat Technical Art SchoolThis collection of examinations is significant because of its completeness with the full range of examinations between 1914 and 1950.Large leather bound books, with leather spine, containing all examinations held at the Ballarat School of Mines (including the Ballarat Technical Art School and Ballarat Junior Technical School). The examination papers were supplied and printed by the Education Department, Victoria. Examinations include: Agriculture, Algebra, Architecture, Arithmetic, Applied Mechanics, Assaying, Biology, Botany, Boilermaking, Building Design, Blacksmithing, Bricklaying, Carpentry and Joinery, Coachbuilding, Cabinet Making, Civil Engineering, Cabinet Making, Commercial, Chemistry, Engineering Drawing, Economics, English, Electrical technology, Electricity and Magnetism, Electric Wiring, Electric Welding, Electrical Fitting, Electrical Trades, Food Analysis, Geology, Geological Mapping, Graphics, Geometry, Heat Engines, Heat Treatment, Hydraulics, Hand Railing, Instrument Making, Millinery, Milling and Gearouting, Machine Shop Practice. Metal Founding, Mining, Metallurgy, Mineralogy, Mathematics, Motor Mechanics, Mine Surveying, Mining Mechanics, Petrology, Physics, Painting and Decorating, Pattern Making, Plastering, Plumbing and Gasfitting, Printing, Refrigeration, Spelling, Science , Shorthand, Surveying. Signwriting. Sheet Metalwork, Toolmaking, Ladies Tailoring, Trigonometry, Typewriting, Welding, Commercial Geography. Millinery, Dressmaking, Needlework, Decorative Needlework, Architecture, Building Design and Construction, Art (Composition in Form and Colour), Art (Casting Clay MOdels) Art (Drapery), Art (Drawing the Human Figure From Casts), Art (Drawing the Antique from Memory), Art (Drawing from Memory); Art (Drawing Plant Forms from Nature, Art (Drawing Plant Forms From Memory), Art (Drawing from Models and Objects), (Drawing From a Flat Example). Art (Drawing in Light and Shade from a Cast of Ornament or Lower Nature), Art (Drawing Ornament from the Cast), Art (Drawing from Models or Objects), Art (Drawing fro Dressmakers' and Milliners' Fashions), Art (Drawing With the Brush), Art (Drawing from a Flat Example); Art (Modelled Design), Art (General Design), Art (Embossed Leatherwork), Art (Practical Plane Geometry), Art (Practical Solid Geometry), Art (Geometrical Drawing), Carpentry and Joinery, Art (Human Anatomy), Art (Historic Ornament), Art (House Decoration), Art (LEttering), Signwriting, Art (Light Metalwork), Art (Modelling), Art (Modelling the Human Figure from a Life), Art (Stencilling); Art (Wood Carving) Refrigeration, Teaching, Boilermaking, Blacksmithing, Carpentry and Joinery, Coachbuilding and Carriage Drafting, Electric Wiring, Electrical Fitting, Graining and Marbling, Instrument Making , Machine Shop Practice, Metal Founding, Milling and Gear Cutting, Motor Mechanics, Painting and Decorating, Sheet Metalwork, Toolmaking, Printing, Pattern Making, Plumbing and gasfitting, examinations, ballarat school of mines, ballarat technical art school, trades, education department victoria, agriculture, algebra, architecture, arithmetic, applied mechanics, assaying, biology, botany, boilermaking, building design, blacksmithing, bricklaying, carpentry and joinery, coachbuilding, cabinet making, civil engineering, commercial, chemistry, engineering drawing, economics, english, electrical technology, electricity and magnetism, electric wiring, electric welding, electrical fitting, electrical trades, food analysis, geology, geological mapping, graphics, geometry, heat engines, heat treatment, hydraulics, hand railing, instrument making, millinery, milling and gearouting, machine shop practice, metal founding, mining, metallurgy, mineralogy, mathematics, motor mechanics, mine surveying, mining mechanics, petrology, physics, painting and decorating, pattern making, plastering, plumbing and gasfitting, printing, refrigeration, spelling, science, shorthand, surveying, signwriting, sheet metalwork, toolmaking, ladies tailoring, trigonometry, typewriting, welding., dressmaking, needlework, decorative needlework, architecture, building design and construction, art (composition in form and colour), art (casting clay models), art (drapery), art (drawing the human figure from casts), art (drawing the antique from memory), art (drawing from memory), art (drawing plant forms from nature, art (drawing plant forms from memory), art (drawing from models and objects), (drawing from a flat example), art (drawing in light and shade from a cast of ornament or lower nature), art (drawing ornament from the cast), art (drawing from models or objects), art (drawing for dressmakers' and milliners' fashions), art (drawing with the brush), art (drawing from a flat example), art (modelled design), art (general design), art (embossed leatherwork), art (practical plane geometry), art (practical solid geometry), art (geometrical drawing), art (human anatomy), art (historic ornament), art (house decoration), art (lettering), art (light metalwork), art (modelling), art (modelling the human figure from a life, art (stencilling), art (wood carving), teaching, coachbuilding and carriage drafting, graining and marbling, milling and gear cutting, commercial geography, exams, examination book -

Glenelg Shire Council Cultural Collection

Glenelg Shire Council Cultural CollectionPhotograph - Photograph - construction workers, Portland, n.d

Port of Portland Authority ArchivesBack: i133# Portland Harbour Premier Printing - Top left, blue biro Purple Photographers stamp Wolfgang Sievers - Centre 3155 AC - centre, pencil 2-1/4 wide ' - bottom r. blue biroport of portland archives, portland harbour, construction, welding, equipment -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Tools, steel 'C' or 'G' clamp, c1900

A clamp is a fastening device to hold or secure objects tightly together to prevent movement or separation through the application of inward pressure. The tool is for temporary use for positioning components during construction and wood working. There are many types of clamps available for many different purposes. Some are temporary, as used to position components while fixing them together, others are intended to be permanent. A C-clamp or G-clamp is a type of clamp device typically used to hold a wood or metal work piece, and often used in carpentry and welding. C-clamps or G-clamps are typically made of steel or cast iron, though smaller clamps may be made of pot metal. At the top of the "C" is usually a small flat edge. At the bottom is a threaded hole through which a large threaded screw protrudes. One end of this screw contains a flat edge of similar size to the one at the top of the frame, and the other end usually a small metal bar, perpendicular to the screw itself, which is used to gain leverage when tightening the clamp. When the clamp is completely closed, the flat end of the screw is in contact with the flat end on the frame. When the clamp is actually used, it is very rare that this occurs. Generally some other object or objects will be contained between the top and bottom flat edges. A steel ‘C’ or ‘G’ Clamp used to hold a wood or metal work piece, used in carpentry and welding.L.W.BANKtools, woodwork, metalwork, welding, carpentry, pioneers, market gardeners, early settlers, bank w.l., moorabbin, cheltenham, bentleigh, ormond -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Tools, steel 'G' Clamp, early 20thC

A C-clamp or G- clamp is a type of clamp device typically used to hold a wood or metal work-piece, and often used in, but are not limited to, carpentry and welding. These clamps are called "C" clamps because of their C shaped frame, but are otherwise often called G-clamps or G-cramps because including the screw part they are shaped like an uppercase letter G. The fixed end is not adjustable so size is not variable. G-clamps are typically made of steel or cast iron, though smaller clamps may be made of pot metal. At the top of the "G" is usually a small flat edge. At the bottom is a threaded hole through which a large threaded screw protrudes. One end of this screw contains a flat edge of similar size to the one at the top of the frame, and the other end usually a small metal bar, perpendicular to the screw itself, which is used to gain leverage when tightening the clamp. When the clamp is completely closed, the flat end of the screw is in contact with the flat end on the frame When used some other object or objects will be contained between the top and bottom flat edges. A steel 'G' Clamp tools, g clamp, screws, steel, clamps, metalwork, woodwork, carpentry, early settlers, pioneers, market gardeners, moorabin, bentleigh, cheltenham -

Coal Creek Community Park & Museum

Coal Creek Community Park & MuseumIncomplete coal auger

unknown8436.1 - Coal boring auger bit, handle missing. Tip is single-pointed; point of attachment for handle is rectangular-prism-shaped and the bit appears to be secured by means of welding together interlayered tonques of metal. -

Coal Creek Community Park & Museum

Coal Creek Community Park & MuseumMetal hook

... of metal, without being welded... a curve of metal, without being welded Metal hook ...8433.1 - S-shaped metal hook, it's eye simple a curve of metal, without being welded -

Moorabbin Air Museum

Moorabbin Air MuseumManual - CAC Commonwealth Aircraft Corporation, Specification for Metal Arc Welding Grade A

... Moorabbin melbourne Specification for Metal Arc Welding Grade ... -

Puffing Billy Railway

Puffing Billy Railway216 NQR - Open Medium Truck, 15/ 1/1914

The NQRs were the standard Medium open goods wagon. Generally the sides and ends were removable thus providing a totally flat truck. Three long drop-down doors formed the sides thus allowing easy loading and unloading. 218 of these goods vehicles were built between 1898 and 1914 ? numbered 1 - 218. Originally, these wagons carried the code letter R as they were built with sides and ends. They later had the R removed. Unlike the Broad Gauge, VR's 2 ft 6 in (762 mm) narrow gauge network never had four-wheeled wagons (aside from a handful of trolleys). Because of this, a single design of open wagon emerged and this was the only type of wagon ever used on these lines. This was the NQR class, a wagon with the same length and loading capacity as a Broad Gauge four-wheeled open wagon to make transferring freight between the gauges easier. The wagons, numbered 1 through 218, were built between 1898 and 1914. The wagons used the same underframe as most other non-locomotives on the VR Narrow Gauge. Letters and numbers were originally painted only on the end bulkheads and doors, both of which could be removed as traffic dictated, and this made wagon identification difficult until the decals were transferred to the underframes of each wagon In the 1910s some NQRs were provided with removable wood and steel frameworks with canvas roof canopies and side curtains, and internal seating to supplement the rest of the passenger stock during busy holiday periods. Puffing Billy has re-created these for emergency capacity. Five more NQRs, numbered 219-223, were built between 1990 and 1992 initially for passenger use so were fitted with the removable frames Vehicle Length 25 feet 2 inches ( 7671 mm) Coupled Length 27 feet 4 inches (8330 mm) Width 6 feet 3 inches (1905 mm) Weight 5 tons Capacity 11 tons Built 1898 - 1915 (1992) Number Built 218 (223) In use 14 To be restored 6 216 NQR - Open Medium Truck 15/ 1/1914 NWS Built new VR Service History *NQR 216.VA - 15/ 1/1914 NWS Built new - / /1926 - To NQ 216.VA - Puffing Billy Service History or Notes April 2016 - Trial fitting of brake rigging May 2016 - Riveting of the draw gear castings in progress July 2016 - Riveting of the draw gear castings in progress. Truss rods threaded ready for fitting Aug 2016 - Rivetting of the draw gear castings in progress. Draw gear and couplers being evaluated. Sept 2016 - Riveting of the draw gear castings in progress. Draw gear and couplers being overhauled. Oct 2016 - Riveting of the draw gear castings completed, brake piping installed. Nov 2016 - Floor installed, under framing welding completed, fitting of side doors, hand brake fitted Dec 2016 - Car Workshop - Side panels fitted, end panels to be fitted Jan 2017 - Couplers fitted, brake rodding connected, transferred to Emerald for bogie work and sign writing. Feb 2017 - At Emerald - Tyres machined, braking system being prepared Historic - Victorian Railways - Narrow Gauge Rolling Stock - NQR Open Medium Truck216 NQR - Open Medium Truck made of Steel and metal216 NQRpuffing billy railway, pbr, rolling stock , 216 nqr - open medium truck, victorian railways, nqr - open medium truck -

Tatura Irrigation & Wartime Camps Museum

Tatura Irrigation & Wartime Camps MuseumBadge

Former possession of local WW2 ex RAAF serviceman. Flight Lieutenant.Zig zag air waves held by a hand in the middle. 2 cut off split pins welded to back of badge.metal badges -

Tatura Irrigation & Wartime Camps Museum

Tatura Irrigation & Wartime Camps Museumbadge, Stokes

Former possession of local WW2 Ex RAAF servicemanZigzag airwaves held by a hand in the middle. 2 cut off split pins welded to the back of badge. Mounted on a thin metal oval and attached by a thin strip of lead.smith,ren, raaf, metal badges -

Tatura Irrigation & Wartime Camps Museum

Tatura Irrigation & Wartime Camps MuseumBadge

Former possession of local WW2 ex RAAF serviceman. Flight Lieutenant.Zig zag air waves held by a hand in the middle. 2 cut off split pins welded to back of badge.metal badges -

Ballarat Tramway Museum

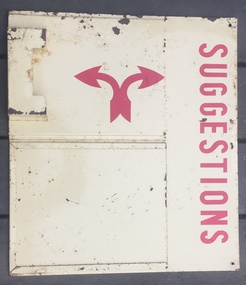

Ballarat Tramway MuseumSign, State Electricity Commission of Victoria (SECV), "Suggestions", mid to late 1960's

... Sign - made from sheet metal, folded and welded to provide... "369375 2 ? and 309981 1 ? 18th Oct" Sign - made from sheet metal ...Demonstrates how suggestions to Management of the SEC depot were made by tram employees and has a strong association with the tram crews.Sign - made from sheet metal, folded and welded to provide a suggestion box for the Ballarat Tram Depot. Has the word "Suggestions" in large Red capital letters, a large tray or box for receiving the suggestions (not too sure how you got them out without undoing the sign and shaking the items - if any - out) and an area for an instruction to be displayed. Painted both sides in a cream colour (SEC tramway cream). Has two screw holes in the top corners. See Reg 3769 for a booklet on the SEC suggestions Scheme/Has pencil marked on the top horizontal white line "369375 2 ? and 309981 1 ? 18th Oct"trams, tramways, sign, sec, depot, crews -

Ballarat Tramway Museum

Ballarat Tramway MuseumDocument - Instruction Book, Westinghouse Brake Company of Australasia Limited and The Westinghouse Brake & Saxby Signal Co. Ltd. of 82 York Road and Kings Cross London, "Westinghouse Railway Operating Data", 2000

Photocopy of 54 data sheets published by Westinghouse Electric & Manufacturing Company of East Pittsburgh Pa, USA c1920. Consists of plastic cover, header page with Westinghouse logo, contents sheets (2 pages), forward, 67 pages (single side photocopy) and heavy rear card cover bound with a green comb binder. Original material lent by Craig Tooke of the Melbourne Tramcar Preservation Association at Haddon. Photocopied by Warren Doubleday March 2000. List of contents produced 30/6/2000 and then bound. Contains data sheets regarding motors, commutators, brushes, armatures, bearings, field coils, pinions, lubrication, air piping, axle collars, resistance grids, gear cases and other technical information. Westinghouse Railway Operating Data 30/6/2000 List of Contents Page No. Care and repair of commutators 1 Undercutting commutators 2 Railway Motor carbon brushes 3 Brush holders 4 Flashing of railway motors 5 Soldering railway armatures 6 Armature Winding 7 Banding armatures 8 Railway Motor Bearings 9 Lubrication of railway motor bearings 10 How to babbitt motor bearings 11 Oil, grease and waster for motors and gears 12 Saturation of motor bearing waste 13 Testing Polarity of Field Coils 14 Charging of storage batteries on Interurban & street rail cars 15 Precautions to be taken with blower installations on motor cars 16 Putting on Railway Motor Pinions 17 How to take armatures out of box frame motors 18 Dipping and Baking of Railway Motors 19 War time dipping and baking outfits 20 Dipping and baking railway motors will decrease troubles 21 Protection of Motor Bearings from Dust 25 Winter Operation of Railway Motor equipments 26 Installation of Air piping to prevent freezing 27 Maintenance of Traction Brake Equipment 28 Maintenance of controller fingers and contacts 29 Hand operated circuit breakers 30 Railway Motor Testing I 31 Railway Motor Testing II 33 Railway Motor Testing III 35 Railway Motor Testing IV 36 Railway Motor Testing V 37 Removing and replacing railway motor armature shaft 39 Mounting and Maintenance of car resistors 40 Lubrication of control apparatus 41 Maintenance of fuse boxes for railway service 42 Does it pay to dip and bake armatures 43 Dipping and Baking as a financial asset 44 Shop Organisation 45 Tinning Malleable Iron Bearing shells 46 Life of armature bearings or railway motors 47 The assembly of complete sets of commutator segments 48 Electric welding as a factor in reclamation 50 Metal to Metal press, shrink and clamping fit allowances 52 Life of railway motor carbon brushes 54 General information of grid resistance design for the operating man 56 Stopping a car by braking with the motors 57 Railway Motor shafts and their maintenance 58 Axle collars 59 Gear cases 60 Ventilated railway motors 62 Revamping Loose armature bearings 64 Life of axle bearings of railway motors 65 Heat-treated bolts for railway service 66 Document imaged over 7 parts 7-9-2016 - see hi res files. trams, tramways, westinghouse, motors, data sheets, technical information -

Ballarat Tramway Museum

Ballarat Tramway MuseumPhotograph - Black & White Photograph/s, State Electricity Commission of Victoria (SECV), c1935

Set of 8 black and white photographs of the SEC Ballarat track welding truck, Reg. No. 119 341. Truck is a British Bedford truck, model WHG, built by GMH Melbourne between 1932 and 1934. Has a fabric roof, chassis fitted with a tray top body, side tool box, metal frame and covered with canvas, fitted out with a motor generator set, welding equipment and oxy acetylene bottles. Also fitted with a spot light - 'Auto Reel Lite". - See Related Items sheet on truck notes provided by Kevin Oates, MFESB workshops, 4/2001. (Scan of this sheet of the Kodak folder added 15-8-2017 - see pdf file.) 1705.1 - side on view of truck with covers down, except for opening at back. Photographed in Wendouree Parade with two different boat sheds in the background. 1705.2 - view with drivers side cover opened, showing equipment arrangement. 1705.3 - close up view of motor generator set and controls and one of the oxy acetylene bottles. 1705.4 - view showing equipment laid out on the roadway, welding cover, seat, grinder, cables, shovels, welding mask etc. 1705.5 - close up view of motor generator control panel and associated cables. 1705.6 - view of side of truck showing all equipment. 1705.7 - vertical format photo from rear of truck showing equipment laid out and wandering lead connected to the overhead. Also shows high voltage wires on a power pole fitted with a bracket arm. 1705.8 - view of truck from the front, with SEC symbol on side, with a covers closed. Thought to be photographed at loop in Wendouree Parade on the View Point line, near Mill St. Prints when donated to the BTM were contained within a red and yellow "Kodak" folder. Folder stored with catalogue worksheet. On rear of folder in ink is number "53569" and stamped on the front is number "984" and written in front top left hand cover, "8 prints" and in top right hand corner word "Sarah". See Notes provided by Kevin Oates of the MFESB (Metro Fire Brigade Melbourne) Thornbury workshops on the truck, manufacture and engine. A survey of Wendouree Parade on 22/4/2001 did not show the boat sheds or power lines featured in the photographed. Thought to be in vicinity of Power station because of the high voltage lines on the power poles.Stamped on rear in black ink, "984" on photos 1705.3 to 1705.8.trams, tramways, welding truck, trackwork, secv, wendouree parade -

Ballarat Tramway Museum

Ballarat Tramway MuseumAdministrative record - Log book, Diary, Collins Bros, 1970

Yields information about the track maintenance activities of the track gang in Ballarat, the work they did, notes, names and other information.Collins Australian Diary, No. 324 printed by Collins Bros, dark blue card covers, sewn sections with ruled sheets providing a diary for 1971, one week per double page. Has "useful information" sheets at from the diary. Used by the SEC Ballarat track gang to record their daily work, leave, welding, track cleaning, truck driver etc. Names of gang often mentioned in the diary undertaking specific jobs and when on leave. Last day work recorded - 24/9/1072. Loose contents Inside front cover Workshop requisition to fill pot holes and note re rail requirements for Daylesford and Hamilton. Clip to page with metal paper clip. 29/8/1971 - note re account numbers and on rear of a pink requisition form - work list for gang. 12/9/1971 - Workshop Requisition form - green dated 6/5/1971 Inside rear cover Circular for a Male Cleaner in Traralgon Workshop Requisition for work at the Zone substation - Ballarat South Circular to authorised drivers re used of defective vehicles. Has W. Vermeend name typed in top left hand corner. SEC Long Service Regulations circular - has name D.Wiseman handwritten in top right hand corner. 5 sheets of blue carbon paper.tram, trams, sec, ballarat, depot, trackwork -

Ballarat Tramway Museum

Ballarat Tramway MuseumDocument - Folder with papers, Railway Track-work Company and Clementine and Thompson and Mercer Sts and Philadelphia and Pennsylvania USA. and Perrot and Adams Ltd, "Railway Track Equipment - Track Grinding Machines, Welding and Bonding Machines - Bonds, Welding Steel, Grinding Wheels and Blocks", 1920's?

Yields information about the type and presentation of books or information folders that were sent to the Electric Supply Company of Victoria about tramway products available on the market and the company the produced them.Folder with 24 pages of advertising pamphlets bound into it with two metal clip binders advertising products available from the Railway Track-Work Company and titled ""Railway Track Equipment - Track Grinding Machines, Welding and Bonding Machines - Bonds, Welding Steel, Grinding Wheels and Blocks". Has brochures or pamphlets for: . The Universal Rotary Track Grinder . Reciprocating Track Grinder . The Atlas Rail Grinder . The Ajax Electric Arc welders .Vertical Rail Lifter . The Jackson Electric Tie Tamper. Generally the lead page of each pamphlet has been imaged. Provides a description of each item, along with method of operation and parts listing generally. The folder has on a number of pages and the back cover, a sticker from Frank R. Perrot (Now Perrot and Adams Ltd), Machinery Merchant of 394 Kent St Sydney. Railway Track-work Company , Clementine, Thompson and Mercer Sts, Philadelphia, Pennsylvania USA. For a full scan of the document see the hi res file.Numerous: Front cover sticky label "1620" in top left hand corner, "Mr Pringle" on front cover and stamp with words "Ballarat Tramway Preservation Society Catalogue No. 10" in ink on front cover. Inside front cover has a pencil note, behind the crease in the bottom right hand corner. On the first pamphlet "Ballarat Tramway Preservation Society Catalogue No. 10" in ink on top right hand corner. On parts page for the Reciprocating Track Grinder has the "Perrot and Adam Ltd" company stamp.trams, tramways, trackwork, equipment, rails -

Tennis Australia

Tennis AustraliaRacquet, Circa 1968

A wooden racquet featuring a decal image on both sides of the throat, of a gold shield featuring the Olympic symbol in the centre. Inscription from head to stem, on both sides: OLYMPIC/FIBRE/WELDED/THROAT/SLAZENGER. Materials: Wood, Nylon, Metal, Glue, Lacquer, Leather, Ink, Ribbon, Plastic, Paint, Stringtennis -

Tennis Australia

Tennis AustraliaRacquet, Circa 1968

A wooden racquet featuring a decal image on both sides of the throat, of a gold shield featuring the Olympic symbol in the centre. Inscription from head to stem, on both sides: OLYMPIC/FIBRE/WELDED/THROAT/SLAZENGER. Materials: Wood, Nylon, Metal, Glue, Lacquer, Leather, Ink, Ribbon, Adhesive tape, Paint, Stringtennis -

Federation University Art Collection

Federation University Art CollectionSculpture - Sculpture - metal, Collier, Betty, [Kangaroo] by Betty Collier

Betty Collier (nee Thege) was a student of the Ballarat Technical Art School, and lectured in Sculpture at the University of Ballarat, both predecessor institutions of Federation University Australia. This work was requested for the collection by Brian McLennan. This item is part of the Federation University Art Collection. The Art Collection features over @000 works and was listed as a 'Ballarat Treasure' in 2007.A large oxy welded sheet steel reclining kangaroo.art, artwork, betty collier, collier, kangaroo, sculpture -

Beechworth RSL Sub-Branch

Beechworth RSL Sub-BranchBoots General Purpose (GP)

These boots had a metal plate inserted in sole to protect the feet of personnel wearing boot. This was after earlier boots without this protection did not protect the wearer from sharpened spikes eg bamboo set in pits or “punji” pits, during the Vietnam war. The laces were done up by knotting one end,threading from bottom hole across to opposite hole,up next hole on same side,across to opposite hole etc. This meant that only one loop per opposite holes was all exposed for a quick and easy cutting to release the boot in case of injury to wearer.These boots were typically worn on parade,training and in combat during the Vietnam war era and after.The LEFT boot solid black leather uppers with split leather tongue sewn to sides - making the boot semi water and insect proof.The sole is hard black rubber compound with 7 cleats on sole and 3 cleats on heel,all part of rubber sole. Woven black cotton laces. 30 mm leather reinforcing strip sewn on inside top of boot. 11 by 5mm metal holes per boot for laces. Sole is welded on. “Dunlop made in Australia” and “5/5” on sole in front of heel. Inscribed on top reinforced inside leather band is- “ B 22 R.B.T 1439 188” on one side and “ 5/6” on the other.boots, general purpose, g.p., vietnam war -

Beechworth RSL Sub-Branch

Beechworth RSL Sub-BranchBoots General Purpose (GP)

These boots had a metal plate inserted in sole to protect the feet of personnel wearing boot. This was after earlier boots without this protection did not protect the wearer from sharpened spikes eg bamboo set in pits or “punji” pits, during the Vietnam war. The laces were done up by knotting one end,threading from bottom hole across to opposite hole,up next hole on same side,across to opposite hole etc. This meant that only one loop per opposite holes was all exposed for a quick and easy cutting to release the boot in case of injury to wearer.These boots were typically worn on parade,training and in combat during the Vietnam war era and after.The RIGHT boot solid black leather uppers with split leather tongue sewn to sides - making the boot semi water and insect proof.The sole is hard black rubber compound with 7 cleats on sole and 3 cleats on heel,all part of rubber sole. Woven black cotton laces. 30 mm leather reinforcing strip sewn on inside top of boot. 11 by 5mm metal holes per boot for laces. Sole is welded on. “Dunlop made in Australia” and “5/5” on sole in front of heel. Inscribed on top reinforced inside leather band is- “ B 22 R.B.T 1439 188” on one side and “ 5/6” on the other.boots, general purpose, g.p., vietnam war