Showing 1355 items

matching form and colour

-

Melbourne Tram Museum

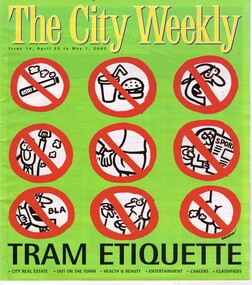

Melbourne Tram MuseumNewspaper, Bridget McManus., Robert Hudson, Peter Weaving, Golding, "Tram Etiquette", "Commuter fare blitz", Apr. 2002

Newspaper - The City Weekly, issue 14, April 25 to May 1, 2002, containing an article titled "Tram Etiquette" and "Commuter fare blitz". Printed in full colour on gloss paper with a front cover in cartoon form of the things you should not do on a tram - Cartoon by Golding. Was a free newspaper. Magazine of Newspaper Covers City Real Estate, out on the town, Health and Beauty, entertainment, classifieds and careers. Page 6 - article titled "Commuter fare blitz" - about proposed checking of Metcards, but there were many complaints and issues with machines not working and legal challenges. Pages 8 and 9 - article "Tram Etiquette", with the sub-headings "in the absence of conductors, have we become confused about public behaviour on privatised trams". Looks at issues at how people use the tram system with photos of people using trams. Also has a side item with people's photographs titled "What's getting up people's noses on Melbourne trams?" Written by Bridget McManus, Pictures by Peter Weaving and Robert Hudson. Two copies held.trams, tramways, passengers, behaviour, trams, public transport, tickets, metcard, cartoons -

Federation University Historical Collection

Federation University Historical CollectionBooks, H.E. Daw Government Printer, Ballarat School of Mines and Industries Departmental Papers, 1914-1950, 1914-1950

Used at the Ballarat School of Mines and the Ballarat Technical Art SchoolThis collection of examinations is significant because of its completeness with the full range of examinations between 1914 and 1950.Large leather bound books, with leather spine, containing all examinations held at the Ballarat School of Mines (including the Ballarat Technical Art School and Ballarat Junior Technical School). The examination papers were supplied and printed by the Education Department, Victoria. Examinations include: Agriculture, Algebra, Architecture, Arithmetic, Applied Mechanics, Assaying, Biology, Botany, Boilermaking, Building Design, Blacksmithing, Bricklaying, Carpentry and Joinery, Coachbuilding, Cabinet Making, Civil Engineering, Cabinet Making, Commercial, Chemistry, Engineering Drawing, Economics, English, Electrical technology, Electricity and Magnetism, Electric Wiring, Electric Welding, Electrical Fitting, Electrical Trades, Food Analysis, Geology, Geological Mapping, Graphics, Geometry, Heat Engines, Heat Treatment, Hydraulics, Hand Railing, Instrument Making, Millinery, Milling and Gearouting, Machine Shop Practice. Metal Founding, Mining, Metallurgy, Mineralogy, Mathematics, Motor Mechanics, Mine Surveying, Mining Mechanics, Petrology, Physics, Painting and Decorating, Pattern Making, Plastering, Plumbing and Gasfitting, Printing, Refrigeration, Spelling, Science , Shorthand, Surveying. Signwriting. Sheet Metalwork, Toolmaking, Ladies Tailoring, Trigonometry, Typewriting, Welding, Commercial Geography. Millinery, Dressmaking, Needlework, Decorative Needlework, Architecture, Building Design and Construction, Art (Composition in Form and Colour), Art (Casting Clay MOdels) Art (Drapery), Art (Drawing the Human Figure From Casts), Art (Drawing the Antique from Memory), Art (Drawing from Memory); Art (Drawing Plant Forms from Nature, Art (Drawing Plant Forms From Memory), Art (Drawing from Models and Objects), (Drawing From a Flat Example). Art (Drawing in Light and Shade from a Cast of Ornament or Lower Nature), Art (Drawing Ornament from the Cast), Art (Drawing from Models or Objects), Art (Drawing fro Dressmakers' and Milliners' Fashions), Art (Drawing With the Brush), Art (Drawing from a Flat Example); Art (Modelled Design), Art (General Design), Art (Embossed Leatherwork), Art (Practical Plane Geometry), Art (Practical Solid Geometry), Art (Geometrical Drawing), Carpentry and Joinery, Art (Human Anatomy), Art (Historic Ornament), Art (House Decoration), Art (LEttering), Signwriting, Art (Light Metalwork), Art (Modelling), Art (Modelling the Human Figure from a Life), Art (Stencilling); Art (Wood Carving) Refrigeration, Teaching, Boilermaking, Blacksmithing, Carpentry and Joinery, Coachbuilding and Carriage Drafting, Electric Wiring, Electrical Fitting, Graining and Marbling, Instrument Making , Machine Shop Practice, Metal Founding, Milling and Gear Cutting, Motor Mechanics, Painting and Decorating, Sheet Metalwork, Toolmaking, Printing, Pattern Making, Plumbing and gasfitting, examinations, ballarat school of mines, ballarat technical art school, trades, education department victoria, agriculture, algebra, architecture, arithmetic, applied mechanics, assaying, biology, botany, boilermaking, building design, blacksmithing, bricklaying, carpentry and joinery, coachbuilding, cabinet making, civil engineering, commercial, chemistry, engineering drawing, economics, english, electrical technology, electricity and magnetism, electric wiring, electric welding, electrical fitting, electrical trades, food analysis, geology, geological mapping, graphics, geometry, heat engines, heat treatment, hydraulics, hand railing, instrument making, millinery, milling and gearouting, machine shop practice, metal founding, mining, metallurgy, mineralogy, mathematics, motor mechanics, mine surveying, mining mechanics, petrology, physics, painting and decorating, pattern making, plastering, plumbing and gasfitting, printing, refrigeration, spelling, science, shorthand, surveying, signwriting, sheet metalwork, toolmaking, ladies tailoring, trigonometry, typewriting, welding., dressmaking, needlework, decorative needlework, architecture, building design and construction, art (composition in form and colour), art (casting clay models), art (drapery), art (drawing the human figure from casts), art (drawing the antique from memory), art (drawing from memory), art (drawing plant forms from nature, art (drawing plant forms from memory), art (drawing from models and objects), (drawing from a flat example), art (drawing in light and shade from a cast of ornament or lower nature), art (drawing ornament from the cast), art (drawing from models or objects), art (drawing for dressmakers' and milliners' fashions), art (drawing with the brush), art (drawing from a flat example), art (modelled design), art (general design), art (embossed leatherwork), art (practical plane geometry), art (practical solid geometry), art (geometrical drawing), art (human anatomy), art (historic ornament), art (house decoration), art (lettering), art (light metalwork), art (modelling), art (modelling the human figure from a life, art (stencilling), art (wood carving), teaching, coachbuilding and carriage drafting, graining and marbling, milling and gear cutting, commercial geography, exams, examination book -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageCeramic - Tile, circa 1878

This Minton floor tile is from the wreck of the LOCH ARD. Other examples of this manufacture have been recovered from the wreck site and form part of the collection at Flagstaff Hill. The iron-hulled clipper ship from the Loch Line was heading for Port Phillip from London when it ran into the cliffs of Mutton Bird Island near Port Campbell and was wrecked on the early morning of June 1, 1878. The LOCH ARD was laden with high-value cargo including luxury goods intended for display at the Melbourne International Exhibition in 1880. One notable survivor from the ship’s freight manifest was the well-packed Minton porcelain peacock, a two-metre-high ceramic masterpiece of vivid glazed colours. The almost total loss of life and property from the LOCH ARD registered as a shocking tragedy for the Colony of Victoria, at a time when social confidence and economic optimism were otherwise high. The wealth generated from gold and wool was increasingly being spent on magnificent private residences and imposing public buildings. The demand for quality furnishings and fittings was therefore strong. Among the products consigned to burgeoning colonial markets by the Milton Pottery at Stoke upon Trent were their new range of colourfully patterned but very durable floor tiles – ideal for the high-traffic spaces in the large civic buildings then being constructed in Australia and America. These new floor tiles were “encaustic”, meaning that their designs and colours were encased within the depth of the tile. Rather than their decorative patterns being glazed onto the surface of the tile, their inlaid designs were created during the manufacturing process, as “coloured slips” (or liquid clay) that were poured into a deep pre-moulded casting. When fired, the resulting tile was colour-fast and design-fast.The Minton encaustic floor tile is significant for its method of manufacture which makes it durable as well as decorative. The shipwreck of the LOCH ARD is of State significance. Victorian Heritage Register S417. Flagstaff Hill’s collection of artefacts from LOCH ARD is significant for being one of the largest collections of artefacts from this shipwreck in Victoria. It is significant for its association with the shipwreck, which is on the Victorian Heritage Register (VHR S417). The collection is significant because of the relationship between the objects, as together they have a high potential to interpret the story of the LOCH ARD. The LOCH ARD collection is archaeologically significant as the remains of a large international passenger and cargo ship. The LOCH ARD collection is historically significant for representing aspects of Victoria’s shipping history and its potential to interpret sub-theme 1.5 of Victoria’s Framework of Historical Themes (living with natural processes). The collection is also historically significant for its association with the LOCH ARD, which was one of the worst and best-known shipwrecks in Victoria’s history.A square Minton floor tile with a black and beige pattern against a white base. This encaustic floor tile was recovered from the shipwreck of the LOCH ARD. On the back, or base, of the tile is inscribed the number “46” and the letters “Minton & Co Patent Stoke upon Trent”.flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, loch line, loch ard, mutton bird island, loch ard gorge, minton floor tile, encaustic tile, melbourne international exhibition, floor tile -

Federation University Historical Collection

Federation University Historical CollectionPostcard - Postcard Booklet, Levi Fils & Co, Vues Detachables

Levy Sons & Co. 1895-1919 Paris, France and London, England In 1864 the Parisian photographic studio of Ferrier pere*, fils & Soulier was bought out and became M. Leon & J. Levy. This partnership lasted until 1872 when Leon left and it was renamed J. Levy & Co., which became an important producer of stereo-views and lantern slides. By 1895 his sons had joined the company and it was renamed once again to Levy Sons & Co. (or Levy et ses Fils). His son Lucien became a well known photographer who began publishing international view-cards from his own work depicting scenes mostly from within the French empire, though quite a number are from England and there are some from Australia and Russia as well. There are few French towns that are not captured by his cards. His name does not appear on the cards but - L.L. follows the title as a photo credit. Many of their cards are not attributed. These cards were printed as colotypes in black & white, sepia, and over speckled color lithography. In 1920 the studio united with Neurdein Freres to become Levy & Neurdein reunis. Their negatives are now owned by the Roger-Viollet Photographic Agency. *Claude Marie Ferrier (1811-1889) was also an important early photographer. He was the 'Pere' in Ferrier Pere, Fils & Soulier - best remembered for their stunning series of glass views. Sorting this collection is a challenge. The postcard rears display a variety of forms - a) garland emblem with LL inside, b) with an addition emblem within (FPS?). Or c) - no emblem which may mean production by another company - however LL. remains on the front as a credit to the photographer. http://www.metropostcard.com/picslogos/pcl-levylucien.jpg.jpg http://www.unpi.com/clem/unpostcards/LON1919PC2Naback.jpg Example Colour Card circa 1920 No. 78 Paris - L'Escalier de l'Opera - LL. http://www.postcardcollector.org/forum/index.php?p=/discussion/1306/levy-fils-cie-paris-specifically-lucien-levy-llAbbeyville was a town in the Somme, so that this is a possible reason that the name has been erased on the postcard. http://www.france-voyage.com/travel-photos/abbeville-11435.htmSmall brown covered book of 12 postcards with views of Abbeyville in the Somme. Issue between each each individual postcard. The cover has an oval on front and the name "Abbeyville" in its centre has been erased. The name of the town has also been erased (censored) throughout the booklet. There is a garland in maroon around the maroon oval on the front cover. Print in dark grey on bottom left and right hand side corners.Print "Modele ... Depose" in dark grey on bottom left and "12 Vues Detachables" on right hand side corners. Names of places printed inside but the name of the town has been erased throughout. "Carte Postale" with logo underneath at centre and "Correspondence" LHS and "Adresse" RHS on top of verso of each postcard in booklet. "Levy Fils & Co, Paris sideways along centre line of postcard on verso.abbeyville, levy fils, postcard, vues, panorama, place de l'amiral-courbet, monument, rue alfred-cendre, alfred-cendre street, statue, saint vulfran church, saint gilles church, museum, prarona statue, avenue de la gars, avenue of the station, chevalier de la barre, river somme, somme, talence bridge, correspondence, carte postale, censor, censored -

Duldig Studio museum + sculpture garden

Duldig Studio museum + sculpture gardenFabric, Mathilda Flogl, Falter designed by Mathilda Flogl 1924-31, 1924-31

This piece of fabric, known Fälter (butterfly), was designed by Mathilda Flögl (1893-1958), who worked in the textile department of the Wiener Werkstätte in Vienna. It is a remnant of the fabric that was used to make a bedspread for Karl and Slawa’s bed in their Vienna apartment where it lay decoratively over a gold brocade eiderdown. The purchase demonstrated Slawa’s interest in and knowledge of modern design and her commitment to the idea of enriching everyday life with beautiful objects, a principal of the Viennese Secession. Following the Duldigs removal from Vienna, the original bedspread and remnant were safeguarded and preserved by Slawa’s sister, Rella, in the basement of her Paris apartment. In 1948 the bedspread and this remnant were sent to Australia. The bedspread was a much-loved item but deteriorated over the years. In 1955 it was made into curtains, which are held in the Duldig Studio Collection. The Photographs of the bedspread in its original location are also held in the collection. The remnant is in pristine condition. The Wiener Werkstätte (Vienna Workshop) was a guild of designers and craftsmen that was founded by the architect Josef Hoffman (1879-1956) and the designer Koloman Moser (1868-1918). The firm manufactured a range of interior furnishings between 1903 and 1932. The textile department opened in 1900, and produced about 1,800 designs, mainly for printed fabrics for furnishings and apparel. The designs were characterised by simplified forms and vivid colours, and inspired by Eastern European peasant art and geometric motifs in contemporary painting. The workshop had a profound impact of European art and design, and its work is still celebrated today. Mathilde Flögl was born in the Czech Republic in 1893, and studied at the Kunstgerwerbeschule in Vienna. In 1916 she began working at the Weiner Werkstätte, and where she designed more than 120 textile patterns. This fabric Fälter or Butterfly was designed in 1924. The butterfly was a favourite motif of Flögl. In this design she plays with a variety of whimsical abstractions and arrangement of both the butterfly and the snail on a background of abstract colour stripes and blocks. Ann Carew 2016The fabric is of great aesthetic interest as an example of the work of the Viennese workshops, and the noted designer textile designer Mathilde Flögl. The original pencil drawings, pencil and gouache designs, and fabric swatches for Fälter are held in the MAK Museum in Vienna, and the Victorian and Albert Museum in London have a sample of piece of the silk fabric in an alternate colour wave. The Museum of Applied Arts in Sydney holds a swatch book of textiles from the Wiener Werkstätte, however Flögl’s work is not represented. The National Gallery of Victoria holds a similar swatch book. The remnant has an excellent provenance, is associated with a powerful personal narrative, and is significant and rare item relating to history of the Wiener Werkstätte in Vienna, and the oeuvre of Matilda Flögl. Ann Carew 2016Remnant of a block-printed silk fabric used to make the bedspread for Karl Duldig and Slawa Horowitz-Duldig's bed in Vienna. -

4th/19th Prince of Wales's Light Horse Regiment Unit History Room

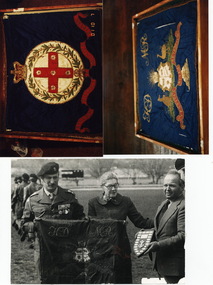

4th/19th Prince of Wales's Light Horse Regiment Unit History RoomRegimental Colour, Kyneton District Mounted Rifles, 1861 (exact)

Address given by Mrs Lavender on the presentation of the Kyneton Colours on 28 February 1861 “Gentlemen of the Kyneton District Mounted Rifles, I feel proud of the honour done me in being deputed by the ladies of Kyneton to present the colours to your honourable Corps. There has always been a peculiar honour and responsibility connected with the colours of a Regiment. They have been unfurled on a battlefield as rallying points for many a splendid troop of gallant soldiers and courageous hearts. They have been spread to the breeze on the storming of many a city and battles hardly fought and dearly won. To retain their position and maintain their integrity, many a brave soldier has freely offered his life in their defence and, when in the hour of adversity they have been lowered, overpowered by the foe, many a brave heart has bit the dust. We might say that the history of our country is written on the banners of our “Fatherland”. The names emblazoned there speak, it is true of many a battlefield, of many a desperate struggle and of many a glorious victory won by British bravery. Gentlemen, your colours are not decorated by names such as Waterloo, Alma, Inkerman, Delhir Cawnpore, and many others I might mention. They are blank and may the God of Peace grant that in this land of adoption, it may be long before necessity of duty calls upon you to maintain the integrity of your colours and win their names. But if in the providence of God, either from internal commotion or external aggression, you should be called into action, may these colours, the token of your Corps, be upheld with the bravery of British Soldiers, their honour maintained with your lives, and may they never be lowered to a foe. Gentlemen, your motto directs: Onward, onward; may it be so Onward at the shout of victory” This item is significant as The Kyneton Colour is the 2nd oldest Regimental Colour knownin Australia, and the oldest Australian Cavalry Colour. It is unique, in that it is hand made from an original design, there is no other colour of this type known to exist. The Kyneton District Mounted Rifles is the oldest ancestor unit of the 4th/19th Prince of Wales's Light Horse Regiment and therefore is historicaly significant to the Regiment in particular and to Australian Military History in general.Regimental Colour of the Kyneton Distric Mounted Rifles. A double sided blue silk damask standard bounded on three sides by 30mm coiled metal fringing. It is heavily embroidered through a silk and cotton layer and these sections are are put back to back forming a sandwich of four layers. Several kinds of metal threads and sequins have been used for the embroidery as well as coloured silk floss, employing satin and stem stitch. The front shows a central insert in white silk divided into four and with a steam engine, bull, plough, and wheat sheaf in the segments. This crest is flanked on the left by a kangaroo and the right by an Emu. Above the crest is a horizontal baton, and above that a smiling sun sitting on a bed of clouds. The initials KD are in the upper hoist area and MD in the upper fly region.Below the crest is a red ribbon with the Latin words VESTICIA NULLA RETRORSUM in metal thread. Below this applique is a green satin stitch shape. The reverse has a red cross with stars surrounded by a green and gold laurel wreath. This is surmounted by a Queen's crown in embroidered metal thread over a base of red silk velvet. The bottom third of the flag is decorated with the words KYNETON DISTRIC MOUNTED RIFLES in embroidered metal thread.See description.standard, colours, kyneton district mounted rifles, kyneton -

Ballarat Tramway Museum

Ballarat Tramway MuseumDocument - Instruction Book, Melbourne and Metropolitan Tramways Board (MMTB), "Sections and Fares", Aug. 1968

One Hundred & Eight (108) page book sewn with end papers on a grey colour Rexene heavy card covers. Titled "Melbourne and Metropolitan Tramways Board / Electric Tramways and Motor Omnibuses. / Sections and Fares / (Conductors) , / August 1966". Issued 14/8/1966, all decimal currency. Signed by R.C. Drummond, Traffic Manager. Details the sections and fares for each tram and bus route on the MMTB System in a tabular form. Page 5 has an index of routes, includes concession fares. General Instructions re fares, such as children, city concession, prepaid tickets, round trip excursion, Scholars concession, excess luggage, newspapers, children carriages, dental centre scholars, swimming class, state schools, Post Office, Police Concession, special hospital tickets, visiting nurses, scouts, Sunday morning, family excursions. all night services and Free Tramway Passes. Gives images of the type of pass, details of issued to, booklet passes, employees pass, blind persons, traffic officers, disabled soldiers, fare concession certificates, Special Metal "T" passes, seeing eye dogs. special prepaid tickets. Has some pasted in amendments.Some of the tables, first ones in the book have been marked with the stop numbers. trams, tramways, rules, instructions, mmtb, fares, conductors -

Ballarat Tramway Museum

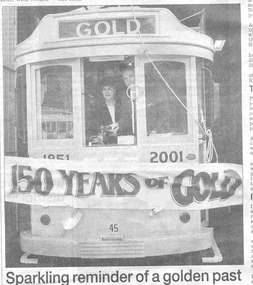

Ballarat Tramway MuseumNewspaper, The Courier Ballarat, "Tram study ready to go", "Sparkling reminder of a golden past", "Section torn from Skipton St", 15/06/2001 12:00:00 AM

Yields information about the launch of the Gold Tram and the people involved on the day.Newspaper cutting, page 4, from The Courier, Ballarat, June 15, 2001, headed "TRAMS IN BALLARAT" featuring three different tram stories. Headed "STUDY" and titled "Tram study ready to go", about the consideration of tenders for the study to consider the return of trams to Ballarat, or other form of transport. Quotes Dianne Smith, Ballarat Tourism Executive Director. Headed "GOLD TRAM" and titled "Sparkling reminder of a golden past", about the launch of the Gold Tram 45, by the Mayor, David Vendy the previous day at the tram depot. Quotes Richard Gilbert as president and Cr. Vendy. Features a photograph of Cr. Liz Sheedy and the Mayor standing along side, breaking through the banner ( See Reg. Item 1777). See Reg item 3839 for a colour photograph of the photo of No. 45. Headed "TRACKS" and titled "Section torn from Skipton St" about the excavation of about 50m of track in Skipton St. Ballarat at the intersection with Drummond St. during the reconstruction of the intersection associated with installation of traffic lights and new traffic islands. Quotes Peter Winspur, Secretary. A number of calls were received about the work. See Reg. Item 1778 for photos on the day.ballarat city tramway, gold tram, skipton st, trackwork -

Eltham District Historical Society Inc

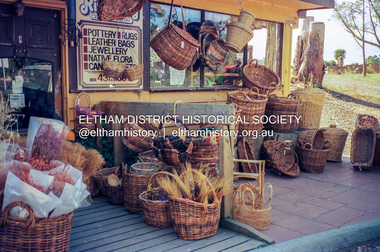

Eltham District Historical Society IncPhotograph (Item) - Negative, Elizabeth Simkin, Riverclay Craft Gallery, 573 Main Road, Eltham, 1988

Riverclay was located along with Ansell and Muirs Chicken shop opposite El;tham Lower Park. The building has since been demolished as it lay within the 1934 flood plain limits. Elizabeth Simkin 1988 Entrant No. 149 Ref: Series 34, Items 39, 111-113 The images in this record were not selected for inclusion. SHIRE OF ELTHAM COMMUNITY PHOTOGRAPHIC SURVEY Photography is an artform which many of us practice, sometimes purely for artistic pursuit, sometimes to record the people and events in our lives. In 1988, as part of a local Bicentennial project, the Shire of Eltham conducted the Eltham Community Photographic Survey. Up to 100 entries were to be selected by a panel of photographers for entry into the Eltham Photographic Survey Exhibition. Entries had to be submitted by May 13, 1988. Entrants whose images were selected for the exhibition were contacted and requested to further submit an entry form providing entrant’s name, area of residence, age, and proposed captions. These details were then used to produce labels for the exhibition mounts. Where negatives had not been supplied, these were requested to support the display of printed enlargements mounted on 10” x 8” cardboard. The mounted prints were made available post exhibition for sale at $8.50 each for colour prints and $7.00 for B&W prints. Residents in the Shire were invited to collect a free roll of film and take a photograph of what they either liked or did not like about the area. A total of 160 entrants submitted multiple entries for the exhibition. Of those selected for exhibition, entrants ranged in age from 9 to 70 years. All custom colour and black and white printing for the exhibition was completed by Wattle Studios of Eltham. The Eltham Photographic Survey was jointly auspiced by the Shire of Eltham and Wattle Studios, of 953 Main Road, Eltham. The project was greatly assisted by: • David McRitchie, Media Studies Lecturer Victoria College, Rusden Campus. • Ian and Annette Toohill of Wattle Studios • Tracy Naughton, Eltham Community Arts Officer • Neville Emerson Pty. Ltd. • Superior Press, Eltham • Kodak Australasia Pty. Ltd. • Agfa Gevaert Ltd. • Townsend Colourtech Pty. Ltd. • The Australian Bicentennial Authority • Eleanor Bowers, Secretary, Eltham Arts Council The exhibition was placed on display in the Woolworths Arcade, Eltham between Monday June 6th and Saturday June 11, 1988. It was also intended to hold the exhibition at a venue in the Shire’s North Riding from Monday, June 20 to Friday June 24. It was then displayed at the Were Street Theatre, Montmorency from Friday, June 24 to Thursday, July 7. Series 34: Eltham Community Photographic Survey 1988 - Prints & Documentation Series consists of 117 photographs of Shire scenes taken by members of the community. Items I - 41 are larger photographs mounted on card, which were exhibited. Items 42 - 117 are unmounted copies, alternative takes and other entries. Corresponding negatives contained in Series 35: Eltham Community Photographic Survey 1988 – Negatives which coThe Eltham Community Photographic Survey collection is significant to the local community as it was curated by the local community - ordinary people of all ages - representing what they liked and did not like in the area where they lived. It represents an unfiltered representation of the Shire of Eltham as it was in 1988. It also represents one of many projects as part of the national programme of events and celebrations to commemorate the bicentenary. It is a time capsule of life in the 1980s of this urban and rural municipality in Melbourne's north. shire of eltham archives, bicentennial project, eltham community photographic survey, film - kodak ga 100 5095, elizabeth simkin, eltham, scan - 35mm negative, series 35, cane baskets, riverclay craft gallery -

Beechworth RSL Sub-Branch

Beechworth RSL Sub-BranchGas mask

This mask would have presumably been manufactred and used as a gas mask during World War One conflicts. It is presumably British made. It could also possibly date to the World War Two era.This item is a piece of protective equipment which presumably dates to the World War One era. As a surviving artefact from the Great War, this item holds historic value.Gas mask with rubberised light brown fabric face cover, plastic goggles for seeing, straps for fastening and a nozzle to attach to a canister. The canister is now missing. The goggles have corroded steel rings around themwhich protrude sloghtly from the mask. The light brown fabric covered rubber nozzle is attached to a black metallic component, which is attached to the mask with a circle of black rubber in between the metal and the mask. There is also another short piece of rubber attached to this black metallic component which is folded and positined between the nozzle and the mask. There is an inscription On the exterior of the mask, where the nose would ordinarilly be positioned. There is also an inscription in the interior on an almost full circular piece of fabric which is stitched into the same posion. This has a circle of metal stitched beneath it, which protrudes in two sections towards the wearers face. On the ends of the protruded sections are square pads of fabric, which are presumably there to position on either side of the wearers nose. The mask has a reinforces rubberised fabric rim where it would be incontact with the face. The main rubber nozzle protrudes through the inside of the mask, forming a mouth piece. There are four black straps and one light brown colour strap stitched to the exterior rim of the mask. Two of the black straps are severed.On the exterior at the nose: 3 On the interior at the nose: 22 109gas mask, mask, world war one, first world war, world war 1, ww1, wwi, the great war -

Melbourne Tram Museum

Melbourne Tram MuseumBook, The Met, "Met Pass", late 1980's

Yellow plastic folder titled "Melbourne Met Pass", with The Met logo in green print on both sides of the outside of the folder. On the inside has two pockets for storing items formed with clear plastic. Map Folded Map of Melbourne Rail and Tram lines, titled "The Met PASS Map to Melbourne" Tram Map - probably soon after conversion of the St Kilda and Port Melbourne lines to Light Rail, though these are not shown. Opened November 1987. Rail Map - shows Route 96 north section as Light Rail, co-ordinated bus routes, and the Altona line as going to Werribee. This route was opened in 1985. Date of Map c1988/1990. Has details of Museums, Art Galleries, Shopping, Gardens and Sports Arenas in Japanese. Sheet of paper advising users on presentation of the Met Pass (not included in the folder) Book - titled "The Met's Guide to Melbourne", sub titled - Get around on The Met. Card covers, perfect bound, 100 pages in colour with maps, guides and information about various locations within Greater Melbourne including Werribee Zoo and Healesville. See also Reg Item 106 to 108 for a similar item and 983 for the document that was used to launch the Met Pass. Two copies held.trams, tramways, the met, melbourne, tickets, tourist tickets -

Bendigo Military Museum

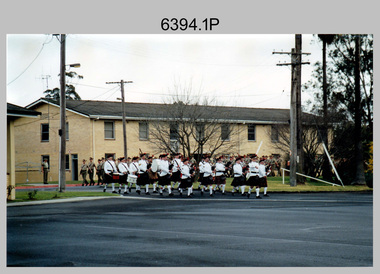

Bendigo Military MuseumPhotograph - Army Survey Regiment – Corps Day Parade, Fortuna Villa, Bendigo, 1995

This set of 23 photographs were taken at the Corps Day Parade held at the Army Survey Regiment, Bendigo on the 1st of July 1995. This occasion was to commemorate the 80th anniversary of the formation of the Royal Australian Survey Corps. The Parade Commander was CO LTCOL Duncan Burns, and the Reviewing Officer was the Deputy Chief of the Defence Force MAJGEN G.D. Carter AM. Also in attendance was his MA MAJ M.D. Bornholt AM and the COL COMDT of the Royal Australian Survey Corps COL Don Swiney MBE. On this occasion the Reviewing Officer presented the Defence Force Service Medal to SGT Graham Hales and SPR Ken Labouchardiere for 15 years of efficient remunerated service in the Australian Army. SSGT Russ Mollenhauer received the Defence Force Service Medal clasp in recognition of 20 years of service. SGT Stuart Symonds received his second Defence Force Service Medal clasp in recognition of 25 years of service.This is a set of 23 photographs of the Corps Day Parade held at the Army Survey Regiment, Fortuna, Bendigo on the 1st July 1995. The colour photographs were printed on photographic paper and are part of the Army Survey Regiment’s Collection. The photographs were scanned at 300 dpi. .1) - Photo, colour, 1995. Fortuna Pipes and Drums lead the Army Survey Regiment onto the parade ground. .2) to .3) - Photo, colour, 1995. Fortuna Pipes and Drums in position on the parade ground. .4) - Photo, colour, 1995. Data Acquisition Squadron marches onto the parade ground, led by L to R: WO2 Peter Imeson, WO2 Bruce Hammond. .5) - Photo, colour, 1995. Data Acquisition Squadron front rank L to R: WO2 Peter Imeson, SPR Stuart Catharall, CPL Damien Killeen, CPL Trevor King, SPR Glen Norrell, SPR Kim Baker, SPR Craig Smith, LCPL Mark Fedden, SGT Graham Hales, SPR Josh Andrews OAM, unidentified (x2), WO2 Bruce Hammond. .6) - Photo, colour, 1995. Army Survey Regiment in position on the parade ground. On left - Product Construction Squadron rear rank L to R: CPL Dave Scott, SPR Shane Campbell, CPL Guenther Ebenwaldner, remainder unidentified. Centre rank L to R: CPL Ian Bowes, remainder unidentified. RSM WO1 Ken Johnston OAM MM. Front rank L to R: WO2 Alan Virtue, SSGT Bob Thrower, CPL Paul Einam, SGT Peter Tuddenham, SPR Dik Brierley, SGT Stuart Ridge, SPR Mick Muzeen, SPR Marty Stradbrook, unidentified, SGT Steve Nokes, SPR James Commons, SPR Lance Hillier. WO2 Gill Park. In centre - Administration Support Squadron. On right - Data Acquisition Squadron. 7.) - Photo, colour, 1995. Officers ready to take posts. L to R: LT Dave Sapparth, CAPT Colin Davidson, CAPT Tony Harder – UK Exchange Officer, LT Jason Selman, CAPT Doug Arman, QM CAPT Bill Griggs, LT Roger Grose, CAPT Bin Fashar Sutimin – Indonesian Exchange Officer in white uniform, MAJ Ross Jenkins, CAPT Gary Warnest. 8.) - Photo, colour, 1995. CO LTCOL Duncan Burns salutes the Reviewing Officer MAJGEN G.D. Carter AM. .9) & .10) - Photo, colour, 1995. Data Acquisition Squadron presents arms. Officers’ rank L to R: CAPT Tony Harder – UK Exchange Officer, CAPT Colin Davidson, LT Dave Sapparth. ADJT CAPT Brenton McDonald at far right. Front rank L to R: WO2 Peter Imeson, SPR Stuart Catharall, CPL Damien Killeen, CPL Trevor King, SPR Glen Norrell, SPR Kim Baker, SPR Craig Smith, LCPL Mark Fedden, SGT Graham Hales, SPR Josh Andrews OAM, unidentified (x2), WO2 Bruce Hammond. 11) - Photo, colour, 1995. Army Survey Regiment presenting arms. L to R: Product Construction Squadron, Administration Support Squadron, Data Acquisition Squadron. .12) - Photo, colour, 1995. Product Construction Squadron presents arms. Officers’ Rank: 2IC MAJ Mick Banham, L to R: CAPT Gary Warnest, OC MAJ Ross Jenkins CAPT Bin Fashar Sutimin – Indonesian Exchange Officer, LT Roger Grose. L to R: RSM WO1 Ken Johnston OAM MM. Front rank L to R: SSGT Bob Thrower, CPL Paul Einam, SGT Peter Tuddenham, SPR Dik Brierley, SGT Stuart Ridge, SPR Mick Muzeen, SPR Marty Stradbrook, unidentified, SGT Steve Nokes, SPR James Commons, SPR Lance Hillier, WO2 Gill Park. Other identifiable personnel in rear ranks L to R: SGT Peter Tuddenham, SPR Ben Lucas, SPR Dik Brierley, SGT Dale Hudson, SPR Annette (Odgers) Wynn, CPL Roger Pearson, SPR Corey Hill, SSGT Russ Mollenhauer. 13) - Photo, colour, 1995. Army Survey Regiment Advances in Review Order. L to R: Product Construction Squadron, Administration Support Squadron, Data Acquisition Squadron. 14) - Photo, colour, 1995. Army Survey Regiment in rank formation slow marches around parade ground L to R: Product Construction Squadron, Administration Support Squadron, Data Acquisition Squadron. .15) & .16) - Photo, colour, 1995. Data Acquisition Squadron slow marches, using ‘Forms’ to turn right in rank formation. Officers’ rank L to R: CAPT Tony Harder – UK Exchange Officer, CAPT Colin Davidson, LT Dave Sapparth. ADJT CAPT Brenton McDonald at far right.front rank L to R: WO2 Peter Imeson, SPR Stuart Catharall CPL Damien Killeen, CPL Trevor King, SPR Glen Norrell, SPR Kim Baker, SPR Craig Smith, LCPL Mark Fedden, SGT Graham Hales, SPR Josh Andrews OAM, unidentified (x2), WO2 Bruce Hammond. Centre Right Marker SPR Cameron Gee OAM is behind SPR Stuart Catharall. .17) - Photo, colour, 1995. Data Acquisition Squadron proceeds past Reviewing Officer on ‘Eyes Right’ command. Officers’ rank L to R: CAPT Tony Harder – UK Exchange Officer, LT Dave Sapparth. CAPT Colin Davidson. Centre Right Marker SPR Cameron Gee OAM. Right rear supernumerary SSGT Rod Skidmore, ADJT CAPT Brenton McDonald to his left. Front rank L to R: WO2 Peter Imeson, SPR Stuart Catharall CPL Damien Killeen, CPL Trevor King, SPR Glen Norrell, SPR Kim Baker, SPR Craig Smith, LCPL Mark Fedden, SGT Graham Hales, SPR Josh Andrews OAM, unidentified (x2), WO2 Bruce Hammond. CO LTCOL Duncan Burns in foreground. .18) - Photo, colour, 1995. Data Acquisition Squadron proceeds past Reviewing Officer on ‘Eyes Right’ command. Rear rank L to R: unidentified, CPL John ‘Doc’ Commons, CPL Tony Jackson, SPR Helen Scorgie. Centre rank L to R: SPR Cameron Gee OAM, SPR Derek Percival, SPR Grant Lloyd. Front rank L to R: WO2 Peter Imeson, SPR Stuart Catharall CPL Damien Killeen, CPL Trevor King, SPR Glen Norrell, SPR Kim Baker, SPR Craig Smith, LCPL Mark Fedden, SGT Graham Hales, SPR Josh Andrews OAM, unidentified (x2), WO2 Bruce Hammond. .19) - Photo, colour, 1995. L to R: MAJGEN G.D. Carter AM returning salute, MA MAJ M.D. Bornholt AM, COL COMDT, COL Don Swiney MBE, in background CPL Warren ‘Waldo’ Shirley, WO2 Pat Lumsden. 20.) - Photo, colour, 1995. Product Construction Squadron L to R: SSGT Paul ‘Hutch’ Hunter, WO2 Jeff Willey, rear rank L to R: CPL Dave Scott, SPR Shane Campbell, CPL Guenther Ebenwaldner, remainder unidentified. Centre rank L to R: CPL Ian Bowes, SPR Ben Lucas, remainder unidentified. MAJGEN G.D. Carter AM, CO LTCOL Duncan Burns, Front rank L to R: WO2 Alan Virtue, remainder unidentified, RSM WO1 Ken Johnston OAM MM, Officers’ Rank: LT Jason Selman, CAPT Bin Fashar Sutimin – Indonesian Exchange Officer, CAPT Gary Warnest, MAJ Ross Jenkins, 2IC MAJ Mick Banham. .21) - Photo, colour, 1995. L to R: Centre marker CPL Ian Bowes, SPR Ben Lucas, remainder unidentified, MAJGEN G.D. Carter AM, COL COMDT, COL Don Swiney MBE, CO LTCOL Duncan Burns, WO2 Allan Virtue. .22) & .23) - Photo, colour, 1995. L to R: WO2 Pat Lumsden, MAJGEN G.D. Carter AM, SGT Graham Hales, SPR Ken Labouchardiere, SSGT Russ Mollenhauer, SGT Stuart Symonds..1P to.23P – The occasion and date are annotated on the plastic sleeve.royal australian survey corps, rasvy, army survey regiment, army svy regt, fortuna, asr -

Bendigo Military Museum

Bendigo Military MuseumAdministrative record - FOLDER AND RECORDS

For historical information refer to notes attached to Cat No 2755.4 See attached sheets for the remainder of pages.Black plastic folder, ring binding with 20 clear plastic sleeves. .1) Photocopy of cover for personnel documents for Herbert Trangmar ALLAN, MC, NX12229, N60005, Captain 2nd Garrison Battalion. A4 page size. .2) Photocopy of WWII attestation form dated 2.5.1940 for NX12229, Herbert Trangmar ALLAN. .3) Photocopy of Medical Exam Section. .4) Photocopy of Medical Exam Section with black & white ID photo. .5) Enlarged photocopy of ID photos of Herbert Trangmar ALLAN. .6) Photocopy of Mobilization attestation form dated 6.10.39 for Herbert Trangmar ALLAN. .7) Photocopy of Termination of Officer's Appointment dated 2.4.1946 for Herbert Trangmar ALLAN, OBE, NX12229. .8) Photocopy of Officers Record of Service for Herbert Trangmar ALLAN. Address at time was Wali, New Guinea .9) Photocopy of Officers Record of Suc for Herbert Trangmar ALLAN OBE MC ED NX12229. Address at time was Wali, New Guinea. First entry: 16.6.1914. Last entry: 1.11.1945. .10) Photocopy of Officers Record of Service, dated 29.8.1950. For NX12229 Herbert Trangmar ALLAN MC OBE ED. Last address Watsons Bay NSW. .11) Photocopy of Determination of Demobilization Priority for NX12229 Herbert Trangmar ALLAN. Dated 5.10.1945. .12) Photocopy of sheet showing service early WWII for Herbert Trangmar ALLAN. .13) Photocopy of sheet showing early WWII service of N60005, Herbert Trangmar ALLAN. .14) Photocopy of Officer's Record of Service sheet for Herbert Trangmar ALLAN OBE MC NX12229. First entry: 17/2/1943. Last entry: 24.8.1944. .15) Photocopy of Record of Service sheet. First entry: 28.9.1944. Last entry: 25.5.1945. .16) Photocopy of Officer's Record of Service for Herbert Trangmar ALLAN OBE MC NX12229. First entry: 1.6.1945. Last entry: 14.3.1946. .17) Photocopy of Record of Service sheet. Mentions MID in SWPA & rank changes. First entry: 21.3.1946. Last entry: 30.9.1950. .18) Photocopy of Officer's Record of Service sheet for NX12229 Herbert Trangmar ALLAN 2nd Garrison Battalion. First entry: 6.9.1944. Last entry: 7.5.1946 .19) Photocopy of Recommendation for an OBE for NX12229 Herbert Trangmar ALLAN MC Major. Tobruk period April / October 1941. .20) Photocopy of a sheet showing medals & awards for N60005 NX12229 Herbert Trangmar ALLAN OBE MC ED MID. .21) Photocopy of a letter to Deputy Commissioner - Repatriation on AIF letterhead. Re: Captain ALLAN H T 17 Battalion. .22) Photocopy of an AIF letterhead Canberra dated 1.5.1950. To Secretary HQ Repat Commission. Re: Capt ALLAN H T 17 Battalion. .23) Photocopy of a sheet showing telephone note re awards, dated 2.7.1955. Re: ALLAN H T. Address Mullaway, Woolgoolga, NSW. .24) Photocopy of ranks & dates for ALLAN H T NX12229. DOB 5.1.1895. Served in 14-18 Yes. First entry: 16.6.1914. Last entry: 29.1.1944. .25) Photocopy of ranks & dates for above. First entry: 13.2.1942. Last entry: 1.4.1945. .26) Photocopy of ranks & dates for ALLAN H T NX12229. DOB 5.1.1895. OBE MC. First entry: 23.7.1945. Last entry: 15.8.1951. .27) Photocopy of a note showing Colonel H T ALLAN, address Mullaway, Woolgoolga, NSW. Written on a note pad with British Aluminium stamped on it. .28) Typed sheet showing a brief (biography) story of the life of Herbert Trangmar ALLAN (Blue). .29) Colour top view photo on A4 paper showing a huge pair of Japanese binoculars mounted on a tripod. .30) Colour R side view photo on A4 paper of Japanese binoculars. .31) Colour rear view photo of huge Japanese binoculars. .32) Colour front view photo on A4 paper of huge Japanese binoculars mounted on a tripod. .33) Colour L side view photo of huge Japanese binoculars. .34) Colour photo of tripod with timber legs & brace to suit binoculars above. .35) Black & white photo of a manufacturers plate featuring Japanese writing & numbers. .36) Colour photo on A4 paper showing manufacturers plate on rear of support brace on the tripod head. .37) Copy of WM Collection photo number 058101 showing an Australian soldier looking into the binoculars, Finschafen New Guinea .38) Menu card. TobrukDay Dinner 2/17th Sgts Mess. Dated Wed 19.11.1941. .39) Christmas card with red ribbon in its fold. Shows a signpost Syria - Australia - & a Rising Sun, a kangaroo with smoke & fire, a laughing kookaburra on a sign post. Stamp. HQ 20 Aust Inf Bde AIF. .38) On rear: Two autographs. .39) Inside: “Best wishes for year 1942-1943 from Brig W (T) V Windeyer and staff”recorrds, certificcats, folders -

Melton City Libraries

Melton City LibrariesPhotograph, 'Melton South Chaff Mill employees, Unknown

Charles E “Ernie” Barrie started constructing a Chaff mill on the corner of Brooklyn and Station road in 1900. It soon became a thriving business and was ideally located close to the railway line. Ernie and his father William and other Barrie brothers had been operated travelling chaff cutters in the district of Melton and Werribee. Within a short time the mill expanded into two big sheds in partnership with his brother James E known as “Ted”. The eldest brother William was in the Manager living in Melton South. In 1906 Ernie applied for a railway crossing on Brooklyn Road to have direct access for railway trucks to be shunted to the mill to be loaded. The Mill was also had the first phone to be connected, No 1, and No’s 2, 3 were the Golden Fleece and Macs Hotels. In 1906 Ernie married Jessie Lang daughter of the Head Teacher at Melton State School No 430 (1896 –1917). The Barrie house on the north side of the mill was completed in August 1906. It survived for almost 60 years until demolition. Chaff mills were very susceptible to fires and often burnt down and would be rebuilt again ready for the peak of the harvesting season. The final demise of the Mill occurred in a spectacular blaze on the night of Friday 2nd December 1977, just before the earth tremor as reported in the local paper. Brian Dobson the local photographer lived close by and captured the night blaze. A video was also taken of the action by the fire brigade. My parents Bon and Edna Barrie were living at 19 First Avenue, and took colour slides of the smouldering ruins in the half -light. Ironically Bon had spent the first year of his life (born in April 1909 and sister Mary born October 1907) at the house beside the mill. Trethowan’s Chaff mill in Brooklyn road was also destroyed by fire, which stated in the evening on Tuesday April 28th 1987. It was established in 1910 by Dixon Brothers, followed by, Ebbot & Kebby, Robinson, Trethowan and Butler and was with the Trethowan family when it burnt down. Melton South was small a community referred to as Melton Railway Station. Member of the community raised the idea to have a public hall. In 1909 Cr Barrie, Mr Nesbitt and Delany formed a committee to build a community hall. Cr Barrie donated the land and The Exford Hall was completed in September 1910 later to be named Victoria Hall. It was demolished in 1992. Colour slide in Barrie archive. In April 1910 the Ernie sold the Mill to Glover Onians (HSK Ward) family moved away to a property in Trundle NSW. Ernie had acquired 640 acres (a square mile) and leased a further 1920 acres of adjoining land. It was the practise of the farmers in the area at the time to buy up or lease the surrounding land from the 640 acre crown land blocks to make up acerage for a viable wheat farm. His wife Jessie found the climate to be very hot and when the Darlingsford property at Melton was put up for sale in the latter part of 1910 and was passed in at the auction. My grandfather saw this an opportunity to return to Melton. The negotiations to Darlingsford were finalised on May 11th 1911. Barrie bothers with connections to Chaff mills and farming in Melton from the 1900s William Henry, Charles Ernest, James Edwin, Samuel John, Robert, Arthur Roger, Albert Walter. Three grandsons and a great-grandson are in business earthmoving and farming in Melton today. (2013) Memoirs by Wendy BarrieEmployees at Chaff Mill, it was located on the corner of Brooklyn and Station Road, Melton South. local identities, agriculture -

Southern Sherbrooke Historical Society Inc.

Southern Sherbrooke Historical Society Inc.Information folder - Germans Gully - Arcady

Folder containing items pertaining to the history of Germans Gully - Arcady, Belgrave Heights. Contents: -4 colour photos, c. 2000, showing house and gardens -sketches, photocopied, by Barbara Smith, dated 29 October 2002, showing stone huts at Arcady prior to mid-1950s, with additional comments by Marian Matta -typescript, "Short History Of Arcady also known as German Gully, 'Carinya' & Church Of Freedom", 1 page, 3 copies including one with small photo -typescript, dated 22 June 97, "Plarre Visit to 'Arcady', Originally Known as 'Carinya'", six pages -hand-written letter, addressed to "Sue & Peter" (Downard) from Ralph (Wilson) dated April 02, containing historical information re. Arcady, 4 sheets double-sided -Yarra Ranges Shire Heritage Study Place Nomination Form for Germans Gully, partially completed -obituary, Herald Sun newspaper, undated but 2003, "Raymond Otto Plarre, Baker had passion for quality produce" -4 page Fairfax newspaper wraparound, "A Recipe For Success", advertising feature commemorating Ferguson Plarre Bakehouse Centenary, 1901-2001 -8 sheets of photocopied photos of Arcady, taken during Plarre ownership -Certificate Of Title (number illegible) dated 10 July 1919, initial purchasers being Robert and Bertha Maurer, 3 copies of obverse sheet (copies) (dups. in A3 folio #1) -Certificate of Title, Vol. 5262, Folio 1052392, dated 18 January 1927, initial purchaser being Bernhard Walk (2 copies, one issued 12 Aug 1996, one issued 17 Apr 1997) (dups. in A3 folio #1) -photo (colour) and hand-drawn map of site, prepared by Ralph Wilson, 2006 -Pamphlet, "Our Place, a celebration of where we live", Shire of Yarra Ranges, Oct. 2006 -photos (2, colour) of fire at Arcady, annotated 'Hello Peter & Sue, more pictures taken by Marty of CFA' -article, Australian Post, 6 Jul. 1972, 'Fool around with SCARLETT!', 2 photos of John Wilson (in A3 folio #1)albert hartung, otto plarre, mr stace, john wilson, count felix von lucknor, mr & mrs smart, plarre family, mr hutter, carinya, raymond otto plarre, ferguson plarre bakehouses, keith cooke, hugh ackland, alexander wynnum king, russell & jean smart -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyBook - Ledger Commercial, "Ledger No. 4", Circa 1895

Historically this ledger not only details the legible hand writing of this era but also the day to day commercial activity in this region(first entry in 1895).The neatness and the diligence of those who were required to pen the information was a requirement by all who were in commercial trade. Emphasis on neatness was ingrained in students at a young age. This era was well before general typewriters and computers. Generally all students of commerce required an accuracy in writing and arithmetic. Neatness and order were a selection requirement. This ledger belonged to a general store, which was a forerunner to supermarkets and specialty stores. The shop provided everything from food, postage stamps, nails, tobacco, boots and Epsom salts. The general store provided nearly every product required to exist in a remote rural area of Australia in the 1800's.This item clearly identifies the Kiewa Valley as having a substantial financial hub to accommodate the various commercial enterprises within a rural environment Circa 1880's. Although Kiewa Valley had mining, agriculture, cattle and sheep it was also composed of a mixed society, encompassing all levels of society at that period. It identifies some the commercial activities(newsagency/general store) undertaken by specific families farming in the Kiewa Valley and relates their history in the pioneer period of the late 1800's. Some of those pioneers still have descendants living on the same home sites provided by the 1847 Land Act.This ledger has a very thick cover of strong compressed cardboard. Originally it had a cloth covering both front and back(Glued on) but due to wear and tear it is only attached to the back cover) and is a faded blue colour. The corners of the opening side of the cover are reinforced by suede cloth,in a triangular shape, and enclose both the front and inside portions of the the ledger. The spine is reinforced by a suede section to provide increased strength and protection. The inside cover (both front and back) has an orange bubbles with red and blue sinuous lines forming shapes in a haphazardous pattern. The grammage of the lined sheets (blue) is approximately 120g/m. Originally the first seven of twelve pages were indented and alphabetically marked with black letters (one letter per page) however this ledger had been modified to cover only the initials of customers and the pages of unused letters were glued to the previous page. The remaining pages are numbered in black print at the top outside edge of each page. There are 890 page numbers. Each page has thirty seven blue horizontal lines and one double red line ( top). Each page has thirteen vertical lines starting from the top horizontal double red lines and ending at the bottom of the page. These lines segregate the page into blocks for the date, the transaction and financial input. There are three double vertical red lines which designate the amount of money of each transaction (in pounds, shillings,and pence).On the suede spine in gold lettering and on a red (port coloured) background "LEDGER"grocery shop, haberdashery, general store -

Villa Alba Museum

Villa Alba MuseumDecorative object - Gilt metal fringe for furnishings - detached

It is not clear that this fringe was ever attached to the curtain suite; it may have come from an associated part of the original ensemble (eg pelmet) or from associated furniture. However, it is certainly connected to the fringe on the tieback tassels, whose tassels are finished with the same product. The detached gilt metal fringe has aesthetic significance as specimen of an opulent furnishing decoration in very lavish contexts, such as gold rush Victoria. Part of it still preserves the original bright gold metal, ie is untarnished; this is probably quite rare in Australian collections.Board wrapped w c.17m of heavy gilt metal fringe (known as bullion fringe) in several pieces, evidently detached from curtains, and/or furniture items. (No sign of it having been attached to the curtains). The fringe is composed of metallic thread very tightly wound over a cotton/linen thread, attached to a narrow header braid with an ornamental design worked in metallic gimp cord. The colour was originally gold, now tarnished on all parts exposed to air, but sections of the fringe under the top layers retain the luxurious gold finish. Westman (2019: 242) explains that 'gold thread' was made of gold fired onto silver bars from which thin, flat or round wires were cut to wrap around a core linen thread for use in trimmings. Shen notes that the very thin layer of gold often wears away, exposing the silver which tarnishes. Bullion fringe: fringe made of bullion, in the sense of precious metal, used for prestigious royal, ecclesiastical and military garments and furnishings. Westman (2019: 193, 240) says that by the 19thC, the name was also used for twisted thread long fringe made of wool, silk, cotton or a mix, as it is today. In this form, 'bullion fringe' became a lavish edge-trim in the early-mid-19thC wherever its vertical look could add richness to drapery. interior decoration - history -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageContainer - Bottle, 1870s-1910s

This clear, green tinged, Half Whirley (or Whirly) salad oil bottle has been handmade by a glassblower from 1870s-1910s. A bottle with such elaborate decoration would have been sought after as there was no need to decant the sauce into another jug or bottle to make it acceptable for table service. It is possible that this bottle was recovered from the Loch Ard, wrecked in 1878. A diver found the bottle on a shipwreck in the coastal waters of Victoria about 100 years from when it was made. The diver who found this bottle has recovered objects from several different shipwrecks between the late 1950s and early 1970s. A sizeable proportion of those objects was from the wreck of the famous clipper ship Loch Ard. This salad oil bottle may very well have been amongst that ship’s cargo. It is part of the John Chance Collection. A paper titled ‘Glass Bottles from the Loch Ard Shipwreck (1878): A Preliminary Study’ by Iain Stuart, (published in Australian Historical Archaeology, 9, 1991) included a study of twelve salad oil bottles from the wreck of the Loch Ard. The bottles were of this same Half Whirley design (half meaning that it was Whirley on the upper half but not on the lower half of the body), as well as the same colour and size. A diagram of one of these twelve bottles matches the bottle in our collection. The paper mentions that eleven of the twelve bottles have a number on their base, just as this one has. It is estimated that foreign and salad oil bottles totalled four percent of all of the bottles carried as cargo on the ship. The Half Whirley bottle has side seams from below the lip to the base, indicating that the bottle was made in a two-piece mould that included the heel, body, shoulder and neck. The fancy ‘whirly’ twist pattern and panelled sides would have been cut into the mould’s inner surface. The uneven thickness of the ridge around the base comes from adding a separately moulded and embossed base after the bottle was removed from the mould. The applied finish (mouth and lip) was also added to the bottle. The elongated bubbles in the glass are evidence of the glass being mouth blown into the mould, thus forming the shape and pattern from the inside shape of the mould. The bottle probably had a glass stopper with a round top and wedge-shaped shank with a ground surface, allowing the bottle to be re-sealed. The ring between upper and lower lip allows the closure to be sealed and anchored. The embossed numbers are either “133” or “833” and may represent a particular bottle pattern, manufacturer or filler. Although the bottle is not currently linked to a particular shipwreck, it is recognised as being historically significant as an example of bottles imported for use in Colonial Victoria in the mid-to-late 19th century. This whirley salad oil bottle is matches the whirley salad oil bottles recovered from the Loch Ard in the 1990s, adding depth of interpretation to the array of salvaged Loch Ard artefacts in Flagstaff Hill’s collection. The salad oil bottle is an example of the type of food condiment containers that were used in Victoria’s early days. The bottle is also significant as it was recovered by John Chance, a diver in Victoria’s coastal waters in the late 1960s to early 1970s. Items that come from several wrecks, including the Loch Ard, have since been donated to the Flagstaff Hill Maritime Village’s museum collection by his family, illustrating this item’s level of historical value. Bottle; glass Half Whirley salad oil bottle, green-tinged, with some opalescence. Handmade, elaborately decorated bottle with round neck and base, and five-sided body. Applied double lip; straight upper, flared lower. The lower neck and shoulder have twisted spiral whirley patterns in the glass. The body tapers slightly inwards towards the base. It has five plain panels, one wider than the others. Side seams run from below the lip to the heel. The heel of the bottle is uneven in width, height and density where it joins the body of the bottle. The base is not level. Embossed characters on base. Glass has elongated bubbles towards the base and orange-brown sediment inside, on one side. Embossed "133" or “833” (the first character may be an “8”) flagstaff hill, warrnambool, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, shipwreck artefact, john chance, glass bottle, antique bottle, handmade, mouth blown, blown bottle, 19th century bottle, collectable, bottle, green glass, tinged green, two piece mould, food bottle, oil bottle, salad oil bottle, whirley, whirly, half whirley, condiment bottle -

Bendigo Military Museum

Bendigo Military MuseumAdministrative record - COMPENDIUM WW1 - WW2, 4) A H Pettifer, Government Printer et al, 2) 14.2.1946; .3) 1.3.1919; .4) 30.11.1954 .5) 24.11.19? - WWI; .6) 31.10.1917; .7) 12.6.1917; .8) Page 1: 20.12.1915, Page 2: 10.12.1915, Page 6: 19.1915; .9) 10.9.1918; .10) 18.4.1919; .11) c.2.3.19?; .12) 18.9.1920; .14) post WWI; .15) 24.4.1920; .17) 18.4.1942; .18) 19.6.1943; .19) 18.3.1947; .20) 1944; .21) 1944; .23) 22.10.1941; .26) 13.9.1944; .27) 1.1944; .30) 7.3.1950; .31) 31.7.1944; .32) 16.4.1942; .33) 13.6.1946; .34) 6.5.1946; .36) a) & b) 3.11.1947; .37) 24.10.1951; .38) 24.9.1957; .39) 9.10.1957; .40) 19.2.1958; .41) 26.2.1958; .42) 1.3.1958; .43) & .44) 7.3.1958; .45) 25.2.1958; .46) 3.1.1948; .47) 26.2.1948; .48) 22.4.1958; .49) 24.2.1958; .50) 12.3.1958; .51) 6.1958; .52) c.Mar/Apr 1958; .53) 5.4.1958; .54) c.end WWII; .55) a.b. 13.6.1967; .56) 26.5.1967; .57) 18.2.1954