Showing 4356 items

matching soft

-

Federation University Historical Collection

Federation University Historical CollectionMagazine, SMB Student Magazine 1939, 1939

School Council, Members of Staff, Magazine Committee, List of Full Course Students 1938, Full Course Commercial Students, Editorial, Personal Column, Obituary - Roy S. Hall - F. J. Martell, S.M.B Old Boys' Association, The Literary Society, Centenary Jottings, Fumes from the Lab, Broken Hill, News from Papua, Sidelights on the B.H.P. Cadet Training Scheme, Arts & Crafts Gossip, Sport, Commercial Notes, The Junior Techs, Junior Technical Sportinggreen, orange and blue soft covered magazine with black and green font. 93 pages including advertisements. Artwork Speciman - By Printing Class Students SMB J. Bickart of Bickarts - Lino Cut - By Bob McHutchison J. Bickart of Bickarts - Lino Cut - By Ernest Gribble Bickarts Lino Cut competition 1st Place - By Max Coward Professor p.3 - By A. Janetski The Treasurer - By Bob McHutchison The Editor - By Max Coward Fi-Fi - By Max Coward A Rustic Corner at White flat - By Enid Johnston Diner and Waiter p.12 - By Max Coward Bickarts Lino Cut competition 2nd Place - By Bob McHutchison Joyce - By Ernest Gribble Hotcha Club p.14 - By Adeline Helm Up from white flat - BY Isobel Boustead "What! Milk again?" - By Max Coward Keith - By Max Coward George - By Bob McHutchison Monty - By Bob McHutchison Frank - By Ernest Gribble Shirley - By Max Coward Bickarts Lino Cut competition section B 1st Place - By Violet D'angri Ice Cream p.25 - By Audrey Janetski Indignant Ratepayer - By Adeline Helm Maxie - By Bob McHutchison Enid - By Ernest Gribble Bickarts Lino Cut competition section B 2nd Place - By Marian Peirce Helper & Victim p.34 - By Max Coward Roma - By Ernest Gribble 1939 Overture - By Ernest Gribble Joan - By Bob McHutchison Barbara - By Fifi Malseed Kath - By Ernest Gribble Bickarts Lino Cut competition section C 1st Place - By W. Rowe Coralie - By Ernest Gribble Marion - By Bessie Sargent Betty - By Bob McHutchison Mick.H - By Bob McHutchison Rooster - By Bessie Sargent Stinker Lees - By Gordon Yorke Sammy - By Bessie Sargent Legs - By Ernest Gribble Jack and Jill - By Ernest Gribble Sunbeam - By Earnest Gribble Marj - By Bob Mchutchison Dorothy - By Bob McHutchison Joan - By Ernest Gribble Betty - By Ernest Gribble Bickarts Lino Cut competition section C 2nd Place - By F.P. Manning Helen - By Maurice Collins Donk - By Maurice Collins Out of Step - By Maurice Collins Rita - By Maurice Collins Betty - By Maurice Collins ballarat school of mines students' magazine 1939, smb, geoffrey angwin, francis butson, alma bayly, isabel boustead, roma bruce, robert w. bates, nataly callow, max coward, tom coburn, maurice collins, lloyd davies, jessie daniel, marion dolan, elsie fisher, ernest gribble, betty george, adeline helm, mavis heinz, gladys james, enid johnston, audrey janetski, lloyd jones, ray jackson, stan laurie, maureen mcrae, margaret mcdougall, bessie martin, sheila moss, ian moscript, bob mchutchison, john moorhouse, fifi malseed, estelle morris, barbara rogers, john robison, john robinson, roma sprake, bessie sargent, joyce scott, una semmler, margaret taylor, norma tatlock, avis vaughan, coral vernon, jeff wilkinson, max webster, gordon yorke -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageWeapon - Cannon, Alexander Hall and Son, c. 1855

The Schomberg Cannon was recovered from the 1855 wreck of the SCHOMBERG in 1974 by Flagstaff Hill divers Peter Ronald, Colin Goodall and Gary Hayden. The wreck site was discovered in August 1973 by Stan McPhee and John Laidlaw. ABOUT THE SCHOMBERG When SCHOMBERG was launched in 1855, she was considered the “Noblest ship that ever floated on water.” SCHOMBERG’s owners, the Black Ball Line, commissioned the ship for their fleet of passenger liners. The ship was built by Alexander Hall of Aberdeen at a cost of £43,103. It was constructed with three skins: one planked fore and aft and two diagonally planked, fastened together with screw-threaded trunnels (wooden rails). Its first-class accommodation was simply luxurious; velvet pile carpets, large mirrors, rosewood, birds-eye maple, mahogany, soft furnishings of satin damask; an oak-lined library and a piano. Overall she had accommodation for 1000 passengers. At the launch, the SCHOMBERG’s 34-year-old master, Captain ‘Bully’ Forbes, had promised Melbourne in 60 days, "with or without the help of God." James Nicol Forbes was born in Aberdeen in 1821 and rose to fame with his record-breaking voyages on the famous Black Ball Line ships; MARCO POLO and LIGHTNING. In 1852 in the MARCO POLO he made the record passage from London to Melbourne in 68 days. There were 53 deaths on the voyage but the great news was of the record passage by the master. In 1954 Captain Forbes took the clipper LIGHTNING to Melbourne in 76 days and back in 63 days, this was never beaten by a sailing ship. He often drove his crew and ship to breaking point to beat his own records. He cared little for the comfort of the passengers. On this, the SCHOMBERG’s maiden voyage, he was going to break records. SCHOMBERG departed Liverpool on her maiden voyage on 6 October 1855 flying the sign “Sixty Days to Melbourne”. The ship departed with 430 passengers and 3000 tons of cargo including iron rails and equipment intended to build the Melbourne to Geelong Railway and a bridge over the Yarra from Melbourne to Hawthorn. She also carried a cow for fresh milk, pens for fowls and pigs, and 90,000 gallons of water for washing and drinking. It also carried 17,000 letters and 31,800 newspapers. The ship and the cargo was insured for $300,000, a fortune in those times. The winds were poor as she sailed across the equator, slowing SCHOMBERG’s journey considerably. Land was first sighted on Christmas Day, at Cape Bridgewater near Portland, and Captain Forbes followed the coastline towards Melbourne. Forbes was said to be playing cards when called by the Third Mate Henry Keen, who reported land about 3 miles off, Due in large part to the captain's regarding a card game as more important than his ship, it eventually ran aground on a sand spit near Curdie's Inlet (about 56 km west of Cape Otway) on 26 December 1855, 78 days after leaving Liverpool. The sand spit and the currents were not marked on Forbes’s map. Overnight, the crew launched a lifeboat to find a safe place to land the ship’s passengers. The scouting party returned to SCHOMBERG and advised Forbes that it was best to wait until morning because the rough seas could easily overturn the small lifeboats. The ship’s Chief Officer spotted SS QUEEN at dawn and signalled the steamer. The master of the SS QUEEN approached the stranded vessel and all of SCHOMBERG’s passengers and crew were able to disembark safely. The SCHOMBERG was lost and with her, Forbes’ reputation. The Black Ball Line’s Melbourne agent sent a steamer to retrieve the passengers’ baggage from the SCHOMBERG. Other steamers helped unload her cargo until the weather changed and prevented the salvage teams from accessing the ship. Later one plunderer found a case of Wellington boots, but alas, all were for the left foot! Local merchants Manifold & Bostock bought the wreck and cargo, but did not attempt to salvage the cargo still on board the ship. They eventually sold it on to a Melbourne businessman and two seafarers. In 1864 after two of the men drowned when they tried to reach SCHOMBERG, salvage efforts were abandoned. Parts of the SCHOMBERG were washed ashore on the south island of New Zealand in 1870, nearly 15 years after the wreck. The wreck now lies in 825 metres of water. Although the woodwork is mostly disintegrated the shape of the ship can still be seen due to the remaining railway irons, girders and the ship’s frame. A variety of goods and materials can be seen scattered about nearby. Flagstaff Hill holds many items salvaged from the SCHOMBERG including a ciborium (in which a diamond ring was concealed), communion set, ship fittings and equipment, personal effects, a lithograph, tickets and a photograph from the SCHOMBERG. One of the SCHOMBERG bells was in the old Warrnambool Library. The Schomberg cannon is currently on loan to the Port Campbell Visitor Information Centre.The SCHOMBERG collection is of historical and archaeological significance at a State level, listed on the Victorian Heritage Register VHR S612. Flagstaff Hill’s collection of artefacts from the SCHOMBERG is significant for its association with the Victorian Heritage Registered shipwreck. The collection is primarily significant because of the relationship between the objects, as together they have a high potential to interpret the story of the SCHOMBERG. The SCHOMBERG collection is archaeologically significant as the remains of an international passenger ship. The shipwreck collection is historically significant for representing aspects of Victoria’s shipping history and its potential to interpret sub-theme 1.5 of Victoria’s Framework of Historical Themes (living with natural processes). The collection is also historically significant for its association with the shipwreck and the ship, which was designed to be the fastest and most luxurious of its day. The SCHOMBERG collection meets the following criteria for assessment: Criterion A: Importance to the course, or pattern, of Victoria’s cultural history. Criterion B: Possession of uncommon, rare or endangered aspects of Victoria’s cultural history. Criterion C: Potential to yield information that will contribute to an understanding of Victoria’s cultural history.Cannon; 6-POUNDER (6pdr) smooth bore cannon, mounted on a wooden frame. The cannon has a metal lug on each side. It is commonly known as the Schomberg cannon. It was recovered from the wreck of the Schomberg in 1974.warrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, schomberg, shipwrecked-artefact, clipper ship, black ball line, 1855 shipwreck, aberdeen clipper ship, captain forbes, peterborough shipwreck, ss queen, cannon, the schomberg cannon, schomberg cannon, peterborough, 1855, sailing ship -

Flagstaff Hill Maritime Museum and Village

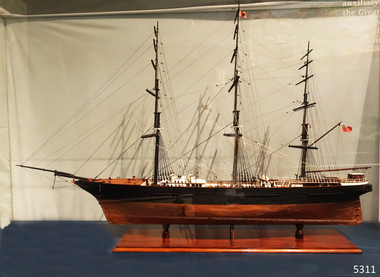

Flagstaff Hill Maritime Museum and VillageCraft - Ship Model, S.S. Schomberg, 1988

This model of the clipper ship SS Schomberg was researched and constructed to a scale of 1:64 by David Lumsden in 1988. When the Schomberg was launched in 1855, she was considered the "Noblest” ship that ever floated on the water. Schomberg's owners, the Black Ball Line had commissioned the ship for their fleet of passenger liners. She was built by Alexander Hall of Aberdeen for £43,103 and constructed with 3 skins. One planked fore and aft and two diagonally planked, fastened together with screw-threaded trunnels (wooden rails). Her First Class accommodation was simply luxurious with velvet pile carpets, large mirrors, rosewood, birds-eye maple and mahogany timbers throughout, soft furnishings of satin damask, and oak-lined library with a piano. Overall she had accommodation for 1000 passengers. At the launch, the Schomberg's 34-year-old master, Captain 'Bully' Forbes, had promised to reach Melbourne in sixty days stating, "with or without the help of God." Captain James Nicol Forbes was born in Aberdeen in 1821 and rose to fame with his record-breaking voyages on the famous Black Ball Line ships; Marco Polo and Lightning. In 1852 in the Marco Polo, he made the record passage from London to Melbourne in 68 days. Unfortunately, there were 53 deaths on the voyage, but the great news was off the record passage by Captain Forbes. In 1854 he took the clipper “Lighting” to Melbourne in 76 days and back in 63 days, this record was never beaten by a sailing ship. He often drove his crew and ship to breaking point to beat his previous records. He cared little for the comfort of the passengers. On this, the Schomberg's maiden voyage, he was determined to break existing records. Schomberg departed Liverpool on her maiden voyage on 6th October 1855 flying a sign that read "Sixty Days to Melbourne". She departed with 430 passengers and 3000 tons cargo including iron rails and equipment intended to build the Melbourne to Geelong Railway and a bridge over the Yarra from Melbourne to Hawthorn. She also carried a cow for fresh milk, pens for fowls and pigs, 90,000 gallons of water for washing and drinking. She also carried 17,000 letters and 31,800 newspapers. The ship and cargo were insured for $300,000 a fortune for the time. The winds were poor as she sailed across the equator, slowing Schomberg's journey considerably. The land was first sighted on Christmas Day, at Cape Bridgewater near Portland, Captain Forbes followed the coastline towards Melbourne. Forbes was said to be playing cards when called by the third mate Henry Keen, who reported land about 3 miles off. Due in large part to the captain's regarding a card game as more important than his ship, it eventually ran aground on a sand spit near Curdie's Inlet (about 56 km west of Cape Otway) on 26th December 1855, 78 days after leaving Liverpool. The sand spit and the currents were not marked on Forbes's map. Overnight, the crew launched a lifeboat to find a safe place to land the ship’s passengers. The scouting party returned to Schomberg and advised Forbes that it was best to wait until morning because the rough seas could easily overturn the small lifeboats. The ship’s Chief Officer spotted the SS Queen at dawn and signaled the steamer. The master of the Queen approached the stranded vessel and all of Schomberg’s passengers and crew disembarked safely. The Black Ball Line's Melbourne agent sent a steamer to retrieve the passengers' baggage from the Schomberg. Other steamers helped unload her cargo until the weather changed and prevented the salvage teams from accessing the ship. Later one plunderer found a case of Wellington boots, but alas, all were for the left foot. Local merchants Manifold & Bostock bought the wreck and cargo but did not attempt to salvage the cargo still on board the ship. They eventually sold it on to a Melbourne businessman and two seafarers. In 1864 after two of the men drowned when they tried to reach Schomberg, salvage efforts were abandoned. In 1870, nearly 15 years after the wreck parts of the Schomberg had washed ashore on the south island of New Zealand. The wreck now lies in 825 metres of water and although the woodwork is mostly disintegrated the shape of the ship can still be determined due to the remaining railway irons, girders and the ship’s frame. A variety of goods and materials can be seen scattered about nearby. There have been many other artefacts salvaged from the wreck include ship fittings and equipment, personal effects, a lithograph, tickets and photographs from the Schomberg. This item was retrieved from the shipwreck site during early salvage efforts on the vessel. And was donated to the Flagstaff Hill collection of Schomberg shipwreck artefacts.This artifact is particularly significant in that along with other items salvaged from the wreck have helped in part to having legislation changed to protect shipwrecks, with far tighter controls being employed to oversee the salvaging of wreck sites. This item forms part of the Schomberg collection at Flagstaff Hill maritime museum. The collection as a whole is of historical and archaeological significance at a State level. Flagstaff Hill’s collection of artefacts from the Schomberg is also significant for its association with the Victorian Heritage Registered Schomberg shipwreck (VHR S 612). The collection is of additional significance because of the relationship between the objects salvaged, as together they help us to interpret the story of the Schomberg. The collection as a whole is historically significant for representing aspects of Victoria's maritime history and its potential to interpret social and historical themes from society at the time of the wreck.Wooden model of the clipper ship SS Schomberg. The three masts are rigged with lines but have no sails. The model is mounted on pedestals on a timber board, exhibited in a glass case. The scale of this model is 1:64.Noneflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, ship model, schomberg ship model, 1855, david lumsden, ship model maker, clipper ship, black ball line, 1855 shipwreck, aberdeen clipper ship, captain forbes, peterborough shipwreck, ss queen -

Bendigo Historical Society Inc.

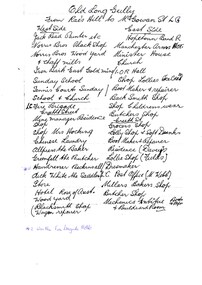

Bendigo Historical Society Inc.Document - LONG GULLY HISTORY GROUP COLLECTION: OLD LONG GULLY FROM RAE'S HILL TO MCGOWAN ST

Titled Old Long Gully From Rae's Hill to McGowan St. LG. West Side - Jack Read Painter etc, Norris Bros Black Shop, Norris Bros Wood Yard & Chaff Mills, Iron Bark East Gold Mine, Sunday School, Tennis Courts Sunday School & Church, LG Fire Brigade, Creeth Street, Mine Managers Residence, Shop, Shop Mrs Hocking, Chinese Laundry, Allpress the Baker, Greenfell the Butcher, Hairdresser Beckinsall was the Fire Brigade Hotel, Dick White the Saddler, Store, Hotel Rose of Australia, Woodyard, Blacksmith Shop Wagon Repairer, Hotel Kocks (Pioneer Hotel), 2 China Shops owned by Chinese, Hotel Silver mines Hotel, Police Station, Grocers Shop (per? Reef Mine Hotel) E Bryant, Mine Windmill, Church Residence, Minister. East Side - Hopetoun Band R, Manchester Arms Hotel, Minister House, Church, IOR Hall, Shop Lollies Icecream, Boot Maker & Repairer, Back Smith Shop, Shop Childrens Wear, Butchers Shop, Creeth Street, Grocers Shop, Lolly Shop & Soft Drinks, Boot Maker & Repairer, Residence (Davey's), Lollie Shop (Fields), Dressmaker, LG Post Office (M Webb), Millars Bakers Shop, Butcher Shop, Mechanics Institute Books & Paper & Billiard Room, Connell the Baker, Dr SElby, Pentreath Organ Builder & Tuner, Blacksmith Shop, Hexagon Toilet, Kocks Machine Shop, Kocks Mine Office, Kocks Material Shop, Police Station, Dyson's Dam Warm waer, Air Station, Mine Battery stone crusher 80 head approx, Kocks Mine, Needle Mine. Some notes written at the end - Norm Shotples used to have Barber Shop - he has gone to Queensland, Violet Street started off as the German School, Wells Street used to run through Victorian Consol ? the other side, Comet Hill would like a visit. Contact Helen Gorlay at Violet Street would line to some video. Alan has good info on the Long Gully School. Betty has book. Views of Bendigo. Frank Cusack - Bendigo Trust. Bendigo School Hisking? School, Violet Street. Older levels lo?ing at Architecture.bendigo, history, long gully history group, the long gully history group - old long gully from rae's hill to mcgowan st, jack read, norris bros, iron bark east gold mine, long gully fire brigade, mrs hicking, allpress, greenfell, beckinsall, dick white, rose of australia, hopetoun band r, manchester arms hotel, ior hall, davey's, fields, m webb, millars, mechanics institute & billiard room, kocks pioneer hoel, silver mines hotel, e bryant, windmill mine, pere? reef mine hotel, connell, dr selby, pentreath, kocks machine shop, kocks mine office, kocks material shop, dyson's dam, kocks mine, needle mine, norm shotples, german school, victoria consols, helen gorlay, long gully school, frank cusack, bendigo trust -

Bendigo Historical Society Inc.

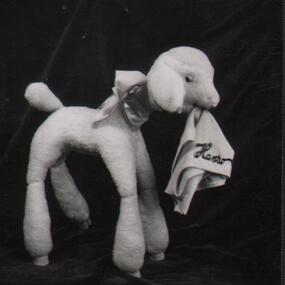

Bendigo Historical Society Inc.Photograph - HANRO COLLECTION: A COLLECTION OF PHOTOGRAPHS OF DECORATIONS FOR HANRO WINDOW DISPLAY

See Item 11000.189A Collection of Photographs of decorations for Hanro Window Display: All black and white photo's. Photo A) A soft toy of a lamb with a bow around its neck and in the mouth is a garment with Hanro embroider on it. On the back is the number 2056 hand written in blue ink. Photo B) has two cane suitcases with handles one smaller than the other. Both have flowers woven through the cane. A petticoat with lace and two thin straps at the top is laid through the larger suitcase and a sign *Hanro* sits on the bench. On the back is 2100 hand written in blue ink and in pencil VV11. Photo C) Is of a Cane French Horn with a bunch of flowers in the horn part. A Hanro sign is attached to the middle of the Horn and a petticoat with a lace bodice and hem and two thin straps is draped through the bottom of the French Horn. Some glue on the back and 2114 in biro, 14 in pencil. Photo D) Is a mock cloths line in front of a dark background with three petticoats. The first has a lace top and hem with two straps pegged to the line, the second is hung upside down with two pegs. It has a lace top with a V neck. The third has a lace V neck top and at the hem line. The garment is pegged to the line by the straps. There are two pots with flowers hanging from the line. Photo E) A vase made of cane with flowers and a Hanro sign attached. Two petticoats either side are laid on the bench both with a lace bodice. There are two Hanro signs on the table. On the back in blue ink hand written is *Dek. Nt.2094 Photo F*. There are three cane baskets with flowers and Hanro signs at the top of each hung on a wall and two cane baskets with flowers on the table. One petticoat is hung up on the wall through the baskets. The petticoat has a lace border at the bodice, The other is laid on the table, has a V neck and lace border. A Hanro sign is in front of the petticoat. On the back printed in blue ink is *Dek. Nr. 2098* Photo G) Is three bunches of flowers to have Hanro sign attached. On the back is *Dek. 2077. Photo H) Is three groups of several crystal balls strung together with pine needles at the top and the sign Hanro at the top of each. On the back hand printed in blue ink is *Dek.2124* The photos were together in a piece of paper which has writing in green ink *Decorations for clients window display*.Reg. V. Brock Studiosphotograph, hanro. reg. v. brock. -

Eltham District Historical Society Inc

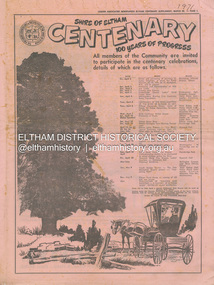

Eltham District Historical Society IncNewspaper - Supplement, Leader Associated Newspapers, Shire of Eltham Centenary; 100 Years of Progress, March 30, 1971

Poduced as a supplement to the Diamond Valley News in celebration of the centenary of the Shire of Eltham in 1971. Contains stories of historical note about people and places of the shire as well as numerous advertisng by local businsesses. Also on page 1 lists the program of events commencing Friday, April 2 commencing with a dinner and previewing of paintings by Justus Jorgensen at Montsalvat attended by the Prime Minister, the Rt. Hon. W. H. McMahon running through to the publication of Pioneers & Painters edited by Alan Marshall. Contents: Page 1 Program of Events Page 2 Wingrove . . man of Eltham Page 3 Council people of 100 years Page 5 Capt. Sweeney, Eltham’s first Irish settler Page 6 Station a tribute to ex-concillor Page 7 Eltham 25 Years Ago just a street Page 9 Kangaroo Ground – once the hub of the shire Page 10 Festival of Arts and Crafts at Montsalvat Page 11 Obelisk honours their memory Page 11 Henry Dendy – an Eltham venture Page 12 Free by rail – if they worked Page 12 The long shadow of Ween Cameron Page 13 McMahon’s – a momentous era Page 14 50 Years Ago . . . Lyon Bros Ford Page 15 Beer at 3d. a pint Page 17 Oldest Home Built in 1850 Page 19 History in black and white . . . . Page 20 Historical Pigeon Bank Page 22 Bridge over log crossing Page 22 Pioneer shot by outlaw Page 23 Milestone for Smith Family Page 24 The Eltham Chamber of Commerce Mardi Gras Advertisers: F.J. & R. Favier (Butcher & Delicatessen Lower Plenty) Eltham Hotel Country Art Store (Eltham) A.R. Warren (Eltham) Heidelberg Travel Service Williams Butcher (Lower Plenty) Greensborough Bulk Store Mac’s Meats (Eltham) Buxton Garden Ornaments (Eltham) Hugh Fisher Photographer (Eltham) Para (Mach. Trading Co. (Greensborough) Westfield Shoppingtown (Doncaster) Clinton’s (Eltham) Gillespie & Lewis P/L (Soft Furnishings Greensborough) T. Hutchinson’s Engineers (Greensborough) Knox & Hellemons Pty Ltd (Builders) Angliss Butchers (Eltham) Rainbow Real Estate (Research) Research Licensed Supermarket Gibsons Research Meat Supply Owen Holmes Motors (Greensborough) Research Pharmacy R. & P. Humphries Delicatessen (Eltham) Montsalvat Eltham Apex Mowerama (Eltham) R.H. Dean & Son Real Estate (Greensborough) L.J. & J.D. Avery Butchers (Eltham) Deylen & Torikov (Motor Engineers Eltham) George Lovitt & Co. Pty Ltd Precision Engineers and Toolmakers Montmorency) Fred’s Mower Repairs (Lower Plenty) Gray’s Milk Bar (Montmorency) Maranne Beauty Salon (Montmorency) Evans Bros. & Newell Pty Ltd (Printing Greensborough) La Ronde Restaurant (Eltham) Terry & Margaret’s Garage (Caltex Lower Plenty) Kevin Dawson Building & Joinery Contractors (Eltham) Montmorency Authorised Newsagency Eltham Produce Store (W.J. Cameron) Consolidated Aluminium (Aust.) Pty Ltd (Eltham) Briar Hill Timber & Trading Co. Pty Ltd Diamond Valley Coaches (Eltham) Lyon Bros Ford (Eltham) The Natural Development Association (Eltham Shire) Alan Whitmore R.E.S.I. (Eltham) Keith Wilkie’s Mensland (Montmorency) Eltham Home Supplies (Eltham) Safeway (Greensborough) Lower Plenty Fish Supply Blue Gum Milk Bar (Eltham) W. Hutchinson Sand Soil & Gravel Suppliers (Greensborough) Keyzers Milk Bar (Greensborough) P.J. Timber & Trading Pty Ltd (Eltham) Diamond Valley Motocycles (Honda Macleod) Neville F. Emerson Real Estate (Lower Plenty) Edon Engineering (Eltham) Mobil Service Centre (Eltham) C.A. & J.M. Kohlman (Panton Hill General Store) C.A. & J.M. Kohlman (Smiths Gully General Store) ANZ (Eltham) Diamond Valley Demolition (Eltham) Volkswagen Specialists (D. Young Greensborough) N.F. Thorpe Pty Ltd Precision Engineers (Briar Hill) Ashley’s Milk Bar (Montmorency) J. Turnbull (General Blacksmith Greensborough) Airlook Service Station (Montmorency) A. & L. Mallios (Grocer Hurstbridge) United Refrigeration Pty Ltd (Greensborough) Peter McDougall & Associates Real Estate (Eltham) Hurstbridge Bus & Taxi Service Pty Ltd Browne Bros. Safeway (Eltham) St Andrews Hotel Eltham Real Estate Pty Ltd Eltham Chamber of Commerce B.P. Evergreen Service Station (Eltham) A.R. Warren Fuel Merchant (Eltham) W. Penna Chemist (Eltham) PPH Produce Paint Hardware (Eltham) Eltham Cake Kitchen (Eltham) Fred Ramak Continental Hairdresser (Eltham) Clinton’s (Eltham) Thompson’s Pharmacy (Eltham) Tillings Timber Supermarket (Eltham) Lyon Bros Ford (Eltham) Bob Clarke’s Men’s Wear (Eltham) Eltham Glen Service Station (Eltham) Miss V. Rampton Naturopath (Eltham) Eltham South Milk Bar (Eltham) Eltham Jewellers (Eltham) Baines Supa-Valu Supermarket (Eltham) Sibbel Builders P/L (Eltham) G. & E. Reivers Fly and Shower Screens (Eltham) Kenton Shoeland (Eltham) Eltham Newsagency (Eltham)One copy marked '1971' on fronta. & l. mallios (grocer hurstbridge), a.r. warren (eltham), a.r. warren fuel merchant (eltham), airlook service station (montmorency), alan whitmore r.e.s.i. (eltham), angliss butchers (eltham), anz (eltham), ashley’s milk bar (montmorency), b.p. evergreen service station (eltham), baines supa-valu supermarket (eltham), blue gum milk bar (eltham), bob clarke’s men’s wear (eltham), briar hill timber & trading co. pty ltd, browne bros. safeway (eltham), buxton garden ornaments (eltham), c.a. & j.m. kohlman (panton hill general store), c.a. & j.m. kohlman (smiths gully general store), clinton’s (eltham), consolidated aluminium (aust.) pty ltd (eltham), country art store (eltham), deylen & torikov (motor engineers eltham), diamond valley coaches (eltham), diamond valley demolition (eltham), diamond valley motocycles (honda macleod), edon engineering (eltham), eltham apex, eltham cake kitchen (eltham), eltham chamber of commerce, eltham glen service station (eltham), eltham home supplies (eltham), eltham hotel, eltham jewellers (eltham), eltham newsagency (eltham), eltham produce store (w.j. cameron), eltham real estate pty ltd, eltham south milk bar (eltham), evans bros. & newell pty ltd (printing greensborough), f.j. & r. favier (butcher & delicatessen lower plenty), fred ramak continental hairdresser (eltham), fred’s mower repairs (lower plenty), g. & e. reivers fly and shower screens (eltham), george lovitt & co. pty ltd precision engineers and toolmakers montmorency), gibsons research meat supply, gillespie & lewis p/l (soft furnishings greensborough), gray’s milk bar (montmorency), greensborough bulk store, heidelberg travel service, hugh fisher photographer (eltham), hurstbridge bus & taxi service pty ltd, j. turnbull (general blacksmith greensborough), keith wilkie’s mensland (montmorency), kenton shoeland (eltham), kevin dawson building & joinery contractors (eltham), keyzers milk bar (greensborough), knox & hellemons pty ltd (builders), l.j. & j.d. avery butchers (eltham), la ronde restaurant (eltham), lower plenty fish supply, lyon bros ford (eltham), mac’s meats (eltham), maranne beauty salon (montmorency), miss v. rampton naturopath (eltham), mobil service centre (eltham), montmorency authorised newsagency, montsalvat, mowerama (eltham), n.f. thorpe pty ltd precision engineers (briar hill), neville f. emerson real estate (lower plenty), owen holmes motors (greensborough), p.j. timber & trading pty ltd (eltham), para (mach. trading co. (greensborough), peter mcdougall & associates real estate (eltham), pph produce paint hardware (eltham), r. & p. humphries delicatessen (eltham), r.h. dean & son real estate (greensborough), rainbow real estate (research), research licensed supermarket, research pharmacy, safeway (greensborough), shire of eltham centenary, sibbel builders p/l (eltham), st andrews hotel, t. hutchinson’s engineers (greensborough), terry & margaret’s garage (caltex lower plenty), the natural development association (eltham shire), thompson’s pharmacy (eltham), tillings timber supermarket (eltham), united refrigeration pty ltd (greensborough), volkswagen specialists (d. young greensborough), w. hutchinson sand soil & gravel suppliers (greensborough), w. penna chemist (eltham), westfield shoppingtown (doncaster), williams butcher (lower plenty), a. roy ford, a.g. thomas, agnes bell, albert h. price, andrew ross, anton w. brinkkotter, arthur brindley, b. bessant, b.w. plant, bell family, charles wingrove, culla hill, dave lyon, david w. bell, e.j. andrew, edwin smith, eltham court house, eltham obelisk, ewen hugh cameron, f.e. griffith, f.v. squire, frank mcmahon, george green, george stebbing, h. eric rundle, harold e. bartlett, henry dendy, henry hurst, henry stooke, herbert a. davies, herbert hewitt, i.g. smedley, j.a. mcdonald, jack baker, jack williams, james k. brice, james rossiter, john lyon, john s. smedley, justus jorgensen, kangaroo ground, larry burke, martin mcmahon, menzies jackson, mott family, mrs andrew, mrs harper, p. harmer, p.j. lester, patrick joseph mcmahon, r.j. galbraith, robert burke, robert charles harris, rosehill, s. willey, shillinglaw cottage, shire of eltham war memorial tower, thomas sweeney, tiny carroll, tom orford, w.b. thomas, william morris -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageAccessory - Diamond ring, about 1855

In 1975, 120 years after the sailing ship Schomberg was wrecked, Flagstaff Hill divers (Peter Ronald, Colin Goodall and Gary Hayden) found an ornate communion set amongst the wreckage. The set comprised a jug, ciborium, lid, chalice and plate. The items, apart from the lid, were then displayed at Flagstaff Hill Maritime Village. The lid had etchings that did not match the chalice and sat in storage for several years. Then in 1978, while the marine concretion inside the lid was being examined, a surface layer came loose and revealed a glint of gold that was assumed to be a piece of brass. The layers of concretion were carefully removed and a ring-like band emerged. Further treatment exposed a 'large faceted stone in an intricate gold setting. Weeks later a detailed examination estimated the value of the ring, known as the Schomberg Diamond, to be $7000. When the Schomberg was launched in 1855, she was considered the "Noblest” ship that ever floated on the water. Schomberg's owners, the Black Ball Line had commissioned the ship for their fleet of passenger liners. She was built by Alexander Hall of Aberdeen at a cost of £43,103 and constructed with 3 skins. One planked fore and aft and two diagonally planked, fastened together with screw-threaded trunnels (wooden rails). Her First Class accommodation was simply luxurious with velvet pile carpets, large mirrors, rosewood, birds-eye maple and mahogany timbers throughout, soft furnishings of satin damask, an oak-lined library with a piano. Overall she had accommodation for 1000 passengers. At the launch, the Schomberg's 34-year-old master, Captain 'Bully' Forbes, had promised to reach Melbourne in sixty days stating, "with or without the help of God." Captain James Nicol Forbes was born in Aberdeen in 1821 and rose to fame with his record-breaking voyages on the famous Black Ball Line ships; Marco Polo and Lightning. In 1852 in the Marco Polo, he made the record passage from London to Melbourne in 68 days. Unfortunately there were 53 deaths on the voyage, but the great news was off the record passage by Captain Forbes. In 1854 he took the clipper “Lighting” to Melbourne in 76 days and back in 63 days, this record was never beaten by a sailing ship. He often drove his crew and ship to breaking point to beat his previous records. He cared little for the comfort of the passengers. On this, the Schomberg's maiden voyage, he was determined to break existing records. Schomberg departed Liverpool on her maiden voyage on 6th October 1855 flying a sign that read "Sixty Days to Melbourne". She departed with 430 passengers and 3000 tons cargo including iron rails and equipment intended to build the Melbourne to Geelong Railway and a bridge over the Yarra from Melbourne to Hawthorn. She also carried a cow for fresh milk, pens for fowls and pigs, 90,000 gallons of water for washing and drinking. She also carried 17,000 letters and 31,800 newspapers. The ship and cargo were insured for $300,000 a fortune for the time. The winds were poor as she sailed across the equator, slowing Schomberg's journey considerably. Land was first sighted on Christmas Day, at Cape Bridgewater near Portland, Captain Forbes followed the coastline towards Melbourne. Forbes was said to be playing cards when called by the third mate Henry Keen, who reported land about 3 miles off. Due in large part to the captain's regarding a card game as more important than his ship, it eventually ran aground on a sand spit near Curdie's Inlet (about 56 km west of Cape Otway) on 26th December 1855, 78 days after leaving Liverpool. The sand spit and the currents were not marked on Forbes's map. Overnight, the crew launched a lifeboat to find a safe place to land the ship’s passengers. The scouting party returned to Schomberg and advised Forbes that it was best to wait until morning because the rough seas could easily overturn the small lifeboats. The ship’s Chief Officer spotted the SS Queen at dawn and signaled the steamer. The master of the Queen approached the stranded vessel and all of Schomberg’s passengers and crew disembarked safely. The Black Ball Line's Melbourne agent sent a steamer to retrieve the passengers' baggage from the Schomberg. Other steamers helped unload her cargo until the weather changed and prevented the salvage teams from accessing the ship. Later one plunderer found a case of Wellington boots, but alas, all were for the left foot. Local merchants Manifold & Bostock bought the wreck and cargo but did not attempt to salvage the cargo still on board the ship. They eventually sold it on to a Melbourne businessman and two seafarers. In 1864 after two of the men drowned when they tried to reach Schomberg, salvage efforts were abandoned. In 1870, nearly 15 years after the wreck parts of the Schomberg had washed ashore on the south island of New Zealand. The wreck now lies in 825 meters of water and although the woodwork is mostly disintegrated the shape of the ship can still be determined due to the remaining railway irons, girders and the ship’s frame. A variety of goods and materials can be seen scattered about nearby. The actual lid in which the ring was found has not yet been completely identified and could belong to a coffee pot, sugar bowl or maybe a jug or something similar. Although all survived the wreck no-one came forward to claim the valuable diamond. The Schomberg Diamond is currently on display in the Great Circle Gallery. Flagstaff Hill Maritime Village along with the rest of the communion set. Other artefacts salvaged from the wreck include ship fittings and equipment, personal effects, a lithograph, tickets and photographs from the Schomberg. One of the Schomberg bells is in the Warrnambool Library.The Schomberg Diamond is particularly significant in that it played a crucial part in having the legislation changed to protect shipwrecks, with far tighter control over the salvaging of items from wreck sites. This ring is registered as Artefact S/105 in the Schomberg collection, the Schomberg collection as a whole is of historical and archaeological significance at a State level. Flagstaff Hill’s collection of artefacts from the Schomberg is also significant for its association with the Victorian Heritage Registered shipwreck (VHR S 612). The collection is of prime significant because of the relationship between the objects salvaged, as together they help us to interpret the story of the Schomberg. The collection as a whole is historically significant for representing aspects of Victoria's maritime history and its potential to interpret social and historical themes. A mid-Victorian gentleman's solitaire diamond dress ring with a Brazilian cut diamond (cushion cut), one and one-third carat set within an 18 carat yellow gold ring consisting of four claws within an open scroll setting and a divided scroll shank. Colour is classified as 'J', clarity SII. The setting is handmade. warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, schomberg, shipwrecked-artefact, clipper ship, black ball line, 1855 shipwreck, aberdeen clipper ship, captain forbes, peterborough shipwreck, ss queen, ciborium, ring, schomberg-diamond, schomberg-ring, gentleman's ring, dress ring -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Document - TOWN HALL, THE BENDIGO CHORAL SOCIETY, 17 December, 1919

Town Hall, The Bendigo Choral Society. (Season 1919-Third Concert) Eleventh Grand Concert, Town Hall. Wednesday, December 17th, 1919. Artists: Miss Claire Colgan, Miss Myrtle Knight, Mr E H Collett, Mr A E Sayer. Conductor: Mr W C Frazier, A.R.C.O. Pianiste: Miss Muriel Hyett, L.A.B. Patron-His Worship the Mayor (Cr. J H Curnow). President-Mr H M Leggo. Vice-Presidents-Sir John Quick, Cr. C W Beebe, Mr Oscar Flight, Mr E S Cahill, Mr D Berrriman, Mr A L Bolton, Mr G E Bolton, Dr W G Long, DR O Penfold, Mr J G Oliphant, Mr Alf E Wallis, Mr A Whitehead, Mr W Watts. From the performing Members-Mr E H Collett, Mr A W McGibboney. Conductor-Mr W C Frazier, A.R.C.O. Sub-Conductor- Mr E A Miller, Pianist-Miss Muriel Hyett, L.A.B. Ass. Sec.-Mr Fred A Wittscheibi. Treasurer-Mr D H Holden. Librarians-Mr R J Duguid & G L McCoy. Auditors-Mr H T Bayton, A.A.I.S. * Harold Walker. Committee-Office Bearers: Mesdames T Scott, & Chisholm, & Misses Colgan, Gall, Field & Wheaton, & Messrs Sleeman, Jeffrey, McClure, Brown, F J Walter & Frank Wittscheibe. Subscribers may book at Flights on and After 12th December, without extra fee. Holders of 2/2 tickets may also book by paying difference, 1/1. Admission- 2/2/ Reserved, 1/1/ Ordinary, including tax. J Hudspeth, Hon. Secretary, 85 Wills Street, Bendigo. Programme. 'Comfort Ye' 'Every Valley' 'And the Glory', Hungarian Danse' No.3, 'Softly Sighs', 'Fire, Fire my Heart', 'Spring', 'Best Pair of Sirens', ' Legende', 'Eleanore', 'Dream Wind', 'Ave Maria', 'Fantasie Pastorale', 'O Great is the Depth'. 'Dream Wind' Words by William Sharp. 'Fire, Fire My Heart' Words by Morley. 'Blest Sirens' ''Voice'' and ''Verse'' Words by Milton. The Bendigo Choral Society. Exists for the worthy production of the choral works of the great composers. Under the leadership of Mr Frazier it cam fairly claim to have accomplished this, at least in some degree, during the past year. Works have been. . . . . . Note - The rehearsals will be resumed 2nd week in February, 1920. Annual Meeting 3rd week. A and b are same, a is in excellent condition, b has some slight discoloration on the back. Both have been folded in half and in half againBolton Bros, Printersprogram, theatre, the bendigo choral society -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Bell, Before 1855

This small ship’s bell, possibly a ‘mess’ or dining room bell, was the smaller of the two bells rescued by the crew of the Schomberg when it was wrecked in 1855. All of the crew from the Schomberg wreck survived. They carried the two ship’s bells with them as they made their way along the coast, eventually arriving at the home of settler, John Manning, who lived at Hopkins Point near Warrnambool. Manning acquired the Schomberg bells, presenting them to two Warrnambool churches; the smaller one to St Joseph’s Catholic Church and the larger bell to St John’s Presbyterian church. This small bell developed a crack after about a year at St Joseph's church and could no longer be used. Thomas Manifold imported a new bell for that church and the cracked belled was stored at his farm and stored. The property was sold years later to John Logan, who donated the discarded bell to the Warrnambool Museum when it first opened in 1886. The Curator, Joseph Archibald, displayed the bell in the entry. The small bell was repaired and re-plated by Briggs Marine in 1986. The larger Schomberg bell was installed in St John’s Presbyterian Church. In 1887 a ‘massive’ new bell, made in Victoria, was installed at the Presbyterian Church, so the old bell was transferred to the nearby Woodford Presbyterian authorities. During World War II the 1887 bell cracked, and could not be repaired. In 1983 the old Schomberg bell from the Woodford church was loaned to Flagstaff Hill Maritime Museum and Village. When the Schomberg was launched in 1855, she was considered the "Noblest” ship that ever floated on the water. Schomberg's owners, the Black Ball Line had commissioned the ship for their fleet of passenger liners. She was built by Alexander Hall of Aberdeen at a cost of £43,103 and constructed with 3 skins. One planked fore and aft and two diagonally planked, fastened together with screw-threaded trunnels (wooden rails). Her First Class accommodation was simply luxurious with velvet pile carpets, large mirrors, rosewood, birds-eye maple and mahogany timbers throughout, soft furnishings of satin damask, and an oak-lined library with a piano. Overall she had accommodation for 1000 passengers. At the launch, the Schomberg's 34-year-old master, Captain 'Bully' Forbes, had promised to reach Melbourne in sixty days stating, "with or without the help of God." Captain James Nicol Forbes was born in Aberdeen in 1821 and rose to fame with his record-breaking voyages on the famous Black Ball Line ships; Marco Polo and Lightning. In 1852 in the ship Marco Polo, he made the record passage from London to Melbourne in 68 days. Unfortunately, there were 53 deaths on the voyage, but the great news was off the record passage by Captain Forbes. In 1854 he took the clipper “Lighting” to Melbourne in 76 days and back in 63 days, this record was never beaten by a sailing ship. He often drove his crew and ship to breaking point to beat his previous records. He cared little for the comfort of the passengers. On this, Schomberg's maiden voyage, he was determined to break existing records. Schomberg departed Liverpool on her maiden voyage on 6th October 1855 flying a sign that read "Sixty Days to Melbourne". She departed with 430 passengers and 3000 tons of cargo including iron rails and equipment intended to build the Melbourne to Geelong Railway and a bridge over the Yarra from Melbourne to Hawthorn. She also carried a cow for fresh milk, pens for fowls and pigs, and 90,000 gallons of water for washing and drinking. She also carried 17,000 letters and 31,800 newspapers. The ship and cargo were insured for $300,000 a fortune for the time. The winds were poor as she sailed across the equator, slowing Schomberg's journey considerably. The land was first sighted on Christmas Day, at Cape Bridgewater near Portland, Captain Forbes followed the coastline towards Melbourne. Forbes was said to be playing cards when called by the third mate Henry Keen, who reported land about 3 miles off. Due in large part to the captain's regarding a card game as more important than his ship, it eventually ran aground on a sand spit near Curdie's Inlet (about 56 km west of Cape Otway) on 26th December 1855, 78 days after leaving Liverpool. The sand spit and the currents were not marked on Forbes's map. Overnight, the crew launched a lifeboat to find a safe place to land the ship’s passengers. The scouting party returned to Schomberg and advised Forbes that it was best to wait until morning because the rough seas could easily overturn the small lifeboats. The ship’s Chief Officer spotted the SS Queen at dawn and signalled the steamer. The master of the Queen approached the stranded vessel and all of Schomberg’s passengers and crew disembarked safely. The Black Ball Line's Melbourne agent sent a steamer to retrieve the passengers' baggage from the Schomberg. Other steamers helped unload her cargo until the weather changed and prevented the salvage teams from accessing the ship. Later one plunderer found a case of Wellington boots, but alas, all were for the left foot. Local merchants Manifold & Bostock bought the wreck and cargo but did not attempt to salvage the cargo still on board the ship. They eventually sold it on to a Melbourne businessman and two seafarers. In 1864 after two of the men drowned when they tried to reach Schomberg, salvage efforts were abandoned. In 1870, nearly 15 years after the wreck parts of the Schomberg had washed ashore on the south island of New Zealand. The wreck now lies in 825 meters of water and although the woodwork is mostly disintegrated the shape of the ship can still be determined due to the remaining railway irons, girders and the ship’s frame. A variety of goods and materials can be seen scattered about nearby.The bell is particularly significant in that along with other items from the wreck helped in part to having the legislation changed to protect shipwrecks, with far tighter controls being employed to oversee the salvaging of wreck sites. This bell forms part of the Schomberg collection at Flagstaff Hill maritime museum. The collection as a whole is of historical and archaeological significance at a State level. Flagstaff Hill’s collection of artefacts from the Schomberg is also significant for its association with the Victorian Heritage Registered Schomberg shipwreck (VHR S 612). The collection is of additional significance because of the relationship between the objects salvaged, as together they help us to interpret the story of the Schomberg. The collection as a whole is historically significant for representing aspects of Victoria's maritime history and its potential to interpret social and historical themes from society at the time of the wreck. A small ship’s bell. The bell bears the ship’s name and year of construction on one side and the name and address of the ship’s builders on the other. These details are deeply engraved into the metal and formed in bold upper-case lettering. The bell has two bell stands, a left and a right side. Both stands have an Iron pipe made into an inverted ‘Y’ shape with a hole made in the single length, and feet attached to a rectangular metal plate at the other two ends. Feet are bolted into a timber base that has a hole drilled through the centre for mounting. Bell's front; “SCHOMBERG” with “1855” below. Bell's back “HALL & SONS (crack splits letter “N”) / BUILDERS (in italics) / ABERDEEN” (crack splits letter “B”).flagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, schomberg, silver plated bell, mess bell, bell stands, captain ‘bully’ forbes, alexander hall and son, james baines and company, liverpool’s black ball line, bell, schomberg bell, ship's bell, small bell, st joseph's church, briggs marine -

Federation University Historical Collection

Federation University Historical CollectionBooklet, The School of Mines Ballaarat: Descriptive papers relating to the institution by the special reporter of "The Ballarat Star", 1875 (exact)

The booklet comprises of a series of papers published in the Ballarat Star, with some revisions. The Administrative Council hoped the publication would increase interest in Technical Education, especially the Art of Mining. He would also hope the public would recognise the Ballarat School of Mines as an institution adapted to supply technical education. The Ballarat School of Mines Council listed at the front of the book includes: Redmond Barry (President and Trustee), Judge Rogers (Vice-President), Somerville Livingstone Learmonth (Trustee), Rivett Henry Bland (Trustee), Charles Gavan Duffy, John A. MacPherson (MLA), William McLellan (MLA), Duncan Gillies (MLA), F. McCoy (University of Melbourne), John I. Bleasdale, W.H. Barnard, James M. Bickett, Henry Richards Caselli, P. Chauncy, J.M. Davey, Joseph Flude, R.F. Hudson, Robert Lewis, James Oddie, Robert M. Serjeant, J. F. Usher, John Walker, J. Williamson, Mayor of the City of Ballaarat, chairman (for the time being) of each of the seven Mining Boards of Victoria. The President of Examiners was Judge Rogers, and the Honorary Auditor was Richard Ford.Stapled, brown soft covered booklet of 48 pages. Section I outlines the establishment of the Ballarat School of Mines, the buildings and land used by the school, describes in detail the former Ballarat Circuit Court and describes the lecture rooms. Section II describes the Ballarat School of Mines Museum, including a description of exhibits. Section III describes the lecture hall, and the apartments on either side of the hall, including the office of the registrar W.H. Barnard, mathematical classroom, chemical laboratory, and metallurgical laboratory. Section IV outlines the subjects offered by the Ballarat School of Mines, including Mathematics taught by John Victor of Grenville College, who had been educated at Trinity College Dublin. Mining and Land Surveying was taught by C.W. Thomas. Mr Croll taught mechanical drawing, followed by Jonathan Robinson of the Union Foundry, and finally S. Keast. It then lists some text books used in the school. Section V mentions the School Council, lack of funds, future directions, mining laboratory. Vi- Describes the land and out buildings, and the proposed building for metal and wood turning, brass foundry, blacksmith, working engine, etc. This section describes some large donations to the school - 50 pounds from the Misses Meglin of Melbourne, 10 pounds 10 shillings to the 'Pyrites fund' by the Walhalla and Long Tunnel Companies in Gippsland. Section VII covers the teaching of chemistry by Joseph Flude. Section VIII outlines the metallurgy classes and the process of assaying. Section IX covers telegraphy taught by Mr Bechervaise Section X describes the examination process at the Ballarat School of Mines. Examiners in mathematics were G.J. Russell (Buninyong) and John Lynch (Smythesdale), mining and land surveying John Lynch and P.C. Fitzpatrick (Ballarat), Principles and Practice of Mining R.M. Serjeant (Band and Albion Consols), Mechanical Engineering John Lewis (New North Company Clunes, Mineralogy and Geology G.H. F. Ulrich, Assayign and Chemistry J. Cosmo Newberry, and Telegraphy R.L.J. Ellery (government astronomer) and Sam W. Macgowan. Underground managers and captains in quart mining was examined by Henry Rosales (Walhalla Company), and alluvial mines by Messrs Bockett, Kent, Martin and Mitchell. Engineers and Engine driving was examined by W.H. Keast,Peter Matthews, Jonathan Robinson and J.M. Troup. Section XI - Covers Annual reports of the school, and honorary correspondents of the school including: John Day (Geelong); R. Evan Day (London); W.W. Evans, M.J.C.E. of New York; J.Y. Fishburne, M.B. of Ararat; Felice Giordano, Inspector of Mines, Italy; Julius Von Haast, Ph. D.F.R.S., Government Geologist of Canterbury; James Hector, M.D., F.R.S., Government Geologist of Wellington, New Zealand, W.F. Hopkins (Grant); Charles A. La Trobe, C.E. (Engineer-in-Chief International Railway Plant, London); Archibald Liversidge, F.G.S. (Professor of Mineralogy and Reader in geology at Sydney University; J.J. Macgregor, M.D. (Creswick); J.T. McKenna (1st class of SMB underground management - Northern Territory); Henry Rosales, M.E. and M. (Walhalla); Harrie Wood (SMB founder and Under-secretary for Mines, Sydney); John Walthew (Stockport, England) .2) Signed 'E.J. Tippett', former President of the Ballarat School of Mines Council melbourne, mla, ballarat school of mines, redmond barry, j f usher, james bickett, w f hopkins, rivett henry bland, s m b, judge rogers, somerville learmonth, charles gavan duffy, gavan duffy, john macpherson, william mclellan, duncan gillies, f mccoy, university, john bleasdale, henry richards caselli, henry caselli, p chauncy, j m davey, joseph flude, r f hudson, robert lewis, james oddie, robert m serjeant, john walker, j williamson, richard ford, ballarat court house, assay, john victor, grenville college, trinity college dublin, c w thomas, jonathan robinson, union foundry, s keast, blessdale, john day, r evan day, w w evans, j y fishburne, felice giordano, julius von haast, james hector, charles a la, trobe, archibald liversidge, j j macgregor, j t mckenna, henry rosales, harrie wood, john walthew, fees, frederick mccoy, w.h. barnard -

Ballarat Tramway Museum

Ballarat Tramway MuseumSlide - 35mm slide/s, Noel Simons, 21/11/1962 12:00:00 AM

Set of 17 transparencies taken on 21/11/1962 on Kodak mounts. 1188.1 - Bendigo No. 11 at Depot Junction McCrae and Arnold St. with driver/conductor changing points. 1188.2 - Bendigo No. 4 at Charing Cross, side on photo, with City Club Hotel and Alexandra Fountain in the background. Tram has Castrol and SEC 'Electric Cooking' ads. 1188.3 - Bendigo No. 4 climbing View St. after tram has passed photographer. Tram has Streets Ice Cream and Cohns Soft Drinks ad on rear dash panel. In the background are the buildings in View St., including the Princess Theatre. Tram has destination of Eaglehawk. 1188.4 - Trams 2 and 4 crossing at the California Gully or Thorpe St Loop. 1188.5 - Bendigo 4 in Mt Korong Road. Tram inbound with destination of Quarry Hill, just leaving Garden Gully Loop. 1188.6 - Bendigo 4 and 17 crossing at the Hayes St. or Iron Bark Gully Loop. No. 17 bound for Eaglehawk, No. 4, Quarry Hill. 17 has two SEC roof ads and a white horse whiskey ad. 1188.7 - No. 17 bound for Eaglehawk, soon after leaving California Gully. Has large mullock heap in background. 1188.8 - Bendigo 2 and 17 crossing at the Thorpe St. or California Gully Loop. Has butchers shop in background. 1188.9 - Bendigo 17 at the Eaglehawk terminus. Has destination of Quarry Hill. In background is the hotel and shops at the terminus, showing ads for "Melbourne Bitter". Tram has two SEC 'Electric Cooking' ads. Driver and conductor about to assist two lady passengers with a pram and baby. 1188.10 - No. 17 at Eaglehawk terminus, awaiting departure. Has Eaglehawk Town Hall and Post Office in background. Tram has a Whitehorse Whiskey ad on the front dash panel. 1188.11 - No. 3 in High St. Eaglehawk, with destination of Eaglehawk. Has the shops on the south side of High St. in the background, including the Eaglehawk fish shop. Tram has two roof ads, one an SEC roof ad, and Cohns Drinks and Streets Ice cream ads on front dash panel. 1188.12 - as above, but after tram has passed photographer. Note the centre of the road poles. 1188.13 - No. 2 outbound for Eaglehawk at the intersection of Mt. Korong Road and the Calder Highway. Photo taken after the tram has passed the photographer. Has an Ampol service station in the background. 1188.14 - No. 11 leaving the Bendigo depot, crossing the bridge, with the Scrubber car in the background. 1188.15 - No. 21 at the North Bendigo terminus. Tram has destination of Golden Square and Cohns drink ad on front dash and two roof ads on side. 1188.16 - No. 11 on Golden Square route, in High St. at intersection with Old High St. 1188.17 - No. 11 at the Golden Square terminus, conductor turning the pole. Hotel on the left side of the photo. Note the road works barrier and red flag behind the tram. Slide has an end of roll mark on the right hand side of the image.Information written on in black ink and date stamped on purple ink. 1188.1 - "Birney car No. 11 in McCrae St. at Cnr of Arnold about to run into depot, Bendigo" 1188.2 - "No. 4 at Alexandra Fountain, Charing Cross Bendigo" 1188.3 - "No. 4 climbing the View St. Hill from Charing Cross, Bendigo (Eaglehawk Route)" 1188.4 - "No. 4 and 2 at Thorpe St. Loop, California Gully" 1188.5 - "No. 4 in Mt Korong Rd., Long Gully, Near Havilah Rd. (Bendigo) (Eaglehawk Route)" 1188.6 - "Nos. 17 and 4 crossing on Hayes St. Loop, Ironbark, Bendigo" 1188.7 - "No. 17 soon after leaving California Gully (Eaglehawk Route)" 1188.8 - "No.2 and 17 crossing on Thorpe St. Loop, California Gully (Eaglehawk Route)" 1188.9 - "No. 17 at Eaglehawk terminus" 1188.10 - "No. 17 at Eaglehawk terminus" 1188.11 - "No. 3 in High St. Eaglehawk" 1188.12 - "No. 3 nearing Eaglehawk terminus" 1188.13 - "No. 2 in Mt. Korong Rd., Ironbark. Calder highway on left (Eaglehawk route) 1188.14 - "Birney car No. 11 leaving Bendigo depot. Scrubber car at rear" 1188.15 - "No. 21 at North Bendigo Terminus" 1188.16 - "Birney car No. 11 in High St. Bendigo at intersection with Old High Street (Golden Square Route)" 1188.17 - "Birney Car No. 11 at Golden Square terminus, High St., Bendigo". tramways, trams, bendigo, depot junction, charing cross, view st., eaglehawk, north bendigo, golden square, tram 2, tram 3, tram 4, tram 11, tram 17, tram 21, tram scrubber -

Flagstaff Hill Maritime Museum and Village

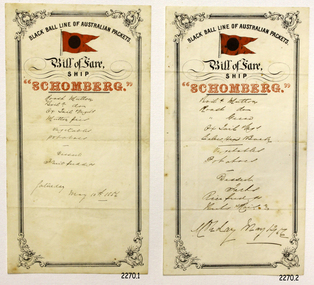

Flagstaff Hill Maritime Museum and VillageDocument - Menu, Bill of Fare ship Schomberg, circa 1855 - May 12 1856

A “Bill of Fare” is a menu or list of food offered for a meal. This Bill of Fare from the sailing ship Schomberg is handwritten in pen in hard-to-read script on the printed pages specifically for the Schomberg ship, of the Black Ball Line of Australian Packets. (‘Packets’ were vessels that had a regular trade run of cargo, passengers and mail; the sailing ship Schomberg was designed for long voyages between England and Australia.) These menus posed a puzzle as they have the handwritten dates of, May 10 and 12, 1856, by which time the Schomberg had sunk (she sunk on December 26, 1855). The donor of these pages of Bill of Fare is a stamp collector from Melbourne. He came across the menus in a package that he bought in 1980 at a stamp auction in Tasmania. He decided to give the menus to Flagstaff Hill this year during his annual family holiday in Warrnambool. A 1981 newspaper article about this donation included an interview with Flagstaff Hill’s curator Mr Peter Ronald, who said that the stationery of these menus is genuine. He went on to say that there would have been much stationery printed for use on the Schomberg although she sank on her maiden voyage. These menus could have been written at a dated late because the surplus Schomberg stationery could have been used for menus on other ships. We will probably never be sure of the answer but none-the-less the pages are still connected to the Schomberg. Below is what we believe the menu consists of although some of the writing is indecipherable - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - (first menu) Roast Mutton Boiled Mutton? Ox Tail Mulligatawny? Or possibly Ox Tail Vegetables? Mutton Pies? ------------------------------- Vegetables Potatoes ---------------------------------- Dessert Fruit Puddings? Saturday May 10, 1856 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - AND - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - (second menu) Boiled Mutton Roast Mutton? Roast Geese? Ox Tail?? Calves Head Broth? ------------------------------- Vegetables Potatoes ------------------------------- Dessert Tarts? Rice Pudding? ?...Maids?? Monday May 12, 1856 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - Background of “SCHOMBERG” When SCHOMBERG was launched in July, 1855, she was considered the “Noblest ship that ever floated on water.” SCHOMBERG’s owners, the Black Ball Line (one of three companies by that name), commissioned the ship for their fleet of passenger liners. She was built by Alexander Hall of Aberdeen, UK at a cost of £43,103. She was constructed with 3 skins: one planked fore and aft, and two diagonally planked, fastened together with screw threaded trunnels (wooden rails). Her first class accommodation was luxurious: velvet pile carpets; large mirrors; rosewood; birds-eye maple; mahogany; soft furnishings of gold satin damask; an oak-lined library; and a piano. Overall she had accommodation for 1000 passengers. SCHOMBERG’s 34 year old master, Captain James ‘Bully’ Forbes, had promised Melbourne in 60 days at the launch, "with or without the help of God." James Nicol Forbes was born in Aberdeen in 1821 and rose to fame with his record-breaking voyages on the famous Black Ball Line ships MARCO POLO and LIGHTNING. In 1852 in the MARCO POLO he made the record passage from London to Melbourne in 68 days. There were 53 deaths on the voyage but the great news was of the record passage by the master. In 1954 Captain Forbes took the clipper LIGHTNING to Melbourne in 76 days and back in 63 days, this was never beaten by a sailing ship. He often drove his crew and ship to breaking point to beat his own records. He cared little for the comfort of the passengers. On this, the SCHOMBERG’s maiden voyage, he was going to break records. SCHOMBERG departed Liverpool on her maiden voyage on 6 October 1855 flying the sign “Sixty Days to Melbourne”. She departed with 430 passengers and 3000 tons cargo including iron rails and equipment intended to build the Melbourne to Geelong Railway as well as a bridge over the Yarra from Melbourne to Hawthorn. She also carried a cow for fresh milk, pens for fowls and pigs, and 90,000 gallons of water for washing and drinking. SCHOMBERG also carried 17,000 letters and 31,800 newspapers. The ship and cargo was insured for $300,000, a fortune for the time. The winds were poor as she sailed across the equator, slowing SCHOMBERG’s journey considerably. Land was first sighted on Christmas Day, at Cape Bridgewater near Portland, and Captain Forbes followed the coastline towards Melbourne. Forbes was said to be playing cards when called by the Third Mate Henry Keen, who reported land about 3 miles off. Due in large part to Forbes regarding a card game as more important than his ship, SCHOMBERG eventually ran aground on a sand spit near Curdie's Inlet (about 56 km west of Cape Otway) on 26 December 1855, 78 days after leaving Liverpool. The sand spit and the currents were not marked on Forbes’s map. Overnight, the crew launched a lifeboat to find a safe place to land the ship’s passengers. The scouting party returned to SCHOMBERG and advised Forbes that it was best to wait until morning because the rough seas could easily overturn the small lifeboats. The ship’s Chief Officer spotted the steamer SS QUEEN at dawn and signalled it. The master of the SS QUEEN approached the stranded vessel and all of SCHOMBERG’s passengers and crew were able to disembark safely. The SCHOMBERG was lost and with her, Forbes’ reputation. The Black Ball Line’s Melbourne agent sent a steamer to retrieve the passengers’ baggage from the SCHOMBERG. Other steamers helped unload her cargo until the weather changed and prevented the salvage teams from accessing the ship. Later one plunderer found a case of Wellington boots, but alas, all were for the left foot! Local merchants Manifold & Bostock bought the wreck and cargo, but did not attempt to salvage the cargo still on board the ship. They eventually sold it on to a Melbourne businessman and two seafarers. In 1864 salvage efforts were abandoned after two men drowned when they tried to reach SCHOMBERG. Parts of the SCHOMBERG were washed ashore on the south island of New Zealand in 1870, nearly 15 years after the wreck. The wreck of the SCHOMBERG lies in 825 metres of water. Although the woodwork is mostly disintegrated, the shape of the ship can still be seen due to the remaining railway irons, girders and the ship’s frame. A variety of goods and materials can be seen surrounding the wreck, by divers. Flagstaff Hill holds many items salvaged from the SCHOMBERG including a ciborium (in which a diamond ring was concealed in concretion), communion set, ship fittings and equipment, personal effects, a lithograph, tickets and photograph from the SCHOMBERG. These Bills of Fare are significant due to their connection to Flagstaff Hill’s collection of artefacts from the Schomberg, which is significant for its association with the Victorian Heritage Registered shipwreck S612. The collection is primarily significant because of the relationship between the objects, as together they have a high potential to interpret the story of the Schomberg. The Schomberg collection is archaeologically significant as the remains of an international passenger ship. The shipwreck collection is historically significant for representing aspects of Victoria’s shipping history and its potential to interpret sub-theme 1.5 of Victoria’s Framework of Historical Themes (living with natural processes). The collection is also historically significant for its association with the shipwreck and the ship, which was designed to be fastest and most luxurious of its day. The Schomberg collection meets the following criteria for assessment: Criterion A: Importance to the course, or pattern, of Victoria’s cultural history. Criterion B: Possession of uncommon, rare or endangered aspects of Victoria’s cultural history. Criterion C: Potential to yield information that will contribute to an understanding of Victoria’s cultural history. Menu, or Bill of Fare, on cream coloured stationery from the sailing vessel “Schomberg”. Two rectangular pieces of paper, each bears the printed words “Black Ball Line of Australian Packets, Bill of Fare, Ship, Schomberg”, a printed symbol of the Black Ball line (a black ball on a red flag) and a decorative border. Both pages are handwritten, in similar but different sized writing, with a Bill of Fare and a date, Page (1) dated May 10th 1856 and (2) dated May 12th ’56, (Both dates are AFTER the Schomberg sank in December 26th 1855.) Both pages have three fold lines spaced across their width. To be used for the return voyage.Printed on the pages ““BLACK BALL LINE OF AUSTRALIAN PACKETS.” “Bill of Fare, / SHIP / “SCHOMBERG”.” Handwritten list of food, and on one page “Saturday May 10 1856” and on the other page “Monday May 12” warrnambool, peterborough, shipwrecked coast, shipwreck coast, flagstaff hill maritime museum, flagstaff hill maritime village, maritime museum, great ocean road, flagstaff hill, sailing ship schomberg, shipwreck schomberg, black ball line of australian packets, bill of fare schomberg, menu schomberg 1856, food mid-1800’s, food on ships mid-1800’s, menu, may 10, 1856, may 12, 1856 -

Melton City Libraries

Melton City LibrariesPhotograph, Mrs Knox and Beryl Gillespie at the First Hundred Years Celebration of Melton State School 430, 1970

Beryl Knox speaking about early life in Melton. Page 1 1949 – 64 years ago. We began our married life at Melton Sth. The house on the corner of the Exford Rd and Staughton St-- dusty gravel roads, box thorns and noxious weeds everywhere and a sprinkling of houses and vacant land. It was a friendly community consisting of old family names. McDonalds, Blacks, Dodemaide, Cahill, Coopers, Minns, Tinklers, Nesbitts, Cochranes, Wickhams, Exells. Mavis Butler. The home owned by Mr. Robinson and Miss Robinson had been shifted in two parts transported from Diggers Rest and it is still standing 2013. Bruce’s father purchased the house and two adjoining blocks, the Conways built on one and the Rawlinson family on the other block. Eileen still resides there, she was only a baby in a pram and the family had not long arrived from England. The railway line was close to the house and the contents would rattle when heavy steams trains went through, and on a clear frosty night the 1am paper train would echo roar through very loudly when labouring towards the Exford Bridge. Then the two carriage motor train was introduced, this was great for the workers and schoolies who travelled to Melbourne. The train pulled up at the crossing or riding to pick up or drop off. Melva Gillespie (nee Hirt) Bill Cahill delivered the milk by the billy and then in bottles. Len Kennedy (Paul Kennedy’s father, Norma Murrays son) delivered Jongebloeds bread, he always had a sweep going for the Melbourne Cup and raffles for the footy club. Mr. Woodgate owned an old bus and pick up point was the Post Office when there was a Saturday film on a Melton. There were no doctors or dentists in the district. If we need a Doctor we had to travel to Bacchus Marsh or discuss problems over the phone. In later years a Bacchus Marsh Doctor rented the Bluestone building in McKenzie St a couple of days a week. If we needed the Dentist we had to travel to West Footscray or Footscray. We did our banking at “State Savings” then the Miss Minns had the agency and then Bardsleys Store. We travelled to Bacchus Marsh to the National and Commercial banks. Station Rd to Western Highway, now (High Street) was a narrow stretch of bitumen and gravel farmland either side and a couple of farm houses and large gum trees on the properties. Page 2 North of the Railway line Mrs Bessie Jones, mother of Chas and Betty Jones managed the Post Office, next door to her Chas and Betty had the Shell Centre, and later moved the business to Melton. Hughie Nesbitt and mother owned the grocery and hardware store, and I bought my first set of saucepans there. On the opposite side of Station road Mr Coombe owned the fruit shop, and also provided soft drinks and lollies for children. The Chaff Mill was on the corner of Station Rd and Brooklyn Rd. Mr Lumsden was manager and later years Bernie Trethowan and Jack Butler were partners. It finally burnt down and is a Service Station now. Along Brooklyn Rd there were a few houses and Victoria Hall, not a very big hall, but catered for lots of functions, Balls, Fancy Dress, Bazaars, Square Dancing and meetings. The Bacchus Marsh Baptists held Sunday School in the hall. A group of shops were built south of the railway line Molly and Len Skinner managed the Post Office and handled a few essential groceries. Tom McDonald and Ron Lunsberg were the butchers. Mary and Syd Cooper lived next door to us and often in turn would run out of something when we had a baking spree we would borrow or exchange, sugar flour etc over the fence. Mavis and Jack Butler lived there before the Coopers. Bernie and Iris Trethowan lived two doors up. Neighbours were invited into their home to view the first black and white television in Melton Sth. Bill Exell was one of the first Melton Sth farmers to sell his land to developers, the land was idle for years before housing developed. I joined the Melton Valley Golf Club in 1960. The Gun Club as our Club House, an old tin shed consisting a water tank, trestle table and forms and dirt floor. It was a 9 hole course with sand scraps and landscape putting before greens. The Common or parkland was part of the Golf Course. It was open for every ones recreation. Roy Norton an old identity trained his trotters on the Common and wouldn’t clear the track for the golfers. The golfers had to avoid him to continue to play. We had to keep clear when the young youths came in their paddock cars and motorbikes. Over the years the Toolern Creek flooded its banks, water and debri covered the course on one year our first Club house was flooded out. It took several working bees to clean it up. We lived at Melton Sth for 15 years and moved to Melton on the farm “Croxton Park.” The Nixon family farm “Mowbray” adjoined the farm. Bruce worked the land cropping the farm when Mrs Nixon died. Page 3 (page 4 on the handwritten script) Bruce had the first offer to buy, in those days it wasn’t easy to get good bank loans. Part of the land is the Golf Course now and Mr O’Shea purchased the bulk. Moving to Melton was totally different – I became involved with Committees, Scouts, Guides, Mothers Clubs, CWA, Church Op shop (8 years). Melton Amateurs players produced and tutored by Mabel Rogers exerts from Pyjama Game, South Pacific, Carousel - later years a group of ladies did gentle water exercise at Essendon and Station Road swimming pool. I was 20 or so years in Probus. The local followed the football, there was always a Gymkhana on the long weekend in June. The tennis always created a lot of interest during the finals. It didn’t matter which team played the supporters were treated to a cup of tea and leftovers from their afternoon tea. In 1978 were the first residents to move into the Jennings Estate Kurunjang and lived there 31 years and retired 4 years ago into Unit. The amazing changes I have experienced. Merrimu supplied our water, after depending on tanks. The landscape changed completely when developers came in, no more dusty plains \ typed web Sept 2013 McFarlane, Mrs Knox and Beryl Gillespie at the First Hundred Years Celebration of Melton State School 430. The event was held at Mechanics Hall, Melton.local identities, local significant events, education -

Eltham District Historical Society Inc

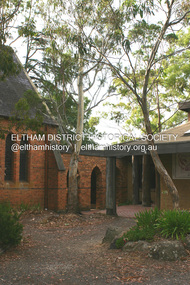

Eltham District Historical Society IncPhotograph - Digital Photograph, Alan King, St Margaret's Anglican Church, Pitt Street, Eltham, 30 January 2008