Showing 1081 items matching "commercial -- australia"

-

Latrobe Regional Gallery

Latrobe Regional GalleryPrint, HENG, Euan b. 1945 Scotland. Arrived Australia 1977, Night Time, 2004

LinocutSigned and dated 'Euan L Heng 04' in lower right under printed image. Title 'Night time' under printed image. Edition 11/25, numbered lower left corner under printed image. -

Latrobe Regional Gallery

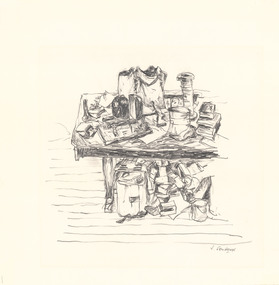

Latrobe Regional GalleryDrawing, SENBERGS, Jan b.1939 Riga, Latvia. Arrived Australia 1950, Untitled, Not dated

Pencil on paperSigned lower right corner beneath drawing, pencil "J.SENBERGES". Not dated. -

Latrobe Regional Gallery

Latrobe Regional GalleryGlass, CLEMENTS, Richard b. 1950 England arr. Australia 1971, Amber perfume bottle with stopper, Not dated

Blown and fused glassEmbossed stamp 'R' (encircled) on lower part towards base. Not dated. -

Latrobe Regional Gallery

Latrobe Regional GalleryPainting, HENG, Euan b. 1945 Scotland. Arrived Australia 1977, Jeeralang Still Life I, 1985

Oil on canvasSigned and dated on reverse top left "Euan L Heng 85" -

![Sculpture, GUNN, Mandy arr. Australia 1966, [W]RAPT, 2012-2013](/media/collectors/510b3f7f023fd725b4cd52a0/items/5faa11d96d17f126301ddb2f/item-media/5faa11ea6d17f126301ddbec/item-fit-380x285.jpg) Latrobe Regional Gallery

Latrobe Regional GallerySculpture, GUNN, Mandy arr. Australia 1966, [W]RAPT, 2012-2013

Recycled paper shopping bags and wrappings on cardboard construction -

Latrobe Regional Gallery

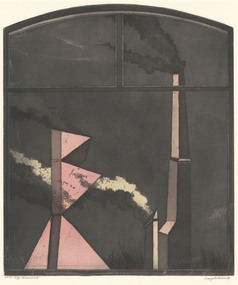

Latrobe Regional GalleryWork on paper, BALDESSIN, George b. 1939, Italy. arr. Australia 1949. d. 1979, Window and factory smoke, 1971

Etching on aluminium foilSigned and dated lower right corner beneath printed image "George Baldessin 71" Edition and title in lower left corner below printed image "Edition 25 'window & factory smoke'" -

Latrobe Regional Gallery

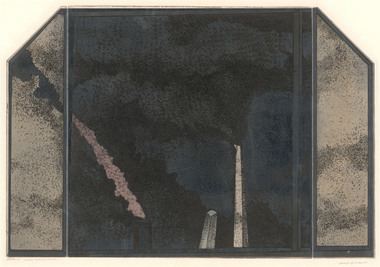

Latrobe Regional GalleryWork on paper - Print, BALDESSIN, George b. 1939, Italy. arr. Australia 1949. d. 1979, City Monuments, 1967

EtchingSigned and dated lower right corner below printed image, "George Baldessin 67" Edition and title "Ed 25 'City Monuments" lower left corner under printed image -

Latrobe Regional Gallery

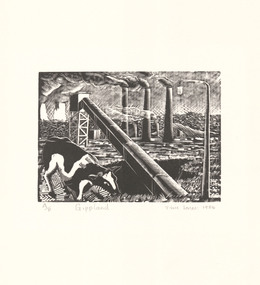

Latrobe Regional GalleryWork on paper - Print, JONES, Timothy b. 1962 North Wales, arr. Australia 1984, Gippsland, 1985

Wood engravingSigned and dated bottom right beneath printed image, "Jones 85" Edition and title in lower left corner "A/P Gibsland" -

Latrobe Regional Gallery

Latrobe Regional GalleryWork on paper - Print, JONES, Timothy b. 1962 North Wales, arr. Australia 1984, Gippland (sic), 1984

Wood engravingSigned and dated lower right corner below printed image "Tim Jones 1984". Edition and title to the lower left below composition, A/P "Gippland" -

National Wool Museum

National Wool MuseumClothing - 1984 Los Angeles Olympics Men's Opening Ceremony Shirt, c. 1984

On the 1984 Los Angeles Olympic Uniforms donator Doug wrote- During the 1980s the Australian wool industry was at its most prosperous times with record numbers of sheep producing wool receiving ever increasing values due to the success of the Reserve Price Scheme, and the overall guidance of the Australian Wool Corporation (AWC). As a humble technician, my role was a low profile newly created position of “Controller, Technical Marketing” where wool was to be marketed on its technical properties, as distinct from the “Product Marketing Group” which exploited trhe traditional high profile approach of marketing wool;s superior fashion attributes. The Woolmark was the tool central to this approach. When the forthcoming Los Angeles Olympic Games was announced, the Product Marketing Group seized upon the chance to show the world that we could make top fashion garments and display them on our elite athletes on the world stage. A concept was launched using a contemporary top designer, Adel Weiss, with the most exclusive fabrics and knits available, and all with a lot of hype. This launch failed dismally for the following reasons- - The designer did a wonderful job presenting an excellent fashion range on perfect skinny models. The AOC however wanted a uniform which had an obvious Australian appearance when fitted to elite, and frequently muscular, athletes. - The fabrics chosen did not reflect the performance required by travelling athletes, there was no recognition of the need for ‘easy care.’ - There was no recognition given to the problem of measuring, manufacturing and distribution of a range of articles when the selected athlete could be domiciled anywhere in Australia. - There was no appreciation of such historical facts as Fletcher Jones, who had been unofficial suppliers dating back to the 1954 Olympics in Melbourne, and the Fletcher Jones board member, who was also an AWC board member, and was not in favour of the change. The project passed from Product Marketing to Public Relations, a big spending off-shoot of the AWC Chairman David Asimus, and due to the day to day operations of the project was passed to me and PR took care of the financial matters. The first task was to meet with the AOC and find out exactly their requirements. This lead to the production of a design and manufacturing brief, cointaining exact time lines for each event required to ensure an appropriate uniform on every athlete chosen to represent his/her country on the date given for the Opening Ceremony in Los Angeles. Working backwards the timeline becomes- 1. Noted the exact date of the Opening Ceremony. 2. Estimated the date for distributing completed garments to each athlete. 3. Estimated the time span available for measuring each athlete and commence making each component of the ensemble to the individual measurements of each athlete. 4. Decided the date for making the final choice of uniform design concept. 5. Decided the date for distribution of the design brief to selected designers. These five steps were spread out over a two year period. The Commonwealth Games occur midway between each Olympic Games, work on the Olympic uniform commences the week after the Commonwealth Games closing ceremony and MUST be ready by the prescribed day two years hence. The project also had to remain cognisant of trade politics existing within the span of the task, as well as the temperament of designers in general. It is no overstatement to say that in the past every designer in Australia believed they could, and should, be chosen to design the Australian Uniform. The final choice of designer almost always faced criticism from the fashion press and any designer who had been overlooked. However, with the contenders receiving an exacting brief the numbers of serious contenders greatly reduced. The Los Angeles Olympic Uniforms. A further reason for the AWC bid failure to design the LA uniform was that the AOC had already chosen Prue Acton to design it. This was based on her proven performance during previous games as she had a talent for creating good taste Australiana. Her design concepts also considered the effect when they were viewed on a single athlete as well as the impact when viewed on a 400 strong team coming on to the arena. A blazer trouser/skirt uniform in bright gold was chosen for the formal uniform. It was my task to select a pure wool faille fabric from Foster Valley weaving mill and have sufficient woven and ready within the prescribed timeline. The trouser/skirt fabric selected was a 60/40 wool polyester plain weave fabric from Macquarie Worsted. This fabric had a small effect thread of linen that was most attractive when dyed to match some eucalyptus bark Prue had brought back from central Australia. For the Opening Ceremony uniform, Prue designed a series of native fauna, a kookaburra for the men’s shirt and a pleated skirt with a rural scene of kangaroos, hills and plants. This presented an insurmountable printing challenge to the local printing industry as it had an unacceptably large repeat size and the number required (50) was also commercially unacceptable. The solution was a DIY mock up at RMIT and the employment of four student designers. The fabric selected for this garment was a light weight 19 micron, pure wool with a very high twist yarn in alternating S and Z twist, warp and weft. This fabric proved to be the solution to a very difficult problem, finding a wool product which is universally acceptable when worn next to the sin by young athletes competing in the heat of a Los Angeles summer. Modifications to this fabric were developed to exploit its success when facing the same problem in future games. Garment Making- The most exacting garment in the ensemble is the tailored blazer, plus the related trouser/skirt. Unfortunately tailoring athletes that come in various shapes and sizes such as; - Weight lifters develop an enormous chest, arms and neck size. A shirt made to a neck size of 52 would produce a shirt with cuffs extending well beyond the wearer’s hands. - Basketball players are up to 7 feet tall and garments relying ona chest measurement grading would produce a shirt with cuffs extending only to elbow length. - Swimmers develop enormous shoulders and slim hips, cyclists by contrast develop thighs I liken to tree trunks and a uniform featuring tight trousers must be avoided at all cost. Suffice to say many ensembles require specialist ‘one off’ treatment for many athletes. Meanwhile there is a comfortable in between group who can accept regular sizes so you can cater for these by having back up stock with plenty of built in contingencies. Athletes may be domiciled anywhere in Australia, this creates a fundamental problem of taking their measurements. The Fletcher Jones organisation was key to answering this problem due to their presence in every capital city, as well as many provincial towns around Australia. Each athlete on being selected for the Olympic Team was simultaneously requested to visit their nearest Fletcher Jones shop. The standardised measurement data collected was shared with the other manufacturers, e.g. Pelaco Shirts, Holeproof Socks and Knitwear, Maddison Belts, and even Hush Puppy Shoes. As the time for the Games approached the AOC made arrangements for combining meeting of all. Selected available athletes at the Australian Institute of Sport, Canberra, where, among other things, they were fitted and supplied with their uniform. The method evolved as follows.Men’s cream coloured button up, collared shirt. Images of a kookaburra have been printed onto the shirt, a single kookaburra on the left breast and a pair of kookaburras on the reverse of the shirt. The kookaburras are printed in a brown tone to complement the cream colour of the fabric.On tag - FMaustralian wool corporation, 1984 los angeles olympics, olympic uniforms, men's uniforms, sport, athletes -

National Wool Museum

National Wool MuseumClothing - 1988 Seoul Olympics women's scarf, c. 1988

The conduct of the LA games changed many factors in a short space of time. The Americans made their Games a huge financial success, whereas other countries, e.g. Canada, was left with a huge debt. The key to this was SPONSORSHIP which soon replaced the old Australian way of fundraising with pub raffles. It also began to change the atmosphere where the AWC had previously been valued for their generous donation. There was a move by commercial specialist uniform marketing organisations paying sponsorship money to publicise the fact that they were clothing high profile athletes. Old loyalties remained but became tested more and more as time progressed. For example, each uniform was expected to include an Akubra hat, why? Because it always had. For the same reason the uniforms also had Driza-Bone Coats. The day before the Seoul Opening Ceremony it rained in Seoul, so at the Opening Ceremony the Australian Team emerged in their Driza-Bones, made from cotton, not a wool fibre in sight, and the wool growers were footing the bill for over a million dollars. Thoroughly embarrassed, I resolved to avoid this situation next time by having all uniform fabrics pre-treated with Scotchguard prior to garment making.The scarf is brightly coloured in blue, green, yellow, purple and red on a plain cream base fabric. The lines of colour run on an angle across the fabric as jagged, irregular lines with small motifs of Australia, the Southern Cross stars, fish, triangles and a wave pattern, placed throughout. The centre of the scarf is dominated by a depiction of Australia presented in yellow. Within Australia are eucalyptus leaf shapes as well as mountainous shapes and the wave shape that is featured elsewhere on the scarf. The left hand short hem of the scarf has a differing pattern with larger lines running on the opposite angle to the rest of the scarf. Within the larger lines the same motifs are again printed. -

National Wool Museum

National Wool MuseumClothing - Overcoat, Dominex, c.1970

This overcoat was designed and tailored by Dominex, a company that sold clothing in high end department stores such as Myer and David Jones in the 1940s through to the 2000s. As pictured in the accompanying advertising, Dominex looked to produce clothes for women to “casually, confidently wear … the exquisite styling and superb tailoring of… Dominex Coats”. This sentiment was carried by the company for more than 60 years. Amanda Morgan, a director of the Dominex fashion label in an interview from 2003 said “Not everybody wants sass, or sex, or high fashion for that matter. Au contraire. Our customers will be stylish, sophisticated and womanly, but we don’t do shoestring straps or asymmetrical lines." Dominex was a label specialising in exceptional quality "traditional" dressing for corporate wear. Their clothes looked to provide women with a return to the tried and true values of elegant, unpretentious, classic dressing. "Our look is European-influenced," Morgan explained further. "Inspired by Armani, Valentino, Chanel and Escada. Suits have been specially dyed in France to ensure the perfect shade of ice blue, lemon, grey, or slate. Fabrics are natural, silk and linen. Shapes are stylish, with an almost 1930s feel; classic pants, silk shirts, structured overcoats with elegant-length” Returning to this overcoat, it has a label on the inside which reads “Pure Wool Material by Godfrey Hirst of Geelong”. Nowadays Godfrey Hirst produce flooring products and are the largest manufacturer and exporter of residential and commercial carpets in Australasia. They have expanded into hard flooring and left their fashion days behind. This overcoat serves as a useful example of a different time for the company; before they made the change to concentrating exclusively on flooring, when they produced fabrics to be tailored for the height of Australian fashion. This overcoat was purchased and worn by Joan Waller, aunty of the donor, Kim Rosenow. Kim said her aunty was from Ballarat but frequently shopped in Melbourne to keep up with the latest trends. Her aunty Joan fitted the target demographic of Dominex well, as she needed to look sophisticated and elegant at social events and work. Kim donated the overcoat to the National Wool Museum in 2021. Green singled breasted overcoat with a narrow overlap and one column of buttons for fastening. The overcoat features notched lapels of a medium width and two large buttons of a green & dark green marble. The overcoat has two semi-visible jetted pockets at the hips. Internally, the overcoat features a black silk lining for comfort. It also features a stitched patch on the left side of the opening which reads “Pure Wool Material by Godfrey Hirst of Geelong”. At the collar, another patch reads “Dominex REGD”. At the cuffs, the overcoat finishes in a type of gauntlet cuff which stretches back over 200mm. The decorative finish utilises no buttons and has thick piping to accentuate this design feature. The overcoat finishes with a simple invisible hem at the bottom.Wording, gold. Patch stitched at collar: “DomineX / REGD.” Wording, black. Patch stitched at left off opening: “PURE WOOL MATERIAL BY / Godfrey Hirst / OF GEELONG”dominex, fashion, women's corporate wear, godfrey hirst, overcoat, wool clothing -

National Wool Museum

National Wool MuseumMachine - Shearing Motor, Sunbeam, 1960-69

With more and more woolsheds being connected to power lines, the need for electric shearing gear markedly increased from the 1960s onwards. The greater economy made electric gear an attractive proposition to many graziers. Requiring only an electric shearing motor, for small and medium scale operations, electric shearing motors were a more economical way of shearing a wool clip. The other option for graziers was Overhead shearing gear, which also required an Engine to provide shared power to a row of shearing stations. Still working, this Sunbeam Electric Shearing Motor – Heavy Duty Model, features a slow speed motor totally enclosed for protection against dust and insects. The full bearing down tube is easily removed and stored to be out of the way when not in use (not pictured). Providing 0.5 hp, which is twice the power ever needed for shearing sheep, this buffer allows for fluctuations in voltages that can occur in rural districts. Inventor Frederick Wolseley made the world's first commercially successful power-shearing system in Australia in 1888. US company Cooper, which had been founded in 1843 as a maker of sheep dip, began selling Wolseley equipment in the USA in 1895. The Chicago Flexible Shaft Company successfully entered the power-shearing market a few years later and entered into a joint venture with Cooper. It set up a branch in Sydney and sold shearing sets, and engines to power them, into the Australian market. In 1921 the US parent company, realising it needed to make products whose sales were not as seasonal as those of shearing equipment, made its first household appliances and branded them Sunbeam. In 1933, changes in exchange rates and taxes led the company to manufacture engines and shearing equipment in Australia via subsidiary Cooper Engineering, which changed its name to Sunbeam in 1946. Although most Australians know of this company as a major manufacturer of household appliances, its rural division flourished and retained the Sunbeam name for shearing equipment even after it was taken over by New Zealand company Tru-Test in 2001. This 0.5 horsepower vertical brushed motor air-cooled engine was designed to drive a single shearing plant. From the central cylinder which features a yellow “Sunbeam” sticker, a grey 240v power lead can be found on the left-hand side. A blue capacitor is located next to this power lead. Below, two legs extend and meet to form a foot which is fastened to a wall. On the right-hand side of the engine, a specification plate is located on the central cylinder. A yellow directional arrow sticker is located on the rotating section of the engine below the specification plate (location for photography, this section is designed to rotate and hence this sticker is not fixed in this location). At the rear of the cylinder, a plastic cap with small air cut outs protects the air-cooled engine from contaminants. At the front of the engine, the location for securing the bearing down tube is located. On the right-hand side of the lock for the bearing down tube is the handle, to which a string is often attached for switching the motor on and off by a shearer bent at the waist (not pictured). Sticker. Gold writing. Front of shearing motor “Sunbeam” Plate. Inscribed. Side of shearing motor. “Sunbeam / SHEARING MOTOR / MADE IN AUSTRALIA / 0.5 H.P. / 220/240 V / 1 PHASE A.C. / 4.0 AMPS / 50 C/S. / CONT. RTG. / 1425 R.P.M. / CLASS A INSUL / NO. J244560 / TYPE: NSB5C2/49." sheep sheering, shearing equipment, sunbeam, electric shearing motor -

National Wool Museum

National Wool MuseumTool - Grinder, 1960-69

Cooper S.E. Ball Bearing Grinder made and guaranteed by Sunbeam Corporation Limited. Grinders like this example have been made the same since the early 1900s, with this grinder thought to have been produced in the 1960s. It is belt driven, with the other end of the belt being attached to an engine; the same engine that would have powered the overhead shearing equipment in shearing sheds. It was common for shearing teams to bring their own equipment, especially pre-1960 as most shearing sheds were not connected to power, and shearers preferred to work with their own equipment. The engines that powered the shears and grinder were typically fuelled with kerosene or petrol. The large circular disks are attached to the bolt that protrudes from the grinder and fastened tightly with a nut. An example of seeing a similar grinder in action can be found on the following link - https://www.youtube.com/watch?v=O7eimI_Gm9o. Inventor Frederick Wolseley made the world's first commercially successful power-shearing system in Australia in 1888. US company Cooper, which had been founded in 1843 as a maker of sheep dip, began selling Wolseley equipment in the USA in 1895. The Chicago Flexible Shaft Company successfully entered the power-shearing market a few years later and entered a joint venture with Cooper. It set up a branch in Sydney and sold shearing sets, and engines to power them, into the Australian market. In 1921 the US parent company, realising it needed to make products whose sales were not as seasonal as those of shearing equipment, made its first household appliances and branded them Sunbeam. In 1933, changes in exchange rates and taxes led the company to manufacture engines and shearing equipment in Australia via subsidiary Cooper Engineering, which changed its name to Sunbeam in 1946. Although most Australians know of this company as a major manufacturer of household appliances, its rural division flourished and retained the Sunbeam name for shearing equipment even after it was taken over by New Zealand company Tru-Test in 2001. The grinder is formed from a central arch shaped block of green painted metal. Much of this paint has been lost to age, leaving the grinder in a ‘farm used’ condition with much surface oxidation present. On the front of the arch is a specification plate, reading “Cooper S.E. ball bearing grinder. Made and guaranteed by Sunbeam”. At the foot of the arch, three bolt holes are found for securing the grinder to the base of a solid wooden surface. Two of the bolt holes are found on the front of the grinder, with another found on the rear. From the central arch, a bolt protrudes to the right of the grinder. This large bolt is for securing a grinding plate to the grinder. Above the central arch is a pendulum which holds the comb / cutter that is being sharpened. From the pendulum, a large arm extends down (not pictured) to meet and strike the plate spinning at a rapid speed. On the left-hand side of the central arch of the grinder, a wheel is found which a belt is attached to for power. This belt is then attached to a separate engine, spinning the wheel and hence powering the grinder. The wheel is partially covered with a section of protective bent tube, designed to provide protection from the rapidly spinning wheel. Below this wheel is the belt shifter. It is designed to move the protective bent tube from one side of the grinder to the other, to accommodate the grinder in the setup of different shearing sheds. The two separate grinding plates are identical. They have a slight slope for sharpening the comb and cutters in the correct method, with a slight bias towards the base, or “tooth”, of the equipment. The disks have a large central bolt for attaching to the grinder. They have tags on the horizontal axis of the grinding plates, for securing the plates in transportation, and to help with initial alignment when setting up the grinder. The reverse of these grinding plates has the same green painted metal finish found on the grinder. This paint is also in a ‘farm used’ condition, with surface oxidation present. The grinder would be provided from the factory with a comb holder, shifter for securing the grinding plates, emery cloth and emery glue. The emery cloth is what does the actual grinding and is applied to the grinding disks, replacing once well worn. These items can be seen in the final images in the multimedia section, showcasing advertising for this grinder. Plate. Inscribed. “Cooper / S.E. BALL BEARING GRINDER / MADE AND GUARANTEED BY / Sunbeam / CORPORATION LIMITED / SYDNEY MELBOURNE / ADELAIDE BRISBANE ”sheep shearing, shearing equipment, sunbeam, grinder -

Koorie Heritage Trust

Koorie Heritage TrustJournal - Serials, Britton, Stephanie, Art Link : Contemporary Australian Aboriginal Art, 1990

Includes: Traditions in Evolution Legal and Lobby Appropriation: a fine line. Lin Onus. Aboriginal Copyright Cases. Martin Hardie. What is Comalco up to? Report from Arukun. Peter Sutton At Last!! The arts & crafts industry review! And what did it achieve? Tim Rowse. Working in Isolation Performing Arts Media Visual Arts Projects / Opinions Artist Profiles Lin Onus Michael Eather Mural at Port Lincoln. Kerry Giles, Melanie Howard talk to Felicity Wright. Kurwingie. (Kerry Giles) Peter Dabah Vincent Megaw Robert Campbell Jnr. Milton Budge Leone Stanford Bluey Roberts Noris Ioannou Tatipai Barsa and Zane Saunders Anna Eglitis. Les Griggs Megan Griggs Judy Watson Margariet Bonnin Shane Pickett Alta Winmar Wanjidari Libby Morgan Ellen Jose Donna Leslie Natalie Greenwood Gordon Bennett Anne Kirker Maree Clarke Natalie Greenwood Seminar series at Power Institute Bronwyn Bancroft Gayle Maddigan Natalile Greenwood Narragunawali in Canberra Sylvia Kleinert Sally Morgan Design in the Commercial Area Organisations120 p.; ill.; 28 cm.Includes: Traditions in Evolution Legal and Lobby Appropriation: a fine line. Lin Onus. Aboriginal Copyright Cases. Martin Hardie. What is Comalco up to? Report from Arukun. Peter Sutton At Last!! The arts & crafts industry review! And what did it achieve? Tim Rowse. Working in Isolation Performing Arts Media Visual Arts Projects / Opinions Artist Profiles Lin Onus Michael Eather Mural at Port Lincoln. Kerry Giles, Melanie Howard talk to Felicity Wright. Kurwingie. (Kerry Giles) Peter Dabah Vincent Megaw Robert Campbell Jnr. Milton Budge Leone Stanford Bluey Roberts Noris Ioannou Tatipai Barsa and Zane Saunders Anna Eglitis. Les Griggs Megan Griggs Judy Watson Margariet Bonnin Shane Pickett Alta Winmar Wanjidari Libby Morgan Ellen Jose Donna Leslie Natalie Greenwood Gordon Bennett Anne Kirker Maree Clarke Natalie Greenwood Seminar series at Power Institute Bronwyn Bancroft Gayle Maddigan Natalile Greenwood Narragunawali in Canberra Sylvia Kleinert Sally Morgan Design in the Commercial Area Organisations art-aborignal, australian-contemporary -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Article, New bid for cinema, 2005

Article on development plans for former quarry site on Middleborough Road for a cinema complex and discount department store.Article on development plans for former quarry site on Middleborough Road for a cinema complex and discount department store.Article on development plans for former quarry site on Middleborough Road for a cinema complex and discount department store.middleborough road, burwood east, reading entertainment australia pty ltd, burwood heights, commercial development, land subdivision -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Document, Particulars of Land Boom Companies

... and banking company of australia ltd commercial finance and property ...Research into Land Boom Companies by Keith PattersonResearch into Land Boom Companies by Keith PattersonResearch into Land Boom Companies by Keith Pattersonland subdivision, city investment and finance co ltd, standard property investment co ltd, freehold investment and banking company of australia ltd, commercial finance and property pty ltd, imperial finance and share company, east suburban property investment company, bay and mountain views company limited, east mitcham brick co ltd, imperial banking company, mitcham brick and pottery co ltd, davies, matthew henry, sir, morton, thomas richards burrowes., lachal, gustave, dow, john lamont, stamp, richard, bulmer, fink, theodore, munro & baillieu, mendell, george, fuller, arthur j, taylor, land discount and mortgage bank limited, blackburn township estate co ltd, springfield estate co ltd, royal land co ltd, gascoigne investment co ltd, tunstall brick and pottery company -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Document, 56-74 Station Street Nunawading, 2013

Major commercial property sale, 394 x 164 metres, sold for $22,000,000. The site is expected to be vacated in April 2015.Major commercial property sale, 394 x 164 metres, sold for $22,000,000. The site is expected to be vacated in April 2015.Major commercial property sale, 394 x 164 metres, sold for $22,000,000. The site is expected to be vacated in April 2015.station street nunawading, nos.56-74, daniel robertson australia pty ltd., brickworks -

Ballarat Heritage Services

Ballarat Heritage ServicesCeramic - Studio Pottery, John Gleeson, Ceramic Platter, 2007

John GLEESON Living at Campbell's Creek for over 30 years, John Gleeson makes a range of functional stoneware pottery. He fell in loved with pottery during a hobby class in Geelong in 1972. He worked for a year at Canny Ridge Pottery in Harcourt. John Gleeson uses white stoneware and porcelain clay from The Bendigo Pottery, and buff clay from Bennetts Pottery in Adelaide. He mixed all his own glazes from commercially sourced raw materials, sometimes supplemented with ash from his fire and local red clay to get special effects.Large celadon platter with incised fish design. john gleason, studio pottery, ceramics, australian studio pottery -

Ballarat Heritage Services

Ballarat Heritage ServicesCeramic, Ceramic vessel with cork lid, c19701-1980s

Hof Pottery was established in 1971 in Fremantle, Western Australia by German born Helmut Hof and Australian born Elizabeth Hof. They set up a commercial pottery business in a small converted house in Naval Base, south of Fremantle. They later built a factory on the site and employed a team of people to make a wide range of slip cast wares. These were sold through retail garden centres and large department stores. The business name was deregistered in 2003. Work may be marked with an incised 'Hof' and/or have a paper label reading 'Hof Pottery made in Australia'.Ceramic vessel with cork lid incised 'Hof'ceramics, hoff, australian studio pottery -

Ballarat Heritage Services

Ballarat Heritage ServicesPhotograph - Photograph - Colour, Clare Gervasoni, Koroit Post Office, 2015, 21/12/2015

... Commercial Street, Koroit, Victoria, Australia ...The town borrows its name from the Koroitch Gundidj people who occupied the area prior to European settlement. (https://en.wikipedia.org/wiki/Koroit, accessed 21 December 2016) Koroit was first surveyed as a township in 1847. Around the 1850 the district had the highest population of Irish immigrants in rural Australia. The Koroit Post Office was designed by architect and engineer John Mason of Port Fairy. (Moyne Shire Heritage Study 2006 Stage 2, Volume 2: Environmental History, Prepared for Moyne Shire Council Helen Doyle in association with Context Pty Ltd, 2006.) Rosebrook Bridge, Rosebrook (1853; replaced) Post Office buildings, Bank Street, Port Fairy (c.1857) The author Henry Handel Richardson lived in the Koroit Post Office as a child after her family moved to Koroit in 1878. Remembering Koroit from her youth, the third volume in her The Fortunes of Richard Mahony trilogy is set in the town. When the author was six, her father Walter died in Koroit on 1 August 1879 and was buried at the Koroit cemetery. (https://en.wikipedia.org/wiki/Koroit, accessed 21 December 2016) In 1878 Mary Richardson was appointed postmistress of the Koroit Post Office at a salary of 72 pounds with free quarters, firewood and kerosene. She lived at the back of the Post Office. (From a Green and Pleasant Land by H. McCorkell and P. Yule.) Photographs showing the bluestone Koroit Post Office, phone box and postbox. It is located at 99 Commercial Road, Koroit. "Historic Area Statement of Significance: The significance of Koroit derives from its role as the urban centre of one of the most concentrated Irish Roman Catholic rural districts in Australia, noted for its mixed livestock and cropping argicultural patterns. This is reflected in two separate and distinctive areas in the town - the administrative/commercial area and the church precinct. The administrative and commercial area (focussing on the Boundary-Commercial Road/High Street intersection and the Koroit Hotel) consists of a number of significant public buildings and leads to a street of relatively intact humble shopfronts and kerbline verandahs, visually punctuated by opposing bank facades. The church precinct is dominated by a group of Catholic buildings larger in scale and more complete in range than those in any comparably sized Victorian town." http://vhd.heritagecouncil.vic.gov.au/places/69338#sthash.ELLuSMvg.dpuf, accessed 21 December 2016."koroit, post office, phone box, payphone, bluestone, henry handel richardson, koroit post office -

Ballarat Heritage Services

Ballarat Heritage ServicesCeramic - Ceramics, Ceramic Canister by Wartook Pottery, c1990

Graham WOOD Wartook Pottery was set up in the early 70s by Graham Wood, and was sucessful for nearly 25 years. It then moved to Halls Gap (The Grampians, Victoria), and the name was changed to Jimmy's Creek Pottery in 1998. The pottery conitnued under that name until 2003. when cheap imports hurt the business. Hand thrown ceramic canister with 'Gum Leaf' design. According to decorator Wendy McGuiness all decoration was made and applied by hand - an extremely time consuming activity. Texture to the body of each piece was created by using a piece of coral. Tenmoku glaze was applied to the top of the pieces, with iron oxide to the main body. This was the first of the Wartook range that sold commercially from around 1987 all over Australia. At the height of production Wartook Pottery had 5 employees, including a new wheel potter (who was adept at creating the pieces as Graham had done before). Additional ranges were still hand thrown, but with a floral wreath (slip cast) applied to the top of each pot, as well as a range that used decals for decoration. australian landscape pottery, les macleman, ceramics, landscape, graham wood -

RMIT Design Archives

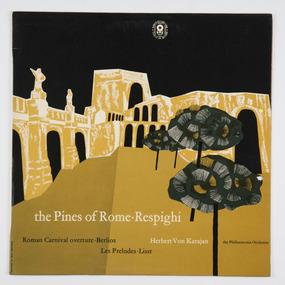

RMIT Design ArchivesRecord sleeve, The Pines of Rome - Respighi

Max Robinson (1934-2018) designed this record sleeve for the World Record Club in 1961. Robinson studied for a year at the Melbourne Technical College (RMIT University), and in his early career worked for Peter Clemenger and the graphic designer, Max Forbes. He produced a number of striking record covers for the World Record Club in the late 1950s and early 1960s. Robinson’s work is familiar to many Australians – he designed the new $10 note in 1993, which featured Banjo Paterson and Dame Mary Gilmore. The World Record Club’s operated in Melbourne from 1957 until 1976; it was a mail order service, and its art director, Geoff Digby commissioned young designers and artist to design the record sleeves. It is regarded now as one of most representative collection of Australian designers’ work of its period, and highlights the years of transition from ‘commercial art’ to ‘graphic design’. The album cover was donated to the Archive by the World Record Club’s art director, Geoff Digby. Ann Carew, 2020This record sleeve is historically significant for its association with Max Robinson, who was inducted into the Australian Graphic Design Association’s (AGDA) Hall of Fame in recognition for his work as graphic artist, but also his tireless advocacy for graphic design in Australia. It is aesthetically significant as an early example of the design work of Max Robinson. It is historically significant for its association with the World Record Club, an organisation that produced a representative collection of Australian graphic designers’ work from 1957 until 1976. the Pines of Rome . Respighi / Roman Carnival overture . Berlioz / Herbert Von Karajan / the Philharmonia Orchestra / Les Preludes . Lisztworld record club, max robinson, rmit university, rmit design archives, geoff digby, record sleeve design, graphic design -

RMIT Design Archives

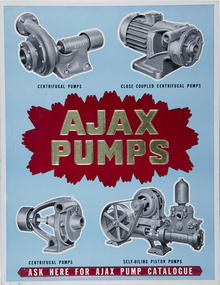

RMIT Design ArchivesAdvertising signs, Ajax Pumps

One of Australia’s most acclaimed printmakers, Grahame King originally trained as a commercial artist in the mid-1930s. The Design Archives holds a collection of embossed advertising showcards designed by King in the 1950s which reveal examples of graphic design and typography in post-war Melbourne. The showcards were used by iconic companies for advertising and promotion on shop counters and in window displays and were produced by Firestone Embossed Showcards. Megan Atkins, 2017 Sign shows centrifugal pumps, close coupled centrifugal pumps and self-oiling piston pumps.Printed text bottom left on verso, Firestone embossed showcards PTY. LTDshowcards, advertising, graphic design, commercial art, artist -

RMIT Design Archives

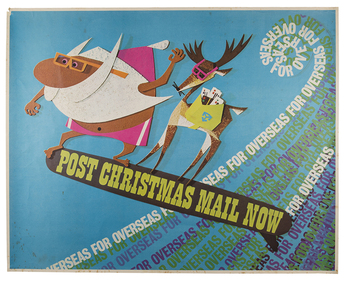

RMIT Design ArchivesPosters, Post Christmas Mail Now For Overseas

In the days before television advertising and the WWW, commercial artists such as John Whittenbury designed posters, railway billboards and trade exhibitions advertising products and services to the masses. Whittenbury’s series of quirky Christmas mail posters for the Post Masters General Office, now known as Australia Post, were displayed in post offices across Australia. He had a wealth of experience in the field, having worked as an illustrator, graphic designer, cartoonist, and mechanical draftsman for the RAAF in Laverton and then Victoria Barracks, and also taking out a qualification in Advertising Art from RMIT in 1961, prior to joining the PMG. Ann Carew, 2017 australia post, christmas, rmit design archives -

Monash University Museum of Computing History

Monash University Museum of Computing HistoryFerranti Sirius mainframe computer, 1961

The Ferranti Sirius is an electronic second-generation transistor computer and is one of three remaining examples of this machine left in the world. It was an important addition to the computing facilities at Monash University in the early 1960s and provided access for computer programming and research for many early computer professionals, academics and teachers. The Ferranti Sirius computer was built in a period of rapid growth in computing technology. The first stored program computers appeared in the late 1940s and used individual designs with valve technology. By the mid-1950s valve technology was replaced by transistors and the first mass produced commercial computers became available. The Ferranti Sirius was announced in 1959 and offered a “small” academic computer. It was designed and built by the English company Ferranti Ltd and sold through a local office of the company in Melbourne. The Sirius was manufactured at the Ferranti Ltd.’s West Gorton, England factory from 1959 to 1963 and, in all, the company produced probably 22 installations although only 16 were actually recorded as sold; this included one at Ferranti’s Bureau in London and one at Ferranti’s Melbourne Bureau. Only 7 were exported and 4 of these 7 were located in Melbourne, Australia. All four were associated with computing at Monash University – the Sirius in the MMoCH collection was purchased by Monash University in 1962, a smaller Ferranti Sirius was used on the Caulfield campus (prior to amalgamation with Monash University) from 1963, the Ferranti company had its own Ferranti Sirius initially temporarily installed at Clayton campus in 1962 and then placed in their office in Queens Road, Melbourne. A fourth computer was purchased by ICIANZ (now Orica) in 1962 and was transferred to Clayton campus in 1967. Only two of these Melbourne examples have survived; one in the MMoCH collection and one at Museums Victoria. There is an example of the Ferranti Sirius in the Science Museum Group collection in the UK as well. The Ferranti Sirius in the MMoCH collection was the first computer purchased by Monash University and it was shipped to Australia to be installed by November 1962. The University had a similar model computer on loan from Ferranti Ltd during the first part of the year and it was returned to the office of the company in Queens Road, Melbourne once the University’s own machine was installed. The computer was placed on site at Clayton campus, Monash University. The computer operated from 1962 until 1972 when it was officially decommissioned. The Ferranti Sirius was sold to Mr Paul Stewart in late 1974 and removed from Monash University. Mr Stewart later donated the computer back to the University in 1988 and it was transferred to the collection of the Monash Museum of Computing History after 2001. The Ferranti Sirius is an electronic second-generation transistor computer and is one of three remaining examples of this machine left in the world. It was an important addition to the computing facilities at Monash University in the early 1960s and provided access for computer programming and research for many early computer professionals, academics and teachers. The Ferranti Sirius is of scientific (technological) significance as one of the early transistor digital computers that transitioned computing from first-generation valve computers to second generation commercial installations. This example of the Sirius is of historical significance in its role as a part of the Computer Centre, Clayton campus, Monash University which provided computing facilities in Melbourne in the early 1960s when there were few installations available for academic, administrative and commercial users. Staff and students were able to undertake investigative research and learn programming techniques. The Computer Centre encouraged the use of the computer across all disciplines and this provided the base to establish computer science as a subject offering and, later, a new department in the University. This growth in computer education eventually culminated in the establishment of the Faculty of Information Technology, Monash University. The Ferranti Sirius in the collection at Monash Museum of Computing History has a main unit with a CPU and memory combined with input/output equipment and one extra cabinet of memory. The Central Processing Unit is a floor-standing unit which contains the computer circuits, power supplies and has a decimal digit display panel and a normal clock. A moveable control panel is placed in front of the Unit (Currently set on a recreated desk/filing cabinet support in the display). The Sirius base unit uses acoustic delay line memory with 1000 word store. An additional 3000 word memory cabinet is set adjacent to the CPU and can be connected to increase the memory. The computer is supported by a range of input/output devices. There is a Ferranti Paper tape reader, located on desk in front of CPU. Red label on front “Ferranti tape reader. Type TR 5. Serial No. 477”. Adjacent to the CPU is a set of Simplified tape editing equipment in three pieces which includes a (1) Table unit with switches on front face. Metal tag on reverse reads “Creed & Co. Model No. S4060. Serial No. 1457. Original Customers Marking GRP7 V706”. The table has a numbered internal tag “Table Serial No. 198579. (2)Creed teletype set on table unit. Metal tag on reverse “Creed & Co. Model No. 75RPR K4M4. Serial No. 5897 Made in England”. (3)Creed paper tape reader set on table unit. This set of equipment could read paper tape and print it, or copy paper tape while allowing it to be edited, or allow a programmer or data preparation person to type and punch a new program or data. It has no electrical connection to the computer. Paper tapes were usually torn off and carried across to the computer. There is also another table unit with switches on front face and changeable setting switch on front right side which holds a Ferranti Westrex paper tape punch set. Label on reverse “Teletype Code BRPE11” This was the Computer’s only output device. BRPE-11 is a teletype model number. -

Numurkah & District Historical Society

Numurkah & District Historical SocietyEquipment - Wooden school rulers x 4

... Bank of ES & A / Commercial Savings Bank of Australia... & A / Commercial Savings Bank of Australia Limited / Drink a Pint of Milk ...Wooden 12 inch / 30cm school rulers with increments in inches and centimetres both sidesBank of ES & A / Commercial Savings Bank of Australia Limited / Drink a Pint of Milk a Day / Standard school Ruleeducation, school, measuring, ruler -

Robin Boyd Foundation

Robin Boyd FoundationLetter, Harold Lander to Robin Boyd and others. (Crawford Productions), 23.11.1967

Memo from Harold Lander, providing background information for a planning meeting to be held to discuss ‘Hunter’ television series. 'Hunter' is an Australian spy drama which ran from 4 July 1967 – 5 March 1969 on Nine Network. Lander writes about considerations for making the show commercially successful including publicity tactics. Robin Boyd is mentioned on page 9. Lander asks for his suggestion on a new set design for the Independent Surveys office for the show.Crawford Productions and Robin Boyd also explored ideas for other television productions, besides the successful 'The Flying Dogtor" series.Typewritten, carbon copy, foolscap, 11 pages.Black pen mark up on pages 1-9, red pen mark up on pages 1 and 2.hunter, australian television, crawford productions, homicide, nine network -

Robin Boyd Foundation

Robin Boyd FoundationSlide, Commercial, 1964

Colour slide in a mount. Jacobs House, Wahroonga, New South Wales, Australia, 1963. (Architects: Allen, Jack+Cottier.)Made in Australia / 25 / OCT 64M / ALLEN, JACK & COTTIER ARCHTECTS. / TEL. 27-7981 / 10 YOUNG STREET, SYDNEYaustralia, slide, robin boyd -

Robin Boyd Foundation

Robin Boyd FoundationSlide, Commercial, 1970

Robin Boyd was appointed Exhibits Architect for the Australian Pavilion at Expo ‘70 in Osaka and travelled to Osaka several times in 1969-1970. Boyd designed the innovative Space Tube, which had over 25 exhibition boxes, projecting from it. Amongst the topics covered were Australian scientific innovation (including brain research, immunology, Antarctic research, Snowy Mountains Hydro-Electric Power Scheme, rainmaking, and the night sky), Australian sport, house interiors, car manufacturing, Australian music and art, and Japanese-Australian relations.Colour slide in a mount. Heavy Seas, Expo '70, Osaka, JapanExpo'70 / Heavy Seas / 29 (Handwritten)expo 70, osaka, robin boyd, slide