Showing 475 items matching " 'the flame'"

-

Federation University Historical Collection

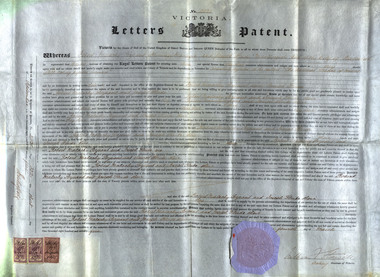

Federation University Historical CollectionDocument, Indenture Between Robert M. Serjeant, Joseph Flude and the Trustees of the Ballarat School of Mines regarding Letters of Patents for the Benefit of the Ballarat School of Mines, 1877, 04/03/1875

R.M. Serjeant was listed as a mining manager and Joseph Flude as a metallurgist. In 1875 they were both living in Ballarat. The patent number is A.D.1875, 4th March. No 2031. According to the patent the hearth of the furnace is in the form of a cone revolving horizontally. The feed is supplied to the apex of the cone by an archimedian screw. The crown of the furnace comprises a double covering or roof with an intermediate chamber for receiving heated air. The inner covering is pierced to admit of the heated air being brought into contact with the pyrites on the face of the revolving hearth. The discharge of the roasted substance is affected by means of a scraper at the base of the cone. It was claimed that this was a new mode of introducing heated air, and the exclusion of flame during the operation of roasting pyrites. The self-acting charge and discharge of the furnace and the peculiar construction of the hot air chambers, and the use of perforated bricks through which the supply of air is affected were also new. (http://patentsvictoria.net/002031.html) From the Goulburn Herald, 14 September 1878 "A feature connected with the school of mines is the yet unfinished pyrites works. The extraction of the gold from pyrites and the utilization for commercial purposes of other substances connected with pyrites are peculiarly important to Ballarat, because were a simple and inexpensive method devised there are millions and millions of tons of quartz that would then be made remunerative. With this thought in their minds two scientific gentlemen invented the school of mines self-acting rotatory furnace. This, for lack of funds, has not been completed as yet, but the amount in hand for the purpose is daily increasing, and it will eventually be an accomplished fact. It is in contemplation also to erect machinery shops in connection with the school, and it is purposed to con struct a steam-engine to do at once the work of the pyrites treatment and the ma chine room. A model shaft and mine too are being prepared for on the reserve, so that practical mining of the most thorough character may be taught on the ground.'Large indenture on red bordered vellum. The indenture was regarding a patent for the benefit of the Ballarat School of Mines. Letters Patent for an Invention for Roasting Pyrites to be called 'the Ballarat School of Mines self-Acting Pyrites Furnace" to Robery Malachy Serjeant and Joseph Flude. The large document is on a vellum type paper complete with stamps and seal. The document is signed by Acting-Governor William Stawell. Inscriptions and Markings Written on verso: "Date of Patent 4th March 1875 No 2031 Letters Patent for An invention for roasting pyrities to be called "The Ballarat School of Mines Self-acting Pyrities Furnace" to Robert Malachy Serjeant and Joseph Flude Melbourne, Victoriaballarat school of mines, serjeant, r.m. serjeant, robert m. serjeant, flude, joseph flude, patent, barry, redmond barry, rogers, judge rogers, bland, rivett henry bland, john airy, warrington rogers, establishment, indenture, legal, cuthbert, ballarat school of mines trustees, william stawell, john warrington rogers -

Federation University Historical Collection

Federation University Historical CollectionDocument, Letters Patent for an Invention for Roasting Pyrites, 1875, 1875

R.M. Serjeant was listed as a mining manager and Joseph Flude as a metallurgist. In 1875 they were both living in Ballarat. The patent number is A.D.1875, 4th March. No 2031. According to the patent the hearth of the furnace is in the form of a cone revolving horizontally. The feed is supplied to the apex of the cone by an archimedian screw. The crown of the furnace comprises a double covering or roof with an intermediate chamber for receiving heated air. The inner covering is pierced to admit of the heated air being brought into contact with the pyrites on the face of the revolving hearth. The discharge of the roasted substance is affected by means of a scraper at the base of the cone. It was claimed that this was a new mode of introducing heated air, and the exclusion of flame during the operation of roasting pyrites. The self-acting charge and discharge of the furnace and the peculiar construction of the hot air chambers, and the use of perforated bricks through which the supply of air is affected were also new. (http://patentsvictoria.net/002031.html) From the Goulburn Herald, 14 September 1878 "A feature connected with the school of mines is the yet unfinished pyrites works. The extraction of the gold from pyrites and the utilization for commercial purposes of other substances connected with pyrites are peculiarly important to Ballarat, because were a simple and inexpensive method devised there are millions and millions of tons of quartz that would then be made remunerative. With this thought in their minds two scientific gentlemen invented the school of mines self-acting rotatory furnace. This, for lack of funds, has not been completed as yet, but the amount in hand for the purpose is daily increasing, and it will eventually be an accomplished fact. It is in contemplation also to erect machinery shops in connection with the school, and it is purposed to con struct a steam-engine to do at once the work of the pyrites treatment and the ma chine room. A model shaft and mine too are being prepared for on the reserve, so that practical mining of the most thorough character may be taught on the ground.'Letters Patent for an Invention for Roasting Pyrites to be called 'the Ballarat School of Mines Self-Acting Pyrites Furnace' to Robert Malachy Serjeant and Joseph Flude. The large document is on a vellum type paper complete with stamps and seal. The document is signed by Acting-Governor William Stawell.Written on verso: "Date of Patent 4th March 1875 No 2031 Letters Patent for An invention for roasting pyrities to be called "The Ballarat School of Mines Self-acting Pyrities Furnace" to Robert Malachy Serjeant and Joseph Flude Melbourne, Victoriaballarat school of mines, serjeant, r.m. serjeant, robert m. serjeant, flude, joseph flude, richard gibbs, stawell, william stawell, pyrities furnace, philately, statute stamp, seal (victoria), ballarat school of mines self-acting pyrities furnace, ballarat school of mines self-acting pyrites furnace -

Department of Energy, Environment and Climate Action

Department of Energy, Environment and Climate ActionProtective Bushfire overalls

At the time of the 1982-83 bushfire season FCV firefighters wore either navy blue issue overalls or their own clothing, generally a checked flannel shirt and jeans. Uncomfortable safety boots and hardhats were issued. The CFA had switched from white overalls to their distinctive yellow kit by 1983. In about 1980, in a far-sighted corporate move for the time, Alan Threader, who was the Chairman of the FCV, established a departmental safety committee, which he personally chaired. The Committee, among other things, wanted to upgrade fire safety clothing. Alan also initiated a radical colour idea after a work trip to the UK in about 1981 and brought home a small sample swatch. Alan believed that the now distinctive bright yellow-green was a good colour contrast to the Victorian bush which is a blue-green hue. Trevor Brown from Stores Branch scored the task to make the change and letters were sent to the UK seeking information about the pigment. The FCV worked with the Commonwealth Dyers Association and Cushen Clothing to replicate the shade on cotton drill, which presented darker when it was treated with the flame-retardant chemical, Proban. The first of the new Kermit Suits were rolled-out in late 1984, and the stylish colour was initially registered and patented to the Department. But it's also fair to say that the new gaudy shade of apparel wasn’t universally popular with staff. The lime green overalls were an Australian first, and forest agencies in other states followed a few years later. In the early 1990s, armed with a pair of dressmaker’s scissors, the baggy one-piece Kermit boilersuits were tailored by Peter Billing from Fire Protection Branch and Trevor Brown in conjunction with the family-owned business, Top Level Workwear, which saw numerous enhancements and prototypes. The two-piece Kermit suits were available in the late 1990s after many years of argy-bargy and complaints from field firefighters. Protective overalls Two types - early FCV (c 1983) and later CNR (1992) forests commission victoria (fcv), protective clothing, safety equipment -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Fire Tongs

Fireplace tongs were used to add wood to the fireplace as well as break down the crackling wood to add more oxygen to growing flames. Of the four tools that were usually found in an upright fireplace set, tongs had the biggest design variation. Some tongs looked like medical calipers that were rounded at the bottom, while others were almost like metronomes with their rectangular shapes. https://www.lovetoknow.com/home/antiques-collectibles/vintage-antique-fireplace-tools Tongs are tools used to handle items, and generally move the item from one place to another, or turn things, like a piece of meat on a barbecue. Tongs usually have flat ends to pick up items without damaging them and to grip onto the items easily, however, some tongs have claws or toothed ends to grab more bulky and slippery items. Tongs are used mainly for handling food or hot items. Modern tongs are usually made from plastic, metal, stainless steel, or other material, depending on their purpose. Originally, tongs were probably wood sticks that eventually became metal sticks around 3000 BC to handle hot items in a fire Tongs are used to extend the hand or as a replacement handler for potentially dangerous items. Tongs usually have a sprung end so that the operator is required to squeeze the middle of the tongs to grab hold of an item, or they have a pivot which requires the user to squeeze the handles at the end to grip onto items, these being more effective at holding heavy items due to the extra force able to be applied. There are many types of tongs including barbecue tongs, salad tongs, blacksmith tongs, crucible tongs, ice cube tongs, sugar cube tongs and fire tongs. Tongs are often called ‘a pair of tongs’ and the word comes from the Old English, ‘tange’ or ‘tang’, meaning ‘that which bites’. There is evidence of Egyptians using metal rods and tong like tools to hold objects over fire, in around 1450 BC. https://tenrandomfacts.com/tongs/Fire tongs are still used with most open fires in homes.Brass fire tongs with holding clip and flat rounded handle at the end.None.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, fireplace tools, tongs -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Light Bracket, Before 1878

This pressed brass artefact is a highly decorative side bracket for distancing a gas lamp flame from the internal wall of a building. It is hollow and made of light gauge metal, with an innovative aesthetic design, but no internal piping to transport gas. It was recovered from the wreck of the LOCH ARD. There are similar artefacts in the Flagstaff Hill collection. The LOCH ARD left Gravesend (London) on 2 March 1878, bound for Melbourne, with a crew of 37, 17 passengers, and a diverse and valuable cargo of manufactured goods, luxury items, and refined metal. Some of the cargo was destined for display at Melbourne’s first International Exhibition in 1880. At 3 am, 1 June 1878, the ship was wrecked against the high limestone cliffs of Mutton Bird Island on Victoria’s south west coast near Port Campbell. Only two people survived the disaster — Tom Pearce, a male crew member, and Eva Carmichael, a female passenger. The cargo proved too difficult to salvage in the vessel’s exposed condition and was largely written off. The manifest of goods in the LOCH ARD’s holds included “Fittings gas (4 cases)”. The gas lighting of streets, public buildings, and the dwellings of wealthier private citizens was already well-advanced in the cities and major towns of the Australian colonies. In 1841 Sydney was the first to be gas-lit with 23 street lamps, 106 hotel lamps, and 200 private residences connected to the Darlinghurst “gasometer” by an underground network of metal pipes. “The dim days of oil and tallow are gone by!” pronounced one newspaper, flushed with civic pride. The 1850s Gold Rush promoted a similar attitude of confidence and affluence in the Colony of Victoria. In 1855 Melbourne was connected to its own system of subterranean gas pipes despite the same high rates of 25 shillings per 1000 cubic feet being charged, (reduced to 15 shillings in 1865 with cheaper sources of coal). By1858 Kyneton had its own gasworks to light the town (fuelled by eucalyptus leaves) and Geelong followed suit in 1860. Had the LOCH ARD reached its intended destination in 1878, it is probable that the 4 cases of brass gas light fittings on board would have found a ready market.The LOCH ARD shipwreck is of State significance — Victorian Heritage Register S417. The gas light bracket is an example of lamp fittings and plumbing from the late 19th century.A pressed brass lighting bracket recovered from the wreck of the LOCH ARD. It would be used for attaching, but simultaneously offsetting, a gas nozzle to a wall. Highly decorative in an unusually ‘modern’ or ‘art-deco’ style, with sweeping curves dissected by angular geometric pattern, and supporting a short, vertical bar with a gas nozzle on top. It is constructed of light gauge metal, with splitting along seams, and some delicate tracery is missing. Outer surface has been polished, removing sediment, but greenish oxidation remains in dents and joins. warrnambool, shipwreck coast, flagstaff hill, shipwrecked coast, flagstaff hill maritime village, flagstaff hill maritime museum, shipwreck artefact, maritime museum, gas lamps, gas lighting, gas works, brass fittings, gas pipes, loch ard, 1878 shipwreck, victorian affluence, colonial gas lighting -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Ship's Wheel, John Hastie et al, Early 20th Century

John Hastie Engineer and millwright John Hastie opened small manufacturing works in Greenock in 1845 and 1853 patented the first self-holding steering gear. The firm became known as John, Hastie and Co. Ltd. in 1898 after taking on limited liability status and their main works were at Kilblain Street, Greenock, where they specialised in ships' steering gear. The company also occupied works at Rue End Street, Greenock. Plans of this unit depict a stockyard to the east, with areas for welding; fitting and assembly; flame, cutting and fabrication; and a machine bay. The company was dissolved in 1991. Brown Brothers Brown Bros Rosebank Ironworks made the steering gears for many large ship's, including The Titanic. Andrew Betts Brown the founder was born in 1741 and closely associated with many improvements in marine engineering. He was educated in his native city and served his apprenticeship as an engineer in the locomotive works of the North British Railway Company at St. Margaret's. During his apprenticeship, he attended the evening classes at Watt College. subsequently going to Manchester to study chemistry. He went to London around 1863 and took over an old brewery, which he converted into an engineering works. During his time there he invented an overhead travelling crane, which was used on the construction of Blackfriars Bridge London. He went on to develop plant which used steam and hydraulic power for discharging ships as a result the company was contracted to install this equipment in Hamburg Docks. By around 1870 he continued to construct machinery in London but realised that conditions were more favourable in Edinburgh. He acquired land at Rosebank adjoining the North British Railway Company's line to Granton, and the necessary infrastructure was completed allowing him to finish the Hamburg contract. The works at Rosebank were eventually extended and added to until they became one of the largest engineering works in the East of Scotland. Mr Brown was a member of numerous engineering institutions, the best known at the time being the Institution of Naval Architects. He was also a Fellow of the Royal Society of Edinburgh, a member of the Institute of Mechanical Engineers and of the Institution of Marine Engineers he died in 1906 at the age of 67.An item made by two marine innovators of marine auxiliary machinery, equipment and itemsShip's wheel, brass, attached to brass pillar. The base has six holes in it for securing it in place. Top of the ship's wheel pillar has a brass, adjustable arrow pointer that is positioned over a dial etched into the flat brass surface. The dial reads " PORT STABD". Lines and degrees are marked, with '0' in centre and every 5 degrees, from 0-35, in both Port and Starboard sidesInscription to wheel hub "Brown Brothers & Co. Ltd, Rosebank Ironworks, Edinburgh"flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, john hastie, john hastie, andrew betts brown, ships wheel, ship steering gear, marine equipment, instrument, navigation -

Federation University Art Collection

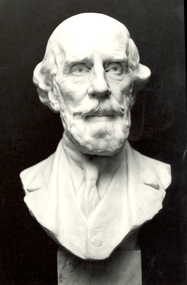

Federation University Art CollectionSculpture - Marble sculpture, 'Professor Alfred Mica Smith' by Paul Montford, 1924

Paul Raphael MONTFORD (1868 - 1938) Paul Montford moved to Australia to carve four buttress groups in granite for the Melbourne Shrine of Remembrance. In 1924 he was teaching at Geelong Technical College. Professor Alfred Mica Smith was a long term lecturer at the Ballarat School of Mines. The sculpture was commissioned by former Students of the Ballarat School of Mines working in Western Australia. One of those former students, William Corbould, remembered his first encounter with the professor fondly:- 'From the Registrar's Office I was led to be introduced to the Professor of Chemistry, one Mica Smith. The initial encounter gave me little encouragement - his large laboratory was filled with hundreds of bottles bearing strange labels with queer symbols on them. My heart sank. At the first opportunity I grabbed my hat and made for the door, but the good professor called me back. I pointed out that I was never any good at school ... so it was no use pretending to be clever enough to understand all those weird symbols! The Professor told me not to worry about that and took me to one of the benches where he found a blowpipe and a charcoal block. Mixing together two powders from bottles on the shelf he transferred a sample to the charcoal and directed the bunsen flame onto it. Soon it began to melt and a white bead appeared in front of my eyes. He then took a test tube and added a little colourless liquid from each of two bottles. A beautiful dark blue colour appeared. My interest was won.' Alfred Mica Smith was the well-loved Professor of Chemistry and Metallurgy at the Ballarat School of Mines between 1881 and 1922. Upon reaching the age of 78 Mica Smith retired having influenced generations of miners. At the time of his death Ballarat School of Mines Students’ Magazine reported: "In the annals of the School, the year 1922 will be noted chiefly as the last year in which Professor Mica Smith taught here. With his retirement, a memorable epoch closed. The Professor has served the School for 42 years with a service, the length and thoroughness of which are unique. … It is not quite realised in this city how famous the School became throughout the world, nor to what extent the Professor was responsible for its high position in the mining and metallurgical world. … This item is part of the Federation University Art Collection. The Art Collection features over 2000 works and was listed as a 'Ballarat Treasure' in 2007.Marble bust of Ballarat School of Mines Professor Alfred Mica Smith by Paul Montford. The bust is mounted on a jarrah pedestal made from timber donated by the Millar Timber and Trading Company. The bust was formally presented to the Ballarat School of Mines on Saturday 13 December1924 in front of Alfred Mica Smith and a large gathering. It is signed 'Paul R. Montford, Sc, 1924' at the back.Professor A. Mica Smith, 1924, Presented by His Old Students Associated with Western Australia as a Token of Affectionate Esteemart, artwork, ballarat school of mines, montford, paul montford, alfred mica smith, mica smith, marble, bust, sculpture -

Melbourne Legacy

Melbourne LegacyBadge, Intermediate Legacy Club Badge

An example of a Melbourne Intermediate Legacy Club Badge. The pin has a cover that screws onto the shaft of the pin to keep it in place. ILC was formed from junior legatees who had become too old for the usual junior legatee activities. It was most active from the 1930s to 1950s. The badge of Legacy is the Torch and Wreath of Laurel. The Torch signifies the undying flame of service and sacrifice of those who gave their lives for their country. The Wreath of Laurel is the symbol of our remembrance of them. Background: The ILC was formed in 1929. The idea of the club sprang from those boys who had outgrown the Junior Legacy Club. In the early days it fielded a lacrosse team and it was this that mainly held the members together. Enthusiasm wained after a few years as it lacked a solid objective. The answer came from one of its members and in 1938 they founded the Don Esses Club. This was a club for the children of incapacitated ex-servicemen which met every Thursday night at 7.30 run by the ILC members. The name came from the signallers' code Disabled Servicemen's Sons. During the second world war 80% of the members of the ILC enlisted in the services. Leaving only 8 members that could not join due to ill health or reserved occupations. They continued the Don Esses and whatever aid they could to Legacy. ILC members had always helped Legacy where possible including being camp leaders or camp staff, with the annual demonstrations, and coffee stalls at the ANZAC dawn service. Post second world war some ILC members were nominated into Legacy, others drifted away in civil occupations. It was found difficult to recruit new blood into the ILC and eventually membership waned when the boys from the Don Esses clubs found other youth activities to join. The ILC ceased to meet regularly in the mid fifties. However a strong comradeship still existed between members and they would meet in one anothers homes. Members were always ready to help the senior Legacy Club in any way in their power and still helped at Christmas parties and summer camps. ILC was a service rendering organisation and was self governing. Non-sectarian and non-political, the members were ex-junior legatees over 18 years of age. After serving in World War 2 members were eligible to become members of Legacy. Was in a folder of material collated about the ILC by an early archive committee.A record of the badge worn by Intermediate Legacy Club members.Gold lapel pin of the Legacy torch with blue enamel containing the words Intermediate Legacy Club.Imprinted 'Stokes' on reverse.ilc, membership -

Melbourne Legacy

Melbourne LegacyBadge, Intermediate Legacy Club Badge

An example of a Melbourne Intermediate Legacy Club Badge. ILC was formed from junior legatees who had become too old for the usual junior legatee activities. It was most active from the 1930s to 1950s. This badge came from a donation of material from a former Junior Legatee, Valma Hutchinson (nee Wigg). She was involved with the Ladies ILC. The badge of Legacy is the Torch and Wreath of Laurel. The Torch signifies the undying flame of service and sacrifice of those who gave their lives for their country. The Wreath of Laurel is the symbol of our remembrance of them. Background: The ILC was formed in 1929. The idea of the club sprang from those boys who had outgrown the Junior Legacy Club. In the early days it fielded a lacrosse team and it was this that mainly held the members together. Enthusiasm wained after a few years as it lacked a solid objective. The answer came from one of its members and in 1938 they founded the Don Esses Club. This was a club for the children of incapacitated ex-servicemen which met every Thursday night at 7.30 run by the ILC members. The name came from the signallers' code Disabled Servicemen's Sons. During the second world war 80% of the members of the ILC enlisted in the services. Leaving only 8 members that could not join due to ill health or reserved occupations. They continued the Don Esses and whatever aid they could to Legacy. ILC members had always helped Legacy where possible including being camp leaders or camp staff, with the annual demonstrations, and coffee stalls at the ANZAC dawn service. Post second world war some ILC members were nominated into Legacy, others drifted away in civil occupations. It was found difficult to recruit new blood into the ILC and eventually membership waned when the boys from the Don Esses clubs found other youth activities to join. The ILC ceased to meet regularly in the mid fifties. However a strong comradeship still existed between members and they would meet in one anothers homes. Members were always ready to help the senior Legacy Club in any way in their power and still helped at Christmas parties and summer camps. ILC was a service rendering organisation and was self governing. Non-sectarian and non-political, the members were ex-junior legatees over 18 years of age. After serving in World War 2 members were eligible to become members of Legacy.A record of the badge worn by Intermediate Legacy Club members.Lapel pin of the Legacy torch with blue enamel containing the letters I.L.C.Imprinted 'Stokes' on reverse.ilc, membership -

Eltham District Historical Society Inc

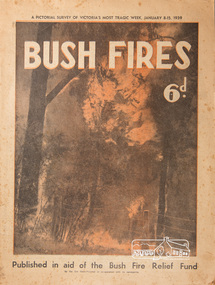

Eltham District Historical Society IncMagazine, Sun News-Pictorial, Bush Fires: A pictorial survey of Victoria's most tragic week, January 8-15, 1939, 1939

THE WEEK REVIEWED (Article; Bush Fires: A pictorial survey of Victoria's most tragic week, January 8-15, 1939. Published in aid of the Bush Fire Relief Fund by the Sun News-Pictorial in co-operation with its newsagents, pp2-3) THE fiercest bush fires Australia has known since its discovery are quiescent at the moment, and Victoria, in the comparative coolness of the change which came with rain on Sunday night, has begun·to count its losses. In the fiery eight days, from Sunday to Sunday, at least sixty-six men, women and children have lost their lives in forest fires, or have succumbed to burns and shock; many others have died from heat; and several serious cases of burns are being treated in hospitals. Two babies in Narrandera district have died, and ten others are in hospital, because of milk soured by the record temperatures of those eight days. Forest damage totals at least a million pounds, and incalculable damage has been done to the seedlings which were to have been the forests of the future. Water conservation will be seriously affected by the silting-up of reservoirs and streams from which protective timber has been taken by the all-engulfing flames. More than a thousand houses have been destroyed, and these, with 40 mills, and schools, post-offices, churches, and other buildings, represent a loss of at least half a million. At least 1500 are homeless. For their aid, money raised in appeals has now passed the £50,000 mark, and the biggest relief organisation ever set up in peace time has swung into operation. The First Hint Victoria's first hint of what was to come appeared on Sunday, January 8, when most parts of the State awoke to find a blistering day awaiting. At 12.20 p.m., when the thermometer reached its highest for the day, 109.6 degrees, the first fire victims were at that moment going to their death on a bush track five feet wide off the main road to Narbethong. They were the forestry officers Charles Isaac Demby and John Hartley Barling, who went to warn Demby of his danger when he parted from his companions, and was himself surrounded by the treacherous fire. It was not until 8 o'clock next morning that the tragic news was flashed throughout the State. Searchers found the two charred bodies close together, one seeking protection in the nook of two logs. Barling's watch had stopped at 1.20. In the meantime, tragedy was spreading its cloak. By Monday, big fires were raging at Toolangi, Erica, Yallourn, Monbulk, Frankston, Dromana, Drouin South, Glenburn, and Blackwood, with smaller outbreaks at many other centres. In the ensuing week, while women and children were evacuated as fast as the flames would permit, Erica-scene of the 1926 fire disaster-thrice escaped doom by a change of wind. Indeed, those who have been in the fire country these past days say that the numbers of times a change of wind has saved towns from destruction is amazing. In the towns they speak of miracles. Monday's Miracles The escapes from Monett's Mill at Erica and from the Hardwood Company's Mill at Murrindindi, near where Demby and Barling went to their death, were Monday's miracles. Twenty came out alive from each mill. At the first a 60ft. dugout provided an oven-like refuge; at the second, 12 women and children survived in the smoke-filled gloom of a three-roomed cottage while their eight men, their clothes sometimes afire, poured water on the wooden walls. Three houses out of ten remained when the fire had passed. Record Temperatures Sunday had been the hottest Melbourne day for 33 years; Monday dropped to a 76.1 degree maximum; but Tuesday dawned hotter than ever, the mercury reaching 112.5. By now rumor was racing ahead of fact; whole towns were being reported lost; the alarm was raised for scores of missing persons. But fact soon overtook rumor, and within a few days the staggering toll began to mount to a figure beyond the wildest imaginings of the panic-stricken. Six died from heat on this torrid Tuesday, and the fires spread in a wide swathe from south-west to north-east across the State. Fish died in shallow streams. A curtain of smoke hid the sky from all Victoria, and hung far out to sea. It alarmed passengers on ships. On the Ormonde, on the voyage to Sydney from Burnie, women ran on deck, believing fire had broken out in the hold. Days later the smoke reached New Zealand. In Melbourne thousands of fire-volunteers were leaving in cars: vans, motor-buses-anything reliable on wheels-to aid the country in its grim fight. In the fires at Rubicon and. Narbethong, seventeen were facing death this day. But not till Wednesday, when Melbourne breathed again in a cool change, while the country still sweltered in temperatures up to 117 degrees, did the news come through the tree blocked roads. A woman and her little daughter, trapped on the road, were among those who died. Their bodies, and those of menfolk with them, were found strewn out at intervals along the road, where the furnace of the surrounding fire had dropped them in their tracks as they ran. Twelve died at a Rubicon mill, five on the road at Narbethong. At Alexandra, not far distant, a baby was born while the fires raged, and stretcher-bearers brought in the injured. On Thursday the State Government voted £5000 for the relief of fire victims. The Governor (Lord Huntingfield) and the Lord Mayor (Cr. Coles) visited some of the stricken areas, and dipped into their pockets personally. Later, the City Council, too, voted £5000. Friday, The 13th Friday, the Thirteenth, justified its evil name. A blistering northerly came early in the morning, presaging destruction, and forcing the mercury to a new record of 114 degrees. Racing fires killed at least ten in those terrible 12 hours. Four children were engulfed in the furnace at Colac. Panic drove them, uncontrollable, into the smoke-filled road when the fire raced down behind their home. They choked to death. In other parts fires were joining to make fronts of scores of miles. Kinglake was being menaced on two fronts, £60,000 worth of timber was going up in smoke in Ballarat district. Warburton was surrounded. Residents at Lorne, favoured resort, were being driven to the sea-front by a fire which destroyed at least 20 homes. Healewille. with flames visible from the town at one stage, was in a trough between two fires which burned four guest-houses, seven homes and left its surrounding beauty-spots wastes of bowed-over, blackened tree-fern fronds; with its famous Sanctuary, however, intact. Most of Omeo was destroyed this black day: Noojee. while 200 residents crouched in the river, was being reduced to a waste of buckled iron and smoking timber; Erica was once again saved by a change of wind. Beneath a pall of smoke, the Rubicon victims were buried at Alexandra. Friday night and the early hours of Saturday saw the streets of beleagured towns strewn with exhausted fire-fighters. Their flails beside them, ready for the next call, they lay where exhaustion overtook them-on footpaths, beside lamp-posts, in gutters, in cars, under trucks. Saturday's dawn brought clear skies and lower temperatures in many parts, and from the burnt-out areas came a great rush of tragic reports. The death-roll rushed past the fifty mark with incredible speed. Some had been trapped on roads, others at mills; some, after burying their treasures, had clung too long to the places they had made their homes for many years. Four men lost their lives because one went back for his dog. By Sunday, when the first of the saving rain came, nearly another score of names had been added to the list.Newspaper magazine, 48 pages (incl. covers). Fully digitised and searchable PDFPublished in aid of the Bush Fire Relief Fund by the Sun News-Pictorial in co-operation with its newsagents.bushfires, 1939 bushfires, black friday, warrandyte -

Melbourne Legacy

Melbourne LegacyBadge, Intermediate Legacy Club Ladies Cloth Badge

An example of a Melbourne Ladies Intermediate Legacy Club Badge that was stitched onto clothes. ILC was formed from junior legatees who had become too old for the usual junior legatee activities. It was most active from the 1930s to 1950s. This badge came from a donation of material from a former Junior Legatee, Valma Hutchinson (nee Wigg). She was involved with the Ladies ILC. The badge of Legacy is the Torch and Wreath of Laurel. The Torch signifies the undying flame of service and sacrifice of those who gave their lives for their country. The Wreath of Laurel is the symbol of our remembrance of them. Background: The ILC was formed in 1929. The idea of the club sprang from those boys who had outgrown the Junior Legacy Club. In the early days it fielded a lacrosse team and it was this that mainly held the members together. Enthusiasm wained after a few years as it lacked a solid objective. The answer came from one of its members and in 1938 they founded the Don Esses Club. This was a club for the children of incapacitated ex-servicemen which met every Thursday night at 7.30 run by the ILC members. The name came from the signallers' code Disabled Servicemen's Sons. During the second world war 80% of the members of the ILC enlisted in the services. Leaving only 8 members that could not join due to ill health or reserved occupations. They continued the Don Esses and whatever aid they could to Legacy. ILC members had always helped Legacy where possible including being camp leaders or camp staff, with the annual demonstrations, and coffee stalls at the ANZAC dawn service. Post second world war some ILC members were nominated into Legacy, others drifted away in civil occupations. It was found difficult to recruit new blood into the ILC and eventually membership waned when the boys from the Don Esses clubs found other youth activities to join. The ILC ceased to meet regularly in the mid fifties. However a strong comradeship still existed between members and they would meet in one anothers homes. Members were always ready to help the senior Legacy Club in any way in their power and still helped at Christmas parties and summer camps. ILC was a service rendering organisation and was self governing. Non-sectarian and non-political, the members were ex-junior legatees over 18 years of age. After serving in World War 2 members were eligible to become members of Legacy.A record of the cloth badge worn by Intermediate Legacy Club members.Cloth badge of the Legacy torch stitched on pale blue fabric containing the words Intermediate Legacy Club - Ladies.Embroidered with 'Intermediate Legacy Club - Ladies'ilc, membership -

Federation University Historical Collection

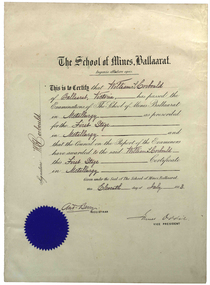

Federation University Historical CollectionCertificate, Ballarat School of Mines, William Corbould's Ballarat School of Mines Metallurgy Certificate, 11/07/1883

William Corbould was the son of a Ballarat tailor. He attended Ballarat College, and obtained certificates in assaying and metallurgy at the Ballarat School of Mines (SMB) in 1883, studying under the revered Professor Mica Smith. Corbould was not a born student and remembered his first experience at SMB: 'From the Registrar's Office I was led to be introduced to the Professor of Chemistry, one Mica Smith. The initial encounter gave me little encouragement - his large laboratory was filled with hundreds of bottles bearing strange labels with queer symbols on them. My heart sank. At the first opportunity I grabbed my hat and made for the door, but the good professor called me back. I pointed out that I was never any good at school ... so it was no use pretending to be clever enough to understand all those weird symbols! The Professor told me not to worry about that and took me to one of the benches where he found a blowpipe and a charcoal block. Mixing together two powders from bottles on the shelf he transferred a sample to the charcoal and directed the bunsen flame onto it. Soon it began to melt and a white bead appeared in front of my eyes. He then took a test tube and added a little colourless liquid from each of two bottles. A beautiful dark blue colour appeared. My interest was won.' During Corbould's mining career he travelled to Europe twice, and visited most of Australia's main mining fields. Corbould started his career as an assayer at Pinnacle Silver Mine, Silverton, and was then a self-employed assayer at Broken Hill. Corbould became an assayer for the infant BHP mine, and later worked in Kalgoorlie and Coolgardie, including managing Hannan's Reward, the oldest gold mine on the Kalgoorlie gold field. He spent 13 years at the Mount Elliott copper fields as general manager. In 1923, at the age of 57, Corbould went to Mount Isa and reported on options, experimented with new metallurgical processes and floated a company. John Carden of CRA said: 'Corbould was the man who brought Urquhart to Mount Isa. He was the man who made it all possible. He is tremendously important in the Mount Isa story, because he was the first technical man, the first professional man on the scene. He was responsible as I said, for bringing finance to the place, but I think even more importantly he was the first man to recognise the need to put all the little claims in the Mount Isa discovery together. I think perhaps his major contribution to Mount Isa was this amalgamation on the various claims. He recognised that the ore bodies at Mount Isa were not as rich as Broken Hill and they would never have survived had it been fragmented, so he was terribly important.' After completing major financial negotiations for Mt Isa Mine from London in 1927 Corbould remained in Europe where he remained until his death. Corbould was awarded the Legion of Honour of the American Institute of Mining and Metallurigical Engineers for fifty years service. Corbould died at Monaco in 1949 at the age of 82. (http://guerin.ballarat.edu.au/curator/honour-roll/honourroll_Corbould,William.shtml)A white paper certificate with black printed and handwritten text, and a blue Ballarat School of Mines seal. The certificate is signed by Andrew Berry (Registrar) and James Oddie (Vice-President).Signed on the left 'W.H. Corbould'mining, ballarat school of mines, mining alumni, metallurgy, james oddie, andrew berry, william corbould, corbould, berry, oddie -

Eltham District Historical Society Inc

Eltham District Historical Society IncFilm - Video (VHS), Diamond Creek Fire Brigade, c.1955-1987

Combination of three movie films. Movie One (1950s): 00:00 – 13:14 Black and white footage of Diamond Creek firemen practising in Diamond Street in the 1950s for forthcoming demonstrations of abilities. Mentions of Gordon Brandy and Joe Hislop Running out hoses from old hose reels along Diamond Street, Diamond Creek Displays from various brigades running out and connecting hoses. Also scenes from the 1950s of Diamond Creek Fire Brigade competing in various locations around Victoria and Tasmania. Mentions of Brigade members Dave Kidd, Bruce Hackett, Ron Kirkbride, Jack Marks, Graham Upton who are prominent in these events. Members of Kyneton Fire Brigade also present. Members competing in running out hose reels, connecting hoses togethers and to hydrants then climbing towers to direct water from hose or at a target hanging above the road. Diamond Creek members identified wearing a diamond on their chest and back. Includes scenes of Scottish pipe bands at the events and significant crowds of spectators. Footage of Mel Stone and Beryl Marks, Stan Redpath and Ron Kirkbride, then Ron Kirkbride and Eric Holt viewing flower displays. Film changes to colour at Diamond Creek oval for practice with fire engine entering oval. Members depicted include Bill May, Jack Sinclair, Jim Cox, Bob Beale, Dave Kidd, Bruce Hackett and Captain Clarrie Stone. Reverts to black and white in the 1950s where the Brigade joins forces with the Diamond Valley Community Hospital for a Gala Day on the Diamond Creek Oval. Changes to colour again, possibly same event and scenes of children on bikes and scooters or with prams and carts racing around the oval. Mention of young lad Brian Laurie who has his own fire truck. Dart throwing, pony rides. Scenes with Dr Don Cordner, Gus Lyons, Vic Cohn (?) and spinning wheel and Diamond Creek School children entertain a large crowd with Maypole dancing. Movie Two (1950s): 13:25 – 19:00 This black and white film was taken by a TV film crew in the 1950s depicts a typical call out for the Diamond Creek Fire Brigade. In this case the careless action of a member of the public throwing a lighted match from a car, which can cause extensive damage. Footage features the Shire of Eltham War Memorial tower at Kangaroo Ground before it was modified with a fire spotter’s cabin. Discusses fire spotting operations from the tower. Shows a fire spotter walking around the top of the tower. A fire is detected, and the information is relayed to the nearest fire station, in this case, Diamond Creek. The telephone call is received, and the alarm sounded. Captain Clarrie Stone and firemen May and Shaw leave their workplaces and prepare for action. Scenes of running across the Main Hurstbridge road showing the shops (Shell service station and Chemist prominent). Scenes entering the fire station which has a pictorial warning covering the entire door “Only you can prevent forest fires – If you’re careless – we’re homeless!” Eric Holt pinpoints the location of the fire while Captain Clarrie Stone and Fireman Shaw take note. The advance vehicle (an FE Holden ute, rego GTE-696) leaves to assess the extent of the fire. Having assessed the fire, Fireman Shaw communicates with base showing radio with call sign VL3JZ. Eric Holt takes the call. In the meantime, Captain Clarrie Stone and Fireman Shaw undertake some limited action to address the fire. Firemen Bill May, Jim Bates and Hugh Bar (?) man the tanker. A photo portrait of Queen Elizabeth is visible hanging on the wall. They are later joined by Firemen Jim Cox, Eric DeBuse (?) and Jack Marks. The tanker is seen departing the station and diverging off before the bridge. Captain Clarrie Stone and Fireman Shaw are seen pumping water on the flames with hand pumps when the tanker arrives. The hose is unreeled, and water turned on the flames. Jack Sinclair joins the action. Jim Cox directs water to the high stuff. The fire put out, Jack Marks and Eric DeBuse wind in the hoses and the team head back to town. It’s peaceful again at the memorial tower. Movie Three (1969-1987): 19:14 – 34:34 Colour film “Fired with Dedication”, Country Fire Authority Victoria, produced by I.L. Wadeson, Commentary by A.M. Hem. Credits with CFA Victoria emblem and then placed over a view of an old-style ladder engine. Opens with the scene of a fire engine outside the Diamond Creek Fire Station then various trophies reflecting the competition success of the brigade in various track and disciplined events. Two trophies shown of particular pride to the brigade were for first place in the Torchlight Procession at the State Championships in Mildura in 1986 and also at Swan Hill in 1981. Still photo scenes of ex Captain Clarrie Stone, Brigade Captain for 21 years; ex Captain Jack Marks, 10 years; ex Captain Ian Douglas, 10 years. Cuts to scene of radio control room, January 1969, and news of a fire on the northern side of the township of Diamond Creek. With scenes of flames in bush, the narration explains that until the early 1960s the area was an orchard district which protected the town against the savagery of bushfires. But due to competition from other areas more suitable for orcharding and easier transport to Melbourne the district could no longer remain competitive, and orchards were replaced by grassed areas, which together with the bush areas were a feeding ground for fire. On 8th January 1969, high temperatures and strong north winds, were, with the carelessness of some individual all that was necessary to produce the worst fire the district had seen. Cuts to scene of blackened fields and cattle - Hundreds of hectares of grass land were blackened, and cattle had to be transported to other areas for agistment. Scene of destroyed buildings in the township – 13 houses and the public hall in the town were destroyed as was the theatre equipment which was owned by the fire brigade. The Church of England Hall and bell tower were badly damaged. The whole town could have been burnt out but for the determination, skill, and courage of the Diamond Creek Fire Brigade. Scenes of all that was left of the home on the hill on the west side of the Church of England. Also, the remains of the old Pisy (?) home on the top of the same hill near Lambert Street, and the ruined Crocker home. Cuts to a scene in the mid-1970s to mid-1980s of a house fire in Haley Street attended by the Diamond Creek Fire Brigade. Although the house was severely damaged, it was saved. Mentions that whilst assistance is appreciated, in some circumstances, those doing so are not properly dressed for fighting fires. Breathing apparatus is a must in structure fire attack. Next scene (either on Mangarook or Coventry oval) showing off four Diamond Creek Fire Brigade efficient and very expensive firefighting units. Features a forward control vehicle Toyota 4WD used for conveying task force personnel to the required areas; a Hino Model 3.2 tanker, diesel powered and carries 3,000 litres of water and has a 16 HP petrol driven pump which delivers 900 litres of water per minute; an International tanker (registration TCM-418) which carries 3,000 litres of water with pumping capacity of 600 litres per minute. The Ford diesel powered pumper (registration MXE-754) is a well-equipped vehicle with a water capacity of 1,000 litres and capable of pumping 1,900 litres of water per minute from the main pump, has many lockers which hose equipment such as breathing apparatus and various types of hose nozzles and foam making equipment. The vehicle carries 360m of 64mm diameter hose which can be laid out from the rear lockers and a portable lighting plant, an Oxy Viva resuscitator to revive smoke inhalation victims and forcible entry tools to gain access to structure fires. Views of the main pump and control panel on the vehicle. As well as the main pump, the vehicle is equipped with an auxiliary pump which allows the facility to pump whilst moving. Fire fighters must undergo constant training and hone their skills, Scenes of a training exercise using the pumper to pump from static water. First, the short lengths of suction hose are coupled, a strainer fitted to ensure debris does not foul the pump. Gauges must be constantly monitored to ensure manageable water pressures are maintained. Pressures are normally controlled to allow two fire fighters to work at each nozzle outlet. Two nozzles are tested, one adjustable jet fog type which is used on flammable gasses or within a structure fire to absorb heat. A straight jet nozzle to project water long distances to protect exposed surfaces close to a fire radiated heat. The pumper is quite a versatile vehicle in handling structure fires, but it also carries specialist equipment needed in containing hazardous chemical incidents. Cuts to scene of parade – the Diamond Creek Fire Brigade has with other neighbouring brigades participated in most town fairs and earns the respect of the watching public. It can be seen why this brigade has been so successful at disciplined contests. Views of Plenty Fire Brigade Road Rescue unit which is equipped with the “Jaws of Life” Scenes of athletic competitions – many neighbouring brigades indulge in friendly but keen competition at the Diamond Creek Town Fair. The young are also encouraged to participate in all aspects of Junior Fire Brigade activities and become tomorrow’s generation of volunteer fire fighters. Scene of the 1986 Diamond Creek Town Fair which was the last time veteran Captain Clarrie Stone BEM marched with the brigade. Clarrie was awarded the British Empire Medal for his service to the Country Fire Authority. Also, scenes of vehicles in the parade. Cuts to scene of brigade members in drill formation for inspection by Acting Chief Harry Rothsay (?) on the occasion of the opening of the new fire station extensions on August 29, 1987. Rudy Libel (?) Captain at the time. Scenes of crowds including many dignitaries of neighbouring brigades present including Lieutenant Gordon Grandy (who came down from Queensland for the occasion) and ex-Secretary David Kidd and wife Betty, also ex Captain Clarrie Stone and Mrs Nel Stone, a life member of the Ladies Auxiliary, the Reverend Jock Ryan, son of J.L Ryan, founder of the Diamond Creek Fire Brigade, Foundation Captain of the fire brigade, Keith Bradbury and Mrs Bradbury. Pauline Dick accepts a community service award for services to the CFA. Recognising over 47 and a half years of service, a presentation is made by Mr Neil Marshall, Acting Chairman of the CFA to ex Captain Clarrie Stone with response by Clarrie. Other members of the official party include Cr. Martin Wright, Shire President Wayne Phillips and local Member of Parliament, Mrs Pauline Toner. Ex foreman John Bennett is presented with a life member’s awards by Captain Rudy Libel. The camera also catches Gwen Cox, Jean Ryan and Bessie Layton (?) Provides historic footage of people, places and equipment and a record of the worst fires expoerienced in Diamond Creek in 1969BASF Standard Quality SQ E-180 VHS dubbing (poor quality) of three films Converted to MP4 file format 0:34:38, 1.85GBOn label: "Donation - August 2000 Diamond Creek Unit Old films made up from Fire Brigade shows at competitions - also Kangaroo Ground Tower being used"video recording, diamond creek fire brigade, 1986 diamond creek town fair, a.m. hem, acting chief harry rothsay, athletic competitions, beryl marks, bessie layton, betty kidd, bill may, bob beale, brian laurie, bruce hackett, captain clarrie stone, chemist, church of england hall, clarrie stone, clarrie stone bem, country fire authority victoria, coventry oval, cr. martin wright, crocker home, dart throwing, dave kidd, david kidd, diamond creek, diamond creek fire station, diamond creek oval, diamond creek school, diamond creek town fair, diamond street, diamond valley community hospital, dr don cordner, eric debuse, eric holt, fe holden ute, fire damage – buildings, fire spotter, fire spotter’s cabin, fire station extension, fired with dedication (film), firefighting units, fireman shaw, firemen jim cox, ford pumper, foundation captain, gala day, gordon brandy, gordon grandy, graham upton, gus lyons, gwen cox, haley street, hino model 3.2 tanker, house fire, i.l. wadeson, ian douglas, international tanker, j.l ryan, jack marks, jack sinclair, january 1969, jaws of life, jean ryan, jim bates and hugh bar, jim cox, joe hislop, john bennett, kangaroo ground, kangaroo ground tower, keith bradbury, kyneton fire brigade, lambert street, main hurstbridge road, mangarook oval, maypole dancing, mel stone, mildura 1986, mrs bradbury, mxe754 vic registration, neil marshall, nel stone, orchard district, oxy viva resuscitator, pauline dick, pauline toner mp, pisy home, plenty fire brigade road rescue unit, pony rides, radio control room, reverend jock ryan, ron kirkbride, rudy libel, shell service station, shire of eltham war memorial, shire president wayne phillips, spinning wheel, stan redpath, state championships, swan hill 1981, tcm418 vic registration, torchlight procession, toyota 4wd, trophies, vic cohn, victorian bushfires - 1969, vl3jz -

Federation University Historical Collection

Federation University Historical CollectionPhotograph, Ballarat School of Mines Corbould Building

Corbould Hall was named after Ballarat School of Mines alumni WIlliam Corbould. William Corbould was the son of a Ballarat tailor. He attended Ballarat College, and obtained certificates in assaying and metallurgy at the Ballarat School of Mines (SMB) in 1883, studying under the revered Professor Mica Smith. Corbould was not a born student and remembered his first experience at SMB: 'From the Registrar's Office I was led to be introduced to the Professor of Chemistry, one Mica Smith. The initial encounter gave me little encouragement - his large laboratory was filled with hundreds of bottles bearing strange labels with queer symbols on them. My heart sank. At the first opportunity I grabbed my hat and made for the door, but the good professor called me back. I pointed out that I was never any good at school ... so it was no use pretending to be clever enough to understand all those weird symbols! The Professor told me not to worry about that and took me to one of the benches where he found a blowpipe and a charcoal block. Mixing together two powders from bottles on the shelf he transferred a sample to the charcoal and directed the bunsen flame onto it. Soon it began to melt and a white bead appeared in front of my eyes. He then took a test tube and added a little colourless liquid from each of two bottles. A beautiful dark blue colour appeared. My interest was won.' During Corbould's mining career he travelled to Europe twice, and visited most of Australia's main mining fields. Corbould started his career as an assayer at Pinnacle Silver Mine, Silverton, and was then a self-employed assayer at Broken Hill. Corbould became an assayer for the infant BHP mine, and later worked in Kalgoorlie and Coolgardie, including managing Hannan's Reward, the oldest gold mine on the Kalgoorlie gold field. He spent 13 years at the Mount Elliott copper fields as general manager. In 1923, at the age of 57, Corbould went to Mount Isa and reported on options, experimented with new metallurgical processes and floated a company. John Carden of CRA said: 'Corbould was the man who brought Urquhart to Mount Isa. He was the man who made it all possible. He is tremendously important in the Mount Isa story, because he was the first technical man, the first professional man on the scene. He was responsible as I said, for bringing finance to the place, but I think even more importantly he was the first man to recognise the need to put all the little claims in the Mount Isa discovery together. I think perhaps his major contribution to Mount Isa was this amalgamation on the various claims. He recognised that the ore bodies at Mount Isa were not as rich as Broken Hill and they would never have survived had it been fragmented, so he was terribly important.' After completing major financial negotiations for Mt Isa Mine from London in 1927 Corbould remained in Europe where he remained until his death. Corbould was awarded the Legion of Honour of the American Institute of Mining and Metallurigical Engineers for fifty years service. Corbould died at Monaco in 1949 at the age of 82. He bequested 6000 pounds to the Ballarat School of Mines, his will stating 'for the purpose of founding a scholarship to commemorate the memory of the late Alfred Mica Smith'. The accumulated income from this sum provides the Mica Smith travelling scholarship, enabling successful students in mining, metallurgy or chemistry to undertake a year's travelling abroad. The first award was made in 1957. In the same year a general purpose hall at SMB was named the Corbould Hall as a tribute to a distinguished former student and generous benefactor.ballarat school of mines corbould building, corbould hall, corbould building -

Department of Energy, Environment and Climate Action

Department of Energy, Environment and Climate ActionPrototype fuel moisture meter

Bushfire behaviour is influenced by many things including temperature, relative humidity, forest type, fuel quantity and fuel dryness, topography and even slope. Wind has a dominant effect on the Rate of Spread (ROS), and also bushfire size, shape and direction. Fuel arrangement is as important as fuel quantity (tonnes/ha). Fibrous and ribbon bark, together with elevated and near-surface scrub fuels act as ladders which lead flames into the tree canopy. But the availability of fuel to burn depends largely on its moisture content. When it exceeds 20-25% not much will burn, whereas 12-15% is generally ideal for fuel reduction burning, but if the moisture content drops as low as 7-10% virtually everything will ignite, and fire behaviour becomes extreme. During the afternoon of the Ash Wednesday bushfires on 16 February 1983 fuel moisture contents were recorded at Stawell as low as 2.7%. Fine fuels like leaves and bark can rapidly absorb moisture after a shower of rain, or from the air when the Relative Humidity (RH) is high, and the temperature is low. Conversely, they can also dry out very quickly. So even though the overall fuel quantity in the forest doesn’t change, the fine fuel availability can increase rapidly from zero after rain to many tonnes per hectare as the fuel dries out. This can happen over a few hours on hot and windy days. Heavy fuels like logs on the ground take longer to dry out. Since the 1930s foresters, firefighters and researchers have been working to develop quick and reliable techniques for measuring fuel moisture content. One of the most accurate methods is slowly drying a sample of fuel in a conventional oven for 24-48 hours to remove all the moisture and measuring the weight difference, but this takes time and is not practical in the field when rapid measurements are needed. But oven drying is often used as a benchmark to compare other methods. Microwave ovens are faster but can cause uneven drying and even char the fuel. They are also not very practical for use in the field. Some mathematical models rely on weather records such as rainfall, wind speed, evaporation, cloud cover, shading, relative humidity, slope, aspect and season of the year to predict soil and fuel moisture. The Keetch-Byram Drought Index of soil dryness is the most common. But complex fuels with leaves, twigs, grass etc make the predictive models often inadequate for fine fuels. The most common technique in Victorian forests until recently was the trusty Speedy Moisture Meter. Originally developed in England during the 1920s for measuring moisture in wheat and other grains it was adapted for Australian forest fuels in the 1950s (I think). Fuel was first ground using a Spong mincer, often attached to the bullbar of a vehicle, and a small sample placed into the Speedy together with a measure of calcium carbide and then sealed. A chemical reaction created gas pressure which was read on the external dial. There were important techniques with cleaning, mincing and using the chemicals with the Speedy to give reliable readings, but it was quick, inexpensive, robust, portable and practical in the field. It was used routinely before igniting a fuel reduction burn or measuring fuel moisture differentials on slash burns. But in about 1996, Karen Chatto and Kevin Tolhurst from the Department’s Creswick Research Station developed the Wiltronics Fuel Moisture meter which measured electrical resistance. Wiltronics is an Australian owned company operating from Ballarat. The final result was a kit that was portable, accurate and could reliably measure fuel moisture contents between 3% and 200%. Although expensive, it is now widely used by fire agencies around the world which has virtually relegated the Speedy to the back cupboard.Prototype Fuel moisture meterT-H Fine Fuel Meterforests commission victoria (fcv), bushfire, forest measurement -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Document - BENDIGO EASTER FAIR FESTIVAL PROGRAM 1997, 26 March 1997

Bendigo Easter Fair Festival Program, 26-31 March, 1997. Festival Features, Evening of Art & Classical Music, Rotary Club of Bendigo. VicHealth Easter Fest, Victorian Health Promotion Foundation & Bendigo Community Health Services. Fine Food Fest. Free Stage. Free Evening Concert & Fireworks, Zaire. Torchlight Procession, sponsored by Prime TV & Coca Cola, Bendigo Market Place. Fireworks Spectacular, Sponsored by Bendigo Market Place & Prime TV. Street Fiesta, sponsored by Arts Victoria. Street Extravaganza, Coca Cola Carnival, Sponsored by Coca Cola. Star for a Day, Power Audio Visual & Prime Television. Handcraft Bazaar, Rotary Club of Bendigo Sandhurst Art & Craft Market. Cosmopolitan Street Café, Arts Victoria. Awakening of the Dragon, Bendigo Chinese Association. Gala Parade, Prime Television & Coca Cola. Firewalking by the Australian Skeptics, Discovery Science & Technology Centre. Up In Flames, Discovery Science & Technology Centre. Barry Kenny's Country Roundup, Nadort Promotions. School's Day. Teddy Bear's Picnic, Dragon City Marshals. Fire Brigades Children's Carnival. Family Event, Bendigo Minister's Fellowship. Bendigo Easter Antique Fair. Historic Photographic Exhibition, Burt Sargent Circa 1900. Open Garden at Nanga Gnulle (''nanga nully''). A parade of Quilts, Strathdale Bendigo Quilters Inc. Tasting the Life, Gail Tavener Studio. Snakes Alive Dangerous Australians, BRIT. Y's Men's Club of Bendigo Book Fair, YMCA. Bendigo Camera Club, BRIT. Bendigo Woodcraft Exhibition, Woodturners Bendigo Inc. Autumn Bonsai, Bendigo Bonsai Club. Convocation, National Trust Bendigo. Arms & Collectables, Golden City Collectors Assoc. In. Rotary Art Show. Rotary Pottery Exhibition. Women's Vision For The Church, Provincial Council of Mothers Union. Historic Toorak House, Lioness Club of Golden City Bendigo. White Hills Cemetery. Bendigo Cemetery. Festival of Flowers, Craft & Garden, Bendigo Jockey Club. Shannons Corporation Motorfest, City Drive Through, Static Display, Motorkhana, Time Trial. Bendigo Bank Dragon Mile. Volkswagen Car Show, a part of the 28th National Bug-In. Repco Cycles, Australian Veteran Cycling Council Inc. Championships. Under 17 Australian Badminton Championships. Palm Sunday, Bendigo Symphony Orchestra. Way of the Cross, Bendigo's Combined Churches. The Easter Story, Kangfluca Music. Sunrise Church Service, Bendigo Ministers' Fellowship. Map of CBD Advertisements: Bendigo Easter Antique Fair. Austar. Bendigo Art Gallery. Bendigo Visitor Information Centre. Prime. Golden Dragon Museum Inc. Bendigo Heritage Tours. Discovery Science & Technology Centre Bendigo. Sponsors: Sandhurst Trustees, Prime, Vic Health, ABC Radio, Arts Victoria, Coca Cola, Events Bendigo, City Of Greater Bendigo, Bendigo Community Health Services, Shannons., Morris Design PH 5448 8777Morris Designevent, easter fair, bendigo easter fair, bendigo easter fair festival program, 26-31 march, 1997. festival features, evening of art & classical music, easter fest, . fine food fest. free stage. free evening concert & fireworks. torchlight procession. fireworks spectacular, street fiesta, street extravaganza, coca cola carnival, star for a day, handcraft bazaar, art & craft market. cosmopolitan street café, awakening of the dragon. gala parade, firewalking australian skeptics, discovery science & technology centre. up in flames, barry kenny's country roundup, nadort promotions. school's day. teddy bear's picnic, fire brigades children's carnival. family event, bendigo minister's fellowship. antique fair. photographic exhibition, burt sargent circa 1900. open garden nanga gnulle a parade of quilts, strathdale bendigo quilters inc. tasting the life, gail tavener studio. snakes alive dangerous australians, brit. book fair, ymca. bendigo camera club, brit. bendigo woodcraft exhibition, woodturners bendigo inc. autumn bonsai, bendigo bonsai club. convocation, national trust bendigo. arms & collectables, golden city collectors assoc. art show. pottery exhibition. women's vision for the church, provincial council of mothers union. historic toorak house, lioness club. white hills cemetery. bendigo cemetery. festival of flowers, craft & garden, bendigo jockey club. motorfest, drive through, static display, motorkhana, time trial. dragon mile. volkswagen car show, national bug-in. repco cycles, australian veteran cycling council inc. championships. under 17 australian badminton championships. palm sunday, bendigo symphony orchestra. way of the cross, bendigo's combined churches. the easter story, kangfluca music. sunrise church service, bendigo ministers' fellowship. map of cbd advertisements: antique fair. golden dragon museum inc. bendigo heritage tours. discovery science & technology centre bendigo. sponsors: sandhurst trustees, vic health, abc radio, arts victoria, coca cola, events bendigo, city of greater bendigo, bendigo community health services, shannons., morris design. prime tv. austar. bendigo art gallery. bendigo visitor information centre. prime, victorian health promotion foundation, zaire, sponsored by bendigo market place & prime tv, sponsored by arts victoria, sponsored coca cola, power audio visual, rotary club of bendigo sandhurst, bendigo chinese association, y's men's club of bendigo -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageAnimal specimen - Whale bone, Undetermined

Prior to carrying out a detailed condition report of the cetacean skeletons, it is useful to have an understanding of the materials we are likely to encounter, in terms of structure and chemistry. This entry invites you to join in learning about the composition of whale bone and oil. Whale bone (Cetacean) bone is comprised of a composite structure of both an inorganic matrix of mainly hydroxylapatite (a calcium phosphate mineral), providing strength and rigidity, as well as an organic protein ‘scaffolding’ of mainly collagen, facilitating growth and repair (O’Connor 2008, CCI 2010). Collagen is also the structural protein component in cartilage between the whale vertebrae and attached to the fins of both the Killer Whale and the Dolphin. Relative proportions in the bone composition (affecting density), are linked with the feeding habits and mechanical stresses typically endured by bones of particular whale types. A Sperm Whale (Physeter macrocephalus Linnaeus, 1758) skeleton (toothed) thus has a higher mineral value (~67%) than a Fin Whale (Balaenoptera physalus Linnaeus, 1758) (baleen) (~60%) (Turner Walker 2012). The internal structure of bone can be divided into compact and cancellous bone. In whales, load-bearing structures such as mandibles and upper limb bones (e.g. humerus, sternum) are largely composed of compact bone (Turner Walker 2012). This consists of lamella concentrically deposited around the longitudinal axis and is permeated by fluid carrying channels (O’Connor 2008). Cancellous (spongy) bone, with a highly porous angular network of trabeculae, is less stiff and thus found in whale ribs and vertebrae (Turner Walker 2012). Whale oil Whales not only carry a thick layer of fat (blubber) in the soft tissue of their body for heat insulation and as a food store while they are alive, but also hold large oil (lipid) reserves in their porous bones. Following maceration of the whale skeleton after death to remove the soft tissue, the bones retain a high lipid content (Higgs et. al 2010). Particularly bones with a spongy (porous) structure have a high capacity to hold oil-rich marrow. Comparative data of various whale species suggests the skull, particularly the cranium and mandible bones are particularly oil rich. Along the vertebral column, the lipid content is reduced, particularly in the thoracic vertebrae (~10-25%), yet greatly increases from the lumbar to the caudal vertebrae (~40-55%). The chest area (scapula, sternum and ribs) show a mid-range lipid content (~15-30%), with vertically orientated ribs being more heavily soaked lower down (Turner Walker 2012, Higgs et. al 2010). Whale oil is largely composed of triglycerides (molecules of fatty acids attached to a glycerol molecule). In Arctic whales a higher proportion of unsaturated, versus saturated fatty acids make up the lipid. Unsaturated fatty acids (with double or triple carbon bonds causing chain kinks, preventing close packing (solidifying) of molecules), are more likely to be liquid (oil), versus solid (fat) at room temperature (Smith and March 2007). Objects Made From the Whaling Industry We all know that men set forth in sailing ships and risked their lives to harpoon whales on the open seas throughout the 1800s. And while Moby Dick and other tales have made whaling stories immortal, people today generally don't appreciate that the whalers were part of a well-organized industry. The ships that set out from ports in New England roamed as far as the Pacific in hunt of specific species of whales. Adventure may have been the draw for some whalers, but for the captains who owned whaling ships, and the investors which financed voyages, there was a considerable monetary payoff. The gigantic carcasses of whales were chopped and boiled down and turned into products such as the fine oil needed to lubricate increasing advanced machine tools. And beyond the oil derived from whales, even their bones, in an era before the invention of plastic, was used to make a wide variety of consumer goods. In short, whales were a valuable natural resource the same as wood, minerals, or petroleum we now pump from the ground. Oil From Whale’s Blubber Oil was the main product sought from whales, and it was used to lubricate machinery and to provide illumination by burning it in lamps. When a whale was killed, it was towed to the ship and its blubber, the thick insulating fat under its skin, would be peeled and cut from its carcass in a process known as “flensing.” The blubber was minced into chunks and boiled in large vats on board the whaling ship, producing oil. The oil taken from whale blubber was packaged in casks and transported back to the whaling ship’s home port (such as New Bedford, Massachusetts, the busiest American whaling port in the mid-1800s). From the ports it would be sold and transported across the country and would find its way into a huge variety of products. Whale oil, in addition to be used for lubrication and illumination, was also used to manufacture soaps, paint, and varnish. Whale oil was also utilized in some processes used to manufacture textiles and rope. Spermaceti, a Highly Regarded Oil A peculiar oil found in the head of the sperm whale, spermaceti, was highly prized. The oil was waxy, and was commonly used in making candles. In fact, candles made of spermaceti were considered the best in the world, producing a bright clear flame without an excess of smoke. Spermaceti was also used, distilled in liquid form, as an oil to fuel lamps. The main American whaling port, New Bedford, Massachusetts, was thus known as "The City That Lit the World." When John Adams was the ambassador to Great Britain before serving as president he recorded in his diary a conversation about spermaceti he had with the British Prime Minister William Pitt. Adams, keen to promote the New England whaling industry, was trying to convince the British to import spermaceti sold by American whalers, which the British could use to fuel street lamps. The British were not interested. In his diary, Adams wrote that he told Pitt, “the fat of the spermaceti whale gives the clearest and most beautiful flame of any substance that is known in nature, and we are surprised you prefer darkness, and consequent robberies, burglaries, and murders in your streets to receiving as a remittance our spermaceti oil.” Despite the failed sales pitch John Adams made in the late 1700s, the American whaling industry boomed in the early to mid-1800s. And spermaceti was a major component of that success. Spermaceti could be refined into a lubricant that was ideal for precision machinery. The machine tools that made the growth of industry possible in the United States were lubricated, and essentially made possible, by oil derived from spermaceti. Baleen, or "Whalebone" The bones and teeth of various species of whales were used in a number of products, many of them common implements in a 19th century household. Whales are said to have produced “the plastic of the 1800s.” The "bone" of the whale which was most commonly used wasn’t technically a bone, it was baleen, a hard material arrayed in large plates, like gigantic combs, in the mouths of some species of whales. The purpose of the baleen is to act as a sieve, catching tiny organisms in sea water, which the whale consumes as food. As baleen was tough yet flexible, it could be used in a number of practical applications. And it became commonly known as "whalebone." Perhaps the most common use of whalebone was in the manufacture of corsets, which fashionable ladies in the 1800s wore to compress their waistlines. One typical corset advertisement from the 1800s proudly proclaims, “Real Whalebone Only Used.” Whalebone was also used for collar stays, buggy whips, and toys. Its remarkable flexibility even caused it to be used as the springs in early typewriters. The comparison to plastic is apt. Think of common items which today might be made of plastic, and it's likely that similar items in the 1800s would have been made of whalebone. Baleen whales do not have teeth. But the teeth of other whales, such as the sperm whale, would be used as ivory in such products as chess pieces, piano keys, or the handles of walking sticks. Pieces of scrimshaw, or carved whale's teeth, would probably be the best remembered use of whale's teeth. However, the carved teeth were created to pass the time on whaling voyages and were never a mass production item. Their relative rarity, of course, is why genuine pieces of 19th century scrimshaw are considered to be valuable collectibles today. Reference: McNamara, Robert. "Objects Made From the Whaling Industry." ThoughtCo, Jul. 31, 2021, thoughtco.com/products-produced-from-whales-1774070.Whale bone was an important commodity, used in corsets, collar stays, buggy whips, and toys.Whale bone in two pieces. Advanced stage of calcification as indicated by deep pitting. Off white to grey.None.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, whale bones, whale skeleton, whales, whale bone, corsets, toys, whips -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageAnimal specimen - Whale bone, Undetermined