Showing 490 items matching "chemical"

-

Bendigo Historical Society Inc.

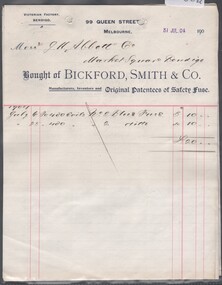

Bendigo Historical Society Inc.Administrative record - Abbott Collection: July to Dec 1904: records and receipts for purchases by J.H. Abbott & Co from a number of companies, 1904

Various (July to Dec) 1904 company letterhead invoices which have supplied predominantly gelignite and fuses to J.H. Abbott .Abbott Collection: July to Dec 1904: records and receipts for purchases gelignite, fuses, etc.; by J.H. Abbott & Co from a wide range of generally Melbourne based companies: 2403.89a five invoices from Bickford, Smith & Co. gelignite and fuses, from 31 July to 30 Nov 1904 2403.89b five invoices from Morris & Meeks, Melbourne, gelignite, from 1 Aug to 1 Dec 1904 2403.89c 33 invoices from Gibbs, Bright & Co., gelignite, from 27 Jun to 24 Dec 1904 2403.89d 17 invoices from Richard Linton, gelatine dynamite, from 7 Jul to 31 Dec 1904 2403.89e 24 invoices from McMicking & Co., from 2 Jul to 30 Dec 1904 2403.89f 21 invoices from Perks Bros. & Co., from 27 Jul to 31 Dec 1904 2403.89g 27 invoices from Dalgety and Company Limited, from 21 Jul to 31 Dec 1904 2403.89g 11 invoices from Briscoe & Company Limited, Wholesale Ironmongers & Hardware Merchants, from 25 Oct 1904 to 30 Dec 1904 2403.89h 27 invoices from Dalgety and Company Limited, from 21 Jil to 31 Dec 1904 2403.89i 36 invoices from Australian Explosives and Chemicals Compy. Ltd, from 1 Jul to 31 Dec 1904trade company invoices 1904, j h abbott -

Orbost & District Historical Society

Orbost & District Historical Societyblack and white photograph, Warren, Mrs H, first half 20th century

This is a photograph of Alan, Keith, Preston and Jim Nixon. George Nixon (1862-1941) selected land in Bete Bolong in the 1890's. He married Emily Warren in 1889 in Orbost. He was a shire councillor. He was a prominent breeder of Clydesdales and after a serious fall off a horse walked with a walking stick and special boot for the rest of his life. He was well-known for his interest in cars, horse-racing and politics.He was married to Emily Warren in 1889 in Orbost. Mrs Nixon (Emily)was the first Red Cross president during WW1. They had ten children.both George and Emily are buried in the Orbost Cemetery. (ref:From White Knowle to Pumpkin Point by Hon Peter Nixon A.O.) The photographer was Warren, Helena (1871-1962) who was a self-taught photographer who became both the local press correspondent and a producer of humorous trompe l'oeil postcard images. Helena Warren was a thirty-two year old settler living on a small mixed farm with her husband, William, at Newmerella, near Orbost in Gippsland, Victoria, when she bought her first camera, an Austral Box quarter-plate. Her family says she was entirely self-taught, like many women photographers who started out with nothing but the instructions on the packets of film and chemicals. In over fifty years practice she graduated from the total novice, who opened all her first mail order plates in bright sunlight and ruined them, to a competent photographer who became both the local press correspondent and an inveterate producer of humorous trompe l’oeil postcard images.This photograph has significance in its association with Helen Frances Warren, a popular Orbost identity who was well known as an accomplished photographer and needleworker, This item is also associated with a prominent Orbost family. George Nixon was the son of James and Alice Nixon. The Nixon families were among the earliest settlers on the Snowy River. It is an example of the early book-keeping of an Orbost business in the early 20th century.A black / white photograph of three boys and a baby in a carved out pumpkin with a flag at each end and "HMAS ORBOST" carved in the front.warren-helena pumpkins nixon -

Federation University Historical Collection

Federation University Historical CollectionBook, A Descriptive Catalogue of the Minerals in the Museum of the School of Mines, Ballaarat, 1882, 1882

The Museum of the Ballarat School of Mines was established in 1872. The curator in 1882 was Ferdinand M. Krause. Prefatory Notice by James Oddie). The want of a guide through the technical collections of The School Mines has long been felt by visitors and students - a guide , not so much to those who merely 'look' at the various exhibits in the Museum, but an instructor to those who desire to take away with them some practical information on the natural occurrence and economical value of the objects exhibited. This want is being filled by the labour of Mr. Krause, whose first installment - 'A Descriptive Catalogue of the Minerals' - is herewith represented to the visiting public." Introduction to the catalogue: " The collection is still in its early growth, and far from being a complete representation of the Mineral Kingdom; many varieties, species, and even whole groups are absent. This state of incompleteness will, no doubt, be adjusted in the sequence, and progressive lists issued from time to time. 'Ad interin' the present catalogue will, be found useful to students and visitors of the School. As far as practicable, the classifications of the minerals accords with that adopted at the Royal School of Mines, London. The numbers prefixed to the species in the catalogue agree with those on the descriptive labels which accompany each specimen, and also with those attached to the specimens themselves. On the descriptive labels the chemical composition of the minerals is expressed in formulae usually employed in standard mineralogical works. Students who have note paid attention to mineralogical chemistry will note that each dot over a symbol is equivalent to one atom of oxygen, .... A bar through a symbol denotes a double atom of the base, .... " In 1882 the collection was housed in 33 cases. The catalogue outlines the specimen types housed in each case. The classification of minerals accords with that adopted at the Royal School of Mines, London. Leather covered book of 94 pages with gold lettering on the front, including "F.M. Krause". The book includes a plan of the museum layout, plan of the grounds and buildings of the Ballarat School of Mines and a prefatory notice by James Oddie.ballarat school of mines, ballarat school of mines museum, museum, krause, ferdinand krause, fm krause, oddie, james oddie, geology, mineralogy, charles boyd, f.m. krause, minerals, curator -

Federation University Historical Collection

Federation University Historical CollectionDocument - Document - Correspondence, VIOSH: Department of Defence - Air Force Office, Canberra, December 1982

Victorian Institute of Occupational Safety and Health (VIOSH) Australia is the Asia-Pacific centre for teaching and research in occupational health and safety (OHS) and is known as one of Australia's leaders on the field. VIOSH has a global reputation for its innovative approach within the field of OHS management. VIOSH had its first intake of students in 1979. At that time the Institution was known as the Ballarat College of Advanced Education. In 1990 it became known as Ballarat University College, then in 1994 as University of Ballarat. It was 2014 that it became Federation University. VIOSH Australia students are safety managers, senior advisors and experienced OHS professionals. They come from all over Australia and industry. Students are taught active research and enquiry; rather than textbook learning and a one-size fits all approach. VIOSH accepts people into the Graduate Diploma of Occupational Hazard Management who have no undergraduate degree - on the basis of extensive work experience and knowledge Letter from the Department of Defence to Dennis Else looking at the possibility of Ballarat College of Advanced Education conducting a short course in occupational health and safety for RAAF hygiene personnel. It would teach the fundamentals of occupational health and environmental monitoring and control. Better use of the practical time allocated is needed. Noise induced hearing loss is the most widespread occupational health risk in the RAAF. Industrial chemicals used and hazardous industrial procedures in the repair and maintenance of aircraft are an issue needing resolution. Existing terminal objectives for basic hygiene inspectors course in occupational health and safety are provided for comment. Information provided by K R Stone, Flight Lieutenant for Director General of Air Force Health Services. Eight A4 pages,typed. Handwritten note top left cornerLetterhead of Department of Defence - Air Force Office.Signature of K R Stoneviosh, victorian institute of occupational safety and health, department of defence, air force office, raaf, ballarat college of advanced education, dennis else, k r stone, flight lieutenant, director general of air force health services, short course in occupational health and safety, raaf hygiene personnel, hearing loss, industrial chemicals, hazardous industrial procedures -

Federation University Historical Collection

Federation University Historical CollectionBook, A Descriptive Catalogue of the Minerals in the Museum of the School of Mines, Ballaarat, 1882, 1882

The Museum of the Ballarat School of Mines was established in 1872. The curator in 1882 was Ferdinand Krause. Prefatory Notice by James Oddie). The want of a guide through the technical collections of The School Mines has long been felt by visitors and students - a guide, not so much to those who merely 'look' at the various exhibits in the Museum, but an instructor to those who desire to take away with them some practical information on the natural occurrence and economical value of the objects exhibited. This want is being filled by the labour of Mr. Krause, whose first installment - 'A Descriptive Catalogue of the Minerals' - is herewith represented to the visiting public." Introduction to the catalogue: " The collection is still in its early growth, and far from being a complete representation of the Mineral Kingdom; many varieties, species, and even whole groups are absent. This state of incompleteness will, no doubt, be adjusted in the sequence, and progressive lists issued from time to time. 'Ad interin' the present catalogue will, be found useful to students and visitors of the School. As far as practicable, the classifications of the minerals accords with that adopted at the Royal School of Mines, London. The numbers prefixed to the species in the catalogue agree with those on the descriptive labels which accompany each specimen, and also with those attached to the specimens themselves. On the descriptive labels the chemical composition of the minerals is expressed in formulae usually employed in standard mineralogical works. Students who have note paid attention to mineralogical chemistry will note that each dot over a symbol is equivalent to one atom of oxygen, .... A bar through a symbol denotes a double atom of the base, .... " In 1882 the collection was housed in 33 cases. The catalogue outlines the specimen types housed in each case. Brown soft covered book of 94 pages with gold lettering on the front. The book includes a plan of the museum layout, plan of the grounds and buildings of the Ballarat School of Mines and a prefatory notice by James Oddie. It also includes handwritten notes by Curator Ferdinand Krause. .2) Business card of I.H. Barbery, engraver with F.W. Niven. The lithography of the plan of the Ballarat School of Mines at the back of the catalogue was undertaken by F.W. Niven.Handwritten inclusion of extra entries (probably by Ferdinand Krause).ballarat school of mines, ballarat school of mines museum, museum, krause, ferdinand krause, fm krause, oddie, james oddie, geology, mineralogy, charles boyd, royal school of mines london, london school of mines, classification -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageCeramic - Cover, circa 1883

This ceramic cover was recovered from the wreck of the 1882-1883 George Roper between the late 1960’s to early 1970’s. It is one of the shipwreck artefacts in the John Chance Collection. The purpose of the cover is unclear. The holes could be for ventilation. The cover may have been used to protect food or keep it at an even temperature. It may also have been used for covering fragrant petals, allowing some scent to escape through the holes. The residue around the underside of the holes and their random placement indicate that the cover could be partially handmade. The discolouration could have come from its time in the sea. The GEORGE ROPER 1882 - 1883 - The George Roper was a 4-masted iron sailing ship built in Liverpool, England, in 1882 for fast international trade with Australia. The large vessel was launched in February 1883. The ship was on its first trip, departing Liverpool for Melbourne, captained by John Ward and a crew of 31. She had almost reached her destination on July 4 1883, approaching Port Phillip Bay and being towed by the steam tug William. The weather changed to rough with fog and both the George Roper and the William hit the dangerous Lonsdale Reef at Port Phillip Heads. The Captain and crew were eventually rescued and taken to Queenscliff. Salvage syndicates were able to recover a lot of the cargo before the George Roper broke up and sank. Amongst the cargo was soft goods, draperies, household items, spirits of malt and distilled liquors, chemicals, dynamite, and 1,400 tons of steel rails for the Victorian Government. Also in the hold were Russell Stourbridge bricks, as paying ballast. The ventilated cover is as an example of domestic ceramic ware of the 1880s. The cover also holds significance as it was recovered by John Chance, a diver from the wreck of the George Groper in the 1960s-70s. Items that come from several wrecks along Victoria's coast have since been donated to the Flagstaff Hill Maritime Village’s museum collection by his family, illustrating this item’s level of historical value. The George Roper is considered historically and archaeologically significant and as such, is listed on the Victorian Heritage Database, VHR S286. It is an example of a vessel built specifically for fast travel to and from Australia with a large shipment of cargo. The George Roper’s cargo of steel rails adds to the historical significance of international trade to the growing colony of Australia and Victoria in particular, with rail transportation soon to become a faster and safer form of transportation between colonial towns. Divers can still access parts of the scattered wreck and other artefacts recovered in the 1970s and 1980s can be viewed in both public and private collections. Cover; unglazed white ceramic, oval shape. The cover has holes randomly poked through its surface, one large hole is a six pointed star shape. Underneath there is a narrow rim placed slightly inside the edge. There is residue on the underneath around the holes. There is orange-brown discolouration and areas where the surface is lighter coloured. flagstaff hill, warrnambool, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, john chance, west coast trader, george roper, w. h. potter & sons, w.t. dickson and son, captain john ward, russell stourbridge bricks, port phillip heads, lonsdale reef, dive wreck, vhr s286, coastal trader, ceramic, vintage, ventilated cover, domestic item -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageContainer - Pill bottle, from mid-19th century to 1902

This small handmade bottle possibly dates from the mid-1840s. It may have been used as a traveller's ink bottle, due to its wide mouth. It was recovered from the wreck of the Inverlochy and is part of the John Chance collection. Small glass ink bottles similar to this one were handmade, blown into a cup shaped mould, and sharply broken off from the blow-pipe at the neck and sealed with a cork or wax. The mouth of this bottle appears to have been added after it was blown. INVERLOCHY 1895-1902 - The Inverlochy was a steel sailing barque built in Scotland in 1895 for international trade. In 1902 the Inverlochy left Liverpool under the command of Captain E.R. Kendrick. There were 21 officers and crew and the captain’s wife Mrs Kendrick, on board, bound for Australia with cargo that included tools, chemicals, liquor (beer, whisky, stout, rum, and brandy), steel, iron, wire netting, hoop iron, tinplate and pig iron), and steel wire for the Melbourne Tramway Company, tiles, soap, soft goods and earthenware. On December 18 almost at their destination, the Inverlochy ran aground on Ingoldsby Reef at Point Addis, near Anglesea. The crew and passengers left the ship via lifeboat and landed at Thompson’s Creek, then walked about 20 kilometres to Barwon Heads. Salvagers were interested in the 10 miles of cable in the hold. Mrs Kendrick’s ‘high grade’ bicycle was amongst the items salvaged but she lost her jewellery and two pianos. By February 1903 the ship had broken up and objects such as bottles and casks of liquor were washed ashore. Bad weather shook the wreck in June 1903, causing the ship’s spars and figurehead to be washed ashore. This handmade bottle is historically significant for its association with being made and used during the mid-to-late 19th century. This handmade glass bottle is significant for its connection with the John Chance Collection, which is historically significant as an example of artefacts from wrecks that had been lost in the coastal waters of Victoria from thirty to over one hundred years before John Chance and others discovered them. These artefacts are a sample of goods carried as cargo or personal possessions, and of ship hardware of that era. The bottle is significant through its connection with the barque, Inverlochy, The Inverlochy is significant for its cargo, which is a snapshot of the array of goods imported into Australia at the turn of the 19th century, including cable for the Melbourne Tramway Company. The Inverlochy is historically significant and is registered on the Victorian Heritage Database, VHR S338. The wreck of the Inverlochy is important as an accessible dive site that shows the remains of a large international trading vessel and its contents. It is valuable for an insight into Victorian era of shipping and maritime history.Bottle, clear glass, handmade, mould-blown. Small pill bottle has round mouth and neck, straight sides, rectangular base, no seams, shiny surface. Thickness of glass varies. Mouth is lop-sided and lip varies in width. Inscription of logo on both wide sides. Inscription embossed on sides [tear drop] logo. flagstaff hill, warrnambool, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, john chance, inverlochy, scotland, captain e.r. kendrick, melbourne tramway company, tramway cable, ingoldsby reef, point addis, anglesea, thompson’s creek, barwon heads, victorian, antique, handmade, mould blown, small glass bottle, rectangular glass bottle, pill bottle -

Federation University Historical Collection

Federation University Historical CollectionBooklet - Magazines, Ballarat School of Mines Magazine, 1924-1930, 1924-1930

The Ballarat School of Mines is a predecessor institution of Federation University Australia. Bound copies of the Ballarat School or Mines Students' Magazine. 1924 * Dr J.R. Pound * Noel Hay Obituary * The History of Chemistry * Literary Society * Herald B. Herbert * Chemistry in Modern Life by Val G. Anderson * Chemistry in Literature by J.R. Pound * School Literary Society * Ladies in Pharmacy * Musings on Modern Literature - Mainly Drama (W.G. C.) * Trip to Newcastle * Appreciation of the Masterpieces of Art * The Antique Room * Dressmaking * Pottery * Sloyd * The Mystery of the Atom *Inorganic Evolution by R.S. Russell * Photography * First Aid Club 1926 * The Trip to Morwell * Chemical Excursions (Yallourn) * Eastern Life and Customs by Rex Warrillow * Organic Evolution by Edwin A. Brophy * Chemistry in the Kitchen * Obituary for Professor Alfred Mica Smith * The Historical Development of Patterns i Silk Fabrics * Pottery * Literary Society * Early Evidence of Metallurgy in Britain * Brief Description of the Magnet Silver Mine, Tasmania * The manufacture of Leather Photographs * SMB Athletics Team, winners of the Herald Shield (M. Timmings, L. Evans, F. Sheahan, R. Collins, A. Murfett, W. Hughes, L. Hillman * SMB Football Team * Ballarat Technical Art School Tennis Four * SMB Girls' Basketball Team * SMB GIrls Hockey Team * Ballarat Junior Technical School Scholarship and Studentship Winners * On Punctuation Advertisements: Sunshine Biscuits, Harris Powell and Sandford, W. Gribble & Co., Gilbert Motors, T.J. Haymes The Wallpaper King, C. Marks and Co., Wilson's Tailors and Mercers, George S. Grant, Miss A. Corin Art Worker, Tunbridges, Felton, Grimwade & Co., Hasten and Ewins, Ballarat Wireless Stores, Fred A. Reed, Suttons, E. Hall-Jones, Stansfield and Smith, Ballarat Gas Company, Richards and Co Studio, F.H. Drew, Adam Scott, R.A. Hudson, Huttons, J.A. Holland, A.E. White, F. Barrow Monumental Sculptor, R. Young, H.A. Evans, Alexandria Tea Rooms, W. Cornell Chemist, Black Cat Tea Rooms, J.A. Reynolds, A.M. Palmer, Morris Cars and Trucks, Mrs Stones, Millers The Clothiers, T.G. Skewes, Wattle TEa Rooms, H.B. Selby, Middleton and Morris, C.P.A. Taylor, Thornton Studios, Fred Irwin, Isaac Abraham, Ballarat Radio Listening-In, Baxter and Stubbs 1927 * Chemists Trip to Melbourne (Mount Lyell Chemical Works, Footscray, Yarraville * Literary Society * Mr J.N. Rowell 1928 * Prohibition in U.S.A. by Ed A. Brophy * Dr. J.W. Mellor and His Work at Stoke, England by Reginald C. Callister * The Science of Chemistry by C.A. Schache * Trip to Yallourn (Brown Coal Deposits, Steam Plant at Yallourn, Switchgear and Transformers, Briquette Factory * Walhalla Past and Present by G.E.B. * The Hand Loom * Precious Stones 1929 * The Old Brewery * The History of Chemistry by J.R. Pound * Occurrence of Mineral Oil in Gippsland * Experiences with Malayan Chinese by R. Warrillow * Organise Colors (Dyestuff Pigments) in Rubber Goods 1930 * News from Chine by Henry Kum Yuen * L'Art Moderne * The Story of Clay by T.H. Trengrove * A Glimpse of England * The Beginnings of Arithmeticballarat school of mines, pottery, ceramics, reginald callister, metallurgy, chemistry, j. pound, alfred mica smith, herald shield, harold herbert, lindsay hillman, john rowell, j.r. pound, noel hay, drawing from antique, yallourn excusion, walhalla, sunshine biscuits, harris powell and sandford, w. gribble & co., gilbert motors, t.j. haymes, the wallpaper king, c. marks and co., wilson's tailors and mercers, george s. grant, miss a. corin art worker, tunbridges, felton, grimwade & co., hasten and ewins, ballarat wireless stores, fred a. reed, suttons, e. hall-jones, stansfield and smith, ballarat gas company, richards and co studio, r.a. hudson, huttons, j.a. holland, a.e. white, f. barrow monumental sculptor, r. young, h.a. evans, alexandria tea rooms, w. cornell chemist, black cat tea rooms, j.a. reynolds, a.m. palmer, morris cars and trucks, mrs stones, millers the clothiers, t.g. skewes, wattle tea rooms, h.b. selby, middleton and morris, c.p.a. taylor, thornton studios, fred irwin, isaac abraham, ballarat radio listening-in, baxter and stubbs, mount lyell chemical works, footscray, c.a. schache, yallourn briquette factory, t.h. trengrove, history of chemistry, excursions, morwell, morwell excursion, women in pharmacy, mt lyall, excursion, slloyd, drawing from the antique, james pound, yallourn, yallourn excursion, ballarat arch of victory, mt macedon, f.h. drew, adam scott, university women -

Department of Energy, Environment and Climate Action

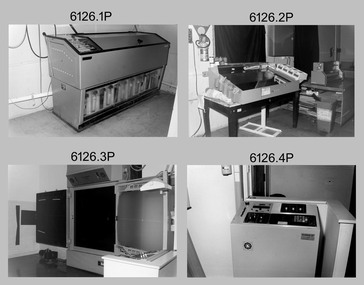

Department of Energy, Environment and Climate ActionPrototype fuel moisture meter

Bushfire behaviour is influenced by many things including temperature, relative humidity, forest type, fuel quantity and fuel dryness, topography and even slope. Wind has a dominant effect on the Rate of Spread (ROS), and also bushfire size, shape and direction. Fuel arrangement is as important as fuel quantity (tonnes/ha). Fibrous and ribbon bark, together with elevated and near-surface scrub fuels act as ladders which lead flames into the tree canopy. But the availability of fuel to burn depends largely on its moisture content. When it exceeds 20-25% not much will burn, whereas 12-15% is generally ideal for fuel reduction burning, but if the moisture content drops as low as 7-10% virtually everything will ignite, and fire behaviour becomes extreme. During the afternoon of the Ash Wednesday bushfires on 16 February 1983 fuel moisture contents were recorded at Stawell as low as 2.7%. Fine fuels like leaves and bark can rapidly absorb moisture after a shower of rain, or from the air when the Relative Humidity (RH) is high, and the temperature is low. Conversely, they can also dry out very quickly. So even though the overall fuel quantity in the forest doesn’t change, the fine fuel availability can increase rapidly from zero after rain to many tonnes per hectare as the fuel dries out. This can happen over a few hours on hot and windy days. Heavy fuels like logs on the ground take longer to dry out. Since the 1930s foresters, firefighters and researchers have been working to develop quick and reliable techniques for measuring fuel moisture content. One of the most accurate methods is slowly drying a sample of fuel in a conventional oven for 24-48 hours to remove all the moisture and measuring the weight difference, but this takes time and is not practical in the field when rapid measurements are needed. But oven drying is often used as a benchmark to compare other methods. Microwave ovens are faster but can cause uneven drying and even char the fuel. They are also not very practical for use in the field. Some mathematical models rely on weather records such as rainfall, wind speed, evaporation, cloud cover, shading, relative humidity, slope, aspect and season of the year to predict soil and fuel moisture. The Keetch-Byram Drought Index of soil dryness is the most common. But complex fuels with leaves, twigs, grass etc make the predictive models often inadequate for fine fuels. The most common technique in Victorian forests until recently was the trusty Speedy Moisture Meter. Originally developed in England during the 1920s for measuring moisture in wheat and other grains it was adapted for Australian forest fuels in the 1950s (I think). Fuel was first ground using a Spong mincer, often attached to the bullbar of a vehicle, and a small sample placed into the Speedy together with a measure of calcium carbide and then sealed. A chemical reaction created gas pressure which was read on the external dial. There were important techniques with cleaning, mincing and using the chemicals with the Speedy to give reliable readings, but it was quick, inexpensive, robust, portable and practical in the field. It was used routinely before igniting a fuel reduction burn or measuring fuel moisture differentials on slash burns. But in about 1996, Karen Chatto and Kevin Tolhurst from the Department’s Creswick Research Station developed the Wiltronics Fuel Moisture meter which measured electrical resistance. Wiltronics is an Australian owned company operating from Ballarat. The final result was a kit that was portable, accurate and could reliably measure fuel moisture contents between 3% and 200%. Although expensive, it is now widely used by fire agencies around the world which has virtually relegated the Speedy to the back cupboard.Prototype Fuel moisture meterT-H Fine Fuel Meterforests commission victoria (fcv), bushfire, forest measurement -

National Wool Museum

National Wool MuseumFilm - 16o8, Abha Gupta, Streamline Media and Communications Group Pty Ltd, 2025

One of three We The Makers videos commissioned by the Programs and Education department at the National Wool Museum to assist in learning and engagement alongside the We The Makers Sustainable Fashion Prize 2025 exhibition at the National Wool Museum. The films feature artist interviews from three finalists from We the Makers, providing insights into their personal influences, the motivations behind their material choices and the impact of culture on artistic practice. This film features designer Abha Gupta and her work '1608'. Artist Statement: ‘16o8' collection by designer Abha Gupta pays tribute to the historic moment when the British first arrived in India, a pivotal event that reshaped the country's fashion landscape for over two centuries. She launched this collection under her brand name, ‘Antiek East’. Designed under the mentorship of RMIT professor Blake Barns, the collection draws inspiration from the era of British colonisation, reflecting its profound influence on Indian fashion history. Drape suit jacket in the collection is meticulously handwoven and handmade by local artisans using natural fibres, embodying a commitment to traditional craftsmanship. Beyond creating aesthetically compelling garments, ‘16o8’ project served as a catalyst for social impact. By prioritising fair wages and opportunities for marginalised communities, she uplifted artisans and craftspeople, embedding sustainability across all levels and stages of her endeavour. This commitment not only resonated through the ethical sourcing of materials but also through the conscientious production practices that minimise environmental impact. Circular design principles guided the approach of this project, emphasising materials that are biodegradable and minimise environmental impact. Natural dyeing processes not only uphold traditional craftsmanship but also reduce harmful chemical runoff into ecosystems. By choosing sustainable fabrics and methods, the project aimed to create garments that are not only beautiful but also ethically and environmentally sound.Three minute eighteen second digital video with audio. abha gupta, fashion, designer, film, we the makers, sustainability, textiles -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageInstrument - Letter Scale, Ca. early 20th century

This handheld portable pendulum quadrant scale was used to weigh small paper items such as letters and documents, powdered chemicals or metals like gold, and animal fleece samples. This mechanical scale can weigh up to a maximum of 10 ounces, which is about 285 grams or one-and-a-half cups of brown sugar. The operator holds the scale’s ring and connects the item to be weighed onto the wire clip. The weight of the item causes the pendulum to pivot, and the scale measures the weight of the object, indicated by the arrow. This scale belonged to Dr William Roy Angus and is now part of Flagstaff Hill’s comprehensive W.R. Angus Collection, donated by the family of Dr W R Angus, 1901-1970, surgeon and oculist. The W.R. Angus Collection: - The W.R. Angus Collection includes historical medical equipment, surgical instruments and material belonging to Dr Edward Ryan and Dr Thomas Francis Ryan, (both of Nhill, Victoria) and Dr Angus’ own belongings. The Collection’s history spans the medical practices of the two Doctors Ryan, from 1885-1926 plus that of Dr Angus, up until 1969. It includes historical medical and surgical equipment and instruments from the doctors Edward and Thomas Ryan of Nhill, Victoria. Dr Angus married Gladys in 1927 at Ballarat, the nearest big city to Nhill where he began as a Medical Assistant. He was also Acting House surgeon at the Nhill hospital where their two daughters were born. During World War II He served as a Military Doctor in the Australian Defence Force. Dr Angus and his family moved to Warrnambool in 1939, where Dr Angus operated his own medical practice. He later added the part-time Port Medical Officer responsibility and was the last person appointed to that position. Both Dr Angus and his wife were very involved in the local community, including the planning stages of the new Flagstaff Hill and the layout of the gardens there. Dr Angus passed away in March 1970.This letter scale is the only one of its type in our collection. It is an example of objects belonging to Dr. W. R. Angus, 1901-1970, surgeon and oculist. The W.R. Angus Collection is significant for still being located at the site it is connected with, Doctor Angus being the last Port Medical Officer in Warrnambool. The Collection includes historical medical objects that date back to the late 1800s.Letter scale, a handheld quadrant fixed pendulum scale made from silver-plated metal. This small weighing instrument is shaped like a quarter-circle with a metal ring, a fixed pendulum counterweight and a decorative pivoting arrow indicator. A hanger clip is attached to a short arm of the scale. Measurements are embossed on the arc of the circle, labelled in ounces (oz) and ranging from 0 to 10 at unequal distances apart. The scale is part of the W.R. Angus Collection.Scale measurements, "OZ" (ounces), "0 /14 1/2 1 2 3 4 5 6 7 8 9 10 "flagstaff hill, warrnambool, maritime village, maritime museum, shipwreck coast, great ocean road, flagstaff hill maritime museum and village, dr w r angus, mira hospital, w.r. angus collection, scale, weighing instrument, measure weight, postal scale, chemist scale, letter, weigh, post, office, quadrant scale, letter scale, handheld, portable, mechanical scale, pendulum scale, fixed balance scale -

Coal Creek Community Park & Museum

Coal Creek Community Park & MuseumBottle, glass, c 1929-1950's ref: AGM mark on bottle base

TROVE : The Argus (Melbourne, Vic. : 1848 - 1957) Thursday 14 February 1867 p 1 Article 'THE EXHIBITION. OFFICIAL DISTRIBUTION OF PRIZES. The culminating point in the history of the Intercolonial Exhibition of 1866-7, was reached yesterday, when His Excellency Sir Henry Manners Sutton, Governor of Victoria, publicly received the reports of the jurors, and formally declared their awards. .........................CHEMICAL AND METALLURGICAL PRODUCTS AND PROCESSES....................... MEDALS - VIctoria .............John Kruse, chemist, Melbourne - For his fluid magnesia...........................'. Haines, Gregory, 1994, Á History of Pharmacy in Victoria, The Australian Pharmaceutical Publishing Company in association with the Pharmaceutical Society of Australai (Victoria) Ltd, Melbourne, Australia.opp. page 54, photo of 'John Kruse' and of 'John Kruse's pharmacy, Russell Street, Melbourne, 1866'. TROVE : Melbourne Punch (Vic. : 1855 - 1900) Thursday 21 January 1897 p 3 Article A Musical Genius. BY X. THERE is a chemist's shop in Hawthorn in the drawingroom over which some of the best, music that has ever been heard under the Southern Cross has been discoursed. Here John Kruse, the famous violinist , has delighted his late father with his violin. Here Nellie Mitchell's (Madame Melba's) voice found appreciative admiration long before she became famous. It is the shop of John Kruse, chemist and druggist, the inventor of fluid magnesia, insecticide and a world of well-known articles of daily consumption. The old mail died some time back, but lived long enough to gratify his chief wish, viz,, to see his famous son, Herr Johann Kruse. John journeyed from Germany to see his dying father. His brief but brilliant sojourn amongst us will be remembered by all lovers of music. TROVE: Colac Herald Friday 1 September 1876, page 4, Article. TROVE: The Argus Tuesday 2 July 1867, page 3, Advertisement. 'Felton Grimwade, 125 Russell Street, Melbourne'Clear glass bottle, oval shaped in section with text embossed on both sides and on base. Embossed on base 'M65' over '1923 6' over 'AGM'. Side 1 : 'KRUSES PRIZE MEDAL MAGNESIA' Side 2 : 'THIS BOTTLE IS THE PROPERTY OF FELTON GRIMWADE & CO PTY. LTD. MELBOURNE'. Over the numeral '1'.chemist, magnesia -

Coal Creek Community Park & Museum

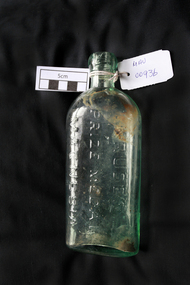

Coal Creek Community Park & MuseumBottle, glass, C. 1866 - 1895

TROVE : The Argus (Melbourne, Vic. : 1848 - 1957) Thursday 14 February 1867 p 1 Article 'THE EXHIBITION. OFFICIAL DISTRIBUTION OF PRIZES. The culminating point in the history of the Intercolonial Exhibition of 1866-7, was reached yesterday, when His Excellency Sir Henry Manners Sutton, Governor of Victoria, publicly received the reports of the jurors, and formally declared their awards. .........................CHEMICAL AND METALLURGICAL PRODUCTS AND PROCESSES....................... MEDALS - VIctoria .............John Kruse, chemist, Melbourne - For his fluid magnesia...........................'. Haines, Gregory, 1994, Á History of Pharmacy in Victoria, The Australian Pharmaceutical Publishing Company in association with the Pharmaceutical Society of Australai (Victoria) Ltd, Melbourne, Australia.opp. page 54, photo of 'John Kruse' and of 'John Kruse's pharmacy, Russell Street, Melbourne, 1866'. TROVE : Melbourne Punch (Vic. : 1855 - 1900) Thursday 21 January 1897 p 3 Article A Musical Genius. BY X. THERE is a chemist's shop in Hawthorn in the drawingroom over which some of the best, music that has ever been heard under the Southern Cross has been discoursed. Here John Kruse, the famous violinist , has delighted his late father with his violin. Here Nellie Mitchell's (Madame Melba's) voice found appreciative admiration long before she became famous. It is the shop of John Kruse, chemist and druggist, the inventor of fluid magnesia, insecticide and a world of well-known articles of daily consumption. The old mail died some time back, but lived long enough to gratify his chief wish, viz,, to see his famous son, Herr Johann Kruse. John journeyed from Germany to see his dying father. His brief but brilliant sojourn amongst us will be remembered by all lovers of music. TROVE: Colac Herald Friday 1 September 1876, page 4, Article. TROVE: The Argus Tuesday 2 July 1867, page 3, Advertisement. 'Felton Grimwade, 125 Russell Street, Melbourne' Clear glass ellipse in section bottle, with embossed text on both sides and initials and numerals on base.'KRUSES PRIZE MEDAL MAGNESIA', 'This bottle is the property of FELTON GRIMWADE & CO Pty Ltd Melbourne on sides. 'S1935' 'AGM' on base.magnesia, kruse, felton, grimwade, chemist -

Department of Energy, Environment and Climate Action

Department of Energy, Environment and Climate ActionProtective Bushfire overalls

At the time of the 1982-83 bushfire season FCV firefighters wore either navy blue issue overalls or their own clothing, generally a checked flannel shirt and jeans. Uncomfortable safety boots and hardhats were issued. The CFA had switched from white overalls to their distinctive yellow kit by 1983. In about 1980, in a far-sighted corporate move for the time, Alan Threader, who was the Chairman of the FCV, established a departmental safety committee, which he personally chaired. The Committee, among other things, wanted to upgrade fire safety clothing. Alan also initiated a radical colour idea after a work trip to the UK in about 1981 and brought home a small sample swatch. Alan believed that the now distinctive bright yellow-green was a good colour contrast to the Victorian bush which is a blue-green hue. Trevor Brown from Stores Branch scored the task to make the change and letters were sent to the UK seeking information about the pigment. The FCV worked with the Commonwealth Dyers Association and Cushen Clothing to replicate the shade on cotton drill, which presented darker when it was treated with the flame-retardant chemical, Proban. The first of the new Kermit Suits were rolled-out in late 1984, and the stylish colour was initially registered and patented to the Department. But it's also fair to say that the new gaudy shade of apparel wasn’t universally popular with staff. The lime green overalls were an Australian first, and forest agencies in other states followed a few years later. In the early 1990s, armed with a pair of dressmaker’s scissors, the baggy one-piece Kermit boilersuits were tailored by Peter Billing from Fire Protection Branch and Trevor Brown in conjunction with the family-owned business, Top Level Workwear, which saw numerous enhancements and prototypes. The two-piece Kermit suits were available in the late 1990s after many years of argy-bargy and complaints from field firefighters. Protective overalls Two types - early FCV (c 1983) and later CNR (1992) forests commission victoria (fcv), protective clothing, safety equipment -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Equipment - 'KIX' Insecticide Powder, DAVID CHEMICALS PTY LTD, for dogs, cats and all animals, 20thC

Kix was first manufactured by Clark King & Co.after World War II. The offices were located in 237 Queen Street Melbourne. Clark, King &Co Pty Ltd started business in the early 1920's and were known as the poultry food specialist. The head of the firm, Mr Clive Harrison Clark was know as a successful poultry farmer and exhibitor of prize birds, he was the secretary of the Brighton Poultry Society.KIX was used by citizens of MoorabbinA yellow heavy cardboard container with metal swivel top containing a white powder. Front: KIX - STRONGEST - INSEDTICIDE - keeps on killing - FLEAS - SILVERFISH - BUGS - LICE - MOTHS - ANTS - COCKROACHES - FOR DOGS, CATS AND ALL ANIMALS BACK: DIRECTIONS Fleas and Lice. Kix keeps on killing fleas and lice for weeks. An occasional dusting will FLEA-PROFF dogs and cats. Dust Kix on the hair of dogs commencing at the neck and ru it in with the fingers. If the dog appears irritated after treatment, it will be due to the efforts of fleas to escape and indicates both the effectiveness of Kix and the necessity of treatment. Sprinkle Kix on the head and neck of cats and rub well in. Use Kix on poultry also. In personal hygiene against fleas Kix may may dusted on underwear socks etc. Use Kix also for head lice and body lice. Silverfish, cockroaches, Bugs, Ants. Duct Kix where necessary and it will remain effective for months. These pest take some hours to die, but death is certain. Active Constituents: 5% Para Para Dichlorodiphenyltrichloroethane, 2.5% Isobornly Thiocyanoacetate. DAVID CHEMICALS PTY LTD. Clayton, Victoria Contents 1½ ozskix, insecticide, ddt, pets, moorabbin, poultry -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Bowl, Late 19th or early 20th Century

The Process of Making Pottery Decorating, Firing, Glazing, Making, Technical There is a rhythm and flow to clay. It can’t be done all at once! Even the making process! It can take weeks to get everything done, especially if you can only work on your pottery once a week! Even though we have three hour classes, it’s often just not enough time! Here is an overview of some of the processes so you have a bit more grasp on some of the technical stuff! Step One – Design There are SO many ideas out there for making stuff in clay! From delicate porcelain jewellery, through to heavy sculptural work and everything in between. Deciding your direction is sometimes not that easy – when you first start, try everything, you will naturally gravitate to the style that you enjoy! The options and variations are endless and can get a wee bit overwhelming too! Check in with me before you start to ensure your ideas will work, what order you might do things, how you could achieve the look you are seeking and any other technical data required! Step Two – Making Clay is thixotropic. This means that as you work with it, the clay first gets sloppier and wetter, before is begins to dry in the atmosphere. For most things, you simply can’t do all parts of the project at once. An example of work order might look like: Get last weeks work out from the shelves Prepare clay for today’s work – roll your clay, prepare balls for throwing, make the first stage of a pinch pot) Clean up last week’s work and put it on the shelf for bisque firing Check that you have any glazing to do – and do enough of it that you will have time to finish your main project Do the next step of your next project – there might be a further step that can’t be complete immediately, in that case, wrap your work well and put onto the shelves. Letting your work rest for a while can really help keep your work clean and professional looking. Many things require bagging under plastic to keep it ready for work the next week – put your name on the outside of the bag so you can find your work easily. We have stickers and markers. Consider how you want to decorate your work – coloured slip can be applied at a fairly wet stage (remembering that it will make your work even wetter!). Trying to apply slip to dry clay won’t work! If you want to do sgraffito – you will need to keep the work leather hard (a state of dryness where you can still work the clay with a little effort and a little water and care). Step Three – Drying Most of the time your work can go into the rack uncovered to let it dry out for the following week. If you want to continue forming or shaping you will need to double bag your work – put your work on a suitable sized bat and put the bat in a bag so the base of the bag is under the bat, then put another bag over the top of the work and tuck the top of the bag under the bat. If you want to trim (or turn) your thrown work the following week, it should also be double bagged. If your work is large, delicate, or of uneven thicknesses, you should lightly cover your work for drying. When considering the drying process, bare in mind the weather, humidity and wind! The hotter and dryer, the faster things dry and work can dry unevenly in the shelves – this can lead to cracking – another time to lightly cover your work for drying. Step Four – Trimming and Cleaning Up Your work is dry! It is called greenware now and it is at it’s most fragile! Handle everything with two hands. I often refer to soft hands – keep everything gentle and with your fingers spread as much as possible. Try to not pick up things like plates too much, and always with both hands! Before your work can be bisque fired it should be “cleaned up”. You work won’t go into the kiln if it has sharp edges – when glazed, sharp edges turn into razor blades! Use a piece of fly wire to rub the work all over – this will scratch a little so be light handed. Use a knife or metal kidney to scrape any areas that require a bit more dynamic treatment than the fly wire offers! Finally, a very light wipe over with a slightly damp sponge can help soften and soothe all of your edges and dags! Trimming thrown work: If you are planning to trim (or turn) your thrown work (and you should be), make sure you bag it well – your work should be leather hard to almost dry for easiest trimming. Use this step to finish the work completely – use a metal kidney to polish the surface, or a slightly damp sponge to give a freshly thrown look. Wipe the sponge around the rim after trimming, and check the inside of the pot for dags! Trimming slip cast work: Usually I will trim the rims of your work on the wheel the following day to make that stage easier, however you will still need to check your work for lumps and bumps. Last but not least – check that your name is still clearly on the bottom of your work. Step Five – Bisque Firing When the work is completely dry it can go into the bisque kiln. The bisque kiln is fired to 1000°C. This process burns off the water in the clay as well as some of the chemically bound water. The structure of the clay is not altered that much at this temperature. Inside the bisque kiln, the work is stacked a little, small bowl inside a larger bowl and onto a heavy plate. Smaller items like decorations or drink coasters might get stacked several high. Consideration is paid to the weight of the stack and shape of the work. A bisque kiln can fire about one and a half times the amount of work that the glaze kiln can fire. The firing takes about 10 hours to complete the cycle and about two days to cool down. Once it has been emptied the work is placed in the glaze room ready for you to decorate! Step Six – Glazing Decorating your work with colour can be a lot of fun – and time consuming! There are three main options for surface treatment at this stage: Oxide Washes Underglazes Glazes Washes and underglazes do not “glaze” the work – It will still need a layer of glaze to fully seal the clay (washes don’t need glaze on surfaces not designed for food or liquid as they can gloss up a little on their own). Underglazes are stable colourants that turn out pretty much how they look in the jar. They can be mixed with each other to form other colours and can be used like water colours to paint onto your work. Mostly they should have a clear glaze on top to seal them. Oxides are a different species – the pink oxide (cobalt) wash turns out bright blue for instance. They don’t always need a glaze on top, and some glazes can change the colour of the wash! The glazes need no other “glaze” on top! Be careful of unknown glaze interactions – you can put any combination of glaze in a bowl or on a plate, but only a single glaze on the outside of any vertical surface! Glazes are a chemical reaction under heat. We don’t know the exact chemicals in the Mayco glazes we use. I can guess by the way they interact with each other, however, on the whole, you need to test every idea you have, and not run the test on a vertical surface! Simply put, glaze is a layer of glass like substance that bonds with the clay underneath. Clay is made of silica, alumina and water. Glaze is made of mostly silica. Silica has a melting point of 1700°C and we fire to 1240°C. The silica requires a “flux” to help it melt at the lower temperature. Fluxes can be all sorts of chemicals – a common one is calcium – calcium has a melting point of 2500°C, however, together they both melt at a much lower temperature! Colourants are metal oxides like cobalt (blue), chrome (green through black), copper (green, blue, even red!), manganese (black, purple and pink) iron (red brown), etc. Different chemicals in the glaze can have dramatic effects. for example, barium carbonate (which we don’t use) turns manganese bright pink! Other elements can turn manganese dioxide brown, blue, purple and reddish brown. Manganese dioxide is a flux in and of itself as well. So, glazes that get their black and purple colours, often interact with other glazes and RUN! Our mirror black is a good example – it mixes really well with many glazes because it fluxes them – causes them to melt faster. It will also bring out many beautiful colours in the glazes because it’s black colouring most definitely comes from manganese dioxide! Glaze chemistry is a whole subject on it’s own! We use commercial Mayco glazes on purpose – for their huge range of colour possibilities, stability, cool interactions, artistic freedom with the ability to easily brush the glazes on and ease of use. We currently have almost 50 glazes on hand! A major project is to test the interactions of all glazes with each other. That is 2,500 test tiles!!!! I’m going to make the wall behind the wheels the feature wall of pretty colours! Step Seven – Glaze (Gloss or sometimes called “Glost”) Firing Most of the time this is the final stage of making your creation (but not always!) The glaze kiln goes to 1240°C. This is called cone 6, or midrange. It is the low end of stoneware temperatures. Stoneware clays and glazes are typically fired at cone 8 – 10, that is 1260 – 1290°C. The energy requirement to go from 1240°C to 1280°C is almost a 30% more! Our clay is formulated to vitrify (mature, turn “glass-like”) at 1240°, as are our glazes. A glaze kiln take around 12 hours to reach temperature and two to three days to cool down. Sometimes a third firing process is required – this is for decoration that is added to work after the glaze firing. For example – adding precious metals and lustres. this firing temperature is usually around 600 – 800°C depending upon the techniques being used. There are many students interested in gold and silver trims – we will be doing this third type of firing soon! After firing your work will be in the student finished work shelves. Remember to pay for it before you head out the door! There is a small extra charge for using porcelain clay (it’s more than twice the price of regular clay), and for any third firing process! Once your work has been fired it can not turn back into clay for millennia – so don’t fire it if you don’t like it! Put it in the bucket for recycling. https://firebirdstudios.com.au/the-process-of-making-pottery/ The bowl is an example of kitchenware used in the 19th century and still in use today.Bowl white ceramic. Crack on side. Badly stained.Backstamp very faint and unable to be read.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, mixing bowl, food preparation, kitchen equipment, ceramic -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Bowl

The Process of Making Pottery Decorating, Firing, Glazing, Making, Technical There is a rhythm and flow to clay. It can’t be done all at once! Even the making process! It can take weeks to get everything done, especially if you can only work on your pottery once a week! Even though we have three hour classes, it’s often just not enough time! Here is an overview of some of the processes so you have a bit more grasp on some of the technical stuff! Step One – Design There are SO many ideas out there for making stuff in clay! From delicate porcelain jewellery, through to heavy sculptural work and everything in between. Deciding your direction is sometimes not that easy – when you first start, try everything, you will naturally gravitate to the style that you enjoy! The options and variations are endless and can get a wee bit overwhelming too! Check in with me before you start to ensure your ideas will work, what order you might do things, how you could achieve the look you are seeking and any other technical data required! Step Two – Making Clay is thixotropic. This means that as you work with it, the clay first gets sloppier and wetter, before is begins to dry in the atmosphere. For most things, you simply can’t do all parts of the project at once. An example of work order might look like: Get last weeks work out from the shelves Prepare clay for today’s work – roll your clay, prepare balls for throwing, make the first stage of a pinch pot) Clean up last week’s work and put it on the shelf for bisque firing Check that you have any glazing to do – and do enough of it that you will have time to finish your main project Do the next step of your next project – there might be a further step that can’t be complete immediately, in that case, wrap your work well and put onto the shelves. Letting your work rest for a while can really help keep your work clean and professional looking. Many things require bagging under plastic to keep it ready for work the next week – put your name on the outside of the bag so you can find your work easily. We have stickers and markers. Consider how you want to decorate your work – coloured slip can be applied at a fairly wet stage (remembering that it will make your work even wetter!). Trying to apply slip to dry clay won’t work! If you want to do sgraffito – you will need to keep the work leather hard (a state of dryness where you can still work the clay with a little effort and a little water and care). Step Three – Drying Most of the time your work can go into the rack uncovered to let it dry out for the following week. If you want to continue forming or shaping you will need to double bag your work – put your work on a suitable sized bat and put the bat in a bag so the base of the bag is under the bat, then put another bag over the top of the work and tuck the top of the bag under the bat. If you want to trim (or turn) your thrown work the following week, it should also be double bagged. If your work is large, delicate, or of uneven thicknesses, you should lightly cover your work for drying. When considering the drying process, bare in mind the weather, humidity and wind! The hotter and dryer, the faster things dry and work can dry unevenly in the shelves – this can lead to cracking – another time to lightly cover your work for drying. Step Four – Trimming and Cleaning Up Your work is dry! It is called greenware now and it is at it’s most fragile! Handle everything with two hands. I often refer to soft hands – keep everything gentle and with your fingers spread as much as possible. Try to not pick up things like plates too much, and always with both hands! Before your work can be bisque fired it should be “cleaned up”. You work won’t go into the kiln if it has sharp edges – when glazed, sharp edges turn into razor blades! Use a piece of fly wire to rub the work all over – this will scratch a little so be light handed. Use a knife or metal kidney to scrape any areas that require a bit more dynamic treatment than the fly wire offers! Finally, a very light wipe over with a slightly damp sponge can help soften and soothe all of your edges and dags! Trimming thrown work: If you are planning to trim (or turn) your thrown work (and you should be), make sure you bag it well – your work should be leather hard to almost dry for easiest trimming. Use this step to finish the work completely – use a metal kidney to polish the surface, or a slightly damp sponge to give a freshly thrown look. Wipe the sponge around the rim after trimming, and check the inside of the pot for dags! Trimming slip cast work: Usually I will trim the rims of your work on the wheel the following day to make that stage easier, however you will still need to check your work for lumps and bumps. Last but not least – check that your name is still clearly on the bottom of your work. Step Five – Bisque Firing When the work is completely dry it can go into the bisque kiln. The bisque kiln is fired to 1000°C. This process burns off the water in the clay as well as some of the chemically bound water. The structure of the clay is not altered that much at this temperature. Inside the bisque kiln, the work is stacked a little, small bowl inside a larger bowl and onto a heavy plate. Smaller items like decorations or drink coasters might get stacked several high. Consideration is paid to the weight of the stack and shape of the work. A bisque kiln can fire about one and a half times the amount of work that the glaze kiln can fire. The firing takes about 10 hours to complete the cycle and about two days to cool down. Once it has been emptied the work is placed in the glaze room ready for you to decorate! Step Six – Glazing Decorating your work with colour can be a lot of fun – and time consuming! There are three main options for surface treatment at this stage: Oxide Washes Underglazes Glazes Washes and underglazes do not “glaze” the work – It will still need a layer of glaze to fully seal the clay (washes don’t need glaze on surfaces not designed for food or liquid as they can gloss up a little on their own). Underglazes are stable colourants that turn out pretty much how they look in the jar. They can be mixed with each other to form other colours and can be used like water colours to paint onto your work. Mostly they should have a clear glaze on top to seal them. Oxides are a different species – the pink oxide (cobalt) wash turns out bright blue for instance. They don’t always need a glaze on top, and some glazes can change the colour of the wash! The glazes need no other “glaze” on top! Be careful of unknown glaze interactions – you can put any combination of glaze in a bowl or on a plate, but only a single glaze on the outside of any vertical surface! Glazes are a chemical reaction under heat. We don’t know the exact chemicals in the Mayco glazes we use. I can guess by the way they interact with each other, however, on the whole, you need to test every idea you have, and not run the test on a vertical surface! Simply put, glaze is a layer of glass like substance that bonds with the clay underneath. Clay is made of silica, alumina and water. Glaze is made of mostly silica. Silica has a melting point of 1700°C and we fire to 1240°C. The silica requires a “flux” to help it melt at the lower temperature. Fluxes can be all sorts of chemicals – a common one is calcium – calcium has a melting point of 2500°C, however, together they both melt at a much lower temperature! Colourants are metal oxides like cobalt (blue), chrome (green through black), copper (green, blue, even red!), manganese (black, purple and pink) iron (red brown), etc. Different chemicals in the glaze can have dramatic effects. for example, barium carbonate (which we don’t use) turns manganese bright pink! Other elements can turn manganese dioxide brown, blue, purple and reddish brown. Manganese dioxide is a flux in and of itself as well. So, glazes that get their black and purple colours, often interact with other glazes and RUN! Our mirror black is a good example – it mixes really well with many glazes because it fluxes them – causes them to melt faster. It will also bring out many beautiful colours in the glazes because it’s black colouring most definitely comes from manganese dioxide! Glaze chemistry is a whole subject on it’s own! We use commercial Mayco glazes on purpose – for their huge range of colour possibilities, stability, cool interactions, artistic freedom with the ability to easily brush the glazes on and ease of use. We currently have almost 50 glazes on hand! A major project is to test the interactions of all glazes with each other. That is 2,500 test tiles!!!! I’m going to make the wall behind the wheels the feature wall of pretty colours! Step Seven – Glaze (Gloss or sometimes called “Glost”) Firing Most of the time this is the final stage of making your creation (but not always!) The glaze kiln goes to 1240°C. This is called cone 6, or midrange. It is the low end of stoneware temperatures. Stoneware clays and glazes are typically fired at cone 8 – 10, that is 1260 – 1290°C. The energy requirement to go from 1240°C to 1280°C is almost a 30% more! Our clay is formulated to vitrify (mature, turn “glass-like”) at 1240°, as are our glazes. A glaze kiln take around 12 hours to reach temperature and two to three days to cool down. Sometimes a third firing process is required – this is for decoration that is added to work after the glaze firing. For example – adding precious metals and lustres. this firing temperature is usually around 600 – 800°C depending upon the techniques being used. There are many students interested in gold and silver trims – we will be doing this third type of firing soon! After firing your work will be in the student finished work shelves. Remember to pay for it before you head out the door! There is a small extra charge for using porcelain clay (it’s more than twice the price of regular clay), and for any third firing process! Once your work has been fired it can not turn back into clay for millennia – so don’t fire it if you don’t like it! Put it in the bucket for recycling. https://firebirdstudios.com.au/the-process-of-making-pottery/ This bowl is an example of kitchenware used in the 19th century and still in use today.Bowl white ceramic plain that has two sets of edging around lip. Inside bowl has plaster designed to look like cooking mixture.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, kitchen equipment, ceramic -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Bowl, J & G Meakin, Late 19th or early 20th Century

The Process of Making Pottery Decorating, Firing, Glazing, Making, Technical There is a rhythm and flow to clay. It can’t be done all at once! Even the making process! It can take weeks to get everything done, especially if you can only work on your pottery once a week! Even though we have three hour classes, it’s often just not enough time! Here is an overview of some of the processes so you have a bit more grasp on some of the technical stuff! Step One – Design There are SO many ideas out there for making stuff in clay! From delicate porcelain jewellery, through to heavy sculptural work and everything in between. Deciding your direction is sometimes not that easy – when you first start, try everything, you will naturally gravitate to the style that you enjoy! The options and variations are endless and can get a wee bit overwhelming too! Check in with me before you start to ensure your ideas will work, what order you might do things, how you could achieve the look you are seeking and any other technical data required! Step Two – Making Clay is thixotropic. This means that as you work with it, the clay first gets sloppier and wetter, before is begins to dry in the atmosphere. For most things, you simply can’t do all parts of the project at once. An example of work order might look like: Get last weeks work out from the shelves Prepare clay for today’s work – roll your clay, prepare balls for throwing, make the first stage of a pinch pot) Clean up last week’s work and put it on the shelf for bisque firing Check that you have any glazing to do – and do enough of it that you will have time to finish your main project Do the next step of your next project – there might be a further step that can’t be complete immediately, in that case, wrap your work well and put onto the shelves. Letting your work rest for a while can really help keep your work clean and professional looking. Many things require bagging under plastic to keep it ready for work the next week – put your name on the outside of the bag so you can find your work easily. We have stickers and markers. Consider how you want to decorate your work – coloured slip can be applied at a fairly wet stage (remembering that it will make your work even wetter!). Trying to apply slip to dry clay won’t work! If you want to do sgraffito – you will need to keep the work leather hard (a state of dryness where you can still work the clay with a little effort and a little water and care). Step Three – Drying Most of the time your work can go into the rack uncovered to let it dry out for the following week. If you want to continue forming or shaping you will need to double bag your work – put your work on a suitable sized bat and put the bat in a bag so the base of the bag is under the bat, then put another bag over the top of the work and tuck the top of the bag under the bat. If you want to trim (or turn) your thrown work the following week, it should also be double bagged. If your work is large, delicate, or of uneven thicknesses, you should lightly cover your work for drying. When considering the drying process, bare in mind the weather, humidity and wind! The hotter and dryer, the faster things dry and work can dry unevenly in the shelves – this can lead to cracking – another time to lightly cover your work for drying. Step Four – Trimming and Cleaning Up Your work is dry! It is called greenware now and it is at it’s most fragile! Handle everything with two hands. I often refer to soft hands – keep everything gentle and with your fingers spread as much as possible. Try to not pick up things like plates too much, and always with both hands! Before your work can be bisque fired it should be “cleaned up”. You work won’t go into the kiln if it has sharp edges – when glazed, sharp edges turn into razor blades! Use a piece of fly wire to rub the work all over – this will scratch a little so be light handed. Use a knife or metal kidney to scrape any areas that require a bit more dynamic treatment than the fly wire offers! Finally, a very light wipe over with a slightly damp sponge can help soften and soothe all of your edges and dags! Trimming thrown work: If you are planning to trim (or turn) your thrown work (and you should be), make sure you bag it well – your work should be leather hard to almost dry for easiest trimming. Use this step to finish the work completely – use a metal kidney to polish the surface, or a slightly damp sponge to give a freshly thrown look. Wipe the sponge around the rim after trimming, and check the inside of the pot for dags! Trimming slip cast work: Usually I will trim the rims of your work on the wheel the following day to make that stage easier, however you will still need to check your work for lumps and bumps. Last but not least – check that your name is still clearly on the bottom of your work. Step Five – Bisque Firing When the work is completely dry it can go into the bisque kiln. The bisque kiln is fired to 1000°C. This process burns off the water in the clay as well as some of the chemically bound water. The structure of the clay is not altered that much at this temperature. Inside the bisque kiln, the work is stacked a little, small bowl inside a larger bowl and onto a heavy plate. Smaller items like decorations or drink coasters might get stacked several high. Consideration is paid to the weight of the stack and shape of the work. A bisque kiln can fire about one and a half times the amount of work that the glaze kiln can fire. The firing takes about 10 hours to complete the cycle and about two days to cool down. Once it has been emptied the work is placed in the glaze room ready for you to decorate! Step Six – Glazing Decorating your work with colour can be a lot of fun – and time consuming! There are three main options for surface treatment at this stage: Oxide Washes Underglazes Glazes Washes and underglazes do not “glaze” the work – It will still need a layer of glaze to fully seal the clay (washes don’t need glaze on surfaces not designed for food or liquid as they can gloss up a little on their own). Underglazes are stable colourants that turn out pretty much how they look in the jar. They can be mixed with each other to form other colours and can be used like water colours to paint onto your work. Mostly they should have a clear glaze on top to seal them. Oxides are a different species – the pink oxide (cobalt) wash turns out bright blue for instance. They don’t always need a glaze on top, and some glazes can change the colour of the wash! The glazes need no other “glaze” on top! Be careful of unknown glaze interactions – you can put any combination of glaze in a bowl or on a plate, but only a single glaze on the outside of any vertical surface! Glazes are a chemical reaction under heat. We don’t know the exact chemicals in the Mayco glazes we use. I can guess by the way they interact with each other, however, on the whole, you need to test every idea you have, and not run the test on a vertical surface! Simply put, glaze is a layer of glass like substance that bonds with the clay underneath. Clay is made of silica, alumina and water. Glaze is made of mostly silica. Silica has a melting point of 1700°C and we fire to 1240°C. The silica requires a “flux” to help it melt at the lower temperature. Fluxes can be all sorts of chemicals – a common one is calcium – calcium has a melting point of 2500°C, however, together they both melt at a much lower temperature! Colourants are metal oxides like cobalt (blue), chrome (green through black), copper (green, blue, even red!), manganese (black, purple and pink) iron (red brown), etc. Different chemicals in the glaze can have dramatic effects. for example, barium carbonate (which we don’t use) turns manganese bright pink! Other elements can turn manganese dioxide brown, blue, purple and reddish brown. Manganese dioxide is a flux in and of itself as well. So, glazes that get their black and purple colours, often interact with other glazes and RUN! Our mirror black is a good example – it mixes really well with many glazes because it fluxes them – causes them to melt faster. It will also bring out many beautiful colours in the glazes because it’s black colouring most definitely comes from manganese dioxide! Glaze chemistry is a whole subject on it’s own! We use commercial Mayco glazes on purpose – for their huge range of colour possibilities, stability, cool interactions, artistic freedom with the ability to easily brush the glazes on and ease of use. We currently have almost 50 glazes on hand! A major project is to test the interactions of all glazes with each other. That is 2,500 test tiles!!!! I’m going to make the wall behind the wheels the feature wall of pretty colours! Step Seven – Glaze (Gloss or sometimes called “Glost”) Firing Most of the time this is the final stage of making your creation (but not always!) The glaze kiln goes to 1240°C. This is called cone 6, or midrange. It is the low end of stoneware temperatures. Stoneware clays and glazes are typically fired at cone 8 – 10, that is 1260 – 1290°C. The energy requirement to go from 1240°C to 1280°C is almost a 30% more! Our clay is formulated to vitrify (mature, turn “glass-like”) at 1240°, as are our glazes. A glaze kiln take around 12 hours to reach temperature and two to three days to cool down. Sometimes a third firing process is required – this is for decoration that is added to work after the glaze firing. For example – adding precious metals and lustres. this firing temperature is usually around 600 – 800°C depending upon the techniques being used. There are many students interested in gold and silver trims – we will be doing this third type of firing soon! After firing your work will be in the student finished work shelves. Remember to pay for it before you head out the door! There is a small extra charge for using porcelain clay (it’s more than twice the price of regular clay), and for any third firing process! Once your work has been fired it can not turn back into clay for millennia – so don’t fire it if you don’t like it! Put it in the bucket for recycling. https://firebirdstudios.com.au/the-process-of-making-pottery/This bowl was made by renowned pottery company J & G Meakin of England. The firm was established in the mid-1800's. The bowl is an example of kitchenware used in the 19th century and still in use today.Bowl; white ceramic, round and tapering inwards towards base. Made by J and G Meakin England.On base, 'Ironstone China Reg SOL 391413' with symbolflagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, mixing bowl, food preparation, j & g meakin, pottery, stoke-on-trent, kitchen equipment, ceramic -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Plate