Showing 161 items

matching grind

-

Orbost & District Historical Society

Orbost & District Historical Societyaxe head

Inspected by Joonna Freslov, archaeologist 2.6.2008. Stone tools were used for a variety of purposes, in ways similar to those of steel knives, axes, hammers and chisels. Ground-edge tools are made from fracture-resistant stone, such as basalt which is able to withstand repeated impact, and is suitable for use in objects such as stone axes. The stone was quarried, and then roughly shaped into a tool blank with blows from a hammerstone. The edges were then sharpened and refined by grinding the tool against a coarse, gritty rock.The necessary tools and equipment for hunting, fishing and warfare were one of the very few items that Aboriginals carried with them from place to place. Most were used for a multiplicity of purposes. Because many were made from raw natural materials, such as wood, generally only partial remains are found today. This axe head is an example of an early stone tool used by the Indigenous people of Eastern Australia.A handmade stone Aboriginal axe head. Finger grips are clear.axehead aboriginal tool stone-artefact -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Tools, whetstone , 'Bridestowe' with box, 20thC

A Whetstone is a sharpening stone used for knives and other cutting tools. Sharpening stones, water stones or whetstones are used to grind and hone the edges of steel tools and implements e.g. scissors, scythes, knives, razors and tools such as chisels, hand scrapers and plane blades. Though it is sometimes mistaken as a reference to the water often used to lubricate such stones, the word "whetstone" is a compound word formed with the word "whet", which means to sharpen a blade, not the word "wet". The process of using a sharpening stone is called stoning.A square block of grey abrasive material used for sharpening steel blades , with the original boxBRIDESTOWE / Picture of ‘Kangaroo, Stag and Emu among radiating wheat stalks’ / TASMANIAwhetstones, sharpeners, steel blades, tools, cutlery, razors, moorabbin, bentleigh, cheltenham, early settlers, -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyMincer Meat, early to mid 1900's

This cast iron kitchen appliance was made in England in the early 1900's and shipped to the "colony" Australia. This was before World War II and the "growing up" of a colony to an independent member of "the British Commonwealth". It was a period when most appliances (be they household) where manufactured in England and shipped to Australian ports. It was not until the late 1960's that the Asian manufacturing giant woke up and started to dominate the market palce.This domestic kitchen appliance is very significant to the Kiewa Valley because it highlights the "made at home" period when food processing was made "in house" due to inability to source food from specialised shops e.g. the butcher or slaughter houses. It was a period before mass food processing factories were established and roads constructed up to the standard for distribution to semi remote regions such as Kiewa Valley was in the beginning of the 1900's.This cast iron (malleable iron) mincer for meat products has a large "funnel" to direct "chunks" of meat to the grinding "wheels". These "star" shaped wheels with "teeth" of three different cutting surfaces (fine, medium and coarse) provide for texture types of the final meat product. The meat is placed into the "loading" funnel and push downwards(gravity feed) through the mincing chamber and out through the front side. There is a long "screw worm" which is rotated by turning the handle. The appliance is table mounted by a vice "G" screw on clamp (hand operated). "BEATRICE No. 3" and "MADE IN ENGLAND", "P 3181"household cast iron appliances, food processors -

Churchill Island Heritage Farm

Churchill Island Heritage FarmFunctional object - mincing machine

Made and imported by Swedish company, Husqvarna, this machine was used to mince larger pieces of meat. The grinder was clamped securely to a table, and meat was then fed into the machine through the funnel at the top. The wooden crank handle was turned, moving the spiral grinding mechanism, and pushing the meat through the sieve-like fitting at the end. While hand mincers were ubiquitous in the late nineteenth and early twentieth-century kitchens, and was responsible for reducing food waste and promoting frugal ideals, the Husqvarna brand sold over 12 million worldwide.Hand operated mincing machine, larger than usual, with multi small holed attachment in place. Tin plating worn off top edge of bell. Plan wooden handle. Stamped with name, number, etc.HUSQVARNA 10 one side; also on attachment holder. RELIANCE/MADE IN SWEDEN + five pointed star on other side. "H" stamped on crank inside.husqvarna, mincer, hand, kitchen tool -

Warrnambool and District Historical Society Inc.

Warrnambool and District Historical Society Inc.Domestic object - Bean Slicer, Spong & Co, England, c.1920

This bean slicer was made about the 1920s by the British firm of Spong & Co. This firm was founded by James Osborn Spong in 1856 in London. James Spong invented over 100 labour-saving devices during his lifetime and his firm became well-known for its production of domestic labour-saving and safety devices, especially its grinding machine and its bean slicer. These domestic items were to be found in most households from the 1880s to the 1950s prior to the advent of electrical items that carried out similar labour-saving processes. This bean slicer is of interest as a reminder of the many labour -saving devices that were available to most women early in the 20th century, even those in the rural and more remote areas in AustraliaThis a heavy metal bean slicer with a circular piece with a rounded cut-out at the top for the insertion of the bean and an attached bolted handle with a wooden top. Attached to the circular top is a circular revolving piece with three cutters. Welded on to the top piece is a metal clamp with a large screw for attaching the slicer to a table or bench. The slicer is painted green and has the name of the manufacturer etched on the top piece.Spong & Co Ltd Made In England No 632 Bean Slicervintage bean slicers, spong & co london, vintage household items -

Orbost & District Historical Society

Orbost & District Historical Societyaxe head

Inspected by Joanna Freslov, archaeologist 2/6/2008. Genuine Aboriginal axe head up to 2000 years old. Possibly came through trading from western district. Stone tools were used for a variety of purposes, in ways similar to those of the steel knives, axes, hammers and chisels. Ground-edge tools are made from fracture-resistant stone, such as basalt.This stone is able to withstand repeated impact, and and wqas generall used for stone axes. The stone was dug or found and then roughly shaped into a tool blank with blows from a hammerstone. The edges were then sharpened and refined by grinding the tool against a coarse, gritty rock. The necessary tools and equipment for hunting, fishing and warfare were one of the very few items that Aboriginals carried with them from place to place. Most were used for a multiplicity of purposes. Because many were made from raw natural materials, such as wood, generally only partial remains are found today. This axe head is an example of an early stone tool used by the Indigenous people of Victoria.Small grey oval-shaped axe head.axehead stone-artifact aboriginal tool -

Orbost & District Historical Society

Orbost & District Historical Societyaxe head

Inspected by Joanna Freslov, archaeologist 2.6.2008. Ground-edged axes first appeared in south-eastern Australia about 4,000 years ago and were used either with handles or hand-held. Stone tools were used for a variety of purposes, in ways similar to those of steel knives, axes, hammers and chisels. Ground-edge tools are made from fracture-resistant stone, such as basalt. This is able to withstand repeated impact making it suitable for use in objects such as stone axes. The stone was quarried, and then roughly shaped into a tool blank with blows from a hammerstone. The edges were then sharpened and refined by grinding the tool against a coarse, gritty rock. The necessary tools and equipment for hunting, fishing and warfare were one of the very few items that Aboriginals carried with them from place to place. Most were used for a multiplicity of purposes. Because many were made from raw natural materials, such as wood, generally only partial remains are found today. This item is an example of a stone tool used by the early Indigenous people of Eastern australia.A handmade stone Aboriginal axe head.axe-head aboriginal tool stone-artefact -

Orbost & District Historical Society

Orbost & District Historical Societyaxe head

Inspected by Joanna Freslov, archaeologist 2.6.2008 Ground-edged axes first appeared in south-eastern Australia about 4,000 years ago and were used either with handles or hand-held. Stone tools were used for a variety of purposes, in ways similar to those of steel knives, axes, hammers and chisels. Ground-edge tools are made from fracture-resistant stone, such as basalt which is able to withstand repeated impact, and so is suitable for use in objects such as stone axes. The stone was quarried, and then roughly shaped into a tool blank with blows from a hammerstone. The edges were then sharpened and refined by grinding the tool against a coarse, gritty rockThe necessary tools and equipment for hunting, fishing and warfare were one of the very few items that Aboriginals carried with them from place to place. Most were used for a multiplicity of purposes. Because many were made from raw natural materials, such as wood, generally only partial remains are found today. This item is an example of an early axe head used by the Indigenous people of East Gippsland.A handmade stone Aboriginal axe head.aboriginal tool stone-artefact axe-head -

Wodonga & District Historical Society Inc

Wodonga & District Historical Society IncDomestic object - Food vitamiser, Semak, c1950

Semak is an Australian company, manufacturing Australian-Made equipment for the Foodservice Industry. It was established in 1948. The most famous Semak appliance is the 'Vitamizer'. Designed in 1948 it quickly became the standard for blending. An updated version was relaunched in 2012. The Semak vitamiser was advertised as a wonder machine which every housewife should have.Advertising claimed that the Semak could whip cream, grind coffee, blend jam, makes soups and sauces, makes cakes, sandwich spreads, ice-cream, special diets, puree fruit drinks, supper snacks, mayonnaise and dessert. It sold for £21. Demonstrations were conducted in electrical stores across the nation. A recipe book and full instructions for operation was included.This item is representative of a popular Australian-made kitchen appliance used across the country. A food vitamiser in 2 sections. Top section is detachable for cleaning. Has electrical cord attached.Surrounding power control: Semak Vitamiser Under base: CAT No. S2/ 230 - 25 V / 240W / 40 - 60kitchen appliances, food vitamisers, semak industries -

NMIT (Northern Melbourne Institute of TAFE)

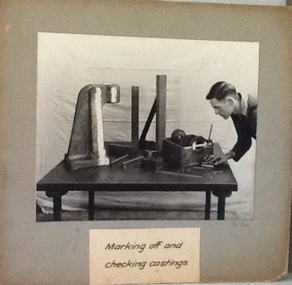

NMIT (Northern Melbourne Institute of TAFE)Photographs - Collingwood Technical School, Allan Studios, Mounted photographs of Trade School CTS, circa 1940, Early 1940s

Collingwood Technical School trained apprentices in many trades. These photographs depict some of the machines and machine parts built in class. Captions : 1. Marking off and checking castings 2. Examples of other machine parts, etc., being made in Youth Employment classes in engineering machine shop. 3. Cutting the traversing screw for a 5 ¼ inch lathe. 4. Grinding lathe spindle. 5. Cutting helical flutes in a shell end mill. 6. Arbor Press. Another valuable machine produced by Youth Employment and senior technical evening students. 7. Milling angular slides of lathe saddle. 8. 5 ¼ inch lathe product of Collingwood Technical School. These are high quality professional photographs taken circa 1940. 8 black and white photographs mounted on brown card. Photographs depict various aspects of lathe work.Each photograph has a hand written caption on the front. Also handwritten in black pen "Allan Studios".collingwood technical school, cts, apprentices, students, lathes, machinery, machine parts, nmit, -

Federation University Historical Collection

Federation University Historical CollectionTool, Handshears

Hand shears needed to be very sharp and often had a leather strap or ‘driver’ which passed over the hand. Others had sheepskin bound around the grip. Blades had to be regularly sharpened on a grinding stone. Most hand shears were made in Sheffield, England, with various models produced offering wide or narrow blades, sharp or rounded points, and various grips and bows. The technique of Australian hand shearing gradually developed from the 1830s using the old English method of cutting the flank with hand shears in a series of circular cuts from the sheep’s neck to the tail. In the early 1930s the Ballarat School of Mines introduced a wide-ranging Wool Classing Course as jobs were in extremely short supply during the Great Depression. Metal handshears used for shearing sheep.ballarat school of mines, shearing, woolclassing, sheep -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Functional object - Seal Embossing Press

The Corona Paint Company Pty. Ltd. Bendigo was formed in November 1920 with £10,000 capital, in £1 shares. By July 1921, the Company had completed its factory and plant at Bendigo East, ready to begin the manufacture of paints. The Corona Paint works were opened on Saturday 28 January by the Prime Minister (Mr. Hughes) during a visit to Bendigo. Many new manufacturing industries were opened during this time after calls to address the decline of mining in the region. The factory of the CORONA PAINT COMPANY, BENDIGO, was advertised for sale in The Argus on 5 October 1923. It consisted of a “building on a railway siding, plant and machinery, including dry grinding plant, kalsomine mixer, paint mill, furnace, electric motor, etc., large stores of raw and finished material, kalsomine with range of 21 colours, oil paints, &c.”A cast iron embossing press. It's painted black with gold coulered floral decorations. The base is 18 centimetres long, nine centimetres wide and one and a half centimetres thick. A curved protrusion rises from the base that is eight centimetres by four centimetres which narrows to four centimetres by two and a half centimetres with a three-quarter centimetre wide slot. Inside the slot is a lever action with a ten centimetre by two and a half centimetre wooden handle. There is a removeable die on the end of the lever and an opposite removeable die the base. A small oval metal disc with paten no 3965 on is attached. The seal is The Corona Paint Company proprietary Limited seal embossing press, corona paint company -

Bendigo Historical Society Inc.

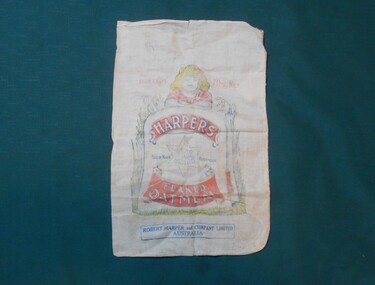

Bendigo Historical Society Inc.Textile - FLOUR BAG COLLECTION: ROBERT HARPER AND COMPANY, 1900-1950

Textiles. Calico bag - ''Harpers Flaked Oatmeal'' Star brand, Trademark Registered ''My Brekfus'' 7 lbs Net. Robert Harper and Company Limited Australia. Head and shoulders drawing of a blonde haired girl surrounded by wheat.On the other side of the bag is a blue and white picture of a box of ''Silver Star Starch''. Robert Harper and Co Ltd. Slogan written on box, '' The best in the world. Won't sick to the Iron''. Robert Harper and Company (1842-1919), businessman and politician, was born in Scotland. He migrated to Melbourne with his family in August 1856. He worked for J.F.McKenzie & Co., roasting and grinding millers. In 1865 he established Robert Harper & Co., trading in tea, coffee and spices from the East Indies and later in oatmeal and flour.textiles, domestic, robert harper and co calico bag -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Textile - FLOUR BAG COLLECTION: ROBERT HARPER AND COMPANY, 1900-1950

Textiles. Calico flour bag printed on one side in red and blue''EMPIRE SELF RAISING FLOUR 25 lbs nett weight. Contains phosphate Baking Powder. Robert Harper & Company Incorporated Victoria, Australia''. In the background is a lighthouse with three beams of light extending from each side. Printed on the light beams- ''LIGHT BREAD, LIGHT PASTRY, LIGHT PUDDINGS, LIGHT LABOUR, LIGHT HEARTS, LIGHT HOMES''. Robert Harper (1842-1919), businessman and politician, was born in Scotland. He migrated to Melbourne with his family in August 1856. He worked for J.F.McKenzie & Co., roasting and grinding millers. In 1865 he established Robert Harper & Co., trading in tea, coffee and spices from the East Indies and later in oatmeal and flour.textiles, domestic, robert harper & co flour bag -

Ballarat Tramway Museum

Ballarat Tramway MuseumPhotograph - Black & White Photograph/s, State Electricity Commission of Victoria (SECV)

Yields information about the griding of wheels at the tram depot following the installation of a grinder by the SEC during the mid 1930's. Shows the nature of the work and set up.Black and White photograph, of the SEC Ballarat depot wheel grinder being used to grind the wheels of a single truck tramcar. Shows a pit man/machinist using the equipment with the drive belts and wheels moving. The machinist is dressed in heavy clothing. Shows the detail of the operation. Date unknown - possibly late 1930's after installation. See Reg Item 1352* and 1353* for photos of the construction of the pits and the installation of the equipment.\ Man identified as Mr Vin Dalton See btm3400doc.pdf for background to the donor and relationship to Reg Item 3806 - Vin Dalton. Record updated 24/6/2014 for information that appeared in the June 2014 issue of Fares Please! See btm3806doc1.pdf for letter from family dated 20/7/14 with a donation. Record updated 3/8/14. See Keith Kings, The Ballarat Tramways, page 36 and The Golden City and its tramways.tramways, trams, wendouree parade, sec depot, rehabilitation, service pits, wheel grinder -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Document - BENDIGO SALEYARDS COLLECTION: LIST OF SUPPLIERS

Two pages of list of suppliers. Page is divided into Five columns - Product, Activity Code, Product Code, Supplier and Supplier No. Products include stationary, hire of equipment, branding pasint, hay, glass, electrical work, repairs, dog food, testing of scales, grinding and cutting wheels. Suppliers were Hi Tech, Hume & Iser, Bendigo Hire, Mettler Toledo, BRB, Abbotts Supply, Dalgety Farmers, Bendigo East Sand and Soil, Bendigo Bearings, Bolton Bros, Fitzpatricks, Bendigo Bolts and Fasteners, CVC, Bendigo Glass Co, Dept Business Employment, DG Walkers, Bendigo Scale Co, Peter Llewellyn, Patches, Bendigo Mower Service, Transcom, Mulqueens Printer, John Truscott, All Bull, Elders Ltd, J H Plant and Son, Surdex, Obriens Glass, W C and H M Bury, BOC Gases, Windscreen City, Cleanaway, RJ and E R Conroy, J Blackwood & Sons.bendigo, council, cattle markets, bendigo saleyards collection - list of suppliers, hi tech, hume & iser, bendigo hire, mettler toledo, brb, abbotts supply, dalgety farmers, bendigo east sand and soil, bendigo bearings, bolton bros, fitzpatricks, bendigo bolts and fasteners, cvc, bendigo glass co, dept business employment, dg walkers, bendigo scale co, peter llewellyn, patches, bendigo mower service, transcom, mulqueens printer, john truscott, all bull, elders ltd, j h plant and son, surdex, obriens glass, w c and h m bury, boc gases, windscreen city, cleanaway, rj and e r conroy, j blackwood & sons -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Machine - CAST IRON COFFEE GRINDER

Black Cast Iron Coffee Grinder With Circular Copper Bowl on top and a curved metal handle which is attached to a central grinding mechanism. Main body shape almost square tapers slightly closer to the top. Coffee grinder has a large pullout tray contained in the bottom of the mill. 140 cm High x 40 cm Wide Previous Catalogue Number 103 Inscription T & C Clark & Co Manufacturer Additional Inscription contained in an elliptical brass plaque Paris Silver Medal 1878 Awarded T. & C. Clark & Co. Plaque Also contains images of a replica of the Jules-Clement Chaplain Art Nouveau Designed Silver Medal Exhibition Prize, Consisting of a laureate bust of Marianne Facing Left surrounded by the words Republique Francaise. Beside It An Image of Victory Hovering Above The Exhibition Wearing A Laurel Wreath Blowing A Bugle Announcing Manufacturing Success & Excellence & Below Him Cupin (Child Genius) Holding A Banner With T & C Clark & Co. Around The Outside Edge Exposition Paris Universelle Internationale De 1878.T & C Clarke Manufacturerdomestic equipment, food consumption, coffee grinder -

Melbourne Tram Museum

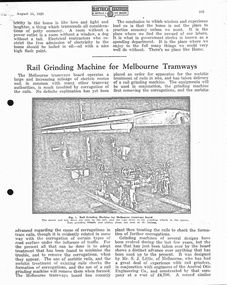

Melbourne Tram MuseumDocument - Report, Electrical Engineer, The Electrical Engineer and Merchandiser, "Rail Grinding Machine for Melbourne Tramways", 1927 - 1950

Set of 6 reports, photocopied onto heat sensitive paper from various magazines. Documents match the image numbers. .1 - .2 pages - Electrical Engineer - 15/8/1928 - "Rail Grinding Machine for Melbourne Tramways" - Grinders .2 - 5 pages - Electrical Engineer - 15/6/`1927 - "Workshop of the Melbourne Tramways Board" - includes a layout drawing - See Reg Item 3675 for a reprint of this document. .3 - 1 sheet - Electrical Engineer - 15/9/1927 - "Worm Driver for Electric Tramcars - new type of truck constructed by Melbourne Tramways Board" - fitted to X1 class cars. Has a sketch of the truck. .4 - 8 pages - The Electrical Engineer and Merchandiser - 15/11/1933 - "A Supervisory Control system for Traction Substation - Equipment designed for the MMTB" - written by C. L. Steele. .5 - 8 pages - "Institute of Engineers Australia" - Dec. 1943 - "Prolonging the life of the tramway rail" - by A. H. Blanch. Note some pages have handwritten additions where the copying is out of line. .6 - 1 page - The Electrical Engineer and Merchandiser - 16-10-1950 - "Noiseless bogie for Tramcars" - PCC bogies. - St Louis Car C B-3 Bogie.trams, tramways, mmtb, rail grinding, rail wear, track materials, grinding, preston workshops, worm drive, x1 class, substation, electrical engineering, electrical equipment, tramway per way, bogies, pcc class -

Tarnagulla History Archive

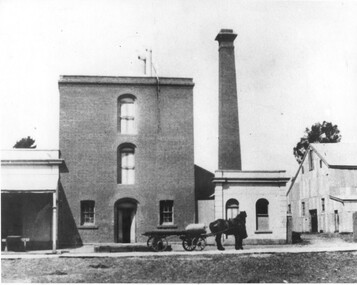

Tarnagulla History ArchivePhotograph - Photograph: Workers at Tarnagulla Flour Mill, c. 1873-1920, probably around 1900

Williams Family Collection. A meeting was called at the Golden Age Hotel on 11th June 1868 when it was resolved to build a flour mill. Tenders were called by H.C. Bristol, in the Tarnagulla Courier of January 10, 1874, for the erection of the mill. Building of the Mill commenced in 1874. Pipes were laid to Company's Dam to obtain water for the Mill's boilers. Steam was got up for the first time on 30th March, 1882. A boiler burst about April 29th. Two men (J.H. Smith and W. Hargreaves) died as a result and two others were seriously injured. The mill commenced operations on 13th June 1882 with Mr. W. Fitzgerald as manager. Thomas Comrie was the proprietor and was responsible for the Mill being built. The Mill operated with grinding stones until 1899 when new rollers and a considerable amount of new equipment was installed, including a new, more powerful engine to drive the Mill. In January 1901, 6,000 bags of wheat were received weekly and it was a common sight to see the streets lined with wagons. In 1913, 15,000 bags of wheat were bought at three shillings and four pence per bushell. In January 1914, wheat came in at the rate of 1500 bags a day with 20,000 bags in storage. Thomas Comrie died on 4th August 1910. The Mill was carried on by his executors, then closed for a short period prior to being sold in September 1918 to a Mr. O. Albert of Talbot. Albert operated the Mill for a few years but during the 1920s it was closed down and then pulled down. It was later re-erected at Mildura where it operated for many years.Monochrome photograph depicting workers at Tarnagulla Flour Mill, some loading or unloading a horse-drawn cart. An original photograph, mounted on card. Handwritten on back: 'L.Williams Tarnagulla' and 'Leo Fitzgerald' and full recipe for a red currant dessert.tarnagulla -

Tarnagulla History Archive

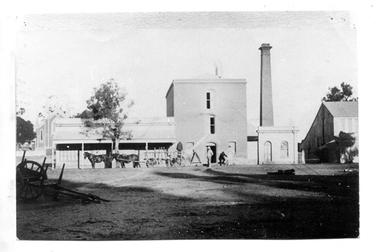

Tarnagulla History ArchivePhotograph of Flour Mill, Tarnagulla, Flour Mill, Tarnagulla, circa 1920

Murray Comrie Collection. Information written by Murray Comrie: A meeting was called at the Golden Age Hotel on 11th June 1868 when it was resolved to build a flour mill. Tenders were called by H.C. Bristol, in the Tarnagulla Courier of January 10, 1874, for the erection of the mill. Building of the Mill commenced in 1874. Pipes were laid to Company's Dam to obtain water for the Mill's boilers. Steam was got up for the first time on 30th March, 1882. A boiler burst about April 29th. Two men (J.H. Smith and W. Hargreaves) died as a result and two others were seriously injured. The mill commenced operations on 13th June 1882 with Mr. W. Fitzgerald as manager. Thomas Comrie was the proprietor and was responsible for the Mill being built. The Mill operated with grinding stones until 1899 when new rollers and a considerable amount of new equipment was installed, including a new, more powerful engine to drive the Mill. In January 1901, 6,000 bags of wheat were received weekly and it was a common sight to see the streets lined with wagons. In 1913, 15,000 bags of wheat were bought at three shillings and four pence per bushell. In January 1914, wheat came in at the rate of 1500 bags a day with 20,000 bags in storage. Thomas Comrie died on 4th August 1910. The Mill was carried on by his executors, then closed for a short period prior to being sold in September 1918 to a Mr. O. Albert of Talbot. Albert operated the Mill for a few years but during the 1920s it was closed down and then pulled down. It was later re-erected at Mildura where it operated for many years. This is a poor copy of an older original. Copy probably made by Murray Comrie in the late 1960s. Monochrome photograph of the Flour Mill in Tarnagulla, around 1920.tarnagulla, commerce, agriculture, food production, mill, milling, horses, transport, buildings, commercial road, main street -

Tarnagulla History Archive

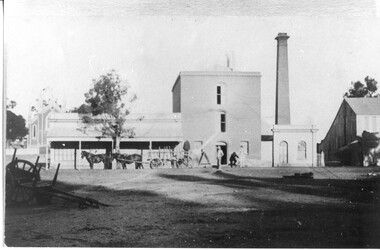

Tarnagulla History ArchivePhotograph of Flour Mill, Tarnagulla, Flour Mill, Tarnagulla, circa 1920 (original image)

Murray Comrie Collection. Information written by Murray Comrie: A meeting was called at the Golden Age Hotel on 11th June 1868 when it was resolved to build a flour mill. Tenders were called by H.C. Bristol, in the Tarnagulla Courier of January 10, 1874, for the erection of the mill. Building of the Mill commenced in 1874. Pipes were laid to Company's Dam to obtain water for the Mill's boilers. Steam was got up for the first time on 30th March, 1882. A boiler burst about April 29th. Two men (J.H. Smith and W. Hargreaves) died as a result and two others were seriously injured. The mill commenced operations on 13th June 1882 with Mr. W. Fitzgerald as manager. Thomas Comrie was the proprietor and was responsible for the Mill being built. The Mill operated with grinding stones until 1899 when new rollers and a considerable amount of new equipment was installed, including a new, more powerful engine to drive the Mill. In January 1901, 6,000 bags of wheat were received weekly and it was a common sight to see the streets lined with wagons. In 1913, 15,000 bags of wheat were bought at three shillings and four pence per bushell. In January 1914, wheat came in at the rate of 1500 bags a day with 20,000 bags in storage. Thomas Comrie died on 4th August 1910. The Mill was carried on by his executors, then closed for a short period prior to being sold in September 1918 to a Mr. O. Albert of Talbot. Albert operated the Mill for a few years but during the 1920s it was closed down and then pulled down. It was later re-erected at Mildura where it operated for many years. This is a poor copy of an older original. Copy probably made by Murray Comrie in the late 1960s. Monochrome photograph of the Flour Mill in Tarnagulla, around 1920. Cropped version of 2019.0047.tarnagulla, commerce, agriculture, food production, mill, milling, horses, transport, buildings, commercial road, main street -

Federation University Art Collection

Federation University Art CollectionWork on paper - Printmaking - Multiplate Etching, Dean Bowen, 'The Car Park' by Dean Bowen, 1994

Dean BOWEN (1957 -) Born Maryborough, Victoria Dean Bowen's work combines humour and gentle irony with technical proficiency to explore the world around him. 'The car park epitomises qualities found in the best of his post 1990 work. Born out of the daily grind of stop-start commuting by car along Melbourne's Punt Road to and from his former workplace, the feeling of this large work (just over two metres long) is of duality. On the one hand there is the crowded chaos of a relentless number of cars choking the roads; on the other, order is imposed in his aerial view of cars 'parked' around intersecting roads as well as the actual charting of roads and interstitial spaces. Zooming in as though from above, cars are alternately cross-sectioned and flattened in outline. Despite his denial that there is nothing reminiscent of Aboriginal art in this work, to the onlooker there are quite a number of similarities. Not that he presumes anything of the Aboriginal experience or imagery (indeed, that it is unconscious is probably the only reason it works), such qualities are nevertheless present. The aerial perspective, for example, is so like the Aboriginal system of painting song lines and dreaming tracks from above. And as seen in the famous 'X ray' paintings of Arnhem Land, his cars and buildings are cross-sectioned to reveal the objects (usually humans) within. The impression of Aboriginally is further given by his use of earthy browns and by the outlining of shapes (cars, roads, trees).' (Susan McCulloch) This work was selected by the Art Acquisitions Committee (1995) to be placed in the 1870 Founders Hall at Mt Helen Campus. The Federation University Art Collection features over 2000 works and was listed as a 'Ballarat Treasure' in 2007.A multiprint etching depicting a carpark that won the 1994 Fremantle Print Award;Edition 12/20art, artwork, dean bowen, bowen, etching, multi-plate etching, printmaking, printmaking etching, carpark -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageRazor Strop

This razor strop is made like a leather strap. ABOUT STROPS Straight razors and cut throat razors were the major tools for shaving before the safety razor was invented in the 1880’s and even today specialty shaving shops still sell the straight razors. Along with the razor, the process of shaving would commonly involve lathering up shaving soap using a shaving brush with boar bristles. Men could own several razors and rotate them through the week and some shops sold the razors in a set, a razor for each day of the week. Straight razors could require stropping more than once during the shaving of a heavy beard, and stropping would also be performed at the end of each shave. Honing would only be performed two or three times a year, preserving the blade’s edge. A lot of skill was needed to hone and strop the blades of these early razors and the methods to do so were a large part of the curriculum in Barber colleges. The razor would be sharpened on a grinding wheel then honed on sharpening stone and finally finished using a strop. Straight edge razors would usually be sold unfinished and that process would be completed by the customer. A razor strop, usually made from leather, thick canvas or light timber, would be used to straighten and polish the straight razor for shaving. Strops could also be used to polish other blades such as knives, small metal tools and chisels. Sometimes an abrasive polishing compound is also used to give a mirror finish. Some strops, such as this one in our Collection, are designed to be used while hanging from a nail or peg, while others are hand held. To use the strop draw the spine of the blade down along the strop with the blade following, without putting any pressure on the blade. At the end of the stroke, rotate the blade over its spine then draw the spine along the strop again so that the edge moves away from the top. The finer grade of leather strap is used to give the final finish. Double Swing Razor Strop. Use for honing razors.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, strop, swing razor strop, barber's equipment, shaving equipment, personal accessory -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillagePaddle Strop

This razor strop is called a paddle strop. ABOUT STROPS Straight razors and cut throat razors were the major tools for shaving before the safety razor was invented in the 1880’s and even today specialty shaving shops still sell the straight razors. Along with the razor, the process of shaving would commonly involve lathering up shaving soap using a shaving brush with boar bristles. Men could own several razors and rotate them through the week and some shops sold the razors in a set, a razor for each day of the week. Straight razors could require stropping more than once during the shaving of a heavy beard, and stropping would also be performed at the end of each shave. Honing would only be performed two or three times a year, preserving the blade’s edge. A lot of skill was needed to hone and strop the blades of these early razors and the methods to do so were a large part of the curriculum in Barber colleges. The razor would be sharpened on a grinding wheel then honed on sharpening stone and finally finished using a strop. Straight edge razors would usually be sold unfinished and that process would be completed by the customer. A razor strop, usually made from leather, thick canvas or light timber, would be used to straighten and polish the straight razor for shaving. Strops could also be used to polish other blades such as knives, small metal tools and chisels. Sometimes an abrasive polishing compound is also used to give a mirror finish. Some strops, such as this one in our Collection, are designed to be used while hanging from a nail or peg, while others are hand held. To use the strop draw the spine of the blade down along the strop with the blade following, without putting any pressure on the blade. At the end of the stroke, rotate the blade over its spine then draw the spine along the strop again so that the edge moves away from the top. The finer grade of leather strap is used to give the final finish. Wooden paddle strop, (or raxor strop or cushion strop). Strop has two leather sides, numbered 1 and 2, on a slotted paddle. Marked on handle “Hamon”. Sides are numbered 1 and 2. Has two slits in body of strop. "Hamon" stamped on handle. "Hamon" stamped on handle. flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, wooden strop, paddle strop, strop, razor strop, shaving accessory, barber's equipment, personal grooming -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillagePaddle Strop

This razor strop is called a paddle strop. ABOUT STROPS Straight razors and cut throat razors were the major tools for shaving before the safety razor was invented in the 1880’s and even today specialty shaving shops still sell the straight razors. Along with the razor, the process of shaving would commonly involve lathering up shaving soap using a shaving brush with boar bristles. Men could own several razors and rotate them through the week and some shops sold the razors in a set, a razor for each day of the week. Straight razors could require stropping more than once during the shaving of a heavy beard, and stropping would also be performed at the end of each shave. Honing would only be performed two or three times a year, preserving the blade’s edge. A lot of skill was needed to hone and strop the blades of these early razors and the methods to do so were a large part of the curriculum in Barber colleges. The razor would be sharpened on a grinding wheel then honed on sharpening stone and finally finished using a strop. Straight edge razors would usually be sold unfinished and that process would be completed by the customer. A razor strop, usually made from leather, thick canvas or light timber, would be used to straighten and polish the straight razor for shaving. Strops could also be used to polish other blades such as knives, small metal tools and chisels. Sometimes an abrasive polishing compound is also used to give a mirror finish. Some strops, such as this one in our Collection, are designed to be used while hanging from a nail or peg, while others are hand held. To use the strop draw the spine of the blade down along the strop with the blade following, without putting any pressure on the blade. At the end of the stroke, rotate the blade over its spine then draw the spine along the strop again so that the edge moves away from the top. The finer grade of leather strap is used to give the final finish. Wooden strop, paddle strop design (sometimes called razor strop). Has leather attached to one side. Has two slits in body of strop. flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, strop, paddle strop, personal effects, shaving equipment, razor strop, barber's equipment -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillagePaddle Strop

This razor strop is called a paddle strop. ABOUT STROPS Straight razors and cut throat razors were the major tools for shaving before the safety razor was invented in the 1880’s and even today specialty shaving shops still sell the straight razors. Along with the razor, the process of shaving would commonly involve lathering up shaving soap using a shaving brush with boar bristles. Men could own several razors and rotate them through the week and some shops sold the razors in a set, a razor for each day of the week. Straight razors could require stropping more than once during the shaving of a heavy beard, and stropping would also be performed at the end of each shave. Honing would only be performed two or three times a year, preserving the blade’s edge. A lot of skill was needed to hone and strop the blades of these early razors and the methods to do so were a large part of the curriculum in Barber colleges. The razor would be sharpened on a grinding wheel then honed on sharpening stone and finally finished using a strop. Straight edge razors would usually be sold unfinished and that process would be completed by the customer. A razor strop, usually made from leather, thick canvas or light timber, would be used to straighten and polish the straight razor for shaving. Strops could also be used to polish other blades such as knives, small metal tools and chisels. Sometimes an abrasive polishing compound is also used to give a mirror finish. Some strops, such as this one in our Collection, are designed to be used while hanging from a nail or peg, while others are hand held. To use the strop draw the spine of the blade down along the strop with the blade following, without putting any pressure on the blade. At the end of the stroke, rotate the blade over its spine then draw the spine along the strop again so that the edge moves away from the top. The finer grade of leather strap is used to give the final finish. Wooden strop, paddle strop design (sometimes called razor strop). Has leather attached to one side. Sides are numbered 1 and 2. Has two slits in body of strop. Stamped Hamon Paris France. "Hamon Paris France. "flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, paddle strop, strop, shaving equipment, personal effects, barber's equipment, personal grooming accessory -

Tarnagulla History Archive

Tarnagulla History ArchivePhotograph of Flour Mill complex, Tarnagulla, Flour Mill complex, Tarnagulla, circa 1882-1920

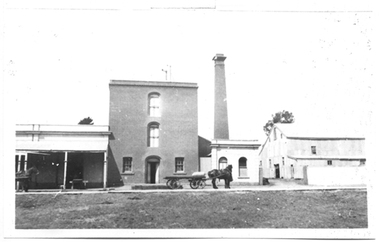

Murray Comrie Collection. Information written by Murray Comrie: A meeting was called at the Golden Age Hotel on 11th June 1868 when it was resolved to build a flour mill. Thomas Comrie was the proprietor and was responsible for the Mill being built. Tenders were called by H.C. Bristol, in the Tarnagulla Courier of January 10, 1874, for the erection of the mill. Building of the Mill commenced in 1874. Pipes were laid to Company's Dam to obtain water for the Mill's boilers. Steam was got up for the first time on 30th March, 1882. A boiler burst about April 29th. Two men (J.H. Smith and W. Hargreaves) died as a result and two others were seriously injured. The mill commenced operations on 13th June 1882 with Mr. W. Fitzgerald as manager. The Mill operated with grinding stones until 1899 when new rollers and a considerable amount of new equipment was installed, including a new, more powerful engine to drive the Mill. In January 1901, 6,000 bags of wheat were received weekly and it was a common sight to see the streets lined with wagons. In 1913, 15,000 bags of wheat were bought at three shillings and four pence per bushell. In January 1914, wheat came in at the rate of 1500 bags a day with 20,000 bags in storage. Thomas Comrie died on 4th August 1910. The Mill was carried on by his executors, then closed for a short period prior to being sold in September 1918 to a Mr. O. Albert of Talbot. Albert operated the Mill for a few years but during the 1920s it was closed down and then pulled down. It was later re-erected at Mildura where it operated for many years. The far left section of the complex was originally John Pierce's Southern Cross General Store, a wholesale grocer and spirit merchant. It was put up for sale after Pierce's death in 1871, and later incorporated into the Mill complex. This is a poor copy of an older original. Copy probably made by Murray Comrie in the 1960s. Monochrome photograph of men, horses and a wagon outside the Flour Mill complex formerly situated on the south east corner of King Street and Commercial Road in Tarnagulla. At far left the Methodist church is partially visible in the background. At far right is part of the Mill's storage shed. Same image as THA-2019.0211Written on reverse: 'M. Comrie'tarnagulla, commerce, agriculture, food production, mill, milling, horses, transport, buildings, commercial road, main street -

Tarnagulla History Archive

Tarnagulla History ArchivePhotograph of Flour Mill complex, Tarnagulla, Flour Mill complex, Tarnagulla, circa 1882-1920

Murray Comrie Collection. Information written by Murray Comrie: A meeting was called at the Golden Age Hotel on 11th June 1868 when it was resolved to build a flour mill. Thomas Comrie was the proprietor and was responsible for the Mill being built. Tenders were called by H.C. Bristol, in the Tarnagulla Courier of January 10, 1874, for the erection of the mill. Building of the Mill commenced in 1874. Pipes were laid to Company's Dam to obtain water for the Mill's boilers. Steam was got up for the first time on 30th March, 1882. A boiler burst about April 29th. Two men (J.H. Smith and W. Hargreaves) died as a result and two others were seriously injured. The mill commenced operations on 13th June 1882 with Mr. W. Fitzgerald as manager. The Mill operated with grinding stones until 1899 when new rollers and a considerable amount of new equipment was installed, including a new, more powerful engine to drive the Mill. In January 1901, 6,000 bags of wheat were received weekly and it was a common sight to see the streets lined with wagons. In 1913, 15,000 bags of wheat were bought at three shillings and four pence per bushell. In January 1914, wheat came in at the rate of 1500 bags a day with 20,000 bags in storage. Thomas Comrie died on 4th August 1910. The Mill was carried on by his executors, then closed for a short period prior to being sold in September 1918 to a Mr. O. Albert of Talbot. Albert operated the Mill for a few years but during the 1920s it was closed down and then pulled down. It was later re-erected at Mildura where it operated for many years. The far left section of the complex was originally John Pierce's Southern Cross General Store, a wholesale grocer and spirit merchant. It was put up for sale after Pierce's death in 1871, and later incorporated into the Mill complex. This is a reasonable copy of an older original. Copy probably made by Murray Comrie in the 1960s. Monochrome photograph of men, horses and a wagon outside the Flour Mill complex formerly situated on the south east corner of King Street and Commercial Road in Tarnagulla. At far left the Methodist church is partially visible in the background. At far right is part of the Mill's storage shed. Same image as THA-2019.0048Written on reverse: 'M. Comrie'tarnagulla, commerce, agriculture, food production, mill, milling, horses, transport, buildings, commercial road, main street -

Tarnagulla History Archive

Tarnagulla History ArchivePhotograph - Photograph: Company's Dam and Flour Mill, Tarnagulla, c. 1880 - 1920

Williams Family Collection. On the 20th December 1873 it was reported in the Tarnagulla Courier that arrangements were being made for the erection of a steam flour mill at Tarnagulla. Mr Bristol had purchased the necessary plant which would be erected with as little delay as possible. The site chosen was the premises occupied previously by Mr John Pierce, grocer and wine and spirit merchant, at the corner of King and Commercial Road. These premises were incorporated in the mill building. Suitable buildings for receiving and storing grain and flour had been erected already. On 10th January, 1874 an advertisement in the Courier called for tenders from masons, bricklayers and carpenters for the erection of a flour mill at Tarnagulla for H. C. Bristol, Esq. with all enquiries to be made from G. Minto, Engineer. In December 1881 the proprietors made a request to the Tarnagulla Borough Council for permission to lay pipes to the Municipal Dam, which was generally known as the Company's Dam, and to obtain water from the dam for milling purposes. This was granted. Steam was got up for the first time on 30th of March, 1882. A large quantity of wheat was stored ready for milling. Just prior to 29th of April 1882 the boiler at the mill burst, as the result of which two men, J. H. Smith and W. Hargreaves died and H. Joyce Bousfield, senior and junior, were seriously injured. The mill commenced operations on 13th June, 1882 with Mr W Fitzgerald as manager. The price offered for wheat was thirty-seven pence per bushell. It operated with grinding stones until considerable renovations were done in the early part of 1899 when new rollers and more up to date equipment installed. The mill was then known as the Tarnagulla Flour Mill Co., with Thos. Comrie as proprietor, Mr Fitzgerald was still manager, and Mr T. Leonard was the traveller. Much new equipment was put in and each of the three floors had different processes. The rollers were on the ground floor, the purifiers and elevators reel were on the second floor, plus the clean wheat bin directly over the Ganz rollers. On the top floor was the chop reel, bran reel, inter-elevator reels, brush machine cyclone sack hoist, dirty wheat shaker, clean wheat bin, dust rooms and also double damping rooms. A plant was also erected for the making of an improved quality of wheaten meal, for which purpose special machinery was procured and a pair of stones was left for grinding the meal. A complete plant for the crushing of oats etc was also erected. The driving power of the mill was supplied by a new engine complete with 16 inch cylinder, manufactured and erected by Bousfield & Co. of Eaglehawk. It was fitted with Pickering governors, connected with the cylinder was a super heater. The boiler was tested and all connections etc. overhauled, with much of it being completely renewed. There was a complete network of belts, spouts, elevators etc. all over the building, all conveniently placed. The plans etc for the new plant were drawn up by Mr J. Kilborn, manager of the firm of Bodington & Co., engineers and millwrights of Carlton, which supplied the whole of the machinery, excepting the engine. The work of erection was carried out by Mr Kilborn and his assistants to the entire satisfaction of Mr Comrie, who had gone to considerable expense to bring the mill to a completely up-todate machine, fitted with all of the most modern appliances available. An advertisement on May 6th, 1899 read: "Tarnagulla Flour Mill Co., Patent Roller Flour. Also their Digestive Wheaten Meal specially prepared for Porridge or Bread." In January 1901, 6000 bags of wheat were received weekly at the mill and it was a common sight to see the streets lined with wagons. In May 1902 the mill was lighted by gas and in July 1906 an application was made to the Tarnagulla Borough Council for permission to lay a tram track from the mill to the Railways Station. Council was agreeable to this provided suitable plans were submitted. In 1913, 15,000 bags of wheat were bought at three shillings and four pence per bushell. In January 1914 the mill was renovated. At this time 1500 bags of wheat were coming in daily, with 20,000 bags in storage. On 15th December, 1917 the mill was advertised for sale, to be sold on Friday, 21st December,.1917, on behalf of the Estate of the Late Thomas Comrie, who had died on 4th August, 1910. The Courier at that time recorded him as being responsible for the building of the mill and with being the sole proprietor. The mill was closed, apparently, for a short period. The Courier reported on 13th of September, 1918 that the mill had been sold to Mr O. Albert of Talbot and that it would re-open. An advertisement read: ALBERT. O. & SON, MILLERS. During 1920 the mill was closed and pulled down. It was later re-erected at Mildura where it operated for many years. (by Donald Clark)Monochrome photograph depicting view of Company's Dam and the flour mill in Tarnagulla. Handwritten on reverse: 'J. Caldwell and photographer's stamp 'C. Bock Photo Tarnagulla'.tarnagulla -

Tarnagulla History Archive

Tarnagulla History ArchivePostcard - Photographic postcard: Company's Dam and Flour Mill, Tarnagulla, c. 1880 - 1920

Williams Family Collection. On the 20th December 1873 it was reported in the Tarnagulla Courier that arrangements were being made for the erection of a steam flour mill at Tarnagulla. Mr Bristol had purchased the necessary plant which would be erected with as little delay as possible. The site chosen was the premises occupied previously by Mr John Pierce, grocer and wine and spirit merchant, at the corner of King and Commercial Road. These premises were incorporated in the mill building. Suitable buildings for receiving and storing grain and flour had been erected already. On 10th January, 1874 an advertisement in the Courier called for tenders from masons, bricklayers and carpenters for the erection of a flour mill at Tarnagulla for H. C. Bristol, Esq. with all enquiries to be made from G. Minto, Engineer. In December 1881 the proprietors made a request to the Tarnagulla Borough Council for permission to lay pipes to the Municipal Dam, which was generally known as the Company's Dam, and to obtain water from the dam for milling purposes. This was granted. Steam was got up for the first time on 30th of March, 1882. A large quantity of wheat was stored ready for milling. Just prior to 29th of April 1882 the boiler at the mill burst, as the result of which two men, J. H. Smith and W. Hargreaves died and H. Joyce Bousfield, senior and junior, were seriously injured. The mill commenced operations on 13th June, 1882 with Mr W Fitzgerald as manager. The price offered for wheat was thirty-seven pence per bushell. It operated with grinding stones until considerable renovations were done in the early part of 1899 when new rollers and more up to date equipment installed. The mill was then known as the Tarnagulla Flour Mill Co., with Thos. Comrie as proprietor, Mr Fitzgerald was still manager, and Mr T. Leonard was the traveller. Much new equipment was put in and each of the three floors had different processes. The rollers were on the ground floor, the purifiers and elevators reel were on the second floor, plus the clean wheat bin directly over the Ganz rollers. On the top floor was the chop reel, bran reel, inter-elevator reels, brush machine cyclone sack hoist, dirty wheat shaker, clean wheat bin, dust rooms and also double damping rooms. A plant was also erected for the making of an improved quality of wheaten meal, for which purpose special machinery was procured and a pair of stones was left for grinding the meal. A complete plant for the crushing of oats etc was also erected. The driving power of the mill was supplied by a new engine complete with 16 inch cylinder, manufactured and erected by Bousfield & Co. of Eaglehawk. It was fitted with Pickering governors, connected with the cylinder was a super heater. The boiler was tested and all connections etc. overhauled, with much of it being completely renewed. There was a complete network of belts, spouts, elevators etc. all over the building, all conveniently placed. The plans etc for the new plant were drawn up by Mr J. Kilborn, manager of the firm of Bodington & Co., engineers and millwrights of Carlton, which supplied the whole of the machinery, excepting the engine. The work of erection was carried out by Mr Kilborn and his assistants to the entire satisfaction of Mr Comrie, who had gone to considerable expense to bring the mill to a completely up-todate machine, fitted with all of the most modern appliances available. An advertisement on May 6th, 1899 read: "Tarnagulla Flour Mill Co., Patent Roller Flour. Also their Digestive Wheaten Meal specially prepared for Porridge or Bread." In January 1901, 6000 bags of wheat were received weekly at the mill and it was a common sight to see the streets lined with wagons. In May 1902 the mill was lighted by gas and in July 1906 an application was made to the Tarnagulla Borough Council for permission to lay a tram track from the mill to the Railways Station. Council was agreeable to this provided suitable plans were submitted. In 1913, 15,000 bags of wheat were bought at three shillings and four pence per bushell. In January 1914 the mill was renovated. At this time 1500 bags of wheat were coming in daily, with 20,000 bags in storage. On 15th December, 1917 the mill was advertised for sale, to be sold on Friday, 21st December,.1917, on behalf of the Estate of the Late Thomas Comrie, who had died on 4th August, 1910. The Courier at that time recorded him as being responsible for the building of the mill and with being the sole proprietor. The mill was closed, apparently, for a short period. The Courier reported on 13th of September, 1918 that the mill had been sold to Mr O. Albert of Talbot and that it would re-open. An advertisement read: ALBERT. O. & SON, MILLERS. During 1920 the mill was closed and pulled down. It was later re-erected at Mildura where it operated for many years. (by Donald Clark)Photographic postcard, front image depicting view of Company's Dam and the flour mill in Tarnagulla. Handwritten on reverse: 'A Merry Christmas and a Happy New Year, E. Bool' and photographer's stamp 'C. Bock Photo Tarnagulla'.tarnagulla