Showing 151 items

matching cast steel

-

Ballarat Tramway Museum

Ballarat Tramway MuseumFunctional Object - Ticket punch

... Steel cast, chrome plated, machined, device used to cancel..." punched on handles near pin, both sides. Steel cast, chrome plated ...Demonstrates aspects of tramway operation, cancelling or showing that tickets had been inspected following sales to passengers by the conductor or motorman. Traditionally used by tramway operators to check or cancel tickets.Steel cast, chrome plated, machined, device used to cancel or punch paper tickets when purchased. Punch of the type that placed a hole that appears to be two joined rectangles in the ticket. Spring loaded, consists of two main parts with a pin & spring. Chrome plated wearing off. - see image. Assumed used in Ballarat.Has number "31" punched on handles near pin, both sides.trams, tramways, ticket punch, tickets, fares -

Puffing Billy Railway

Puffing Billy RailwayZeehan & North East Dundas Tramway Bogie 1896, wagon bogie, 1896

... trucks and cars have cast-steel wheels 21 inches in diameter... for mails and parcels. All trucks and cars have cast-steel wheels ...Zeehan & North East Dundas Tramway Bogie 1896 The North East Dundas Tramway (NEDT) was a 2 ft (610 mm) narrow gauge tramway on West Coast Tasmania that ran between Zeehan and Deep Lead (now Williamsford). It was part of Tasmanian Government Railways. The line was opened in 1896 to carry ore from the Williamsford mines to Zeehan where it would be loaded onto another train for shipment to Burnie. The narrow-gauge (2 ft) was chosen because of the extremely difficult terrain that the railway crossed, requiring several big trestle bridges, including one at the foot of Montezuma Falls. After some rain the engine and carriages would get soaked by spray from the falls. There was a break-of-gauge with the mainline 1,067 mm (3 ft 6 in) system at Zeehan. The railway was closed in 1932. The rolling stock for the Tramway was built in the Launceston Railway workshops, and comprised twenty five eight-wheel low-side trucks, tare 3 tons 1 cwt. 1 qr., load 10 tons; six eight-wheel flat trucks, tare 2 tons 18 cwt. 1 qr., load 10 tons; two four-wheel bolster trucks, for carrying long timber, tare 1 ton 19 cwt., load 5 tons; and four passenger cars, each with six cross-seats with reversible backs, to carry eighteen passengers, also a locker for mails and parcels. All trucks and cars have cast-steel wheels 21 inches in diameter and are fitted with automatic vacuum brakes. The trucks have side levers and the cars have hand-screw brakes. The vacuum brake can be worked from the engine or from the passenger cars, which act as brake vans. When this brake was introduced, one effect was to accelerate the journey speed by about 10 minutes owing to more even running on down gradients. Historic - Industrial Narrow Gauge railway - Bogie used on the Zeehan & North East Dundas Tramway, Tasmania, Australia Bogie made from steel, iron and wrought ironZN & NTDS ML TRAM 1896 Griffinpuffing billy, bogie, zeehan & north east dundas tramway bogie, zeehan & north east dundas tramway, industrial narrow gauge railway, gauge: 2' (610 mm) -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietySquare Headed Wrench

... Cast iron or steel - 1 and three sixteenth of an inch... measurement on the handle Cast iron or steel - 1 and three sixteenth ...Used to tighten fasteners. This wrench is large so may have been used for fasteners on farm machinery or in the SECV workshop.Used by residents and workers in the Kiewa Valley.Cast iron or steel - 1 and three sixteenth of an inch embossed on one side and 8 and a quarter inches long on the other. This wrench has a square hollow (box ring) at one end which is used ro provide grip and mechanical advantage in applying torque to turn objects - usually rotary fasteners, such as nuts and bolts - or keep them from turning.embossed measurement on the handlewrench, tool -

Geelong Naval and Maritime Museum

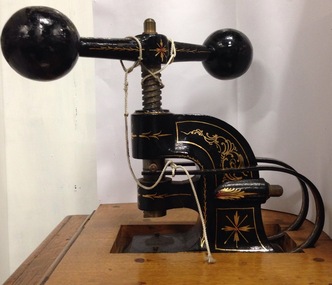

Geelong Naval and Maritime MuseumCommon Seal, Geelong Harbor Trust Commissioner's Seal, c.1909

... the Geelong Harbor Trust. Object is made of cast iron, brass... is made of cast iron, brass and steel with a large winding handle ...The Geelong Harbour Trust (GHT) was formed in 1905. This seal was used by the Trust Commissioner from 1909-1981 for impressing official documents. It's use was strictly controlled and dictated by the Regulations as contained in the Geelong Harbor Trust Annual Report from 1909. "The common seal of the Commissioner shall be kept under lock and key. Two locks shall be kept by the Chairman of Commissioners and the other of which the Secretary shall have a key. A duplicate key of each lock shall be lodged at such Bank as the Commissioner may direct. The common seal shall be used only by order of the Commissioners" (Regulations, Geelong Harbor Trust, Annual Report 1909). Captain George A. Molland was appointed Harbor Master of the Port (1900-1905) and then Harbor Master of the GHT from 1900-1936 when he retired, aged 88 years. He was replaced by Captain H. Saunders (1936-1950) followed by Captain D.G. Hancox.The seal is significant for its connections to physical changes made to the Geelong waterfront by the Harbor Trust from 1905. The Official Seal was a highly regarded formal object that was used for nearly 80 years by the Trust. The object is significant for its historic connections to the Harbor Masters and Commissioners who used it as part of official communication from the Trust.A seal used for impressing official stationary from the Geelong Harbor Trust. Object is made of cast iron, brass and steel with a large winding handle, screwed to a wooden board and painted black. Gold decorative paint is on the main body and a small portion of the winding handle."F.J. King/ Maker Melbourne"geelong harbor trust, commissioners seal, official seal, geelong maritime museum, captain h. saunders, captain d.g. hancox, captain george molland -

Wodonga & District Historical Society Inc

Wodonga & District Historical Society IncFunctional object - Bolex Paillard M 8 Projector, Bolex Paillard, 1949

... A small projector and carrying case. It is made of cast... of cast aluminum and steel, painted with a Grey Silver finish ...The firm of Bolex Paillard Ltd is world-famous for its accomplishments in the field of amateur cinematography. Paillard Bolex cine cameras and projectors are designed and manufactured in Sainte-Croix, Switzerland, which was also the centre of the Swiss watchmaking industry. Originally Bol, the company was founded by Charles Haccius and Jacques Bogopolsky in 1925. The M8 line of projectors were first manufactured in 1949. Its relatively light weight, affordability and portability made this model popular with home movie and amateur film makers.This projector is representative of several types of home projectors popular in the second half of the 20th Century.A small projector and carrying case. It is made of cast aluminum and steel, painted with a Grey Silver finish. The upper reel arm folds downward and locks for storage and also serves as a carrying handle. The lens assembly pivots outward for easy film loading and unloading. The front legs can be adjusted individually for height. An AC outlet is position at the rear of the projector. The carrying case includes slots to hold film reels and the power cord.On one side: " Bolex Paillard/ Fabrication Suisse/ Made in Switzerland" M 8bolex paillard, cimematography, home entertainment -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Firedogs

... made of metal, cast iron or steel, but are sometimes ceramic... made of metal, cast iron or steel, but are sometimes ceramic ...Firedogs is the common name for andirons and Chenets and have been in use since ancient Greek times. Firedogs are the decorative metal supports or stands that hold logs in a fireplace, allowing air to circulate around the fire to keep it burning, and preventing logs from rolling out of the fireplace. They are usually made of metal, cast iron or steel, but are sometimes ceramic. They have two feet joined across the front and one at the back. Some firedogs, mainly for kitchen use, were plain with forked uprights so that a bar could rest between them on which a cooking pot or a roasting spit could hang. Some firedogs are made in the likeness of animals, shields, crosses, figures and keys. This pair of firedogs are representative of the firedogs that were common to domestic use in previous centuries when home heating and cooking were only possible with open fires. Firedogs or andirons, pair of two decorative cast iron log supports for use in a fireplace hearth. flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, fire dogs, firedogs, fire grates, log stands, domestic furniture, open fireplace equipment, andirons, chenets, domestic heating -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Wood moulding Plane, Auburn Tool Company, 1870 to 1893

... wrought iron and cast steel. The Auburn Tool Company was among... wrought iron and cast steel. The Auburn Tool Company was among ...Moulding Plane: A moulding plane is a specialised plane used for making the complex shapes found in wooden mouldings that are used to decorate furniture or other wooden object. Traditionally, moulding planes were blocks of wear resistant hardwood, often beech or maple, which were worked to the shape of the intended moulding. The blade, or iron was likewise formed to the intended moulding profile and secured in the body of the plane with a wooden wedge. A traditional cabinetmakers shop might have many, perhaps hundreds, of moulding planes for the full range of work to be performed. Large crown mouldings required planes of six or more inches in width, which demanded great strength to push and often had additional peg handles on the sides, allowing the craftsman's apprentice or other worker to pull the plane ahead of the master who guided it. Auburn Tool Company: The Auburn Tool Company is known to exist from 1864 to 1893. George Casey reorganized the firm of Casey, Clark and Company as a joint-stock company in 1864, under the company name of Auburn Tool Company. The 1865 New York State Census noted the firm as a manufacturer of the plane, plane irons, and skates. The production that year was listed as 30,000 pairs of skates and 35,000 planes along with 25,000 dozen plane irons. The plane irons carried the trademark "Thistle". Both skates and plane irons were made from welded wrought iron and cast steel. The Auburn Tool Company was among the five leading plane manufacturing firms existing in the mid to late 19th century USA. Others were: H. Chapin's Son; Greenfield Tool Company; and Sandusky Tool Company. Auburn Tool Company, with these others, was also a founding member of the Plane Makers Association, organized around 1858 to fix prices. Most of the companies tools were manufactured by prisoners and in 1866 the firm was outbid for prison labour by J M Easterly and Co. After losing the contract with the prison authority they constructed a new building and continued in the plane manufacturing business with private labour. The 1870 US Census reported the firm had 21 machines, driven by water power, employing 66 males, producing annual products valued at us$70, 000. After A. Howland and Company was dissolved in 1874, the Auburn Tool Company again resumed using contract labour at the State Prison until 1877. The Auburn Tool Company merged with the Ohio Tool Company of Columbus, Ohio, on Nov 14, 1893. Although plane manufacturing was continued at Auburn until after 1907, after this merger the firm went under the name of the Ohio Tool Company. A significant item from the mid to late 19th century that today is quite rare and sought after by collectors. It gives us a snapshot of how furniture was made predominately by hand and with tools that were themselves hand made shows the craftsmanship used to make such a unique item. It also gives an insight into how many manufacturing companies bid for the rights to use prison labour to make their products at this time in our history. Decorative wood Moulding, plane Round type Auburn New York. Owner A Neudt Size 14 flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Ballarat Tramway Museum

Ballarat Tramway MuseumFunctional Object - Ticket punch

... Brass cast body with steel pins and screws, chrome plated.... Trams tramways Ticket Punch Tickets Fares Brass cast body ...Demonstrates aspects of tramway operation, cancelling or showing that tickets had been inspected following sales to passengers by the conductor or motorman. Traditionally used by tramway operators to check or cancel tickets.Brass cast body with steel pins and screws, chrome plated, machined, device used to cancel or punch paper tickets when purchased or inspected. Placed a round hole in the ticket. Spring loaded, consists of two main parts with a pin, screws & spring in addition. . Chrome plate in good condition. The initials "ECV" have been cast in to the body of the main component. A relatively heavy unit compared to others, does not appear to have had a lot of use.trams, tramways, ticket punch, tickets, fares -

Ballarat Tramway Museum

Ballarat Tramway MuseumFunctional Object - Ticket punch, Bell Punch Ltd

... Steel cast, chrome plated, machined, device used to cancel... of the handle. Steel cast, chrome plated, machined, device used ...Demonstrates aspects of tramway operation, cancelling or showing that tickets had been inspected following sales to passengers by the conductor or motorman. Traditionally used by tramway operators to check or cancel tickets.Steel cast, chrome plated, machined, device used to cancel or punch paper tickets when purchased. Placed a four pointed star hole in the ticket. Spring loaded, consists of two main parts with a pin & spring in addition. Has a circular steel ring for a finger hold. Chrome plate started to wear off in some places. Has letter "D6" punched onto one arm and "Supplied by Bell Punch Ltd Uxbridge" just below the slit in the punch for the ticket.Has letter "D6" punched inside of handles near pin and letter "C: on inside of both handles and "X" near the outer edge of one the insides of the handle.trams, tramways, ticket punch, tickets, fares -

Flagstaff Hill Maritime Museum and Village

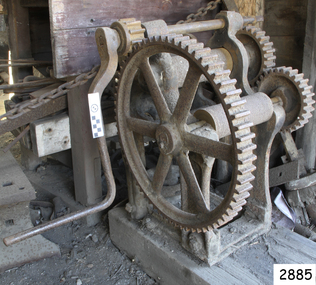

Flagstaff Hill Maritime Museum and VillageTyre Bender, 1884

... wheel steel rims. Made from cast iron and steel, double geared... BROS. PHILAP. PA” cast into the side of machine Steel tyre ...A tyre bender is used to bend and shape metal rims for wooden wagon wheels. This tyre bender’s model first appeared in the Day Bros catalogue in 1884 as the “Giant” model. The catalogue of 1883 only showed a lighter duty model called the “Lion”. It can be assumed that this later “Giant” model was a heavy duty improvement over the 1883 "Lion" and other smaller models which were still being advertised for sale in 1884. The Day Bros foundry, makers of this tyre bender, was operating as the manufacture of wheel right and blacksmith tools and general machinery in the 19th century in the USA and successfully exported their goods all over the world. Wagon tyre benders would have been very common circa 1850-1920, so there were probably many makers over the years. Early on, it would have become clear to the blacksmiths about which designs worked best so, eventually, the various makers would have made similar products to each other. This tyre bender was once used by Harry Goodall of H. Goodall & Sons Pty. Ltd. corner of McKinnon and High Streets, Terang. Victoria. Henry Goodall & Sons Henry Goodall (1870-1936) was proprietor of garages as H. Goodall & Sons Pty. Ltd., at both Terang (McKinnon and High Streets) and Mortlake (Dunlop Street). His business was in operation in at least in 1916 and perhaps well before, considering the date of the tyre bender and its use for wagons with wooden wheels. It was still in operation in 1953, chasing up debtors in Mount Gambier Court. Amongst the employees of H. Goodall & Sons Pty. Ltd. was Ernie Entwistle, a blacksmith (a soldier who died in 1916 ) and Alfred Hodgetts, radio expert (killed in a fatal accident in 1943, when he was in his early 30s ). Henry Goodall was involved in the community as a Justice of Peace, a deputy coroner, President of the Mortlake Hospital, trustee of the Soldiers’ Memorial Hall, and as a prominent Freemason. He and his wife had two sons (Charles and John) and one daughter (Mrs. Chas. Newton, of Skipton). The tyre bender is significant as it demonstrates how blacksmiths or wheelwrights could make new metal rims for wagon wheels for carts, wagons, stage coaches and carriages over a 135 years ago. The machine is a part of our social history as it demonstrates part of the process of making wagon wheels, which played an important part in aiding the continuation of daily transport needs that people had at the time, such as farming, personal transport and commercial activities. The machine or tool is locally significant as it was used by a local company in Terang and Mortlake in their blacksmith, wheelwright and garage business. Steel tyre bender mounted on timber base, used for wagon wheel steel rims. Made from cast iron and steel, double geared with four cogs to unite the upper and lower steel rollers. There are adjustable guide collars to keep the iron in line while it is being bent. It can also be used with two cranks for heavy duty work utilising the use to two operators. It is the Giant model, made in 1884 by Day Bros. of Philadelphia. This tyre bender once belonged to Harry Goodall & Sons, blacksmith's of Terang. Victoria. “DAY BROS. PHILAP. PA” cast into the side of machineflagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, machinery, wagon wheel, wheelwrights, blacksmith, steel rim wheels, tyre bender, tire bender, the giant tyre bender, henry goodall (1870-1936), terang, wheelwright tool, blacksmith trade, blacksmithing equipment and supplies, wagon tyre bender, day bros. philadelphia pennsylvania, h. goodall & sons of terang, terang blacksmith, h. goodall & sons pty ltd, mortlake, ernie entwistle blacksmith, alfred hodgetts radio expert, charles goodall, john goodall, mrs. chas. newton nee goodall -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Wood Mitre & Trimmer Guillotine, Early 20th century

... of cast iron with tempered steel guillotine blades. It is used..., and sturdily built of cast iron with tempered steel guillotine blades ...The mitre trimmer is a classic hand-powered tool for picture framers and trim carpenters that has remained relatively unchanged for decades. It is heavy, simple, and sturdily built of cast iron with tempered steel guillotine blades. It is used for taking super accurate, paper-thin slices off the ends of mitres and butt joints, and leaving behind a glassy-smooth surface. Also used in picture frame making or cabinet woodworking, by placing a piece of timber in one side after setting the desired angle and pulling a handle that operates a guillotine blade thereby cutting the timber or decorative trim to the required angle.A significant tool still in use today in many cabinet makers workshops. The subject tool gives insight into how this type of tool development, design and use has not progressed since it’s original invention. It is still for sale from many tool manufacturing companies and use in small craftsmen boutique workshops today as it was many decades ago.Cast Iron wood Trimmer bench like construction on raised feet with 2 adjustable gates. Noneflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, cabinet makers tools, picture framing, mitre cutting, wood trimming -

Bendigo Historical Society Inc.

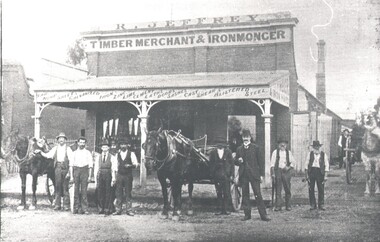

Bendigo Historical Society Inc.Photograph - HARRY BIGGS COLLECTION: R JEFFERY TIMBER MERCHANT & IRONMONGER

... , sashes, cast shear Blistered Steel. At the side of the verandah... iron, zinc, lime cement, laths, doors, sashes, cast shear ...Photograph. Harry Biggs Collection. 2 black & white photos (1 smaller) of 8 men with horses & drays standing in front of the R Jeffery Store. At the back of this group can be seen 3 people under the verandah. At the side is another man & also a horse & dray. On the verandah structure are the words - Bar, Hoop, sheets galvanised iron, zinc, lime cement, laths, doors, sashes, cast shear Blistered Steel. At the side of the verandah are the words Timber & Iron Yard. Plate 126 Premises of Jeffery Bros, Victoria Street, Eaglehawk. (Robinson Photo). 1 photocopy of these photos.Robinson Photoplace, building, commercial, harry biggs collection, r jeffery timber merchant & ironmonger, eaglehawk -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyIron - Kerosene

... This black iron is made of cast iron with a steel base... This black iron is made of cast iron with a steel base and a black ...Kerosene irons were used c1930 - 1950 especially where electricity wasn't available. Shelite was another fuel that could be used instead of kerosene. The advantage of the kerosene iron was that it didn't require a stove to be lit (especially in summer) to heat the iron and it didn't require electricity.Residents in the Kiewa Valley used kerosene irons.This black iron is made of cast iron with a steel base and a black wooden handle. This Comfort iron has a ball shaped container with a screw-on lid to hold the fuel (kerosene or Shelite). At the bottom of this ball is a pipe going down then meeting another pipe at right angles to it leading into the iron. At the pipe junction there is a handle on a screw to limit the amount of fuel. The Kerosene would flow through this pipe. There is a filler plug air stem on top. This is a self-heating iron.Comfort iron / Self Heating Comfort Iron MFD by / National Stamping and Electric Works / made in U.S.A. Chicago iron, domestic, laundry, pressing clothes, household, kerosene, shelite -

Puffing Billy Railway

Puffing Billy RailwayV. R. Krupp 1888. IV. Rail, 1888

... of high-quality cast steel, especially equipment for the railroads... of high-quality cast steel, especially equipment for the railroads ...60lbs rail that was used throughout the Victorian rail network. In 1887 Gibbs, Bright and Co. had a contract with Victorian Railways for railway and canal construction and supply of Krupp Rails. Gibbs, Bright and Co were merchant bankers and shipping agents and merchants who where also Directors of the GWR ( Great Western Railway ) and the Ship The "Great Britain" in England Gibbs, Bright and Company had principally been involved in shipping and trading, mainly in the West Indies, but following the discovery of gold in Victoria they established an office in Melbourne and soon became one of the leading shipping agents and merchants in the Colony. They expanded into passenger shipping and soon established offices in Brisbane, Sydney, Newcastle, Adelaide and Perth as well as launching passenger services between England, Mauritius and New Zealand. Gibbs, Bright also held a number of financial agencies from British mortgage, finance and investment companies as well as representing several British insurance companies in Australia. In addition they conducted a growing import business as well as an export business that included livestock, dairy produce, wool and flour. Also the company played a substantial part in the development of Australia's mineral resources, starting with lead in 1895, and later venturing into tin, gold, copper, cement and super phosphates. In Australia, after WWI, many of the larger companies were managing their own import and export so Gibbs, Bright and Company tended to focus its Agency business on smaller companies while expanding their interest into other markets such as timber, wire netting, zinc, stevedoring, road transport, marine salvage, gold mining as well as mechanical, structural, electrical and marine engineering. The Company's shipping interests continued to grow as well and still formed a major part of its business. In 1948 the parent company in England took the major step from tradition when they changed the business from a partnership into a private limited company. The name was the same, Antony Gibbs and Sons Limited, and in practice the effect of the change was very little. Some of the firm's branches and departments had already become limited companies and the formation of a parent company simplified the structure. The Australian operation was in time changed to Gibbs Bright & Co Pty Ltd in 1963. In 1848 Alfred Krupp becomes the sole proprietor of the company which from 1850 experiences its first major growth surge. In 1849 his equally talented brother Hermann (1814 - 1879) takes over the hardware factory Metallwarenfabrik in Berndorf near Vienna, which Krupp had established together with Alexander Schöller six years earlier. The factory manufactures cutlery in a rolling process developed by the brothers. Krupp's main products are machinery and machine components made of high-quality cast steel, especially equipment for the railroads, most notably the seamless wheel tire, and from 1859 to an increased extent artillery. To secure raw materials and feedstock for his production, Krupp acquires ore deposits, coal mines and iron works. On Alfred Krupp's death in 1887 the company employs 20,200 people. His great business success is based on the quality of the products, systematic measures to secure sales, the use of new cost-effective steel-making techniques, good organization within the company, and the cultivation of a loyal and highly qualified workforce among other things through an extensive company welfare system. From 1878 August Thyssen starts to get involved in processing the products manufactured by Thyssen & Co., including the fabrication of pipes for gas lines. In 1882 he starts rolling sheet at Styrum, for which two years later he sets up a galvanizing shop. The foundation stone for Maschinenfabrik Thyssen & Co. is laid in 1883 with the purchase of a neighboring mechanical engineering company. In 1891 August Thyssen takes the first step toward creating a vertical company at the Gewerkschaft Deutscher Kaiser coal mine in [Duisburg-]Hamborn, which he expands to an integrated iron and steelmaking plant on the River Rhine. Just before the First World War he starts to expand his group internationally (Netherlands, UK, France, Russia, Mediterranean region, Argentina). info from The company thyssenkrupp - History https://www.thyssenkrupp.com/en/company/history/the-founding-families/alfred-krupp.htmlHistoric - Victorian Railways - Track Rail - made by Krupp in 1888Section of VR Krupp 1888 Rail mounted on a piece of varnished wood. Rail made of ironpuffing billy, krupp, rail, victorian railways -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Tools, steel 'G' Clamp, early 20thC

... of steel or cast iron, though smaller clamps may be made of pot... of steel or cast iron, though smaller clamps may be made of pot ...A C-clamp or G- clamp is a type of clamp device typically used to hold a wood or metal work-piece, and often used in, but are not limited to, carpentry and welding. These clamps are called "C" clamps because of their C shaped frame, but are otherwise often called G-clamps or G-cramps because including the screw part they are shaped like an uppercase letter G. The fixed end is not adjustable so size is not variable. G-clamps are typically made of steel or cast iron, though smaller clamps may be made of pot metal. At the top of the "G" is usually a small flat edge. At the bottom is a threaded hole through which a large threaded screw protrudes. One end of this screw contains a flat edge of similar size to the one at the top of the frame, and the other end usually a small metal bar, perpendicular to the screw itself, which is used to gain leverage when tightening the clamp. When the clamp is completely closed, the flat end of the screw is in contact with the flat end on the frame When used some other object or objects will be contained between the top and bottom flat edges. A steel 'G' Clamp tools, g clamp, screws, steel, clamps, metalwork, woodwork, carpentry, early settlers, pioneers, market gardeners, moorabin, bentleigh, cheltenham -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Tools, steel 'C' or 'G' clamp, c1900

... and welding. C-clamps or G-clamps are typically made of steel or cast... are typically made of steel or cast iron, though smaller clamps may ...A clamp is a fastening device to hold or secure objects tightly together to prevent movement or separation through the application of inward pressure. The tool is for temporary use for positioning components during construction and wood working. There are many types of clamps available for many different purposes. Some are temporary, as used to position components while fixing them together, others are intended to be permanent. A C-clamp or G-clamp is a type of clamp device typically used to hold a wood or metal work piece, and often used in carpentry and welding. C-clamps or G-clamps are typically made of steel or cast iron, though smaller clamps may be made of pot metal. At the top of the "C" is usually a small flat edge. At the bottom is a threaded hole through which a large threaded screw protrudes. One end of this screw contains a flat edge of similar size to the one at the top of the frame, and the other end usually a small metal bar, perpendicular to the screw itself, which is used to gain leverage when tightening the clamp. When the clamp is completely closed, the flat end of the screw is in contact with the flat end on the frame. When the clamp is actually used, it is very rare that this occurs. Generally some other object or objects will be contained between the top and bottom flat edges. A steel ‘C’ or ‘G’ Clamp used to hold a wood or metal work piece, used in carpentry and welding.L.W.BANKtools, woodwork, metalwork, welding, carpentry, pioneers, market gardeners, early settlers, bank w.l., moorabbin, cheltenham, bentleigh, ormond -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Plough, Syracuse Chilled Plow Co, 1876-1900

... having the share and mould-board of chilled semi steel or cast... having the share and mould-board of chilled semi steel or cast ...The Syracuse Chilled Plough Company was created in 1876 and specialised in the manufacture of agricultural ploughs. Harry Wiard invented the chilling process in plough manufacture. The company was originally founded as the Robinson Chilled Plough Company in 1876 and changed its name 3 years later. At its peak, in the early 20th century. The company made more than 100,000 horse-drawn ploughs and road scrapers of various designs that were sold from the Syracuse plant each year and exported around the world. The company slogan of the day was, “The sun never sets on a Syracuse plough." Eventually, other farming implements were added to the line. The company employed more than 300 people in its local plant, which covered a square block on the cities Near West Side. In 1910-11, Deere and Company began expanding its holdings, and with the success of the Syracuse Chilled Plough Company, Deere sought to acquire the company. The management of the Syracuse operation after John Deere took over remained in the hands of Wiard and Chase, and the manufacturing operations were left in Syracuse. The only change from previous Syracuse operations was the selling of the companies products through Deere retail outlets instead of directly to the trade. The factory in Syracuse continued to produce ploughs until 1955. The subject item in the Flagstaff collection is an early model Syracuse Chilled plough with a wooden beam frame it is very much lighter in weight and was adapted to work sandy or light loamy soil. This plough has a sloping landside, which tends to keep the clods and dirt from falling into the furrow, making the ploughman's work much more comfortable and easy. This design was made in eight sizes for both right and left-handed ploughing and became very popular in the far West and South of the USA. Note: The definition of a chill plough means : a plough having the share and mould-board of chilled semi steel or cast iron.The subject item is believed to be a very early plough given its wooden beam frame and was made before 1900 probably around 1880. This makes it a significant example of the types of plough that early settlers were using in Victoria. There would not be very many of this type of vintage plough left with a wooden beam and frame, making it today a desirable collector's item. Syracuse Wood Beam Chilled single furrow plough metal wheel in front. Syracuse Chiller Co Syracuse & 50 L stamped on ploughshare.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, plough, syracuse chiller co, chiller plourh, farm equipment, furrow -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Bench Saw Vice, Henry Disston & Sons, 1910 -1925

... by the early 20th century, cast the first crucible steel in the nation... by the early 20th century, cast the first crucible steel in the nation ...The subject item is a saw blade sharpening clamp that attaches to a bench allowing the operator to sharpen the teeth on a saw with a file while keeping the saw blade in an upright position. Henry Disston (1819–1878) began his career as an American saw maker in Philadelphia. He emigrated from England in 1833 and started making saws and squares in 1840. In 1850, he founded the company that would become the largest saw maker in the world the ”Keystone Saw Works” on the Delaware River. Some five years later, Disston built a furnace possibly the first melting plant for steel in America and began producing the first crucible saw steel ever made in the United States. While his competitors were buying good steel from Britain, he was making his own, to his specification, for his own needs. Disston subsequently constructed a special rolling mill exclusively for saw blades. Over the following decade, the Disston company continued to grow, even while dedicating itself to the Union Army's war effort. In 1865, when his son Hamilton Disston rejoined the business after serving in the Civil War, Disston changed the company's name to Henry Disston & Son. Henry Disston and his sons set the standards for American saw makers, both in terms of producing high-quality saws and developing innovative manufacturing techniques. Disston also started making files in 1865. In September 1872, Henry Disston and two other men dug a part of the foundation for what was to become the largest saw manufacturing facility in the world: Disston Saw Works. This was in the Tacony section of Philadelphia. Having previously moved his expanding business from near Second and Market Streets to Front and Laurel Streets, Disston sought to establish his business away from this cramped area. It took over 25 years to move the entire facility to Tacony. This Philadelphia neighborhood seems to have been the only company town in the United States established within an existing city. At its peak of operations, Disston Saw Works employed 8,000 people and the factory covered 300 acres. The company, known as Henry Disston and Sons, Inc by the early 20th century, cast the first crucible steel in the nation from an electric furnace in 1906. The firm's Armour plate building near Princeton Avenue and Milnor Street contributed tremendously to the World War II effort. But the company's innovation and industriousness would not last forever. In 1955, with mounting cash-flow problems and waning interest on the family's part to run the firm, Henry Disston and Sons were sold to the H.K. Porter Company of Pittsburgh. Porter's Disston Division was sold in 1978 and became the Henry Disston Division of Sandvik Saw of Sweden. This division was then sold in 1984 to R.A.F. Industries of Philadelphia and became known as Disston Precision Incorporated, a maker of specialized flat steel products. In 2013, R.A.F. Industries sold Disston Precision Inc. in a private sale. Although the company has ceased making Disston handsaws, the Disston brand name still exists in this firm. A significant American company that pioneered the making of high-quality steel and saws along with other tools and accessories. The subject item is significant as it was made at a time when the company was in its hay day. Adjustable Ball & Socket Saw Sharpening vice, cast iron, with clamp to attach to a workbench. Made by Henry Disston & Co. No 1 painted greyflagstaff hill, warrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, saw clamp, henry disston & sons, saw sharpening, tool accessories, wood saws -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Saw gauge, Henry Disston, 1890-1920

... , cast the first crucible steel in the nation from an electric..., cast the first crucible steel in the nation from an electric ...Disston Saw Works of Philadelphia was one of the better known and highly regarded manufacturers of handsaws in the United States. During the Machine Age, the company was known as Henry Disston & Sons, Inc. a supplier of industrial saw blades. History: The story of handsaws in the United States mirrors the technical and development of steel in Sheffield, England, which was the center of handsaw production during the 18th century and through most of the 19th century. England's political and economic lock-on steel making in the colonies held American saw makers at bay until well after the Revolutionary War. American steel producers were unable to compete until the US government introduced import tariffs to level the playing field in 1861. Henry Disston: Henry Disston (1819–1878) began his career as an American saw maker in Philadelphia. He had emigrated from England in 1833 and started making saws and squares in 1840. In 1850, he founded the company that would become the largest saw maker in the world, the Keystone Saw Works. Some five years later, Disston built a furnace—perhaps the first melting plant for steel in America and began producing the first crucible saw steel ever made in the United States. While his competitors were buying good steel from Britain, he was making his own, to his specification, for his own needs. Disston subsequently constructed a special rolling mill exclusively for saw blades. Over the following decade, the Disston company continued to grow, even while dedicating itself to the Union Army's war effort. In 1865, when his son Hamilton Disston rejoined the business after serving in the Civil War, Disston changed the company's name to Henry Disston & Son. Henry Disston and his sons began to set the standards for American saw makers, both in terms of producing high-quality saws and files in 1865 through his development of innovative manufacturing techniques. In September 1872, Henry Disston and two other men dug a part of the foundation for what was to become the largest saw manufacturing facility in the world: Disston Saw Works. This was in the Tacony section of Philadelphia. Having previously moved his expanding business from near Second and Market Streets to Front and Laurel Streets. It took over 25 years to move the entire facility to Tacony. Henry Disston was renowned for having one of the first industries that exhibited environmental responsibility, as well as a paternalistic view towards his employees. For example, he had thousands of homes built in Tacony for his workmen. Funds to purchase these homes were made available through a building and loan association set up by the Disston firm. His caring influence on the community was evident in everyday life. To meet employees' cultural needs, a hall and a library were built with Henry Disston agreeing to pay a fixed sum towards its maintenance. The Tacony Music Hall was erected in 1885, also with the assistance of Disston money. Henry Disston had fallen ill by 1877 and never truly recovered; he suffered a stroke and died the next year. This came only one and a half years after seeing his products receive the highest honors at the great Philadelphia Centennial Exposition of 1876. His vision of a working-class community and the completion of the transfer of his enormous saw plant was carried out by his wife and his sons. The company, by the early 20th century, cast the first crucible steel in the nation from an electric furnace in 1906. The firm's armor-plate building near Princeton Avenue and Milnor Street contributed tremendously to the World War II effort. But the company's innovation and industriousness would not last forever. In 1955, with mounting cash-flow problems and waning interest on the family's part to run the firm, Henry Disston and Sons were sold to the H.K. Porter Company of Pittsburgh. Porter's Disston Division was sold in 1978 and became the Henry Disston Division of Sandvik Saw of Sweden. This division was then sold in 1984 to R.A.F. Industries of Philadelphia and became known as Disston Precision Incorporated, a maker of specialized flat steel products. In 2013, R.A.F. Industries sold Disston Precision Inc. in a private sale. Although the company has ceased making Disston handsaws, the Disston brand name still exists in this firm. A tool used to set and sharpen cross cut saws used to fell trees for building construction made by a well known American maker whos firm pioneered the making of saws and their related items including files.combination cross cut saw raker and gauge/jointerDisston USA in the castingflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Orbost & District Historical Society

Orbost & District Historical Societymeat slicer, Early 20th century

This item was used in Dicken's Store. Originally the Pardew Brothers store in Nicholson Street, Orbost, Frank Dicken purchased the shop business. It was a bakery and general store and was known as F.B. Dicken and Son. In 1948 they bought the shop freehold . The store remains today converted into two separate shops. The meat slicer was purchased from Henry Berry and Company a large wholesale grocers and general merchant company, first established in Melbourne in 1859.The Dicken store is a prominent Orbost building. Frank and May Dicken moved to Orbost in 1936 where Frank became manager of Pardew Brothers store in Nicholson Street. In 1945, Frank purchased the business and in 1947, formed a partnership with his son, Selwyn. The store was then called F.B. Dicken and Son. The premises are still retained by the Dicken family although the shop business was sold in 1981. (ref. In Times Gone By - Deborah Hall)A heavy commercial meat slicer which sits on bench. Frame is painted red. The tray moves as the handle turns. The main structure is cast iron. It has a circular steel blade. The chrome output tray is detachable. The movable carriage has a cast aluminium tray with spikes to hold the meat and there is an adjustable clamp to secure the meat.INVICTA Model No 302 21 HENRY BERRY PTY LTD MELBfood-preparation dicken-store meat-slicer -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Leg Vice, Mid 19th Century

The blacksmith leg vise is also called the "solid box vise" and is one of the most important tools in the blacksmith's shop. It firmly holds hot iron while it is hammered, chiseled, or twisted. These are the only vises that are designed to take this kind of use day in and day out. A small 30-pound blacksmith's vise can survive pounding that would wreck a much heavier cast iron bench model. Three things make a blacksmith's vice special. One is that they are forgings, not cast iron or ductile iron. The second is the leg that provides support to the floor or from a sunken post. The last is the hinge, while not a perfect way to construct a vice the pin joint is durable and can take a considerable beating. If sheared it is easy to replace. These things all combine into a tool that can take decades of heavy use and abuse. Most in use is one to two hundred years old.Some of these vises were made by specialists such as Atwood of Stourbridge England, Steel City and Columbian in the U.S. and others were made in anvil manufacturing plants such as "Mousehole Forge" and "Peter Wright" in England and "Fisher-Norris" and others in North America. The design of these vises right down to the last chamfer seems to have been perfected in the 1600s and remained more or less the same until the 20th century. The bodies are forged wrought iron or mild steel and they have hard steel surfaces welded into the jaws. The jaws have little or very shallow serrations which are generally worn off.Around the turn of the 20th Century during the hey-day of the blacksmith shop in North America, these tools were considered so standard a commodity that they were sold without reference to the manufacturer. Very few were even marked with the maker's name. Size is best defined by weight as there is some variation in jaw size from manufacturer to manufacturer. They were sold by the pound and are still best judged by the pound.A vintage tool used in a Blacksmiths shop during the early 19th century to the beginning of the 20th century. Regarded as a significant into social history of the time.Leg Vice attached with screws to bench via a block of wood. Has large metal pole which practically reaches the floor. Also has a metal device to either tighten or slacken vice.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Butter Churn, Malleys Ltd, 1930-1950

This is a steel, bench-mounted, hand-operated (60 rpm) butter churn for making small amounts of butter from cream in the home. It was made by the Sydney firm of Malleys Ltd from the 1930s until the 1950s and came in 3 and 5 quart sizes. Malleys Ltd was established in about 1890 by Francis Malley (1863-1932). This firm was located in the Sydney suburb of Alexandria, in McEvoy Street. They manufactured items for use in the dairy industry, as well as for hardware related to building and plumbing. Many of the Malley dairy products were sold under the "Sunrise" name. Malley retired in 1912. In 1931 there were branches at Parramatta, Hurstville & North Sydney. Butter churns were machines used to produce butter by the violent agitation of separated cream. Depending on the design of the churn, the agitation would be variously achieved by a repetitive thrashing, centrifugal motion or internal paddles. Churns were typically constructed from wood, glass and cast-iron; with tin or steel commonly used for some fixtures. The subject item gives an insight into domestic life where butter was made in the home.Heavy red cast iron base, with a long handle, wooden grip, connected to a shaft along the base, thence, to a cog wheel, and gear, to a second shaft and paddle in a metal basin. Basin has lid, and hole in base with a screw cap to allow the draining of the butter milk. Designed to be placed on a bench, with the handle over the edge. Malleys is written in raised letters on the base, and on the handle, '60 rev. pr. min.'warrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, malleys, butter churn, domestic object, dairy machine -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageContainer - Medical container, Late 19th century or early 20th century

THE DISCOVERY OF STAINLESS STEEL Harry Brearley Since the dawn of man colonies have raced against each other to uncover new technologies, to be the first to stamp their names on a discovery, and although we’ve evolved over millions of years, the urge to be the first remains at the very core of our nature. This sense of passion and pride can lead some of the more unscrupulous humans to claim others discoveries as their own. Of course many breakthroughs are genuinely made in tandem, or are simultaneously occurring, but unless you can categorically prove that you were the pioneer of these incredible findings, then the other party involved will always dispute the fact. And so we come to stainless steel. The first point to note is that ‘inventor’ is a very ambiguous term. Is this the first person to think, to document, to patent, or to produce? The second point is that stainless steel wasn’t truly defined until 1911, so are we to cast aside those chromium-iron alloys that don’t quite meet the minimum requirement of 10.5% chromium? It seems like anyone and everyone has a different claim to being labelled the ‘inventor’ of stainless steel; from Britain, Germany, France, Poland, the U.S.A., and even Sweden. The cogs were set in motion by Englishmen Stoddart and Faraday circa 1820 and Frenchman Pierre Berthier in 1821. These scientists, among others, noted that iron-chromium alloys were more resistant to attack by certain acids, but tests were only carried out on low chromium content alloys. Attempts to produce higher chromium alloys failed primarily because of scientists not understanding the importance of low carbon content. In 1872 another pair of Englishmen, Woods and Clark, filed for patent of an acid and weather resistant iron alloy containing 30-35% chromium and 2% tungsten, effectively the first ever patent on what would now be considered a stainless steel. However, the real development came in 1875 when a Frenchman named Brustlein detailed the importance of low carbon content in successfully making stainless steel. Brustlein pointed out that in order to create an alloy with a high percentage of chromium, the carbon content must remain below around 0.15%. Thus ensued two decades of stagnation for the development of stainless steel, and while many scientists attempted to create a low carbon stainless steel, none succeeded. Hans Goldschmidt It wasn’t until 1895, when Hans Goldschmidt of Germany developed the aluminothermic reduction process for producing carbon-free chromium, that development of stainless steels became a reality. In 1904 French Scientist Leon Guillet undertook extensive research on many iron-chromium alloys. Guillet’s work included studies on the composition of what would now be known as 410, 420, 442, 446 and 440-C. In 1906 Guillet went on to analyse iron-nickel-chrome alloys, which would now be considered the basics of the 300 series. However, while noting the chemical composition of his alloys, Guillet failed to acknowledge the potential corrosion resistance of his materials. Albert Portevin In 1909 Englishman Giesen published an in-depth work regarding chromium-nickel steels, while the French national, Portevin, studied what is now regarded as 430 stainless steel. However, it wasn’t until 1911 that the importance of a minimum chromium content was discovered by Germans P. Monnartz and W. Borchers. Monnartz and Borchers discovered the correlation between chromium content and corrosion resistance, stating that there was a significant boost in corrosion resistance when at least 10.5% chromium was present. The pair also published detailed works on the effects of molybdenum on corrosion resistance. It is at this point we introduce Harry Brearley, born in Sheffield, England in 1871, he was appointed lead researcher at Brown Firth Laboratories in 1908. In 1912 Brearley was given a task by a small arms manufacturer who wished to prolong the life of their gun barrels which were eroding away too quickly. Brearley set out to create an erosion resistant steel, not a corrosion resistant one, and began experimenting with steel alloys containing chromium. During these experiments Brearley made several variations of his alloys, ranging from 6% to 15% chromium with differing levels of carbon. On the 13th August 1913 Brearley created a steel with 12.8% chromium and 0.24% carbon, argued to be the first ever stainless steel. The circumstances in which Brearley discovered stainless steel are covered in myth; some enchanted tales of Brearley recite him tossing his steel into the rubbish, only to notice later that the steel hadn’t rusted to the extent of its counterparts, much like Alexander Fleming’s experience 15 years later. Other more plausible, (but less attractive), accounts claim it was necessary for Brearley to etch his steels with nitric acid and examine them under a microscope in order to analyse their potential resistance to chemical attack. Brearley found that his new steel resisted these chemical attacks and proceeded to test the sample with other agents, including lemon juice and vinegar. Brearley was astounded to find that his alloys were still highly resistant, and immediately recognised the potential for his steel within the cutlery industry. The Half Moon Brearley struggled to win the support of his employers, instead choosing to produce his new steel at local cutler R. F. Mosley. He found difficulty producing knife blades in the new steel that did not rust or stain and turned to his old school friend, Ernest Stuart, Cutlery Manager at Mosley’s Portland Works, for help. Within 3 weeks, Stuart had perfected the hardening process for knives. Brearley had initially decided to name his invention ‘Rustless Steel’, but Stuart, dubbed it ‘Stainless Steel’ after testing the material in a vinegar solution, and the name stuck. And that’s how Harry Brearley discovered stainless steel…. well, not quite… During the 5 year period between 1908 and Brearley’s discovery in 1913 many other scientists and metallurgists have potential claims to Brearley’s title. In 1908 the Germans entered the fray, the Krupp Iron Works in Germany produced a chrome-nickel steel for the hull of the Germania yacht. The Half Moon, as the yacht is now known, has a rich history and currently lies on the seabed off the east coast of Florida. Whether the steel contains the minimum 10.5% chromium content remains inconclusive. Employees of the Krupp works, Eduard Maurer and Benno Strauss, also worked from 1912-1914 on developing austenitic steels using <1% carbon, <20% nickel and 15-40% chromium. Not happy with Europe hogging the glory, the USA got in on the act. Firstly, Elwood Haynes, after becoming disenchanted at his rusty razor, set out to create a corrosion resistant steel, which he supposedly succeeded in doing during 1911. Two other Americans, Becket and Dantsizen, worked on ferritic stainless steels, containing 14-16% chromium and 0.07-0.15% carbon, in the years 1911-1914. Elwood Haynes During 1912 Max Mauermann of Poland is rumoured to have created the first stainless steel, which he later presented to the public during the Adria exhibition in Vienna, 1913. Finally, a recently discovered article, which was published in a Swedish hunting and fishing magazine in 1913, discusses a steel used for gun barrels, (sound familiar?), which seems to resemble stainless steel. Although this is purely speculation, the Swedes have still made an audacious claim that they were in fact responsible for the first practical application for stainless steel. That concludes the shambolic discovery of stainless steel! Although there is much mystery and speculation behind the discovery of this wonderful material, there is no question that without the combined effort of all the above scientists and metallurgists, (and all the many more that were not mentioned), we would not have such a rich and versatile metal at our fingertips. https://bssa.org.uk/bssa_articles/the-discovery-of-stainless-steel/#:~:text=On%20the%2013th%20August%201913,the%20first%20ever%20stainless%20steel. This stainless steel container was donated to Flagstaff Hill Maritime Village by the family of Doctor William Roy Angus, Surgeon and Oculist. It is part of the “W.R. Angus Collection” that includes historical medical equipment, surgical instruments and material once belonging to Dr Edward Ryan and Dr Thomas Francis Ryan, (both of Nhill, Victoria) as well as Dr Angus’ own belongings. The Collection’s history spans the medical practices of the two Doctors Ryan, from 1885-1926 plus that of Dr Angus, up until 1969. ABOUT THE “W.R.ANGUS COLLECTION” Doctor William Roy Angus M.B., B.S., Adel., 1923, F.R.C.S. Edin.,1928 (also known as Dr Roy Angus) was born in Murrumbeena, Victoria in 1901 and lived until 1970. He qualified as a doctor in 1923 at University of Adelaide, was Resident Medical Officer at the Royal Adelaide Hospital in 1924 and for a period was house surgeon to Sir (then Mr.) Henry Simpson Newland. Dr Angus was briefly an Assistant to Dr Riddell of Kapunda, then commenced private practice at Curramulka, Yorke Peninsula, SA, where he was physician, surgeon and chemist. In 1926, he was appointed as new Medical Assistant to Dr Thomas Francis Ryan (T.F. Ryan, or Tom), in Nhill, Victoria, where his experiences included radiology and pharmacy. In 1927 he was Acting House Surgeon in Dr Tom Ryan’s absence. Dr Angus had become engaged to Gladys Forsyth and they decided he would take time to further his studies overseas in the UK in 1927. He studied at London University College Hospital and at Edinburgh Royal Infirmary and in 1928, was awarded FRCS (Fellow from the Royal College of Surgeons), Edinburgh. He worked his passage back to Australia as a Ship’s Surgeon on the on the Australian Commonwealth Line’s T.S.S. Largs Bay. Dr Angus married Gladys in 1929, in Ballarat. (They went on to have one son (Graham 1932, born in SA) and two daughters (Helen (died 12/07/1996) and Berenice (Berry), both born at Mira, Nhill ) Dr Angus was a ‘flying doctor’ for the A.I.M. (Australian Inland Ministry) Aerial Medical Service in 1928 . The organisation began in South Australia through the Presbyterian Church in that year, with its first station being in the remote town of Oodnadatta, where Dr Angus was stationed. He was locum tenens there on North-South Railway at 21 Mile Camp. He took up this ‘flying doctor’ position in response to a call from Dr John Flynn; the organisation was later known as the Flying Doctor Service, then the Royal Flying Doctor Service. A lot of his work during this time involved dental surgery also. Between 1928-1932 he was surgeon at the Curramulka Hospital, Yorke Peninsula, South Australia. In 1933 Dr Angus returned to Nhill where he’d previously worked as Medical Assistant and purchased a share of the Nelson Street practice and Mira hospital from Dr Les Middleton one of the Middleton Brothers, the current owners of what was once Dr Tom Ryan’s practice. Dr L Middleton was House Surgeon to the Nhill Hospital 1926-1933, when he resigned. [Dr Tom Ryan’s practice had originally belonged to his older brother Dr Edward Ryan, who came to Nhill in 1885. Dr Edward saw patients at his rooms, firstly in Victoria Street and in 1886 in Nelson Street, until 1901. The Nelson Street practice also had a 2 bed ward, called Mira Private Hospital ). Dr Edward Ryan was House Surgeon at the Nhill Hospital 1884-1902 . He also had occasions where he successfully performed veterinary surgery for the local farmers too. Dr Tom Ryan then purchased the practice from his brother in 1901. Both Dr Edward and Dr Tom Ryan work as surgeons included eye surgery. Dr Tom Ryan performed many of his operations in the Mira private hospital on his premises. He too was House Surgeon at the Nhill Hospital 1902-1926. Dr Tom Ryan had one of the only two pieces of radiology equipment in Victoria during his practicing years – The Royal Melbourne Hospital had the other one. Over the years Dr Tom Ryan gradually set up what was effectively a training school for country general-practitioner-surgeons. Each patient was carefully examined, including using the X-ray machine, and any surgery was discussed and planned with Dr Ryan’s assistants several days in advance. Dr Angus gained experience in using the X-ray machine there during his time as assistant to Dr Ryan. Dr Tom Ryan moved from Nhill in 1926. He became a Fellow of the Royal Australasian College of Surgeons in 1927, soon after its formation, a rare accolade for a doctor outside any of the major cities. He remained a bachelor and died suddenly on 7th Dec 1955, aged 91, at his home in Ararat. Scholarships and prizes are still awarded to medical students in the honour of Dr T.F. Ryan and his father, Dr Michael Ryan, and brother, John Patrick Ryan. ] When Dr Angus bought into the Nelson Street premises in Nhill he was also appointed as the Nhill Hospital’s Honorary House Surgeon 1933-1938. His practitioner’s plate from his Nhill surgery states “HOURS Daily, except Tuesdays, Fridays and Saturday afternoons, 9-10am, 2-4pm, 7-8pm. Sundays by appointment”. This plate is now mounted on the doorway to the Port Medical Office at Flagstaff Hill Maritime Village, Warrnambool. Dr Edward Ryan and Dr Tom Ryan had an extensive collection of historical medical equipment and materials spanning 1884-1926 and when Dr Angus took up practice in their old premises he obtained this collection, a large part of which is now on display at the Port Medical Office at Flagstaff Hill Maritime Village in Warrnambool. During his time in Nhill Dr Angus was involved in the merging of the Mira Hospital and Nhill Public Hospital into one public hospital and the property titles passed on to Nhill Hospital in 1939. In 1939 Dr Angus and his family moved to Warrnambool where he purchased “Birchwood,” the 1852 home and medical practice of Dr John Hunter Henderson, at 214 Koroit Street. (This property was sold in1965 to the State Government and is now the site of the Warrnambool Police Station. ). The Angus family was able to afford gardeners, cooks and maids; their home was a popular place for visiting dignitaries to stay whilst visiting Warrnambool. Dr Angus had his own silk worm farm at home in a Mulberry tree. His young daughter used his centrifuge for spinning the silk. Dr Angus was appointed on a part-time basis as Port Medical Officer (Health Officer) in Warrnambool and held this position until the 1940’s when the government no longer required the service of a Port Medical Officer in Warrnambool; he was thus Warrnambool’s last serving Port Medical Officer. (The duties of a Port Medical Officer were outlined by the Colonial Secretary on 21st June, 1839 under the terms of the Quarantine Act. Masters of immigrant ships arriving in port reported incidents of diseases, illness and death and the Port Medical Officer made a decision on whether the ship required Quarantine and for how long, in this way preventing contagious illness from spreading from new immigrants to the residents already in the colony.) Dr Angus was a member of the Australian Medical Association, for 35 years and surgeon at the Warrnambool Base Hospital 1939-1942, He served as a Surgeon Captain during WWII1942-45, in Ballarat, Victoria, and in Bonegilla, N.S.W., completing his service just before the end of the war due to suffering from a heart attack. During his convalescence he carved an intricate and ‘most artistic’ chess set from the material that dentures were made from. He then studied ophthalmology at the Royal Melbourne Eye and Ear Hospital and created cosmetically superior artificial eyes by pioneering using the intrascleral cartilage. Angus received accolades from the Ophthalmological Society of Australasia for this work. He returned to Warrnambool to commence practice as an ophthalmologist, pioneering in artificial eye improvements. He was Honorary Consultant Ophthalmologist to Warrnambool Base Hospital for 31 years. He made monthly visits to Portland as a visiting surgeon, to perform eye surgery. He represented the Victorian South-West subdivision of the Australian Medical Association as its secretary between 1949 and 1956 and as chairman from 1956 to 1958. In 1968 Dr Angus was elected member of Spain’s Barraquer Institute of Barcelona after his research work in Intrasclearal cartilage grafting, becoming one of the few Australian ophthalmologists to receive this honour, and in the following year presented his final paper on Living Intrasclearal Cartilage Implants at the Inaugural Meeting of the Australian College of Ophthalmologists in Melbourne In his personal life Dr Angus was a Presbyterian and treated Sunday as a Sabbath, a day of rest. He would visit 3 or 4 country patients on a Sunday, taking his children along ‘for the ride’ and to visit with him. Sunday evenings he would play the pianola and sing Scottish songs to his family. One of Dr Angus’ patients was Margaret MacKenzie, author of a book on local shipwrecks that she’d seen as an eye witness from the late 1880’s in Peterborough, Victoria. In the early 1950’s Dr Angus, painted a picture of a shipwreck for the cover jacket of Margaret’s book, Shipwrecks and More Shipwrecks. She was blind in later life and her daughter wrote the actual book for her. Dr Angus and his wife Gladys were very involved in Warrnambool’s society with a strong interest in civic affairs. Their interests included organisations such as Red Cross, Rostrum, Warrnambool and District Historical Society (founding members), Wine and Food Society, Steering Committee for Tertiary Education in Warrnambool, Local National Trust, Good Neighbour Council, Housing Commission Advisory Board, United Services Institute, Legion of Ex-Servicemen, Olympic Pool Committee, Food for Britain Organisation, Warrnambool Hospital, Anti-Cancer Council, Boys’ Club, Charitable Council, National Fitness Council and Air Raid Precautions Group. He was also a member of the Steam Preservation Society and derived much pleasure from a steam traction engine on his farm. He had an interest in people and the community He and his wife Gladys were both involved in the creation of Flagstaff Hill, including the layout of the gardens. After his death (28th March 1970) his family requested his practitioner’s plate, medical instruments and some personal belongings be displayed in the Port Medical Office surgery at Flagstaff Hill Maritime Village, and be called the “W. R. Angus Collection”. The W.R. Angus Collection is significant for still being located at the site it is connected with, Doctor Angus being the last Port Medical Officer in Warrnambool. The collection of medical instruments and other equipment is culturally significant, being an historical example of medicine from late 19th to mid-20th century. Dr Angus assisted Dr Tom Ryan, a pioneer in the use of X-rays and in ocular surgery. Medical box; rectangular stainless steel base and separate lid, from the W.R. Angus Collection.warrnambool, flagstaff hill maritime museum, great ocean road, dr w r angus, dr ryan, surgical instrument, t.s.s. largs bay, warrnambool base hospital, nhill base hospital, mira hospital, flying doctor, medical treatment, stainless steel medical container, medical container, stainless steel -

Bendigo Military Museum

Bendigo Military MuseumCeremonial object - SHIPS BELL, HMAS BENDIGO 1941, 1941

HMAS BENDIGO (J187) was an Australian made "Corvette" which served throughout WW2 until 'paid off' on 27 September 1946. The Bendigo Military Museum also holds the last ensign of HMAS BENDIGO, it has a large number of auto graphs. We also hold the wooden crest and Battle Honours Board, this is on loan for 5 years. Refer to Cat 4546 Ensign.1. This is a medium size ships bell. It is cast from Brass. It has a protrusion on the top with a hole in it, used for mounting. The words HMAS BENDIGO 1941 are engraved into the side and painted black. The exterior surface has a few pits, but has been polished numerous times. The interior surface is rough cast, with a large quantity of dints, where it has been struck by the clapper. 2. This is the clapper. There is a steel hook under which is a weight of steel. Under that is a ring. Suspended from the bottom ring is the rope handle. This is an excellent example of navy rope work. At the top of it is a metal ring. Under that is a white and red stylised crown. Under the 'headband' of the crown is a white rope handle with blue inserts. At the bottom is a large rope "Ball" with numerous rope threads of about 180mm length.ww2, ran, hmas bendigo -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyScales - Baby

These scales may have been used by the Maternal Infant Welfare Centre sister at Mt Beauty during regular check ups of babies to make sure that the babies were gaining weight and therefore healthy.During the 1950's, Mt Beauty's population was rapidly increasing due to the post war baby boom and because the work force was young having moved into the area because of the opportunity for work on the construction of the Kiewa Hydro Electric Scheme. Letter dated 2nd July 1994 thanking the CWA, Tawonga Branch for their donation of the baby scales that were used by the baby Health Centre.White cast metal rectangular base with rectangular box attached in centre. The box has a curved top and a round face at the front. The face is covered with clear glass protecting the black marks which measure pounds and ounces. The numbers face the outside of the circumference. A black metal pointer rotates from the centre. At the top of the box in the centre a metal rod protrudes with a rectangular steel base on top and 4 screws for the container to hold the baby. The rod is attached to a spring and moves up and down moving the pointer.Face of scales "Hughes" / Baby Weigher / No. 48B" "To weigh 20lb by 1 oz / British Made" "Salter" written above its logo Numbers are written facing outside.baby scales. maternal infant welfare centre. mt beauty. healthy babies. -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyCream Separator

Dairy farms used cream separators to separate the milk and the cream before using it themselves or selling it to the dairy companies, shops or directly to the public.This cream separator was used by P & R Creamer on their dairy farm in the Kiewa Valley.3 parts - top brass lid with hollow cylinder enclosed across its top and extending beyond its circumference. 2. Stainless Steel hollow cylinders that fit the base and the lid but has 2 long curved spouts extending out - one for the milk and one for the cream to come out 3. Black cast iron stand that houses the gear mechanisms that drive the separator cones. The gear speed reduction wheel is on one side. "Alfa-Laval MOB / 80 Gall Capacity per hr / 48 Rev of Crank per Minute / Alfa-Laval Separator / Co. Ltd / 299 Sussex St. / Sydney" - on bottom side of the machinedairy; cream separator; kiewa valley; creamer family -

Eltham District Historical Society Inc

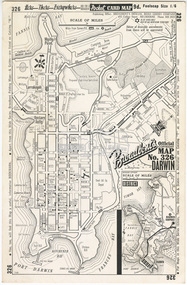

Eltham District Historical Society IncDocument - Folder, Survey Maps and Technical Drawings

alan gardiner collection, maps -

Waverley RSL Sub Branch

Waverley RSL Sub BranchMess kit

Probably of US origin Can , Meat (Mess Kit), M-1910, M-1918 The older style mess kits had the flat lid that could also be used as a plate. The M-1932 (not unit in our collection) unit had the plate divided into two sections so food could be separated. The folding handle, when closed, fits into the groove formed by the divider. The ring on the plate was moved to the end of the groove so the lip of the handle fits right into it. The M-1932 Meat Can was made of "corrosion resistant" galvanized steel, not aluminium. It used the same WW I style narrow profile steel handle attached by a cast hinge.Oval aluminium mess kit with steel handle which acts as a lid lock when folded. Cover has a mounted bracket for a ring fitting for attachment to belt.Nilmess kit, m-1918, m-1910 -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageBolt Cutter, 1878

Cyrus Chambers was a self-described mechanic who started out winding bobbins in his father's woollen mill and went on to invent machines that changed their industries. Cyrus Chambers came from Quaker parents the ninth of thirteen siblings, he once said a year before his death. “I believe I have succeeded because, first, I was industrious; second, because I made a study of the subject that was before me.” At age 7, Chambers went to work in his father’s mill. His job was to monitor bobbins—wooden spindles around which thread was wound and to remove and replace them as they became full. "There was no child labour law at that time," he later recalled. Chambers loved machinery and always regarded himself as a mechanic rather than an inventor. At age 16, Chambers was sent to learn dentistry with an older brother, (Edwin) who was already in the field and willing to take him on as an apprentice. Chambers was talented at working with small parts. He used his brother's dental instruments to build a miniature high-pressure steam engine of silver. It ran at 3,000 revolutions per minute and weighed less than a half-ounce. At that time it was the smallest engine that had ever been constructed. The engine was displayed at the 1876 Centennial and is now in a permanent collection at the Franklin Institute USA. Chambers major invention was the paper folding machine and came from reading that school teachers made less than the young girls who were employed to fold book pages as they came off the press. He told friends that his first efforts were to make the machine that would fold newspapers after demonstrating his device he met with Horace Greeley of the New York Tribune who advised Chambers would never invent the machine that would be able to fold his newspaper or books. In less than a year Chambers had built a full-size machine capable of folding large newspapers and books and was installed at J B Lippincott & Co folding pages for the "Comly Speller" this machine ran successfully for twenty-five years until the printing works burnt down. Chambers then went into partnership with a brother and they established the firm "Chambers, Brother & Co" at a plant in Philadelphia. It was also observed in 1910 and a fact that there was not a periodical or newspaper printed or recently published book that had not gone through one of Chambers inventions. Chambers went on to produce many mechanical inventions and improvements to existing tools and machinery most notable was his invention for the machine that would make clay bricks. This machine made forty bricks per hour and by the end of Chambers life after many improvements, it could make more than four hundred. Although there were a large number of bold cutters made of this patent at Cyrus Chamber’s foundry in Philadelphia, the item is associated with a notable American inventor of the nineteenth century. This particular patent for a bolt and rivet cutter won Chambers the prestigious Elliott Cresson Medal. This cutter is just one of the many inventions and mechanical improvements that Cyrus Chambers made during his lifetime, contributing to the ongoing development of mechanical improvements that were occurring in American industry of the time and therefore a notable addition to the Flagstaff collection.Cast iron bolt cutter with removable tempered steel cutter. Chambers New No. 2.Raised embossed lettering on cast body of cutter "New No 2" on one side, "Chambers Bros & Co" on the other sideflagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, cyrus chambers, bolt cutter, paper folding machine, brick making machine, elliot cresson, elliot cresson medal, franklin institute, gold medal, rivet cutter -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Cooking pot and lid, T & C Clarke and Co Ltd, 1880 to1910

T & C Clark & Company Limited, based at Shakespeare Foundry, was founded in 1795 by Thomas and Charles Clark and grew to be one of the largest iron foundries in Wolverhampton. The firm was the pioneers of Enamelled Cast ironware and the founder Charles Clerk went on to became mayor of Wolverhampton in 1860 after also serving as a Councilor, Alderman, and later Chief Magistrate. The company exhibited many products at the International Exhibition of 1862 at South Kensington, alongside the gardens of the Royal Horticultural Society. The company was also awarded the silver medal for its products at the International Paris Exhibition in 1878. The company's product range included thousands of items, both domestic and industrial. T & C Clark pioneered the use of enamelled cast ironware, after taking out a patent in 1839 guaranteed to be free of lead or arsenic. In the late 1940s and 1950s the company produced acid-resisting enamelled cast iron boiling pans; steam-jacketed pans; stills; square and rectangular tanks; open and closed mixing vessels; flanged pipes; bends and tees; laboratory equipment; small scale plant; evaporating bowls; beakers; sulphonates; and glass-lined mild steel tanks for beer, mineral water, and food. The company is listed as enamelled chemical plant manufacturers in Kelly's 1962 Wolverhampton Directory, but within a few years, the company had ceased trading. The cooking pot is significant because it demonstrates one of the social norms founded by early settlers to this region. That close ties to "Mother England" and the "establishment" was still very strong. The social and family values from the British way of life was ingrained in colonial society until well past Australian Federation in July of 1900. It was not until the friendly "American soldier" invasion during World War II that the Empire mindset was slowly being eroded away. This change was the slowest in semi remote rural areas such as the Warrnambool district. Cast iron open fire cooking pot with lidCLARK & Co. PATENT", Below this a six star triangle with the letter "C" in the middleflagstaff hill museum, cooking appliance, camp fire pot, cast iron, t & c clark & co, drovers cooking pot