Showing 9557 items

matching water-rates

-

Wodonga & District Historical Society Inc

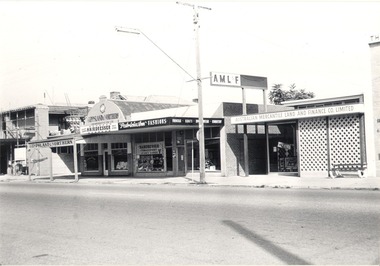

Wodonga & District Historical Society IncPhotograph - Mann Collection Album - Terminus Hotel; Gippsland & Northern

This photo is part of a collection of Wodonga Town Photos donated by Elaine Mann. Elaine was married to David Mann, a successful Wodonga businessman and community leader who passed away in Wodonga in June 2012. David was a member of the Mann family who began their business in Wodonga in 1920. Elaine was a teacher in Wodonga for many years and an active member of the community. The Terminus Hotel In 1873, James Thompson Hatch built the two-storeyed Terminus Hotel at 79 Sydney Road (later known as High Street), then sold it to George Day and Kenneth McLennan for £1,230. It was first licensed to J. G. Morton in January 1874. In 1879, Annie Allen, from Ireland, took over as licensee of the hotel containing 14 rooms, after she and her husband, George James Allen, purchased it. He became licensee in 1883. Under the Allens, the Terminus became, ‘a principal rendezvous for visitors to the town.’ September 1888 saw additions to the building that included a billiard room, a dining room, and 18 other rooms. Following the death of her husband in 1889, Annie Allen continued to run the Terminus Hotel. She later married John Haldon and was licensee of the hotel until 1893 when the licence was transferred to William Carkeek. In the early 1900s the Hotel was thoroughly renovated. The Terminus Hotel was for sale by auction on 5th March 1909. It comprised about 50 rooms, a two-storey building built of brick and iron with hot and cold water service and acetylene gas throughout. The principal hotel in Wodonga, was let from 1st January 1909 on a seven years’ lease at a rental of £9 per week. 1935 saw extensive improvements by proprietor W. P. Kinney, while in 1941 further extensive improvements were carried out to make a good hotel better. A pall of shock and disbelief descended over Wodonga’s historic Terminus Hotel on 1st June 1998 when it was destroyed by fire then demolished in 1999. The site was sold for almost $1 million and redeveloped for a medical clinic.This photo collection is of significance as it documents how the businesses and buildings in Wodonga have evolved and contributed to community throughout the late 20th century.Terminus Hotel; Gippsland & Northern Co-operative Pty. Ltd.; Graham Bradbury Men's Hairdresser; Patricia Anne Fashions; Australian Mercantile Land and Finance Company (A.M.L. & F). on the west side of High Street. The Terminus Hotel was built C. 1873. and was destroyed by fire in 1998, The Gippsland and Northern Co-operative Co. Ltd was formed in 1905, but the date of its establishment in Wodonga is not confirmed, but they were holding fortnightly sales at the Wodonga sale yards by early 1919.wodonga businesses, high st wodonga, terminus hotel, gippsland & northern -

Wodonga & District Historical Society Inc

Wodonga & District Historical Society IncUniform - Scout Master's Hat Badge, Whistle and Gilwell Woggle

These items were regular elements of a Scout Master's equipment. The hat badge and the woggle were specifically part of the Leader's uniform and differed from similar uniform items of younger or more junior scouts. The first proposal to form a Scouts Corps in Wodonga was raised at a public meeting in Wodonga in November 1909. One of their earliest activities in January 1910 was a march from Wodonga to Bright and return with Scouts from Albury. This first Troop was probably called the 1st Belvoir Scouts. Several other attempts were made to form Scout Troops in Wodonga over the ensuing years. In 1929 the Boy Scout Movement was taken up seriously at Wodonga by approximately 40 boys, together with 30 Cubs (juniors). However this was short-lived. Over the following decade several Scout Troops were formed but lapsed and several Wodonga boys joined the Albury Scout Troop. In 1939 Mr Ray Foster, with eight members put the Scouts on a more enduring basis. Their meeting place was a room below the Water Tower. During the early 1940s the 1st Wodonga Scouts struggled for Leaders to run the activities because so many people were caught up in the Second World War (either overseas or domestically). Mr David Mann gathered together all the small scouting groups in the Wodonga area and turned them from disorganised and disconnected groups into one scouting unit. He led the Scouts in their formative years and went on to become the 1st Wodonga Scouts first King's Scout. He had a long association with the 1st Wodonga Scouts and all the district scouting troops over the following decades. David Mann was also instrumental in the late 1940s in working for a Scout Hall to be built in Reid Street, Wodonga to secure a permanent home. These items were donated by a former member of the 1st Wodonga Scout Group who shared positive memories of the leadership of David Mann and the lessons learned in the Scouting Movement.These items are significant because they are representative of an important local, national and international organisation.A set of Scout uniform equipment including a Scout Master's Hat Badge, a whistle and a knotted leather woggle.On badge" Scout Symbol above "BE PREPARED" Engraved on Whistle - Fleur de Lis symbolwodonga scouts, 1st wodonga scouts, scouting equipment, david mann -

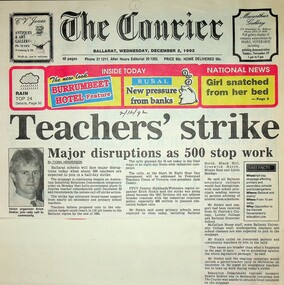

Unions Ballarat

Unions BallaratBallarat Trades Hall Scrapbook: newspaper clippings 1988-1993, The Courier (newspaper), various

Newspaper clippings 1991-1993. 1. Teachers' strike: Major disruptions as 500 stop work [Ballarat] Paper: The Courier Date: 2 December 1992 2. Strikes in 3 sectors [Ballarat] Paper: The Courier Date: 3 December 1992 3. Letter to the editor: Change priorities for a better city [Ballarat] Paper: The Courier? Author: P. Murphy Date: n.d. 4. Traynor's comments criticised [regarding penalty rates] Paper: The Courier? Date: 27 July 1991 5. Trades Hall seeks urgent talks on health funding [Ballarat] Paper: The Courier? Date: 29 July 1991 6. Stewart condemns weekend shearing [Ballarat] Paper: The Courier Date: 1 August 1991 7. Working class poet [Geoff Goodfellow] recites with the power of language Paper: The Courier Date: 8 August 1991 8. Budget '91: Budget brings little local joy Paper: The Courier? Date: 21 August 1991 9. State Budget '91: Budget hits low income earners Paper: The Courier? Date: 28 August 1991 10. Job cuts face local bakery [Sunicrust, Ballarat] Paper: The Courier? Date: 29 August 1991 11. Factory closure will put 50 out of work [Vitclay, Ballarat] Paper: The Courier? Date: 3 September 1991 12. Protest for jobs urged [Ballarat] Paper: The Courier Date: 7 September 1991 13. Bank staff cuts 'astound' Trades Hall secretary [Ballarat] Paper: The Courier? Date: 12 September 1991 14. Pixelated black and white portrait photo of Graeme Shearer 15. Abattoirs picket line supported [Camperdown] Paper: The Courier Date: n.d. 16. Shearers to set up AWU committee [Ballarat} Paper: The Courier Date: 19 September 1991 17. Group fights for Ballarat national rail freight link Paper: The Courier Date: 1 October 1991 18. National jobless rate 10.2.% [Ballarat] Paper: The Courier? Date: 11 October 1991 19. Shearers establish committee [Ballarat] Paper: The Courier Date: 23 October 1991 20. Wage decision backed by employers, unions [Ballarat] Paper: The Courier Date: n.d. 21. Meeting to focus on aged care: QEGC budget cuts spark local concern [Central Highlands] Paper: The Courier Date: 4 December 1991 22. Mayor urges jobless to rally to the cause [Ballarat] Paper: The Courier? Date: 7 December 1991 23. New dole record: District's jobless queue lengthens again [Ballarat] Paper: The Courier? Date: 13 December 1991 24. Begonia bans: Unions act on retirement village [Ballarat] Paper: The Courier? Date: 24 December 1991 25. Another stoppage over WorkCare [Ballarat] Paper: The Courier? Date: 5 August 1990 26. BTHC hits anti-strike proposal Paper: The Courier Date: 16 November 1991 27. Businesses eager; unions more wary. Paper: The Courier? Date: 22 November 1991 28a. Project halted: review of $60m retirement village [Ballarat] 28b. Retirement Group 'too big, too fast' [Ballarat] 28c. Retirement village work halted [Ballarat] Paper: The Courier? Date: n.d. 29. QEGC managers criticised over budget cutbacks [Ballarat] Paper: The Courier? Date: n.d. 30. Unions' aid call [Ballarat] 30a. How unions want the $6 billion spent Paper: The Courier? Date: 11 February 1991 31. Threat to bread: Bunge strike action escalates [Ballarat] Paper: The Courier? Date: 27 February 1992 32. Bunge moves rye to Albury: Workers walk out [Ballarat] Paper: The Courier? Date: 26 February 1992 33. Merry makers' labours worry Trades Hall [Kryal Castle, Ballarat] Paper: The Courier? Date: 21 February 1992 34. Agreement will put end to retirement village dispute [Ballarat] Paper: The Courier Date: 22 February 1992 35. Mill strikers call for reinstatements [Ballarat] Paper: The Courier Date: 27 February 1992 36. No debate for BRB [Ballarat] Paper: The Courier? Date: n.d. 37. Statement will be our only hope [Ballarat] Paper: The Courier Date: 12 February 1992 38. Union hits catering [Ballarate & Victoria] Paper: The Courier? Date: ?? February 1992 39. Thanks - Bunge strikers thank you to Graeme Shearer et al Paper: The Courier? Date: n.d. 40. ANZ under fire from Trades Hall Secretary [Ballarat] Paper: The Courier Date: 19 March 1992 41. Assurance sought over Melb rail line [Ballarat] Paper: The Courier Date: 18 March 1992 42. In and out of town: Premier to visit [Ballarat] Paper: The Courier? Date: n.d. 43. Regional board wants to improve its image [Ballarat] Paper: The Courier? Date: n.d. 44. Time to amalgamate (letter to the editor) [Ballarat] Paper: The Courier Date: 13 May 1992 45. Another unemployment record for Ballarat Paper: The Courier? Date: 8 May 1992 46. Trouble brews in Ballarat (opinion) Paper: The Courier? Date: 9 May 1992 47. Trades Hall warns of student exploitation [Ballarat] Paper: The Courier Date: 29 February 1992 48. Bunge unions stay firm [Ballarat] Paper: The Courier? Date: 12 March 1992 49. Workers, Bunge settle dispute [Ballarat] Paper: The Courier? Date: 4 March 1992 50. Proposal could end Bunge strike [Ballarat] Paper: The Courier? Date: 3 March 1992 51. Village payment / payment at village Paper: The Courier? Date: 6 March 1992 52. Public outcry over hike in milk price [Ballarat] Paper: The Courier? Date: n.d. 53. Workers dig deep to help Somalia [Ballarat] Paper: The Courier? Date: 10 October 1992 54. 'Callous attack on the poor': union chief [Ballarat] Paper: The Courier? Date: 13 October 1992 55. No Labour swing, says Shearer [Ballarat] Paper: The Courier? Date: 6 October 1992 56. Ballarat joins strike Paper: The Courier Date: 24 October 1992 57. Workers would revolt against Libs: Shearer Paper: The Courier? Date: 28 September 1992 58. Wage rise disgraceful [Ballarat] Paper: The Courier? Date: 31 October 1992 59. Shearer seeks guarantees for rail link [Ballarat] Paper: The Courier? Date: 19 September 1992 60. Cleaners ready to tackle Coalition [Ballarat] Paper: The Courier? Date: 19 September 1992 61. The Ballarat strike (picture) Paper: The Courier? Date: 11 November 1992 62. Workers voice their concern [Daylesford] Paper: The Courier? Date: 11 November 1992 63. The Ballarat strike Paper: The Courier Date: 11 November 1992 64. 53 railway jobs to go: union chief [Ballarat] Paper: The Courier? Date: 23 November 1992 65. Trades Hall urges support for rally [Ballarat] Paper: The Courier? Date: 25 November 1992 66. Doubt cast on our unemployed rate [Ballarat] Paper: The Courier Date: 20 August 1992 67. Wage claim justified: Shearer Paper: The Courier? Date: 20 August 1992 68. Pool plan for jobs money attacked Paper: The Courier Date: 22 August 1992 69. Fight for rail link [Geelong-Ballarat] Paper: Geelong Advertiser Date: 18 September 1992 70. Rail pledge demand Paper: Geelong Advertiser Date: 1 October 1992 Condition: very poor 71. Union calls for railway guarantee [Ballarat] Paper: n.a. Date: 21 October 1992 72. A strike is the last thing Victoria needs Paper: The Courier Date: 27 ? 1992 73.Industry turmoil: Ford plant is up for sale [Ballarat] Paper: The Courier? Date: 20 August 1992 74. Regional Board retains job counsellor [Ballarat] Paper: The Courier Date: 20 August 1992 75. Jobless figures need special consideration [Ballarat] Paper: The Courier Date: 20 August 1992 76a. Local strike chaos: All services likely to be affected [Ballarat] 76b.Strike is an act of hypocrisy [Ballarat] Paper: The Courier Date: 10 November 1992 77. Ronaldson angered by union attack blunder [Ballarat] Paper: The Courier Date: 11 November 1992 78. Ballarat rally against Govt Paper: The Courier Date: 4 November 1992 79.Payouts a form of 'blackmail' [Ballarat] Paper: The Courier? Date: 27 November 1992 80. Union leader gives job loss breakdown [Ballarat] Paper: The Courier? Date: 27 November 1992 81. Deficit levy protest: Unions seize on wide discontent [Ballarat] Paper: The Courier? Date: 26 November 1992? 82. WorkCover under fire at city rally [Ballarat] Paper: The Courier Date: 26 November 1992 83. Coalition is 'cruel': Shearer Paper: The Courier? Date: 22 August 1992 84. Policy to 'decimate unions' Paper: The Courier? Date: 26th August 1992 85. Review immigration call Paper: The Courier? Date: 16 July 1992 86. Union boss blasts Libs' proposals [Ballarat] Paper: The Courier Date: n.d. 87. Both towns could win rail link: NRC [Geelong-Ballarat] Paper: The Courier? Date: n.d. 88. Teachers rally against cuts [Ballarat] Paper: The Courier? Date: 20 May 1993 89. Five workers die in 2 years Paper: The Courier Date: 14 October 1996Significant collection of press articles that include comment from Unions Ballarat Secretary, Graeme Shearer, around the period when Jeff Kennett (Liberal Party Victoria) became premier of Victoria. Focus upon a variety of social and industrial issues impacting the Ballarat region.Newspaper articles - scanned.btlc, ballarat trades and labour council, shearer graeme, kennett jeff, railway link geelong-ballarat, liberal party victoria, industrial action - rallies, workcover, various, ballarat trades and labour council - secretary -

Warrnambool and District Historical Society Inc.

Warrnambool and District Historical Society Inc.Artefact, G.W.Scott & Sons, Picnic Case, 1930s

This is a car picnic set made by the English firm of G. W. Scott and Sons who were producers of wickerwork crafts, basketry and luxury leather goods. The business was founded in 1661 and ceased operations in 1967. The picnic set belonged to Dr Horace Iles Holmes (1877-1959) who was born and educated in Tasmania and completed a medical degree at Melbourne University. He commenced a practice in Warrnambool in 1906 and was the Honorary Medical Officer at the Warrnambool Hospital and Warrnambool’s Health Officer. His practice was at ‘Ierne’ at the corner of Spence and Kepler Streets. He was an early member of the Royal Australian College of Surgeons and was prominent in Warrnambool community affairs (Foundation President of Warrnmbool Rotary Club, a member of the local Masonic Lodge for over 50 years, Warrnambool Hospital Committee member, long-term Trustee of the Warrnambool Methodist Church and President of the Lyndoch Hostel for the Aged Committee). Dr Holmes also had agricultural interests and enjoyed fishing, golf and bowls. He also had a motor car and this picnic set would have been used for family picnics. This picnic set is of considerable significance because: 1. It is a good example of the luxury picnic sets owned by more affluent people in the 1930s and 40s. 2. It has important local provenance as it belonged to Horace Holmes, a doctor associated with the professional and community life of Warrnambool for over 50 years. This is a rectangular wooden box with a leather covering. It has metal hinges on the corners of the box and two two metal catches on the side with a leather belt and metal buckle on one of these catches with one leather belt missing on the other side. These leather straps were to attach the picnic box to the running board of the car. There are also two metal catches or locks on the front of the box. Inside the box there is a white lining with a plaited wickerwork insert containing spaces for the following: 1. large china container with a silver top 2. smaller metal container with a silver lid 3. small rectangular metal tin with a silver lid. This container still has some loose tea leaves inside 4. four china cups 5. two circular china dishes for jam and butter 6. four china saucers 7. one glass bottle with a silver top 8. one metal phial, silver-coloured 9. one amber-coloured glass bottle (probably not an original) 10. four nickel silver spoons 11. three metal forks 12. three white enamel plates, blue edged Numbers 10,11 and 12 are held in place by leather straps on the inside of the lid of the box 13. two loose metal straps 14. one metal kettle with a handle with cane strapping, a brass lid, a brass spout with an end chain and a metal inscription 15. The kettle is sitting in a metal tray which has a lighting mechanism to heat the water The picnic set has some rusted metal catches on the exterior of the box and the leather is very stained and torn in places. ‘Remove screw before lighting G.W.S. & S ‘ ‘Coracle brand’ antique luxury picnic set, dr horace holmes, history of warrnambool -

The 5th/6th Battalion Royal Victoria Regiment Historical Collection

The 5th/6th Battalion Royal Victoria Regiment Historical CollectionArtwork, other - Portrait, Captain Oswald Birley M.C et al, King George V (Duke of Kent) 1935, c.1935

Portrait of King George V (Duke of Kent) 1935Presented to the 6th Battalion Royal Melbourne Regiment by an Allied Battalion the Royal Fusiliers as a toke of friendship and esteem. This Portrait would have hung pride of place in the officers mess from 1935-? The portarait is also signed by the artist, an M.C reciepient, as well as the the reigning monarch, and colonel in chief of the presenting unit. It is supported by a letter from the colonel of the Presenting unit, Maj Gen Hill CB.CMG.DSO, and as such is hghly provinanced Colour print of His Magesty King George V wearing the unaiform of the the Royal Fusilliers, Read coat with decorations and blue sash under a navy blue over coat. The print is signed in lead pencil by the artist and by King George V on the lower edge. A regimental badge is present in the top right of the image. The picture is framed in a pewter coloured frame with ornate leaf mouldings in the corners. On the lower edge of the frame is a plaque which states " From the Colonel and Officers of the Royal Fusilliers 1935" Also included with the portait is a letter on Royal Fusiliers letterhead dated October 23 1935 " From - Maj-Gen. W.P.H. Hill. CB. CMG. DSO., Colonel. The Royal Fusiliers Dear Armstrong I am forwarding to you under a separate cover an engraving of a portrait of His Majesty, King George V, Colonel - in - Chief, the Royal Fusiliers, in the uniform of the Regiment, This portrait was painted by Captain Oswald Birley, M.C., late Royal Fusiliers, and presented to the Regiment by Lord Wakefield to commemorate the 250th anniversary of the raising of the Regiment of Fusiliers at the Tower of London in 1685. His Majesty has graciously signed this copy for presentation to your Regiment from the Corps of the Royal Fusiliers, and we trust that you will accept it as a token of friendship / and esteem .... and esteem we feel for our Allied Battalion, the 6th Battalion, the Royal Melbourne Regiment Yours Sincerely W.F.H. Hill Lieutenant-Colonel C.E. Armstrong , Comdg. 6th Bn. The Royal Melbourne Regt., Carlton, Victoria, Australia" This letter is supported by framing card , which has some water damage on the lower right corner and right side signed by King George and the artist From the Colonel and Officers of the Royal Fusilliers 1935" 5/6 rvr, officer's / sergeant's mess, 6th battalion, royal melbourne regiment, king george v, royal fusiliers -

Melbourne Tram Museum

Melbourne Tram MuseumPhotograph - Black & White Photograph/s, c1926

Black and white photograph of the construction of the tram track in St Kilda Road, during 1925 or 1926 by the Foundation Construction Ltd, with a concrete mixer tracked vehicle and two aggregate or crushed rock trucks. Photo from the Collection of the Department of Infrastructure now with the Public Records Office - image number H514. Note: this photo is now out of copyright and was not an original VR photograph, but one copied from another source and collected as their Heritage series. See Image 3674i2 and 3674i3 for a digital image of the card photograph at the PRO on 7/1/2019 that this photograph comes from. Further notes from Rod Atkins 11/7/2019: The cement mixer was state of the art machine at the time. "Buddy" in the USA were making them but this one is slightly different and may have been made by a company call AAC in Sheffield U.K. You can just make out the word " ….field" etc … on the water tank . The sign; now this is very interesting. "The Foundation Company" is the Australian company of the one in London.. from The Argus at the time. run by no less than by Herbert Del Cott Ply Ltd. (you can just make that out in the bottom line of the sign.) A rather interesting person in Melbourne society between the wars. His name pops up a lot in The Argus. was not short of a pound either.... Had his "Buick" stolen from Russell Street in 1920. Had some issues with wages on Wellington Street conversion. Looks to have run a electrical business before seeing opportunity with cable tram replacement coming up. In the 1930' lived in Stevenson Street, Kew. Travelled a lot to Europe. (Austria) …..Has Department of Infrastructure copy right stamp on rear and number "H 514" in ink on rear and "2-1"trams, tramways, st kilda rd, trackwork, construction, conversion -

University of Melbourne, Burnley Campus Archives

University of Melbourne, Burnley Campus ArchivesAlbum - Black and white prints and negatives, James Leslie Provan, Photograph Collection, 1940-1950

Collection of 39 black and white photographs. Some photographs with handwritten annotations in what looks like the handwriting of J.L. Provan. Mostly at Burnley, some at Moorabbin. (1) "Opium Poppy 1942 Burnley. Publicity Branch Department of Agriculture." Negative in envelope marked, "Prints 1 of No. 398 Department of Agriculture 'McP.' " (2) Grape vine and cabbages. (3) Rows of seedlings in the Orchard. (4) Orange tree? unpruned. (5) Flowers. (6) "Double and single rows of French Beans." (7) "Sage & marjoram." (8) Hydrangeas. (9)Sprinkler on newly planted cabbages. (10a)"Lettuce Iceberg 1/1/43." Seeds on soil surface. (10b) "Lettuce Iceberg 1/1/43." Seedlings emerging. (11)? planted in terracotta pipes. (12) Rows of seedlings in the Orchard. (13) "A student sowing Parsnip seed in a drill row. School of Horticulture Burnley Gardens." (14) Student distributing fertilizer? (15) Similar. (16) Similar. (17a) Flowers. (17b) Flowers. (18)"Beetroot Crimson Globe." (19) A seed drill. (20)Canna. (21a) Vegetable rows. (21b) ? (22) Student hoeing. (23) Student hoeing. (24) Similar. (26) "Cabbage Burbees Allhead 2/2/43," seedlings. (27) Water, manure, etc. (28) "Celery beds Ray Marriott Moorabbin April 2nd 1943." (29-37) Also at Moorabbin probably: (29) Vegetables. (30) Onions. (31) Vegetables. (32) Planting seedlings. (33) Vegetables. (34) Celery, carrots, turnips on display. (35) Carrots growing and just pulled up. (36) Peas. (37) Ploughing with horse. (38) Student spraying vegetables at Burnley. (39) House?j.l. provan, burnley, moorabbin, opium poppy, grape vine, cabbages, seedlings, orchards, orange trees, flowers, french beans, sage, marjoram, hydrangea, sprinkler, lettuce iceberg, seeds, students sowing, parsnips, school of horticulture burnley gardens, beetroot, hoeing, water, manure, celery, vegetables beds, ray marriott, onions, carrots, turnips, peas, ploughing, horse, spraying -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Newspaper - NEWSPAPER COLLECTION: BENDIGO ADVERTISER - HERALD SUN 2009 BUSHFIRES

1) The Advertiser - Red Alert - February 06, 2009 2) The Advertiser - Headline Moments of the Past-July 03, 2009 3) Herald Sun - Black Saturday - February 07, 2009 4) Herald Sun - Fire-storm - February 08, 2009 5) Herald Sun - 84 Dead - February 09, 2009 6) Herald Sun - We'll Help - February 09, 2009 7) The Advertiser - Hellfire Heartache - February 09, 2009 8) The Advertiser - Thumbs Up On Water - February 09, 2009 9) Herald Sun - We Will Rebuild - February 10, 2009 10) Herald Sun - All Lost - February 10, 2009 11) The Advertiser - How We Lost Our Brother - February 10, 2009 12) The Advertiser - Counting the Cost - February 10, 2009 13) Herald Sun - Alive - February 11, 2009 14) Herald Sun - Act of Terror - February 11, 2009 15) Herald Sun - Never Again - February 12, 2009 16) Herald Sun - The Tiniest Victims - February 12, 2009 17) Herald Sun - Heart of a Nation - February 13, 2009 18) Bendigo Weekly - City Unites - February 13, 2009 19) Herald Sun - Love from the Ashes - February 14, 2009 20) The Advertiser - Black Saturday - February 14, 2009 21) The Advertiser - Black Saturday - February 14, 2009 22) Herald Sun - Portraits of Grief - February 14, 2009 23) Herald Sun - Salute Our Heroes - February 15, 2009 24) The Advertiser - One Brick at the Time - February 16, 2009. Folder 111 now in Box 417 AV 03/11/2022newspaper, bendigo advertiser -

Eltham District Historical Society Inc

Eltham District Historical Society IncNewspaper - News Clipping, Herald, The big Eltham clean-up gets under way, Herald, 4 March, p3, 1965

Full page newspaper clipping featuring the March 1965 Victorian bushfires. Items include: Photograph - TWO-WOMAN BUCKET BRIGADE, Mrs Henry Marsden (left) and Mrs Moureen Ellis, whose fire-fighting efforts yesterday were highly praised today by their Eltham neighbours, carry out mopping-up operations Photograph - DOGS MADE HOMELESS by the fire in North Eltham yesterday are being cared for at First-Constable Doug. Mummery's kennels at Eltham and here is kennel maid Helen Oliver, 17, with some of them today. The two basset hounds are owned by Mr Bill Guy who lost about 100 daschund and basset hound puppies and dogs in the fire. Photograph - He died at Eltham [Picture of John Lawrence Coleman] Builder Mr John Lawrence Coleman, 31, of Main Rd., Eltham, one of three men burnt to death yesterday in the fire at North Eltham. The other two were XXXXX, 33 who lives opposite the Colemans and Mr William Elwers, 64 of Batman Rd., Eltham. John Lawrence Coleman (1934-1965) born January 10, was the son of Raymond John Coleman and Hanna May (Gillet) Coleman. He married Margaret Frances Dare in 1955 and was the father of two children. He died whilst attempting to rescue an older man trapped in the bushfire at North Eltham on March 3, 1965 Other news stories of the day: Bushfires rage in Victoria, Snowy: Three dead (1965, March 4). The Canberra Times (ACT : 1926 - 1995), p. 1. Retrieved May 19, 2022, from http://nla.gov.au/nla.news-article131758981 Includes two photos of the fire in North Eltham “Firemen make for safety as fire rages in Upper Glen Park Road, North Eltham, Victoria. The smoke hides a house.” and “A house explodes into flames at North Eltham, Victoria. Firemen said bottled gas went up.” Canberra Times (ACT : 1926 - 1995), Thursday 4 March 1965, page 1 ________________________________________ Firemen make for safety as fire rages in Upper Glen Park Road. North Eltham. Victoria. The smoke hides a house. A house explodes into flames at North Eltham. Victoria. Firemen said bottled gas went up. Bushfires rage in Victoria, Snowy: Three dead MELBOURNE, Wednesday.—Three people died today in a bush» fire which raged through North Eltham, about 15 miles from Melbourne. The victims were three men. A fourth man is feared to be dead. Another bushfire. sparked off by the heatwave sizzling over south-eastern Australia, is burning out of control in the Kosciusko State Park, in the Snowy Mountains. Firefighters fear that if it reaches pine forests up the Yarrangobilly River, they will be powerless to stop it. The three victims of the North Eltbam fire were trapped by flames in a valley. Their bodies were found only a few yards apart. They were named by police tonight as Mr. George Crowe, 78, of North Eltham, William John Ewers, 64, and John Laurence Coleman, 31, both of Eltham. The other two have not been identified. They are believed to be a man aged about 40 and an 18-year-old youth. At least 12 homes were destroyed by the fire, the worst in Victoria since 1962, when eight lives were lost and hundreds of homes burnt down at Warrandyte. At one time the township of Eltham was threatened, but a cool change swept in from the south and held back the wall of flames. More than 100 dogs, worth about £4,000, died when the fire raced through two kennels in Short Street, Eltham. and Upper Glen Park Road, North Eltham. A trickle of water Residents ran into the streets as the blaze raced towards their houses. Others frantically dug firebreaks around their homes. Mrs. Sue Recourt wept when firemen arrived while she was vainly trying to stop the flames with a trickle of water from the garden hose. A stack of firewood was blazing, but the firemen managed to save the house and rescue four goats. Many homes in Eltham were saved after flames had crept to within feet of their fences. Students at North Eltham State School had to be evacuated when the blaze threatened the building. Fire fighters were severely hampered by lack of water and narrow roads. The blaze, which began in above century heat, turned toward Wattle Glen, where two houses were gutted. Then the flames raced towards Hurstbridge to the north. Firemen battling desperately, controlled the fire late this afternoon. Five forest fires were still burning in Victoria tonight. IN VICTORIA THIS WEEK Tragic lack of central fire authority (1965, March 9). The Canberra Times (ACT : 1926 - 1995), p. 2. Retrieved May 19, 2022, from http://nla.gov.au/nla.news-article131759928 Canberra Times (ACT : 1926 - 1995), Tuesday 9 March 1965, page 2 ________________________________________ IN VICTORIA THIS WEEK Tragic lack of central fire authority From Rohan Rivett It was the worst week for Victorian fire fighters since Black Friday 27 years ago. On that day one pilot up in a spotter plane said afterwards: "It seemed at times that half the State was on fire." This time, for three days on end, Gippsland men, women and children had moments of conviction that their towns would have blackened into anonymity before the weekend was out. The week began with horror at Eltham on the North-eastern edge of Melbourne. Eltham today is something of an artists' colony. Oil painters, water colourists, potters and sculptors proliferate. A number of University folk have emulated the example of Professor MacMahon Ball who pioneered the way by moving to Eltham and carving a home out of the bush in the thirties. Innermost Eltham is barely 14 miles from the G.P.O. Farthest Eltham stretches miles beyond. It served to illustrate the tragi-ludicrous truncation of Victoria's fire control. Part of Eltham is under the protection of the Melbourne Fire Brigade. But this responsibility ceases at some invisible and incomprehensible line — apparently determined by the meanderings of the water mains. At this point everybody's property throughout the rest of Eltham is dependent on the Country Fire Authority. Half an hour before midday on Wednesday, a fire suddenly started on the West side of Upper Glen road on the edge of Eltham. Before the fire brigade could arrive, it was burning on a widening front through timber and high grass north of Eltham. Two wind changes in rapid succession saw the fire leaping Diamond Creek. With a freshening wind it struck home after home in three streets. More than one of them exploded suddenly as if hit by an incendiary bomb. There is no piped gas in the Eltham area, hence many housewives use bottle gas. The flames outside caused the bottles to explode. Altogether twelve homes were completely incinerated and four more were badly damaged. Thirty prize dogs perished. About three hours after the fire started it raced suddenly down a gully hillside trapping an elderly man. Two other men apparently raced to the rescue. Flames caught the three men within yards of each other, not 200 yards off the Upper Glen Park Road where safety lay. They were burned to death. Next evening an angry and convincing secretary of the Fire Brigade Union, Mr. W. M. Webber, came on television and appealed to the people of Victoria to end the ridiculous and dangerous dualism in fire-fighting control. The Eltham fire, he said, had precisely illustrated the situation. The Metropolitan Fire Brigade area touched Eltham, but where the fire had gutted and killed, was just outside its area. Mr. Webber said his union had constantly urged one authority for the State with a complete reorganisation of fire protection. On Wednesday the union had repeated its call for an inquiry into fire protection in Victoria to the Chief Secretary, Mr Rylah. "No matter how close the liaison between the two organisations, there are always divided sections of thinking," Mr. Webber told viewers. "I don't know how much tragedy the com-munity can take before it demands that it is properly protected." Rumours that differences in gauge between taps and hose nozzles (as between the two authorities) accentuated the damage were denied by fire chiefs who said that all appliances were now carrying adaptors so that hoses could be linked to mains everywhere. But there is grave concern in the Metropolitan Fire Brigade's higher councils at the action of several Federal authorities with projects in and around Melbourne. They are installing non-standard equipment without reference to the State authorities or any dovetailing of appliances and equipment. Public alarm was not diminished by the publication on Friday and Saturday of a heart tearing letter from the young widow of John Lawrence Coleman, 31 year old father of two, who had died in the flames apparently trying to rescue the old man trapped in the gully. By that time, a Vast area of Gippsland was in flames and the troops had been sent in to back up the overworked and often helpless fire-fighters. By Saturday, the Leader of the Opposition, Mr. Stoneham, who has previously demanded a Royal Commission into fire-fighting arrangements, repeated his demand. To add to the Chief Secretary's worries he was publicly rebuked for allegedly implying on television that lives had been lost at Eltham because people went to the wrong place at the wrong time. In a letter to the Press, Professor MacMahon Ball pointed out that two of the men involved were experienced bushmen who had gone "to help an old man in great danger fully aware of the danger to themselves". As Victoria faced its sixth day of total State-wide fire ban, it looked likely that even official resistance was not going to silence the demand for one central authority to control the fire fiend. At the moment, the 400 square miles where two million Victorians live in Greater Melbourne are divorced from the rest of the State in planning, communications, equipment and control of personnel. No one doubts the whole-hearted co-operation and willingness to back each other up of the M.F.B. and the C.F.A., both at top-level and among the firemen themselves. However, when a city straggles so deeply into the country side, the absence of a single authority, to oversee and analyse the fire threat as a whole, suggests suicidal policy of divide and fuel. Emphasis of the tragic loss of a member of a pioneering family who died whilst helping others in his communitybushfire, cfa, country fire authority, fire brigrade, glen park road, heroes, john lawrence coleman, north eltham, victorian bushfires - 1965, volunteers, william john elwers, fire fighter, frank martin, george john crowe, ken gaston, orchard avenue, doug mummery, helen oliver, mrs henry marsden, mrs moureen ellis -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Bowl, Late 19th or early 20th Century

The Process of Making Pottery Decorating, Firing, Glazing, Making, Technical There is a rhythm and flow to clay. It can’t be done all at once! Even the making process! It can take weeks to get everything done, especially if you can only work on your pottery once a week! Even though we have three hour classes, it’s often just not enough time! Here is an overview of some of the processes so you have a bit more grasp on some of the technical stuff! Step One – Design There are SO many ideas out there for making stuff in clay! From delicate porcelain jewellery, through to heavy sculptural work and everything in between. Deciding your direction is sometimes not that easy – when you first start, try everything, you will naturally gravitate to the style that you enjoy! The options and variations are endless and can get a wee bit overwhelming too! Check in with me before you start to ensure your ideas will work, what order you might do things, how you could achieve the look you are seeking and any other technical data required! Step Two – Making Clay is thixotropic. This means that as you work with it, the clay first gets sloppier and wetter, before is begins to dry in the atmosphere. For most things, you simply can’t do all parts of the project at once. An example of work order might look like: Get last weeks work out from the shelves Prepare clay for today’s work – roll your clay, prepare balls for throwing, make the first stage of a pinch pot) Clean up last week’s work and put it on the shelf for bisque firing Check that you have any glazing to do – and do enough of it that you will have time to finish your main project Do the next step of your next project – there might be a further step that can’t be complete immediately, in that case, wrap your work well and put onto the shelves. Letting your work rest for a while can really help keep your work clean and professional looking. Many things require bagging under plastic to keep it ready for work the next week – put your name on the outside of the bag so you can find your work easily. We have stickers and markers. Consider how you want to decorate your work – coloured slip can be applied at a fairly wet stage (remembering that it will make your work even wetter!). Trying to apply slip to dry clay won’t work! If you want to do sgraffito – you will need to keep the work leather hard (a state of dryness where you can still work the clay with a little effort and a little water and care). Step Three – Drying Most of the time your work can go into the rack uncovered to let it dry out for the following week. If you want to continue forming or shaping you will need to double bag your work – put your work on a suitable sized bat and put the bat in a bag so the base of the bag is under the bat, then put another bag over the top of the work and tuck the top of the bag under the bat. If you want to trim (or turn) your thrown work the following week, it should also be double bagged. If your work is large, delicate, or of uneven thicknesses, you should lightly cover your work for drying. When considering the drying process, bare in mind the weather, humidity and wind! The hotter and dryer, the faster things dry and work can dry unevenly in the shelves – this can lead to cracking – another time to lightly cover your work for drying. Step Four – Trimming and Cleaning Up Your work is dry! It is called greenware now and it is at it’s most fragile! Handle everything with two hands. I often refer to soft hands – keep everything gentle and with your fingers spread as much as possible. Try to not pick up things like plates too much, and always with both hands! Before your work can be bisque fired it should be “cleaned up”. You work won’t go into the kiln if it has sharp edges – when glazed, sharp edges turn into razor blades! Use a piece of fly wire to rub the work all over – this will scratch a little so be light handed. Use a knife or metal kidney to scrape any areas that require a bit more dynamic treatment than the fly wire offers! Finally, a very light wipe over with a slightly damp sponge can help soften and soothe all of your edges and dags! Trimming thrown work: If you are planning to trim (or turn) your thrown work (and you should be), make sure you bag it well – your work should be leather hard to almost dry for easiest trimming. Use this step to finish the work completely – use a metal kidney to polish the surface, or a slightly damp sponge to give a freshly thrown look. Wipe the sponge around the rim after trimming, and check the inside of the pot for dags! Trimming slip cast work: Usually I will trim the rims of your work on the wheel the following day to make that stage easier, however you will still need to check your work for lumps and bumps. Last but not least – check that your name is still clearly on the bottom of your work. Step Five – Bisque Firing When the work is completely dry it can go into the bisque kiln. The bisque kiln is fired to 1000°C. This process burns off the water in the clay as well as some of the chemically bound water. The structure of the clay is not altered that much at this temperature. Inside the bisque kiln, the work is stacked a little, small bowl inside a larger bowl and onto a heavy plate. Smaller items like decorations or drink coasters might get stacked several high. Consideration is paid to the weight of the stack and shape of the work. A bisque kiln can fire about one and a half times the amount of work that the glaze kiln can fire. The firing takes about 10 hours to complete the cycle and about two days to cool down. Once it has been emptied the work is placed in the glaze room ready for you to decorate! Step Six – Glazing Decorating your work with colour can be a lot of fun – and time consuming! There are three main options for surface treatment at this stage: Oxide Washes Underglazes Glazes Washes and underglazes do not “glaze” the work – It will still need a layer of glaze to fully seal the clay (washes don’t need glaze on surfaces not designed for food or liquid as they can gloss up a little on their own). Underglazes are stable colourants that turn out pretty much how they look in the jar. They can be mixed with each other to form other colours and can be used like water colours to paint onto your work. Mostly they should have a clear glaze on top to seal them. Oxides are a different species – the pink oxide (cobalt) wash turns out bright blue for instance. They don’t always need a glaze on top, and some glazes can change the colour of the wash! The glazes need no other “glaze” on top! Be careful of unknown glaze interactions – you can put any combination of glaze in a bowl or on a plate, but only a single glaze on the outside of any vertical surface! Glazes are a chemical reaction under heat. We don’t know the exact chemicals in the Mayco glazes we use. I can guess by the way they interact with each other, however, on the whole, you need to test every idea you have, and not run the test on a vertical surface! Simply put, glaze is a layer of glass like substance that bonds with the clay underneath. Clay is made of silica, alumina and water. Glaze is made of mostly silica. Silica has a melting point of 1700°C and we fire to 1240°C. The silica requires a “flux” to help it melt at the lower temperature. Fluxes can be all sorts of chemicals – a common one is calcium – calcium has a melting point of 2500°C, however, together they both melt at a much lower temperature! Colourants are metal oxides like cobalt (blue), chrome (green through black), copper (green, blue, even red!), manganese (black, purple and pink) iron (red brown), etc. Different chemicals in the glaze can have dramatic effects. for example, barium carbonate (which we don’t use) turns manganese bright pink! Other elements can turn manganese dioxide brown, blue, purple and reddish brown. Manganese dioxide is a flux in and of itself as well. So, glazes that get their black and purple colours, often interact with other glazes and RUN! Our mirror black is a good example – it mixes really well with many glazes because it fluxes them – causes them to melt faster. It will also bring out many beautiful colours in the glazes because it’s black colouring most definitely comes from manganese dioxide! Glaze chemistry is a whole subject on it’s own! We use commercial Mayco glazes on purpose – for their huge range of colour possibilities, stability, cool interactions, artistic freedom with the ability to easily brush the glazes on and ease of use. We currently have almost 50 glazes on hand! A major project is to test the interactions of all glazes with each other. That is 2,500 test tiles!!!! I’m going to make the wall behind the wheels the feature wall of pretty colours! Step Seven – Glaze (Gloss or sometimes called “Glost”) Firing Most of the time this is the final stage of making your creation (but not always!) The glaze kiln goes to 1240°C. This is called cone 6, or midrange. It is the low end of stoneware temperatures. Stoneware clays and glazes are typically fired at cone 8 – 10, that is 1260 – 1290°C. The energy requirement to go from 1240°C to 1280°C is almost a 30% more! Our clay is formulated to vitrify (mature, turn “glass-like”) at 1240°, as are our glazes. A glaze kiln take around 12 hours to reach temperature and two to three days to cool down. Sometimes a third firing process is required – this is for decoration that is added to work after the glaze firing. For example – adding precious metals and lustres. this firing temperature is usually around 600 – 800°C depending upon the techniques being used. There are many students interested in gold and silver trims – we will be doing this third type of firing soon! After firing your work will be in the student finished work shelves. Remember to pay for it before you head out the door! There is a small extra charge for using porcelain clay (it’s more than twice the price of regular clay), and for any third firing process! Once your work has been fired it can not turn back into clay for millennia – so don’t fire it if you don’t like it! Put it in the bucket for recycling. https://firebirdstudios.com.au/the-process-of-making-pottery/ The bowl is an example of kitchenware used in the 19th century and still in use today.Bowl white ceramic. Crack on side. Badly stained.Backstamp very faint and unable to be read.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, mixing bowl, food preparation, kitchen equipment, ceramic -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Bowl

The Process of Making Pottery Decorating, Firing, Glazing, Making, Technical There is a rhythm and flow to clay. It can’t be done all at once! Even the making process! It can take weeks to get everything done, especially if you can only work on your pottery once a week! Even though we have three hour classes, it’s often just not enough time! Here is an overview of some of the processes so you have a bit more grasp on some of the technical stuff! Step One – Design There are SO many ideas out there for making stuff in clay! From delicate porcelain jewellery, through to heavy sculptural work and everything in between. Deciding your direction is sometimes not that easy – when you first start, try everything, you will naturally gravitate to the style that you enjoy! The options and variations are endless and can get a wee bit overwhelming too! Check in with me before you start to ensure your ideas will work, what order you might do things, how you could achieve the look you are seeking and any other technical data required! Step Two – Making Clay is thixotropic. This means that as you work with it, the clay first gets sloppier and wetter, before is begins to dry in the atmosphere. For most things, you simply can’t do all parts of the project at once. An example of work order might look like: Get last weeks work out from the shelves Prepare clay for today’s work – roll your clay, prepare balls for throwing, make the first stage of a pinch pot) Clean up last week’s work and put it on the shelf for bisque firing Check that you have any glazing to do – and do enough of it that you will have time to finish your main project Do the next step of your next project – there might be a further step that can’t be complete immediately, in that case, wrap your work well and put onto the shelves. Letting your work rest for a while can really help keep your work clean and professional looking. Many things require bagging under plastic to keep it ready for work the next week – put your name on the outside of the bag so you can find your work easily. We have stickers and markers. Consider how you want to decorate your work – coloured slip can be applied at a fairly wet stage (remembering that it will make your work even wetter!). Trying to apply slip to dry clay won’t work! If you want to do sgraffito – you will need to keep the work leather hard (a state of dryness where you can still work the clay with a little effort and a little water and care). Step Three – Drying Most of the time your work can go into the rack uncovered to let it dry out for the following week. If you want to continue forming or shaping you will need to double bag your work – put your work on a suitable sized bat and put the bat in a bag so the base of the bag is under the bat, then put another bag over the top of the work and tuck the top of the bag under the bat. If you want to trim (or turn) your thrown work the following week, it should also be double bagged. If your work is large, delicate, or of uneven thicknesses, you should lightly cover your work for drying. When considering the drying process, bare in mind the weather, humidity and wind! The hotter and dryer, the faster things dry and work can dry unevenly in the shelves – this can lead to cracking – another time to lightly cover your work for drying. Step Four – Trimming and Cleaning Up Your work is dry! It is called greenware now and it is at it’s most fragile! Handle everything with two hands. I often refer to soft hands – keep everything gentle and with your fingers spread as much as possible. Try to not pick up things like plates too much, and always with both hands! Before your work can be bisque fired it should be “cleaned up”. You work won’t go into the kiln if it has sharp edges – when glazed, sharp edges turn into razor blades! Use a piece of fly wire to rub the work all over – this will scratch a little so be light handed. Use a knife or metal kidney to scrape any areas that require a bit more dynamic treatment than the fly wire offers! Finally, a very light wipe over with a slightly damp sponge can help soften and soothe all of your edges and dags! Trimming thrown work: If you are planning to trim (or turn) your thrown work (and you should be), make sure you bag it well – your work should be leather hard to almost dry for easiest trimming. Use this step to finish the work completely – use a metal kidney to polish the surface, or a slightly damp sponge to give a freshly thrown look. Wipe the sponge around the rim after trimming, and check the inside of the pot for dags! Trimming slip cast work: Usually I will trim the rims of your work on the wheel the following day to make that stage easier, however you will still need to check your work for lumps and bumps. Last but not least – check that your name is still clearly on the bottom of your work. Step Five – Bisque Firing When the work is completely dry it can go into the bisque kiln. The bisque kiln is fired to 1000°C. This process burns off the water in the clay as well as some of the chemically bound water. The structure of the clay is not altered that much at this temperature. Inside the bisque kiln, the work is stacked a little, small bowl inside a larger bowl and onto a heavy plate. Smaller items like decorations or drink coasters might get stacked several high. Consideration is paid to the weight of the stack and shape of the work. A bisque kiln can fire about one and a half times the amount of work that the glaze kiln can fire. The firing takes about 10 hours to complete the cycle and about two days to cool down. Once it has been emptied the work is placed in the glaze room ready for you to decorate! Step Six – Glazing Decorating your work with colour can be a lot of fun – and time consuming! There are three main options for surface treatment at this stage: Oxide Washes Underglazes Glazes Washes and underglazes do not “glaze” the work – It will still need a layer of glaze to fully seal the clay (washes don’t need glaze on surfaces not designed for food or liquid as they can gloss up a little on their own). Underglazes are stable colourants that turn out pretty much how they look in the jar. They can be mixed with each other to form other colours and can be used like water colours to paint onto your work. Mostly they should have a clear glaze on top to seal them. Oxides are a different species – the pink oxide (cobalt) wash turns out bright blue for instance. They don’t always need a glaze on top, and some glazes can change the colour of the wash! The glazes need no other “glaze” on top! Be careful of unknown glaze interactions – you can put any combination of glaze in a bowl or on a plate, but only a single glaze on the outside of any vertical surface! Glazes are a chemical reaction under heat. We don’t know the exact chemicals in the Mayco glazes we use. I can guess by the way they interact with each other, however, on the whole, you need to test every idea you have, and not run the test on a vertical surface! Simply put, glaze is a layer of glass like substance that bonds with the clay underneath. Clay is made of silica, alumina and water. Glaze is made of mostly silica. Silica has a melting point of 1700°C and we fire to 1240°C. The silica requires a “flux” to help it melt at the lower temperature. Fluxes can be all sorts of chemicals – a common one is calcium – calcium has a melting point of 2500°C, however, together they both melt at a much lower temperature! Colourants are metal oxides like cobalt (blue), chrome (green through black), copper (green, blue, even red!), manganese (black, purple and pink) iron (red brown), etc. Different chemicals in the glaze can have dramatic effects. for example, barium carbonate (which we don’t use) turns manganese bright pink! Other elements can turn manganese dioxide brown, blue, purple and reddish brown. Manganese dioxide is a flux in and of itself as well. So, glazes that get their black and purple colours, often interact with other glazes and RUN! Our mirror black is a good example – it mixes really well with many glazes because it fluxes them – causes them to melt faster. It will also bring out many beautiful colours in the glazes because it’s black colouring most definitely comes from manganese dioxide! Glaze chemistry is a whole subject on it’s own! We use commercial Mayco glazes on purpose – for their huge range of colour possibilities, stability, cool interactions, artistic freedom with the ability to easily brush the glazes on and ease of use. We currently have almost 50 glazes on hand! A major project is to test the interactions of all glazes with each other. That is 2,500 test tiles!!!! I’m going to make the wall behind the wheels the feature wall of pretty colours! Step Seven – Glaze (Gloss or sometimes called “Glost”) Firing Most of the time this is the final stage of making your creation (but not always!) The glaze kiln goes to 1240°C. This is called cone 6, or midrange. It is the low end of stoneware temperatures. Stoneware clays and glazes are typically fired at cone 8 – 10, that is 1260 – 1290°C. The energy requirement to go from 1240°C to 1280°C is almost a 30% more! Our clay is formulated to vitrify (mature, turn “glass-like”) at 1240°, as are our glazes. A glaze kiln take around 12 hours to reach temperature and two to three days to cool down. Sometimes a third firing process is required – this is for decoration that is added to work after the glaze firing. For example – adding precious metals and lustres. this firing temperature is usually around 600 – 800°C depending upon the techniques being used. There are many students interested in gold and silver trims – we will be doing this third type of firing soon! After firing your work will be in the student finished work shelves. Remember to pay for it before you head out the door! There is a small extra charge for using porcelain clay (it’s more than twice the price of regular clay), and for any third firing process! Once your work has been fired it can not turn back into clay for millennia – so don’t fire it if you don’t like it! Put it in the bucket for recycling. https://firebirdstudios.com.au/the-process-of-making-pottery/ This bowl is an example of kitchenware used in the 19th century and still in use today.Bowl white ceramic plain that has two sets of edging around lip. Inside bowl has plaster designed to look like cooking mixture.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, kitchen equipment, ceramic -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Bowl, J & G Meakin, Late 19th or early 20th Century

The Process of Making Pottery Decorating, Firing, Glazing, Making, Technical There is a rhythm and flow to clay. It can’t be done all at once! Even the making process! It can take weeks to get everything done, especially if you can only work on your pottery once a week! Even though we have three hour classes, it’s often just not enough time! Here is an overview of some of the processes so you have a bit more grasp on some of the technical stuff! Step One – Design There are SO many ideas out there for making stuff in clay! From delicate porcelain jewellery, through to heavy sculptural work and everything in between. Deciding your direction is sometimes not that easy – when you first start, try everything, you will naturally gravitate to the style that you enjoy! The options and variations are endless and can get a wee bit overwhelming too! Check in with me before you start to ensure your ideas will work, what order you might do things, how you could achieve the look you are seeking and any other technical data required! Step Two – Making Clay is thixotropic. This means that as you work with it, the clay first gets sloppier and wetter, before is begins to dry in the atmosphere. For most things, you simply can’t do all parts of the project at once. An example of work order might look like: Get last weeks work out from the shelves Prepare clay for today’s work – roll your clay, prepare balls for throwing, make the first stage of a pinch pot) Clean up last week’s work and put it on the shelf for bisque firing Check that you have any glazing to do – and do enough of it that you will have time to finish your main project Do the next step of your next project – there might be a further step that can’t be complete immediately, in that case, wrap your work well and put onto the shelves. Letting your work rest for a while can really help keep your work clean and professional looking. Many things require bagging under plastic to keep it ready for work the next week – put your name on the outside of the bag so you can find your work easily. We have stickers and markers. Consider how you want to decorate your work – coloured slip can be applied at a fairly wet stage (remembering that it will make your work even wetter!). Trying to apply slip to dry clay won’t work! If you want to do sgraffito – you will need to keep the work leather hard (a state of dryness where you can still work the clay with a little effort and a little water and care). Step Three – Drying Most of the time your work can go into the rack uncovered to let it dry out for the following week. If you want to continue forming or shaping you will need to double bag your work – put your work on a suitable sized bat and put the bat in a bag so the base of the bag is under the bat, then put another bag over the top of the work and tuck the top of the bag under the bat. If you want to trim (or turn) your thrown work the following week, it should also be double bagged. If your work is large, delicate, or of uneven thicknesses, you should lightly cover your work for drying. When considering the drying process, bare in mind the weather, humidity and wind! The hotter and dryer, the faster things dry and work can dry unevenly in the shelves – this can lead to cracking – another time to lightly cover your work for drying. Step Four – Trimming and Cleaning Up Your work is dry! It is called greenware now and it is at it’s most fragile! Handle everything with two hands. I often refer to soft hands – keep everything gentle and with your fingers spread as much as possible. Try to not pick up things like plates too much, and always with both hands! Before your work can be bisque fired it should be “cleaned up”. You work won’t go into the kiln if it has sharp edges – when glazed, sharp edges turn into razor blades! Use a piece of fly wire to rub the work all over – this will scratch a little so be light handed. Use a knife or metal kidney to scrape any areas that require a bit more dynamic treatment than the fly wire offers! Finally, a very light wipe over with a slightly damp sponge can help soften and soothe all of your edges and dags! Trimming thrown work: If you are planning to trim (or turn) your thrown work (and you should be), make sure you bag it well – your work should be leather hard to almost dry for easiest trimming. Use this step to finish the work completely – use a metal kidney to polish the surface, or a slightly damp sponge to give a freshly thrown look. Wipe the sponge around the rim after trimming, and check the inside of the pot for dags! Trimming slip cast work: Usually I will trim the rims of your work on the wheel the following day to make that stage easier, however you will still need to check your work for lumps and bumps. Last but not least – check that your name is still clearly on the bottom of your work. Step Five – Bisque Firing When the work is completely dry it can go into the bisque kiln. The bisque kiln is fired to 1000°C. This process burns off the water in the clay as well as some of the chemically bound water. The structure of the clay is not altered that much at this temperature. Inside the bisque kiln, the work is stacked a little, small bowl inside a larger bowl and onto a heavy plate. Smaller items like decorations or drink coasters might get stacked several high. Consideration is paid to the weight of the stack and shape of the work. A bisque kiln can fire about one and a half times the amount of work that the glaze kiln can fire. The firing takes about 10 hours to complete the cycle and about two days to cool down. Once it has been emptied the work is placed in the glaze room ready for you to decorate! Step Six – Glazing Decorating your work with colour can be a lot of fun – and time consuming! There are three main options for surface treatment at this stage: Oxide Washes Underglazes Glazes Washes and underglazes do not “glaze” the work – It will still need a layer of glaze to fully seal the clay (washes don’t need glaze on surfaces not designed for food or liquid as they can gloss up a little on their own). Underglazes are stable colourants that turn out pretty much how they look in the jar. They can be mixed with each other to form other colours and can be used like water colours to paint onto your work. Mostly they should have a clear glaze on top to seal them. Oxides are a different species – the pink oxide (cobalt) wash turns out bright blue for instance. They don’t always need a glaze on top, and some glazes can change the colour of the wash! The glazes need no other “glaze” on top! Be careful of unknown glaze interactions – you can put any combination of glaze in a bowl or on a plate, but only a single glaze on the outside of any vertical surface! Glazes are a chemical reaction under heat. We don’t know the exact chemicals in the Mayco glazes we use. I can guess by the way they interact with each other, however, on the whole, you need to test every idea you have, and not run the test on a vertical surface! Simply put, glaze is a layer of glass like substance that bonds with the clay underneath. Clay is made of silica, alumina and water. Glaze is made of mostly silica. Silica has a melting point of 1700°C and we fire to 1240°C. The silica requires a “flux” to help it melt at the lower temperature. Fluxes can be all sorts of chemicals – a common one is calcium – calcium has a melting point of 2500°C, however, together they both melt at a much lower temperature! Colourants are metal oxides like cobalt (blue), chrome (green through black), copper (green, blue, even red!), manganese (black, purple and pink) iron (red brown), etc. Different chemicals in the glaze can have dramatic effects. for example, barium carbonate (which we don’t use) turns manganese bright pink! Other elements can turn manganese dioxide brown, blue, purple and reddish brown. Manganese dioxide is a flux in and of itself as well. So, glazes that get their black and purple colours, often interact with other glazes and RUN! Our mirror black is a good example – it mixes really well with many glazes because it fluxes them – causes them to melt faster. It will also bring out many beautiful colours in the glazes because it’s black colouring most definitely comes from manganese dioxide! Glaze chemistry is a whole subject on it’s own! We use commercial Mayco glazes on purpose – for their huge range of colour possibilities, stability, cool interactions, artistic freedom with the ability to easily brush the glazes on and ease of use. We currently have almost 50 glazes on hand! A major project is to test the interactions of all glazes with each other. That is 2,500 test tiles!!!! I’m going to make the wall behind the wheels the feature wall of pretty colours! Step Seven – Glaze (Gloss or sometimes called “Glost”) Firing Most of the time this is the final stage of making your creation (but not always!) The glaze kiln goes to 1240°C. This is called cone 6, or midrange. It is the low end of stoneware temperatures. Stoneware clays and glazes are typically fired at cone 8 – 10, that is 1260 – 1290°C. The energy requirement to go from 1240°C to 1280°C is almost a 30% more! Our clay is formulated to vitrify (mature, turn “glass-like”) at 1240°, as are our glazes. A glaze kiln take around 12 hours to reach temperature and two to three days to cool down. Sometimes a third firing process is required – this is for decoration that is added to work after the glaze firing. For example – adding precious metals and lustres. this firing temperature is usually around 600 – 800°C depending upon the techniques being used. There are many students interested in gold and silver trims – we will be doing this third type of firing soon! After firing your work will be in the student finished work shelves. Remember to pay for it before you head out the door! There is a small extra charge for using porcelain clay (it’s more than twice the price of regular clay), and for any third firing process! Once your work has been fired it can not turn back into clay for millennia – so don’t fire it if you don’t like it! Put it in the bucket for recycling. https://firebirdstudios.com.au/the-process-of-making-pottery/This bowl was made by renowned pottery company J & G Meakin of England. The firm was established in the mid-1800's. The bowl is an example of kitchenware used in the 19th century and still in use today.Bowl; white ceramic, round and tapering inwards towards base. Made by J and G Meakin England.On base, 'Ironstone China Reg SOL 391413' with symbolflagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, mixing bowl, food preparation, j & g meakin, pottery, stoke-on-trent, kitchen equipment, ceramic -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Plate

The Process of Making Pottery Decorating, Firing, Glazing, Making, Technical There is a rhythm and flow to clay. It can’t be done all at once! Even the making process! It can take weeks to get everything done, especially if you can only work on your pottery once a week! Even though we have three hour classes, it’s often just not enough time! Here is an overview of some of the processes so you have a bit more grasp on some of the technical stuff! Step One – Design There are SO many ideas out there for making stuff in clay! From delicate porcelain jewellery, through to heavy sculptural work and everything in between. Deciding your direction is sometimes not that easy – when you first start, try everything, you will naturally gravitate to the style that you enjoy! The options and variations are endless and can get a wee bit overwhelming too! Check in with me before you start to ensure your ideas will work, what order you might do things, how you could achieve the look you are seeking and any other technical data required! Step Two – Making Clay is thixotropic. This means that as you work with it, the clay first gets sloppier and wetter, before is begins to dry in the atmosphere. For most things, you simply can’t do all parts of the project at once. An example of work order might look like: Get last weeks work out from the shelves Prepare clay for today’s work – roll your clay, prepare balls for throwing, make the first stage of a pinch pot) Clean up last week’s work and put it on the shelf for bisque firing Check that you have any glazing to do – and do enough of it that you will have time to finish your main project Do the next step of your next project – there might be a further step that can’t be complete immediately, in that case, wrap your work well and put onto the shelves. Letting your work rest for a while can really help keep your work clean and professional looking. Many things require bagging under plastic to keep it ready for work the next week – put your name on the outside of the bag so you can find your work easily. We have stickers and markers. Consider how you want to decorate your work – coloured slip can be applied at a fairly wet stage (remembering that it will make your work even wetter!). Trying to apply slip to dry clay won’t work! If you want to do sgraffito – you will need to keep the work leather hard (a state of dryness where you can still work the clay with a little effort and a little water and care). Step Three – Drying Most of the time your work can go into the rack uncovered to let it dry out for the following week. If you want to continue forming or shaping you will need to double bag your work – put your work on a suitable sized bat and put the bat in a bag so the base of the bag is under the bat, then put another bag over the top of the work and tuck the top of the bag under the bat. If you want to trim (or turn) your thrown work the following week, it should also be double bagged. If your work is large, delicate, or of uneven thicknesses, you should lightly cover your work for drying. When considering the drying process, bare in mind the weather, humidity and wind! The hotter and dryer, the faster things dry and work can dry unevenly in the shelves – this can lead to cracking – another time to lightly cover your work for drying. Step Four – Trimming and Cleaning Up Your work is dry! It is called greenware now and it is at it’s most fragile! Handle everything with two hands. I often refer to soft hands – keep everything gentle and with your fingers spread as much as possible. Try to not pick up things like plates too much, and always with both hands! Before your work can be bisque fired it should be “cleaned up”. You work won’t go into the kiln if it has sharp edges – when glazed, sharp edges turn into razor blades! Use a piece of fly wire to rub the work all over – this will scratch a little so be light handed. Use a knife or metal kidney to scrape any areas that require a bit more dynamic treatment than the fly wire offers! Finally, a very light wipe over with a slightly damp sponge can help soften and soothe all of your edges and dags! Trimming thrown work: If you are planning to trim (or turn) your thrown work (and you should be), make sure you bag it well – your work should be leather hard to almost dry for easiest trimming. Use this step to finish the work completely – use a metal kidney to polish the surface, or a slightly damp sponge to give a freshly thrown look. Wipe the sponge around the rim after trimming, and check the inside of the pot for dags! Trimming slip cast work: Usually I will trim the rims of your work on the wheel the following day to make that stage easier, however you will still need to check your work for lumps and bumps. Last but not least – check that your name is still clearly on the bottom of your work. Step Five – Bisque Firing When the work is completely dry it can go into the bisque kiln. The bisque kiln is fired to 1000°C. This process burns off the water in the clay as well as some of the chemically bound water. The structure of the clay is not altered that much at this temperature. Inside the bisque kiln, the work is stacked a little, small bowl inside a larger bowl and onto a heavy plate. Smaller items like decorations or drink coasters might get stacked several high. Consideration is paid to the weight of the stack and shape of the work. A bisque kiln can fire about one and a half times the amount of work that the glaze kiln can fire. The firing takes about 10 hours to complete the cycle and about two days to cool down. Once it has been emptied the work is placed in the glaze room ready for you to decorate! Step Six – Glazing Decorating your work with colour can be a lot of fun – and time consuming! There are three main options for surface treatment at this stage: Oxide Washes Underglazes Glazes Washes and underglazes do not “glaze” the work – It will still need a layer of glaze to fully seal the clay (washes don’t need glaze on surfaces not designed for food or liquid as they can gloss up a little on their own). Underglazes are stable colourants that turn out pretty much how they look in the jar. They can be mixed with each other to form other colours and can be used like water colours to paint onto your work. Mostly they should have a clear glaze on top to seal them. Oxides are a different species – the pink oxide (cobalt) wash turns out bright blue for instance. They don’t always need a glaze on top, and some glazes can change the colour of the wash! The glazes need no other “glaze” on top! Be careful of unknown glaze interactions – you can put any combination of glaze in a bowl or on a plate, but only a single glaze on the outside of any vertical surface! Glazes are a chemical reaction under heat. We don’t know the exact chemicals in the Mayco glazes we use. I can guess by the way they interact with each other, however, on the whole, you need to test every idea you have, and not run the test on a vertical surface! Simply put, glaze is a layer of glass like substance that bonds with the clay underneath. Clay is made of silica, alumina and water. Glaze is made of mostly silica. Silica has a melting point of 1700°C and we fire to 1240°C. The silica requires a “flux” to help it melt at the lower temperature. Fluxes can be all sorts of chemicals – a common one is calcium – calcium has a melting point of 2500°C, however, together they both melt at a much lower temperature! Colourants are metal oxides like cobalt (blue), chrome (green through black), copper (green, blue, even red!), manganese (black, purple and pink) iron (red brown), etc. Different chemicals in the glaze can have dramatic effects. for example, barium carbonate (which we don’t use) turns manganese bright pink! Other elements can turn manganese dioxide brown, blue, purple and reddish brown. Manganese dioxide is a flux in and of itself as well. So, glazes that get their black and purple colours, often interact with other glazes and RUN! Our mirror black is a good example – it mixes really well with many glazes because it fluxes them – causes them to melt faster. It will also bring out many beautiful colours in the glazes because it’s black colouring most definitely comes from manganese dioxide! Glaze chemistry is a whole subject on it’s own! We use commercial Mayco glazes on purpose – for their huge range of colour possibilities, stability, cool interactions, artistic freedom with the ability to easily brush the glazes on and ease of use. We currently have almost 50 glazes on hand! A major project is to test the interactions of all glazes with each other. That is 2,500 test tiles!!!! I’m going to make the wall behind the wheels the feature wall of pretty colours! Step Seven – Glaze (Gloss or sometimes called “Glost”) Firing Most of the time this is the final stage of making your creation (but not always!) The glaze kiln goes to 1240°C. This is called cone 6, or midrange. It is the low end of stoneware temperatures. Stoneware clays and glazes are typically fired at cone 8 – 10, that is 1260 – 1290°C. The energy requirement to go from 1240°C to 1280°C is almost a 30% more! Our clay is formulated to vitrify (mature, turn “glass-like”) at 1240°, as are our glazes. A glaze kiln take around 12 hours to reach temperature and two to three days to cool down. Sometimes a third firing process is required – this is for decoration that is added to work after the glaze firing. For example – adding precious metals and lustres. this firing temperature is usually around 600 – 800°C depending upon the techniques being used. There are many students interested in gold and silver trims – we will be doing this third type of firing soon! After firing your work will be in the student finished work shelves. Remember to pay for it before you head out the door! There is a small extra charge for using porcelain clay (it’s more than twice the price of regular clay), and for any third firing process! Once your work has been fired it can not turn back into clay for millennia – so don’t fire it if you don’t like it! Put it in the bucket for recycling. https://firebirdstudios.com.au/the-process-of-making-pottery/Ceramics have evolved over thousands of years.White earthenware dinner plate. Crazing evident all over.Backstamped ‘Made in England S LTD’flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, ceramics, tableware -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Plate, Alfred Meakin