Showing 104 items matching "spinning wheel"

-

Lakes Entrance Historical Society

Lakes Entrance Historical SocietyPhotograph - Market, Lakes Post Newspaper, 1/12/1995 12:00:00 AM

... Black and white photograph taken of spinning wheel... of spinning wheel and Kenny Koala on truck tray set up for Myer Street ...Black and white photograph taken of spinning wheel and Kenny Koala on truck tray set up for Myer Street Traders Twilight Market. In background Fashion Network previously Stewart's Butchers and Galleon Coffee Lounge Lakes Entrance Victoriatrading, business -

National Wool Museum

National Wool MuseumBook, Sonya's Mob: the life and times of a Polish-Australian family

... Textile Art Spinning Spinning wheels Carrington wheel Carrington ..."Sonya's Mob: the life and times of a Polish-Australian family" - Lois and George Carrington, Canberra, 1996 (self published). Includes a seperately printed index and location guide to Sonya Carrington's khilims. Biography of Sonya Carrington-Zakrzewska, artist and weaver. Inludes information about her husband, Wlodek Zakrzewski who made and repaired spinning wheels.To the National Wool Museum / with our best wishes / Lois Carrington / George Carringtonweaving textile art, spinning, spinning wheels, carrington wheel, carrington-zakrzewska, mrs sonya zakrzewski, mr wlodzimierz, weaving, textile art -

Flagstaff Hill Maritime Museum and Village

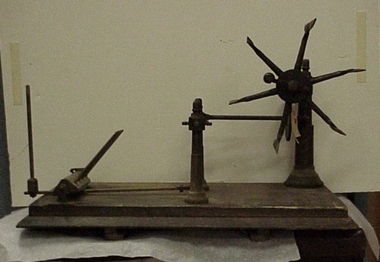

Flagstaff Hill Maritime Museum and VillageMachine - Treadle Machine, Early 20th century

... operate many devices such as a sewing machine or spinning wheel... or spinning wheel. Treadle machines were used to power sewing machines ...This foot-powered treadle machine could be used to manually operate many devices such as a sewing machine or spinning wheel. Treadle machines were used to power sewing machines, dental drills, lathes, spinning wheels and saws The machine is mounted on a board to demonstrate treadle operation.This mounted, smoothly working treadle machine demonstrates the treadle mechanism that was used in the early 20th century to power mechanical devices and in turn to save time, energy and money. The treadle was used in domestic and industrial environments. The Collection at Flagstaff Hill Maritime Museum and Village has two treadle-operated dentist's drills, a treadle sewing machine, a saw, a lathe and a treadle paper numbering machine.Treadle-powered machine; a black painted metal wheel with four curved spokes, connected to a wooden treadle. The height of the wheel is adjustable. The mechanical device is mounted on a thick rectangular wooden block. The working treadle mechanism turns smoothly. flagstaff hill, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, treadle machine, manual machine, foot treadle, display treadle, treadle, demonstration, education, working model -

Melbourne Legacy

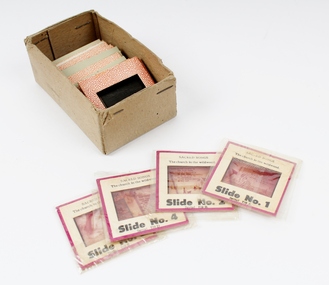

Melbourne LegacySlide - Slides, Comradeship songs

... you truly, The old spinning wheel The good old summer time... truly, The old spinning wheel The good old summer time Swannee ...The subject of these slides is not known until they are looked at again, their titles could give clues to the contents. Some titles that can be seen are; Tavern in the Town, I love you truly, The old spinning wheel The good old summer time Swannee River Bell's of St Mary's Nursie Little brown jugA record of the types of songs sung by Legatees at Comradeship gatherings. Comradeship meetings were very important to the Legatees. Legatees supported each other by coming together for various events throughout the year. Coloured 35mm slides, coloured photo surrounded by cardboard border.Various titles of songs on individual slides.comradeship, songs -

National Wool Museum

National Wool MuseumClothing - Suit, 1987

... horizontal spinning wheel. It was then dyed pink using natural dyes... on a Sheridan horizontal spinning wheel. It was then dyed pink using ...Hand spun, hand dyed, hand woven and hand sewn suit which won best garment in the 1987 Geelong show. Size 12 in a design by Chanel. It was spun with variegated natural greys on a Sheridan horizontal spinning wheel. It was then dyed pink using natural dyes. The jacket had commercially brought warp and hand spun weft in twill on a 24” loom. All spinning, dyeing and weaving was by Jean Inglis of Geelong. The suit was sewn by Caroline Mogic of Geelong, with iron on interfacing, commercially brought trim. It was worn only once in the parade at the Geelong show. The pink suit jacket has four pockets with gold buttons on front, size 12. The jacket has a checker-plate pattern in which the predominate pink is always present and is accompanied in areas which have grey or white showing through the pink. This checker plate pattern continues down the sleeves of the jacket. The edge of the jacket has a lighter pink trim. A pink skirt accompanies the suit jacket. It has horizontal lines with pink as the predominate colour and areas of grey and white showing through in sections. geelong show, hand spun, hand dyed, hand woven, hand sewn, channel -

Orbost & District Historical Society

Orbost & District Historical Societywheel

... spins a large wheel on the treadle frame, connected by a thin... spins a large wheel on the treadle frame, connected by a thin ...Many of the early sewing machines were powered by a treadle mechanism. The treadle was operated by pressing down on it with a foot, or both feet, to cause a rocking movement. This movement spins a large wheel on the treadle frame, connected by a thin leather belt to a smaller driving wheels on the sewing machine.A treadle sewing machine flywheel mad of cast iron. It is three tangent circles within a larger circle.3treadle sewing-machine flywheel -

Great Stupa of Universal Compassion

Great Stupa of Universal CompassionCeremonial object - Prayer wheel, hand-held

... worship. Tibetans believe that spinning the prayer wheel which... for personal worship. Tibetans believe that spinning the prayer wheel ...A prayer wheel is used in Tibetan Buddhism for personal worship. Tibetans believe that spinning the prayer wheel which as thousands or millions of mantras inside is equal to saying that many mantras, while being done in a fraction of the time. This helps accumulate merits, purify negative karma and obstacles on the path to enlightenment. This wheel has a hollow metal cylinder attached to a rod handle, made of ivory (with carved elephants), inlaid with coral and turquoise. Inside the cylinder is a tightly wound scroll printed with numerous mantras and wrapped around a spindle. The cylinder is embossed and decorated with inlaid coral and turquoise. A chain with a small weight at the end (made out of copper alloy) is affixed to the cylinder, allowing it to be spun by a slight rotation of the wrist. tibetan buddhism, holy objects, worship devices -

National Wool Museum

National Wool MuseumClothing - Jacket, 1978

... and then tease out for a spinning wheel. The donor Philip Allnutt had... and then tease out for a spinning wheel. The donor Philip Allnutt had ...The wool for this jacket began on the back of two sheep many kilometres apart. The first fleece for the warp was shorn from a single Merino at Currotha in Moree, NSW. The wool was 21-22 micron and the bloodline is a cross between Bundemar, Rossmore and Eural. The second sheep that provided wool for the weft was shorn in Beaufort, Victoria. It was a single Corriedale fleece shorn at Niawanda. The distance between these two towns is approximately 1250kms; a 15-hour car ride between paddocks. The two fleeces were spun and weaved together by the donor’s mother, Marjorie Allnutt. A level of talent is required to spin Merino fleeces. It is easier to spin cross bred wool, such as Corriedale, because it is less dense and much easier to comb, card and then tease out for a spinning wheel. The donor Philip Allnutt had a suit tailored out of the completed fabric at Ravensdale J & Son, 37 Swanson Street, Melbourne. The tailor was then a member of the Master Tailors Federation of Victoria. The business closed around 1986. Adding to the jacket’s story is its relationship to the household board game “Squatter”. Marjorie Allnutt was the sister-in-law of Robert Crofton Lloyd, the inventor of the wool themed boardgame. With more than 500,000 games sold in Australia as of 2007, it is the most successful board game ever produced in the country. The original “Squatter” board game is located within the National Wool Museum’s Collection. Philip Allnutt donated the Jacket to the National Wool Museum Collection in 2021. Cream singled breasted jacket with a narrow overlap and one column of buttons for fastening. The jacket features notched lapels of a medium width and two buttons of a cream & brown marble. The jacket has three visible pockets. A jetted pocket with no flap is on the right breast. A further two jetted no flap pockets finish an inch above the hem, on either side of the opening. Internally, the jacket features a further two pockets and a white silk lining for comfort. At the cuffs, the jacket utilises another 2 buttons of the same cream & brown marble.merino, currotha, moree, nsw, niawanda, corriedale, beaufort, victoria, hand spun, hand weaved -

National Wool Museum

National Wool MuseumTool - Grinder, 1960-69

... to a separate engine, spinning the wheel and hence powering the grinder... engine, spinning the wheel and hence powering the grinder ...Cooper S.E. Ball Bearing Grinder made and guaranteed by Sunbeam Corporation Limited. Grinders like this example have been made the same since the early 1900s, with this grinder thought to have been produced in the 1960s. It is belt driven, with the other end of the belt being attached to an engine; the same engine that would have powered the overhead shearing equipment in shearing sheds. It was common for shearing teams to bring their own equipment, especially pre-1960 as most shearing sheds were not connected to power, and shearers preferred to work with their own equipment. The engines that powered the shears and grinder were typically fuelled with kerosene or petrol. The large circular disks are attached to the bolt that protrudes from the grinder and fastened tightly with a nut. An example of seeing a similar grinder in action can be found on the following link - https://www.youtube.com/watch?v=O7eimI_Gm9o. Inventor Frederick Wolseley made the world's first commercially successful power-shearing system in Australia in 1888. US company Cooper, which had been founded in 1843 as a maker of sheep dip, began selling Wolseley equipment in the USA in 1895. The Chicago Flexible Shaft Company successfully entered the power-shearing market a few years later and entered a joint venture with Cooper. It set up a branch in Sydney and sold shearing sets, and engines to power them, into the Australian market. In 1921 the US parent company, realising it needed to make products whose sales were not as seasonal as those of shearing equipment, made its first household appliances and branded them Sunbeam. In 1933, changes in exchange rates and taxes led the company to manufacture engines and shearing equipment in Australia via subsidiary Cooper Engineering, which changed its name to Sunbeam in 1946. Although most Australians know of this company as a major manufacturer of household appliances, its rural division flourished and retained the Sunbeam name for shearing equipment even after it was taken over by New Zealand company Tru-Test in 2001. The grinder is formed from a central arch shaped block of green painted metal. Much of this paint has been lost to age, leaving the grinder in a ‘farm used’ condition with much surface oxidation present. On the front of the arch is a specification plate, reading “Cooper S.E. ball bearing grinder. Made and guaranteed by Sunbeam”. At the foot of the arch, three bolt holes are found for securing the grinder to the base of a solid wooden surface. Two of the bolt holes are found on the front of the grinder, with another found on the rear. From the central arch, a bolt protrudes to the right of the grinder. This large bolt is for securing a grinding plate to the grinder. Above the central arch is a pendulum which holds the comb / cutter that is being sharpened. From the pendulum, a large arm extends down (not pictured) to meet and strike the plate spinning at a rapid speed. On the left-hand side of the central arch of the grinder, a wheel is found which a belt is attached to for power. This belt is then attached to a separate engine, spinning the wheel and hence powering the grinder. The wheel is partially covered with a section of protective bent tube, designed to provide protection from the rapidly spinning wheel. Below this wheel is the belt shifter. It is designed to move the protective bent tube from one side of the grinder to the other, to accommodate the grinder in the setup of different shearing sheds. The two separate grinding plates are identical. They have a slight slope for sharpening the comb and cutters in the correct method, with a slight bias towards the base, or “tooth”, of the equipment. The disks have a large central bolt for attaching to the grinder. They have tags on the horizontal axis of the grinding plates, for securing the plates in transportation, and to help with initial alignment when setting up the grinder. The reverse of these grinding plates has the same green painted metal finish found on the grinder. This paint is also in a ‘farm used’ condition, with surface oxidation present. The grinder would be provided from the factory with a comb holder, shifter for securing the grinding plates, emery cloth and emery glue. The emery cloth is what does the actual grinding and is applied to the grinding disks, replacing once well worn. These items can be seen in the final images in the multimedia section, showcasing advertising for this grinder. Plate. Inscribed. “Cooper / S.E. BALL BEARING GRINDER / MADE AND GUARANTEED BY / Sunbeam / CORPORATION LIMITED / SYDNEY MELBOURNE / ADELAIDE BRISBANE ”sheep shearing, shearing equipment, sunbeam, grinder -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Dentist Drill, Late 19th century

... were used and modified to power a treadle spinning wheel of one... spinning wheel of one of the volunteer spinners at Flagstaff Hill ...The design of this and other similar treadle powered dental engine (or dentist drill) was in common use by dentists from the 1870’s into the 1920's. When electricity became accessible to most communities the electrically powered dental engines began to take over from the treadle power. Over the ages teeth were extracted using picks and scissors and other gouging instruments. Bow drills, hand drills and even a "bur thimble" drill were later used to prepare cavities for filling. Some drills were made bendable by attaching flexible shanks between the metal bur and the handle, giving access to the teeth at the back of the mouth. Other mechanical devices were introduced along the way, such as clockwork drills, but they were hard to handle and inefficient. Over the centuries “dentistry has been performed by priests, monks and other healers. This was followed by barbers; the barber’s chair may well have been the precursor to the dental chair. “(SA Medical Heritage Society Inc.) In 1871 James Morrison patented the first commercially manufactured 'foot treadle dental engine', the first practica dental engine although others had been introduced as early as 1790 (by John Greenwood). Handmade steel burs or drills were introduced for dental handpieces, taking advantage of the significant increase in the speed of the drill. In 1891 the first machine-made steel burs were in use. The treadle drill reduced the time to prepare a cavity from hours to less than ten minutes. In 1876 the Samuel S. White Catalogue of Dentist Instruments listed a 12 ½ inch wheel diameter dental engine, with 14 bright steel parts, for sale at US $55 In today’s market, this is the equivalent to US $1200 approx. The specifications of that dental engine are very similar to the this one in our Flagstaff Hill Maritime Village’s collection. It is interesting to note that workings of a similar treadle dentist drill were used and modified to power a treadle spinning wheel of one of the volunteer spinners at Flagstaff Hill Maritime Village. The foot treadle dental engine was a milestone in dental history. “Historic importance of treadle powered machines; they made use of human power in an optimal way” (Lowtech Magazine “Short history of early pedal powered machines”) The invention of a machine to speed up the process of excavation of a tooth lead to the invention of new burs and drills for the handpieces, improving speed and the surgical process of dentistry. They were the fore-runner of today’s electrically powered dental engines. This treadle-powered dentist drill, or dentist engine, is made of iron and steel and provides power for a mechanical dental hand-piece that would be fitted with a dental tool. The drill has a three footed cast iron base, one foot being longer than the other two. A vertical C shaped frame is joined into the centre of the base, holding an axle that has a driving-wheel (or flywheel) and connecting to a crank. A slender, shoulder height post, made from telescoping pipes, joins into the top of this frame and is height adjusted by a hand tightened screw with a round knob. On the post just above the frame is a short metal, horizontal bar (to hold the hand-piece when it is not in use). A narrow tubular arm is attached to the top of the stand at a right angle and can move up and down. At the end of the arm is a firmly fixed, flexible rubber hose protected for a short distance by a sheath of thin metal. At the end of the hose there is a fitting where the drill’s hand-piece would be attached; a small, silver coloured alligator clip is also at the end. A treadle, or foot pedal, is hinged to the heel to the long foot of the base, and joined at the toe to the crank that turns the driving-wheel. There is a spring under the toe of the treadle. The metal driving-wheel has a wide rim. Touching the inside of the rim are four tubular rings that bulge towards the outside of the driving-wheel, away from the pole, and all meet at the hub of the axle. The axle is bulbous between the inside of the driving-wheel and the frame then passes through the frame and is attached on the other side. The driving-wheel has a groove around which a belt would sit. The belt would also fit around a pulley on the arm, at the top of the post. The pulley is joined to a rod inside the arm and this spins the drill's hand-piece and dental tool holder. The two shorter feet of the base are made from a long metal bar that has been curved outwards, and its centre is bolted to the base of the pole. Under the ends of the curved legs of the base are wedge shaped feet. The driving-wheel is decorated in light coloured paint on both sides, each side having three sets of floral decals evenly spaced around them, and each about a sixth of the wheel's circumference. Similar decoration is along the sides of the frame. The foot pedal has decorative cutout patterns in the centre of the foot and at the toe. On the long foot of the stand is some lettering with a fine, light coloured border around it. The lettering is hard to read, being a dark colour and flaking off. There are also remnants of fine, light coloured flourishes. The foot pedal has lettering of the maker’s trade mark cast into the metal at the ball of the foot. Lettering on the base is peeling and difficult to read. The foot pedal has a trade mark cast into it that looks like a combination of ‘C’ , ‘S’ , ‘A’, ‘R’. flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, dentist, teeth, dental drill, dental engine, treadle drill, foot powered drill, treadle engine, orthodontics, dental surgery, james morrison -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Dentist Drill, Late 19th century

... were used and modified to power a treadle spinning wheel of one... spinning wheel of one of the volunteer spinners at Flagstaff Hill ...The design of this and other similar treadle powered dental engine (or dentist drill) was in common use by dentists from the 1870’s into the 1920's. When electricity became accessible to most communities the electrically powered dental engines began to take over from the treadle power. Over the ages teeth were extracted using picks and scissors and other gouging instruments. Bow drills, hand drills and even a "bur thimble" drill were later used to prepare cavities for filling. Some drills were made bendable by attaching flexible shanks between the metal bur and the handle, giving access to the teeth at the back of the mouth. Other mechanical devices were introduced along the way, such as clockwork drills, but they were hard to handle and inefficient. Over the centuries “dentistry has been performed by priests, monks and other healers. This was followed by barbers; the barber’s chair may well have been the precursor to the dental chair. “(SA Medical Heritage Society Inc.) In 1871 James Morrison patented the first commercially manufactured 'foot treadle dental engine', the first practica dental engine although others had been introduced as early as 1790 (by John Greenwood). Handmade steel burs or drills were introduced for dental handpieces, taking advantage of the significant increase in the speed of the drill. In 1891 the first machine-made steel burs were in use. The treadle drill reduced the time to prepare a cavity from hours to less than ten minutes. In 1876 the Samuel S. White Catalogue of Dentist Instruments listed a 12 ½ inch wheel diameter dental engine, with 14 bright steel parts, for sale at US $55 In today’s market, this is the equivalent to US $1200 approx. The specifications of that dental engine are very similar to the this one in our Flagstaff Hill Maritime Village’s collection. It is interesting to note that workings of a similar treadle dentist drill were used and modified to power a treadle spinning wheel of one of the volunteer spinners at Flagstaff Hill Maritime Village. The foot treadle dental engine was a milestone in dental history. “Historic importance of treadle powered machines; they made use of human power in an optimal way” (Lowtech Magazine “Short history of early pedal powered machines”) The invention of a machine to speed up the process of excavation of a tooth lead to the invention of new burs and drills for the handpieces, improving speed and the surgical process of dentistry. They were the fore-runner of today’s electrically powered dental engines. This treadle-powered dentist drill, or dentist engine, is made of iron and steel and provides power for a mechanical dental handpiece that would be fitted with a dental tool. On the foot is painted lettering naming it "The Brentfield" and there is a fine line of light coloured paint creating a border around the name. The paint under the lettering is peeling off. The drill has a Y-shaped, three footed cast iron base, one foot being longer than the other two. A vertical frame is joined into the centre of the base, holding an axle that has a driving-wheel (or flywheel) and connecting to a crank. A slender, shoulder height post, made from adjustable telescoping pipes, joins into the top of this frame. On the post just above the frame is a short metal, horizontal bar (to hold the hand-piece when it is not in use). A narrow tubular arm is attached to the top of the stand at a right angle and can move up, down and around. There is a pulley each side of the joint of the arm and a short way along the arm is fitted a short metal pipe. A little further along the arm a frayed-ended cord hangs down from a hole. At the end of the arm is another pulley and a joint from which hangs a long, thin metal pipe with two pulleys and a fitting on the end. A treadle, or foot pedal, is joined to the long foot of the base, and joined at the toe to the crank that turns the driving-wheel. The metal driving-wheel has a wide rim. Touching the inside of the rim are four tubular rings that bulge towards the outside of the driving-wheel, away from the pole, and all meet at the hub of the axle. The axle fits between the inside of the driving-wheel and the frame then passes through the frame and is attached on the other side. The driving-wheel has a groove around which a belt would sit. The belt would also fit around a pulley on the arm, at the top of the post. The pulley is joined to a rod inside the arm and this spins the drill's hand-piece and dental tool holder. The foot pedal has a cross-hatch pattern on the heel and the ball of the foot has tread lines across it. The end of the toe and the instep areas have cut-out pattern in them. "The ____/ Brentfield / __ DE IN L___" (Made in London) painted on the long foot of the base. Marked on the drill connection is “Richter De Trey, Germany”flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, dentist, teeth, dental drill, dental engine, treadle drill, foot powered drill, treadle engine, orthodontics, dental surgery, james morrison, the brentfield, richter de trey, german dental fitting, london dental drill -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Pulley Sheave, 1873

... a belt, wire rope, or rope. The grooved wheel spins on an axle... for holding a belt, wire rope, or rope. The grooved wheel spins ...A sheave is a pulley with a grooved wheel for holding a belt, wire rope, or rope. The grooved wheel spins on an axle or bearing inside the frame of the block. This allows the wire or rope to move freely minimizing friction and wear on the cable. Sheaves can be used to redirect a cable or rope, lift loads, and transmit power. The words sheave and pulley are sometimes used interchangeably. The sheave was recovered at the time of the discovery of the Loch Ard wreck site in the 1970s. History of the Loch Ard: The Loch Ard got its name from ”Loch Ard” a loch that lies to the west of Aberfoyle, and the east of Loch Lomond. It means "high lake" in Scottish Gaelic. The vessel belonged to the famous Loch Line which sailed many vessels from England to Australia. The Loch Ard was built in Glasgow by Barclay, Curdle and Co. in 1873, the vessel was a three-masted square-rigged iron sailing ship that measured 79.87 meters in length, 11.58 m in width, and 7 m in depth with a gross tonnage of 1693 tons with a mainmast that measured a massive 45.7 m in height. Loch Ard made three trips to Australia and one trip to Calcutta before its fateful voyage. Loch Ard left England on March 2, 1878, under the command of 29-year-old Captain Gibbs, who was newly married. The ship was bound for Melbourne with a crew of 37, plus 17 passengers. The general cargo reflected the affluence of Melbourne at the time. Onboard were straw hats, umbrellas, perfumes, clay pipes, pianos, clocks, confectionery, linen and candles, as well as a heavier load of railway irons, cement, lead and copper. There were other items included that were intended for display in the Melbourne International Exhibition of 1880. The voyage to Port Phillip was long but uneventful. Then at 3 am on June 1, 1878, Captain Gibbs was expecting to see land. But the Loch Ard was running into a fog which greatly reduced visibility. Captain Gibbs was becoming anxious as there was no sign of land or the Cape Otway lighthouse. At 4 am the fog lifted and a lookout aloft announced that he could see breakers. The sheer cliffs of Victoria's west coast came into view, and Captain Gibbs realised that the ship was much closer to them than expected. He ordered as much sail to be set as time would permit and then attempted to steer the vessel out to sea. On coming head-on into the wind, the ship lost momentum, the sails fell limp and Loch Ard's bow swung back towards land. Gibbs then ordered the anchors to be released in an attempt to hold their position. The anchors sank some 50 fathoms - but did not hold. By this time the ship was among the breakers and the tall cliffs of Mutton Bird Island rose behind. Just half a mile from the coast, the ship's bow was suddenly pulled around by the anchor. The captain tried to tack out to sea, but the ship struck a reef at the base of Mutton Bird Island, near Port Campbell. Waves subsequently broke over the ship and the top deck became loosened from the hull. The masts and rigging came crashing down knocking passengers and crew overboard. When a lifeboat was finally launched, it crashed into the side of Loch Ard and capsized. Tom Pearce, who had launched the boat, managed to cling to its overturned hull and shelter beneath it. He drifted out to sea and then on the flood tide came into what is now known as Loch Ard Gorge. He swam to shore, bruised and dazed, and found a cave in which to shelter. Some of the crew stayed below deck to shelter from the falling rigging but drowned when the ship slipped off the reef into deeper water. Eva Carmichael a passenger had raced onto the deck to find out what was happening only to be confronted by towering cliffs looming above the stricken ship. In all the chaos, Captain Gibbs grabbed Eva and said, "If you are saved Eva, let my dear wife know that I died like a sailor". That was the last Eva Carmichael saw of the captain. She was swept off the ship by a huge wave. Eva saw Tom Pearce on a small rocky beach and yelled to attract his attention. He dived in and swam to the exhausted woman and dragged her to shore. He took her to the cave and broke the open case of brandy which had washed up on the beach. He opened a bottle to revive the unconscious woman. A few hours later Tom scaled a cliff in search of help. He followed hoof prints and came by chance upon two men from nearby Glenample Station three and a half miles away. In a complete state of exhaustion, he told the men of the tragedy. Tom then returned to the gorge while the two men rode back to the station to get help. By the time they reached Loch Ard Gorge, it was cold and dark. The two shipwreck survivors were taken to Glenample Station to recover. Eva stayed at the station for six weeks before returning to Ireland by steamship. In Melbourne, Tom Pearce received a hero's welcome. He was presented with the first gold medal of the Royal Humane Society of Victoria and a £1000 cheque from the Victorian Government. Concerts were performed to honour the young man's bravery and to raise money for those who lost family in the disaster. Of the 54 crew members and passengers on board, only two survived: the apprentice, Tom Pearce and the young woman passenger, Eva Carmichael, who lost her family in the tragedy. Ten days after the Loch Ard tragedy, salvage rights to the wreck were sold at auction for £2,120. Cargo valued at £3,000 was salvaged and placed on the beach, but most washed back into the sea when another storm developed. The wreck of Loch Ard still lies at the base of Mutton Bird Island. Much of the cargo has now been salvaged and some items were washed up into Loch Ard Gorge. Cargo and artefacts have also been illegally salvaged over many years before protective legislation was introduced in March 1982. One of the most unlikely pieces of cargo to have survived the shipwreck was a Minton majolica peacock- one of only nine in the world. The peacock was destined for the Melbourne 1880 International Exhibition. It had been well packed, which gave it adequate protection during the violent storm. Today the Minton peacock can be seen at the Flagstaff Hill Maritime Museum in Warrnambool. From Australia's most dramatic shipwreck it has now become Australia's most valuable shipwreck artifact and is one of very few 'objects' on the Victorian State Heritage Register. The shipwreck of the Loch Ard is of significance for Victoria and is registered on the Victorian Heritage Register ( S 417). Flagstaff Hill has a varied collection of artefacts from Loch Ard and its collection is significant for being one of the largest accumulation of artefacts from this notable Victorian shipwreck. The collections object is to also give us a snapshot into history so we can interpret the story of this tragic event. The collection is also archaeologically significant as it represents aspects of Victoria's shipping history that allows us to interpret Victoria's social and historical themes of the time. The collections historically significance is that it is associated unfortunately with the worst and best-known shipwreck in Victoria's history. Pulley sheave; round wooden block with metal disc in centre. Metal disc has large central machined hole and three equidistant small holes closer to the edge. Part of the rope groove is uneven. Recovered from the wreck of the Loch Ard. Noneflagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, loch line, loch ard, captain gibbs, eva carmichael, tom pearce, glenample station, mutton bird island, loch ard gorge, pulley sheave, pulley, ship rigging -

National Wool Museum

National Wool MuseumMachine - Wrap Reel

Wrap reel manufactured at Valley Worsted Mill and possibly used in the laboratory. "Wrap reels were used to check the yarn count in a spinning mill. A set length of yarn was wound off several test bobbins and weighed, if the weight was not the correct amount expected the spinning machines draft could be re calculated and the machine draft wheel ( cog ) changed to achieve the required count". - Greg AldridgeA small hand operated wrap reel. The reel is on a wooden base, the winding mechanism is metal and turned by a wooden handle. There is a metal plaque on the base inscribed MAKERS VWM. A wood and metal yarn feeder has broken off its mount.MAKERS/ VWMtextile machinery textile production weaving, valley worsted mill valley worsted mill, warping machinery, textile machinery, textile production, weaving, wrap reel, skein winder -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Functional object - Lawn sprinkler

Lawn sprinkler with two splayed legs acting as a stand. Hose fixture on one side. Top shaft with nozzle at either end. Shaft on wheel to allow it to spin.Rain King Pat Fan 1956 P2056 Chicago Flexible Shaft Co Chicago.domestic items, gardening