Showing 1264 items

matching manufacturing industries

-

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Razor, John Clarke Ltd, 1930s

In 1848, 43-year-old John Clarke launched a cutlery business in Harvest Lane in Neepsend, Sheffield UK. Clarke entered the trade late in life he was indenture and apprenticed to Octavius Twigg, a razor maker. Clarke was granted his Freedom in 1856 and began using the trademark 'NEVA'. By the 1860s, Thomas Clarke's son by his wife Elizabeth had joined the firm. When John Clarke died at his home at Augusta Place, Rock Street, Sheffield on 25 July 1873 (aged 68), he only employed six workmen. By 1881, Thomas had expanded this number to twenty. He sold a wide range of cutlery and was also an ‘emigration agent’, the Sheffield Independent, of 7th September in 1886 had an article published stating Thomas helped to recruit personnel from England for cutlery centers in America. In 1893 Clarke’s showroom displayed miniature knives from '5/16ths-inch long to the most expensive sportsman's knives, that were gold and silver mounted. Table knives and carvers were also manufactured (or factored). Agencies were opened in London, New York, and Melbourne. Besides ‘NEVA, the ‘EXPRESS’ and ‘RING’ marks were used on razors; and Clarke’s marketed the American ‘GEM’ safety razor. By 1901, the firm had moved to Mowbray Street, where its Mowbray Works overlooked the River Don. Thomas Clarke died at Harrogate on 26 April 1902, aged 62, and was buried in the same Burngreave cemetery as his parents. Thomas’s sons, John Roome Clarke (1860-1925) and Thomas Edward Clarke, were directors, another son George William Clarke was a shareholder. John Roome Clarke died on 3 February 1925, aged 64 his son, John Clarke, of Crimicar Lane, remained as the senior partner. Clarke’s was one of the last producers of hand-made pocket knives and it also produced a large output of sheath knives for scouting associations. The firm was liquidated in 1964, but the company name was resurrected and Its last address after 1980 was at 65 Garden Street Sheffield. The company trademark passed on to Meteor Industries and then to Egginton Ltd. Weber & Co: The Clarke company purchased or (factored) many of its blades for razors and knives from Weber & Co of Solingen Germany. The full name of the firm originally was Jowika Stahlwarenfabrik Eugen Weber & Altenbach KG. It was founded in Solingen prior to 1928, under the name Johann & Wilhelm Kleinewefers GMBH, Messerfabrik. JWK for short, hence JoWiKa. The company was sold to Eugen Weber in the 1930s. Weber was married to a woman named Altenbach, from a family that manufactured innovative low-priced pocketknives, as well as other cutlery items. In 1960 Weber opened a branch factory in Listowel Ireland. It was sold to Albert M. Baer of Imperial Schrade in 1978. The Listowel factory was closed about a year and a half before the U.S. Schrade factory closed in 2004 and the Jowika factory in Solingen had closed in 1984.An item with an interesting manufacturing history from the 1930s showing how one man can grow a business into a successful concern that made quality products that stand the test of time.Razor metal folding blade with horn handle in its original cardboard box Inscription Made by John Clarke and Son England. "Champion" razor. On box " The Champion 10/6d" and "Weber Lohmann & Co SOLINGEN".flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Sewing Machine & case

... clothing manufacture tailor industry garment "PFAFF" Sewing machine ...Sewing machine and case. Hand operated portable sewing machine, PFAFF brand. Wood inlaid design. Black machine body has gold floral decorations."PFAFF"flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, sewing machine, hand operated sewing machine, clothing, clothing manufacture, tailor, industry, garment -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageInstrument - Clock, 1920s

In 1902, William E Sessions and other family members purchased a controlling interest in the E.N. Welch Company, a clock manufacturer located in Forestville, Connecticut. Sessions' father owned a foundry located in the town of Bristol, Connecticut that produced cases for E.N Welch Co. On January 9, 1903, the company was reorganized and registered as The “Sessions Clock Company”. Within a few years the Sessions Clock Company was producing clock movements, cases, dials, artwork and castings for their line of mechanical clocks. Between 1903 and 1933 Sessions produced 52 models of mechanical clocks, ranging from Advertisers, large and small clocks with logos of various businesses, to wall, or regulator clocks, and shelf or mantel clocks, designed for the home. Many of the Session clocks from this period are prized by collectors. In 1930, the company expanded to produce electric clocks and timers for radios, while continuing to produce traditional brass mechanical movements. Beginning at the end of World War II Sessions W Model (electric) was widely used by various casting companies for their clocks. The dial of the W Model read Movement by Sessions. In the early 1950s Sessions begin to produce timers for television. In 1956, Sessions was absorbed by a company interested mainly in their timing devices. In 1959, William K. Sessions, grandson of William E. Sessions left the Sessions Clock Company and formed the New England Clock Company. In 1960, one of the Sessions Clock buildings was sold to the Bristol Instrument Gears Company. Kept as the Sessions Company, the new owners ran the operation until 1969 when changes in the market forced the Sessions Company into liquidation. In 1970, the remaining buildings were sold to Dabko Industries, a machine parts manufacturer.The item marks a time when clock production in America was at it’s peak producing clocks for sale in many countries, they were keenly priced, mass produced and available to all. The company had a relatively short life span life regards clock manufacture later diversifying into electric timer mechanisms. Yet it was perhaps inevitable with the advent of electricity along with stiff competition from other clock manufactures that would ultimately herald the end in 1935 of the Sessions company's ability to continue manufacturing mechanical clocks. Clock mantle type face set in a painted black case designed to represent a Greek building with gold decorative pillars. Free standing with decorative feet. No markings or inscriptions on clock case or mechanism flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, sessions, mantel clock, clock, clock industries -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageClock, 1867-1870

Chauncey Jerome (1793–1868) was an American clock maker in the early to mid 19th century. He made a fortune selling his clocks, and his business grew quickly. Jerome was born in Canaan USA in 1793 son of a blacksmith and nail-maker. He began his career in Plymouth, making dials for long-case clocks where he learned all he could about clocks, particularly clock cases, and then went to New Jersey to make seven-foot cases for clocks mechanisms. In 1816 he went to work for Eli Terry making "Patent Shelf Clocks," learning how to make previously handmade cases using machinery. Deciding to go into business for himself, Jerome began to make cases, trading them to Terry for wooden movements. In 1822 Jerome moved his business to Bristol New Haven, opening a small shop with his brother Noble and began to produce a 30-hour and eight-day wooden clocks. By 1837 Jerome's company was selling more clocks than any of his competitors. A one-day wood-cased clock, which sold for six dollars had helped put the company on the map. A year later his company was selling that same clock for four dollars. The company also sold one line of clocks at a wholesale price of 75 cents and by 1841 the company was showing an annual profit of a whopping $35,000, primarily from the sale of its brass movements. In 1842 Jerome moved his clock-case manufacturing operation to St. John Street in New Haven. Three years later, following a fire that destroyed the Bristol plant, Jerome relocated the entire operation to Elm City factory. Enlarging the plant, the company soon became the largest industrial employer in the city, producing 150,000 clocks annually. In 1850 Jerome formed the Jerome Manufacturing Co. as a joint-stock company with Benedict & Burnham, brass manufacturers of Waterbury. In 1853 the company then became known as the New Haven Clock Co, producing 444,000 clocks and timepieces annually, then the largest clock maker in the world. Jerome's future should have been secure but in 1855 he bought out a failed Bridgeport clock company controlled by P.T. Barnum, which wiped him out financially, leaving the Jerome Manufacturing Co. bankrupt. Jerome never recovered from the loss. By his admission, he was a better inventor than a businessman. When Jerome went bankrupt in 1856 the New Haven Clock Company purchased the company. One of the primary benefits of Jerome purchasing New Haven in the first place was the good reputation of the Jerome brand and the network of companies that remained interested in selling its clocks. In England, Jerome & Co. Ltd. sold Jerome clocks for the New Haven company until 1904, when New Haven purchased the English firm outright. After his involvement with the New Haven Company in 1856, Jerome traveled from town to town, taking jobs where he could, often working for clock companies that had learned the business of clock making using Jerome's inventions. On returning to New Haven near the end of his life, he died, penniless, in 1868 at the age of 74. The company struggled on after Jerome's bankruptcy until after World War II, when the company endeavored to continue through disruptions caused by a takeover along with poor sales, finally having to fold its operations in 1960 a little more than 100 years after it had been founded. The item is significant as it is associated with Chauncey Jerome who had made a historic contribution to the clock making industry during the 19th century when he began to substitute brass mechanisms for wooden mechanisms in his clocks. This was said to be the greatest and most far-reaching contribution to the clock industry. Because of his discovery of stamping out clockwork gears rather than using castings, Jerome was producing the lowest-priced clocks in the world. That can only add to his significance as the major clock manufacture of the 19th century. Jerome may have made and lost, a fortune selling his clocks but was perhaps the most influential and creative person associated with the American clock business during the mid-19th century. Also, he had served his community as a legislator in 1834, a Presidential elector in 1852 and mayor of New Haven, Connecticut from 1854 to 1855.Eight day movement wall clock with Roman numerals, octagonal shaped rosewood veneered casing, hinged face with locking clip. Wound from front. Face has adjustment for Fast-to-Slow.Part paper label on back of case can just make out "Jerome" and "ight and One" probable meaning is "Eight and One Day" describing the movements operational time between winding the mechanism.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, clock maker, jerome & co, new haven, chauncey jerome, canaan -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageContainer - Ink Bottle, Caldwell’s Ink Factory, Late 19th to early 20th centuries

This design of the bottle is sometimes called a ‘cottage’ or ‘boat’ shape. The Caldwell’s handmade glass ink bottle was mouth-blown into a three-piece mould, a method often used in the late 19th and early 20th centuries, with the maker's name engraved into the mould section for the base. The glass blower would cut the bottle off the end of his blowpipe with a tool and join a mouth onto the top, rolling the lip. The bottle was then filled with ink and sealed with a cork. This method of manufacture was more time-consuming and costly to produce than those made in a simple two-piece mould and 'cracked' off the blowpipe. The capacity for a bottle such as this was about 3 ½ oz (ounces) equal to about 100 ml. This particular bottle is unusual as it has four sloping indents at the corners of the shoulder, most likely for resting a pen with its nib upwards and the handle resting on a flat surface. Most of the bottles made during this era had horizontal pen rests that were indented into both of the long sides of the shoulder. Pen and ink have been in use for handwriting since about the seventh century. A quill pen made from a bird’s feather was used up until around the mid-19th century. In the 1850s a steel point nib for the dip pen was invented and could be manufactured on machines in large quantities. This only held a small amount of ink so users had to frequently dip the nib into an ink well for more ink. Handwriting left wet ink on the paper, so the blotting paper was carefully used to absorb the excess ink and prevent smudging. Ink could be purchased as a ready-to-use liquid or in powdered form, which needed to be mixed with water. In the 1880s a successful, portable fountain pen gave smooth-flowing ink and was easy to use. In the mid-20th century, the modern ballpoint pen was readily available and inexpensive, so the fountain pen lost its popularity. However, artisans continue to use nib pens to create beautiful calligraphy. Caldwell’s Ink Co. – F.R. Caldwell established Caldwell’s Ink Company in Australia around 1902. In Victoria, he operated from a factory at Victoria Avenue, Albert Park, until about 1911, then from Yarra Bank Road in South Melbourne. Newspaper offices were appointed as agencies to sell his inks, for example, in 1904 the New Zealand Evening Star sold Caldwell’s Flo-Eesi blue black ink in various bottle sizes, and Murchison Advocate (Victoria) stocked Caldwell’s ink in crimson, green, blue black, violet, and blue. Caldwell’s ink was stated to be “non-corrosive and unaffected by steel pens”. A motto used in advertising in 1904-1908 reads ‘Makes Writing a Pleasure’. Stationers stocked Caldwell’s products and hawkers sold Caldwell’s ink stands from door to door in Sydney in the 1910s and 1920s. In 1911 Caldwell promised cash for returned ink bottles and warned of prosecution for anyone found refilling his bottles. Caldwell’s Ink Stands were given as gifts. The company encouraged all forms of writing with their Australian-made Flo-Eesi writing inks and bottles at their impressive booth in the ‘All Australian Exhibition’ in 1913. It advertised its other products, which included Caldwell’s Gum, Caldwell’s Stencil Ink (copy ink) and Caldwell’s Quicksticker as well as Caldwell’s ‘Zac’ Cough Mixture. Caldwell stated in a 1920 article that his inks were made from a formula that was over a century old, and were scientifically tested and quality controlled. The formula included gallic and tannic acids and high-quality dyes to ensure that they did not fade. They were “free from all injurious chemicals”. The permanent quality of the ink was important for legal reasons, particularly to banks, accountants, commerce, municipal councils and lawyers. The Caldwell’s Ink Company also exported crates of its ink bottles and ink stands overseas. Newspaper advertisements can be found for Caldwell’s Ink Company up until 1934 when the company said they were the Best in the business for 40 years.This hand-blown bottle is significant for being the only bottle in our collection with the unusual sloping pen rests on its shoulder. It is also significant for being made in a less common three-piece mould. The method of manufacture is representative of a 19th-century handcraft industry that is now been largely replaced by mass production. The bottle is of state significance for being produced by an early Melbourne industry and exported overseas. This ink bottle is historically significant as it represents methods of handwritten communication that were still common up until the mid-20th century when fountain pens and modern ballpoint pens became popular and convenient and typewriters were becoming part of standard office equipment.Ink bottle; rectangular base, hand-blown clear glass bottle with its own cork. The bottle has side seams from the base to the mouth, an indented base and an applied lip. The corners of the shoulder sides have unusual diagonal grooves that slope down and outwards that may have been used as pen rests. Inside the bottle are remnants of dried blue-black ink. The glass has imperfections and some ripples on the surface. The bottle has an attached oval black label label with gold-brown printed text and border. The base has an embossed inscription. The bottles once contained Caldwell’s blend of blue black ink.Printed on label; “CALDWELL's BLUE BLACK INK” Embossed on the base "CALDWELLS"flagstaff hill, warrnambool, maritime village, maritime museum, shipwreck coast, great ocean road, ink, nib pen, writing ink, writing, copying, banks, lawyers, commerce, student, permanent ink, blue black ink, stationery, record keeping, handwriting, writing equipment, writing accessory, office supply, cottage bottle, boat bottle, mouth-blown bottle, cork seal, f r caldwell, caldwell’s ink company, albert park, south melbourne, inkstands, stencil ink, copy ink, quicksticker, zac cough mixture, three part mould, cauldwells, cauldwell's -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Cow Bell, Circa 1878

The artefact is a damaged brass cow bell recovered from the 1878 shipwreck of the LOCH ARD near Port Campbell. It was raised by Flagstaff Hill divers in 1973 and is in storage at the Maritime Village. The LOCH ARD was constructed on the Clyde in 1873 for the prestigious Loch Line of colonial clipper ships, designed for the Australian run. She sailed from England on 1 March 1878 carrying 37 crew, 17 passengers and a diverse general cargo ranging from luxury items to bulk railway iron. On 1 June 1878, emerging from fog and hearing too late the sound of breakers against the tall limestone cliffs, the vessel struck the southern foot of Mutton Bird Island and sank in 23 metres of water. Of the fifty-four people on board only two survived, one young male crewman and one young female passenger. A century later, despite the pounding seas and the efforts of looters, the wreck site continued to provide ample evidence of the extraordinary range of goods being imported into the Colony of Victoria in the post-Gold Rush era. Flagstaff Hill divers in the 1970s reported finds of “Bottles of champagne, window panes, rolls of zinc, barrels of cement, iron rails, clocks, lead shot, corrugated iron, lead, marble, salad oil bottles, ink bottles, copper wire, gin bottles, rolls of carpet, floor tiles, copper rivets, gas light fittings, pocket knives, toys, crystal chandeliers, beer mugs, cutlery, candles sticks, wick scissors, cow bells, and sauce bottles.” From this array of objects on the ocean floor emerged the humble brass cow bell. Cow bells were common to colonial agriculture and transport, used wherever animals were turned out to graze overnight and had to be rounded up again next morning. Bells were fastened around the necks of household milking cows, domestic goats, bullock teams, horse teams, and camel teams, to help find them in the pre-dawn light. Station shepherds and cattle drovers also used them to warn of any disturbances to their flocks and herds overnight. The bells were a necessary item in a largely unfenced continent. So important, that Anthony Mongon began making his pot-bells at Yackandandah from 1861, August Menneke produced the “Wagga Pot” from 1867, and Samuel Jones started manufacturing his distinctively shaped “Condamine Bell” in 1868. However, these deeply resonant Australian bells were made from iron — Mongon and Jones were blacksmiths who simply beat old pitsaw blades into shape. Few genuinely brass cow bells were made here, the vast majority being imported from Britain where the industry of brass founding was already well established. (Some bells were also imported from the United States, but these too were nearly all of iron).This bell is historically significant as typical of a cow bell used by farmers and herdsmen in Colonial Victoria. It was included in the cargo of the Loch Ard. Its significance is increased by being one of a collection of artefacts recovered by the Flagstaff Hill Divers from the wreck of the Loch Ard in the early 1970s. Items that come from several wrecks along Victoria's coast have also been recovered for Flagstaff Hill Maritime Village’s museum collection under a Government permit, illustrating this item’s level of historical value. The cow bell is also significant for being part of Flagstaff Hill’s collection of artefacts from LOCH ARD, which is significant for being one of the largest collections of artefacts from this shipwreck in Victoria. It is significant for its association with the shipwreck, which is on the Victorian Heritage Register (VHR S417). The collection is significant because of the relationship between the objects, as together they have a high potential to interpret the story of the LOCH ARD. The LOCH ARD collection is archaeologically significant as the remains of a large international passenger and cargo ship. The LOCH ARD collection is historically significant for representing aspects of Victoria’s shipping history and its potential to interpret sub-theme 1.5 of Victoria’s Framework of Historical Themes (living with natural processes). The collection is also historically significant for its association with the LOCH ARD, which was one of the worst and best-known shipwrecks in Victoria’s history.Cow bell; a small brass bell, blunt-wedge shaped. The sides expand outwards from the smaller rectangular roof of the bell to a larger open rectangle or bell mouth. The handle, now missing, was fixed in two places at the top. A neat half-circle piece has been cut from the base on a long edge. Recovered from the wreck of the Loch Ard.flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, loch line, loch ard, eva carmichael, mutton bird island, loch ard gorge, brass cow bell, colonial cow bells, 1878 shipwreck, shipwreck artefact, flagstaff hill divers, cow bell -

Gippsland Vehicle Collection

Gippsland Vehicle CollectionVulcan Truck, 1922 Vulcan Tray Truck

Manufactured by The Vulcan Motor and Engineering Company at Southport Lancashire, England. It's early history is unknown. It was resurected from an old disused brick kiln in Penrith, N. S.W. where it was in a rusty disused state. Restoration was completed about 1990., and included replacing many missing items, icluding having a reproduction 'Blacksmith' radiator mascot.This truck is significant as it is representative of the early type of hand cranked (no starter motor) Vulcan trucks used in the Maffra district, particularly in the dairying industry. Allthough commonly used in the period, it is fairly rare, as not many have survived. It has cast iron wheels, with solid rubber tyres, at a time when most vehicles were using pneumatic tyres.vulcan, vulcan truck, vintage truck, old truck -

Richmond & Burnley Historical Society

Richmond & Burnley Historical SocietyCondom Mould

... , as it is associated with the use and manufacture of sexual health devices ...This wooden condom former has no defined manufacture date and was used in the production of rubber condoms in Melbourne by the rubber goods manufacturer Ansell. Wooden formers of this type were used from 1905 till 1945. The condom former would be dipped tip first into liquid rubber and the covering left to dry, and then the resulting condom packaged and sold. This object was acquired by the Richmond and Burnley Historical Society in the 1970’s on the closing of the Ansell factory located on River St, Richmond. This object has historical significance at a national level, as it is associated with the use and manufacture of sexual health devices within the broader Australian context. It also holds local historical significance as a marker of local manufacturing and industry in Victoria. Alongside these points it is also a large part of the story that surrounds the creation of Ansell Industries as we know them in a modern context. Wooden condom former/ mold. Frame consists of 11 individual upright moulds. Used by the Ansell Rubber Co. Pty Ltd in the production of condoms. Obtained in 1970's from an old factory site occupied by Ansell. None visibleansell, condom machinery, richmond industry, moulds, rubber products, sexual health, contraception, condom -

Glen Eira Historical Society

Glen Eira Historical SocietyPlan - Pritchard Steam Power Company

... Chesterfield HA Manufacturing Industry Victory Milk Plant BL Coram ...This file contains one item: 1/A draft of a plan for a museum exhibit from the Spirit of Enquiry Workbook, by Denis Shephard, and dated 07/08/2007, pertaining to alternative energy research within the suburbs of Melbourne between 1950 and 1980. Much of the content is irrelevant to Glen Eira. However; one of the two principle subjects of the exhibit, discussed between pages 20 and 28, is the work of Ted Pritchard, who was based out of Caulfield. Ted and his father, Arnold Pritchard, aspired to reinvent the steam engine for use within the contemporary era. To that end, they fitted a Chevrolet pickup truck with one of their prototypes – with the result being one of the main items constituting the exhibit. Ted’s interest in steam power had been spurred by a working tabletop model of a steam engine that Arnold built for him – which constitutes another of the exhibit’s items. Also included is a brief history of the development of Caulfield. The plan is embellished with numerous images, with relevant ones including maps of Caulfield and black-and-white photographs of the Pritchards’ truck, model and workshop.engines, engineering, engineers, inventions, inventors, steam engines, steam power vehicles, pritchard ted, pritchard arnold, pritchard steam power company, caulfield, shephard denis, pritchard mrs., trucks, pritchard edward, holland grove, balaclava road, workshops, grants, pritchard automotive steam designs, caulfield racecourse, caulfield technical school, caulfield trades school, caulfield technical college, chisholm institute, camden town, southdown knitting company, home street, fl hutchison, fowler street, vale knitting mills, nepean road, winterfold spinning mills, acme knitting mills, glen eira road, mj ryan knitwear, leather industry, lane joseph, hotham street, casey william, glen huntly road, pickering william, paris leather manufactory, woorayl street, tv tatchell, premier wire works, webb street, chesterfield ha, manufacturing industry, victory milk plant, bl coram & sons -

Flagstaff Hill Maritime Museum and Village

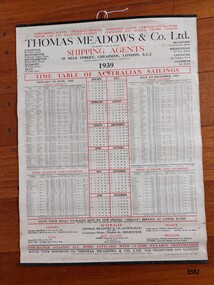

Flagstaff Hill Maritime Museum and VillagePoster - Shipping Timetable, Barclay and Fry Ltd. London, Time Table of Australian Sailings, circa 1939

"Freight forwarding" is the arranging of the shipping of goods from their point of origin to their final destination. Freight Forwarders worked as an intermediary between companies that needed to ship products and the shipping and transportation firms that could ensure delivery. A key element of "freight forwarding" was the advice and professional handling of documentation and customs requirements provided. Early "freight forwarders" tended to be innkeepers who forwarded on the luggage of their hotel guests. One of the first "freight forwarding" companies was established by Thomas Meadows in 1836 which made it one of the earliest freight companies in Europe. More reliable rail and steamships were beginning to be used to transport goods and this created a demand for the new "freight forwarding" industry. The combination of railroads and steamships became very important in the late 19th and early 20th century. International shipments became common and freight forwarding that could handle their complexity became an integral part of the manufacturing and shipping landscape. Thomas Meadows & Company Ltd moved to offices in Milk Street, London in 1854 (where they remained until 1969 when they moved out of the city to Leytonstone) and continued in the freight business until 1987 when the company was acquired by Rockwell International Freight. The growth of Thomas Meadows & Company Ltd coincided with the growth and development of the colony of Victoria with an increasing need for the transporting of large numbers of people as well as important goods required by the growing colony - furniture, spirits, food, clothing, agricultural implements, household items etc. In the late 1840's only two or three overseas ships a month visited Melbourne but by late 1852 (after gold was discovered) more than a dozen ships arrived each week. By 1939, Thomas Meadows & Co. Ltd. had offices in Canada, U.S.A., New Zealand, France, Belgium and in Flinders Street Melbourne. This poster was sold by "Smarts Authorised Newsagency" in 1988 in Warrnambool - a business that had been owned by Neil and Shirley Smart at 168 Timor Street, Warrnambool since 1976. Previously it had been "Reed's Newsagency and Book Shop" (a local business established by William Reed circa 1912 and known as "William Reed Bookseller and Stationer"). The original owners, Reed's Newsagency and Bookshop were operating the shop in 1939 which suggests the poster may have been on display (for the information of their customers) in their shop at that time. This poster is significant through its association with Thomas Meadows and Co. Ltd. who is considered to be the founder of the "freight forwarding" industry in the early 19th century. It is an example of advertising used by shipping agents in the mid-19th to early 20th centuries. Its information includes the addresses of the firm's different offices in the U.K. and abroad, ships, shipping lines and ports used and the timetable the vessels were likely to follow. It is also significant through its association with a well known and long standing local Warrnambool business.A 1939 Timetable of "Australian Sailings" produced by the shipping agents Thomas Meadows and Co Ltd. It lists all their ships (plus dates and ports) sailing from the UK to Australia as well as the addresses of their offices in other cities in the U.K., Canada, U.S.A., Australia, New Zealand, France and Belgium. It has three vertical columns depicting (from left to right) January to June sailings, a simple 1939 calendar and their July to December 1939 sailings. The poster is attached on the top and bottom to two thin black metal strips. The top strip has a metal ring with a hole. A stamped label on the back of the poster has the name, telephone number and address of Smarts newsagency plus the date.Front of poster - "FORWARDING AGENTS. INSURANCE BROKERS.PASSENGER AGENTS.CARTAGE CONTRACTORS / MOTOR CAR AND MACHINERY PACKERS.FURNITURE AND GENERALEXPORT PACKERS" "THOMAS MEADOWS & CO Ltd." "ESTABLISHED OVER 100 YEARS" "SHIPPING AGENTS / 35 MILK STREET, CHEAPSIDE, LONDON, E.C.2" "PACKING WAREHOUSES IN LONDON & MANCHESTER" "1939" "TIME TABLE OF AUSTRALIAN SAILINGS" "JANUARY TO JUNE, 1939/ FROM LONDON" "JULY TO DECEMBER, 1939 / FROM LONDON" "HAVE YOUR SMALL PACKAGES SENT BY OUR SPECIAL "SMALLS" SERVICE AT LOWER RATES/RATES TO PORT ONLY OR INCLUDING DELIVERY THROUGHOUT AUSTRALIA" "INSURANCE AGAINST ALL RISKS EFFECTED WITH CLAIMS PAYABLE DESTINATION" "ROUTE YOUR SHIPMENTS VIA THOMAS MEADOWS & CO LTD. FOR PROMPTNESS AND ECONOMY" Stamp on back of poster - "SMART'S AUTHORISED NEWSAGENCY' "168 Timor Street, Warrnambool 3280" "Telephone: (055) 62 2092" "12 DEC 1988" Sticker at bottom - "51"flagstaff hill maritime museum and village, great ocean road, shipping, shipping agents, freight forwarding, freight, shipping time table, thomas meadows & co. ltd., thomas meadows shipping agent, shipping and forwarding agent, smart's newsagency, warrnambool, warrnambool newsagency, chart, poster, smart's authorised newsagency, neil and shirley smart, william reed, reed's newsagency and bookshop -

Federation University Historical Collection

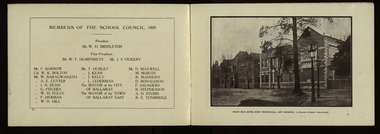

Federation University Historical CollectionBooklet, The Ballarat School of Mines and Industries 1870-1920 Jubilee Booklet, 1920 (estimated)

The first school of Mines in Australia was established at Ballarat in 1870. At the time of its jubilee (1930) the following people were members of the School Council: W.H. Middleton (President), W.T. Humphreys (VP), J.S. Vickery (VP), F. Barrow, Col. W.K. Bolton, William Baragwanath, A.E. Cutter, J.N. Dunn, G. Fitches, W.H. Fleay, F. Herman. W.D. Hill, T. Hurley, K. Kean. J. Kelly, L. Lederman, Mayor of Ballarat, Mayour of Ballarat East, D. Maxwell, M. Martin, R. Maddern, D. Ronaldson, F. Saunders, R. Stephenson, A.O. Stubbs, R.E. Tunbridge. The School Staff in 1920 comprised: Herbert H. Smith, Walter Rowbotham, Reginald L. Cutter, M.C. Young, Hilda Wardle, M. Wiliamson, P.S. Richards, L.H. Archibald, J. Woods, Ken Moss, W. Kenneth, Mrs McIlvena. B. Robinson, S. Rowe, E. Hope-Jones, Miss Abrams, L.St.G.P. Austin, Alfred Mica Smith, J.R. Pound, Herbert R. Murphy, N.H. Junner, Maurice Copland, L.H. Archibald, E.J.A. McConnon, Newton King, D.m. Hull, T.R. Gordon, John M. Sutherland, T.K. Jebb, Dick Richards, C. Tonkin, A.W. Steane, J. Paterson, H.W. Malin, R.V. Maddison, S.M. Mayo, F.A. King, W.H. Steane, T.R. Gordon, T.A. Williams, H. Waldron, G. Black, E.J. McConnon, R.V. Duncan. R. Cutter, E.G. Vawdrey, Hilda WardleWhite stapled booklet - landscape format - 20pp + soft covers with blue writing. Includes an historical sketch of the Ballarat School of Mines. Contains images of the school from around 1920. The history outlined in the booklet follows: 'Ballarat has helped to influence the life and destinies of Australia in many ways, the recital of which would perhaps prove tedious to the citizens of less favoured localities! However, it can be said, without much fear of contradiction, that only less known thought Australia than its fame as a gold field is the reputation won for it by its school of Mines, ... Ballarat was still quite a new place when the School was founded, but a very propserous and popular place all the same, with a go-ahead lot of citizens brim full of the spirit of enterprise which seemsto animate mining populations generally. Money was plentiful, and they launched out into ventures, which later, were to develop and take the place of the gold mines, while what is more to the point, they understood the value of education. the old digging days were passing away. So far as Ballarat itself was concerned the day of the cradle and tin dish had already passed into an antiquity "as dead and distant as the age of the Tubal Caon," said dir redmond Barry on declaring the School open. Mining had become a serious business, and the mining engineer, the metallurgist, and the geologist had become a power in the land. In these circumstances the suggestions to found a School of Mines met with ready acceptance. The late Mr James M. Bickett had the honor of bringing forward the proposition at a meeting of the Ballarat Mining Board in October, 1869. it was agreed to, and the Government, having been approached for assistance, granted a lease of the old Supreme Court buildings at a nominal reantal. A modest sum, including 100 pounds from the Borough Council of Ballarat West, was subscribed by a number of sympathisers, and on the 26th October, 1870, the inaugural address was delivered by Sir Redmond Barry, the first President of the School. Classes were commenced on the 23rd January, 1871. The students at first were mostly adults. They were chiefly men emloyed at the mines, who had the wisdom and energy to devote their spare time to study, and, though their attendance was somewhat irregular, they made very good progress. Old prints which have been preserved show them at work at furnaces, big bearded men of the old-fashioned type of miner. It is interesting to note that among those who gave evidence and encouragement was Sir Roderick Murchison, who many years before had advised Cornish miners to emigrate to Australia to search for gold, and who in 1848 was in possession of gold ore sent from this country. Sir Roderick sent a parcel of books for the library, and gave useful advice as to the curriculum which should be adopted. The Museum, which now contains a most valuable collection of minerals, was one of the first things attended to, and the reports presented to the Council from time to time speak of additions being made from all parts of the world. New equipment was constantly being added to the School, a good deal of assay work was done, and some specimens were sent from the East Indies for examination as far back as 1873. By this time there was a difficulty in providing accomodation for the students who wished to enrol, and the number of instructors had grown from two to four. In 1882 the first building was being erected on what was then part of the gaol reserve. A little more than ten years afterwards a buildnig formerly serving as a Methodist Church was absorbed, while later on, the demand for accomodation increasing, the attack upon the gaol was renewed. The School continued to grow in reputation and size, and became the science centre of the district, and in 1889 a learge new building was opened by Sir Alexander Peacock. Students came from over seas as well as from all the States of Australia, and after going through their courses they took with them the name and fame of the old School to all parts of the globe. School of Mines boys have played a great part in developing the mining fields of Western Australia, South Australia, and africa, while old students who have made a name in their profession are constantly dropping in to see how the old place is getting along. It was not to be expected, however, that the Ballarat School would be left without rivals, its very success inspiring competition. Mining Schools were started in other parts of Australia, and, at the same time, Victoria ceased to hold first place as a mining state. On the other hand there was a great advance in manufacturing, and the demand for technicaly trained men became a great and as insistent as ever it had been for trained mining men. The Council was quick to adapt the school to the new conditions, and the result is seen in the institution, which is one of Ballarat's proudest possession. Instruction is given in all branches of technical work, and the classes are filled with students who are building up for Ballarat a reputation as an industrial centre, which promises to equal that which it formerly held as a mining town. Owing to its bracing climate, its abundant opportunities for recreations, and its accessibilty, Ballarat as a city is an ideal place for educational purposed, and is yearly becoming more and more appreciated throughout the State. The chairman of one of Ballarat's biggests industries claims that the workman can do twice the day's work here that he can do in Melbourne. he was a little enthusiastic over it, perhaps, but it is a well-known fact that the healthy and invigourating Ballarat climate is conducive to both physical and mental activity, and the records of the School provide ample proof of it. One of the most interesting and successful branches of the School of Mines and Industries - if the name be enlarged with the enlargement of its scope - is the Technical Art School. "The City of Statues" has from its earliest days been a stronghold of art. Art schools have flourised here, and in 1905 the Education Department came to the conclusion that the best thing to do with them was to place them under the management of the School of Mines Council. A magnificent new Technical Art School was built at a cost of some 12,000 pounds on the site of the old Supreme Court building, and was formally opened on the 23rd July, 1915. The results have not only been justified but surpassed all anticipations. The most comprehensive list of subjects is taught, and this list is constantly added to. Students have flocked to the art School, which may be said to occupy a unique position in Australia, and its record of success is really astonishing. Its students supply art teachers for the newer schools that are being built, and many occupy leading positinos in important business houses. So well is its reputation known that orders are constantly being received, not only from Victoria, but from other States, for honor boards and challenge shields to be designed and made. The most recent addition to the School of Mines and Industries is the Junior Technical School, for which a new building is now being erected on a portion of the gaol site, transferred to the School of Mines Counci by the Government. At the present moment temporary quarters are being occupied. Some students after passing through the Junior School go straight to employment, continuing perhaps to attend the evening trade classes, while others move on to the senior School. In a review of the work of the School of Mines mention must be made of a series of industrial research carried out under supervision of the Principal. One in particular, regarding the suitability of the local ores for the manufacture of pigments attracted much attention, while the experiemtns on the manufacture of white potery from Victorian clayes were considered of sufficient importance by the Federal Advisory Council of Science and Industry to warrant the appointment of a special investigator. The results of these have been most encouraging, and may have far-reaching consequences. The vocational training of returned soldiers also should not be overlooked. The work was taken in hand from the first, before the Repatriation Department gave assistance, and now with the help of the department of the School has become one of the largest vocational training centres in Victoria outside of Melbourne. The soldiers, trained in a variety of occupations, have made remarkable progress, and already considerable numbers have found employment in local workshops and factories. To sum up, the School is divided into the following departments, each well staffed and equipped: - The School of Mines, science, and Engineering; the Techncial Art School, the Boys' Junior Technical School, the Girl's Preparatory Technical Classes, Trade Classes, and the Commercial School. The school of Mines, science and Engineering, comprises the following branches: - Mining, Metallurgy, Geology, Electrical Engineering, Civil Engineering, Mechanical Engineering, Applied Chemistry, and Pharmacy. Battery treatments, Cyanide Testing, Smelting, Assays, and Clay Testing from a regular part of the School's work. Students gaining qualifications obtain concession in their courses at the university, should they proceed there to continue their studies. The technical Art school curriculum includes training in all branches of pictorial and applied art, an Architectural Diploma Course, a Draughtman's Course, technical Art teachers' Course, Photography,Ticket Writing, Art Metal Work, Woodcarving, Needlework, and Leather work. The Trade Classes give instruction in Telephone Mechanics, telegraphy, Carpentry, Cabinet Making, Plumbing, Blacksmithing, Fitting, Electric Wiring, and Printing. Numerous Scholarships are offered every year, and altogether students will find few places to equal the Ballarat School of Mines and Industries as a training place for their life's work. One of the first in the continent to be established, its Jubilee finds it still in the front rank, keeping pace with the times, and offering to the youths of this country the means of taking advantage of Australia's teeming opportunities. william, battery, smith, herbert, drawing from the antique, ballarat school of mines botanical gardens, ballarat school of mines, redmond barry, alfred mica smith, james bickett, museum, dick richards, ballarat junior technical school, s m b, ballarat school of mines and industries, ballarat technical art school, model mine, james m bickett, j m bickett, roderick murchison, vocational training rooms, wesley church, methodist church, alexander peacock, lathes, repatriation, repatriatin department, war service, school council, baragwanath, gold mining, mining laboratory, plaster cast, r.w. richards, anniversary, jubilee -

Federation University Historical Collection

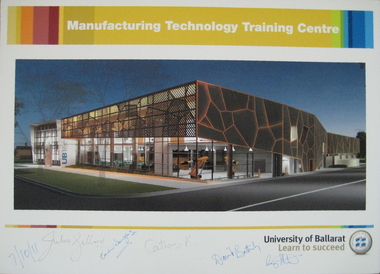

Federation University Historical CollectionPhotograph - Poster, University of Ballarat Manufacturing Technology Training Centre poster signed by Prime Minister Julia Gillard, 07/10/2011 (approx 11.15am)

The new Manufacturing Technology Training Centre (MTTC), a part of the proposed Building Construction Training Centre (BCTC), will be a purpose-built, stand-alone, fully fitted-out industry-standard facility. This new space will accommodate current course provision along with specialist training spaces for developing skill requirements in manufacturing technology such as robotics, mechatronics, engineering and industrial automation. Project funding was provided by the Education Investment Fund from the Australian Government Department of Education, Employment and Workplace Relations. The project budget is $18.09m, and the resulting building will have a floor space of 4,755m2. The Manufacturing Technology Training Centre is being built in conjunction with the Technical Education Centre (UBTec). While the buildings will have separate street identities the buildings will be joined with shared amenities areas. UBTec will provide a facility including individual learning spaces, learning studios, administration/office space, circulation, open plan learning space, staff common areas, computer rooms, meeting rooms, staff work areas and kitchen areas as well as car parking and site-wide amenities. While the buildings will have separate street identities the buildings will be joined with shared amenities areas. Funding for the UBTec component of the building is provided by Maintaining the Advantage: Skilled Victorians from the Victorian State Government. A colour poster prepared for the 'turning of the sod' at the site of the proposed University of Ballarat Manufacturing Technology Training Centre (MTTC), Grant Street, Ballarat. The poster was signed on Friday 7 October 2011 at about 11:15 am at the Building Construction Training Centre (BCTC), Grant Street, Ballarat by: Hon. Julia Gillard MP Hon. Catherine King MP (Ballarat ) Prof. David Battersby, Vice Chancellor, University of Ballarat Mayor, Cr Craig Fletcher, Mayor of the City of Ballarat appointed in December 2010 Mrs. Karen Douglas, Chair University of Ballarat Building & Infrastructure Committee The poster is signed by the Prime Minister of Australia, the Hon. Julia Gillard MP; Karen Douglas; the Hon. Catherine King MP (Ballarat ); Prof. David Battersby (Vice Chancellor); Craig Fletcher (Mayor, City of Ballarat)university of ballarat, david battersby, julia gillard, prime minister, catherine king, ubtec, karen douglas, manufacturing technology training centre, grant street, architecural feature -

Federation University Historical Collection

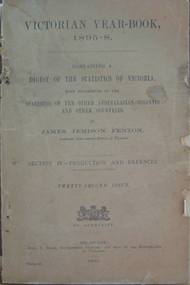

Federation University Historical CollectionBook, Robert S. Brain, Government Printer, Victorian Year Book 1895-8, 1901

This year book was published in the year of Australian Federation. It was the 22nd issue of the Victorian Year BookBrown soft covered book of 1000 page. The book contains a digest of the statistics of Victoria with reference to the other Australasian Colonies and other countries. Topics include the land system of Victoria, Crown lands, Agricultural statistics, cultivation, industry, livestock, wool, dairy farms, cattle, rabbits, manufactures, alcohol production, mining, defense. Statistics were provided by J.J. Fenton, Assistant Government Statist. -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageContainer - Ink Bottle with pens, Early 20th century

This handmade, aqua glass ink bottle's design is sometimes called a ‘boat’ shape. The base was mouth-blown into a rectangular mould, evidenced by the lack of seams, the pontil, crease lies and the uneven thickness of the glass. The shoulder section was mouth-blown into a two-piece mould and then cut off from the blowpipe. The lip is sometimes referred to as a 'burst-lip, which was often filed to be smooth. This method of making bottles was often used in the mid-to-late 19th century. The bottle would then be filled with ink and sealed with a cork. More expensive bottles would have a lip added, which was more time-consuming and costly. The capacity for a bottle such as this was about 3 ½ oz (ounces) equal to about 100 ml. Pens are a common item for that period. Pen and ink have been used for handwriting since about the seventh century. A quill pen made from a bird’s feather was used until the mid-19th century. In the 1850s a steel point nib for the dip pen was invented and could be manufactured on machines in large quantities. The nis only held a small amount of ink so users had to frequently dip the nib into an ink well for more ink. Handwriting left wet ink on the paper, so the blotting paper was carefully used to absorb the excess ink and prevent smudging. Ink could be purchased as a ready-to-use liquid or in powdered form, which needed to be mixed with water. In the 1880s a successful, portable fountain pen gave smooth-flowing ink and was easy to use. In the mid-20th century, the modern ballpoint pen was readily available and inexpensive, so the fountain pen lost its popularity. However, artisans continue to use nib pens to create beautiful calligraphy.The ink bottle is of interest, being made of aqua glass rather than the more common clear glass. This set of ink bottles and pens is significant because of the bottle's method of manufacture, which is representative of a 19th-century handcraft industry that has now been largely replaced by mass production. The bottle and pens are historically significant as tools used for handwritten communication until the mid-20th century when fountain pens and modern ballpoint pens became popular and convenient and mechanical typewriters became part of standard office equipment.Victorian 'Boat' ink bottle, small rectangular, aqua glass ink bottle with grooves along the long sides for pen rests. The base has a pontil, no seams, and the glass is uneven in thickness. The shoulder has two side seams and there is a ridge where it is joined onto the base; there are round indents on each of the shoulder, on the short sides, four in all. The mouth has rough edges. The neck leans to one side. The glass has impurities, crease lines and bubbles. There is dried ink in the bottle. Two pens with metal nibs are included with the ink bottle. flagstaff hill, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, ink, nib pen, writing ink, writing, copying, banks, lawyers, commerce, student, permanent ink, stationery, record keeping, handwriting, writing equipment, writing accessory, office supply, cottage bottle, boat bottle, mouth-blown bottle, two-part mould, sheer-lip bottle, burst-lip, cork seal, copy ink, aqua glass -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageContainer - Ink Bottle and Pen, Caldwell’s Ink Factory, Early 20th century

This shaped ink bottle made by Caldwell's is called a 'boat ink bottle'. It was shaped especially to hold a nib pen when the pen was not in use. The design of the bottle is sometimes called a ‘cottage’ or ‘boat’ shape. The Caldwell’s handmade glass ink bottle was mouth-blown into a two-piece mould, a method often used in the mid-to-late 19th century. The glass blower burst the bottle off the end of his blowpipe with a tool, leaving an uneven mouth and sharp edge on the bottle, which was usually filed. The bottle was then filled with ink and sealed with a cork. More expensive bottles would have a lip added, which was more time-consuming and costly to produce. The capacity for a bottle such as this was about 3 ½ oz (ounces) equal to about 100 ml. Pen and ink have been in use for handwriting since about the seventh century. A quill pen made from a bird’s feather was used up until around the mid-19th century. In the 1850s a steel point nib for the dip pen was invented and could be manufactured on machines in large quantities. The nis only held a small amount of ink so users had to frequently dip the nib into an ink well for more ink. Handwriting left wet ink on the paper, so the blotting paper was carefully used to absorb the excess ink and prevent smudging. Ink could be purchased as a ready-to-use liquid or in powdered form, which needed to be mixed with water. In the 1880s a successful, portable fountain pen gave smooth-flowing ink and was easy to use. In the mid-20th century, the modern ballpoint pen was readily available and inexpensive, so the fountain pen lost its popularity. However, artisans continue to use nib pens to create beautiful calligraphy. Caldwell’s Ink Co. – F.R. Caldwell established Caldwell’s Ink Company in Australia around 1902. In Victoria, he operated from a factory at Victoria Avenue, Albert Park, until about 1911, then from Yarra Bank Road in South Melbourne. Newspaper offices were appointed as agencies to sell his inks, for example, in 1904 the New Zealand Evening Star sold Caldwell’s Flo-Eesi blue black ink in various bottle sizes, and Murchison Advocate (Victoria) stocked Caldwell’s ink in crimson, green, blue black, violet, and blue. Caldwell’s ink was stated to be “non-corrosive and unaffected by steel pens”. A motto used in advertising in 1904-1908 reads ‘Makes Writing a Pleasure’. Stationers stocked Caldwell’s products and hawkers sold Caldwell’s ink stands from door to door in Sydney in the 1910s and 1920s. In 1911 Caldwell promised cash for returned ink bottles and warned of prosecution for anyone found refilling his bottles. Caldwell’s Ink Stands were given as gifts. The company encouraged all forms of writing with their Australian-made Flo-Eesi writing inks and bottles at their impressive booth in the ‘All Australian Exhibition’ in 1913. It advertised its other products, which included Caldwell’s Gum, Caldwell’s Stencil Ink (copy ink) and Caldwell’s Quicksticker as well as Caldwell’s ‘Zac’ Cough Mixture. Caldwell stated in a 1920 article that his inks were made from a formula that was over a century old, and were scientifically tested and quality controlled. The formula included gallic and tannic acids and high-quality dyes to ensure that they did not fade. They were “free from all injurious chemicals”. The permanent quality of the ink was important for legal reasons, particularly to banks, accountants, commerce, municipal councils and lawyers. The Caldwell’s Ink Company also exported crates of its ink bottles and ink stands overseas. Newspaper advertisements can be found for Caldwell’s Ink Company up until 1934 when the company said they were the Best in the business for 40 years.This pen and ink bottle set is of significance as the bottle has its original cork and retains remnants of ink, which was made from a recipe that at the time was over 100 years old, according to Caldwell.. The handmade, mould blown method of manufacture is representative of a 19th-century handcraft industry that is now been largely replaced by mass production. The bottle and its contents are of state significance for being produced by an early Melbourne industry and exported overseas. The pen and ink set is historically significant as it represents methods of handwritten communication that were still common up until the mid-20th century when fountain pens and modern ballpoint pens became popular and convenient and typewriters were becoming part of standard office equipment.Victorian boat ink bottle; small rectangular clear glass ink bottle with horizontal grooves made in the glass for resting and holding the pen. The set includes one pen and nib with the bottle and cork. The bottle is made by Caldwell's and contains its Flo-Eesi Blue Black Ink brand."Caldwell's Flo-Eesi Blue Black Ink."flagstaff hill, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, ink, nib pen, writing ink, writing, copying, banks, lawyers, commerce, student, permanent ink, flo-eesi, blue black ink, stationery, record keeping, handwriting, writing equipment, writing accessory, office supply, cottage bottle, boat bottle, mouth-blown bottle, two-part mould, sheer-lip bottle, burst-lip, cork seal, f r caldwell, caldwell’s ink company, albert park, south melbourne, inkstands, stencil ink, copy ink, quicksticker, zac cough mixture -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageClothing - Boots, Tony Lama, Early 20th century

The inscription "T L" on these early 20th century ladies button-up boots lead to the maker likely to be Tony Lama, a famous USA boot manufacturer, son of Italian immigrants. The "Rome" is the style of boot. The "6" is likely to be the soot size. Tony Lama began work at age 11 years in the leather trade industry, serving an apprenticeship as a shoemaker. He joined the US Cavalry when he was 16, after lying about his age, working as a cobbler to make boots for the soldiers. His workmanship became popular, particularly for the 'Western' style of boot. TONY LAMA boots In 1911 Lama established a company in Texas, first repairing boots, then adapting his shop to manufacture boots in order to meet the many orders he was receiving. He married and he and his wife Esther brought up six children who also went on to work in the family business. The business continued to grow through WWII. Part of the business included custom boot making and Tony's eldest son Joseph presented President Truman with a pair of kangaroo skin boots. The prosperous business became a company and eventually, in 1990, was sold to Justin Industries.This pair of boots is an example of women's footwear dating around the early 20th century. Pair of ladies leather button-up boots. Two-tone style: black bottom strong leather bottom and white, soft kid leather top. Boots have a curved fly fastened by 11 white buttons with metal shanks. Boots are constructed with cork filling. Inscriptions of both boots. "6 101" "TL" " Rome" "Cork Filled"flagstaff hill, warrnambool, maritime-museum, shipwreck-coast, flagstaff hill maritime museum & village, ladies button up boots, footwear, victorian era, granny boots, tony lama, ladie's boots, ladies' fashion, women's clothing, rome, kid leather, two-tone boots, leather boots, button-up boots -

Flagstaff Hill Maritime Museum and Village

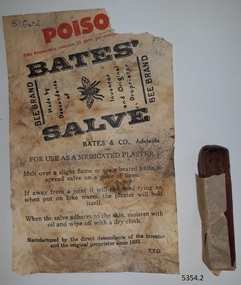

Flagstaff Hill Maritime Museum and VillageArticle - Ointment, Bates & Co. (William Usher), 1851 - mid-1900s

Bates' Salve has been used as a home remedy for the treatment of boils, skin infections, splinters, pimples and insect bites for decades, from the mid-1800s to the mid-1900s. It is a drawing application for bringing out foreign bodies and pusses from a wound. There are still many families who remember using it and others who have been using it and are down to their last ‘inch’. One comment from a reader from Queensland tells how his Dad was a sleeper cutter in the 1950s and on school holidays his brother and he used to help their Dad. When doing this task after a wet season they would be confronted with spear grass about a metre high. Sometimes the spears would enter their skin, and when the spears were wet they would screw like a corkscrew into their flesh. If they left them for too long it was impossible to dig them out with a needle. That's when the Bates Salve was put into action to draw the spearhead out. "It worked wonders. It was a marvellous invention." Many people say that they would love to be able to purchase more of it today and hope that someone will produce a ‘safe’ version of it. There are several versions of a recipe for the salve available online. It appears that the salve is named after Daisy Bates, wife of the Bates’ Salve proprietor, William Usher. William’s son Victor continued making Bates’ Salve well into the mid-1900s, with the business being carried on by Victor’s only son, Alan. There are still descendants in the family home in Norwood, Adelaide. William’s great-grandchild has stated that, despite being subject to the salve during childhood, there have been no noticeable ill effects. A small notice in the Adelaide Advertiser in 1915 made a suggestion “It is said that Bates’ Salve is the popular line with OUR BOYS in Gallipoli. They recently sent to the Adelaide Red Cross for a supply, so it would be a good line to put in soldiers’ Christmas Billies.“ Over 700 ‘Christmas Billies’ were sent from generous Warrnambool citizens to our soldiers in the trenches in Gallipoli. The average cost of filling a billy with gifts was Ten Shillings, calculated at about Fifty-four Dollars in 2021. The contents included Christmas puddings and tobacco. The huge project was coordinated by a local Committee and involved generous businesses and hundreds of kind-hearted community members, with recognition sown by naming many of those involved in an article in the Warrnambool Standard. The project’s idea was initiated by Australia’s Department of Defence and all states were involved in supporting the soldiers in this way. Mr Bates (Theopholis) of Hull, England, was the original owner of the Bates’ Salve recipe. When he died he left his business to William Usher, his son-in-law. William arrived in South Australia in 1851 after he had sold his recipe to an English firm, giving them the rights to make and sell it all over the world, except in Australia. Bates then became the registered proprietor of Bates’ Salve for the Commonwealth and still had a large market for his product. William Usher made the salve at his Norwood home, in a wood-fired copper in the garden within a three-sided enclosure. The ointment was then taken to a room in the house where it was divided, labelled and packaged. It was then sent to Faulding’s Wholesale Chemist for distribution. William and his wife May (or Mary) had three children; Jack, Victor and Ivy. When May died, William married Mary Williams (May’s maid, from Tasmania, twenty years younger than William) and had seven more children. The treatment’s packaging labels it as a POISON. It seems that its active ingredient was lead oxide (22 per cent), which is no longer considered unsafe. A member of the public mentioned that in 2016 they found some Bates’ Salve in an old family medicine chest. Its label stated that the product “contains a minimum of 25.8 per cent of red lead oxide”. That particular sample was made at 470 Wallon Road, West Molesey, Surrey, England. Some people would love to be able to use the product still and even take the risk of poisoning. Instructions for its use are included on the wrapper. Here is a transcription - "Bates' Salve. Bee Brand. POISON. This Preparation contains 22 parts per centum [lead oxide]… Made by Descendants of the Inventor and Original Proprietor. For use as a medicated plaster. Melt over a slight flame or use a heated knife to spread the salve on a piece of linen. If away from a joint it will not need tying as, when put on lukewarm, the plaster will hold itself. When the salve adheres to the skin moisten it with oil and wipe it off with a dry cloth. Manufactured by the direct descendants of the inventor and the original proprietor since 1833."This package of Bates' Salve has been used as a home remedy since the mod-1800s and even up to now in 2019 by those who consider themselves lucky to still have some at home. It was promoted as a 'cure all' treatment and kept handy for use at home and away. It represents our early industry and health management when medical treatment was often difficult to access. The product is the part of many childhood memories of those alive today.Bates’ Salve ointment; oblong stick of firm, brown waxy substance wrapped in waxed paper, with an outer printed wrapper. Text on wrapper warns that it is POISON and includes instructions for use as a medicated plaster, to be heated and spread onto linen then applied to the injury. Made by Bates & Co., Adelaide. The wrapper shows an emblem of a bee. The formula has been used since 1833.Text on wrapper includes "POISO[N]", "BATES' SALVE", "BEE BRAND", "BATES & CO., ADELAIDE". "This Preparation contains 22 parts per centum [lead oxide]" There is an emblem of a bee with wings outstretched.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, bates’ salve, bates’ salve medicated plaster, bates and co adelaide, bee brand, medicated plaster, medical treatment, remedy, drawing treatment for infection, medicine cabinet, home remedy, pharmacy treatment, mid 1800s – mid 1900s remedy, topical application, treatment for boils, bites, splinters and infections, poison, preparation for treatment, ointment -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageCalipers, Moore & Wright, 1925-1935

Established in 1906, Frank Moore soon became well known amongst discerning tradespeople for the quality & accuracy of his tools. The Company was acquired by John Shaw & Son in 1945 & James Neill & Co in 1970. Currently part of the Bower Meteorology UK Group, they still produce superb tools & measuring instruments in Sheffield. The subject item is made from high-grade carbon silver tool steel with the patented 'Firm Lock' joint, that identifies the maker as Moore & Wright.A tool used for external measurement of items made by a maker who patented the "firm lock" jointing system now used on many different types of tools in many different industries. These items are now collectible and quite rare as a result are sought by tool collectors in the USA and UK.‘Firm Joint’ external measuring calipers believed made by Moore & Wright. Impressed into the metal "L A J S" (Probably the owner and company that used the item nothing to do with manufacturing) flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, calipers, callipers, external calipers, outer caliper, pottery tools, masonry tools, glass making tools, external measurement -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageMachine - Treadle Lathe, 1920-1923

The lathe-making business incorporated in 1902 as Drummond Bros Ltd originated in the fertile mind of Mr Arthur Drummond, said to have been living at that time at Pinks Hill, on the southern edge of Broad Street Common, west of Guildford. Mr Drummond, whose accomplishments included several pictures hung in the Royal Academy, was unable to find a lathe suitable for use in model engineering. In 1896 he designed for himself a ‘small centre lathe … which had a compound slide rest with feed-screws and adjustable slides’. He also designed and built ‘lathes of 4.5 inch and 5 inch centre height, which had beds of a special form whereby the use of a gap piece was eliminated but the advantages of a gap-bed lathe were retained’. Assisted by his brother, Mr Frank Drummond, who had served an apprenticeship to an engineering firm at Tunbridge Wells, the first lathes were made in a workshop adjoining Arthur Drummond’s house. The demand that speedily built up led to the decision to form a company and manufacture the lathes for sale commercially. Land was acquired nearby, at Rydes Hill, and the first factory built. The enterprise was a success, and the company quickly established ‘a high reputation in this country and abroad for multi-tool and copying lathes, and gear-cutting machines’. Other lathes were added to the range, including the first of the ’round bed’ machines for which the firm became widely known. A Drummond 3.5 inch lathe was among the equipment of Captain Scott’s 1912 expedition to the South Pole, and large numbers of 3.5 inch and 4 inch designs were exported to Australia, Canada and India. By the outbreak of war in 1914, 5 inch, 6 inch and 7 inch screw cutting lathes, arranged for power drive, were on sale. Large orders were received from the government for 3.5 inch lathes, for use in destroyers and submarines, and 5 inch lathes for the mechanised section of the Army Service Corps. The latter were used in mobile workshops. The factory worked night and day to supply the forces’ needs, until production was disrupted by a fire which destroyed a large part of the works in May 1915. As soon as rebuilding was complete work restarted. At the end of the war the entire production was being taken by the Government departments, a special feature being a precision screw lathe, bought by the Ministry of Munitions in 1918. Between the wars Drummond Bros Ltd introduced new machines for the motor vehicle, and later the aircraft industry, and the works were extended on many occasions to fulfill the increasing orders. The Maxicut multi-tool lathe (1925), designed for high-production turning operations, was one of the first machines of this type to be built in England. It was followed (1928) by an hydraulic version for turning gear blanks, and similar work. Further developments provided machines which, during the Second World War, turned all the crankshafts and propeller shafts for Bristol engines. Others, ordered by the Ministry of Supply were employed in turning shells, and many other specific needs of vehicle and aircraft manufacture were catered for by new types of Drummond lathes. Production of the small centre lathes ceased during the war when the company needed to concentrate on building multi-tool lathes and gear shapers. After the war a completely new Maxicut range was introduced, replacing the older versions, and fully automatic. The types were continually developed, and new versions manufactured until the end of the company’s life in 1980. The disappearance from the scene of Mr Arthur Drummond in 1946, and the end of the company’s autonomous existence in 1953 when the company was acquired by William Asquith Ltd, which was in turn bought by Staveley in 1966, meant that the factory at Rydes Hill became one – albeit very effective – part of a large national engineering company. Achievements at the Guildford works during its last years included the development of automated Maxicut gear-shapers in what was ‘probably the most fully automated gear shop in the country’, while a machine from Guildford was sent to the Osaka Fair in 1962. In 1963 an agreement was signed with Hindustan Machine Tools for the manufacture of Maxicut gear-shapers in state owned factories in Bangalore and Chandigarh. During 1963 the two largest multi-tool lathes ever made in the UK were installed in Ambrose Shardlow’s works in Sheffield for handling cranks up to 14 foot long. In 1976 Drummond lathes were included in Staveley’s £14,000,000 installation in Moscow of an automated production line for Zil motor cars. Up to the end invention continued at Guildford: a new Drummond Multi-turn memory-controlled machine was shown at the International Machine Tool Exhibition in 1977. This could not save the works from the pressures of the late 1970s, and Staveley Industries closed its Guildford site in 1980.An early example of a lathe that was designed primarily for the hobbyist model maker. It is in good condition and sought today by collectors as many of it's attributes were innovative at the time and lead to further development and incorporation of some of its features into more industrial models of production machinery. Lathe, round bed, treadle powered lathe, Drummond Type A, Serial number and maker's inscription. 1920-1923, Made by Drummond Brothers in Guildford, Surrey, England. Lathe is complete with Chuck, Tool post and Tail Stock in situ (30 extra parts)"MADE BY DRUMMOND BROTHERS LIMITED - PATENT TEES - RYDE'S HILL n GUILDFORD SURREY", "Serial Number 01470," "L44" or "L45 " flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, lathe 1920-1923, round bed lathe, treadle lathe, drummond type a, guildford surrey, drummond brothers guildford surrey england, tread'e -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Company seal embosser, Unknown

The former Albion (West) Woollen and Worsted Mills is a functional structure which has been built in stages, possibly dating from the 1880s, with the earliest sections near to the Barwon River.The Worsted mill operated for about 50 years and at its peak employed around 500 people. In 1973 the mill merged with the British John Foster and Sons Company under some controversial stock and shareholding issues. The mill continued for a short period before closing at a time when much of the Australian textile industry was finding it difficult to compete with overseas operations. In the 30 plus years after the closure, the site was used for several ventures, including the Mill Vintage Markets and a vehicle trim manufacturing operation. In 2011 the site was purchased by Little Creatures of Western Australia to become their main brewery for the eastern states of Australia. Now owned by the Lion Group, Little Creatures started their 60 million dollar transformation of the old mill in 2012. Finally, in 2013 these former walls of industry were soon rattling away to the sounds of a different type of industry, as the first bottles of beer made their way out of the Geelong Little Creatures Brewery. The remaining building of the former Albion Woollen and Worsted Mills has historical significance as one of Geelong's major woollen mills. The venture has operated on the same site for more than a century. The Albion Woollen Mill was one of the four key sites along with Victoria, Barwon and Union Mills that was established in the late 1860s to mid-1870s. These mills were in constant operation on the west side of the Barwon Bridge over the last century and led to Geelong's fame as milling and scouring locality. The Albion Mill was probably the most successful survivor of the early private company operations. It was regarded as a model mill in the late 1880s and was, from all accounts, well-planned and organised with machinery on a par with the great mills of England. It produced high-quality tweeds. Together with the (now demolished) Union Mill it was regarded as the borough's principal industry over the 1870-1900 period and was one of Australia's most significant producers of tweed by 1900. These two mills were more successful, competitive and long-lived than the Barwon and Victoria Mills. The remaining building form is an important reminder of the private ventures of both the Albion and Union Mills and represents a key site of spinning, carding and finishing as well as scouring and dying that occurred in the lower section near to the river. The loss of the adjacent former Union Mill is unfortunate because the complex, together with the former Collins Union Mill office building, was an important reminder of the success of these industries and the reputation they earned for the Geelong region as a centre for quality textile products. Company seal embosser hand operated matte black & brass colour Western District Worsted Mills emblem on frontflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Sewing Machine, Early 20th century