Showing 122 items matching " cartons"

-

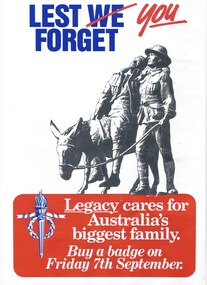

Melbourne Legacy

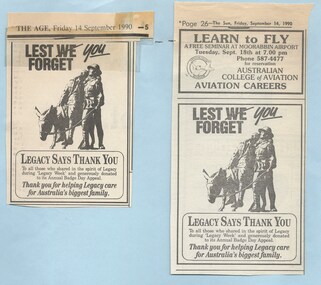

Melbourne LegacyPoster, Lest YOU forget. Legacy cares for Australia's biggest family. Buy a badge on 7th September, 1990

This is an example of Melbourne Legacy promotional material. It is a poster from 1990 and it was in a folder with marketing material from the 1990s. The slogan "Lest YOU forget" was used with an image of the statue of Simpson and his donkey rather than a personality. See other examples of how this image was used, Item 01520 when it was used in newspaper advertisements and on the side of a milk carton, also 01251. The main time of year for fundraising is September when Legacy holds 'Badge Week'. Often there is a celebrity who gives his or her time as 'Personality of the Year'. Examples are Sir Weary Dunlop (1992), Clive James (1993), the Scott family (1994), The Emmanuel brothers (1995), Daryl Somers (1996 and 1997), and Patsy Adam Smith (1994?). Was in a folder with marketing material from the 1990s to 2009, see items 01240 to 01258. The collection shows the types of marketing materials that were produced and the celebrities that were helping Legacy.An example of promotional material from the 1990s. Marketing material and photos were compiled and released to newspapers, also printed as brochures and sometimes as stickers and collection tin wrappers.Colour A4 promotional leaflet for Legacy Week, featuring the statue of Simpson and his donkey.legacy promotion, badge appeal, legacy week, marketing -

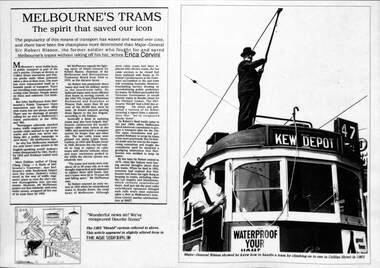

Melbourne Tram Museum

Melbourne Tram MuseumPhotograph, The Age, Frith, "Melbourne's Trams - the spirit that saved our icon", c1980

Laminated A3 sheet featuring photograph and newspaper clippings. 1 - an Article written by Erica Cervini titled "Melbourne's Trams - the spirit that saved our icon", about Major General Sir Robert Risson and his influence on keeping Melbourne's trams which have since become an icon. Quotes John McPherson of the PTUA and Marc Fiddian, author of "Clang Clang clang" refers to a carton by Frith, The Herald 1955 about the opening of Bourke St. See Reg Item 5814i2. 2 - Photo of Risson on the top of a tram showing how to handle a trolley pole - 1963 newspaper clipping. 3 - Cartoon by Frith about the opening of Bourke St, featuring Risson.trams, tramways, robert risson, bourke st, opening, trolley poles, accidents, melbourne, mmtb -

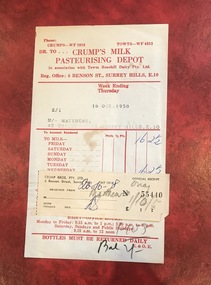

Surrey Hills Historical Society Collection

Surrey Hills Historical Society CollectionDocument - Account and receipt, Receipt signed (?) ES - possibly Eric Scanlan, Crump's Milk Pasteurising Depot account with attached receipt, 2 October 1958 /6 October 1958

Crumps Dairy (Milk Pasteurising Depot) was located at 6 Benson Street, Surrey Hills on the corner of Weybridge Street until c1973. It was demolished after it had been badly vandalised. The business closed after cartons replaced glassperishables including milk, bread, meat and fruit and vegetables bottles for sale of milk. It was one of many small local facilities for processing and delivering milk that existed from the early 1920s. Eric William Walker Crump (1903-1981) headed the family business. Also involved were Kevin Eric Crump, Eric William Scanlan. NB/ Also held in this collection is a copy of a project by Chatham Primary School student, Susanne Pascoe, dated 1956 which includes photos of the dairy's operations. An oral history by Dave Croft, a driver for the dairy, who lived close by, is also relevant. The account also mentions 'Towt'. Canterbury Oliver Towt (1890-1962) was another dairyman whose premises was on the corner of Chatham and Mont Albert Roads.This is material evidence of business practice c1920s-1960s when accounts for goods received, especially perishables, were often hand-delivered on a weekly basis, with monies owed collected at the door. A paper account printed red on cream (discoloured) paper with the details of the date, account holder and address typed in and the amount owed hand-written in blue ink. The attached receipt has been stuck onto the account and filled out in grey pencil and blue ink. The amounts are in pounds, shillings and pence.Typed: 2/1; 2 OCT. 1958 M/- MATTHEWS, 42 GUILDFROD RD. SURREY HILLS, E.10dairies, crumps dairy, crumps milk pasteurising depot, kevin eric crump, eric william scanlan, eric william walker crump, towt's dairy, canterbury oliver towt, accounts, receipts, guildford road, geoff matthews, ruth matthews, benson street, towts rosehill dairy -

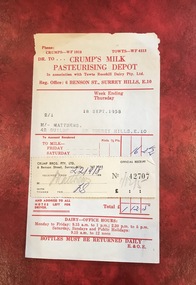

Surrey Hills Historical Society Collection

Surrey Hills Historical Society CollectionDocument - Account and receipt, Receipt signed (?) ES - possibly Eric Scanlan, Crump's Milk Pasteurising Depot account with attached receipt, 16 October 1958 /20 October 1958

Crumps Dairy (Milk Pasteurising Depot) was located at 6 Benson Street, Surrey Hills on the corner of Weybridge Street until c1973. It was demolished after it had been badly vandalised. The business closed after cartons replaced glassperishables including milk, bread, meat and fruit and vegetables bottles for sale of milk. It was one of many small local facilities for processing and delivering milk that existed from the early 1920s. Eric William Walker Crump (1903-1981) headed the family business. Also involved were Kevin Eric Crump, Eric William Scanlan. NB/ Also held in this collection is a copy of a project by Chatham Primary School student, Susanne Pascoe, dated 1956 which includes photos of the dairy's operations. An oral history by Dave Croft, a driver for the dairy, who lived close by, is also relevant. The account also mentions 'Towt'. Canterbury Oliver Towt (1890-1962) was another dairyman whose premises was on the corner of Chatham and Mont Albert Roads.This is material evidence of business practice c1920s-1960s when accounts for goods received, especially perishables, were often hand-delivered on a weekly basis, with monies owed collected at the door. A paper account printed red on cream (discoloured) paper with the details of the date, account holder and address typed in and the amount owed hand-written in blue ink. The attached receipt has been stuck onto the account and filled out in grey pencil and blue ink. The amounts are in pounds, shillings and pence.Typed: 2/1; 16 OCT. 1958 M/- MATTHEWS, 42 GUILDFROD RD. SURREY HILLS, E.10dairies, crumps dairy, crumps milk pasteurising depot, kevin eric crump, eric william scanlan, eric william walker crump, towt's dairy, canterbury oliver towt, accounts, receipts, guildford road, geoff matthews, ruth matthews, benson street, towts rosehill dairy -

Surrey Hills Historical Society Collection

Surrey Hills Historical Society CollectionDocument - Account and receipt, Receipt signed (?) ES - possibly Eric Scanlan, Crump's Milk Pasteurising Depot account with attached receipt, 18 September 1958 /22 September 1958

Crumps Dairy (Milk Pasteurising Depot) was located at 6 Benson Street, Surrey Hills on the corner of Weybridge Street until c1973. It was demolished after it had been badly vandalised. The business closed after cartons replaced glassperishables including milk, bread, meat and fruit and vegetables bottles for sale of milk. It was one of many small local facilities for processing and delivering milk that existed from the early 1920s. Eric William Walker Crump (1903-1981) headed the family business. Also involved were Kevin Eric Crump, Eric William Scanlan. NB/ Also held in this collection is a copy of a project by Chatham Primary School student, Susanne Pascoe, dated 1956 which includes photos of the dairy's operations. An oral history by Dave Croft, a driver for the dairy, who lived close by, is also relevant. The account also mentions 'Towt'. Canterbury Oliver Towt (1890-1962) was another dairyman whose premises was on the corner of Chatham and Mont Albert Roads.This is material evidence of business practice c1920s-1960s when accounts for goods received, especially perishables, were often hand-delivered on a weekly basis, with monies owed collected at the door. A paper account printed red on cream (discoloured) paper with the details of the date, account holder and address typed in and the amount owed hand-written in blue ink. The attached receipt has been stuck onto the account and filled out in grey pencil and blue ink. The amounts are in pounds, shillings and pence.Typed: 2/1; 18 SEPT. 1958 M/- MATTHEWS, 42 GUILDFROD RD. SURREY HILLS, E.10dairies, crumps dairy, crumps milk pasteurising depot, kevin eric crump, eric william scanlan, eric william walker crump, towt's dairy, canterbury oliver towt, accounts, receipts, guildford road, geoff matthews, ruth matthews, benson street, towts rosehill dairy -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Document - BILL ASHMAN COLLECTION: BENDIGO ELECTRONIC COMPANY

Cream booklet with brown printing titled Bendigo Electronic Company of Australia Proprietary Limited. Includes Capital, number of Shares, Directors, Solicitors, Bankers Registered Office, Copy of a letter re Patents, Information about Scalebuoys, Users of Scalebuoys, What Scalebuoys Do and Where they are used, Also copies of letters from the Victorian Railways, City Overseer Bendigo, Lane's Motors Pty Ltd Melbourne, Union Oil, Soap & Candle Co. Ltd NZ, Knox Home NZ, Maungatapere Co-Op Dairy Co. Ltd., Whangarei Co-operative Dairy Company Ltd. NZ, Kettering Cartons Limited England, Pennsylvania Rubber Company USA, and the Kansas City Public Service Company USAsciences, instruments - general, scalebuoy, bill ashman collection - correspondence, bendigo electronic company of australia pty ltd, a s bloomfield, r h s abbott jnr, harry ponsonby mackenzie rn (retd), arthur robinson & co, the commercial banking company of sydney limited melbourne, a t madden, h a abbott, e c eyers, frank stevenson, city of bendigo, frank h day, lane's motors pty ltd, h c holland, national mutual chambers (n.z.) ltd, union oil soap & candle co ltd, knox home, n a duthie, w h mccorkindale, maungatapere co-op dairy co ltd, j stevenson, the whangarei co-op dairy company ltd, w h millingford, kettering cartons limited, j g arlidge, pennsylvania rubber company, paul a douden & company, w e humphrey, kansas city public service company, h w smith, j t picken & sons -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Manufactured Glass, bottle PURA Cream 4oz, 20thC

There are two distinct types of milk consumption: a natural source of nutrition for all infant mammals and a food product for humans of all ages that is derived from other animals. Milk is a key contributor to improving nutrition and food security particularly in developing countries. Improvements in livestock and dairy technology offer significant promise in reducing poverty and malnutrition in the world. Pasteurization is used to kill harmful micro-organisms by heating the milk for a short time and then immediately cooling it. In the past, milk was always packaged in glass milk bottles The first glass bottle packaging for milk was used in the 1870s. The first company to do so may have been the New York Dairy Company in 1877 with a small glass lid and a tin clip. Lewis P. Whiteman holds the first patent for a glass milk bottle c1884,which was sealed with a waxed paper disk. The Express Dairy Company in England began glass bottle production in 1880. Melbourne Glass Bottle Works Spotswood 1880 - 1990. Milk cartons first came to Australia in 1958, when the Model Dairy in Melbourne began packaging milk in 150 ml and 500 ml cartons. At the time, 160,000 new glass bottles were needed in Melbourne alone every week to keep up the delivery of 1.3 million bottles of milk a day. n 1970, the blow-moulded disposable plastic milk bottle was introduced. In 1987, only about 2% of milk was still being sold in glass bottles. Glass milk bottles are now rare .Melbourne Glass Bottle Works Co Pty Ltd (1903 - 1915) Registered in Victoria in 1903 the company amalgamated with the Waterloo Glass Bottle Works Ltd in 1915 to form Australian Glass Manufacturers Company, Limited. Melbourne Glass bottle works Spotswood 1872- 1915 The Melbourne Glass Bottle Works (former), comprising a complex of buildings constructed between 1880 and 1940, at Booker Street, Douglas Parade, 2-38 Hudson Road, Raleigh Street and Simcock Avenue, Spotswood. The former glassworks was established in 1890 and originally made bottles for pharmacists Felton Grimwade before it was sold to the state government by US multinational, OI glass manufacturers A clear glass 4 oz bottle for PURA Creamery Carnegie. . A waxed cardboard disc lid from Devonshire Dairy Hepburn Springs is not related to this bottle but is an example of the typical lid used during this period Bottle : PURA / CREAMERY / CARNEGIE / CONTENTS 4 OZS Base : 120 Lid circumference : DEVONSHIRE DAIRY HEPBURN SPRINGS:/ Lid centre: PURE MILK/ T.B. TESTED COWS / PHONE 223 melbourne glass bottle works, spotswood melbourne, milk, dairy, dairy produce, dairy farmers, market gardeners, pioneers, early settlers, moorabbin, cheltenham, pasteur louis, pasteurization, pura creamery carnegie, devonshire dairy, hepburn springs, waxed paper milk bottle lids, felton grimwade co ltd, -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyNewspaper Article - Tawonga School Centenary 1980 x2, Alpine Courier incorporating The Hydro Courier, 1980

This newspaper article was produced at a time when newspapers were the main source of local information. The period before the explosion of mobile communication technology and the cost effectiveness of communication by "texting" and internet "social connections, eg. facebook and other social media networkings" The newspapers were the main links between and within large regions. The Hydro Courier was first printed in 1950 as a YMCA community service publication by Mr. Albert Clarke YMCA Officer and Mr. Alex McCullough a State Electricity Commission employee. This paper was one very important publication that provided relevant community information to all and was the major contributer to the "Valley" cohesive fibre and unity. This article not only records the celebration (centenary) of the Tawonga School but also presents the history of the school and important events such as various relocations of classrooms and how the region was settled and developed from the 1870's onward. The yawonga school opened in 1880 on 8 acres of land. It consisted of one large wooden building (22 ft x 11 ft). It had two windows, one brick chimney, bare wooden floor and a shingle roof. This article also presents the time when Mount Beauty area was likened to an island and occasionally school children could not attend school because of a flooded Kiewa river. The article also covers the changes brought about by the increased employment opportunities from SEC Kiewa Works(1935), the Sawmill(1946), the Gold mine(1949) and the Tobacco Industry (largest growing area in Australia).This item is a one page (original) article of the centenary celebrations for Tawonga Primary School came from the Alpine Observer and incorporated the Hydro Courier. It covers the arrangements for the celebration of the 100 years of the school's existence. The printed layout is typical of the typeset in use in 1980's. There are seven distinctive type collumns separated by a printed line. Three photographs are published with one photograph of a demountable classromm ,circa 1980, and the other two of student class photos of 1899 and 1914. Teacher and student names are listed below each photograph. On the back of this page are "specials" for "Sam's Cut Price Stores", specifically the Myrtleford store. Of interest is the advertisement of "Cartons of Cigarettes at cut prices". The page was produced as part of a "run" with "telltale" holes at each corner for stabilising the page in the printing process."Centenary Celebrations For Tawonga Primary School" below this in an enclosed heading "ALPINE OBSERVER" underneath in smaller print "WITH WHICH IS INCORPORATED" below this in larger print "THE HYDRO COURIER" and below this from left to right, "No. 719 (Vol. 3) THURSDAY, 23rd OCTOBER, 1980" next "in smaller print Recommended Price Single Copy, 20c "(cents)rural school development, tawonga school centenary, kiewa valley development 1880 to 1980 -

Melbourne Legacy

Melbourne LegacyDocument, Lest YOU forget. Legacy cares for Australia's biggest family, 1990

This is an example of Melbourne Legacy promotional material. It was used in newspaper advertising and also printed on milk cartons. The slogan "Lest YOU forget" was used with an image of the statue of Simpson and his donkey rather than a personality. The newspaper advertising varied slightly, from 'Buy a badge on Friday 7th September' to 'Legacy Says Thank You' when it was published on 14 September. It was in a folder with marketing material from the 1990s also see item 01250. The slogan "Lest YOU forget" was used with an image of the statue of Simpson and his donkey rather than a personality. The main time of year for fundraising is September when Legacy holds 'Badge Week'. Often there is a celebrity who gives his or her time as 'Personality of the Year'. Examples are Sir Weary Dunlop (1992), Clive James (1993), the Scott family (1994), The Emmanuel brothers (1995), Daryl Somers (1996 and 1997), and Patsy Adam Smith (1994?). Was in a folder with marketing material from the 1990s to 2009, see items 01240 to 01258. The collection shows the types of marketing materials that were produced and the celebrities that were helping Legacy.An example of promotional material from the 1990s. Marketing material and photos were compiled and released to newspapers, also printed as brochures and sometimes as stickers and collection tin wrappers. Examples of the use of a promotional image for Legacy Week in 1990, featuring the statue of Simpson and his donkey.legacy promotion, badge appeal, legacy week -

Glen Eira Historical Society

Glen Eira Historical SocietyArticle - Webb Family

There are six items in this file. A photocopy from 500 Victorians 1934 edition of Percy Barrett Webb, engineer, manufacturer, of Webb Brothers, City Road South Melbourne. Includes carton illustration and personal details. Handwritten biographical information about Charles Webb, architect. Includes list of properties designed and two pages of references. Handwritten lists of two properties associated with George Octavius Webb, 1871 and 1887. Handwritten list of one property associated with Walter E. Webb, 1891. Two original photographs and one photocopy of statue of Isabella Webb, daughter of Justice Webb d.1891 located in Glen Eira City Hall as of 2000. One photograph taken in 1981 includes Mrs. Marie Langton, left, and Mrs. Margaret Moscham. Verso is handwritten description of photographs and photocopy. These were donated by Mrs. Langton March 2000. Two pages torn from Melbourne Weekly Bayside, April 14, 2010 entitled A Manor of Magnificence from Windsor Hotel to Winston Manor Charles Webb’s legacy remains unmatched by Kay Keighery on buildings designed by Charles Webb. The record page comprises description of 2 Manor Street, Brighton, designed by Webb, for sale at five million dollars.webb percy barrett, webb charles, webb george octavius, webb isabella, webb justice, langton mrs. marie, moscham margaret, glen eira city hall, orrong road, caulfield, st. mary’s caulfield, glenhuntly road, glenhuntly, duffy f.g., hopetoun street, korang street, glen tana, glentana, bambra road, currall road, ballantyne k., architetcts, architectural features, architectural styles, architecture, churches, mansion houses, sculpture, statues -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyBottle Milk, early 1900's

This glass milk bottle was manufactured and used mid to late 1900's (1834 Victorian dairy industry was founded) up to the time that a cheaper container was invented(plastic bottles and polyethylene plastic lined cardboard cartons) and produced. In 1909 the supply of pure bottled milk was required for babies to overcome infant mortality due to unhygienic milk sources (unclean containers and unpasteurized milk). Due to the volume of milk being processed and hand milking could not keep up with demand, dairy farms introduced milking machines in the late 1930's. The great increases in dairy herds from the average of 18 cows per heard in 1950's to 142 cows per herd in 1996 required milk tankers to pick up the regions milk supply. This bottle was so constructed to be easily moved within the milk processing plants from the delivery vats/holding tanks to the final corking/sealing of the bottles for eventual distribution. From 1958 the milk bottle slowly became phased out of production. At this point in time Melbourne was drawing 160,000 bottles per week from the two major glass bottle works companies, e.g. Melbourne Glass Bottle Works Co. Victoria was the major state supplier of cows milk in the history of Australian milk production from the early 1800's. The Kiewa Valley and its region was a major contributor to meet that demand. Each bottle was "branded" during manufacturing to show the contents (pasteurized milk) and where it originated from (region and supplier). This method of recycling the bottles back to specific dairy farms was a good control method but an uneconomical "on cost" which was replaced by the "throw away" less costly plastic and cardboard containers. Kiewa Valley dairy herds had marked bottles bearing "90/9", "6/18", "6/33", "6/35" and "6/36" This heavy gauged glass milk bottle has a rim and a distinctive head at the top. This head has been manufactured to facilitate the movement of the bottled along the milk production line. The method of pouring milk into the bottle has been part of the "production line". This bottle has a one pint capacity and is made from "clear" glass. There are other milk bottles that have a "green" tint in them.Around the bottom side of the bottle and blown into the glass "ONE PINT" and on the opposite side "MILK". Below these markings is "This BOTTLE BELONGS TO MILK BOTTLES RECOVERY LTD" below this "AND CANNOT BE USED WITHOUT WRITTEN PERMISSION. On the base of the bottle is molded a big "M". An identification mark of "90" over "9" is beneath the "M". glass bottles, commercial milk containers, domestic milk bottles, pasteurized milk bottles, milk, dairy, farms, kiewa valley -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyBottle Milk, mid to late 1900's

This glass milk bottle was manufactured and used mid 1800's (1834 Victorian dairy industry was founded) to the time that a cheaper container was invented(plastic bottles and polyethylene plastic lined cardboard cartons). In 1909 the supply of pure bottled milk was required for babies to overcome infant mortality due to unhygienic milk sources (unclean containers and unpasteurized milk). Due to the large volume of milk being processed and hand milking could not keep up with demand, dairy farms introduced milking machines in the late 1930's. The great increases in dairy herds from the average of 18 cows per heard in 1950's to 142 cows per herd in 1996 required milk tankers to pick up the regions milk supply. This bottle was so constructed to be easily moved within the milk processing plants from the delivery vats/holding tanks to the final corking/sealing of the bottles for eventual distribution. From 1958 the milk bottle slowly became phased out of production. At this point in time Melbourne was drawing 160,000 bottles per week from the two major glass bottle works companies, e.g. Melbourne Glass Bottle Works Co.Victoria was the major state supplier of cows milk in the history of Australian milk production from the early 1800's. The Kiewa Valley and its region was a major contributor to meet that demand. Each bottle was "branded" during manufacturing to show the contents (pasteurized milk) and where it originated from (region and supplier). This method of recycling the bottles back to specific dairy farms was a good control method but an uneconomical "on cost" which was replaced by the "throw away" less costly plastic and cardboard containers. Kiewa Valley dairy herds had marked bottles bearing "90/9", "6/18", "6/33", "6/35" and "6/36"This heavy gauged glass milk bottle has a rim and a distinctive head at the top. This head has been manufactured to facilitate the movement of the bottled along the milk production line. The method of pouring milk into the bottle has been part of the "production line". This bottle has a one pint capacity and is made from "light green" coloured glass(a protection against sunlight penetration). There are other milk bottles that do not have a "green" tint in them. This thick glass bottle to contain milk required its thickness because of the extensive handling before final consumption. Milk was delivered by the "milk man" direct to the homes of consumers. During this period delivery to homes in cities and towns was made initially by horse and cart and later by truck.On the bottom end of this bottle a circle within it 6/33 and next to this "ONE PINT" and under this "THIS BOTTLE BELONGS TO MILK BOTTLE RECOVERY LTD" and below this "AND CANNOT BE USED WITHOUT WRITTEN PERMISSION" on the base "M" underneath this "4"glass bottles, commercial milk containers, domestic milk bottles, pasteurized milk bottles -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyBottle Milk, circa mid to late 1900's

This glass milk bottle was manufactured and used mid to late 1900's (1834 Victorian dairy industry was founded) up to the time that a cheaper container was invented(plastic bottles and polyethylene plastic lined cardboard cartons). In 1909 the supply of pure bottled milk was required for babies to overcome infant mortality due to unhygienic milk sources (unclean containers and unpasteurized milk). Due to the volume of milk being processed and hand milking could not keep up with demand, dairy farms introduced milking machines in the late 1930's. The great increases in dairy herds from the average of 18 cows per heard in 1950's to 142 cows per herd in 1996 required milk tankers to pick up the regions milk supply. This bottle was so constructed to be easily moved within the milk processing plants from the delivery vats/holding tanks to the final corking/sealing of the bottles for eventual distribution. From 1958 the milk bottle slowly became phased out of production. At this point in time Melbourne was drawing 160,000 bottles per week from the two major glass bottle works companies, e.g. Melbourne Glass Bottle Works Co.Victoria was the major state supplier of cows milk in the history of Australian milk production from the early 1800's. The Kiewa Valley and its region was a major contributor to meet that demand. Each bottle was "branded" during manufacturing to show the contents (pasteurized milk) and where it originated from (region and supplier). This method of recycling the bottles back to specific dairy farms was a good control method but an uneconomical "on cost" which was replaced by the "throw away" less costly plastic and cardboard containers. Kiewa Valley dairy herds had marked bottles bearing "90/9", "6/18", "6/33", "6/35" and "6/36" Found under house at 1 Beauty Ave., Mt Beauty.This heavy gauged glass milk bottle has a rim and a distinctive head at the top. This head was manufactured to facilitate the movement of the bottled along the milk production line. The method of pouring milk into the bottle has been part of the "production line". This bottle has a one pint capacity and is made from "light green" coloured glass(a protection against light penetration). There are other milk bottles that do not have a "green" tint in them. This thick glass bottle which contained milk required its thickness because of the extensive handling before final consumption. Milk was delivered by the "milk man" direct to the homes of consumers. During this period delivery to homes in cities and towns was made initially by horse and cart and later by truck.On the bottom end of this bottle a circle within it "6/18" and next to this "MILK" and opposite "ONE PINT". Below this "THIS BOTTLE BELONGS TO MILK BOTTLE RECOVERY LTD" and below this "AND CANNOT BE USED WITHOUT WRITTEN PERMISSION" on the base "M" underneath this "3"glass bottles, commercial milk containers, domestic milk bottles, pasteurized milk bottles -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyBottle Milk, mid to late 1900's

This glass milk bottle was manufactured and used mid to late 1900's (1834 Victorian dairy industry was founded) until the time that a cheaper container was invented(plastic bottles and polyethylene plastic lined cardboard cartons). In 1909 the supply of pure bottled milk was required for babies to overcome infant mortality due to unhygienic milk sources (unclean containers and unpasteurized milk). Due to the volume of milk being processed and hand milking could not keep up with demand, dairy farms introduced milking machines in the late 1930's. The great increases in dairy herds from the average of 18 cows per heard in 1950's to 142 cows per herd in 1996 required milk tankers to pick up the regions milk supply. This bottle was so constructed to be easily moved within the milk processing plants from the delivery vats/holding tanks to the final corking/sealing of the bottles for eventual distribution. From 1958 the milk bottle slowly became phased out of production. At this point in time Melbourne was drawing 160,000 bottles per week from the two major glass bottle works companies, e.g. Melbourne Glass Bottle Works Co.Victoria was the major state supplier of cows milk in the history of Australian milk production from the early 1800's. The Kiewa Valley and its region was a major contributor to meet that demand. Each bottle was "branded" during manufacturing to show the contents (pasteurized milk) and where it originated from (region and supplier). This method of recycling the bottles back to specific dairy farms was a good control method but an uneconomical "on cost" which was replaced by the "throw away" less costly plastic and cardboard containers. Kiewa Valley dairy herds had marked bottles bearing "90/9", "6/18", "6/33", "6/35" and "6/36" Found under house at 1 Beauty Ave., Mt Beauty.This heavy gauged glass milk bottle has a rim and a distinctive head at the top. This head has been manufactured to facilitate the movement of the bottle along the milk production line. The method of pouring milk into the bottle has been part of the "production line". This bottle has a one pint capacity and is made from "light green" coloured glass(a protection against light penetration). There are other milk bottles that do not have a "green" tint in them. This thick glass bottle to contain milk required its thickness because of the extensive handling before final consumption. Milk was delivered by the "milk man" direct to the homes of consumers. During this period delivery to homes in cities and towns was made initially by horse and cart and later by truck.On the bottom end of this bottle a circle within it "6/36" and next to this "MILK" and opposite "ONE PINT". Below this "THIS BOTTLE BELONGS TO MILK BOTTLE RECOVERY LTD" and below this "AND CANNOT BE USED WITHOUT WRITTEN PERMISSION" on the base "M" underneath this "15" glass bottles, commercial milk containers, domestic milk bottles, pasteurized milk bottles -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyBottle Milk, mid to late 1900's

This glass milk bottle was manufactured and used mid to late1900's (1834 Victorian dairy industry was founded) up until the time that a cheaper container was invented(plastic bottles and polyethylene plastic lined cardboard cartons). In 1909 the supply of pure bottled milk was required for babies to overcome infant mortality due to unhygienic milk sources (unclean containers and unpasteurized milk). Due to the volume of milk being processed and hand milking could not keep up with demand, dairy farms introduced milking machines in the late 1930's. The great increases in dairy herds from the average of 18 cows per heard in 1950's to 142 cows per herd in 1996 required milk tankers to pick up the regions milk supply. This bottle was so constructed to be easily moved within the milk processing plants from the delivery vats/holding tanks to the final corking/sealing of the bottles for eventual distribution. From 1958 the milk bottle slowly became phased out of production. At this point in time Melbourne was drawing 160,000 bottles per week from the two major glass bottle works companies, e.g. Melbourne Glass Bottle Works Co.Victoria was the major state supplier of cows milk in the history of Australian milk production from the early 1800's. The Kiewa Valley and its region was a major contributor to meet that demand. Each bottle was "branded" during manufacturing to show the contents (pasteurized milk) and where it originated from (region and supplier). This method of recycling the bottles back to specific dairy farms was a good control method but an uneconomical "on cost" which was replaced by the "throw away" less costly plastic and cardboard containers. Kiewa Valley dairy herds had marked bottles bearing "90/9", "6/18", "6/33", "6/35" and "6/36" Found under the house at 1 Beauty Ave., Mt BeautyThis heavy gauged glass milk bottle has a rim and a distinctive head at the top. This head has been manufactured to facilitate the movement of the bottled along the milk production line. The method of pouring milk into the bottle has been part of the "production line". This bottle has a one pint capacity and is made from "light green" coloured glass(a protection against light penetration). There are other milk bottles that do not have a "green" tint in them. This thick glass bottle to contain milk required its thickness because of the extensive handling before final consumption. Milk was delivered by the "milk man" direct to the homes of consumers. During this period delivery to homes in cities and towns was made initially by horse and cart and later by truck.On the bottom end of this bottle a circle within it "6/18" and next to this "MILK" and opposite "ONE PINT". Below this "THIS BOTTLE BELONGS TO MILK BOTTLE RECOVERY LTD" and below this "AND CANNOT BE USED WITHOUT WRITTEN PERMISSION" on the base "M" underneath this "4"glass bottles, commercial milk containers, domestic milk bottles, pasteurized milk bottles -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyBottle Milk, mid to late 1900's

This glass milk bottle was manufactured and used mid to late 1900's (1834 Victorian dairy industry was founded), until the time that cheaper containers were invented(plastic bottles and polyethylene plastic lined cardboard cartons). In 1909 the supply of pure bottled milk was required for babies to overcome infant mortality due to unhygienic milk sources (unclean containers and unpasteurized milk). Due to the volume of milk being processed and hand milking could not keep up with demand, dairy farms introduced milking machines in the late 1930's. The great increases in dairy herds from the average of 18 cows per heard in 1950's to 142 cows per herd in 1996 required milk tankers to pick up the regions milk supply. This bottle was so constructed to be easily moved within the milk processing plants from the delivery vats/holding tanks to the final corking/sealing of the bottles for eventual distribution. From 1958 the milk bottle slowly became phased out of production. At this point in time Melbourne was drawing 160,000 bottles per week from the two major glass bottle works companies, e.g. Melbourne Glass Bottle Works Co.Victoria was the major state supplier of cows milk in the history of Australian milk production from the early 1800's. The Kiewa Valley and its region was a major contributor to meet that demand. Each bottle was "branded" during manufacturing to show the contents (pasteurized milk) and where it originated from (region and supplier). This method of recycling the bottles back to specific dairy farms was a good control method but an uneconomical "on cost" which was replaced by the "throw away" less costly plastic and cardboard containers. Kiewa Valley dairy herds had marked bottles bearing "90/9", "6/18", "6/33", "6/35" and "6/36" Found under the house at 1 Beauty Ave., Mt BeautyThis heavy gauged glass milk bottle has a rim and a distinctive head at the top. This head has been manufactured to facilitate the movement of the bottled along the milk production line. The method of pouring milk into the bottle has been part of the "production line". This bottle has a one pint capacity and is made from "light green" coloured glass(a protection against light penetration). There are other milk bottles that do not have a "green" tint in them. This thick glass bottle, to contain milk, required its thickness because of the extensive handling (man and machine) before final consumption. Milk was delivered by the "milk man" direct to the homes of consumers. During this period delivery to homes in cities and towns was made initially by horse and cart and later by truck.On the bottom end of this bottle is a circle within it "6/35" and next to this "MILK" and opposite "ONE PINT". Below this "THIS BOTTLE BELONGS TO MILK BOTTLE RECOVERY LTD" and below this "AND CANNOT BE USED WITHOUT WRITTEN PERMISSION" on the base "M" underneath this "20"milk, dairy, glass bottle -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyBottle Milk, mid to late 1900's

This glass milk bottle was manufactured and used mid to late 1900's (1834 Victorian dairy industry was founded) up until the time that a cheaper container was invented(plastic bottles and polyethylene plastic lined cardboard cartons). In 1909 the supply of pure bottled milk was required for babies to overcome infant mortality due to unhygienic milk sources (unclean containers and unpasteurized milk). Due to the volume of milk being processed and hand milking could not keep up with demand, dairy farms introduced milking machines in the late 1930's. The great increases in dairy herds from the average of 18 cows per heard in 1950's to 142 cows per herd in 1996 required milk tankers to pick up the regions milk supply. This bottle was so constructed to be easily moved within the milk processing plants from the delivery vats/holding tanks to the final corking/sealing of the bottles for eventual distribution. From 1958 the milk bottle slowly became phased out of production. At this point in time Melbourne was drawing 160,000 bottles per week from the two major glass bottle works companies, e.g. Melbourne Glass Bottle Works Co.Victoria was the major state supplier of cows milk in the history of Australian milk production from the early 1800's. The Kiewa Valley and its region was a major contributor to meet that demand. Each bottle was "branded" during manufacturing to show the contents (pasteurized milk) and where it originated from (region and supplier). This method of recycling the bottles back to specific dairy farms was a good control method but an uneconomical "on cost" which was replaced by the "throw away" less costly plastic and cardboard containers. Kiewa Valley dairy herds had marked bottles bearing "90/9", "6/18", "6/33", "6/35" and "6/36" Found under the house at 1 Beauty Ave., Mt BeautyThis heavy gauged glass milk bottle has a rim and a distinctive head at the top. This head has been manufactured to facilitate the movement of the bottle along the milk production line. The method of pouring milk into the bottle has been part of the "production line". This bottle has a half pint capacity and is made from "clear" glass. There are other milk bottles that have a "green" tint in them and this tint was to protect the contents from sun damage. This thick glass bottle to contain milk required its thickness because of the extensive handling before final consumption. Milk was delivered by the "milk man" direct to the homes of consumers. During this period delivery to homes in cities and towns was made initially by horse and cart and later by truck.On the top half of this bottle is "MILK" and opposite "HALF PINT". Below this "THIS BOTTLE BELONGS TO MILK BOTTLE RECOVERY LTD" and below this "AND CANNOT BE USED WITHOUT WRITTEN PERMISSION" on the base is "2 M" underneath this "8/11" and underneath is "ISM -169"glass bottles, commercial milk containers, domestic milk bottles, pasteurized milk bottles -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyBottle Milk, Circa mid to late 1900's

This glass milk bottle was manufactured and used mid to late 1900's (1834 Victorian dairy industry was founded) up to the time that a cheaper container was invented(plastic bottles and polyethylene plastic lined cardboard cartons) and produced. In 1909 the supply of pure bottled milk was required for babies to overcome infant mortality due to unhygienic milk sources (unclean containers and unpasteurized milk). Due to the volume of milk being processed and hand milking could not keep up with demand, dairy farms introduced milking machines in the late 1930's. The great increases in dairy herds from the average of 18 cows per heard in 1950's to 142 cows per herd in 1996 required milk tankers to pick up the regions milk supply. This bottle was so constructed to be easily moved within the milk processing plants from the delivery vats/holding tanks to the final corking/sealing of the bottles for eventual distribution. From 1958 the milk bottle slowly became phased out of production. At this point in time Melbourne was drawing 160,000 bottles per week from the two major glass bottle works companies, e.g. Melbourne Glass Bottle Works Co. Victoria was the major state supplier of cows milk in the history of Australian milk production from the early 1800's. The Kiewa Valley and its region was a major contributor to meet that demand. Each bottle was "branded" during manufacturing to show the contents (pasteurized milk) and where it originated from (region and supplier). This method of recycling the bottles back to specific dairy farms was a good control method but an uneconomical "on cost" which was replaced by the "throw away" less costly plastic and cardboard containers. Kiewa Valley dairy herds had marked bottles bearing "90/9", "6/18", "6/33", "6/35" and "6/36" This particular one has "7/14".This heavy gauged glass milk bottle has a rim and a distinctive head at the top. This head has been manufactured to facilitate the movement of the bottled along the milk production line. The method of pouring milk into the bottle has been part of the "production line". This bottle has a one Imperial pint capacity and is made from "clear" glass. There are other milk bottles that have a "green" tint in them. Around the bottom side of the bottle and blown into the glass "ONE IMPERIAL PINT". Below these markings and stenciled is "KIEWA" (in freehand style and underlined) underneath is "PASTEURISED FULL CREAM MILK" underneath this ,in freehand stiyle is "USE" next to this in block style "KIEWA BUTTER, CREAM, AND ICE CREAM MIX" to the left of this ,and barely readable is stenciled "THIS BOTTLE ALWAYS REMAINS/ THE PROPERTY OF/ NORTH EASTERN DAIRY Co. Ltd". On the base of the bottle is molded a big "2". with a smaller "m". An identification mark of "7" over "14" is within a circled boundary. Below this is moulded "RM - 15". glass bottles, commercial milk containers, domestic milk bottles, pasteurized milk bottles -

Unions Ballarat

Unions BallaratPhotograph: Labour Day March - Ballarat - 2019, 11/3/19

Labour Day originates from the eight-hour day movement - eight hours for work, eight hours for recreation, and eight hours for rest. On 21 April 1856 Stonemasons and building workers on building sites around Melbourne, Australia, stopped work and marched from the University of Melbourne to Parliament House to achieve an eight-hour day. Their direct action protest was a success, and they are noted as the first organised workers in the world to achieve an eight-hour day with no loss of pay, which subsequently inspired the celebration of Labour Day and May Day. (Wikipedia, 12 March 2019: https://en.wikipedia.org/wiki/Public_holidays_in_Australia#Labour_Day) The eight-hours campaign ran contemporaneously in Ballarat. -------- The Labour day parade is an annual event in Ballarat. All unions and individuals are welcome to attend. Ballarat Labour Day march is held at the same date as the Begonia Festival parade; inception of the Begonia Festival was several decades later in 1953. -------- Photo 1 Labour Day march: We are Union banner and AMIWU banner with people. Photo 2 Labour Day march: We are Union, Trades Hall, Free West Papua banners, Trades Hall ute, various individuals including Don Henderson, Jenny Beacham, Tracey Brown, Simon Hammersley, Moses, Ben Davison, Angela McCarthy, Eddie Beacham, Gary Carton, Bob Bassett, Colin Muir, et al. Photo 3 Labour Day march: We are Union, ANMF, Trades Hall banners, various individuals including Don Henderson, Jenny Beacham, Tracey Brown, Simon Hammersley, Moses, Ben Davison, Angela McCarthy, Eddie Beacham, Gary Carton, Bob Bassett, Colin Muir, Ron Woods et al. Photo 4 Labour Day march: Change the Rules and AMIWU banners, various persons including Chris Kelly, Angela McCarthy, Ross Kenna, et al. Photo 5 Labour Day barbeque: Various persons including Allen Townsend, Fred Ladiges, Cameron McIntyre, Judy Henderson, Don Henderson, Cameron Bannam, Janine Brownlee, Dave Brownlee, Bernie Constable, Ian Fullerton, Ben Davison, et al. Photo 6 Labour Day barbeque group photograph: Various persons including Moses, Emma Pritchard, Kamuda, Allen Townsend, Tess Marshall, Chris Kelly, Fred Ladiges, Ross Kenna, Ben Davison, Don Henderson, Judy Henderson, Gabriel Waldron, Cameron McIntyre, Orry Pilven, Lana Cormie, Bob Bassett, Clinton Bannam, Angela McCarthy, Tracey Brown, Ron Woods, Ian Fullerton, Colin Muir, et al. Photo 7 Labour Day barbeque group photograph: Various persons including Moses, Emma Pritchard, Kamuda, Allen Townsend, Tess Marshall, Chris Kelly, Fred Ladiges, Ross Kenna, Ben Davison, Don Henderson, Judy Henderson, Gabriel Waldron, Cameron McIntyre, Orry Pilven, Lana Cormie, Bob Bassett, Clinton Bannam, Angela McCarthy, Tracey Brown, Ron Woods, Ian Fullerton, Colin Muir, et al. Photo 8 Labour Day March: We are Union banner, various persons including Chris Kelly, Angela McCarthy, Clinton Bannam, Orrie and Gem Pilven, Janine Brownlee, et al.Significant to the inception of the eight hour day, history of unions and campaigns in Australia and the current Change the Rules campaign.8 colour photographs; soft copy.btlc, ballarat trades hall, ballarat trades and labour council, labour day - 2019, unions - delegates, change the rules, amiwu, anmf, we are union, unions - campaigns, early closing association, begonia festival - ballarat -

Federation University Art Collection

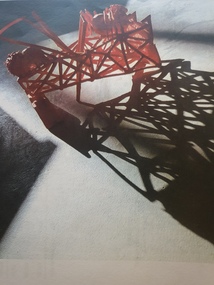

Federation University Art CollectionCeramic - Artwork - Ceramics, 'Parliament House' by Pattie Beerens, 2018

Pattie BEERENS (1962- ) Born Sunshine, Victoria Pattie Beerens was enrolled in the Graduate Diploma of Ceramics at Federation University in 2018 after completing a Graduate Certificate Visual Art at the Victorian College of Arts, University of Melbourne in 2017.Artists' Statement: Red. Broken structure on its side supported with an unrecognisable form. It is cast from an electronics packaging carton. Triangular arrows piece the structure with a spider on either side. I created fertility spiders to protect the Minoan women from predators. I collected spiders as a child to ward off the bullies and, like the octopus, spiders have eight legs and a head and body. The stylised spiders reference links between the Minoan octopus and other symbols of fertility. The natural light elongates the form in a shadow reflection on the floor. The form is surrounded by black space. This piece took on an anger I felt on the day that [Malcolm] Turnbull was overthrown and materialises the bully-boy behaviour we were witnessing. What is most interesting about this piece is that I created it as a Minoan reflection. It dawned on me , when I had it ready for the kiln - on the day that Dutton challenged the Turnbull leadership, that my anger was both reflective and contemporary because nothing seemed to have changed. We were witnessing first hand how the power struggles continue and goodwill suffers." Winner of the 2018 Deputy Vice-Chancellor's Awardpattie beerens, ceramics, sculpture, available ceramics -

National Wool Museum

National Wool MuseumMillion Dollar Bale Wool Sample, 1995

The wool was shorn from sheep of the Wyndarra and Rockbank bloodlines. A flock of 290 sheep were kept undercover at Kadinia, the property of the Appledore family from Brim in the Wimmera district of Victoria. Their record-breaking wool was produced by giving the sheep a special diet and providing each one with a UV-protective coat. Around 180 fleeces were selected for the million dollar bale. The sale of the first bale of wool measuring below 14 microns was held in the Auction Room here at the National Wool Museum. Bidding began at $600/kg and steadily increased until there were only two bidders left. The bidders represented the Japanese firm Aoki International and Loro Piana of Italy. The hammer fell at $10,300/kg, with Aoki International paying $1,194,800 for the 116kg bale. The fleece was scoured (cleaned) at the Goulburn Wool Scour, New South Wales. The degree of preparation and care taken with the task was extreme. The Scour closed production three days before and was extensively cleaned. On the day of scouring 12 tonnes of 17 micron wool was washed to condition the water, then nine bales of extra super fine wool, worth over $300,000 was washed as a trial run. Toabo Agaki Japan was employed to process the scoured wool into suit cloth. Taobo required the scoured wool to contain 0.5% residual grease, 12% moisture and a yield of 83kg. These requirements were met. The entire staff of the Scour wanted to be part of washing the best wool in the world. Without asking for payment both the night shift and afternoon shift crews assisted the day shift in the task. The bale was fed into the scour in seven minutes and fitted into three bowls, half the scour. It completely disappeared into the dryer and the last wool was fed before the first wool was out. The clean wool was hand-packed into cardboard cartons and freighted to Japan. Aoki International, based in Yokohama Japan, cut three suit lengths from the cloth, then blended the remaining wool into an exclusive line of commercially-available suits. These suits are labeled Kadinia.Wool sample from the Million Dollar Balewool sales, million dollar bale -

National Wool Museum

National Wool MuseumFunctional object - Auctioneer's Gavel, c. 1950s

Michael Crooks was the auctioneer responsible for selling Australia's million dollar wool bale on the 11th January, 1995 in Geelong, using this gavel. The wool was shorn from sheep of the Wyndarra and Rockbank bloodlines. A flock of 290 sheep were kept undercover at Kadinia, the property of the Appledore family from Brim in the Wimmera district of Victoria. Their record-breaking wool was produced by giving the sheep a special diet and providing each one with a UV-protective coat. Around 180 fleeces were selected for the million dollar bale. The sale of the first bale of wool measuring below 14 microns was held in the Auction Room here at the National Wool Museum. Bidding began at 40,000 (cents a kilogram) and steadily increased until there were only two bidders left. The bidders represented the Japanese firm Aoki International and Loro Piana of Italy. The hammer fell at 1,030,000 cents per kilogram, with Aoki International paying $1,194,800 for the 116kg bale. The fleece was scoured (cleaned) at the Goulburn Wool Scour, New South Wales. The degree of preparation and care taken with the task was extreme. The Scour closed production three days before and was extensively cleaned. On the day of scouring 12 tonnes of 17 micron wool was washed to condition the water, then nine bales of extra super fine wool, worth over $300,000 was washed as a trial run. Toabo Agaki Japan was employed to process the scoured wool into suit cloth. Taobo required the scoured wool to contain 0.5% residual grease, 12% moisture and a yield of 83kg. These requirements were met. The entire staff of the Scour wanted to be part of washing the best wool in the world. Without asking for payment both the night shift and afternoon shift crews assisted the day shift in the task. The bale was fed into the scour in seven minutes and fitted into three bowls, half the scour. It completely disappeared into the dryer and the last wool was fed before the first wool was out. The clean wool was hand-packed into cardboard cartons and freighted to Japan. Aoki International, based in Yokohama Japan, cut three suit lengths from the cloth, then blended the remaining wool into an exclusive line of commercially-available suits. These suits are labelled Kadinia.Small wooden hammer, with handle and double sided face.gavel, michael crooks, auctioneer, wool industry, million dollar bale, geelong, auction, kadinia, appledore -

National Wool Museum

National Wool MuseumPhotograph - Appledore Family, Growers Gallery, National Wool Centre, Geelong, 11 January 1995

This photograph depicts people gathered in the Growers Gallery on the 11th January, 1995 at the National Wool Centre, Geelong. It shows the emotions of Murray, Ian and Kaye Appledore while bidding took place for the million dollar bale. The wool was shorn from sheep of the Wyndarra and Rockbank bloodlines. A flock of 290 sheep were kept undercover at Kadinia, the property of the Appledore family from Brim in the Wimmera district of Victoria. Their record-breaking wool was produced by giving the sheep a special diet and providing each one with a UV-protective coat. Around 180 fleeces were selected for the million dollar bale. The sale of the first bale of wool measuring below 14 microns was held in the Auction Room here at the National Wool Museum. Bidding began at 40,000 (cents a kilogram) and steadily increased until there were only two bidders left. The bidders represented the Japanese firm Aoki International and Loro Piana of Italy. The hammer fell at 1,030,000 cents per kilogram, with Aoki International paying $1,194,800 for the 116kg bale. The fleece was scoured (cleaned) at the Goulburn Wool Scour, New South Wales. The degree of preparation and care taken with the task was extreme. The Scour closed production three days before and was extensively cleaned. On the day of scouring 12 tonnes of 17 micron wool was washed to condition the water, then nine bales of extra super fine wool, worth over $300,000 was washed as a trial run. Toabo Agaki Japan was employed to process the scoured wool into suit cloth. Taobo required the scoured wool to contain 0.5% residual grease, 12% moisture and a yield of 83kg. These requirements were met. The entire staff of the Scour wanted to be part of washing the best wool in the world. Without asking for payment both the night shift and afternoon shift crews assisted the day shift in the task. The bale was fed into the scour in seven minutes and fitted into three bowls, half the scour. It completely disappeared into the dryer and the last wool was fed before the first wool was out. The clean wool was hand-packed into cardboard cartons and freighted to Japan. Aoki International, based in Yokohama Japan, cut three suit lengths from the cloth, then blended the remaining wool into an exclusive line of commercially-available suits. These suits are labelled Kadinia.Colour photograph showing an interior view of rows of people seated and standing in room.michael crooks, auctioneer, wool industry, million dollar bale, geelong, auction, kadinia, appledore, keith jackson, sale room -

National Wool Museum

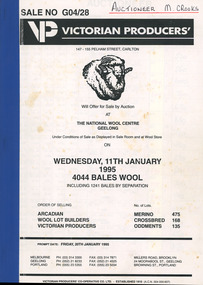

National Wool MuseumDocument - Victorian Producers' Sale Catalogue, National Wool Centre, Geelong, Victorian Producers' Co-operative Limited, 11 January 1995

This sales catalogue was the one used by Auctioneer Michael Crooks on 11th January 1995 when the million dollar bale was sold at the National Wool Centre, Geelong. The wool was shorn from sheep of the Wyndarra and Rockbank bloodlines. A flock of 290 sheep were kept undercover at Kadinia, the property of the Appledore family from Brim in the Wimmera district of Victoria. Their record-breaking wool was produced by giving the sheep a special diet and providing each one with a UV-protective coat. Around 180 fleeces were selected for the million dollar bale. The sale of the first bale of wool measuring below 14 microns was held in the Auction Room here at the National Wool Museum. Bidding began at 40,000 (cents a kilogram) and steadily increased until there were only two bidders left. The bidders represented the Japanese firm Aoki International and Loro Piana of Italy. The hammer fell at 1,030,000 cents per kilogram, with Aoki International paying $1,194,800 for the 116kg bale. The fleece was scoured (cleaned) at the Goulburn Wool Scour, New South Wales. The degree of preparation and care taken with the task was extreme. The Scour closed production three days before and was extensively cleaned. On the day of scouring 12 tonnes of 17 micron wool was washed to condition the water, then nine bales of extra super fine wool, worth over $300,000 was washed as a trial run. Toabo Agaki Japan was employed to process the scoured wool into suit cloth. Taobo required the scoured wool to contain 0.5% residual grease, 12% moisture and a yield of 83kg. These requirements were met. The entire staff of the Scour wanted to be part of washing the best wool in the world. Without asking for payment both the night shift and afternoon shift crews assisted the day shift in the task. The bale was fed into the scour in seven minutes and fitted into three bowls, half the scour. It completely disappeared into the dryer and the last wool was fed before the first wool was out. The clean wool was hand-packed into cardboard cartons and freighted to Japan. Aoki International, based in Yokohama Japan, cut three suit lengths from the cloth, then blended the remaining wool into an exclusive line of commercially-available suits. These suits are labelled Kadinia.Bound paper booklet, approximately 35 pages, with printed and handwritten text.Front: [handwritten] AUCTIONEER M. CROOKS Front: [printed] SALE NO G04/28 / VICTORIAN PRODUCERS' / 147-155 PELHAM STREET, CARLTON / Will Offer for Sale by Auction / AT / THE NATIONAL WOOL CENTRE / GEELONG / Under Conditions of Sale as Displayed in Sale Room and at Wool Store / ON / WEDNESDAY, 11TH JANUARY / 1995 / 4044 BALES WOOL / INCLUDING 1241 BALES BY SEPARATIONmichael crooks, auctioneer, wool industry, million dollar bale, geelong, auction, kadinia, appledore, keith jackson, sale room, geelong wool centre -

National Wool Museum

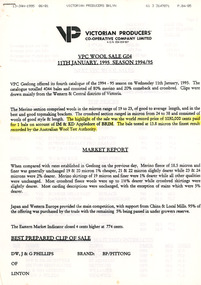

National Wool MuseumDocument - Victorian Producers' Market Report, Victorian Producers' Co-operative Limited, 11 January 1995

Victorian Producers Market Report, featuring details of the sale of the million dollar bale on Wednesday 11th January, 1995 in Geelong. The wool was shorn from sheep of the Wyndarra and Rockbank bloodlines. A flock of 290 sheep were kept undercover at Kadinia, the property of the Appledore family from Brim in the Wimmera district of Victoria. Their record-breaking wool was produced by giving the sheep a special diet and providing each one with a UV-protective coat. Around 180 fleeces were selected for the million dollar bale. The sale of the first bale of wool measuring below 14 microns was held in the Auction Room here at the National Wool Museum. Bidding began at 40,000 (cents a kilogram) and steadily increased until there were only two bidders left. The bidders represented the Japanese firm Aoki International and Loro Piana of Italy. The hammer fell at 1,030,000 cents per kilogram, with Aoki International paying $1,194,800 for the 116kg bale. The fleece was scoured (cleaned) at the Goulburn Wool Scour, New South Wales. The degree of preparation and care taken with the task was extreme. The Scour closed production three days before and was extensively cleaned. On the day of scouring 12 tonnes of 17 micron wool was washed to condition the water, then nine bales of extra super fine wool, worth over $300,000 was washed as a trial run. Toabo Agaki Japan was employed to process the scoured wool into suit cloth. Taobo required the scoured wool to contain 0.5% residual grease, 12% moisture and a yield of 83kg. These requirements were met. The entire staff of the Scour wanted to be part of washing the best wool in the world. Without asking for payment both the night shift and afternoon shift crews assisted the day shift in the task. The bale was fed into the scour in seven minutes and fitted into three bowls, half the scour. It completely disappeared into the dryer and the last wool was fed before the first wool was out. The clean wool was hand-packed into cardboard cartons and freighted to Japan. Aoki International, based in Yokohama Japan, cut three suit lengths from the cloth, then blended the remaining wool into an exclusive line of commercially-available suits. These suits are labelled Kadinia.Two pages held with staple in top left corner with printed black text.Front: [printed] VP / VICTORIAN PRODUCERS' / CO-OPERATIVE COMPANY LIMITED / A. C. N. 004 059 607 / VPC WOOL SALE G04 / 11TH JANUARY, 1995 SEASON 1994/95michael crooks, auctioneer, wool industry, million dollar bale, geelong, auction, kadinia, appledore, keith jackson, sale room, geelong wool centre -

National Wool Museum

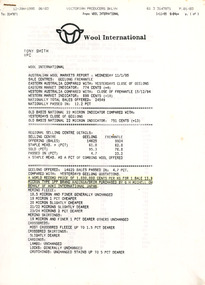

National Wool MuseumDocument - Australian Wool Markets Report, Wool International, 11 January 1995

Australian Wool Markets Report, featuring details of the sale of the million dollar bale on Wednesday 11th January, 1995 in Geelong. The wool was shorn from sheep of the Wyndarra and Rockbank bloodlines. A flock of 290 sheep were kept undercover at Kadinia, the property of the Appledore family from Brim in the Wimmera district of Victoria. Their record-breaking wool was produced by giving the sheep a special diet and providing each one with a UV-protective coat. Around 180 fleeces were selected for the million dollar bale. The sale of the first bale of wool measuring below 14 microns was held in the Auction Room here at the National Wool Museum. Bidding began at 40,000 (cents a kilogram) and steadily increased until there were only two bidders left. The bidders represented the Japanese firm Aoki International and Loro Piana of Italy. The hammer fell at 1,030,000 cents per kilogram, with Aoki International paying $1,194,800 for the 116kg bale. The fleece was scoured (cleaned) at the Goulburn Wool Scour, New South Wales. The degree of preparation and care taken with the task was extreme. The Scour closed production three days before and was extensively cleaned. On the day of scouring 12 tonnes of 17 micron wool was washed to condition the water, then nine bales of extra super fine wool, worth over $300,000 was washed as a trial run. Toabo Agaki Japan was employed to process the scoured wool into suit cloth. Taobo required the scoured wool to contain 0.5% residual grease, 12% moisture and a yield of 83kg. These requirements were met. The entire staff of the Scour wanted to be part of washing the best wool in the world. Without asking for payment both the night shift and afternoon shift crews assisted the day shift in the task. The bale was fed into the scour in seven minutes and fitted into three bowls, half the scour. It completely disappeared into the dryer and the last wool was fed before the first wool was out. The clean wool was hand-packed into cardboard cartons and freighted to Japan. Aoki International, based in Yokohama Japan, cut three suit lengths from the cloth, then blended the remaining wool into an exclusive line of commercially-available suits. These suits are labelled Kadinia.Three pages held with staple in top left corner with printed black text.Front: [printed] Wool International / TONY SMITH / VPC / WOOL INTERNATIONAL / AUSTRALIAN WOOL MARKETS REPORT: WEDNESDAY 11/1/95michael crooks, auctioneer, wool industry, million dollar bale, geelong, auction, kadinia, appledore, keith jackson, sale room, geelong wool centre -

National Wool Museum

National Wool MuseumPhotograph - Million Dollar Bale, National Wool Centre, Geelong, 11 January 1995

This photograph shows Grower Ian Appledore, Auctioneer Michael Crooks and Wool Manager Keith Jackson posing with the million dollar bale after it was sold on 11th January 1995 in Geelong. The wool was shorn from sheep of the Wyndarra and Rockbank bloodlines. A flock of 290 sheep were kept undercover at Kadinia, the property of the Appledore family from Brim in the Wimmera district of Victoria. Their record-breaking wool was produced by giving the sheep a special diet and providing each one with a UV-protective coat. Around 180 fleeces were selected for the million dollar bale. The sale of the first bale of wool measuring below 14 microns was held in the Auction Room here at the National Wool Museum. Bidding began at 40,000 (cents a kilogram) and steadily increased until there were only two bidders left. The bidders represented the Japanese firm Aoki International and Loro Piana of Italy. The hammer fell at 1,030,000 cents per kilogram, with Aoki International paying $1,194,800 for the 116kg bale. The fleece was scoured (cleaned) at the Goulburn Wool Scour, New South Wales. The degree of preparation and care taken with the task was extreme. The Scour closed production three days before and was extensively cleaned. On the day of scouring 12 tonnes of 17 micron wool was washed to condition the water, then nine bales of extra super fine wool, worth over $300,000 was washed as a trial run. Toabo Agaki Japan was employed to process the scoured wool into suit cloth. Taobo required the scoured wool to contain 0.5% residual grease, 12% moisture and a yield of 83kg. These requirements were met. The entire staff of the Scour wanted to be part of washing the best wool in the world. Without asking for payment both the night shift and afternoon shift crews assisted the day shift in the task. The bale was fed into the scour in seven minutes and fitted into three bowls, half the scour. It completely disappeared into the dryer and the last wool was fed before the first wool was out. The clean wool was hand-packed into cardboard cartons and freighted to Japan. Aoki International, based in Yokohama Japan, cut three suit lengths from the cloth, then blended the remaining wool into an exclusive line of commercially-available suits. These suits are labelled Kadinia.Colour photograph showing three men standing around a bale of wool.michael crooks, auctioneer, wool industry, million dollar bale, geelong, auction, kadinia, appledore, keith jackson, sale room, geelong wool centre -

National Wool Museum

National Wool MuseumPhotograph - Armed Guards with Million Dollar Bale, 11 January 1995

This photograph shows armed guards and Wool Manager Keith Jackson posing with the million dollar wool bale after it was sold by auctioneer Michael Crooks on the 11th January, 1995 in Geelong. The wool was shorn from sheep of the Wyndarra and Rockbank bloodlines. A flock of 290 sheep were kept undercover at Kadinia, the property of the Appledore family from Brim in the Wimmera district of Victoria. Their record-breaking wool was produced by giving the sheep a special diet and providing each one with a UV-protective coat. Around 180 fleeces were selected for the million dollar bale. The sale of the first bale of wool measuring below 14 microns was held in the Auction Room here at the National Wool Museum. Bidding began at 40,000 (cents a kilogram) and steadily increased until there were only two bidders left. The bidders represented the Japanese firm Aoki International and Loro Piana of Italy. The hammer fell at 1,030,000 cents per kilogram, with Aoki International paying $1,194,800 for the 116kg bale. The fleece was scoured (cleaned) at the Goulburn Wool Scour, New South Wales. The degree of preparation and care taken with the task was extreme. The Scour closed production three days before and was extensively cleaned. On the day of scouring 12 tonnes of 17 micron wool was washed to condition the water, then nine bales of extra super fine wool, worth over $300,000 was washed as a trial run. Toabo Agaki Japan was employed to process the scoured wool into suit cloth. Taobo required the scoured wool to contain 0.5% residual grease, 12% moisture and a yield of 83kg. These requirements were met. The entire staff of the Scour wanted to be part of washing the best wool in the world. Without asking for payment both the night shift and afternoon shift crews assisted the day shift in the task. The bale was fed into the scour in seven minutes and fitted into three bowls, half the scour. It completely disappeared into the dryer and the last wool was fed before the first wool was out. The clean wool was hand-packed into cardboard cartons and freighted to Japan. Aoki International, based in Yokohama Japan, cut three suit lengths from the cloth, then blended the remaining wool into an exclusive line of commercially-available suits. These suits are labelled Kadinia.Colour photograph showing three men with a bale of wool in front of an armaguard truck. Two of the men are armed guards standing either side of the wool bale, one is holding a shotgun. Another man in a suit and tie is crouching near the bale.gavel, michael crooks, auctioneer, wool industry, million dollar bale, geelong, auction, kadinia, appledore, keith jackson, armed guards, armaguard -

National Wool Museum

National Wool MuseumPhotograph - Sale Room, National Wool Centre, Geelong, 11 January 1995

This photograph shows bidding underway for the million dollar bale in the Sale Room on the 11th January, 1995 at the National Wool Centre, Geelong. People depicted include Sale Team Baxter Murray, Auctioneer Michael Crooks and Wool Manager Keith Jackson. The wool was shorn from sheep of the Wyndarra and Rockbank bloodlines. A flock of 290 sheep were kept undercover at Kadinia, the property of the Appledore family from Brim in the Wimmera district of Victoria. Their record-breaking wool was produced by giving the sheep a special diet and providing each one with a UV-protective coat. Around 180 fleeces were selected for the million dollar bale. The sale of the first bale of wool measuring below 14 microns was held in the Auction Room here at the National Wool Museum. Bidding began at 40,000 (cents a kilogram) and steadily increased until there were only two bidders left. The bidders represented the Japanese firm Aoki International and Loro Piana of Italy. The hammer fell at 1,030,000 cents per kilogram, with Aoki International paying $1,194,800 for the 116kg bale. The fleece was scoured (cleaned) at the Goulburn Wool Scour, New South Wales. The degree of preparation and care taken with the task was extreme. The Scour closed production three days before and was extensively cleaned. On the day of scouring 12 tonnes of 17 micron wool was washed to condition the water, then nine bales of extra super fine wool, worth over $300,000 was washed as a trial run. Toabo Agaki Japan was employed to process the scoured wool into suit cloth. Taobo required the scoured wool to contain 0.5% residual grease, 12% moisture and a yield of 83kg. These requirements were met. The entire staff of the Scour wanted to be part of washing the best wool in the world. Without asking for payment both the night shift and afternoon shift crews assisted the day shift in the task. The bale was fed into the scour in seven minutes and fitted into three bowls, half the scour. It completely disappeared into the dryer and the last wool was fed before the first wool was out. The clean wool was hand-packed into cardboard cartons and freighted to Japan. Aoki International, based in Yokohama Japan, cut three suit lengths from the cloth, then blended the remaining wool into an exclusive line of commercially-available suits. These suits are labelled Kadinia.Colour photograph showing an interior view of people seated at rows of tables with an auctioneers stand at front of the room.michael crooks, auctioneer, wool industry, million dollar bale, geelong, auction, kadinia, appledore, keith jackson, sale room -

National Wool Museum

National Wool MuseumPhotograph - Million Dollar Bale, National Wool Centre, Geelong, Gordon Robertson, 11 January 1995

This photograph shows Growers Ian Appledore, Kaye Appledore and Murray Appledore, Wool Manager Keith Jackson, Wool Classer Phillip Gibson, Geoff Allibon and Brendan Dart posing with the million dollar bale after it was sold on 11th January 1995 in Geelong. The wool was shorn from sheep of the Wyndarra and Rockbank bloodlines. A flock of 290 sheep were kept undercover at Kadinia, the property of the Appledore family from Brim in the Wimmera district of Victoria. Their record-breaking wool was produced by giving the sheep a special diet and providing each one with a UV-protective coat. Around 180 fleeces were selected for the million dollar bale. The sale of the first bale of wool measuring below 14 microns was held in the Auction Room here at the National Wool Museum. Bidding began at 40,000 (cents a kilogram) and steadily increased until there were only two bidders left. The bidders represented the Japanese firm Aoki International and Loro Piana of Italy. The hammer fell at 1,030,000 cents per kilogram, with Aoki International paying $1,194,800 for the 116kg bale. The fleece was scoured (cleaned) at the Goulburn Wool Scour, New South Wales. The degree of preparation and care taken with the task was extreme. The Scour closed production three days before and was extensively cleaned. On the day of scouring 12 tonnes of 17 micron wool was washed to condition the water, then nine bales of extra super fine wool, worth over $300,000 was washed as a trial run. Toabo Agaki Japan was employed to process the scoured wool into suit cloth. Taobo required the scoured wool to contain 0.5% residual grease, 12% moisture and a yield of 83kg. These requirements were met. The entire staff of the Scour wanted to be part of washing the best wool in the world. Without asking for payment both the night shift and afternoon shift crews assisted the day shift in the task. The bale was fed into the scour in seven minutes and fitted into three bowls, half the scour. It completely disappeared into the dryer and the last wool was fed before the first wool was out. The clean wool was hand-packed into cardboard cartons and freighted to Japan. Aoki International, based in Yokohama Japan, cut three suit lengths from the cloth, then blended the remaining wool into an exclusive line of commercially-available suits. These suits are labelled Kadinia.Colour photograph showing three six men and one woman standing around a bale of wool.michael crooks, auctioneer, wool industry, million dollar bale, geelong, auction, kadinia, appledore, keith jackson, sale room, geelong wool centre