Showing 109 items

matching melter

-

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Administrative record - Central Red White and Blue Gold Mine Gold Book, 1919 - 1926

Off white soft cover book, black binding on spine. Front cover of book has been removed. Written on front of book " Central Red White and Blue Co'. Entries in gold book date from June 1919 to May 24, 1926. Affixed to inside of back cover: thirteen forms: 'Particulars of Gold Melted and Assayed on Account of Central Red White and Blue Co' .showing weight before melting, weight after melting, assay, standard, price and amount paid. Gold Book forms part of the Margaret Roberts Mining Collection. Entries include gold entries from the battery, tributors and cyanide. bendigo, margaret roberts, mccoll, gold, gold book, bullion, central red white and blue gold mining co. -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

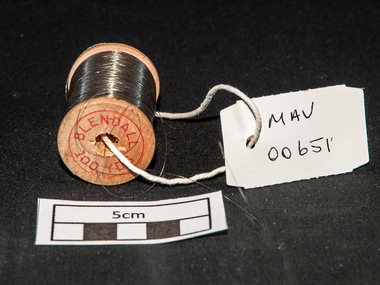

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Sewing Equipment, reel of nylon thread, c1950

Nylon is a thermoplastic, silky material, first used commercially in a nylon-bristled toothbrush (1938), followed more famously by women's stockings ("nylons"; 1940) after being introduced as a fabric at the 1939 New York World's Fair. Nylon was intended to be a synthetic replacement for silk and substituted for it in many different products after silk became scarce during World War II. It replaced silk in military applications such as parachutes and flak vests, and was used in many types of vehicle tyres. Nylon is clear and colourless, or milky, but is easily dyed. Multi-stranded nylon cord and rope is slippery and tends to unravel. The ends can be melted and fused with a heat source such as a flame or electrode to prevent this.A wooden reel of ' BLONDAL' Nylon sewing thread 100ydsBLONDAL 100ydsmoorabbin, brighton, early settlers, pioneers, cheltenham, dressmaking, craftwork, nylon thread, blondal pty ltd -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Administrative record - Birds Reef Co. Gold Book, 1910 - 1915

Patterned blue hard cover, black binding on spine. On cover on white sticker: 'Bird Reef Co. in a/c with Bank of Victoria'. Entries in gold book date from 5th April 1910 to 15th August 1915. Entries show gold purchased at bank, bullion, advanced upon, to company and to tributes. Affixed to inside back cover: 1. Bank of Victoria Limited statement of gold melted and assayed for Birds Reef Co. 15th September 1910 2. Bank of Victoria pay in slip for credit of Birds Reef Co., 19th June 1911. Gold Book forms part of the Margaret Roberts Mining Collection. Entries include gold entries from the battery, tributors and cyanide. bendigo, margaret roberts, mccoll, rankin and stanistreet, gold, birds reef co., gold book, bullion -

Flagstaff Hill Maritime Museum and Village

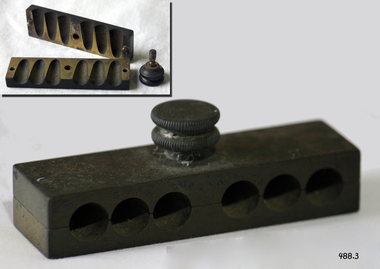

Flagstaff Hill Maritime Museum and VillageEquipment - Suppository Mould

Before factory production became commonplace in medicine, dispensing was considered an art and pill and suppository machines such as these were a vital component of any chemist’s collection. This mould dates back to the days when the local chemist or apothecary bought, sold, and manufactured all his own drugs and medicines to everybody who lived within the local community. In Victorian times, there was no such thing as off-the-shelf medicine. Every tablet, pill, suppository, ointment, potion, lotion, tincture and syrup to treat anything from a sore throat to fever, headaches or constipation, was made laboriously by hand, by the chemist. Some medicines are formulated to be used in the body cavities: the suppository (for the rectum), the pessary (for the vagina) and the bougie (for the urethra or nose). History Suppositories, pessaries and bougies have been prescribed for the last 2000 years but their popularity as a medicinal form increased from around 1840 - suppositories for constipation, haemorrhoids and later as an alternative method of drug administration, pessaries for vaginal infections and bougies for infections of the urethra, prostate, bladder or nose. Manufacture The basic method of manufacture was the same for each preparation, the shape differed. Suppositories were "bullet" or "torpedo" shaped, pessaries "bullet" shaped but larger and bougieslong and thin, tapering slightly. A base was required that would melt at body temperature. Various oils and fats have been utilised but, until the advent of modern manufactured waxes, the substances of choice were theobroma oil (cocoa butter) and a glycerin-gelatin mixture. The base was heated in a spouted pan over a water-bath until just melted. The medicament was rubbed into a little of the base (usually on a tile using a spatula) and then stirred into the rest. The melted mass was then poured into the relevant mould. Moulds were normally in two parts, made from stainless steel or brass (silver or electroplated to give a smooth surface). To facilitate removal the moulds were treated with a lubricant such as oil or soap solution. To overcome the difficulty of pouring into the long, thin bougie mould, it was usual to make a larger quantity of base, to partially unscrew the mould, fill with base and then screw the two halves of the mould together thus forcing out the excess. When cool, any excess base was scraped from the top of the mould, the mould opened and the preparations removed, packed and labelled with the doctor's instructions. https://www.rpharms.com/Portals/0/MuseumLearningResources/05%20Suppositories%20Pessaries%20and%20Bougies.pdf?ver=2020-02-06-154131-397The collection of medical instruments and other equipment in the Port Medical Office is culturally significant, being an historical example of medicine from late 19th to mid-20th century.Proctological mould for making suppositories.None.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, suppositories, medicine, health -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Suppository Mould

Before factory production became commonplace in medicine, dispensing was considered an art and pill and suppository machines such as these were a vital component of any chemist’s collection. This mould dates back to the days when the local chemist or apothecary bought, sold, and manufactured all his own drugs and medicines to everybody who lived within the local community. In Victorian times, there was no such thing as off-the-shelf medicine. Every tablet, pill, suppository, ointment, potion, lotion, tincture and syrup to treat anything from a sore throat to fever, headaches or constipation, was made laboriously by hand, by the chemist. Some medicines are formulated to be used in the body cavities: the suppository (for the rectum), the pessary (for the vagina) and the bougie (for the urethra or nose). History Suppositories, pessaries and bougies have been prescribed for the last 2000 years but their popularity as a medicinal form increased from around 1840 - suppositories for constipation, haemorrhoids and later as an alternative method of drug administration, pessaries for vaginal infections and bougies for infections of the urethra, prostate, bladder or nose. Manufacture The basic method of manufacture was the same for each preparation, the shape differed. Suppositories were "bullet" or "torpedo" shaped, pessaries "bullet" shaped but larger and bougieslong and thin, tapering slightly. A base was required that would melt at body temperature. Various oils and fats have been utilised but, until the advent of modern manufactured waxes, the substances of choice were theobroma oil (cocoa butter) and a glycerin-gelatin mixture. The base was heated in a spouted pan over a water-bath until just melted. The medicament was rubbed into a little of the base (usually on a tile using a spatula) and then stirred into the rest. The melted mass was then poured into the relevant mould. Moulds were normally in two parts, made from stainless steel or brass (silver or electroplated to give a smooth surface). To facilitate removal the moulds were treated with a lubricant such as oil or soap solution. To overcome the difficulty of pouring into the long, thin bougie mould, it was usual to make a larger quantity of base, to partially unscrew the mould, fill with base and then screw the two halves of the mould together thus forcing out the excess. When cool, any excess base was scraped from the top of the mould, the mould opened and the preparations removed, packed and labelled with the doctor's instructions. https://www.rpharms.com/Portals/0/MuseumLearningResources/05%20Suppositories%20Pessaries%20and%20Bougies.pdf?ver=2020-02-06-154131-397The collection of medical instruments and other equipment in the Port Medical Office is culturally significant, being an historical example of medicine from late 19th to mid-20th century.Proctological mould for making suppositories.None.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, suppositories, medicine, health -

The Ed Muirhead Physics Museum

The Ed Muirhead Physics MuseumMeldometer, Joly

Joly Meldometer The Joly meldometer was created to determine the melting point of minerals. W.E. Wilson, an astronomer and author, stated in 1900 that the Joly meldometer consisted of a ‘a strip of platinum on which minute fragments of any mineral can be placed, while any alteration in its length can be determined by means of a micrometer screw which touches a lever connected with one end of the strip. The strip can be heated by an electric current, and is calibrated by observing the micrometer readings corresponding to the temperatures at which some substances of known melting-points melt’i . One reason why the Joly meldometer was seen as a successful addition to science was the small amount of any substance that it required for testing. Only a minute sample was needed for the instrument to work and so a tiny part could be taken from a delicate item without destroying itii . The instrument was originally manufactured by the Irish company Yeates & Son of Dublin. The Yeates family business was established in the early 1790’s and is thought to have operated until approximately 1922iii . Their business slogan was recorded as ‘Instrument makers to the University’, a slogan which proudly exhibited their relationship with Trinity College, Dublin. The company was located directly opposite Trinity College, the place where the Joly meldometer was created. Working in such close proximity must have assisted this business relationship. The inventor of this meldometer was Irishman John Joly. Joly was born in 1857 at the Church of Ireland Rectory, Hollywood House. His education led him to Trinity College Dublin where, by 1891, he had obtained a Bachelor of Engineering degree as well as a Doctorate of Science. The entirety of his working life appears to have taken place at Trinity College although he is known to have travelled in order to consult with other scientists such as the world renowned Sir Ernest Rutherford. The Joly meldometer was used for a variety of different purposes, with scientists often adapting the instrument to suit their own needs. For instance, the previously mentioned astronomer W.E. Wilson adapted the meldometer to assist him in measuring the radiation of the suniv . Joly used his device in an attempt to ascertain the age of the earth. In 1913, along with Sir Rutherford, Joly came to the conclusion that the earth was approximately 400 million years old. They did this by analysing the decay of radioactivity in minerals. According to our present knowledge of the earth this was a much more accurate date than the dates Joly had previously derived. He had first thought that the earth was 97 million years old due to the volume of sodium in the oceans. Joly’s second analysis of the topic had resulted in the age of 80 million years. This figure was based on the accumulation of sediment. Apart from designing his meldometer, Joly is also remembered for his work with colour photography. In 1894 Joly discovered a method for creating colour photographs from a single platev . He also studied the use of radiation as a treatment for cancer and persuaded the Royal Dublin Society to establish the Radium Institute to assist hospitals. In 1933 Joly passed away at the age of seventy-six. Jacqueline Eager Student Projects Placement, Cultural Collections 2005 iMollan, Charles, Irish National Inventory of Scientific Instruments, Samton Limited, 1995, p. 302. iiJoly, John, 'On the determination of the melting points of minerals, Part 1. Uses of the meldometer', Proceedings of the Royal Irish Academy, Vol. 2., 1891. iiiInstitute for Learning Technologies, "Stephan Mitchell Yeates' http://www.ilt.columbia.edu/projects/bluetelephone/html/yeates.html, accessed on 04.10.2005 ivMollan, Charles, Irish National Inventory of Historic Scientific Instruments, op cit. vMollan, Charles, The Mind and the Hand: Instruments of Science 1685-1932, Samton Limited, Dublin, 1995, p. 34.The following from #2975 in UDE UNIVERSITY COLLEGE DUBLIN ENGINEERING list in the “Irish National Inventory of Historical Scientific Instruments” by Charles Mellon (P/C in file for Cat no 272. “....meldometer as an instrument ‘for the purpose of finding the melting-points of minerals, hence its name. As used by him (Joly), it consists of a strip of platinum,on which minute fragments of any mineral can be placed, while any alteration in its length can be determined by means of a micrometer screw which touches a lever connected with one end of the strip. The strip can be heated by an electric current, and is calibrated by observing the micrometer readings corresponding to the temperatures at which some substances of known melting-points melt’.” Ref. : J. Joly, Proc. Roy. Irish Acad. 3rd series vol 2 (1891),38-64. -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyPot Melting, circa mid to late 1900's

Before 1908 the words "melting pot" was a term relating to a "crucible" with a meaning of "a pot in which metals and other substances are melted (fused) to provide metal items of varying shapes and uses. From the mid 1900's this term changed and became more related to the "mixing" of social and ethnically diverse populations. The description used here is that of pre 1908. This melting pot was used in the early to late 1900's when produce and hardware shops were too far away from the Kiewa Valley and time was at the essence. The ability to manufacture as many "crucial " items at the home property was the difference between running a successful rural business or not. The isolation of the Kiewa Valley (before the 1950's), hindered the "time down" of machinery and important "widget" replacements. The ability of self sufficiency on properties is still a boon to rural properties as time lost is never really recovered.This melting pot is highly significant to the Kiewa Valley as it provides evidence that the graziers and cattle stations required to be self sufficient in all aspects of day to day maintenance and replenishment of worn materials requiring to be "manufactured " at the property and lack of replacements from commercially shelved products. This aspect of "survival" in the "bush" can be seen in the "huts" built on the Bogong High Plains to accommodate the seasonal grazing of cattle from the Kiewa Valley.This black melting pot is made of cast iron. The lid is missing. The top rim of the pot has three lips for poring accuracy. The formation of these lips are in a "triangle" formation. The top section of the body has a curve inwards reducing the pot diameter from 270mm at the base to 135mm.at the top. The handle is made from heavy gauge wire which is fastened to the body through two lugs (welded onto the top section of the pot) and fasten through a hole at the top of each lug. The handle has a "U" shape as it goes through the lug hole, ensuring no accidental fixture to any side thus allowing free swiveling from one side to the other . "BH" indented within a diamond shape. Opposite "No 3"camp fire cooking utensils, hot plate, cast iron cooking appliance, drovers kitchen -

Wodonga & District Historical Society Inc

Wodonga & District Historical Society IncPhotograph - Bradford Kendall, Wodonga

Bradford Kendall was established in 1922 by Lesley Bradford and Jim Kendall, investing their winnings on a race horse. They both previously worked at the BHP Steel Works. They gained contracts with the railways and mining industry. During World War II they also manufactured armaments. During the boom of the 1950s they established several foundries in South Australia, Western Australia, Queensland and Victoria. Bradford Kendall Ltd Wodonga foundry was established in 1954. It melted down old railway wheels, rails and redundant machinery to produce a range of low-alloy steel products, especially for earth-moving vehicles, railways, oil rigs and sugar factories. Wodonga was ideally placed as a change point between the different rail gauges of Victoria and New South Wales, close to the Hume Highway and the Snowy Mountain Scheme. The first sod for the site was turned on 2nd June 1954 and the first melt and pour of molten metal at Wodonga took place on 7th July 1954. Bradford Kendall Plant No.5 in Wodonga became one of the most profitable foundries in the Bradford Kendall group. Bill Black became the first plant Manager, a position he held for 30 years. Another long term employee was Pat Gooding who began work at a 15 year old and retired for the position of Bradken foundry Manufacturing Manager 51 years later. In the early 1980s, Australian National Industries Ltd bought Bradford Kendall and other heavy engineering companies. The Wodonga foundry with its (then) 170 or so staff became part of Bradken Consolidated along with nine other foundries in Australia and New Zealand. In 1989, Kerry Packer’s Consolidated Press Holdings Ltd took control of ANI. In January 1999, Smorgon Steel Group acquired ANI, which included the Bradken business. The company changed hands again in 2001 when Smorgon Steel Group sold Bradken to Castle Harlan Australian Mezzanine Partners (CHAMP). In 2016 negotiations began for Bradken to be taken over by Hitachi Construction for A$689 million. In April 2017 Bradken became a wholly owned subsidiary of Hitachi Construction Machinery Co. Limited.A collection of black and white images and advertising for Bradford Kendall (Bradken) Wodonga.bradford kendall, wodonga industries, wodonga businesses -

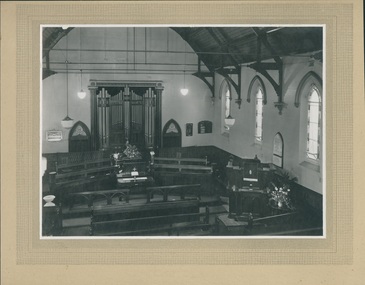

Uniting Church Archives - Synod of Victoria

Uniting Church Archives - Synod of VictoriaPhotograph, Undated c.1900

The Wesleyan Church, Denham Street in Lower Hawthorn, as the area was then called, was opened on 2 May 1886. The building was designed by Geelong architect William Henry Cleverdon and was built of brick in the Gothic style. Its dimensions were 55 x 33 ft and the façade incorporated a rose window and spire 50 ft high. A wooden vestry was placed to the rear. The building and the organ were seriously damaged by fire on 1 April 1970, started by a painter's blowtorch. The church was not rebuilt. The organ was built in 1900 by E. Cornwall Cook, of Barrington Place, Burwood Road, Hawthorn. It was opened on 8 August 1901 by George Peake. The Swell strings may have been added (or substituted for earlier material) by Frederick Taylor, whose workshop was nearby in Burwood Road. At some stage the colourfully decorated façade pipes were repainted in a gold finish. The organ was badly damaged in the 1970 fire and the metal pipes were sent to Hill, Norman & Beard who melted them down for scrap.B & W photograph of the interior of the Denham St. Methodist Church, Hawthorn. Mounted on card.denham street methodist church, organ, hall, e. cornwall cook, george peake, norman & bead, frederick taylor -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Grater

François Boullier of France and Isaac Hunt of England both took credit for inventing the cheese grater in the 1540s. Ingredient supplies, mainly milk, ebbed and flowed in both France and England, as they have in the United States during this coronavirus pandemic. Boullier originally aimed to use up an overabundance of cheese in Paris. An avoidance of meat led French farmers to convert their meat herds (often boys) to dairy-producers (girls), which led to more milk and even too much milk, which led to a market flooded with cheese. Boullier made his first cheese grater out of pewter to grate hard, sometimes dried out cheeses, which turned them into a sort of condiment. Pewter is known as a rather soft metal, and Boullier’s original grater is reportedly on display in a museum in Le Havre, France. Isaac Hunt wanted to stretch cheese due to a shortage in England, so he grated and melted it for Welsh rarebit and other dishes. Grating cheese allowed more even distribution of the cheese to melt it in cooking and still does. During the Great Depression of the 1930s, Philadelphia cheesemonger and entrepreneur Jeffrey Taylor also wanted to stretch cheese for to bulk up cheese features, including vegetables, to make them look like more filling food during difficult economic times. Taylor read about Boullier’s invention and made his own by sharpening the holes of a metal shower drain. For the last century, many companies have tried to improve the cheese grater and invent a new “latest” one that we all must-have. Graters are now made of all sorts of materials including bamboo, wood, and various metals. Some are decorated with clowns’ heads, some are shaped like plastic frogs, while others bear knuckle protectors. They vary in size, shape, and function. Grating slots come with different angles and shapes of slots and can grate everything from zucchini, onions and cheese, to cooked eggs, coconut, potatoes, cabbage, and lemon and orange peel, and possibly even create wood shavings. Smaller graters grate ginger and garlic. https://www.cheeseprofessor.com/blog/antique-cheese-gratersThe grater has been used for hundreds of years and has proved its worth in the kitchen throughout history.Grater metal (3 parts) Tripartite with hinges for folding.None.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, grater -

Bendigo Historical Society Inc.

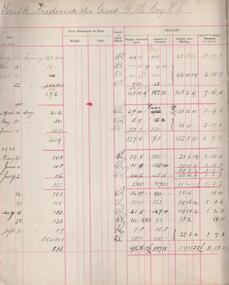

Bendigo Historical Society Inc.Administrative record - South Frederick the Great Gold Mining Company N.L. Gold Book, 1934 - 1917

Patterned hard cover, black binding on spine.Written across top of first page: South Frederick the Great GM Coy N.L. Inside pages a double spread recording the 'Gold Purchased by Bank; weight advanced upon, amount of advance, weight after melting, mint and bank charges, eq standard weight, value and balance of assay. Dates from August 1934 to December 193k7. Inserted in pages of gold book: a. receipts " Commercial Banking Company of Sydney (Bendigo) recording the particulars of gold melted and assayed on account of South Frederick the Great Co. N.L. and slips from Royal Mint, Melbourne Branch, showing out turn of deposits left for coinage. Weight before and after melting, assay reports of gold and assay report of silver and standard gold oz., total value assessed. b. Letter May 13th, 1935 from Herbert L. Archbold, enclosing cheque for 9/5/- for described weight: 11 tons, 18 cwt, 3 q. bendigo, margaret roberts, south frederick the great gold mining co. n.l., sebastian, mccoll, rankin and stanistreet -

Federation University Historical Collection

Federation University Historical CollectionPostcard - Postcard - black and white, La Colonne Vendome, Paris, c1911

Colonne Vendôme is located in the centre of the Place Vendome square and was erected by Napoleon as the Colonne d'Austerlitz. The column in 44 metres tall and is modeleld after Rome's Trajan Column. It was built to commemorate the victory at Austerlitz in 1805, one of Napoleon's greatest. The column's continuous ribbon of bas-relief bronze plates by the sculptor Pierre-Nolasque Bergeret were made from 1200 cannons taken from the combined armies of Russia and Austria during that battle. The reliefs depict scenes during the Napoleonic Wars between 1805 and 1807. The Column was later was given the names of Colonne de la Victoire (Victory Column) and Colonne de la Grande Armée (Column of the Great Army). Today it is commonly known as the Colonne Vendôme. A statue of Napoleon was installed at the top of the column in 1810. Later, the statue of the emperor was removed and the bronze melted down to provide the bronze for the recast of the equestrian statue of Henri IV on the Pont Neuf. A new statue was installed in 1833 which was later replaced by the statue that is seen today. It was erected by Napoleon III and depicts Napoleon I as a Roman emperor.Black and white postcard of a sculptural column in Paris. chatham-holmes family collection, sculpture, napoleon, paris, vendome, world war, world war 1, world war one, column -

The Beechworth Burke Museum

The Beechworth Burke MuseumGeological specimen - Greenstone / Gabbro, Unknown

This specimen was recovered from Ceres West of Geelong, Victoria. Greenstone is the name for any metamorphosed basic igneous rock (in the case of this specimen, Gabbro) that gains its greenish colour to the presence of the minerals chlorite, actinolite, or epidote, hence the term 'green' and 'stone'. Greenstone is often formed through metamorphsis along a convergent plate boundary. In the rock cycle (the series of processes that creates the various types of rocks) there are identified three different types of rocks, which are the sedimentary, the igneous and the metamorphic. Metamorphic rocks started out as sedimentary, igneous or earlier metamorphic rocks but changed from their original condition under the effect of high heat, high pressure or hot, mineral-rich fluid. However, if pressure or heat is too high, then the rock will melt, resulting in the formation of an igneous rock. The name used to describe these types of rocks reflects this specific inherent trait of change, since the word “metamorphic” derives from the Greek word “metamorphosis”, meaning “change of form or structure”. Metamorphic rocks form in the Earth`s crust but can be also found on the surface, due to elevation of the Earth`s surface. They are divided into two categories: the foliated metamorphic and the non-foliated metamorphic rocks. Gabbro is a highly useful mineral that is often polished to create cemetery markers and kitchen benches. It is notable for its qualities of durability, being able to withstand extreme elements and wear. Whilst not rare, Gabbro is of great utility and has been highly desirable for its qualities. This specimen is part of a larger collection of geological and mineral specimens collected from around Australia (and some parts of the world) and donated to the Burke Museum between 1868-1880. A large percentage of these specimens were collected in Victoria as part of the Geological Survey of Victoria that begun in 1852 (in response to the Gold Rush) to study and map the geology of Victoria. Collecting geological specimens was an important part of mapping and understanding the scientific makeup of the earth. Many of these specimens were sent to research and collecting organisations across Australia, including the Burke Museum, to educate and encourage further study.Greenstone is a solid hand-sized metamorphic mineral of a green colour. Greenstone is the name for any metamorphosed basic igneous rock (in the case of this specimen, Gabbro) that gains its greenish colour to the presence of the minerals chlorite, actinolite, or epidote, hence the term 'green' and 'stone'. Gabbro is a medium to coarse grained rocks that consist primarily of plagioclase feldspar and pyroxene. Greenstone is often formed through metamorphsis along a convergent plate boundary. Gabbro forms due to cooling and crystallization of magma underneath Earth's surface. Greenstone/Gabbro/from Ceres west/of Geelong. Has old Geological Survey label/and probably collected by/Richard Daintree in 1861/C.Willam 15/4/21/ Other label: 62 /greenstone, metamorphosed, igneous rock, gabbro, chlorite, actinolite, epidote, metamorphsis, rock cycle, various types of rocks, sedimentary, high heat, high pressure, mineral-rich fluid, metamorphosis, foliated metamorphic, non-foliated metamorphic, convergent plate boundary, greenish colour, minerals -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Slide - Dunn's Rock Eppalock, 2012

The low rolling hills of the Kimbolton countryside consist of ancient, hard and fractured Ordovician rock up to 65 million years old, which was originally deposited deep under the sea. Rocks mainly are sandstone, mudstone, black shale and quartz conglomerates. Marine fossils can be found in the area. Around seven million years ago a basalt flow buried the original bedrock along the along the Campaspe River. Ongoing weathering, wind and water movement over the following years has produced younger clay, sand, silt and gravel deposits throughout the area. Patches of White Hills Gravel are also found in the area. Another unique geological feature of this area is the Permian Glacial Pavement rocks north and south of Eppalock and glacial sediments (such as “Dunn’s Rock” and “Kellams Rock”). During the ice age (up to 280 million years ago) large glaciers moving over the countryside, scoured out sediments, pulverized bedrock, polished and cut grooves into bedrock in the direction of ice movement. When the ice melted boulders etc where left behind in areas of entirely different rock types, such as a 100 Tonne granite block known as ‘The Stranger’ near Derrinal. Dunn's Rock (Glaciated Pavement) Eppalock - Photos of the rock and a field group collecting date with Lake Eppalock (Knowsley) in the backgroundhistory, bendigo, dunn's rock eppalock, kimbolton forest, lake eppalock, gately collection -

Forests Commission Retired Personnel Association (FCRPA)

Forests Commission Retired Personnel Association (FCRPA)Uniform - Safety Boot (Yellow back), Oliver Stevens in Ballarat, circa 1982

These boots were manufactured by Oliver Stevens in Ballarat to the Forests Commission's own specification. Safety boots were a bit "hit and miss" back in 1981. As well as the steel toe caps these boots had a screwed, glued and stitched Sherpa-pattern rubber nitrile sole. The sole was oil resistant and didn't melt on hot coals. The yellow heels signified safety boots. There were two styles with different leather and staff were all personally fitted and given their choice of style. The only thing that has fundamentally changed over 40 years is there is much more choice and comfort in boots today. These boots proved to be the catalyst for boot manufacturers realising there was a market outside of the armed forces not being served. Ankle injuries along with elastic sided boots were virtually eliminated by these boots. The iconic Tasmanian company, Blundstone, had a work boot called "Forester" at the time. It had won an Australian Design Award and had a bonded Sherpa sole. Unfortunately, the soles tended to separate from the boot under field test conditions. Eventually they perfected the process Oliver Stevens' main issue was not being able to recruit enough workers to meet the increased demand. Info: Trevor Brown.First safety boots issued to Victorian forest firefightersYellow Back safety boots with leather laces. FCV marked on the heel fire fighting, bushfire, forests commission victoria (fcv), protective clothing -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Bottle, c. 1850's - 1900's

Glass bottles and glass jars are in many households around the world. The first glass bottles were produced in south-east Asia around 100 B.C. and the Roman Empire around 1 AD. America's glass bottle and glass jar industry were born in the early 1600s when settlers in Jamestown built the first glass-melting furnace. The invention of the automatic glass bottle blowing machine in 1880 industrialized the process of making bottles. In 2019, plans were made to re-introduce milk glass bottle deliveries to Auckland in early 2020 The earliest bottles or vessels were made by ancient man. Ingredients were melted to make glass and then clay forms were dipped into the molten liquid. When the glass cooled off, the clay was chipped out of the inside leaving just the hollow glass vessel. This glass was very thin as the fire was not as hot as modern-day furnaces. The blowpipe was invented around 1 B.C. This allowed molten glass to be gathered at the end of the blowpipe and blown into the other end to create a hollow vessel. Eventually, the use of moulding was introduced, followed by the invention of the semi-automatic machine called the Press and Blow. In 1904 Michael Owens invented the automatic bottle machine. Before this time most glass bottles in England were hand blown. This is one of four bottles in our Collection that were recovered by a local diver from the quarantine area just inside the Port Phillip Heads. Ships were required to pull into this area to check for diseases etc before they could head up to Melbourne. Quite often they would drink and throw the bottles overboard. Handmade glass bottle, manufactured in the 1850s-1900s. The bottle gives a snapshot into history and a social life that occurred during the early days of Melbourne's development and the sea trade that visited the port in those days. 1850's Pontiled Black Glass Stout/Porter/Ale Beer Bottle, solid colour brown glass,concave base with Pontil scar, tapering slightly wider towards shoulder then inwards towards neck; ring of glass just below opening cork and wire type.Label "c.1850's "Stubby ale" hand made in England flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, brown glass bottle, handmade glass bottle, handmade beer bottle, handmade late 19th century bottle -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageContainer - Jar Base

Human beings appear to have been making their own ceramics for at least 26,000 years, subjecting clay and silica to intense heat to fuse and form ceramic materials. The earliest found so far were in southern central Europe and were sculpted figures, not dishes. The earliest known pottery was made by mixing animal products with clay and baked in kilns at up to 800°C. While actual pottery fragments have been found up to 19,000 years old, it was not until about ten thousand years later that regular pottery became common. An early people that spread across much of Europe is named after its use of pottery, the Corded Ware culture. These early Indo-European peoples decorated their pottery by wrapping it with rope, while still wet. When the ceramics were fired, the rope burned off but left a decorative pattern of complex grooves on the surface. The invention of the wheel eventually led to the production of smoother, more even pottery using the wheel-forming technique, like the pottery wheel. Early ceramics were porous, absorbing water easily. It became useful for more items with the discovery of glazing techniques, coating pottery with silicon, bone ash, or other materials that could melt and reform into a glassy surface, making a vessel less pervious to water. https://en.wikipedia.org/wiki/CeramicThe discovery and development of ceramics in numerous shapes, form and materials, revolutionised the world.White ceramic container, glazed with single groove around circumference near lipNoneflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, ceramics -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Bottle, 1850's - 1900's

This bottle is sometimes referred to as a black glass 'Gallon' bottle. It is used for storing and transporting liquor such as stout, porter or ale. Glass bottles and glass jars are in many households around the world. The first glass bottles were produced in south-east Asia around 100 B.C. and the Roman Empire around 1 AD. America's glass bottle and glass jar industry were born in the early 1600s when settlers in Jamestown built the first glass-melting furnace. The invention of the automatic glass bottle blowing machine in 1880 industrialized the process of making bottles. In 2019, plans were made to re-introduce milk glass bottle deliveries to Auckland in early 2020. The earliest bottles or vessels were made by ancient man. Ingredients were melted to make glass and then clay forms were dipped into the molten liquid. When the glass cooled off, the clay was chipped out of the inside leaving just the hollow glass vessel. This glass was very thin as the fire was not as hot as modern-day furnaces. The blowpipe was invented around 1 B.C. This allowed molten glass to be gathered at the end of the blowpipe and blown into the other end to create a hollow vessel. Eventually, the use of moulding was introduced, followed by the invention of the semi-automatic machine called the Press and Blow. In 1904 Michael Owens invented the automatic bottle machine. Before this time most glass bottles in England were hand blown. This is one of four bottles in our Collection that were recovered by a local diver from the quarantine area just inside the Port Phillip Heads. Ships were required to pull into this area to check for diseases and other medical issues before they could head up to Melbourne. Quite often they would drink and throw the bottles overboard. Handmade glass bottle, manufactured in the 1850s-1900s. The bottle gives a snapshot into history and a social life that occurred during the early days of Melbourne's development and the sea trade that visited the port in those days. Bottle, glass, solid dark brown (black), round, matt surface. Glass ring below mouth, neck is slightly bulbous, seam line around shoulder, body tapers slightly inward from shoulder to base. Base is concave with pontil mark. Bottle has a white mark down the side. No inscription. Generally used for storing stout, porter or ale.flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, handmade bottle, handmade english beer bottle, pontil bottle, black glass, gallon -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageContainer - Bowl, Late 19th or early 20th Century

Human beings appear to have been making their own ceramics for at least 26,000 years, subjecting clay and silica to intense heat to fuse and form ceramic materials. The earliest found so far were in southern central Europe and were sculpted figures, not dishes. The earliest known pottery was made by mixing animal products with clay and baked in kilns at up to 800°C. While actual pottery fragments have been found up to 19,000 years old, it was not until about ten thousand years later that regular pottery became common. An early people that spread across much of Europe is named after its use of pottery, the Corded Ware culture. These early Indo-European peoples decorated their pottery by wrapping it with rope, while still wet. When the ceramics were fired, the rope burned off but left a decorative pattern of complex grooves on the surface. The invention of the wheel eventually led to the production of smoother, more even pottery using the wheel-forming technique, like the pottery wheel. Early ceramics were porous, absorbing water easily. It became useful for more items with the discovery of glazing techniques, coating pottery with silicon, bone ash, or other materials that could melt and reform into a glassy surface, making a vessel less pervious to water. https://en.wikipedia.org/wiki/CeramicThe discovery and development of ceramics in numerous shapes, form and materials, revolutionised the world.Plain cream ceramic bowl with flat bottom inside. Shiny glaze fades to flat texture towards base. Possibly hand thrown pottery. No backstamp. Bad crazing and staining.None.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, ceramics -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageContainer - Bottle, 1850's - 1900

This bottle is sometimes referred to as a black glass 'Gallon' bottle. It is used for storing and transporting liquor such as port or madeira. Glass bottles and glass jars are in many households around the world. The first glass bottles were produced in south-east Asia around 100 B.C. and the Roman Empire around 1 AD. America's glass bottle and glass jar industry were born in the early 1600s when settlers in Jamestown built the first glass-melting furnace. The invention of the automatic glass bottle blowing machine in 1880 industrialized the process of making bottles. In 2019, plans were made to re-introduce milk glass bottle deliveries to Auckland in early 2020. The earliest bottles or vessels were made by ancient man. Ingredients were melted to make glass and then clay forms were dipped into the molten liquid. When the glass cooled off, the clay was chipped out of the inside leaving just the hollow glass vessel. This glass was very thin as the fire was not as hot as modern-day furnaces. The blowpipe was invented around 1 B.C. This allowed molten glass to be gathered at the end of the blowpipe and blown into the other end to create a hollow vessel. Eventually, the use of moulding was introduced, followed by the invention of the semi-automatic machine called the Press and Blow. In 1904 Michael Owens invented the automatic bottle machine. Before this time most glass bottles in England were hand blown. This is one of four bottles in Flagstaff Hill Maritime Museum collection that were recovered by a local diver from the quarantine area just inside the Port Phillip Heads. Ships were required to pull into this area to check for diseases and other medical issues before they could head up to Melbourne. Quite often they would drink and throw the bottles overboard. Handmade glass bottle, manufactured in the 1850s. The bottle gives a snapshot into history and a social life that occurred during the early days of Melbourne's development and the sea trade that visited the port in those days. Bottle, glass, solid dark purple (black), round, matt surface. Glass ring below mouth, neck is slightly bulbous, body tapers slightly inward from shoulder to base. Base is concave with pontil mark. Bottle has no inscription. Generally used for storing port.flagstaff hill, warrnambool, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, handmade bottle, handmade english beer bottle, pontil bottle, black glass, gallon, purple bottle, ale bottle, porter bottle -

Seaworks Maritime Museum

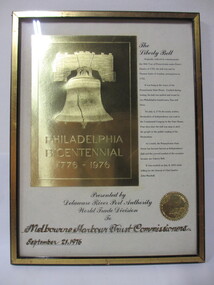

Seaworks Maritime MuseumCertificate

Certificate from the Delaware Port Authority featuring large gold image of the Liberty Bell, Short description of the bell and the seal of the organisation. Sits in a gold frame. Philadelphia/ Bicentennial/ 1776-1976/ The Liberty Bell/ originally ordered to commemorate/ the 50th year of Pennsylvania under Penn's/ charter of 1701, the bell was cast by/ Thomas Lister of London, arriving here in/ 1752/ It was hung in the tower of the/ Pennsylvania State House. Cracked during/ testing, the bell was melted and recast by/ two Philadelphia foundrymen, Pass and/ Stow./ On July 4, 1776 the newly written/ Declaration of Independence was read to / The continental Congress in the State House./ Four days later the bell was rung to alert/ the people to the public reading of the / declaration./ As a result, the Pennsylvania State / House has become known as Independence / Hall and the revered symbol of the occasion / became our Liberty Bell./ it was cracked on July 8, 1835 while/ tolling for the funeral of Chief Justice/ John Marshall./ Presented by/ Delaware River Port Authority/ World Trade Division/ to/ Melbourne Harbor Trust Commissioners/ September 21, 1976." verso: PMA 0288 -

Wodonga & District Historical Society Inc

Wodonga & District Historical Society IncDomestic object - Lady's Fruit Knife

This item is from a collection donated by descendants of John Francis Turner of Wodonga. Mr. Turner was born on 6 June 1885. He completed all of his schooling at Scotts Boarding School in Albury, New South Wales. On leaving school, he was employed at Dalgety’s, Albury as an auctioneer. In 1924 John was promoted to Manager of the Wodonga Branch of Dalgety’s. On 15/03/1900 he married Beatrice Neal (born 7/12/1887 and died 7/2/1953) from Collingwood, Victoria. They had 4 daughters – Francis (Nancy), Heather, Jessie and Mary. In 1920, the family moved from Albury to Wodonga, purchasing their family home “Locherbie” at 169 High Street, Wodonga. "Locherbie" still stands in Wodonga in 2022. The collection contains items used by the Turner family during their life in Wodonga. This "lady’s" fruit knife was used up to the late 1900's by influential and "well off" ladies, not only as a fashion statement but as a practical tool when away from the kitchen/home to peel fruit and provide a cutting instrument for small items. The first true stainless steel was melted on August 13,1913. However, it did not produce blades that held an edge nor could edges be put onto blades easily so its inventor, Harry Brealey soon earned the reputation of being the inventor of the "knife that would not cut". Over the following decade further developments to the composition of stainless steel led to its wide use in the manufacture of cutlery.A small fruit knife with stainless steel blade. It has an ivory handle and a leather cover for the blade.On blade: Stainless Steel"cutlery, stainless steel, lady's fruit knife -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Bottle, c. 1850's - 1900's

This is one of four bottles in our Collection that were recovered by a local diver from the quarantine area just inside the Port Phillip Heads. Ships were required to pull into this area to check for diseases etc before they could head up to Melbourne. Quite often they would drink and throw the bottles overboard. Handmade glass bottle, manufactured in 1850's - 1900's. Glass bottles and glass jars are in many households around the world. The first glass bottles were produced in south-east Asia around 100 B.C. and the Roman Empire around 1 AD. America's glass bottle and glass jar industry were born in the early 1600s when settlers in Jamestown built the first glass-melting furnace. The invention of the automatic glass bottle blowing machine in 1880 industrialized the process of making bottles. In 2019, plans were made to re-introduce milk glass bottle deliveries to Auckland in early 2020. The earliest bottles or vessels were made by ancient man. Ingredients were melted to make glass and then clay forms were dipped into the molten liquid. When the glass cooled off, the clay was chipped out of the inside leaving just the hollow glass vessel. This glass was very thin as the fire was not as hot as modern-day furnaces. The blowpipe was invented around 1 B.C. This allowed molten glass to be gathered at the end of the blowpipe and blown into the other end to create a hollow vessel. Eventually, the use of moulding was introduced, followed by the invention of the semi-automatic machine called the Press and Blow. In 1904 Michael Owens invented the automatic bottle machine. Before this time most glass bottles in England were hand blown. This is one of four bottles in our Collection that were recovered by a local diver from the quarantine area just inside the Port Phillip Heads. Ships were required to pull into this area to check for diseases etc before they could head up to Melbourne. Quite often they would drink and throw the bottles overboard. Handmade glass bottle, manufactured in the 1850s-1900s. The bottle gives a snapshot into history and a social life that occurred during the early days of Melbourne's development and the sea trade that visited the port in those days. Bottle, solid colour brown glass,concave base, tapering slightly wider towards shoulder then inwards towards neck; ring of glass just below opening. Base is blown glass; pontil mark on base. Label "c.1850's STUBBY ALE", "ENGLISH HAND MADE, CORK & WIRE SEAL", "PONTIL MARK ON BASE $6" flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, brown glass bottle, handmade glass bottle, handmade beer bottle, handmade late 19th century bottle -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Bottle, c. 1850's - 1900's

This is one of four bottles in our Collection that were recovered by a local diver from the quarantine area just inside the Port Phillip Heads. Ships were required to pull into this area to check for diseases etc before they could head up to Melbourne. Quite often they would drink and throw the bottles overboard. Handmade glass bottle, manufactured in 1850's - 1900's. Glass bottles and glass jars are in many households around the world. The first glass bottles were produced in south-east Asia around 100 B.C. and the Roman Empire around 1 AD. America's glass bottle and glass jar industry were born in the early 1600s when settlers in Jamestown built the first glass-melting furnace. The invention of the automatic glass bottle blowing machine in 1880 industrialized the process of making bottles. In 2019, plans were made to re-introduce milk glass bottle deliveries to Auckland in early 2020 The earliest bottles or vessels were made by ancient man. Ingredients were melted to make glass and then clay forms were dipped into the molten liquid. When the glass cooled off, the clay was chipped out of the inside leaving just the hollow glass vessel. This glass was very thin as the fire was not as hot as modern-day furnaces. The blowpipe was invented around 1 B.C. This allowed molten glass to be gathered at the end of the blowpipe and blown into the other end to create a hollow vessel. Eventually, the use of moulding was introduced, followed by the invention of the semi-automatic machine called the Press and Blow. In 1904 Michael Owens invented the automatic bottle machine. Before this time most glass bottles in England were hand blown. This is one of four bottles in our Collection that were recovered by a local diver from the quarantine area just inside the Port Phillip Heads. Ships were required to pull into this area to check for diseases etc before they could head up to Melbourne. Quite often they would drink and throw the bottles overboard. Handmade glass bottle, manufactured in the 1850s-1900s. The bottle gives a snapshot into history and a social life that occurred during the early days of Melbourne's development and the sea trade that visited the port in those days. Bottle, opaque brown glass, concave base, tapering slightly wider towards shoulder then inwards towards neck; ring of glass just below opening. Base is blown glass; pontil mark on base. "STUBBY 1850-1900 SMALL SIZE", ENGLISH 3 PIECE MOULD, HAND MADE TOP", "PAPER LABEL, CORK & WIRE SEAL $6flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, brown glass bottle, handmade glass bottle, handmade beer bottle, handmade late 19th century bottle -

Melbourne Legacy

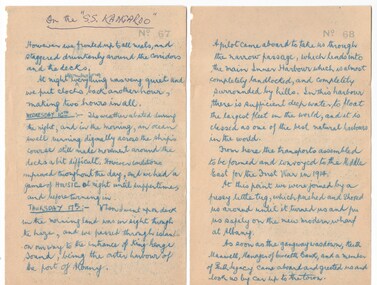

Melbourne LegacyDocument - Document, diary

A diary written by Legatee Frank Doolan as he sailed to Perth and then visited Legatee Ivan Davies and his wife Mercy. He mentions docking at King George Sound which was the harbour from which transport assembled to convoy to the Middle East for the first World War. He was greeted by a member of Perth Legacy, Keith Manwell. He mentions visiting Mt Clarence and The Anzac Desert Mounted Monument "which was destroyed by Nasser's Gyppos at Port Said, and of which the pieces were transported back to Australia, stone base and all complete. Where a new model was made by Ray Ewen at Frankston and was sent back to Italy to be melted down and recast. It is double life size and very striking, depicting an Anzac charging from a horse which has been shot down under shellfire, to a new charger - rearing to go." He leaves the SS Kangaroo for a few days to visit a "Legacy pal", Ivan Davies. They toured his farm 'Carngham'. His observation at the end shows the comradeship of Legatees. "time to depart after several glorious days of perfect hospitality. To be accepted spontaneously as one of the family is the test of true friendship, and we received the full treatment from Mercy and Ivan at 'Carngham'". The year is unknown but the trip was in March. It could have been before a Legacy Conference in Perth. Was with other memorabilia that has come from Frank Doolan from both his war service and his time with Legacy. Frank Doolan posted this copy of his diary to Ivan Davies in 1978. Not sure how it and the cover letter (01131) were returned to Legacy's collection. The diary shows that Legatees from different regions of Australia visited each other and had strong friendships over the years. A carbon copy of a diary x 11 pages, written by L/- Frank Doolan on a trip on the SS Kangaroo and a visit to L/- Ivan Davies.Dairy is handwritten. Pages are numbered 67 to 78 in printed numerals in top right of each page.comradeship, frank doolan -

Falls Creek Historical Society

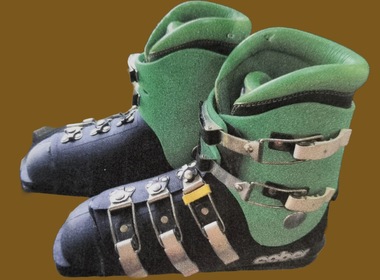

Falls Creek Historical SocietyEquipment - Caber Ski Boots

Giovanni Caberlotto was born on 27 February 1941 in Montebelluna, Italy into a family of boot makers and street vendors. In 1960 Giovanni was called up for military training and enlisted in the Alpini skiing company, learning to ski and gained a military instructor's license. During this time, he learned to recognize boots and materials and looked for innovative solutions to make them more comfortable. He returned home after his military service and convinced his father he no longer wanted to be a street vendor. In 1963 the Caberlotto family sold a piece of land to finance the new business: Caber and established a ski boot factory. In 1965, upon the death of his father, Giovanni took over the reins of the family business. He looked with interest at a new material for ski boots: plastic, travelling to the USA to carry out further investigation. Giovanni began to use plastic polymers which, once heated and melted, were injected directly into the mold and left to cool. He also began a range of sponsorships to promote his brand including the 1964 World Cup slalom event in Cortina d'Ampezzo. He also gained a four year deal with the Italian Winter Sports Federation (FISI). In 1974 he sold Caber to the US company Spalding, remaining as President of the company until 1979. In 1974 the Caberlotto brothers exploited the second part of the family surname and founded Lotto. For non-competition reasons they work on tennis and leisure shoes. The new company, in addition to tennis, becomes a successful brand in football, basketball and athletics. Giovanni left Spalding in 1980 and returned to Montebelluna, becoming the General Manager of Lotto. He died on 3 March 1997 In 1990, Rossignol acquired the Caber boot factory in Italy and rebranded the product under the Rossignol label.These boots are significant because they represented an advance in ski boot technology and were a popular brand in the 1970s.Lime green and black Caber ski boots. Each boot has five metal fastenings.On side of boots - Cabercaber ski boots, skiing equipment, skiing technology -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Domestic object - Kitchen Equipment, household soap, c1900

Common soap was made from mixing animal fat with potash a form of the potassium based alkali present in plant and wood material. Early settlers, made their own soap from the waste fats and ashes they saved from their daily work. They did not then have to rely on waiting for soap to be shipped from England and waste their goods or money in trade for soap. In making soap the first ingredient required was a liquid solution of potash commonly called lye. Animal fat, when removed from the animals during butchering, must be rendered to remove all meat tissues and cooking residue before soap of any satisfactory quality can be made from it. To render, fats and waste cooking grease were placed in a large kettle with an equal amount of water. Then the kettle was placed over the open fire outdoors, because the smell from rendering the fats was too strong to wish in anyone's house. The mixture of fats and water were boiled until all the fats had melted. After a longer period of boiling to insure completion of melting the fats, the fire was stopped and into the kettle was placed another amount of water about equal to the first amount of water. The solution was allowed to cool down and left over night. By the next day the fats had solidified and floated to the top forming a layer of clean fat. All the impurities being not as light as the fat remained in water underneath the fat. In another large kettle or pot the fat was placed with an amount of lye solution ( known by experience ). This mixture was boiled until the soap was formed - 6-8 hours - a thick frothy mass, and a small amount placed on the tongue caused no noticeable "bite". The next day a brown jelly like slippery substance was in the kettle and this was 'soft soap' . To make hard soap, common salt was thrown in at the end of the boiling and a hard cake of soap formed in a layer at the top of the pot. But as salt was expensive most settlers used 'soft soap',. The soap could be scented with oils such as lavender for personal use. These 3 cakes of home-made soap are examples of the self sufficiency of the early settlers as they had to be self reliant ,growing food and making and mending their own farm equipment, tools and clothes while establishing their market gardens in Moorabbin Shire3 cakes of home-made, white hard household soap. 1 cake of soap eaten by a brush tailed possum when he entered the Cottage via the chimney 27/4/2014soap making, market gardeners, pioneers, early settlers, moorabbin, brighton, dendy's special survey 1841. kitchen equipment, laundry equipment, bentleigh -

Mission to Seafarers Victoria

Mission to Seafarers VictoriaDecorative object - Finial, c. 1920

Appearances to the contrary, the item is not a weathervane but a finial. It was the gift of Mr John Sanderson (Jottings Easter 1920), from John Sanderson & Co., wool merchants, stock and station agents, commission and shipping agents before he leaves for England to become senior partner in Sanderson Murray & Elder, London, import and export agents. It was designed by Walter & Richard Butler Architects. (sketch published in Building : the magazine for the architect, builder, property owner and merchant vol.33, no 193, 12 Sept. 1923). The finial was already drawn on the sketch of the Central Institute made by Walter Butler. The maker of the finial, was Henry Alfred George Arnold Saw (born June 1881 in Hotham, Victoria was the son of Edward Saw (1854-1926) a tinsmith and Catherine Barton (1863-1907). He worked as a metal artificer for a metal-working business located opposite the Trades Hall in Lygon Street and was given the job of making the copper ship finial. Henry married Florence Charlotte Reeder and they had four children. Also known as Harry Saw according to his grandson Brian, he died on 9th February 1960. Henry and Florence both died within two months of each other in 1960. It is not clear when the ship was actually installed on the roof, the earliest photograph dating from 1927. The windvane fell or moved several times because of gale forces: - In 1995 : After the funds were raised to repair it, it was treated by sculptor David Hope, and reinstalled in the 1998 (Ship to Shore #3 Sept 1998). - In 2017: Carmela Lonetti from the Grimwade Centre for Cultural Materials Conservation (Ship to Shore Autumn 2017) - In 2019: a generous passerby donated the necessary funds for the conservation. It was sent to Grimwade Centre for Cultural Materials Conservation (Ship to Shore 2019), treated by Evan Tindal (City of Melbourne Magainze Oct. 2020). It was reinstalled over the Summer of 2019-2020 (Ship to Shore Summer 2020). The weathervane was stolen during the night of the 6-7 March 2022. Copper price surge sparks rise in theft in Victoria in 2021-22 so it's likely the vane was stolen to be melted This sculpture is closely associated with the 1917 building and described in clippings and annual reports when the building was first newly opened. It can be seen in some of the earliest photographs of the new building and in the artist/architect Butler's impressions. The galleon is often a decorative design of Mission to Seafarers wind vane (London, Adelaide).Bronze and copper sculpture fashioned as a Wind Vane in the form of a Galleon style sailing ship with 2 pennants flying and two sails rigged atop with lower cross piece with wind directions N S E W . There is a decorative ornamental pierced scrollwork ferrule / finial with reinforcing chrome steel piping armature at base of main support which attaches to the roof or a base support. See also comments below weather vane, wind vane, sculpture, galleon, sailing ship, finial, henry alfred saw, david hope, windvane, weathervane, walter richmond butler (1864–1949), richard butler, john sanderson -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageContainer - Bottle, Late 19th century or early 20th century

Glass manufacturing has evolved over thousands of years. Glass making has been traced back to 3500 BC in Mesopotamia. The earliest known glass objects were beads, perhaps made by accident while working with metal. In the late Bronze Age, several civilizations discovered how to make vessels and glass bottles by wrapping threads of melted glass around cores of sand or clay. Later, moulds were used to form dishes and table wares. Around the 1st century BC, glassblowing was discovered. This made glass containers less expensive than pottery. Mould-blown glass, the process of blowing a piece of molten glass into a wooden or metal mould, was invented during the 1st century AD. This technique was faster with more consistent results. It paved the way for mass production. It wasn’t until the late 1800s that the production process to become more efficient. In 1887, a company in England created a semi-automatic process that could produce up to 200 bottles an hour. This process has been refined to the point where modern machines can yield more than 600 containers per minute. Blown vs. Manufactured Glass Bottles Nowadays, glass bottles, jars, and cups are usually manufactured on a bigger scale than is found in individual glassblowing studios. If we still depended on hand-blown glass for all of our glass containers, we would see some major differences in the process of creating bottles and jars. First, there's the time. Hand blowing glass takes a significant amount of time, even for one simple container. In contrast, hundreds of jars per minute can be made using modern technology. This leads to the second advantage: price. Because of the automated and streamlined process, the price for manufactured containers is much lower than that of hand-blown glass. Third, manufactured bottles will be much more consistently uniform than bottles blown by hand. Automated glass manufacturing produces nearly identical batches of jars. Glass blowing is awesome for unique, beautiful pieces of art. But for lots of lower priced and uniformly shaped containers, automatic manufacturing is the preferred method to create glass bottles and jars. https://www.containerandpackaging.com/resources/glass-bottles-brief-history The invention and development of glass for domestic items including bottles, has been nothing short of revolutionary. The use of glass bottles, that could be easily washed, led to improved hygiene, and mass manufacturing of drinks of all types, including milk, cordial and alcoholic beverages.Green Glass Bottle Possibly a ginger beer bottle.Concave indentation at the base. Also on base are two raised lumps. flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, glass -

Federation University Art Collection

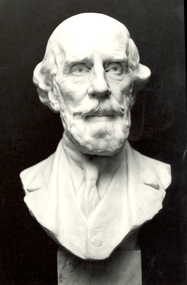

Federation University Art CollectionSculpture - Marble sculpture, 'Professor Alfred Mica Smith' by Paul Montford, 1924

Paul Raphael MONTFORD (1868 - 1938) Paul Montford moved to Australia to carve four buttress groups in granite for the Melbourne Shrine of Remembrance. In 1924 he was teaching at Geelong Technical College. Professor Alfred Mica Smith was a long term lecturer at the Ballarat School of Mines. The sculpture was commissioned by former Students of the Ballarat School of Mines working in Western Australia. One of those former students, William Corbould, remembered his first encounter with the professor fondly:- 'From the Registrar's Office I was led to be introduced to the Professor of Chemistry, one Mica Smith. The initial encounter gave me little encouragement - his large laboratory was filled with hundreds of bottles bearing strange labels with queer symbols on them. My heart sank. At the first opportunity I grabbed my hat and made for the door, but the good professor called me back. I pointed out that I was never any good at school ... so it was no use pretending to be clever enough to understand all those weird symbols! The Professor told me not to worry about that and took me to one of the benches where he found a blowpipe and a charcoal block. Mixing together two powders from bottles on the shelf he transferred a sample to the charcoal and directed the bunsen flame onto it. Soon it began to melt and a white bead appeared in front of my eyes. He then took a test tube and added a little colourless liquid from each of two bottles. A beautiful dark blue colour appeared. My interest was won.' Alfred Mica Smith was the well-loved Professor of Chemistry and Metallurgy at the Ballarat School of Mines between 1881 and 1922. Upon reaching the age of 78 Mica Smith retired having influenced generations of miners. At the time of his death Ballarat School of Mines Students’ Magazine reported: "In the annals of the School, the year 1922 will be noted chiefly as the last year in which Professor Mica Smith taught here. With his retirement, a memorable epoch closed. The Professor has served the School for 42 years with a service, the length and thoroughness of which are unique. … It is not quite realised in this city how famous the School became throughout the world, nor to what extent the Professor was responsible for its high position in the mining and metallurgical world. … This item is part of the Federation University Art Collection. The Art Collection features over 2000 works and was listed as a 'Ballarat Treasure' in 2007.Marble bust of Ballarat School of Mines Professor Alfred Mica Smith by Paul Montford. The bust is mounted on a jarrah pedestal made from timber donated by the Millar Timber and Trading Company. The bust was formally presented to the Ballarat School of Mines on Saturday 13 December1924 in front of Alfred Mica Smith and a large gathering. It is signed 'Paul R. Montford, Sc, 1924' at the back.Professor A. Mica Smith, 1924, Presented by His Old Students Associated with Western Australia as a Token of Affectionate Esteemart, artwork, ballarat school of mines, montford, paul montford, alfred mica smith, mica smith, marble, bust, sculpture