Showing 773 items matching "mechanical"

-

Puffing Billy Railway

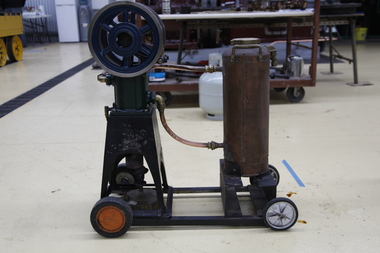

Puffing Billy RailwayHeinrici Hot Air Motor, 1900s

Louis Heinrici, Germany, circa 1900 a small Stirling type hot air engine in which a body of air is worked constantly, being alternately heated and cooled during each revolution of the crankshaft. Heinrici hot air engines are of the valveless, closed cycle type, generally called Stirling cycle engines, after Robert Stirling, the Scottish Presbyterian minister who pioneered their development in the early 1800's. They operate by alternately heating and cooling a quantity of air, called the working fluid, contained in the engine's internal spaces. Heat is applied externally and passes through the cylinder wall, heating the working fluid, which is then expanded against a piston to do mechanical work. After heating and expanding, the working fluid is moved to a cool space where it cools and contracts before being returned to the hot space for the cycle to repeat. It has a displacer (just a loose piston), below and in the same cylinder as the power piston to which it is connected via cranks and linkages so as to lead by 90degrees of crankshaft angle. The displacer space and the piston space are connected by the annular gap around the loose fitting displacer so that the working fluid moves between these spaces and changes volume by the appropriate ratio as the engine rotates. Because they have no valves and experience no sudden pressure changes, Stirling engines are noted for quietness and reliability. Heinricis use air at atmospheric pressure for their working fluid, but for higher specific output (power for size) and better efficiency, modern Stirling cycle engines use pressurised gas- air, nitrogen, helium or hydrogen.Historic - Hot Air Engine - MotorHot Air Motor made of Steel with two drive wheels. a small Stirling type hot air engine in which a body of air is worked constantly, being alternately heated and cooled during each revolution of the crankshaft. Heinrici Motorheinrici hot air motor, puffing billy -

Federation University Art Collection

Federation University Art CollectionPainting - Oil on Canvas, Johnson, George, 'Symbols of Life' by George Johnson, 1965

George JOHNSON (18 August 1926- ) Born Nelson, New Zealand Arrived Australia 1953 George Johnson's formalised abstractions usually feature a pattern of small related geometrical shapes which give life, luminosity and fluidity to forms which might be mechanical and lifeless. Later his forms become become much larger and more architonic. The work of George Johnson debuted at the Herald Outdoor Art Show in 1953. The George Johnson Mural was commissioned by the Ballarat Teachers' College Students' Representative Council in 1965. It was purchased with funds raised by staff and students. At the unveiling of this work at the Ballarat Teachers' College Johnson's work was described at belonging to the "Hard Edged" school of abstract painters who had set themselves far above the mass of abstract painters by the vitality and artistic ability displayed in their work. Of the work John JOhnson said "We are all part of life and are growing and developing in many different ways, the process of development is often taking place without us even being aware of it. In my painting the embryo shapes appear and grow. I have tried to make the mural symbolic of life and growth. I do not thank that anything has been left to chance in the mural. Everything is working, and, I feel, working well. It has balance and harmony - and perhaps discord, as does life - one malfunction or imbalance throws everything out." This item is part of the Federation University Art Collection. The Art Collection features over 2000 works and was listed as a 'Ballarat Treasure' in 2007.A painted mural in three panels, including hession collage. art, artwork, george johnson, johnson, ballarat teachers' college art collection, mural, hard edged -

Wodonga & District Historical Society Inc

Wodonga & District Historical Society IncDomestic object - Lehmann Tin Lithographed Windup Zikra Zebra Cart, Ernest Lehmann Co, 1920s

This item is from a collection donated by descendants of John Francis Turner of Wodonga. Mr. Turner was born on 6 June 1885. He completed all of his schooling at Scotts Boarding School in Albury, New South Wales. On leaving school, he was employed at Dalgety’s, Albury as an auctioneer. In 1924 John was promoted to Manager of the Wodonga Branch of Dalgety’s. On 15/03/1900 he married Beatrice Neal (born 7/12/1887 and died 7/2/1953) from Collingwood, Victoria. They had 4 daughters – Francis (Nancy), Heather, Jessie and Mary. In 1920, the family moved From Albury to Wodonga, purchasing their family home “Locherbie” at 169 High Street, Wodonga. "Locherbie" still stands in Wodonga in 2022. The collection contains items used by the Turner family during their life in Wodonga. The Ernest Lehmann Co was founded in 1881 by Ernest Paul Lehmann in Brandenburg, Germany. Lehmann exported vast quantities of toys to the United States from 1895 to 1929 (excluding years of WWI). In 1921, Mr. Lehmann’s cousin, Johannes Richter joined the firm and built on the Lehmann reputation by patenting toys. Lehmann specialized in lithographed tinplate, mechanical transportation toys, and figures known for colorful patina. This toy was manufactured between 1924 and 1935. The Lehmann catalogue describes the toy as “[a] Mexican zebra team. The zebra refuses to be tamed and leaps about wildly.” It is believed to have been inspired by an unsuccessful German stud farm in Dar es Salaam that attempted to cross-breed zebra with domesticated horse.This item comes from a collection used by a prominent citizen of Wodonga. It is representative of popular children's toys in the 1920s and 1930s.This is a tin, lithographed, windup toy featuring a zebra and Mexican style driver. The seated driver has a green top and cream trousers and yellow and green pointed hat, zebra with red ears and cord tail. The cart is red and cream, embossed with the Lehmann company emblem and other patent information. The number 1881 on the back of the cart represents the year Ernest Lehmann Co was founded.On back of cart" ZIKRA/ 1881/LEHMANN" Behind driver: "PAT USA APP FOR" and PATENT USA 22 JAN 07/ 2 DEC 13" On side of cart:"DEUTCHES REICH PATENT" Around wheel rim: "LEHMANN MARKE SCHULTZ MUSTER"tin toys, zikra the zebra, ernest lehmann co -

Frankston RSL Sub Branch

Frankston RSL Sub BranchDrift Recorder, W & G, A M Drift Recorder MKII, 1930 - 1939

Purpose built mechanical calculation machine for determining the drift of aircraft when operating in crosswind conditions. This device has an eyepiece and a prismatic periscope for viewing a distant feature being tracked. This device has calibrated rotary scales for height, speed (in KNOTS and MPH), and an adjustment to preset the 'crab angle' of the aircaft for cross wind compensation. The device can be opened for cleaning or maintenance purposes. Refer to the following extracts for information about bomb drift: "Crosswinds brought into the bombing problem a new factor, "drift" In order to fly a given ground track in a crosswind, an aircraft had to "crab" into the wind; the angle formed between the aircraft's true heading and its ground track was called the "drift angle" In a crosswind, the bomb would impact directly behind the aircraft and along its longitudinal axis at the moment of release. But this meant that the bomb would strike the ground at some point downwind of the aircraft's ground track. Thus, in order to score a hit, the bomber had to fly a ground track that ran upwind of the target." "Air resistance acting on a bomb after release caused it to lag behind the drop point and hit somewhere behind the bomber. The distance from a point beneath the aircraft at the instant of bomb impact to the point of bomb impact was called "trail." Trail increased as the bomber's airspeed increased or as its altitude increased. Furthermore, since different bombs encountered different resistance in the air, trail was also a factor of bomb shape."A. M. Drift Recorder MKII REF. No 6B/190 No 2668/41 X/ 3606 3E4H28 -

NMIT (Northern Melbourne Institute of TAFE)

NMIT (Northern Melbourne Institute of TAFE)Plumbing tools: CTS and PTS 1920s onwards, Plumbing tools and texts used in teaching 1920s

A number of Plumbing tools dating from 1880s-1970s and used in teaching at Collingwood Technical School then also at Preston Technical School and at Northern Metropolitan College of TAFE's Heidelberg campus. Includes: Kerosene blow torch X 2 (1930s-); Stillson Grips; Pipe Cutter; Mash hammer; Adjustable spanner X 3 different sizes; Caulking tool; 5 way tee, 2X3 way tee, 4 way tee (1930s-); Old Handmade lead traps (student work) X 2; Metal tool tray holding; Offset adjustable spud spanner; Pear shaped lead working mallet; Bossing tool for lead work (1880s-1920s); Soldering iron (1920s-); Set square; Large screwdriver; Also Plumbing texts: • Problems for elementary physics, new rev. edn., by Thomas Tasker and Alexander Boden, Science Press, Sydney, 1966. • Gasfitting. Printed and published by McCarron Bird Pty. Ltd. [Melbourne] • Trade science for plumbing apprentices, Education Dept. Victoria, 1954 • Sanitary Plumbing and water supply, Dept. of Labour • Gasfitting, produced by members of the Colonial Gas Association Limited, Gas and Fuel Corporation of Victoria, and the Technical Division of the Education Department of Victoria. Rev metric edn. 1976 • Mechanical world year book 1953, Manchester Emmott & Co., 1953 collingwood technical school, preston technical school, northern metropolitan college of tafe, plumbing tools, plumbing texts, nmit -

Ballarat Tramway Museum

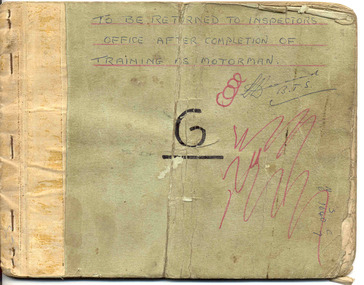

Ballarat Tramway MuseumBook, State Electricity Commission of Victoria (SECV), Ballarat Motorman (Driver) Training Manual or Guide - not a formal title, 1960's?, 1950's?

Demonstrates aspects of the Ballarat Tramways system of training Motorman or drivers in the 1960's and the information there were given on driving trams. Shows the training methods of the time. 3486.1 - also details "Dead Man Brakes"Thirty Three page - carbon copy - within stapled light card covers - Ballarat Motorman (Driver) Training Manual or Guide - not a formal title. On front cover is large letter "G" and words "To be returned to the inspectors office after completion of Training as Motorman" First four pages has index and covers: (A) Tramcar Equipment - electrical - items or clauses 1 to 28 (B) Location of Faults - items 29 - 41 (C) Tramcar Braking - items 42 to 59 (D) Failure of the Mechanical Brakes - items 60 to 67 (E) Tramcar Emergency Braking (Accident Prevention) - items 68 - 72 (F) Automatic Electric Signals - items 73 - 82 - gives locations of signals. (G) General Instructions - items 83 to 98. See condition notes - not in the best condition - needs careful handling. 3486.4 - ditto - similar to above, but 34 pages through to instruction 104. Added section (F) after (E) - "Automatic Braking - clauses 72 - 79, possibly an earlier version of above when trams were fitted with dead man controls. Held within a cardboard folder with a metal binder. Cover has been covered with brown paper and adhesive tape, but only remains on the inside of the cover. Item added 3/10/2007. See Reg Item 8110i for a Bendigo, c1940 version.See above 3486.1 - has "Hall G - M.Cond" on front cover. Another name has been rubbed out.trams, tramways, driver training, sec, signals, braking, equipment, emergency, dead man controls -

Ballarat Tramway Museum

Ballarat Tramway MuseumBook, State Electricity Commission of Victoria (SECV), Instructions or Rules to Motormen, post 1945

Handmade book with light green covers made from a cut file holder with brown paper glued on the inside, containing 39 typed (original) sheets of paper giving Instructions or Rules to Motormen. Has five page index, then 34 pages, with 104 rules or instructions, covering Tramcar Equipment (electrical), location of faults, tramcar braking, failure of the mechanical brakes, tramcar emergency braking, automatic braking, automatic electric signals and general instructions for Ballarat. The brown paper appears to have been placed on the outside, as it is cut and glued on the inside of the book. Individual sheets held into the book with a metal clip. On the rear of the book, a small piece of cardboard has been glued over the back of the metal strip. Notes mentions bogie trams, so therefore post 1945. Gives details of route electric signals, use of doors on the trams relevant to the central median strip. On page 4, has hand drawn diagram showing the motors in series and parallel. On page 8 has a hand drawn diagram showing the car lighting circuit arrangements. Has been folded in the middle so as to store in pockets of a coat. Images show .1 - book, .2 - inside front cover and index sheet, .3 - hand made drawing - car lighting circuit. See Destination Eaglehawktrams, tramways, secv rules, rules, motormen, conductors -

NMIT (Northern Melbourne Institute of TAFE)

NMIT (Northern Melbourne Institute of TAFE)DVDs: Promotional DVDs NMIT 1990-2010

Instructional and promotional DVDs ranging in date from 1990-2010 promoting courses and services of NMIT. 1990s An Introduction to NMIT 1996 X 2 Building & Construction Heidelberg 1992 Building & Construction Heidelberg 1992 1, 2, 3 (Umatic) Concrete pour - Heidelberg 1992 Greensborough Music Promotional 1994 Making the move 1996 (also booklet) NMCOT College Promotion 1990 NMCOT College promotion 1992 NMCOT Corporate Video 1992 NMCOT Corporate video 1994 NMCOT Enrolment form 1991 (Umatic) NMCOT Enrolment Form 1992 NMCOT To Market to Market Promotional video 1993 NMCOT To Market to Market Promotional video 1994 NMIT School of Arts & Social Sciences 1996 NMIT School of Building & Construction 1996 NMIT School of Business 1996 NMIT School of Electrical, Electronics & Sciences 1996 NMIT School of Horticulture & Rural Studies 1995 NMIT School of Horticulture & Rural Studies 1996 NMIT School of Manufacturing Engineering 1996 NMIT School of Mechanical Manufacturing 1996 NMIT School of Tourism & Hospitality 1996 NMIT Faculty of Earch Sciences 1998 NMIT The Electrical Connection 1995 Open Day 1992 Student Information 2003-2008 Advanced Diploma of Music Performance (undated) Challenges accepted, NMIT Roadshow 2005 Mechanical manufacturing 2003 Promotional video (master) 2006 Songwriting competition NMIT 2008 The Electrical connection 2003 2009 Animal Studies 2009 Bachelor of Viticulture & winemaking 2009 Certificate III in Aged Care 2009 Children’s Services 2009 Courses through Design Drafting & Interior Fittings 2009 X2 Equine Studies 2009 (also accompanying book) Erection and Dismantling procedure for an Oldfields Mobile Scaffold 2009 Facilitate Individual Learning Activity The REV shop Case Study 2009 Formwork to Columns and Beams 2009 Green skills Centre of Excellence : Contributing to sustainability directly through the design, our actions and by educating future generations on sustainable technology, [DVD], NMIT Epping Campus, [2009] Interior design 2009 Locksmith Apprenticeships 2009 Secondary to Tertiary: the Journey begins 2009 X 2 Visual Arts at NMIT 2009 2010 Advanced Diploma of Building design 2010 Bachelor of Accounting 2010 Bachelor of Equine Studies 2010 Certificate III in Farriery (Trade) 2010 Civil Engineering 2010 Cloisonne Enamel 2010 Conservation and Land Management 2010 Health & Community studies 2010 Horticulture 2010 How to check and adjust a single stage Liquid Petroleum Gas Regulator 2010 Locksmithing more than a trade 2010 Music, Sound & Television 2010 Pragmatic Failures in Intercultural Communication 2010 Technical Education Centre, Youth Unit, NMIT 2010 Viticulture & Winemaking 2010 Why study Community Services at NMIT 2010 courses, handbooks, nmit -

Warrnambool and District Historical Society Inc.

Warrnambool and District Historical Society Inc.Medal - Medal VHAS, Villiers and Heytesbury Agricultural Association, Circa 1880

Historical information: this medallion has historical details on three fronts. Firstly the Villiers & Heytesbury Agricultural Association. This association began with the first meeting held on May 17th 1853 at Woodford. The minutes of that meeting read “That in the opinion of this meeting, the formation of an agricultural association would be of great benefit to persons in this district engaged in farming and pastoral pursuits. It initially embraced the following: ploughing, agricultural produce, machines and implements, and livestock of all descriptions. The first show was held at Warrnambool on April 10th 1855 on a green bounded by Fairy, Henna, and Koroit Streets. It was held there until 1875 when it moved to the present Showgrounds site in Koroit Street. At the 37th Annual show in 1890 Warrnambool held its first Grand National Show, being granted by the Chamber of Agriculture in turn, in Victoria. It became known as the Warrnambool Agricultural Society in 1911. Secondly the winner, Mr Hugh Lennon. He was one of the most successful innovators and manufacturers of agricultural implements in early Australia. Although born in Ireland, he served an apprenticeship in Scotland in mechanical engineering. The Lennon plough became known Australia wide. For many years he operated his business at the northern of Elizabeth Street in Melbourne. He was active in local affairs. He died in 1886 at the age of 52. Thirdly, Stokes and Martin. Thomas Stokes came to Australia in the 1850’s and established a successful business at Mincing Lane Melbourne, manufacturing buttons, medals and tokens. Martin joined the partnership in 1873, which lasted until a disastrous fire in 1893. The business was renamed Stokes & Sons Pty Ltd and it became a public company in 1962. It is currently situated at Ringwood in the business of spare parts for electrical equipment The Villiers and Heytesbury Agricultural Association was a significant event and organisation within the Western District over a large number of years. It was one of the earliest organisations in the district and is testament to its importance to the agricultural, social, and cultural life of the district. It is significant that this particular medallion was awarded to an innovator in the ploughing industry and that it was made by a company which is still in business 130 years later. Circular copper medallion cast with Villiers & Heytesbury Agricultural Assoctn around edge with winner and event details engraved in centre. The reverse is cast with horse, cow and sheep standing above wheat sheaf and farm implements. The edge of the medallion is plain.Villiers & Heytesbury Agricultl Assoctn around rim. 1st Prize awarded to Hugh Lennon for double furrow plough, Warrnambool Oct 19 1880. Stokes & Martin Melbourne in small lettering on the reverse.warrnambool, villiers & heytesbury, hugh lennon, stokes & martin, lennon plow, lennon plough -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Sculling Oar, Mid to late 19th century

An oar is an implement used for water-borne propulsion. Oars have a flat blade at one end. Rowers grasp the oar at the other end. The difference between oars and paddles is that oars are used exclusively for rowing. In rowing the oar is connected to the vessel by means of a pivot point for the oar, either an oarlock, or a hole. The oar is placed in the pivot point with a short portion inside the vessel, and a much larger portion outside. The rower pulls on the short end of the oar, while the long end is in the water. By contrast, paddles, are held in both hands by the paddler, and are not attached to the vessel. Rowers generally face the stern of the vessel, reach towards the stern, and insert the blade of their oar in the water. As they lean back, towards the vessel's bow, the blade of their oars pivots in the oarlock, and the end in the water moves towards the stern, providing forward thrust. There also is another way of propelling a small craft it's called a sculling oar which is attached to the transom and used to propel a small vessels rather than using two oars as previously described. It is believed the subject item is just such an oar given it’s long blade associated with a sculling oar. For thousands of years vessels were powered either by sails, or by the mechanical work of rowers, or by paddlers. Some ancient vessels were propelled by both oars and sail, depending on the speed and direction of the wind. Wooden oars, with canoe-shaped pottery, dating from 5000–4500 BC have been discovered in a Hemudu culture site at Yuyao, Zhejiang, in modern China. The history of man using wooden oars to propel a boat has a considerable record in marine archaeology going back many centuries. The item is significant for marine archaeology as it gives a snapshot into how a small row boat was powered using a wooden sculling oar. A method of propelling a small boat still used today an example is the gondoliers in Venice using a sculling oar in a circular motion to propel his craft. Single sculling oar with long flat blade, two copper bands, on blade with rowlock fittingNoneflagstaff hill, warrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, boat oar, sculling oar, row boat -

Puffing Billy Railway

Puffing Billy RailwayNRT1, Ruston & Hornsby Diesel Locomotive, 1951

NRT1 - Ruston & Hornsby Diesel Locomotive Built in 1951 to a gauge of 3', this Ruston diesel locomotive or rail tractor operated on the State Electricity Commission of Victoria’s Kiewa scheme. Some years later, it was regauged to 2'6" and was operated by the Melbourne & Metropolitan Board of Works. NRT1 is a Ruston & Hornsby diesel locomotive, built in England in 1951 to a gauge of 3 feet, and was initially employed by the State Electricity Commission of Victoria. It was later re-gauged to 2' 6" and ended it's working life in 1977 when it was transferred to Puffing Billy. In 1977, it was taken to the P.B.P.S. Steam Museum and stored until 1978 when it was taken to the Emerald Carriage Workshops. Later in 1983 it was returned to service as NRT1 following the V.R. classification procedure as a narrow-gauge rail tractor, but it had number plates installed and was painted Hawthorn green. It will eventually be painted the red of V.R. rail tractors with the number & class painted on in black. This type of locomotive was popular in many industrial locations, with their unique clutch-less 3 speed gearbox meaning the driver could control them whilst walking alongside, a bonus when shunting. Adjustable tie rods meant that as the axles moved on the springs, they followed the radius of the drive chains, reducing the chances of chain snatch LOCOMOTIVE DETAILS NRT class No. originally constructed : No. in service : 1 No. stored: Wheel arrangement : 0-4-0DM Roadworthy weight : 9T 3cwt. Maximum axle load : 4T 15cwt. Tractive effort (85%) : Length overall: 15' 6" Height overall: 10' Driving wheel diameter: 18" Date of manufacture: 1950 Manufacturer : Ruston Hornsby Place of manufacture: Lincoln, England Locomotive type : Diesel Mechanical Manufacturers classification : 48 DL Historic - Industrial narrow Gauge Railway - Ruston & Hornsby diesel locomotive used by State Electricity Commission of Victoria - NRT1 - Ruston & Hornsby Diesel Locomotive NRT1 - Ruston & Hornsby Diesel Locomotive made of steel NRT1 ruston & hornsby diesel locomotive, nrt1 diesel locomotive, nrt1, puffing billy -

Wodonga & District Historical Society Inc

Wodonga & District Historical Society IncFunctional object - Edison Phonograph Records

Edison cylinders were the earliest commercial medium for recording and reproducing sound. These hollow cylindrical objects have an audio recording engraved on the outside surface which can be reproduced when they are played on a mechanical cylinder phonograph. Beginning in 1889, pre-recorded wax cylinders were marketed. These have professionally made recordings of songs, instrumental music or humorous monologues in their grooves. The earliest cylinders were made from soft wax and later hard wax was utilised. Further developments by several companies, led to the introduction of celluloid cylinders. In late 1908, Thomas Edison had introduced wax cylinders that played for about four minutes (instead of the usual two) under the Amberol brand. The Amberols were manufactured with flat rim-ends, to prevent confusion with the earlier bevel-edged two-minute version. In 1912, the Edison company eventually acquired patents to the celluloid technology, and almost immediately started production under new brand as Edison Blue Amberol Records. Cylinder records continued to compete with the growing disc record market into the 1910s. In 1912, Columbia Records, which had been selling both discs and cylinders, dropped the cylinder format, while Edison introduced his Diamond Disc format, played with a diamond stylus. From 1915, new Edison cylinders were re-recordings from Edison discs. Although his cylinders continued to be sold in steadily dwindling quantities, Edison continued to support the owners of cylinder phonographs by making new titles available in that format until the company ceased manufacturing all records and phonographs in November 1929.This item is significant because it is representative of home entertainment in the late 19th and early 20th century.Two phonograph cylinders in cardboard boxes. The first cylinder is an earlier 2 minute Edison Gold Moulded Record with Issue Number 9184. It features a recording of "Paddle your own Canoe" by Arthur F. Collins and Byron G. Harlan and was released in January 1906. The second cylinder is a 4 minute Edison Amberol Record (NO. 647) featuring the Levy-Athan Polka performed by Charles Daab on xylophone and accompanied by an orchestra. It was released in February 1911. The case is cylindrical in shape and made of cardboard. It is coloured green, white, and black on the outside, while the base is not coloured. The tube is open at the top, and sealed at the base. Inside the tube is a white fabric lining. The top section of the outside of the tube is dark green. Below this is an outer sleeve. The outer sleeve has a half white, half green background with a black stripe, with gold outline, running horizontally around the top and bottom. The words "Thomas A. Edison" are printed in green cursive along the band. In the centre of the sleeve is the text " EDISON AMBEROL RECORD FOUR MINUTE" in green ink. To the left of that text is a green-toned image of Thomas Edison in an ornate, gold border. This is surrounded by the words “Copyright 1900 by the National Phonograph Co. Orange N.J. U.S.A". To the right of the text is a rectangular text box with a black border, which contains patent information in green text. edison phonograph, home entertainment, music early 20th century -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Photograph - Back to Cheltenham State School - A memento 28.11.1936, 1936

A reunion gathering for past students of Cheltenham State School held in November 1936A black and white photograph of a large group of men and women in a semicircle on a school play yard beside a weatherboard building .They all appear to be smartly dressed, many women wearing hats and the men in suits. Cheltenham School Reunion. The third annual "Back to Cheltenham State school" reunion attracted an attendance of 600 former scholars to the school on Saturday afternoon. The proceedings were opened by tho mayor of Moorabbin (Cr. J. W. Allnut). The oldest teacher present was Mrs. Grant, of Sorrento, who, as Miss Fraser, had charge of the school from 1880 to 1883. Another old identity was Mr. T. Evans, of Kew, who is 82 years of age — he was the head teacher from 1802 to 1800. Photographs were taken of Mrs. Grant with fifteen of her former pupils, and of Mr. Evans, who mustered 72 of his old scholars. The roll call showed that there were 50 pupils present who attended tho school more than half a century ago. Mrs. Buckley, of Mentone, who is 84, and Mr. W. P. Fairlam, of Cheltenham, 80 years, were the oldest former scholars in attendance. Mr. Fairlam, notwithstanding his age, still carries on the business of an auctioneer. Bouquets were presented to Mrs. Grant and Mrs Buckley by the president of the mothers' club (Mrs. Marshall). An enjoyable day was wound up by a dance at night in the mechanical institute, when 200 attended. (Age, Monday 30 November 1936, page 5)cheltenham primary school, state school, charman road, cheltenham, school, charman stephen, gettens mary, spring grove, balcombe road, nepean road, dairy farmers, market agrdeners, poultry farmers, methodist church, cancel, 1936 -

Federation University Historical Collection

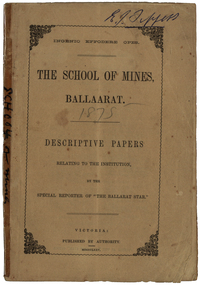

Federation University Historical CollectionBooklet, The School of Mines Ballaarat: Descriptive papers relating to the institution by the special reporter of "The Ballarat Star", 1875 (exact)

The booklet comprises of a series of papers published in the Ballarat Star, with some revisions. The Administrative Council hoped the publication would increase interest in Technical Education, especially the Art of Mining. He would also hope the public would recognise the Ballarat School of Mines as an institution adapted to supply technical education. The Ballarat School of Mines Council listed at the front of the book includes: Redmond Barry (President and Trustee), Judge Rogers (Vice-President), Somerville Livingstone Learmonth (Trustee), Rivett Henry Bland (Trustee), Charles Gavan Duffy, John A. MacPherson (MLA), William McLellan (MLA), Duncan Gillies (MLA), F. McCoy (University of Melbourne), John I. Bleasdale, W.H. Barnard, James M. Bickett, Henry Richards Caselli, P. Chauncy, J.M. Davey, Joseph Flude, R.F. Hudson, Robert Lewis, James Oddie, Robert M. Serjeant, J. F. Usher, John Walker, J. Williamson, Mayor of the City of Ballaarat, chairman (for the time being) of each of the seven Mining Boards of Victoria. The President of Examiners was Judge Rogers, and the Honorary Auditor was Richard Ford.Stapled, brown soft covered booklet of 48 pages. Section I outlines the establishment of the Ballarat School of Mines, the buildings and land used by the school, describes in detail the former Ballarat Circuit Court and describes the lecture rooms. Section II describes the Ballarat School of Mines Museum, including a description of exhibits. Section III describes the lecture hall, and the apartments on either side of the hall, including the office of the registrar W.H. Barnard, mathematical classroom, chemical laboratory, and metallurgical laboratory. Section IV outlines the subjects offered by the Ballarat School of Mines, including Mathematics taught by John Victor of Grenville College, who had been educated at Trinity College Dublin. Mining and Land Surveying was taught by C.W. Thomas. Mr Croll taught mechanical drawing, followed by Jonathan Robinson of the Union Foundry, and finally S. Keast. It then lists some text books used in the school. Section V mentions the School Council, lack of funds, future directions, mining laboratory. Vi- Describes the land and out buildings, and the proposed building for metal and wood turning, brass foundry, blacksmith, working engine, etc. This section describes some large donations to the school - 50 pounds from the Misses Meglin of Melbourne, 10 pounds 10 shillings to the 'Pyrites fund' by the Walhalla and Long Tunnel Companies in Gippsland. Section VII covers the teaching of chemistry by Joseph Flude. Section VIII outlines the metallurgy classes and the process of assaying. Section IX covers telegraphy taught by Mr Bechervaise Section X describes the examination process at the Ballarat School of Mines. Examiners in mathematics were G.J. Russell (Buninyong) and John Lynch (Smythesdale), mining and land surveying John Lynch and P.C. Fitzpatrick (Ballarat), Principles and Practice of Mining R.M. Serjeant (Band and Albion Consols), Mechanical Engineering John Lewis (New North Company Clunes, Mineralogy and Geology G.H. F. Ulrich, Assayign and Chemistry J. Cosmo Newberry, and Telegraphy R.L.J. Ellery (government astronomer) and Sam W. Macgowan. Underground managers and captains in quart mining was examined by Henry Rosales (Walhalla Company), and alluvial mines by Messrs Bockett, Kent, Martin and Mitchell. Engineers and Engine driving was examined by W.H. Keast,Peter Matthews, Jonathan Robinson and J.M. Troup. Section XI - Covers Annual reports of the school, and honorary correspondents of the school including: John Day (Geelong); R. Evan Day (London); W.W. Evans, M.J.C.E. of New York; J.Y. Fishburne, M.B. of Ararat; Felice Giordano, Inspector of Mines, Italy; Julius Von Haast, Ph. D.F.R.S., Government Geologist of Canterbury; James Hector, M.D., F.R.S., Government Geologist of Wellington, New Zealand, W.F. Hopkins (Grant); Charles A. La Trobe, C.E. (Engineer-in-Chief International Railway Plant, London); Archibald Liversidge, F.G.S. (Professor of Mineralogy and Reader in geology at Sydney University; J.J. Macgregor, M.D. (Creswick); J.T. McKenna (1st class of SMB underground management - Northern Territory); Henry Rosales, M.E. and M. (Walhalla); Harrie Wood (SMB founder and Under-secretary for Mines, Sydney); John Walthew (Stockport, England) .2) Signed 'E.J. Tippett', former President of the Ballarat School of Mines Council melbourne, mla, ballarat school of mines, redmond barry, j f usher, james bickett, w f hopkins, rivett henry bland, s m b, judge rogers, somerville learmonth, charles gavan duffy, gavan duffy, john macpherson, william mclellan, duncan gillies, f mccoy, university, john bleasdale, henry richards caselli, henry caselli, p chauncy, j m davey, joseph flude, r f hudson, robert lewis, james oddie, robert m serjeant, john walker, j williamson, richard ford, ballarat court house, assay, john victor, grenville college, trinity college dublin, c w thomas, jonathan robinson, union foundry, s keast, blessdale, john day, r evan day, w w evans, j y fishburne, felice giordano, julius von haast, james hector, charles a la, trobe, archibald liversidge, j j macgregor, j t mckenna, henry rosales, harrie wood, john walthew, fees, frederick mccoy, w.h. barnard -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageVehicle - Tip Dray, Prior to 1930s

A Dray is a type of dead axle wagon that was used to transport heavy loads or objects. They had a flat level floor and while some had no sides, others had box bodies and sides. Tip Drays (also known as Tip Carts, Muck Cart, Scotch Cart, Tumbrel or Putt in different parts of England) were smaller than other drays as their loads were heavy and usually only pulled by one horse. Their basic design included two wheels, a tipping body and shafts. The Tip Dray has a unique mechanism that allows the top to tip backwards to tip the load out of the back of the dray. The tipper was activated by a handle at the front allowing the driver to operate it while still having control over the horse. A Tip Dray was an indispensable piece of equipment in the days before tractors and mechanical trucks. They were used by farmers and carters to transport hay, rocks, bricks, gravel and rubbish etc. and because they were useful for dumping loads, they were favoured for use in road and railway construction. A photo in the collection of the Lorne Historical Society shows a tipping dray being used during the construction of the Great Ocean Road. They were part of the daily street traffic in towns and cities around Australia from the early days of settlement. In Australia in the early 1900's, carters began to join unions to protect their jobs and pay. N.S.W. had a "Trolley, Draymen and Carters Union", Queensland had a "Tip Dray Men's Association" and in W. A. the "Top Dray Driver's Union" had a "cessation of work" in 1911 when they were fighting for an increase in their day's wages. In 1910 a meeting of Tip Carters was held in Geelong at the Trades Hall to discuss the formation of a union (The Geelong Tip Dray Carters) which was a success and a schedule of rates for all carting, whether by contract or day labor, was fixed. By 1912 they had "labelled" more than 50 drays and had representatives on the "Trades Hall and Eight Hours Committee". By the mid 1930's and early 1940's, tip drays were being superseded by mechanical trucks and utes. However tip drays continued to be used in some circumstances. They were a practical solution to the problem of petrol rationing during W. W. 2. It was noted in a letter to the editor in the "Sunshine Advocate" in 1938 that a positive argument for continued use of Tip Drays for rubbish collection related to the idea that a horse drawn vehicle involved with lots of stops and starts at different houses (very like a milkman's delivery route) often involved the horse "driving itself" while the driver picked up the rubbish - something a motor truck was unable to do! Another article written in August 1935 and published in the Age in a parliamentary report into the rubber industry noted "tip drays had almost disappeared and in their place, metal was carted in 5 ton motor trucks" but the report went on to say that as a part of the Government relief work (during the Great Depression) the Government had "to some extent reintroduced the tip drays so that a greater number of men would be employed". This particular tip dray was owned by Mr. Oswald (Jack) Bourke. He used it to deliver dry goods from Sunbury to the Queen Victoria Market in Melbourne several times a week in the 1930's and then (between 1945 and 1962) Mr. Bourke used it on the garbage round in Springvale Victoria for the Springvale Council. The Council owned three drays and the "No. 3" painted on this dray is in recognition of its original number. After the death of Mr. Bourke in 1990, one of Mr. Bourke's sons (Andy) found the dray in a shed and restored it. The sign writing on the back and side panels were added during the restoration. This Tipping Dray is a significant example of a horse drawn vehicle that was used by workers from the early days of white settlement through to the 1940's and even into the early 1960's. It was used in a range of "working class" occupations - road construction, railway construction, carting goods, rubbish collection etc. and would have been found in cities, country towns and on farms.A wooden and metal tipping dray with a box body and four sides. It has two iron and wooden wheels (with 14 spokes), two wooden shafts and a metal tipping mechanism. The back panel folds down to allow loads to be dumped out. It is painted in green and cream with sign writing on one of the sides and on the front and back panels. It features decorative painted lines and designs in burgundy, cream and light blue on most of the wooden parts. The tipping mechanism is on the front of the dray's left side and consists of a metal pin secured with a metal ring, and a lever.Front of dray - "No. 3" Side of dray - "A. & M. BOURKE / Contractors / LONGWARRY" Back of dray - "G.T. ANDREWS / QUEEN VICTORIA MARKET - Stand C23 / Phone DANDENONG 225"flagstaff hill maritime museum and village, warrnambool, shipwreck coast, tipping dray, dray, tip dray, tip cart, vehicles, horse drawn vehicle, springvale council, jack bourke, muck cart, scotch cart, tumbrel, putt, box body, oswald bourke, sunbury, queen victoria market, melbourne, no. 3 -

Federation University Historical Collection

Federation University Historical CollectionDocument - Document - Proposal, VIOSH : Ballarat College of Advanced Education; Proposal for a Post-Graduate Diploma Course in OHM, 1977

Victorian Institute of Occupational Safety and Health (VIOSH) Australia is the Asia-Pacific centre for teaching and research in occupational health and safety (OHS) and is known as one of Australia's leaders on the field. VIOSH has a global reputation for its innovative approach within the field of OHS management. VIOSH had its first intake of students in 1979. At that time the Institution was known as the Ballarat College of Advanced Education. In 1990 it became known as Ballarat University College, then in 1994 as University of Ballarat. It was 2014 that it became Federation University. VIOSH Australia students are safety managers, senior advisors and experienced OHS professionals. They come from all over Australia and industry. Students are taught active research and enquiry; rather than textbook learning and a one-size fits all approach. VIOSH accepts people into the Graduate Diploma of Occupational Hazard Management who have no undergraduate degree - on the basis of extensive work experience and knowledge. Documents relate to the planning for the introduction of a Graduate Diploma in Occupational Safety and Health to begin in 1978. It was developed for the Victorian Institute of Colleges 1977-81 Academic Master Plan. The working party submitted a Third Draft in April 1977. The Course Co-ordinator was Derek Viner, Senior Lecturer, School of Engineering. The internal working party was Dr E Phillips, Head of School of Applied Science; Derek Woolley, Head of School of Engineering; Tom Norwood, Head of Department of Mechanical Engineering; Max Brooke, School of Business Studies; G Fernandez, School of Business Studies; J Harvey, School of Applied Science; B Rollins, School of Community and General Studies. An External Advisory Panel was also formed was different safety and injury bodies. Eric Wigglesworth - Injury Research Project became lectured at BCAE when the course began.Typed pages - A4 and foolscapviosh, victorian institute of occupational safety and health, graduate diploma in occupational safety and health, victorian institute of colleges, academic master plan, derek viner, course co-ordinator, school of engineering, dr e phillips, head of applied science, internal working party, derek woolley, head of school of engineering, tom norwood, head of department od mechanical engineering, max brooke, school of business studies, g fernandez, j harvey, school of applied science, b rollins, school of community and general studies, external woking party, s barklay, loss control officer, dr w cooper, medical officer gmh, f davis, risk management consultant, w jinkins, industrial safety advisory council, h jones, f mccabe, c polglaze, sec, w spratt, royal insurance co., f turley, national safety council victoria, eric wigglesworth, royal australian college of surgeons, c willis, loss control consultant -

Federation University Historical Collection

Federation University Historical CollectionMedal, Ballarat School of Mines Hillman Award (medal), c1992

Lindsay F.J. Hillman was born in Ballarat in 1910, and attended the Ballarat Junior Technical School. He became a cadet in Electrical Engineering Laboratory at the Ballarat School of Mines where he gained eventually gained a student Teachership for diploma studies at the School. Hillman was particularly active and excelled in a wide range of sporting interests and in student activities. In 1928 and 1928 he was awarded the Ballarat School of Mines Honour blazer by the Old Boys' association for all round athletic ability, leadership and scholarship. After spending two years with the Melbourne City Council Electric Supply Department gaining industrial experience Hillman was awarded his Diploma of electrical engineering in 1931, returning to the School in 1932 to teach apprentices and senior students. Hillman was appointed lecturer in Engineering Design and Graphics in 1937, lecturer in Engineering Design and Civil Engineering in 1944, Lecturer-in-Charge of Mechanical and Civil Engineering in 1948 and Head of the Electrical Engineering Department in 1949, a position he held until his retirement in 1973. In 1975 Lindsay Hillman was appointed to the Council of the Ballarat School of Mines and played an active role in school affairs.As Vice-President of Council from 1981 until his death in 1991 Hillman took a leading part in the implementation of many of the major building projects on the Lydiard Street Campus. The L.F.J. Hillman Award was established by the Ballarat School of Mines Council in conjunction with and through the generosity of the Hillman family in honour of the late Lindsay Frederick John Hillman. The bronze medal was presented annually to an enrolled student in an accredited course in the field of electrical/electronics studies at the Ballarat School of Mines. specific Criteria for the Award consisted of a balance of academic performance, leadership qualities, commitment to further study and involvement in sporting and/or community groups. Bronze medal designed depicting the portrait of Lindsay Hillman. The medal has a copper finish, and is presented in a blue hinged box. The first Hillman Award was presented in 1992. The recipients are: 1992 - Brett A. Hovey 1993 - Nil 1994 - Brent L. Ferguson 1995 - Kirsty McKenzie 1996 - Peter J. White 2000 - Roger Bush 2001 - Thomas Edward George 2002 - Mark William Holden 2003 - David James Hopwood 2004 - Leighton Dunn 2005 - Donald Pirouet 2006 - Mark Irvin 2007 - Ricky Wilson 2008 - Luther Dean 2009 - Daniel Thatcher 2010 - Craig Coulter 2011 - Sarah Draper 2012 - Rhys Hendrickson 2013 - Jayden Hooper "Lindsay Hillman Memorial Medal" Verso: "The School of Mines and Industries Ballarat, Est. 1870 Presented to "ballarat school of mines, hillman, lindsay hillman, medal, numismatics, honour blazer, electrical engineering, electronics, hillman medal, hillman award -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillagePen Rack

The origins of the pen rack probably began when quill pens were being replaced by steel nib pens that were held at oblique angles for writing this method of writing started to gain popularity around 1820-1860. To understand the development of display racks to hold pens on a desk we need to understand the development of the pen itself. Before the early 19th-century steel pens were almost universally all barrel pens affixed to a holder pretty permanently. Pens were also not disposable. There were even steel pen repair services, just like the same services around at the time to repair you're fine quills. Individual slip nib pens which fit into a holder were originally pieces of a quill which came in a box of nibs and fit into a holder. These were disposable and meant to obviate the need to mend your quills. By 1831 you start to see more what they called “slip nib pens” or “portable pens” (easier to carry than a long barrel pen), but the idea of holding the nib at an oblique angle in the holder was an idea new enough that it warranted a patent. In 1831, an enterprising and very successful stationer and inventor, Sampson Mordan (inventor of the silver mechanical pencil) combined with one William Brockedon to patent the first oblique pen and oblique holder. In the patent application, they mention as the benefits that this would allow the writer to hold the pen more comfortably as well as it should allow the pen to last longer since both tines will be moving across the paper evenly. It appears at the time the idea of holding a pen obliquely was new. As a result of the popularity of the oblique pen many different designs of pen desk holders were being made, to keep pens suspended on a rack alleviated the possibility that the expensive new steel nibs with their holder could be damaged if left in a desk draw with other items.Double sided Pen Rack, decorative metal with four metal legsflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Puffing Billy Railway

Puffing Billy RailwaySmiths Setric Electric Clock, circa 1937

Electric Clock - Smiths Setric Clock From 1937 the trademark "Sectric" appears on their synchronous models.Usually on the dial but sometimes also on the back cover. Early clocks had a prominent "T" in sectric. Smiths English Clocks 1931 Smiths, then called S. Smith and Sons (Motor Accessories) Ltd, entered the domestic clock market and formed a new company, Smiths English Clocks Ltd, as the Clock and Watch division with Cricklewood as the main factory. Smiths were one of the first companies to produce synchronous electric clocks. These were put on the market towards the end of 1931. Smiths formed a subsidiary company called Synchronous Electric Clocks to produce these clocks as the first models carry this name. 1932 Smiths purchased English Clock and Watch Manufacturers of Coventry, and acquired the trade names Astral and Empire. 1934 Smiths produced a synchronous alarm clock which they named the Callboy. 1934 They bought the Enfield Clock Co. The Smith's 8 day Calotte clock made its debut at the British Industries Fair in 1934. Prior to this date calottes had been exclusively of foreign manufacture. Also that year, Smiths introduced the Batriclock which was intended for areas where the synchronous clock could not be used. 1935 They introduced the Synfinity, which Smiths described as "the clock that never stops". They said it was "the remarkable combination of a synchronous electric movement with the essential elements of a fine precision lever escapement". If the electric supply failed the clock would run for up to six hours and rewind when the power returned. Apparently the synchronous motor also corrected the mechanical time train at intervals. Smiths produced a synchronous electric chiming clock. 1937 The trade name Sectric appears on Smiths electric clocks. Also the introduction by Smith's of a calotte clock with an alarm movement.Historic - Smiths English Setric Electric Clock Electric Clock - Smiths Setric Clock It is round with the numbers one to twelve, three hands with a white face. Smiths Sectricpuffing billy, clock, time, smiths sectric -

Bendigo Historical Society Inc.

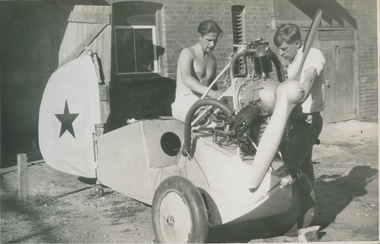

Bendigo Historical Society Inc.Photograph - Gliding in Bendigo, Late 1930s

These are the recollections of Alan Menere (1915 – 2001). Alan grew up in Moonee Ponds, Victoria, and moved to Bendigo while in his early 20s. There he met some like-minded young men who enjoyed challenges and matters mechanical. Flying was the adventure of the time, and they decided to give it a go. There was no intention to be on the leading edge of gliding technology. The challenge was to fly, and by their own efforts. They were aided in this by the embryonic regulatory arrangements covering light aircraft construction and flying, a sense of optimistic can-do, and the cavalier estimation of risks that goes with being in your early 20s. The events described here took place against a darkening political background. Alan and his mates were politically aware, very left wing, and viewed the gathering storm in Europe with apprehension. They could see from early on that war was coming, and it would change everything. Prevented from joining the Air Force by his red-green colour blindness, Alan joined the Army the day after the Pearl Harbour attack. He served in an Armoured Reconnaissance Unit in Western Australia, then with the Army Education Service in New Britain. After the War he joined the Commonwealth Public Service. He moved to Canberra, but his Bendigo habits stayed with him, as he built sailboards and carved propellers, to the admiration of his sons. Alan developed macular degeneration in his mid-60s. He retired to Port Stephens, fishing and socializing when he wasn’t tinkering with wing-sails for his catamaran. As he could touch-type, he quickly learned to use a computer. Very aware that he was the last member of the Bendigo group still alive, he resolved to set down his flying experiences. The images he selected are included, but there are many more from the Bendigo days.A CD entitled "Alan Menere - Recollections of Gliding in Bendigo in the late 1930s". The CD contains 33 documents consisting of one word file, one PDF file (entitled "The Urge to Fly") and the rest are of either photos of the Bendigo Gliding club or generally around Bendigo itself. Also included are some paper clippings of accidents that happened and description of flights.history, bendigo, bendigo gliding club, alan menere -

National Wool Museum

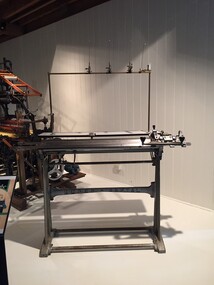

National Wool MuseumMachine - Knitting Machine, Coppo, 1960s

The knitting machine is a recently designed instrument, especially when it is compared with its ancient counterpart, the loom. It enables the creation of many metres of fabric very quickly. A knitting machine is composed of a series of needles which mimic the process of manual knitting. The mechanism engages numerous mechanical elements simultaneously and enables the creation of many metres of fabric very quickly. In addition, a knitting machine can be setup to produce unique bolts of fabric. The density of the fabric may be modified and a knitting machine can produce double-faced effects. A doubled-faced effect creates colour combinations through the introduction of an additional colour to the knitting pattern. This knitting machine is a Coppo brand. It contains over five hundred needles and was produced in the 1960s. It is a representation of the best available in the world at that time. Originating from Italy, it was designed for commercial use. Through both precision and capacity, Italian artisans were seen to be the best in the world of textiles and knitwear. Through emigration, globalisation and the regularly available quantities of wool, Australia came to compete on this stage. The owner of this particular machine migrated from Italy in 1959. When she did, she brought with her a Dubied knitting machine. She later replaced it with this Coppo. When in Australia the owner began work as a piece worker, knitting jumpers and worked for some of the iconic names in the Australian knitting trade including ES Poratt and Alpin Manufacturing. The owner’s role progressed from a piece worker to a wool garment designer and she won many Wool Industry Awards in the 1970s and 1980s. Her high quality of work using and her individual custom designs were spoken about by many of her customers and she had a very large private clientele. She designed and knitted fully fashioned tailored jumpers for people for around 30 years.Knitting table sits on a stand with wide metal legs. Legs contain lettering 'COPPO torino'. Legs are connected via three thin metal poles as well as a metal band and the bed of knitting table at top. The connecting metal band has the lettering 'SUPER - COPTAL' attached. The Knitting table itself contains two beds and a bench at the rear. Attached to the bench is a thin metal structure for the elevation of yarn. It has four crane esk structures above on this metal structure. The bench is covered in a pale grey laminate in the imitation of wood. Attached to the knitting bed is a sliding contraptions containing two handles at the front followed by a complex semi-circle sliding mechanism used to move the knitting mechanism front and back.Left Stand. Lettering: Coppo Torino Right Stand. Lettering: Coppo Torino Centre Stand. Lettering SUPER - COPTALcoppo, knitting machine, design, italy, wool, business, migrants -

Trafalgar Holden Museum

Trafalgar Holden MuseumVehicle - VN Commodore, 1988

The VN Commodore was available in Executive, S, SS, Berlina and Calais specification levels, although a more basic SL model (opt. code A9K) was supposedly offered to government and fleet buyers, as it was not officially listed as part of the Commodore range. Changes in the relative values of the Australian dollar, the Japanese yen, and the US dollar made it impractical to continue with the well-regarded Nissan engine of the VL. Instead, Holden manufactured their own 90-degree V6 based on an old Buick design from the US, although initially it was imported. The 5.0-litre V8 remained optional and received a power boost to 165 kW (221 hp). Both these engines used multi point GM EFI and the V6 using 3 coil-packs for ignition. Holden and HSV developed this car as the basis for racing in Group A Confederation of Australian Motor Sport events. While the minimum number of cars built to qualify in Australian Touring car Championships, with modified body kit, brakes or engine is 500, only 302 VN were built but CAMS granted an exemption allowing them to compete.Holden and HSV had worked hard to develop this car to be a serious competitor to the Skyline, Ford Sierra and the BMW which had dominated in the previous years. This was to be the Holden’s answer and coincided with the return of Peter Brock back to the Holden team from 1987.Mechanically the cars were fitted with reworked version of Holden’s 4.9 litre V8. The engine block was cast for additional strength, modified cylinder heads roller rockers and high fuel flow fuel injection was applied. Output was 215 kw at 5200revs and, though at today’s standard, that is not that much it was very impressive at that time. The drive was through a six speed ZF gearbox with a heavy duty racing clutch and a limited slip differential.Under the Hawke government's Button car plan, which saw a reduction in the number of models manufactured locally, and the introduction of model sharing, the VN Commodore was rebadged as the Toyota Lexcen, named after the late America's Cup yacht designer, Ben Lexcen. Subsequently, the Toyota Corolla and Camry were, similarly, badged as the Holden Nova and Holden Apollo.Red executive 4 door sedanHolden Lion and stone emblem grille centre, Commodore boot LHS, Lion and stone emblem boot RHS.vehicle, vn commodore, holden, car -

Bendigo Military Museum

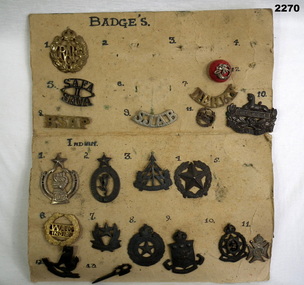

Bendigo Military MuseumBadge - BADGE COLLECTION MOUNTED, C.WW2

Items in the collection re Ian McLeod RWAFF, refer Cat No 2262.2 for service details.Panel One only, a lot of Indian badges. .1) RAF badge .2), .3), .4) .6) missing .5) SAFA 11 SAVA .7) Derby .8) RSAP .9) SJAB .10) Gloucestershire, Eygpt with Lion .11) Eygpt, Lion, Surronded by oak leaf cluster .12) Red button badge, with a bugle and K R motif over it Panel Two .1) Circular badge .2) Indian signals corps badge. oval shape surmounted with 5 pointed star .3) Indian reconaisance corp badge symbolic tree and arrow .4) Indian engineers badge. 5 point star surrounded by oak leaf cluster .5) Missing .6) WAC India .7) Indian intelligence corps. 5 pointed star .8) Indian electrical and mechanical engineers badge .9) Indian army ordinance badge .10) Indian army medical corps .11) Symbolic cross .12) Burma intelligence corps .13) Stylised trench raid weapon Panel Three .1) Crossed khukris .2) Cross khukris .3) Simple doughnut shaped ring .4) Doughnut shaped ring. surmounted by a crown in center is letters X1 .5) JAT Regiment badge large letters IX surmounted with a crown .6) Regiment cluster of leaves .7) Madras regiment badge .8) Unknown 4 sort of legs surrounded with a crown .9) Dogras Regt. In the centre are the number 17 surmounted with a crown .10) Punjab regt. Center is a 5 pointed star with numbers 14 surmounted with a crown .11) Missingbadges, collection, indian -

Ballarat Tramway Museum

Ballarat Tramway MuseumFunctional Object - Tramcar, Melbourne and Metropolitan Tramways Board (MMTB), Tramcar 504, 1928

A four motor bogie drop centre combination tram of the Melbourne W2 class. Body built by the James Moore and Co. of South Melbourne as a W2 class tram. Delivered to the MMTB Preston Workshops where the electrical and mechanical equipment was fitted. Issued to traffic 18/4/1928. Allocated to Essendon Depot. The tram was part of the Transporting Art project suggested by the artist Clifton Pugh (1924-1990) in Jan. 1978 to the Lord Mayor of Melbourne Cr. Irvin Rockman. The concept was enthusiastically supported by Victorian Premier Rupert Hamer. Clifton Pugh's tram was the second tram to appear. Described by the artist as "The apostle birds in flight, as if the tram has run into a group of them and they're flying along the sides. Then I found the route was to be through Collingwood and Hawthorn football territory and one cannot be one-eyed in that worlds, there are a magpie and a hawk on each side." The tram was retained by the State and stored until 2015 when it was transported to the Museum's Offsite store. Formal ownership was transferred to the Museum during 2019. Conservation planning for the tram's return to service and the restoration of the artwork is underway. 1986 - withdrawn from service following a minor accident and stored. In 2015 tram relocated to the Museum's offsite store and during 2019 transferred to ownership of the Museum. See btm.org.au/trams/504.html for further detail. Photos - i1 - Ray Marsh 1978 i2 - Alastair Reither - 3/6/2015 showing the damaged side. i3 - Clifton Pugh on board his tram. Photo from the Diners Club Signature Magazine April/May 1982, from an article titled Moving Masterpieces. Photo courtesy of the Melbourne Tram Museum. See Destination Citytrams, w2 class, transporting art, tram 504 -

The Beechworth Burke Museum

The Beechworth Burke MuseumDecorative object - Swinging Clock, Charles Frederick Falck, 1855

This clock was made by Charles Frederick Falck who was a watchmaker and jeweller in Beechworth from 1863-1908. Falck was born in Körlin, Prussia on May 22nd in 1833 and died at the age of 75 in 1908. Ovens and Murray Advertiser, Beechworth: edition June 13, 1908 OBITUARY: Falck was brought up to the business of watch-making, in which he developed exceptional mechanical ingenuity. Attracted by the favourable prospects held out by the Australian discoveries of gold he, like many other young adventurous spirits, left his native land to seek his fortune in the great southern Eldorado, arriving in Adelaide in 1854, and shortly after came to Melbourne where he worked as a journeyman, and subsequently started in business on his own account. Feeling inclined to test his fortune on the goldfields, he went to Blackwood but, meeting with little success, he returned to Melbourne where he was married. In 1862, he moved to Beechworth, where he commenced business as watchmaker and gold-buyer. He then embarked in vine-growing on the Sydney road, but eventually resumed his business avocations. His skill in practical horology was evinced in a clock of his own design and manufacture, surmounted by a golden eagle, which was exhibited at the first Melbourne Exhibition in 1856, and which afterwards formed a pre-eminent attraction in the window of his business premises in Ford Street. For many years, he filled the position of timekeeper to the Beechworth Racing Club, with complete satisfaction also at various sports meetings. He leaves a family of six sons and one daughter (Mrs. Jas. Broadfoot) all arrived at maturity. The funeral, which was well attended by a number of residents, took place at the Beechworth Cemetery on Sunday, the burial service being performed by the Ven. Archdeacon Potter. The cortege was capably supervised by Mr. D. Wilson, undertaker. The clock was returned to Beechworth in 2020 through the generous support of the Copland Foundation. Given that Mr. C. F. Falck traded as a watchmaker and jeweller in Beechworth for 45 years and traded with the 1855 clock mounted in his front window, there is a direct link between the clocks and the social, cultural and economic life of nineteenth century Beechworth at time when the town was developing and expanding in response to gold mining. This clock represent the significant skill and expertise of Charles Falck as an horologist. Medium-sized pendulum clock featuring a carved gilt wood eagle with wings outstretch (épandre - expanded with wing-tips directed upwards) and perched above a pendulum rod that holds a silver dial clock face within a reeded sunburst surround. The clock has an eight-day fuse movement with dead beat escapement wound from the clock face. C. F. F. FALCK / EXHIBITION 1856 / MELBOURNEburke museum, copland foundation, beechworth, leonard joel, auction, purchase, clock, pendulum, eagle, eagle clock, charles frederick falck, c. f. falck, falck, horology, pendulum clock, melbourne -

The Beechworth Burke Museum

The Beechworth Burke MuseumDecorative object - Swinging Clock, Charles Frederick Falck, 1870

This clock was made by Charles Frederick Falck who was a watchmaker and jeweller in Beechworth from 1863-1908. Falck was born in Körlin, Prussia on May 22nd in 1833 and died at the age of 75 in 1908. Ovens and Murray Advertiser, Beechworth: edition June 13, 1908 OBITUARY: Falck was brought up to the business of watch-making, in which he developed exceptional mechanical ingenuity. Attracted by the favourable prospects held out by the Australian discoveries of gold he, like many other young adventurous spirits, left his native land to seek his fortune in the great southern Eldorado, arriving in Adelaide in 1854, and shortly after came to Melbourne where he worked as a journeyman, and subsequently started in business on his own account. Feeling inclined to test his fortune on the goldfields, he went to Blackwood but, meeting with little success, he returned to Melbourne where he was married. In 1862, he moved to Beechworth, where he commenced business as watchmaker and gold-buyer. He then embarked in vine-growing on the Sydney road, but eventually resumed his business avocations. His skill in practical horology was evinced in a clock of his own design and manufacture, surmounted by a golden eagle, which was exhibited at the first Melbourne Exhibition in 1856, and which afterwards formed a pre-eminent attraction in the window of his business premises in Ford Street. For many years, he filled the position of timekeeper to the Beechworth Racing Club, with complete satisfaction also at various sports meetings. He leaves a family of six sons and one daughter (Mrs. Jas. Broadfoot) all arrived at maturity. The funeral, which was well attended by a number of residents, took place at the Beechworth Cemetery on Sunday, the burial service being performed by the Ven. Archdeacon Potter. The cortege was capably supervised by Mr. D. Wilson, undertaker. The clock was returned to Beechworth in 2020 through the generous support of the Copland Foundation and the Friends of the Burke. Given that Mr. C. F. Falck traded as a watchmaker and jeweller in Beechworth for 45 years and traded with the 1855 clock mounted in his front window, there is a direct link between the clocks and the social, cultural and economic life of nineteenth century Beechworth at time when the town was developing and expanding in response to gold mining. This clock represent the significant skill and expertise of Charles Falck as an horologist. Large swinging clock featuring a carved gilt wood eagle with its wings outstretched (abaisé - expanded with wing-tips lowered) and perched above a pendulum rod that holds a silvered dial clock face within a reeded sunburst surround. (Similar to #2019.056.01) The clock has an eight-day fuse movement with dead beat escapement wound from the clock face. C. F. FALCK / WATCHMAKERburke museum, copland foundation, beechworth, leonard joel, auction, purchase, clock, pendulum, eagle, eagle clock, charles frederick falck, c. f. falck, falck, horology, pendulum clock, melbourne -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageInstrument - Letter Scale, Ca. early 20th century

This handheld portable pendulum quadrant scale was used to weigh small paper items such as letters and documents, powdered chemicals or metals like gold, and animal fleece samples. This mechanical scale can weigh up to a maximum of 10 ounces, which is about 285 grams or one-and-a-half cups of brown sugar. The operator holds the scale’s ring and connects the item to be weighed onto the wire clip. The weight of the item causes the pendulum to pivot, and the scale measures the weight of the object, indicated by the arrow. This scale belonged to Dr William Roy Angus and is now part of Flagstaff Hill’s comprehensive W.R. Angus Collection, donated by the family of Dr W R Angus, 1901-1970, surgeon and oculist. The W.R. Angus Collection: - The W.R. Angus Collection includes historical medical equipment, surgical instruments and material belonging to Dr Edward Ryan and Dr Thomas Francis Ryan, (both of Nhill, Victoria) and Dr Angus’ own belongings. The Collection’s history spans the medical practices of the two Doctors Ryan, from 1885-1926 plus that of Dr Angus, up until 1969. It includes historical medical and surgical equipment and instruments from the doctors Edward and Thomas Ryan of Nhill, Victoria. Dr Angus married Gladys in 1927 at Ballarat, the nearest big city to Nhill where he began as a Medical Assistant. He was also Acting House surgeon at the Nhill hospital where their two daughters were born. During World War II He served as a Military Doctor in the Australian Defence Force. Dr Angus and his family moved to Warrnambool in 1939, where Dr Angus operated his own medical practice. He later added the part-time Port Medical Officer responsibility and was the last person appointed to that position. Both Dr Angus and his wife were very involved in the local community, including the planning stages of the new Flagstaff Hill and the layout of the gardens there. Dr Angus passed away in March 1970.This letter scale is the only one of its type in our collection. It is an example of objects belonging to Dr. W. R. Angus, 1901-1970, surgeon and oculist. The W.R. Angus Collection is significant for still being located at the site it is connected with, Doctor Angus being the last Port Medical Officer in Warrnambool. The Collection includes historical medical objects that date back to the late 1800s.Letter scale, a handheld quadrant fixed pendulum scale made from silver-plated metal. This small weighing instrument is shaped like a quarter-circle with a metal ring, a fixed pendulum counterweight and a decorative pivoting arrow indicator. A hanger clip is attached to a short arm of the scale. Measurements are embossed on the arc of the circle, labelled in ounces (oz) and ranging from 0 to 10 at unequal distances apart. The scale is part of the W.R. Angus Collection.Scale measurements, "OZ" (ounces), "0 /14 1/2 1 2 3 4 5 6 7 8 9 10 "flagstaff hill, warrnambool, maritime village, maritime museum, shipwreck coast, great ocean road, flagstaff hill maritime museum and village, dr w r angus, mira hospital, w.r. angus collection, scale, weighing instrument, measure weight, postal scale, chemist scale, letter, weigh, post, office, quadrant scale, letter scale, handheld, portable, mechanical scale, pendulum scale, fixed balance scale -

Federation University Historical Collection

Federation University Historical CollectionPhotographs - Colour, Hillman Award Agreement and Presentation, 1991, 1991

Lindsay F.J. Hillman was born in Ballarat, and attended the Ballarat Junior Technical School. He became a cadet in Electrical Engineering Laboratory at the Ballarat School of Mines where he gained eventually gained a student Teachership for diploma studies at the School. Hillman was particularly active and excelled in a wide range of sporting interests and in student activities. In 1928 and 1928 he was awarded the Ballarat School of Mines Honour blazer by the Old Boys' association for all round athletic ability, leadership and scholarship. After spending two years with the Melbourne City Council Electric Supply Department gaining industrial experience Hillman was awarded his Diploma of electrical engineering in 1931, returning to the School in 1932 to teach apprentices and senior students. Hillman was appointed lecturer in Engineering Design and Graphics in 1937, lecturer in Engineering Design and Civil Engineering in 1944, Lecturer-in-Charge of Mechanical and Civil Engineering in 1948 and Head of the Electrical Engineering Department in 1949, a position he held until his retirement in 1973. In 1975 Lindsay Hillman was appointed to the Council of the Ballarat School of Mines and played an active role in school affairs.As Vice-President of Council from 1981 until his death in 1991 Hillman took a leading part in the implementation of many of the major building projects on the Lydiard Street Campus. The L.F.J. Hillman Award was established by the Ballarat School of Mines Council in conjunction with and through the generosity of the Hillman family in honour of the late Lindsay Frederick John Hillman. The bronze medal was presented annually to an enrolled student in an accredited course in the field of electrical/electronics studies at the Ballarat School of Mines. specific Criteria for the Award consisted of a balance of academic performance, leadership qualities, commitment to further study and involvement in sporting and/or community groups. The first Hillman Award was presented in 1991. The recipients are: 1991: Paul Donald 1992 - Brett A. Hovey 1994 - Brent L. Ferguson 1995 - Kirsty McKenzie 1996 - Peter J. WhiteEighteen colour photographs of the signing of the Hillman award agreement and the first presentation of the award in 1991 to Paul Donald . .2) Gregor Hillman, Judith Tinney and Caroline Bethune .4) Judith Tinney or Caroline Bethune and Bill Gribble sign the agreement .8) Gregor Hillman, Judith Tinney and Caroline Bethune sign the agreement, along with President of the Ballarat School of Mines, Bill Gribble. .10) Paul Donald with his L.F.J. Hillman Award, 1991 .11) Ballarat School of Mines Principal, Peter Shiells, speaks at the lectern watched on by members of the Hillman family.ballarat school of mines, hillman, lindsay hillman, medal, numismatics, electrical engineering, electronics, gregor hillman. judith tinney, caroline bethune, tinney, bethune, hovey, ferguson, mckenzie, white, paul donald, donald -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageInstrument - Foghorn, Late 19th century

A foghorn is a device that uses sound to warn of navigational hazards like rocky coastlines, or boats of the presence of other vessels, in foggy conditions. The term is most often used with marine transport. When visual navigation aids such as lighthouses are obscured, foghorns provide an audible warning of rocky outcrops, shoals, headlands, or other dangers to shipping. An early form of fog signal was to use a bell, gong, explosive signal or firing a cannon to alert shipping. From the early 20th century an improved device called the diaphone was used in place of these other devices, The diaphone horn was based directly on the organ stop of the same name invented by Robert Hope-Jones, creator of the Wurlitzer organ. Hope-Jones' design was based on a piston that was closed only at its bottom end and had slots, perpendicular to its axis, cut through its sides, the slotted piston moved within a similarly slotted cylinder. Outside of the cylinder was a reservoir of high-pressure air. Initially, this air would be admitted behind the piston, pushing it forward. When the slots of the piston aligned with those of the cylinder, air passed into the piston, making a sound and pushing the piston back to its starting position, whence the cycle would be repeated. This method of producing a low audible sound was further developed as a fog signal by John Northey of Toronto and these diaphones were powered by compressed air produced by an electric motor or other mechanical means that admitted extremely powerful low-frequency notes. The example in the Flagstaff collection is an early cased and portable diaphone used on pleasure or sailing craft. By manually turning the crank handle air is produced and fed into valves that direct air across vibrating metal reeds to produce the required sound. in foggy weather, fog horns are used to pinpoint a vessels position and to indicate how the vessel is sailing in foggy conditions. One blast, when sailing on starboard tack and two blasts, when sailing on a port tack and three dots, when with wind is behind the vessel. Since the automation of lighthouses became common in the 1960s and 1970s, most older foghorn marine installations have been removed to avoid the need to run the complex machinery associated with them, and have been replaced with an electrically powered diaphragm or compressed air horns. The example in the collection is significant as it was used in the early 19th century for sailing vessels was important but these portable crank fog horns have also been superseded by modern electric varieties. Therefore the item has a historical connection with sailing and maritime pursuits from our past.English Rotary Norwegian Pattern nautical foghorn within a boxed pine varnished case with exposed corner dovetailing, original leather carrying strap, brass side crank, and original copper trumped horn. Card accessory with Directions for Use in both English and French.Noneflagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, foghorn, maritime technology, maritime communication, marine warning signal, portable foghorn, bellows foghorn, crank handle, robert hope-jones, john northey -

Wodonga & District Historical Society Inc

Wodonga & District Historical Society IncFunctional object - Edison Home Phonograph